Responsivity and NEP Improvement of Terahertz Microbolometer by High-Impedance Antenna

Abstract

1. Introduction

- The proposed bolometer with the reduction in heater width can simultaneously improve the responsivity and NEP performance of the detector.

- Comprehensive investigation of the microbolometer performance both electrically, by an alternating-current (AC) power supply, and optically, by a THz radiation source.

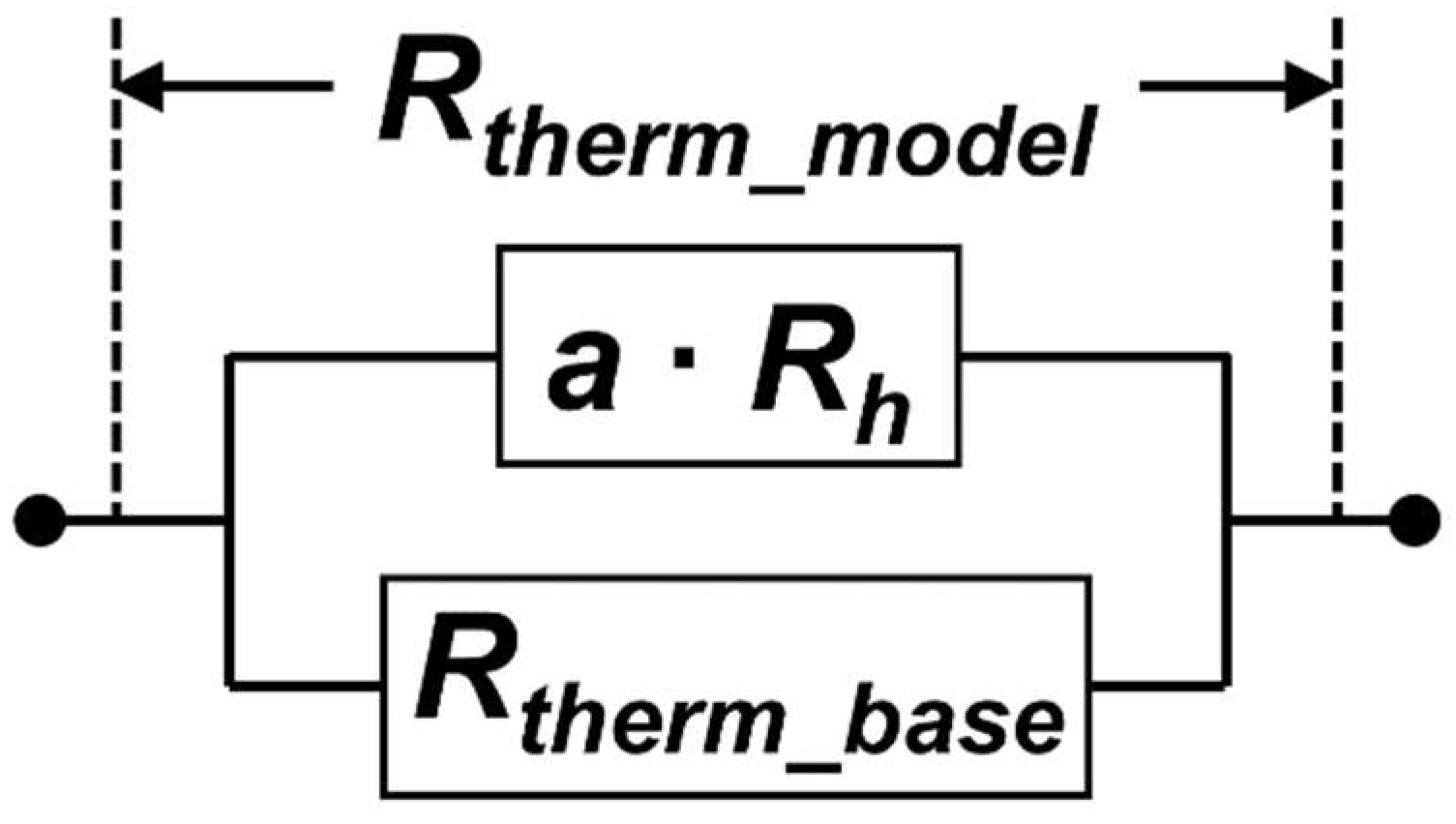

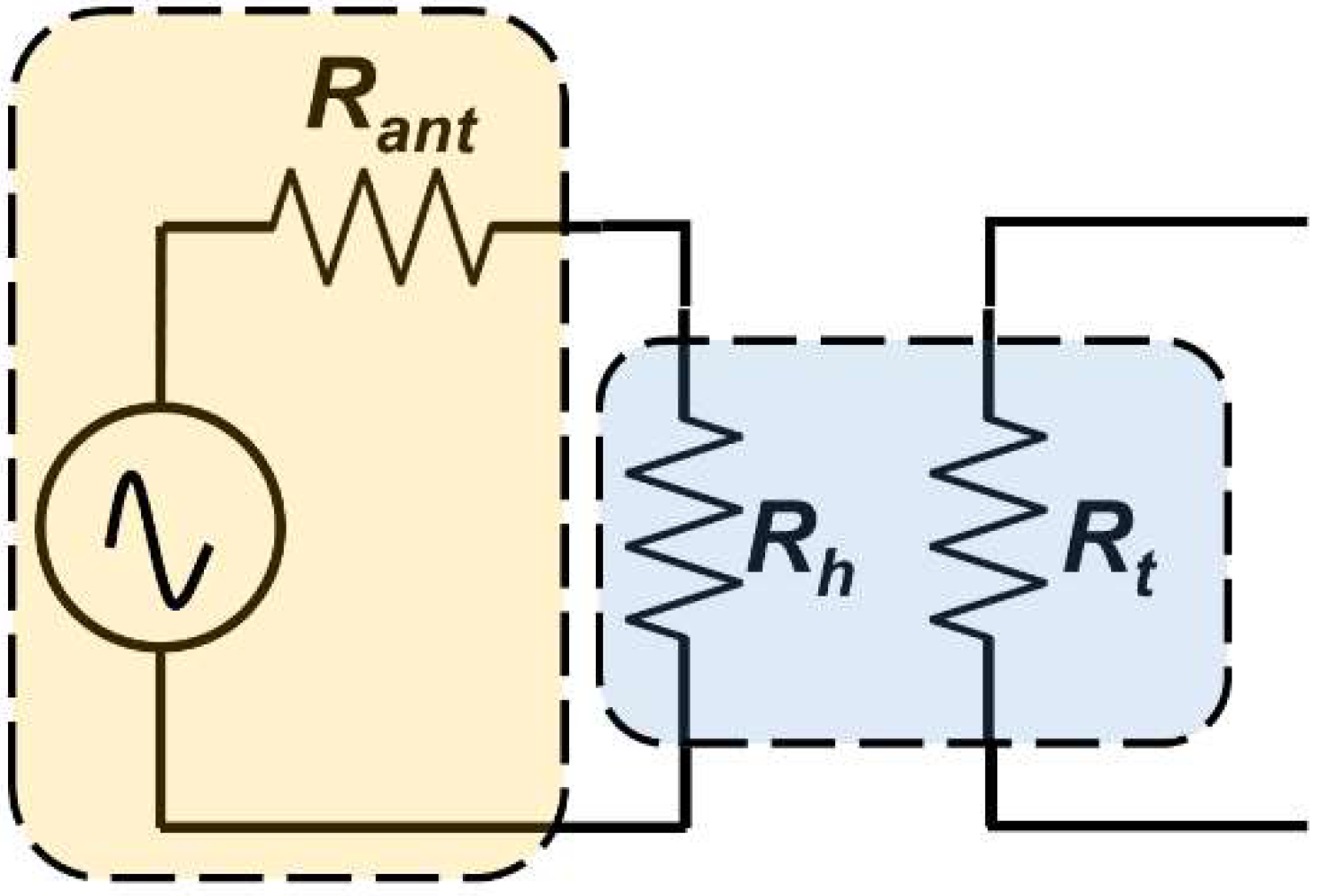

- Thermal conduction analysis of the microbolometer structure by a proposed thermal circuit model to verify the electrical and optical measurement results with the average discrepancies of less than 1%.

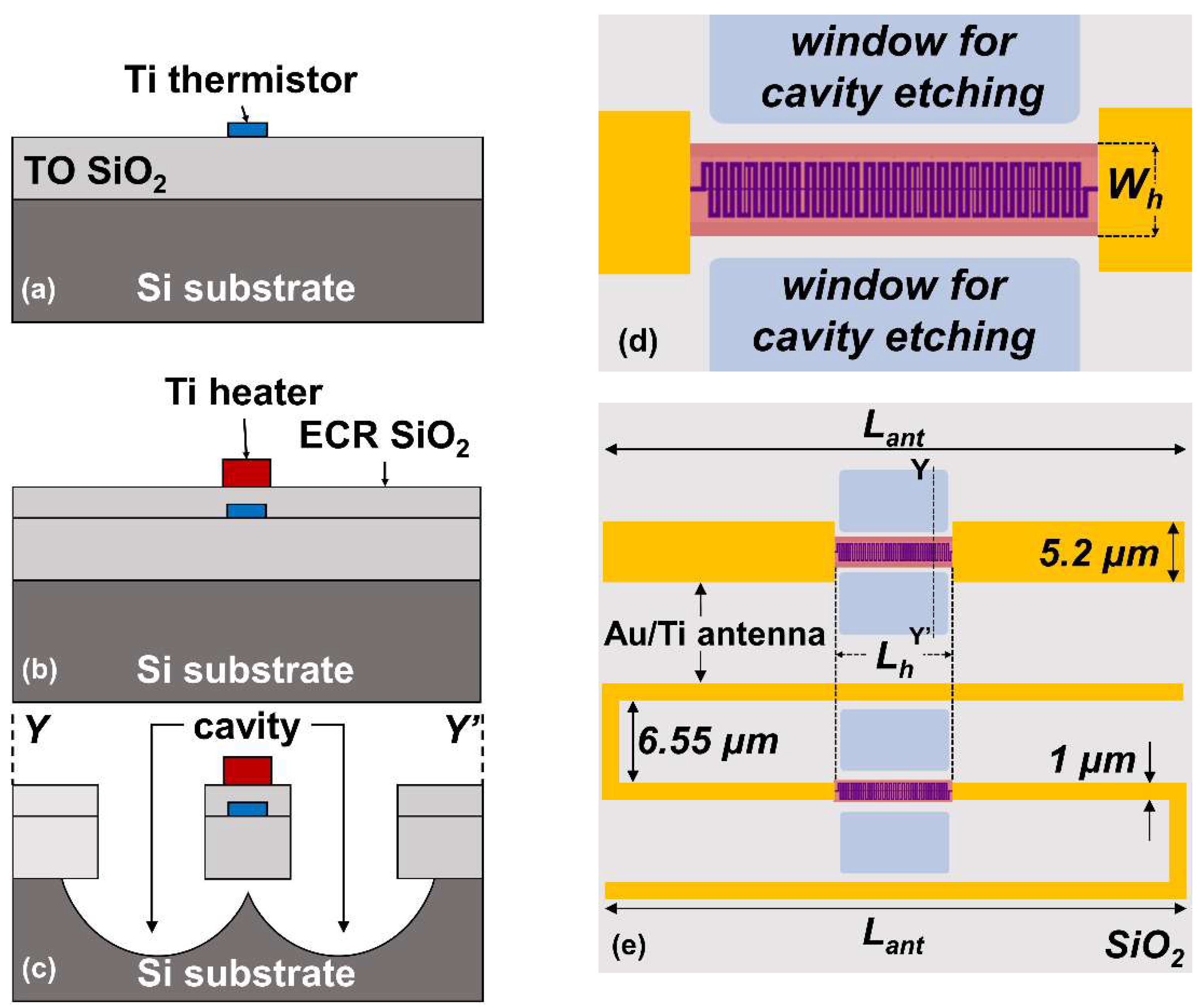

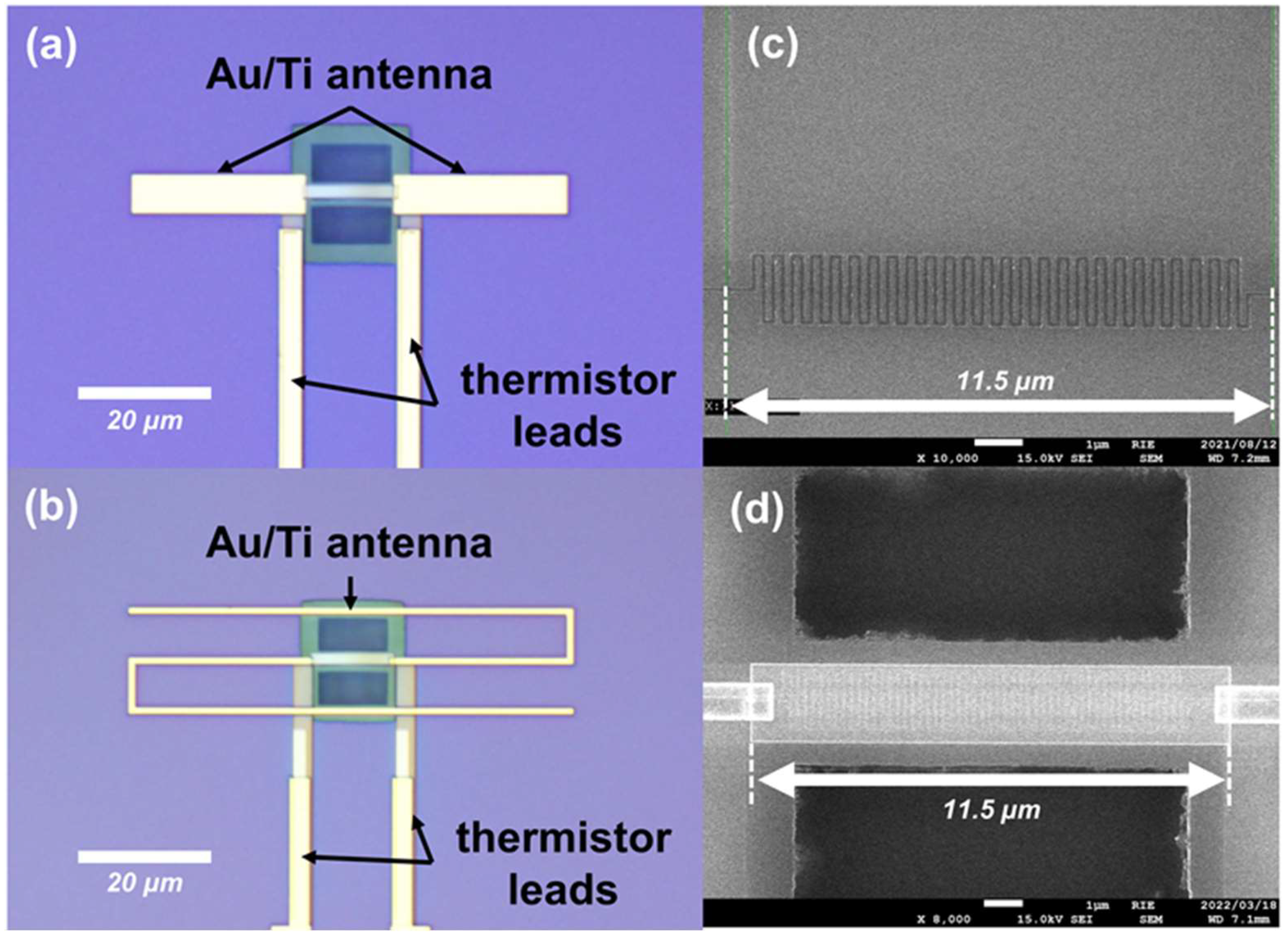

2. Fabrication Process

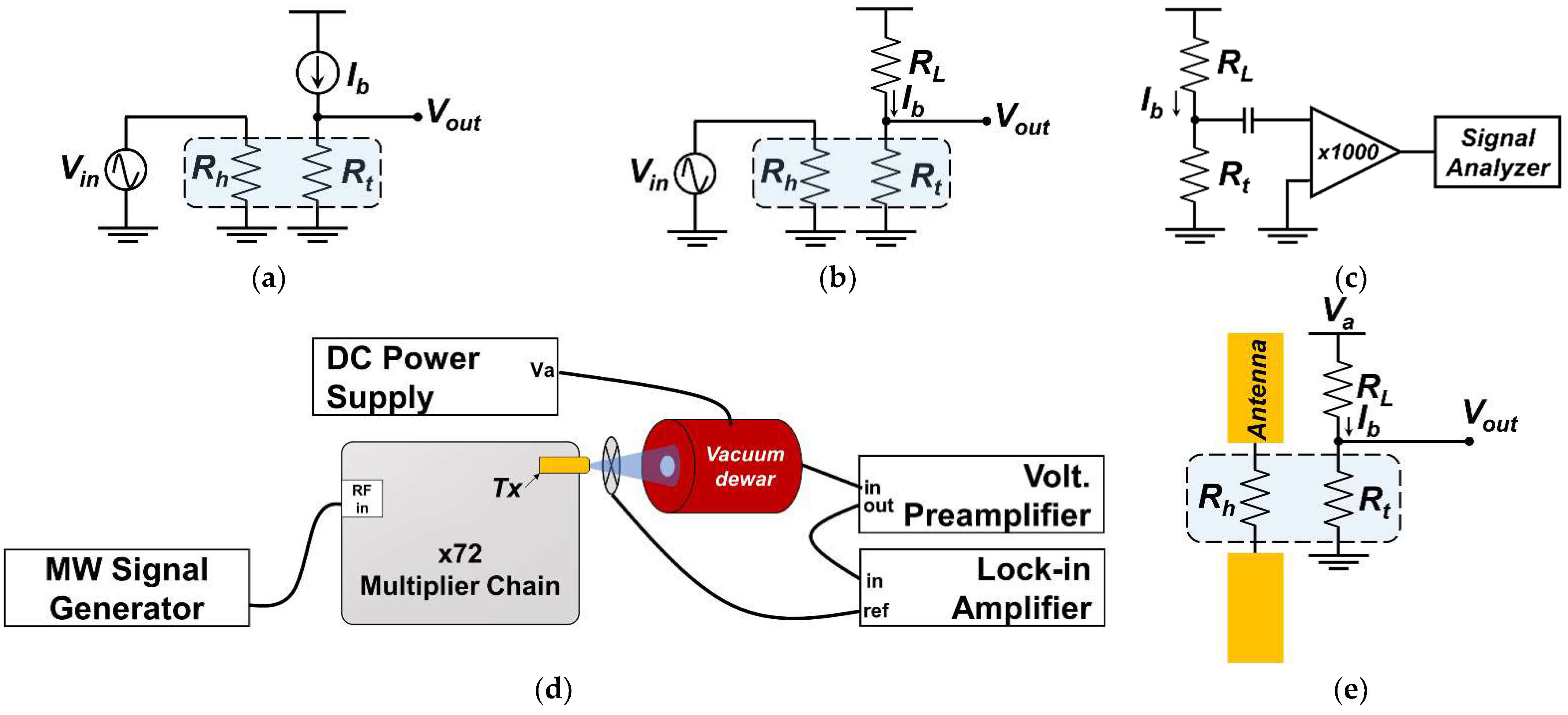

3. Methods of Characterization

4. Results and Discussion

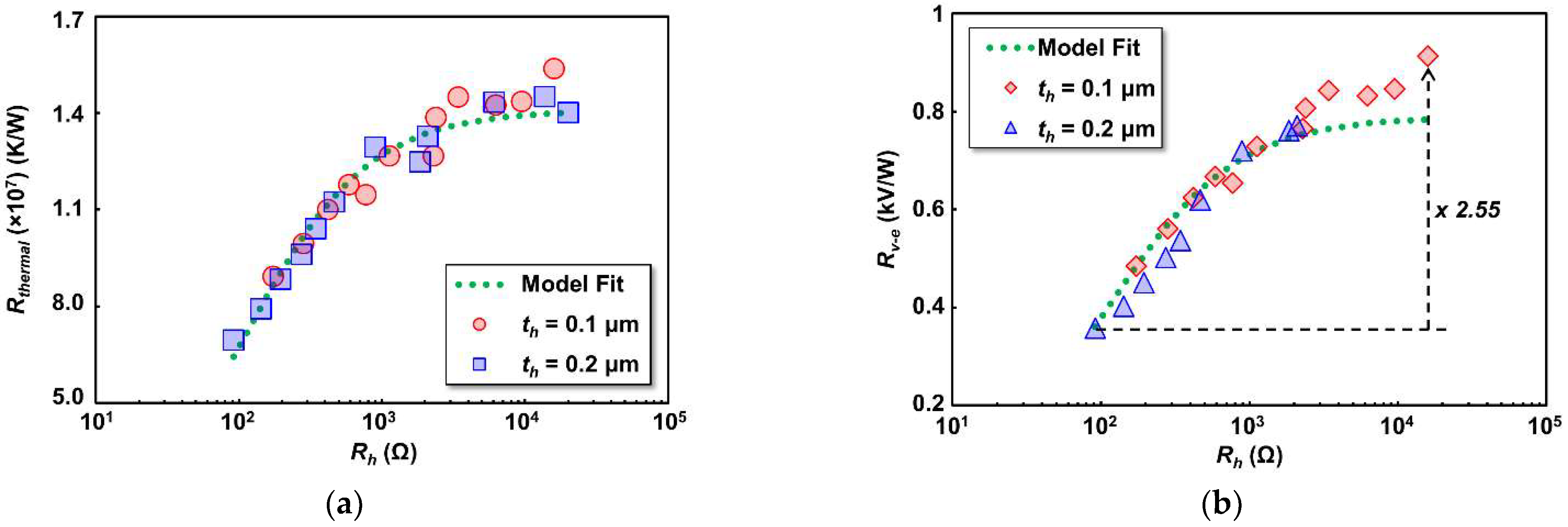

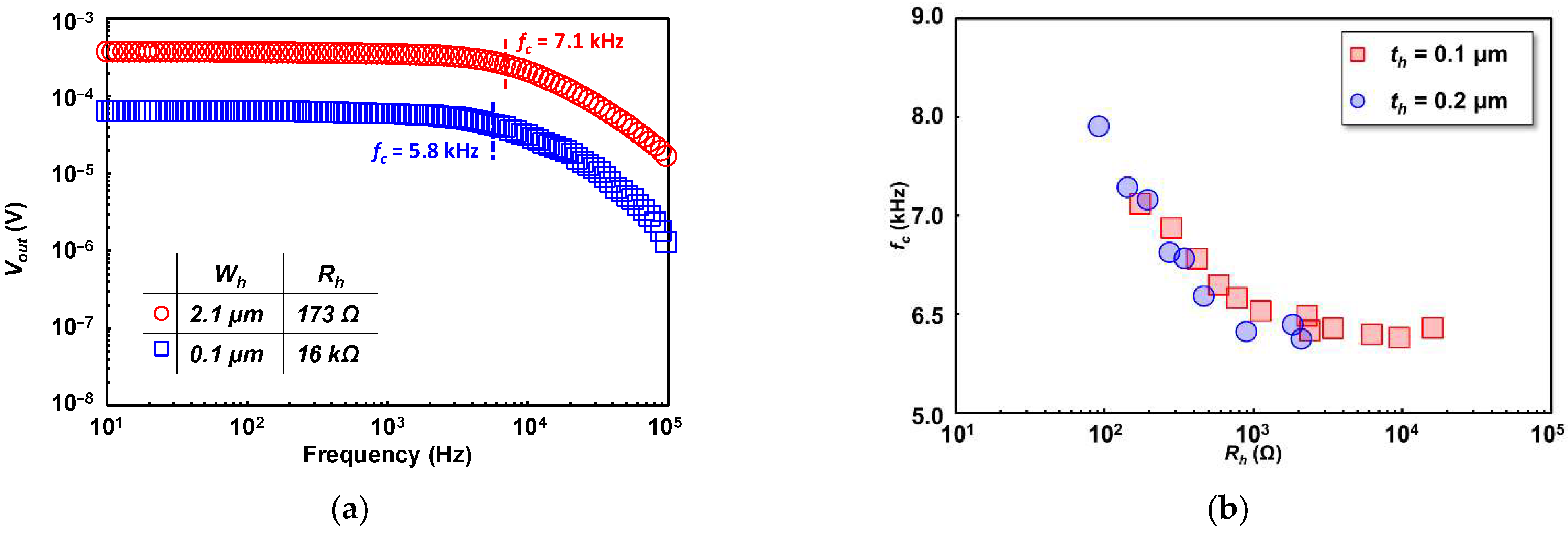

4.1. Electrical Characterization

4.1.1. Material Parameters

4.1.2. Electrical Responsivity

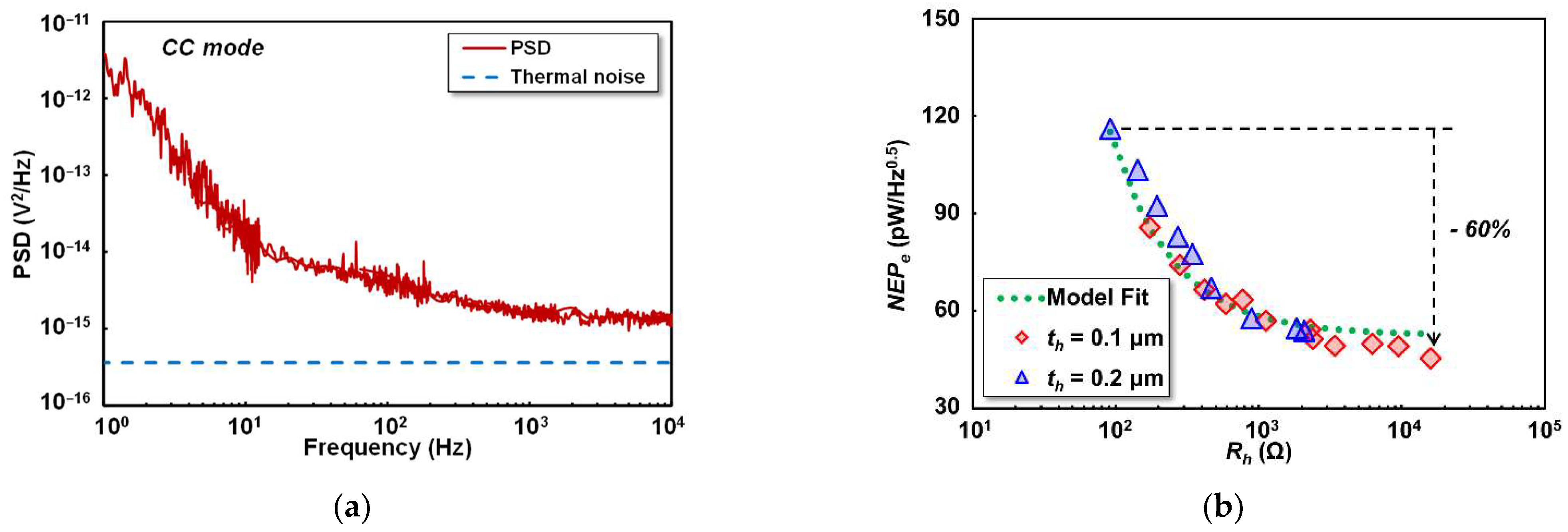

4.1.3. Noise Characteristics

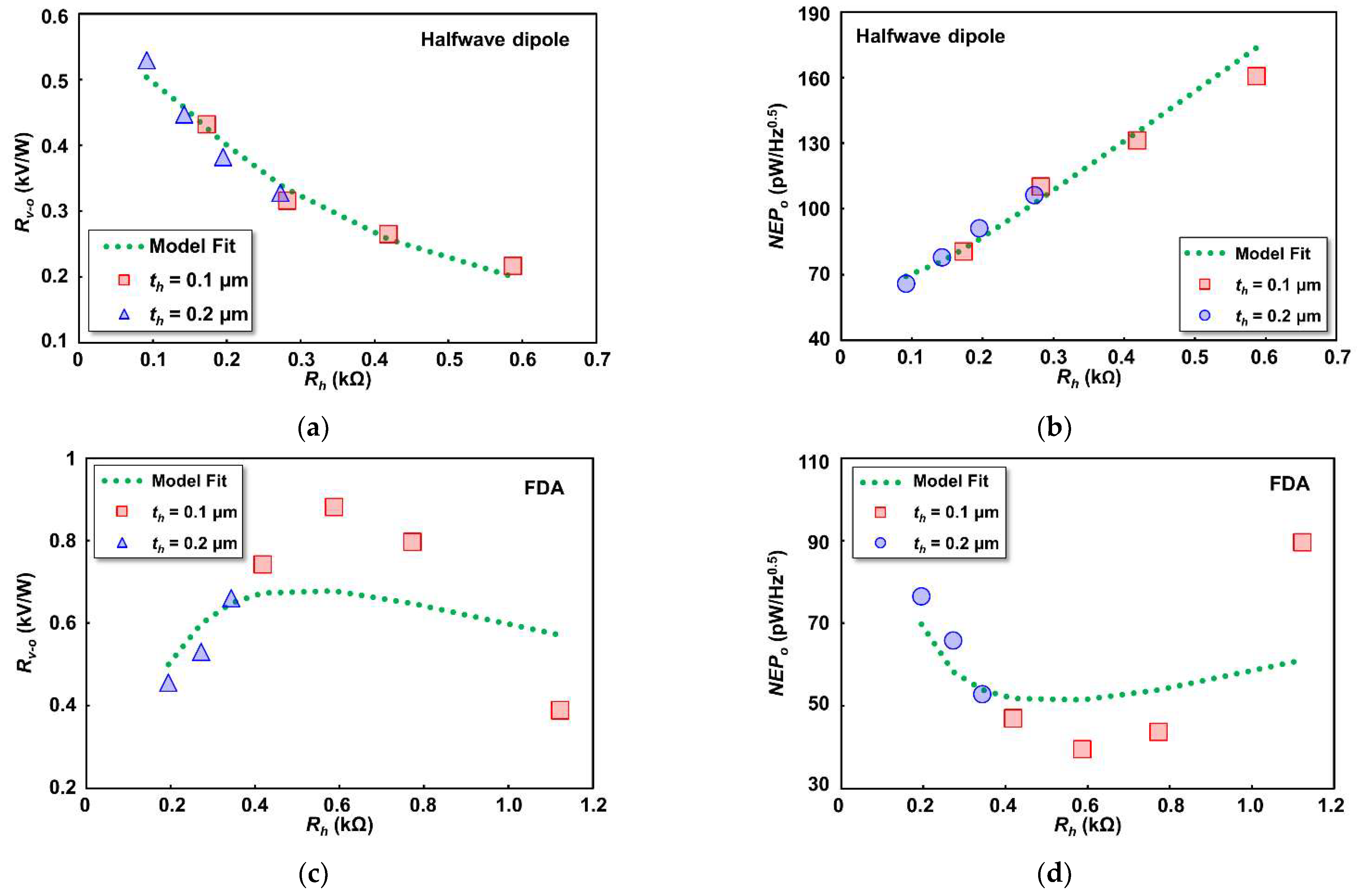

4.2. THz Characterization

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Siegel, P.H. Terahertz Technology. IEEE Trans. Microw. Theory Tech. 2002, 50, 910–928. [Google Scholar] [CrossRef]

- Rogalski, A.; Sizov, F. Terahertz Detectors and Focal Plane Arrays. Opto-Electron. Rev. 2011, 19, 346–404. [Google Scholar] [CrossRef]

- Koral, C.; Mazaheri, Z.; Papari, G.P.; Andreone, A.; Drebot, I.; Giove, D.; Masullo, M.R.; Mettivier, G.; Opromolla, M.; Paparo, D.; et al. Multi-Pass Free Electron Laser Assisted Spectral and Imaging Applications in the Terahertz/Far-IR Range Using the Future Superconducting Electron Source BriXSinO. Front. Phys. 2022, 10, 725901. [Google Scholar] [CrossRef]

- Elayan, H.; Amin, O.; Shihada, B.; Shubair, R.M.; Alouini, M.S. Terahertz Band: The Last Piece of Rf Spectrum Puzzle for Communication Systems. IEEE Open J. Commun. Soc. 2020, 1, 1–32. [Google Scholar] [CrossRef]

- Huq, K.M.S.; Busari, S.A.; Rodriguez, J.; Frascolla, V.; Bazzi, W.; Sicker, D.C. Terahertz-Enabled Wireless System for Beyond-5G Ultra-Fast Networks: A Brief Survey. IEEE Netw. 2019, 33, 89–95. [Google Scholar] [CrossRef]

- Wang, K.; Sun, D.W.; Pu, H. Emerging Non-Destructive Terahertz Spectroscopic Imaging Technique: Principle and Applications in the Agri-Food Industry. Trends Food Sci. Technol. 2017, 67, 93–105. [Google Scholar] [CrossRef]

- Ren, A.; Zahid, A.; Fan, D.; Yang, X.; Imran, M.A.; Alomainy, A.; Abbasi, Q.H. State-of-the-Art in Terahertz Sensing for Food and Water Security—A Comprehensive Review. Trends Food Sci. Technol. 2019, 85, 241–251. [Google Scholar] [CrossRef]

- Gong, A.; Qiu, Y.; Chen, X.; Zhao, Z.; Xia, L.; Shao, Y. Biomedical Applications of Terahertz Technology. Appl. Spectrosc. Rev. 2020, 55, 418–438. [Google Scholar] [CrossRef]

- Yang, X.; Zhao, X.; Yang, K.; Liu, Y.; Liu, Y.; Fu, W.; Luo, Y. Biomedical Applications of Terahertz Spectroscopy and Imaging. Trends Biotechnol. 2016, 34, 810–824. [Google Scholar] [CrossRef]

- Liu, L.; Weng, C.; Li, S.; Husi, L.; Hu, S.; Dong, P. Passive Remote Sensing of Ice Cloud Properties at Terahertz Wavelengths Based on Genetic Algorithm. Remote Sens. 2021, 13, 735. [Google Scholar] [CrossRef]

- Rogalski, A. Infrared and Terahertz Detectors, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2019; ISBN 9781138198005. [Google Scholar]

- Ryger, I.; Lobotka, P.; Steiger, A.; Chromik, S.; Lalinsky, T.; Raida, Z.; Pítra, K.; Zehetner, J.; Spankova, M.; Gazi, S.; et al. Uncooled Antenna-Coupled Microbolometer for Detection of Terahertz Radiation. J. Infrared Millim. Terahertz Waves 2021, 42, 462–478. [Google Scholar] [CrossRef]

- Wang, J.; Li, W.; Gou, J.; Wu, Z.; Jiang, Y. Fabrication and Parameters Calculation of Room Temperature Terahertz Detector with Micro-Bridge Structure. J. Infrared Millim. Terahertz Waves 2015, 36, 49–59. [Google Scholar] [CrossRef]

- Trontelj, J.; Valušis, G.; Venckevičius, R.; Kašalynas, I.; Sešek, A.; Švigelj, A. A High Performance Room Temperature THz Sensor. In Proceedings of the SPIE Optical Engineering + Applications Conference on Terahertz Emitters, Receivers, and Applications V, San Diego, CA, USA, 17–18 August 2014; Volume 9199, pp. 114–123. [Google Scholar]

- Yang, H.H.; Rebeiz, G.M. Uncooled Ni-Cr Micro/Nano-Bolometers with NEP of 14 PW/Hz1/2. In Proceedings of the 2015 IEEE MTT-S International Microwave Symposium, Phoenix, AZ, USA, 17–22 May 2015; IEEE: New York, NY, USA, 2015; pp. 1–3. [Google Scholar]

- Wang, X. Monolithic Resonant CMOS Fully Integrated Triple-Band THz Thermal Detector. Opt. Express 2020, 28, 22630. [Google Scholar] [CrossRef] [PubMed]

- Xiao, P.; Tu, X.; Jiang, C.; Li, Z.; Zhou, S.; Pan, D.; Zhao, Q.; Jia, X.; Zhang, L.; Kang, L.; et al. Planar Double-Slot Antenna Integrated into a Nb 5 N 6 Microbolometer THz Detector. Opt. Lett. 2020, 45, 2894. [Google Scholar] [CrossRef]

- Zhang, Y.; Hosono, S.; Nagai, N.; Song, S.H.; Hirakawa, K. Fast and Sensitive Bolometric Terahertz Detection at Room Temperature through Thermomechanical Transduction. J. Appl. Phys. 2019, 125, 151602. [Google Scholar] [CrossRef]

- Tu, X.; Kang, L.; Wan, C.; Xu, L.; Mao, Q.; Xiao, P.; Jia, X.; Dou, W.; Chen, J.; Wu, P. Diffractive Microlens Integrated into Nb_5N_6 Microbolometers for THz Detection. Opt. Express 2015, 23, 13794. [Google Scholar] [CrossRef]

- Xiao, P.; Tu, X.; Kang, L.; Jiang, C.; Zhai, S.; Jiang, Z.; Pan, D.; Chen, J.; Jia, X.; Wu, P. Reflective Grating-Coupled Structure Improves the Detection Efficiency of THz Array Detectors. Sci. Rep. 2018, 8, 8032. [Google Scholar] [CrossRef]

- Tong, J.; Suo, F.; Zhang, T.; Huang, Z.; Chu, J.; Zhang, D.H. Plasmonic Semiconductor Nanogroove Array Enhanced Broad Spectral Band Millimetre and Terahertz Wave Detection. Light Sci. Appl. 2021, 10, 58. [Google Scholar] [CrossRef]

- He, Y.; Wang, Y.; Li, T. Simultaneously Controlling Heat Conduction and Infrared Absorption with a Textured Dielectric Film to Enhance the Performance of Thermopiles. Microsyst. Nanoeng. 2021, 7, 36. [Google Scholar] [CrossRef]

- Zheng, X.; Wu, Z.; Gou, J.; Liu, Z.; Wang, J.; Zheng, J.; Luo, Z.; Chen, W.; Que, L.; Jiang, Y. Enhancement of Real-Time THz Imaging System Based on 320 × 240 Uncooled Microbolometer Detector. J. Infrared Millim. Terahertz Waves 2016, 37, 965–976. [Google Scholar] [CrossRef]

- Bevilacqua, S.; Cherednichenko, S. Low Noise Nanometer Scale Room-Temperature YBa2Cu3O7-x Bolometers for THz Direct Detection. IEEE Trans. Terahertz Sci. Technol. 2014, 4, 653–660. [Google Scholar] [CrossRef]

- Ikamas, K.; But, D.B.; Lisauskas, A. Homodyne Spectroscopy with Broadband Terahertz Power Detector Based on 90-Nm Silicon CMOS Transistor. Appl. Sci. 2021, 11, 412. [Google Scholar] [CrossRef]

- Javadi, E.; But, D.B.; Ikamas, K.; Zdanevičius, J.; Knap, W.; Lisauskas, A. Sensitivity of Field-Effect Transistor-Based Terahertz Detectors. Sensors 2021, 21, 2909. [Google Scholar] [CrossRef] [PubMed]

- Palenskis, V.; Minkevičius, L.; Matukas, J.; Jokubauskis, D.; Pralgauskaitė, S.; Seliuta, D.; Čechavičius, B.; Butkutė, R.; Valušis, G. InGaAs Diodes for Terahertz Sensing—Effect of Molecular Beam Epitaxy Growth Conditions. Sensors 2018, 18, 3760. [Google Scholar] [CrossRef]

- Mou, J.; Xue, Q.; Guo, D.; Lv, X. A THz Detector Chip with Printed Circular Cavity as Package and Enhancement of Antenna Gain. IEEE Trans. Antennas Propag. 2016, 64, 1242–1249. [Google Scholar] [CrossRef]

- Bauer, M.; Ramer, A.; Chevtchenko, S.A.; Osipov, K.Y.; Cibiraite, D.; Pralgauskaite, S.; Ikamas, K.; Lisauskas, A.; Heinrich, W.; Krozer, V.; et al. A High-Sensitivity AlGaN/GaN HEMT Terahertz Detector with Integrated Broadband Bow-Tie Antenna. IEEE Trans. Terahertz Sci. Technol. 2019, 9, 430–444. [Google Scholar] [CrossRef]

- Sun, J.; Zhu, Y.; Feng, W.; Ding, Q.; Qin, H.; Sun, Y.; Zhang, Z.; Li, X.; Zhang, J.; Li, X.; et al. Passive Terahertz Imaging Detectors Based on Antenna-Coupled High-Electron-Mobility Transistors. Opt. Express 2020, 28, 4911. [Google Scholar] [CrossRef]

- Golenkov, A.; Sizov, F.; Lysiuk, I. Frequency Sensitive Effect of Rectifying FET Terahertz Detectors. In Proceedings of the 2016 46th European Microwave Conference (EuMC), London, UK, 4–6 October 2016; IEEE: New York, NY, USA, 2016; pp. 1107–1110. [Google Scholar]

- Tiwari, A.; Satoh, H.; Aoki, M.; Takeda, M.; Hiromoto, N.; Inokawa, H. Fabrication and Analytical Modeling of Integrated Heater and Thermistor for Antenna-Coupled Bolometers. Sens. Actuators A Phys. 2015, 222, 160–166. [Google Scholar] [CrossRef][Green Version]

- Aoki, M.; Takeda, M.; Hiromoto, N. Electromagnetic Simulation for THz Antenna-Coupled Microbolometers Operated at Room Temperature. Makara J. Technol. Ser. 2013, 17, 1. [Google Scholar] [CrossRef]

- Kruse, P.W. Uncooled Thermal Imaging Arrays, Systems, and Applications; SPIE Press: Bellingham, WA, USA, 2001. [Google Scholar]

- Cheng, Y.L.; Wei, B.J.; Shih, F.H.; Wang, Y.L. Stability and Reliability of Ti/TiN as a Thin Film Resistor. ECS J. Solid State Sci. Technol. 2013, 2, Q12–Q15. [Google Scholar] [CrossRef]

- Tanaka, A.; Matsumoto, S.; Tsukamoto, N.; Itoh, S.; Chiba, K.; Endoh, T.; Nakazato, A.; Okuyama, K.; Kumazawa, Y.; Hijikawa, M.; et al. Infrared Focal Plane Array Incorporating Silicon IC Process Compatible Bolometer. IEEE Trans. Electron. Devices 1996, 43, 1844–1850. [Google Scholar] [CrossRef]

- Ju, S.-B.; Yong, Y.-J.; Kim, S.-G. Design and Fabrication of a High-Fill-Factor Microbolometer Using Double Sacrificial Layers. In Proceedings of the SPIE Infrared Technology and Applications XXV, Orlando, FL, USA, 5–8 April 1999; pp. 180–189. [Google Scholar]

- Tiwari, A.; Satoh, H.; Aoki, M.; Takeda, M.; Hiromoto, N.; Inokawa, H. THz Antenna-Coupled Microbolometer with 0.1-µm-Wide Titanium Thermistor. Int. J. ChemTech Res. 2014, 7, 1019–1026. [Google Scholar]

- Tiwari, A.; Satoh, H.; Aoki, M.; Takeda, M.; Hiromoto, N.; Inokawa, H. Scaling Study of Antenna-Coupled Microbolometer. In Proceedings of the 46th conference on Solid State Devices and Materials (SSDM), Tsukuba, Japan, 8 September 2014. [Google Scholar]

- Inokawa, H.; Banerjee, A.; Elamaran, D.; Satoh, H.; Hiromoto, N. Impact of Downscaling on Terahertz Antenna-Coupled Bolometers. In Proceedings of the 2019 16th International Conference on Quality in Research (QIR): International Symposium on Electrical and Computer Engineering, Padang, Indonesia, 22–24 July 2019; IEEE: New York, NY, USA, 2019; pp. 1–4. [Google Scholar]

- Endo, T.; Sunahara, Y.; Satoh, S.; Katagi, T. Resonant Frequency and Radiation Efficiency of Meander Line Antennas. Electron. Commun. Jpn. (Part II Electron.) 2000, 83, 52–58. [Google Scholar] [CrossRef]

- Liu, L.; Rahman, S.M.; Jiang, Z.; Li, W.; Fay, P. Advanced Terahertz Sensing and Imaging Systems Based on Integrated III-V Interband Tunneling Devices. Proc. IEEE 2017, 105, 1020–1034. [Google Scholar] [CrossRef]

- Montero-de-Paz, J.; Ugarte-Munoz, E.; Garcia-Munoz, L.E.; Camara Mayorga, I.; Segovia-Vargas, D. Meander Dipole Antenna to Increase CW THz Photomixing Emitted Power. IEEE Trans. Antennas Propag. 2014, 62, 4868–4872. [Google Scholar] [CrossRef]

- Hoefle, M.; Haehnsen, K.; Oprea, I.; Cojocari, O.; Penirschke, A.; Jakoby, R. Compact and Sensitive Millimetre Wave Detectors Based on Low Barrier Schottky Diodes on Impedance Matched Planar Antennas. J. Infrared Millim. Terahertz Waves 2014, 35, 891–908. [Google Scholar] [CrossRef]

- Banerjee, A.; Satoh, H.; Elamaran, D.; Sharma, Y.; Hiromoto, N.; Inokawa, H. Performance Improvement of On-Chip Integrable Terahertz Microbolometer Arrays Using Nanoscale Meander Titanium Thermistor. J. Appl. Phys. 2019, 125, 214502. [Google Scholar] [CrossRef]

- Aji, A.P.; Satoh, H.; Apriono, C.; Rahardjo, E.T.; Hiromoto, N.; Inokawa, H. Performance Improvement of THz Microbolometer by Folded-Dipole Antenna. In Proceedings of the 68th JSAP Spring Meeting 2021, Online, 16–19 March 2021. 18p-Z09-2. [Google Scholar]

- Kominami, M.; Pozar, D.; Schaubert, D. Dipole and Slot Elements and Arrays on Semi-Infinite Substrates. IEEE Trans. Antennas Propag. 1985, 33, 600–607. [Google Scholar] [CrossRef]

- Aji, A.P.; Satoh, H.; Apriono, C.; Rahardjo, E.T.; Inokawa, H. Responsivity Calibration of Terahertz Pyroelectric Detector Based on Blackbody Radiator. In Proceedings of the 2021 17th International Conference on Quality in Research (QIR): International Symposium on Electrical and Computer Engineering, Depok, Indonesia, 13–15 October 2021; IEEE: New York, NY, USA, 2021; pp. 94–97. [Google Scholar]

- Liu, W.; Asheghi, M. Thermal Conduction in Ultrathin Pure and Doped Single-Crystal Silicon Layers at High Temperatures. J. Appl. Phys. 2005, 98, 123523. [Google Scholar] [CrossRef]

- Inokawa, H.; Satoh, H.; Akiba, K. Thermal Conductance and Heat Capacity Measurement Utilizing Suspended-Wire Resistor. In Proceedings of the 2017 15th International Conference on Quality in Research (QiR): International Symposium on Electrical and Computer Engineering, Nusa Dua, Bali, Indonesia, 24–27 July 2017; IEEE: New York, NY, USA, 2017; pp. 124–127. [Google Scholar]

- Rycerz, A. Wiedemann–Franz Law for Massless Dirac Fermions with Implications for Graphene. Materials 2021, 14, 2704. [Google Scholar] [CrossRef]

- Banerjee, A.; Satoh, H.; Tiwari, A.; Apriono, C.; Rahardjo, E.T.; Hiromoto, N.; Inokawa, H. Width Dependence of Platinum and Titanium Thermistor Characteristics for Application in Room-Temperature Antenna-Coupled Terahertz Microbolometer. Jpn. J. Appl. Phys. 2017, 56. [Google Scholar] [CrossRef]

- Banerjee, A.; Satoh, H.; Sharma, Y.; Hiromoto, N.; Inokawa, H. Characterization of Platinum and Titanium Thermistors for Terahertz Antenna-Coupled Bolometer Applications. Sens. Actuators A Phys. 2018, 273, 49–57. [Google Scholar] [CrossRef]

- Salazar, A. On Thermal Diffusivity. Eur. J. Phys. 2003, 24, 351–358. [Google Scholar] [CrossRef]

- Kato, R.; Hatta, I. Thermal Conductivity and Interfacial Thermal Resistance: Measurements of Thermally Oxidized SiO2 Films on a Silicon Wafer Using a Thermo-Reflectance Technique. Int. J. Thermophys. 2008, 29, 2062–2071. [Google Scholar] [CrossRef]

- Komatsu, S.; Ikeda, M. Thermal Conductivity and Electrical Resistivity of Titanium and Its Alloys. Titanium 1998, 46, 1–4. [Google Scholar]

- Balanis, C. Antenna Theory: Analysis and Design. In Antenna Theory: Analysis and Design; Wiley: Hoboken, NJ, USA, 2016; pp. 75–78. ISBN 978-1-118-64206-1. [Google Scholar]

- Hiromoto, N.; Banerjee, A.; Elamaran, D.; Aoki, M.; Apriono, C.; Satoh, H.; Bruendermann, E.; Rahardjo, E.T.; Inokawa, H. Room-Temperature Terahertz Antenna-Coupled Microbolometers with Titanium Thermistor and Heater. In Proceedings of the 2019 16th International Conference on Quality in Research (QIR): International Symposium on Electrical and Computer Engineering, Padang, Indonesia, 22–24 July 2019; IEEE: New York, NY, USA, 2019; pp. 1–5. [Google Scholar]

- Rahman, S.M.; Jiang, Z.; Xing, H.; Fay, P.; Liu, L. Lens-coupled Folded-dipole Antennas for Terahertz Detection and Imaging. IET Microw. Antennas Propag. 2015, 9, 1213–1220. [Google Scholar] [CrossRef]

| Device | Material | Dimensions (μm) | ||

|---|---|---|---|---|

| Length | Width | Thickness | ||

| Thermistor | Ti | 89.5 † | 0.1 | 0.05 |

| Heater | Ti | 11.5 | 0.1–2.1 (Wh) | 0.1, 0.2 |

| Halfwave dipole | Au/Ti | 52 | 5.2 | 0.2/0.02 |

| Folded dipole | Au/Ti | 61 | 1 | 0.2/0.02 |

| Antenna Type | Assumed Area for Input Power Calculation (m2) | Max. (V/W) | Min. NEPo (W/Hz0.5) | |

|---|---|---|---|---|

| Halfwave Dipole | 1.42 × 10−8 | 529.5 | 65.8 | |

| Folded Dipole | 881.7 | 39.5 | ||

| Halfwave Dipole | 3.49 × 10−9 | 2153 | 16.2 | |

| Folded Dipole | 4.00 × 10−9 | 3122 | 11.2 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aji, A.P.; Satoh, H.; Apriono, C.; Rahardjo, E.T.; Inokawa, H. Responsivity and NEP Improvement of Terahertz Microbolometer by High-Impedance Antenna. Sensors 2022, 22, 5107. https://doi.org/10.3390/s22145107

Aji AP, Satoh H, Apriono C, Rahardjo ET, Inokawa H. Responsivity and NEP Improvement of Terahertz Microbolometer by High-Impedance Antenna. Sensors. 2022; 22(14):5107. https://doi.org/10.3390/s22145107

Chicago/Turabian StyleAji, Arie Pangesti, Hiroaki Satoh, Catur Apriono, Eko Tjipto Rahardjo, and Hiroshi Inokawa. 2022. "Responsivity and NEP Improvement of Terahertz Microbolometer by High-Impedance Antenna" Sensors 22, no. 14: 5107. https://doi.org/10.3390/s22145107

APA StyleAji, A. P., Satoh, H., Apriono, C., Rahardjo, E. T., & Inokawa, H. (2022). Responsivity and NEP Improvement of Terahertz Microbolometer by High-Impedance Antenna. Sensors, 22(14), 5107. https://doi.org/10.3390/s22145107