An Automated Machine Learning Approach for Real-Time Fault Detection and Diagnosis

Abstract

:1. Introduction

- an AutoML approach that enables non-ML experts to implement data-driven RT-FDD in the industry since it requires human contributions only in the automation and maintenance domains;

- a method to combine discrete events and continuous variables composing the features for RT-FDD in DMMs, that considered its cyclic sequential behavior;

- the evaluation of how the combination of discrete timed-events and continuous variables as features contributes to the enhancement of models’ performance;

- the evaluation of the generated models’ capacity to correctly diagnose faults, even when only a few samples of the faulty conditions are available.

2. Materials and Methods

2.1. Auto-ML Approach for RT-FDD

- the initial event of the sequential cycle;

- the analog IO variables (i.e., temperatures, pressures, distances, positions, and speeds);

- the digital IO variables (i.e., sensors’ status and actuators’ commands);

- labels regarding the machine’s working status (i.e., normal, faulty, or anomalous).

2.2. Automated Model Development

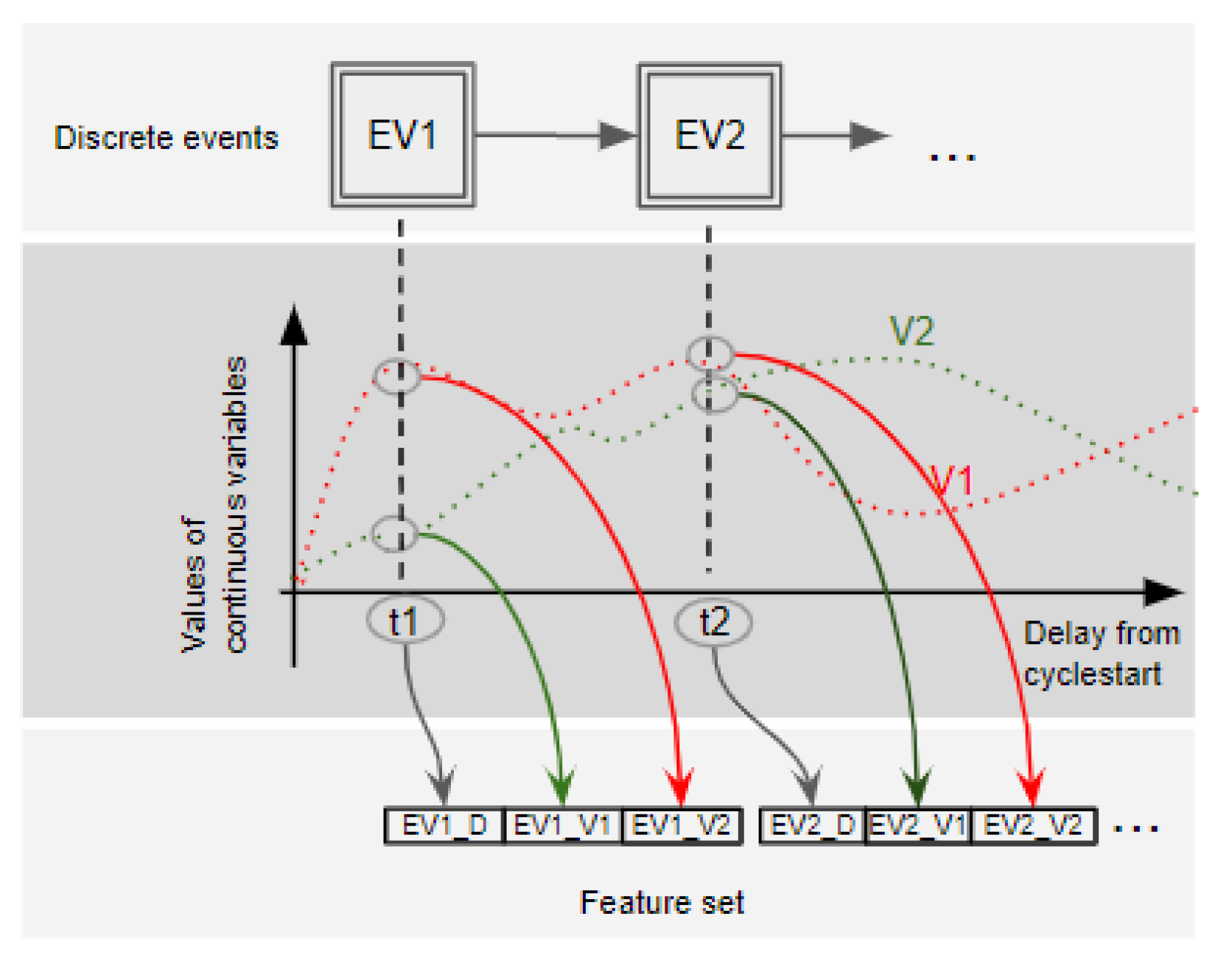

2.2.1. Process I: Feature Set Preparation

- discrete events that occur in a machine cycle;

- the value of the continuous variables during an interval from the beginning of the cycle;

- and the generated feature set.

2.2.2. Process II: Dataset Preparation

- 1.

- Each n discrete event delay feature (EVn_D) is filled with the time elapsed between its occurrence and the initial cycle event;

- 2.

- For each n discrete event delay feature (EVn_D), k continuous variables features are filled with their current value when (EVn_D) occurs.

- 3.

- All missing data are filled with a negative number with -1 since all valid values are positive.

2.2.3. Process III: FDD Model Selection

2.3. Model Execution

Process IV: RT-FDD Task Execution

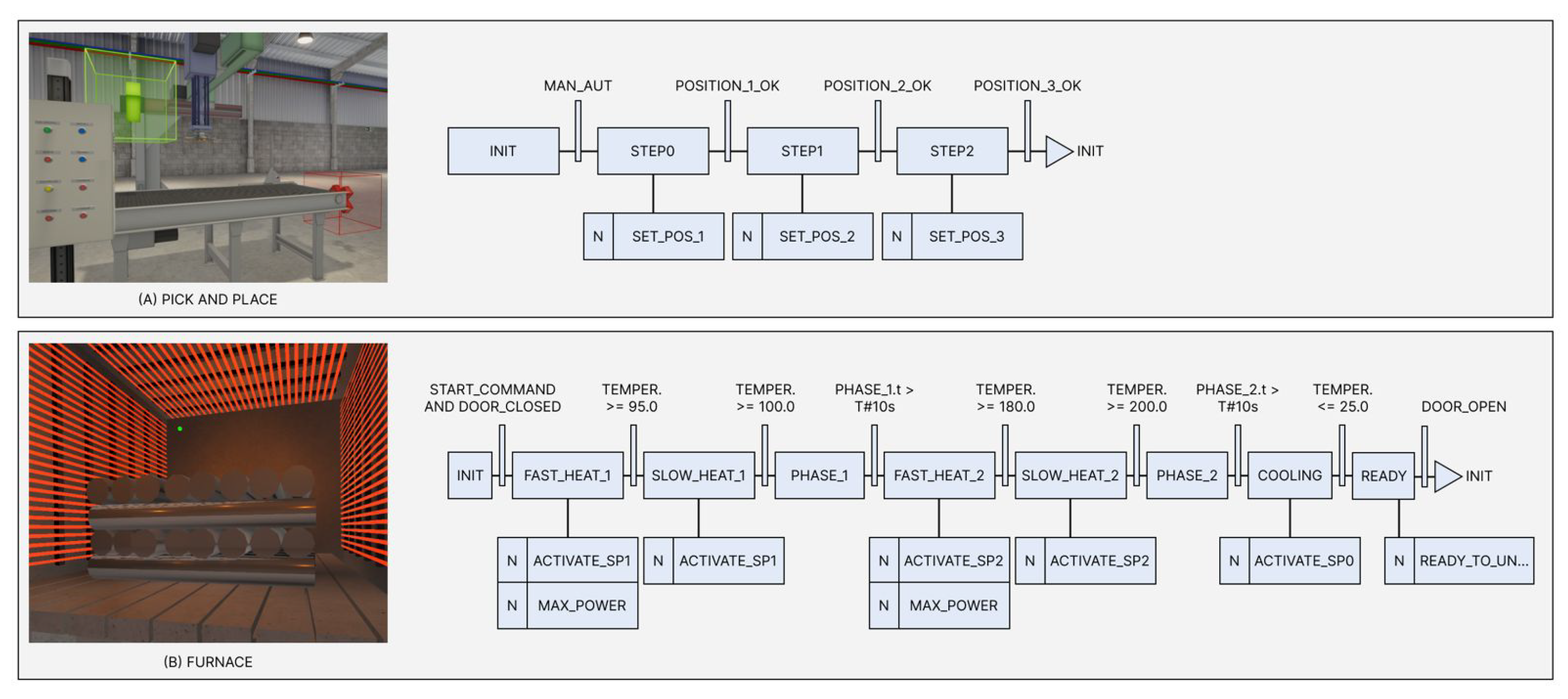

2.4. 3D Real-Time Machine and Fault Simulation

- The pick and place machine is implemented using forces systems that simulate the power of the motors, as well as frictions and loads;

- The electric furnace machine is implemented using the dynamic model of an electric heating system and discrete simulation for door conditions.

2.4.1. Pick and Place Machine

2.4.2. Furnace Machine

3. Results and Discussion

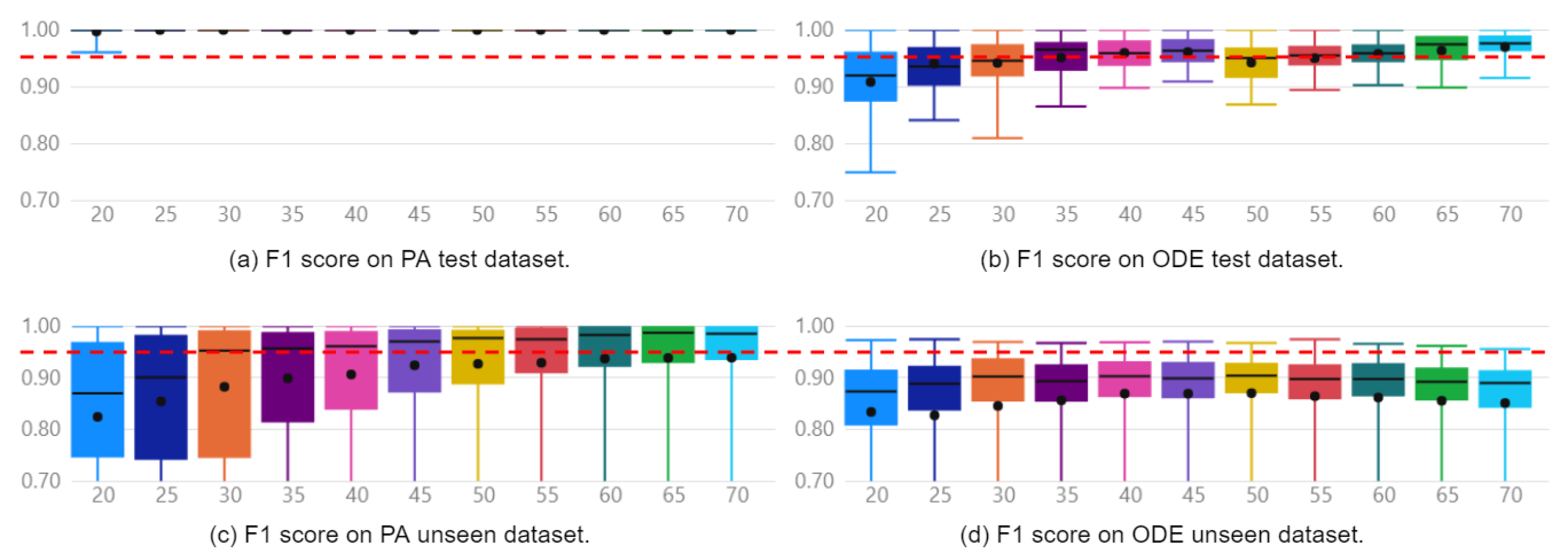

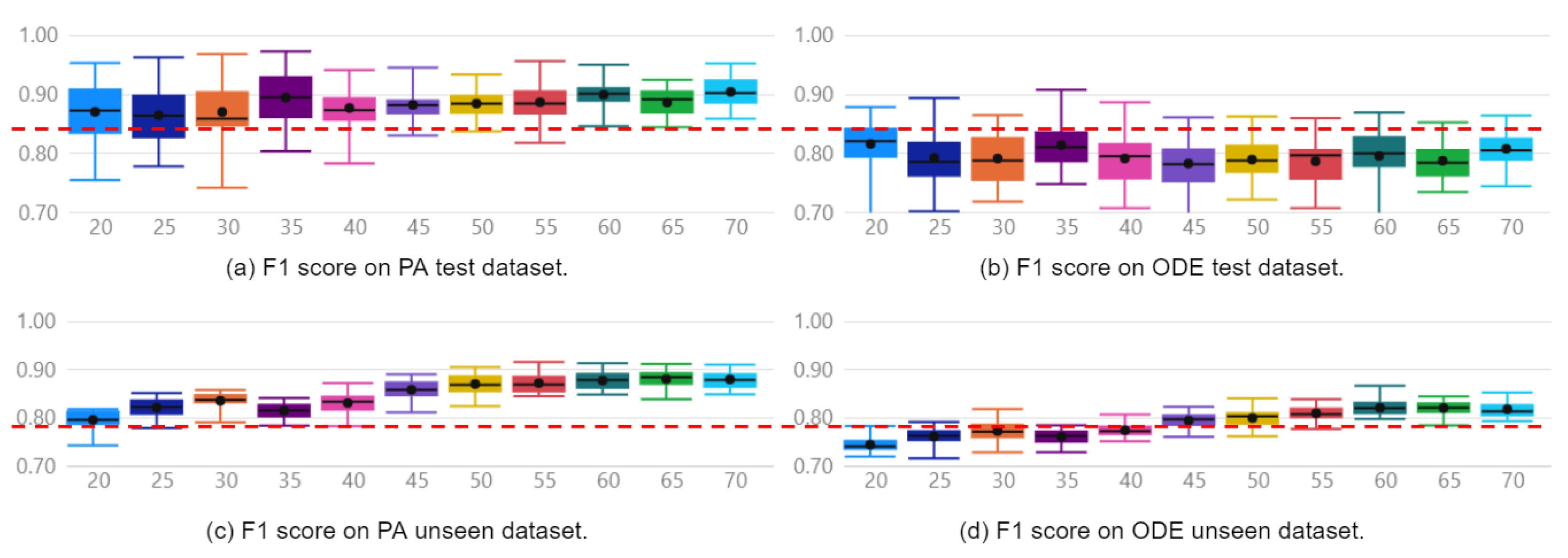

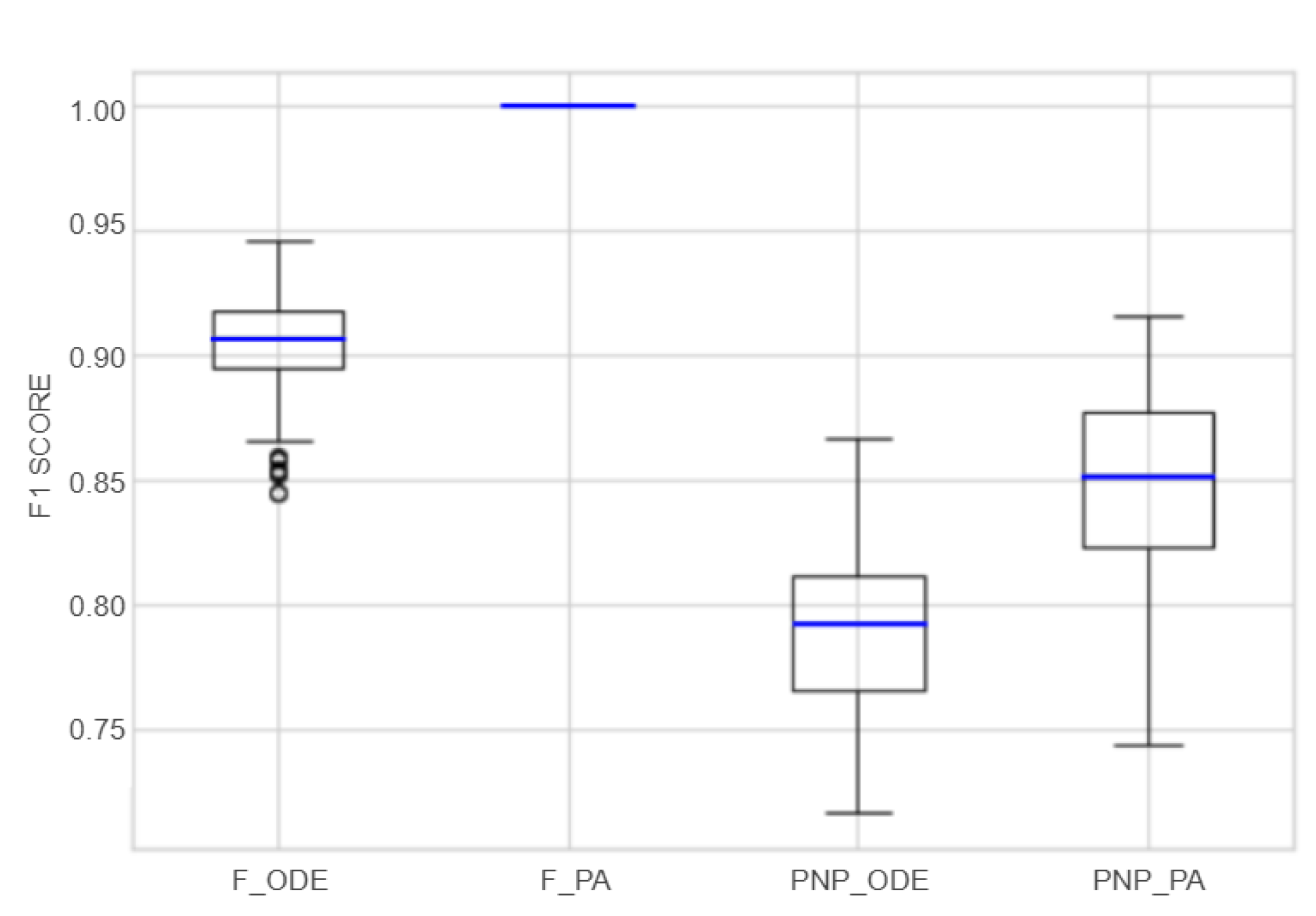

- the overall performance of the selected models and the influence of combining discrete and continuous variables (Section 3.1);

- the performance of all 16 models implemented with different classifiers in the model selection process, their sensitivity to the dataset split, and the initialization (Section 3.2);

- the performance by class of the selected models using a confusion matrix (Section 3.3);

- the relevance of timed-events and continuous variables features from a feature importance analysis (Section 3.4);

- the impact of the dataset size on the performance of the models using the F1 Score (Section 3.5).

3.1. Overall Performance Evaluation

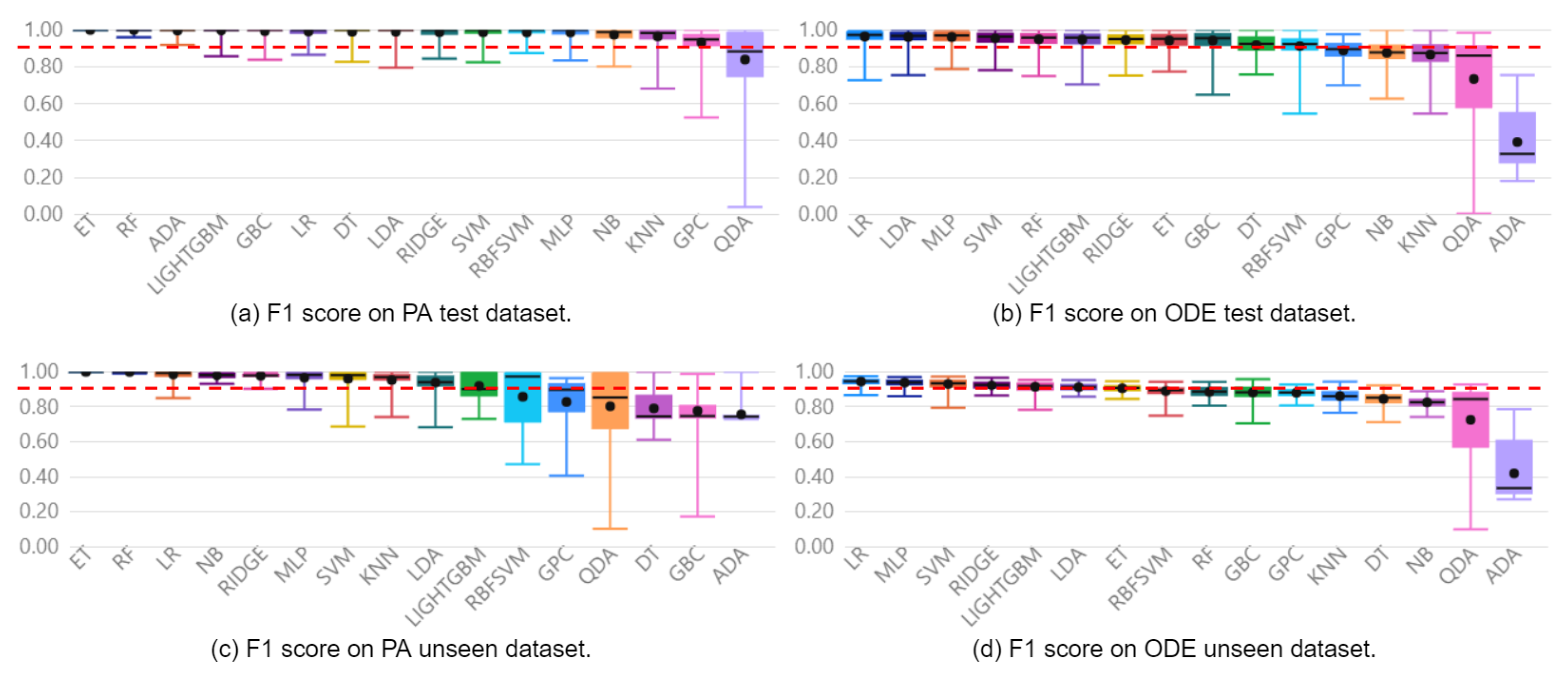

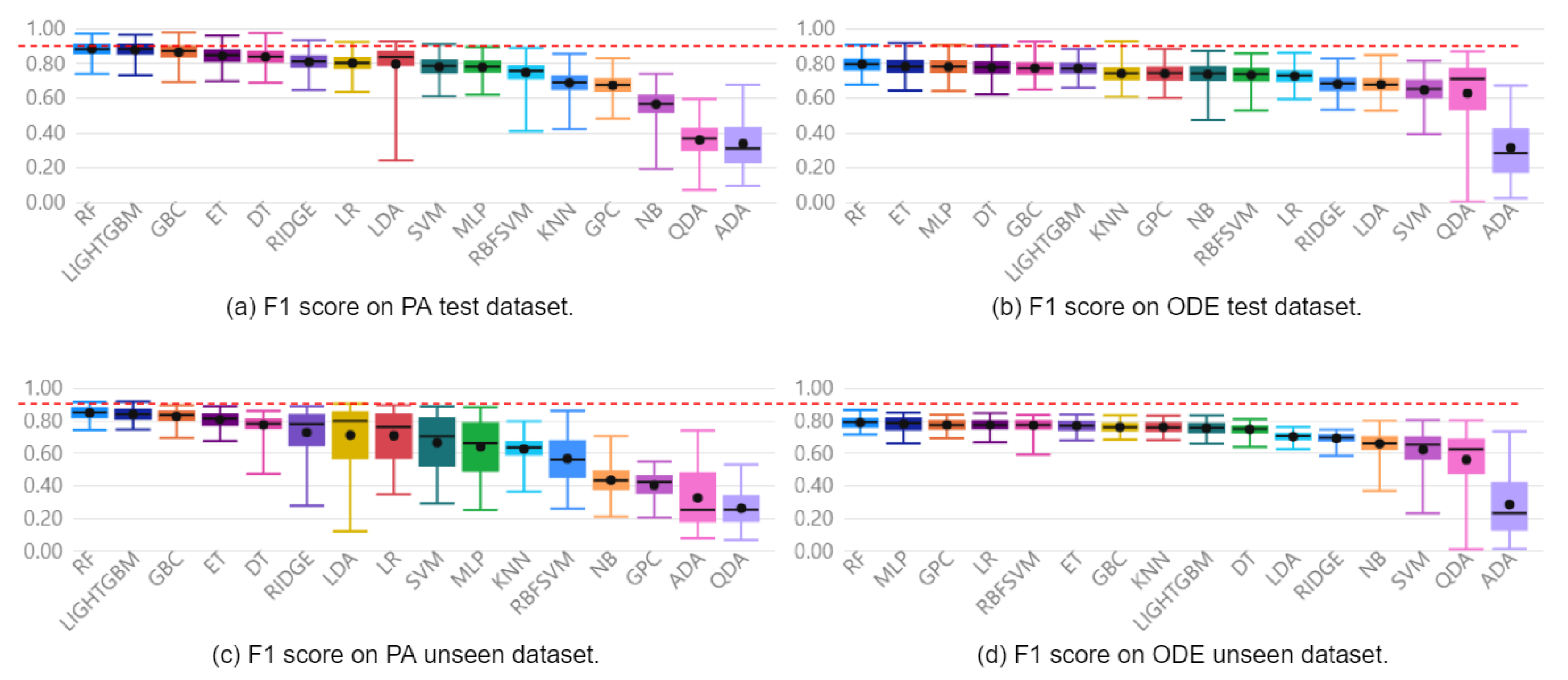

3.2. Considered Classifiers Performance

3.3. Performance Evaluation by Class

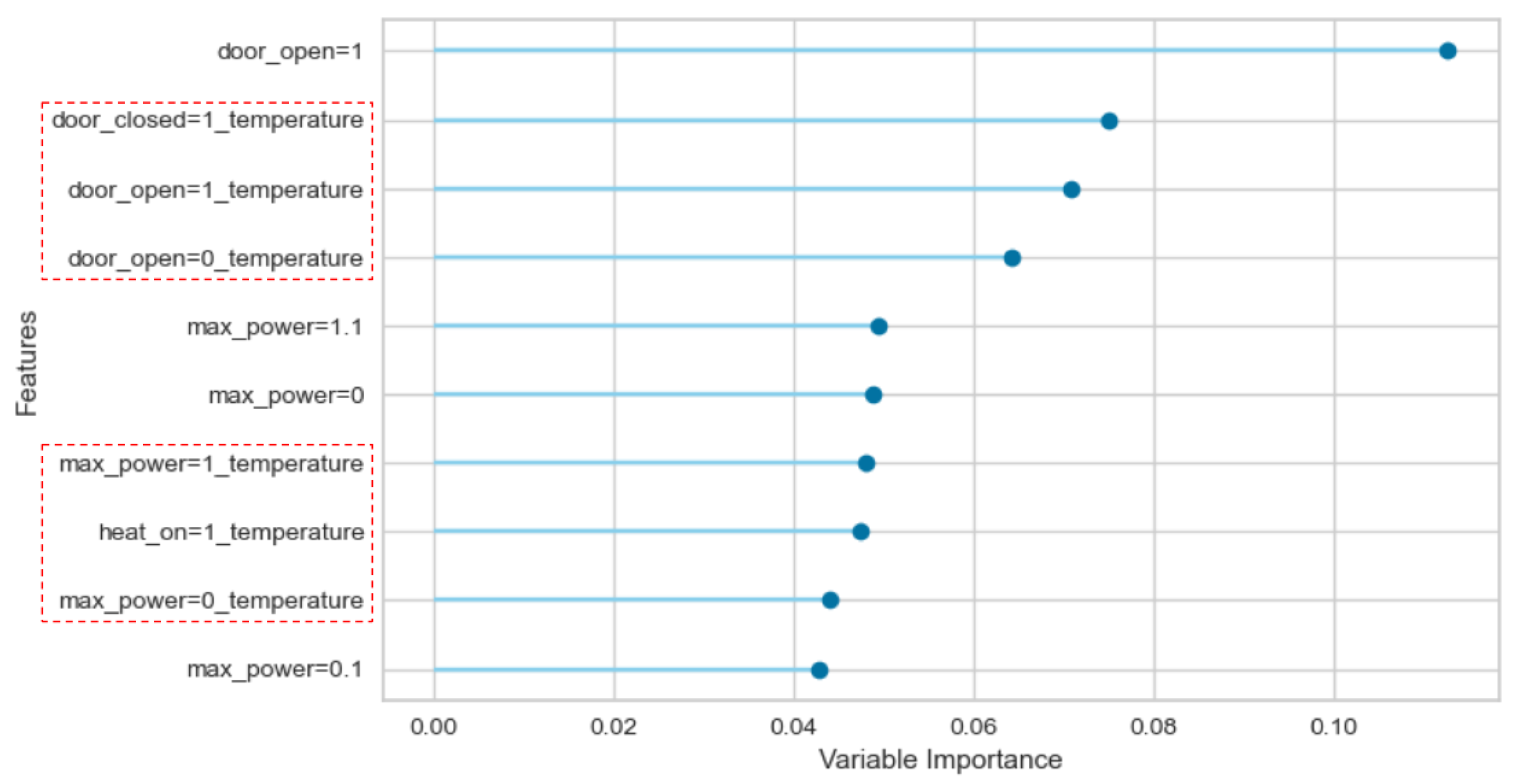

3.4. Feature Importance Analysis

3.5. Sensitivity to the Dataset Size and Improvement Capacity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RT-FDD | Real Time Fault Detection and Diagnosis |

| AutoML | Automated Machine Learning |

| DMM | Discrete Manufacturing Machines |

| KB | knowledge based |

| PM | Physical Models |

| LR | Logistic Regression |

| KNN | K Neighbors Classifier |

| NB | Naive Bayes |

| DT | Decision Tree Classifier |

| SVM | Support Vector Machine |

| RBFSVM | SVM—Radial Kernel |

| MLP | Multilayer Perceptron Classifier |

| RIDGE | Ridge Classifier (RIDGE) |

| RF | Random Forest Classifier |

| QDA | Quadratic Discriminant Analysis |

| ADA | Ada Boost Classifier |

| GBC | Gradient Boosting Classifier |

| LDA | Linear Discriminant Analysis |

| ET | Extra Trees Classifier (ET) |

| LIGHTGBM | Light Gradient Boosting Machine |

| GPC | Gaussian Process Classifier |

| TP | True Positive |

| FP | False Positive |

| FN | False Negative |

| PA | Proposed Approach |

| ODE | Only with Discrete Events |

References

- Westbrink, F.; Chadha, G.S.; Schwung, A. Integrated IPC for data-driven fault detection. In Proceedings of the 2018 IEEE Industrial Cyber-Physical Systems, ICPS, Petersburg, Russia, 15–18 May 2018; pp. 277–282. [Google Scholar] [CrossRef]

- Arpitha, V.; Pani, A.K. Machine Learning Approaches for Fault Detection in Semiconductor Manufacturing Process: A Critical Review of Recent Applications and Future Perspectives. Chem. Biochem. Eng. Q. 2022, 36, 1–16. [Google Scholar] [CrossRef]

- Pouliezos, A.; Stavrakakis, G.S. Real Time Fault Monitoring of Industrial Processes; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; Volume 12. [Google Scholar]

- Cohen, J.; Jiang, B.; Ni, J. Utilizing timed petri nets to guide data-driven fault diagnosis of PLC-timed event systems. In Proceedings of the 2020 Joint 11th International Conference on Soft Computing and Intelligent Systems and 21st International Symposium on Advanced Intelligent Systems, SCIS-ISIS, Hachijo Island, Japan, 5–8 December 2020. [Google Scholar] [CrossRef]

- Ghosh, A.; Qin, S.; Lee, J.; Wang, G.N. FBMTP: An Automated Fault and Behavioral Anomaly Detection and Isolation Tool for PLC-Controlled Manufacturing Systems. IEEE Trans. Syst. Man Cybern. Syst. 2017, 47, 3397–3417. [Google Scholar] [CrossRef]

- Monsef, H.; Ranjbar, A.M.; Jadid, S. Fuzzy rule-based expert system for power system fault diagnosis. IEE-Proc.-Gener. Transm. Distrib. 1997, 144, 186–192. [Google Scholar] [CrossRef]

- Nan, C.; Khan, F.; Iqbal, M.T. Real-time fault diagnosis using knowledge-based expert system. Process Saf. Environ. Prot. 2008, 86, 55–71. [Google Scholar] [CrossRef]

- Li, W.; Li, H.; Gu, S.; Chen, T. Process fault diagnosis with model- and knowledge-based approaches: Advances and opportunities. Control. Eng. Pract. 2020, 105, 104637. [Google Scholar] [CrossRef]

- Koujok, E.; Ragab, A.; Koujok, E. A Multi-Agent Approach Based onMachine-Learning for Fault Diagnosis. IFAC-PapersOnLine 2019, 52, 103–108. [Google Scholar] [CrossRef]

- El Koujok, M.; Ragab, A.; Ghezzaz, H.; Amazouz, M. A Multiagent-Based Methodology for Known and Novel Faults Diagnosis in Industrial Processes. IEEE Trans. Ind. Inform. 2021, 17, 3358–3366. [Google Scholar] [CrossRef]

- Ren, H.; Chai, Y.; Qu, J.; Ye, X.; Tang, Q. A novel adaptive fault detection methodology for complex system using deep belief networks and multiple models: A case study on cryogenic propellant loading system. Neurocomputing 2018, 275, 2111–2125. [Google Scholar] [CrossRef]

- Chiu, M.C.; Tsai, C.D.; Li, T.L. An Integrative Machine Learning Method to Improve Fault Detection and Productivity Performance in a Cyber-Physical System. J. Comput. Inf. Sci. Eng. 2020, 20, 021009. [Google Scholar] [CrossRef]

- Furukawa, Y.; Deng, M. Fault detection of tank-system using ChangeFinder and SVM. In Proceedings of the International Conference on Advanced Mechatronic Systems, ICAMechS 2020, Hanoi, Vietnam, 10–13 December 2020; pp. 260–265. [Google Scholar] [CrossRef]

- Makridis, G.; Kyriazis, D.; Plitsos, S. Predictive maintenance leveraging machine learning for time-series forecasting in the maritime industry. In Proceedings of the 2020 IEEE 23rd International Conference on Intelligent Transportation Systems, ITSC 2020, Rhodes, Greece, 20–23 September 2020. [Google Scholar] [CrossRef]

- Lee, J.S.; Chuang, C.C. Development of a Petri net-based fault diagnostic system for industrial processes. In Proceedings of the IECON Proceedings (Industrial Electronics Conference), Porto, Portugal, 3–5 November 2009; pp. 4347–4352. [Google Scholar] [CrossRef]

- Li, G.; Yuan, C.; Kamarthi, S.; Moghaddam, M.; Jin, X. Data science skills and domain knowledge requirements in the manufacturing industry: A gap analysis. J. Manuf. Syst. 2021, 60, 692–706. [Google Scholar] [CrossRef]

- Santu, S.K.K.; Hassan, M.M.; Smith, M.J.; Xu, L.; Zhai, C.; Veeramachaneni, K. AutoML to Date and Beyond: Challenges and Opportunities. ACM Comput. Surv. 2022, 54, 1–36. [Google Scholar] [CrossRef]

- He, X.; Zhao, K.; Chu, X. AutoML: A survey of the state-of-the-art. Knowl.-Based Syst. 2021, 212, 106622. [Google Scholar] [CrossRef]

- Sader, S.; Husti, I.; Daróczi, M. Enhancing failure mode and effects analysis using auto machine learning: A case study of the agricultural machinery industry. Processes 2020, 8, 224. [Google Scholar] [CrossRef]

- Garouani, M.; Ahmad, A.; Bouneffa, M.; Hamlich, M.; Bourguin, G.; Lewandowski, A. Towards big industrial data mining through explainable automated machine learning. Int. J. Adv. Manuf. Technol. 2022, 120, 1169–1188. [Google Scholar] [CrossRef]

- Larocque-Villiers, J.; Dumond, P.; Knox, D. Automating Predictive Maintenance Using State-Based Transfer Learning and Ensemble Methods. In Proceedings of the IEEE International Symposium on Robotic and Sensors Environments, ROSE 2021, Virtual, 28–29 October 2021. [Google Scholar] [CrossRef]

- Li, X.; Zheng, J.; Li, M.; Ma, W.; Hu, Y. One-shot neural architecture search for fault diagnosis using vibration signals. Expert Syst. Appl. 2022, 190, 116027. [Google Scholar] [CrossRef]

- Kefalas, M.; Baratchi, M.; Apostolidis, A.; Van Den Herik, D.; Back, T. Automated Machine Learning for Remaining Useful Life Estimation of Aircraft Engines. In Proceedings of the 2021 IEEE International Conference on Prognostics and Health Management, ICPHM 2021, Detroit, MI, USA, 7–9 June 2021. [Google Scholar] [CrossRef]

- Ali, M. PyCaret: An Open Source, Low-Code Machine Learning Library in Python; PyCaret Version 2.3. 2020. Available online: https://www.marktechpost.com/2020/04/18/pycaret-an-open-source-low-code-machine-learning-library-in-python/ (accessed on 24 July 2022).

- Buitinck, L.; Louppe, G.; Blondel, M.; Pedregosa, F.; Mueller, A.; Grisel, O.; Niculae, V.; Prettenhofer, P.; Gramfort, A.; Grobler, J.; et al. API design for machine learning software: Experiences from the scikit-learn project. In Proceedings of the ECML PKDD Workshop: Languages for Data Mining and Machine Learning, Prague, Czech Republic, 23–27 September 2013; pp. 108–122. [Google Scholar]

- Kang, Z.; Catal, C.; Tekinerdogan, B. Machine learning applications in production lines: A systematic literature review. Comput. Ind. Eng. 2020, 149, 106773. [Google Scholar] [CrossRef]

- Huang, J.; Wen, J.; Yoon, H.; Pradhan, O.; Wu, T.; Neill, Z.O. Energy & Buildings Real vs. simulated: Questions on the capability of simulated datasets on building fault detection for energy efficiency from a data-driven perspective. Energy Build. 2022, 259, 111872. [Google Scholar] [CrossRef]

- Xu, Y.; Sun, Y.; Liu, X.; Zheng, Y. A Digital-Twin-Assisted Fault Diagnosis Using Deep Transfer Learning. IEEE Access 2019, 7, 19990–19999. [Google Scholar] [CrossRef]

- Zhang, W.; Li, X. Federated Transfer Learning for Intelligent Fault Diagnostics Using Deep Adversarial Networks with Data Privacy. IEEE/ASME Trans. Mechatron. 2022, 27, 430–439. [Google Scholar] [CrossRef]

- Zhang, W.; Li, X.; Luo, Z.; Li, X. Universal Domain Adaptation in Fault Diagnostics with Hybrid Weighted Deep Adversarial Learning. IEEE Trans. Ind. Informatics 2021, 17, 7957–7967. [Google Scholar] [CrossRef]

- Vargas, R.E.V.; Munaro, C.J.; Ciarelli, P.M.; Medeiros, A.G.; do Amaral, B.G.; Barrionuevo, D.C.; de Araújo, J.C.D.; Ribeiro, J.L.; Magalh aes, L.P. A realistic and public dataset with rare undesirable real events in oil wells. J. Pet. Sci. Eng. 2019, 181, 106223. [Google Scholar] [CrossRef]

- Lerner, U.; Parr, R.; Koller, D. Bayesian Fault Detection and Diagnosis in Dynamic Systems. In Proceedings of the Aaai/iaai, Austin, TX, USA, 30 July–3 August 2000; pp. 531–537. [Google Scholar]

- Downs, J.J.; Vogel, E.F. A plant-wide industrial process control problem. Comput. Chem. Eng. 1993, 17, 245–255. [Google Scholar] [CrossRef]

| Cycles | Class Description |

|---|---|

| 100 | Normal operation |

| 100 | F1: Punctual obstruction on axis X. |

| 100 | F2: Punctual obstruction on axis Y. |

| 100 | F3: Punctual obstruction on axis Z. |

| 100 | F4: 2% Speed loss on axis X. |

| 100 | F5: 2% Speed loss on axis Y. |

| 100 | F6: 2% Speed loss on axis Z. |

| Predicted | |||||

|---|---|---|---|---|---|

| Actual | N | F1 | F2 | F3 | |

| N | 30 | 0 | 0 | 0 | |

| F1 | 0 | 23 | 0 | 7 | |

| F2 | 0 | 0 | 30 | 0 | |

| F3 | 3 | 9 | 0 | 18 | |

| Predicted | |||||

|---|---|---|---|---|---|

| Actual | N | F1 | F2 | F3 | |

| N | 30 | 0 | 0 | 0 | |

| F1 | 0 | 30 | 0 | 0 | |

| F2 | 0 | 0 | 30 | 0 | |

| F3 | 0 | 0 | 0 | 30 | |

| Predicted | ||||||||

|---|---|---|---|---|---|---|---|---|

| Actual | N | F1 | F2 | F3 | F4 | F5 | F6 | |

| N | 23 | 5 | 0 | 1 | 0 | 0 | 1 | |

| F1 | 11 | 12 | 0 | 0 | 0 | 1 | 0 | |

| F2 | 0 | 0 | 29 | 0 | 0 | 1 | 0 | |

| F3 | 0 | 1 | 0 | 27 | 1 | 1 | 0 | |

| F4 | 0 | 8 | 0 | 1 | 18 | 2 | 1 | |

| F5 | 0 | 0 | 1 | 0 | 0 | 29 | 0 | |

| F6 | 0 | 0 | 0 | 1 | 0 | 0 | 29 | |

| Predicted | ||||||||

|---|---|---|---|---|---|---|---|---|

| Actual | N | F1 | F2 | F3 | F4 | F5 | F6 | |

| N | 24 | 6 | 0 | 0 | 0 | 0 | 0 | |

| F1 | 6 | 19 | 0 | 0 | 5 | 10 | 0 | |

| F2 | 0 | 0 | 29 | 0 | 0 | 1 | 0 | |

| F3 | 0 | 0 | 0 | 29 | 1 | 1 | 0 | |

| F4 | 1 | 1 | 0 | 0 | 28 | 0 | 0 | |

| F5 | 0 | 0 | 0 | 0 | 0 | 30 | 0 | |

| F6 | 0 | 0 | 0 | 0 | 0 | 0 | 30 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leite, D.; Martins, A., Jr.; Rativa, D.; De Oliveira, J.F.L.; Maciel, A.M.A. An Automated Machine Learning Approach for Real-Time Fault Detection and Diagnosis. Sensors 2022, 22, 6138. https://doi.org/10.3390/s22166138

Leite D, Martins A Jr., Rativa D, De Oliveira JFL, Maciel AMA. An Automated Machine Learning Approach for Real-Time Fault Detection and Diagnosis. Sensors. 2022; 22(16):6138. https://doi.org/10.3390/s22166138

Chicago/Turabian StyleLeite, Denis, Aldonso Martins, Jr., Diego Rativa, Joao F. L. De Oliveira, and Alexandre M. A. Maciel. 2022. "An Automated Machine Learning Approach for Real-Time Fault Detection and Diagnosis" Sensors 22, no. 16: 6138. https://doi.org/10.3390/s22166138

APA StyleLeite, D., Martins, A., Jr., Rativa, D., De Oliveira, J. F. L., & Maciel, A. M. A. (2022). An Automated Machine Learning Approach for Real-Time Fault Detection and Diagnosis. Sensors, 22(16), 6138. https://doi.org/10.3390/s22166138