Direct Measuring Particulate Matters in Smoke Plumes from Chimneys in a Textile Dyeing Industrial Park by a Self-Developed PM Detector on an UAV in Yangtze River Delta of China

Abstract

:1. Introduction

2. Materials and Methods

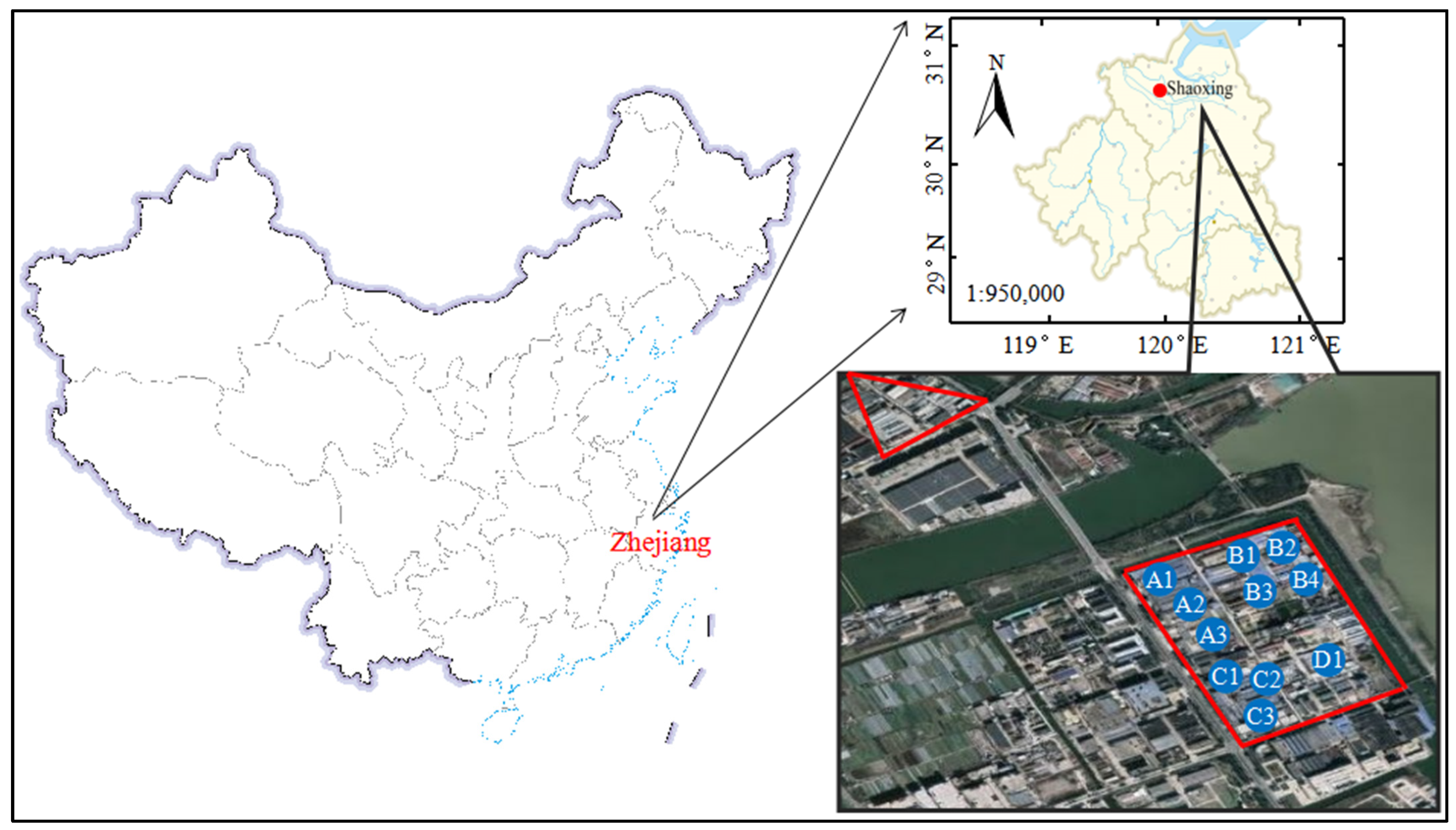

2.1. Sampling Locations

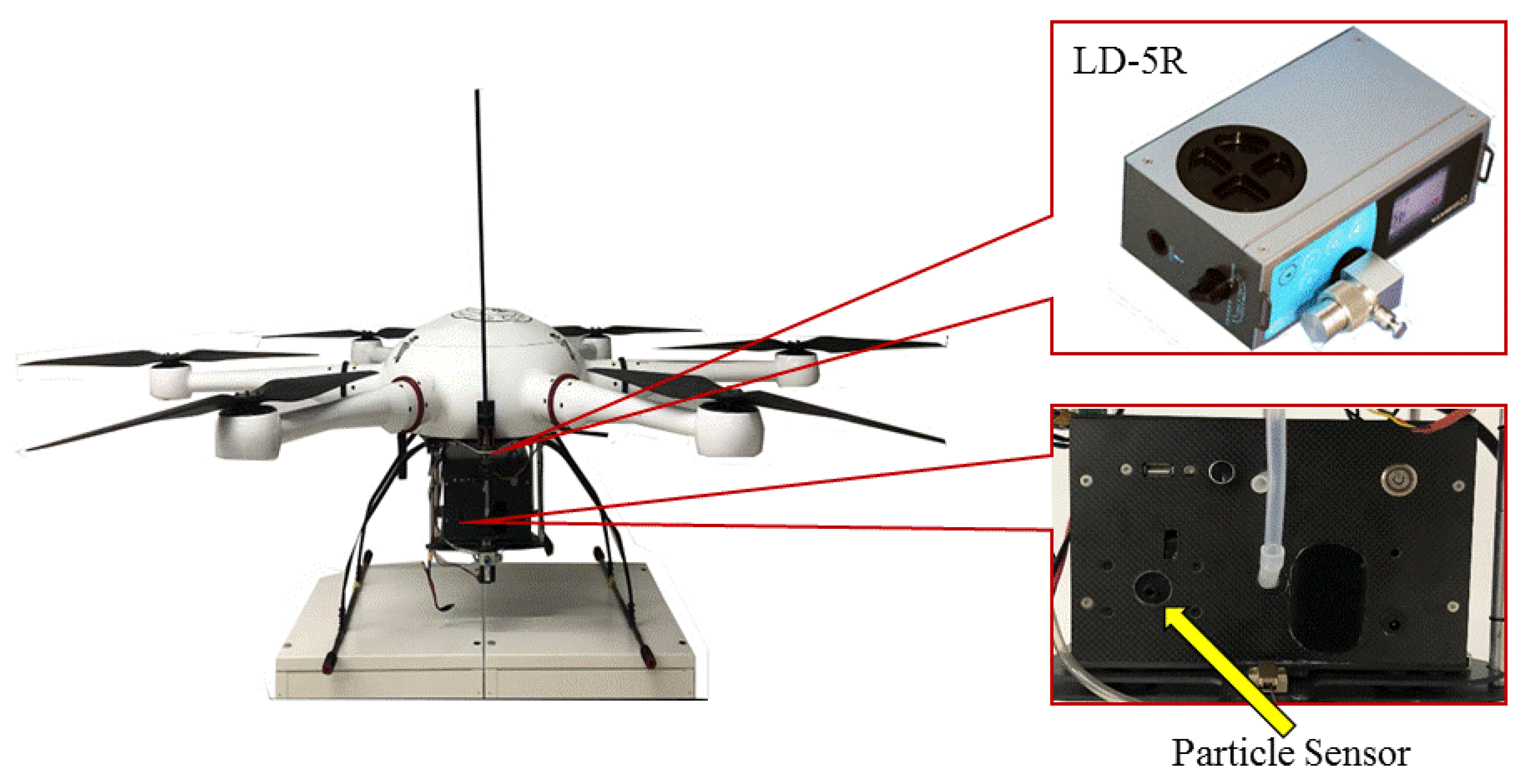

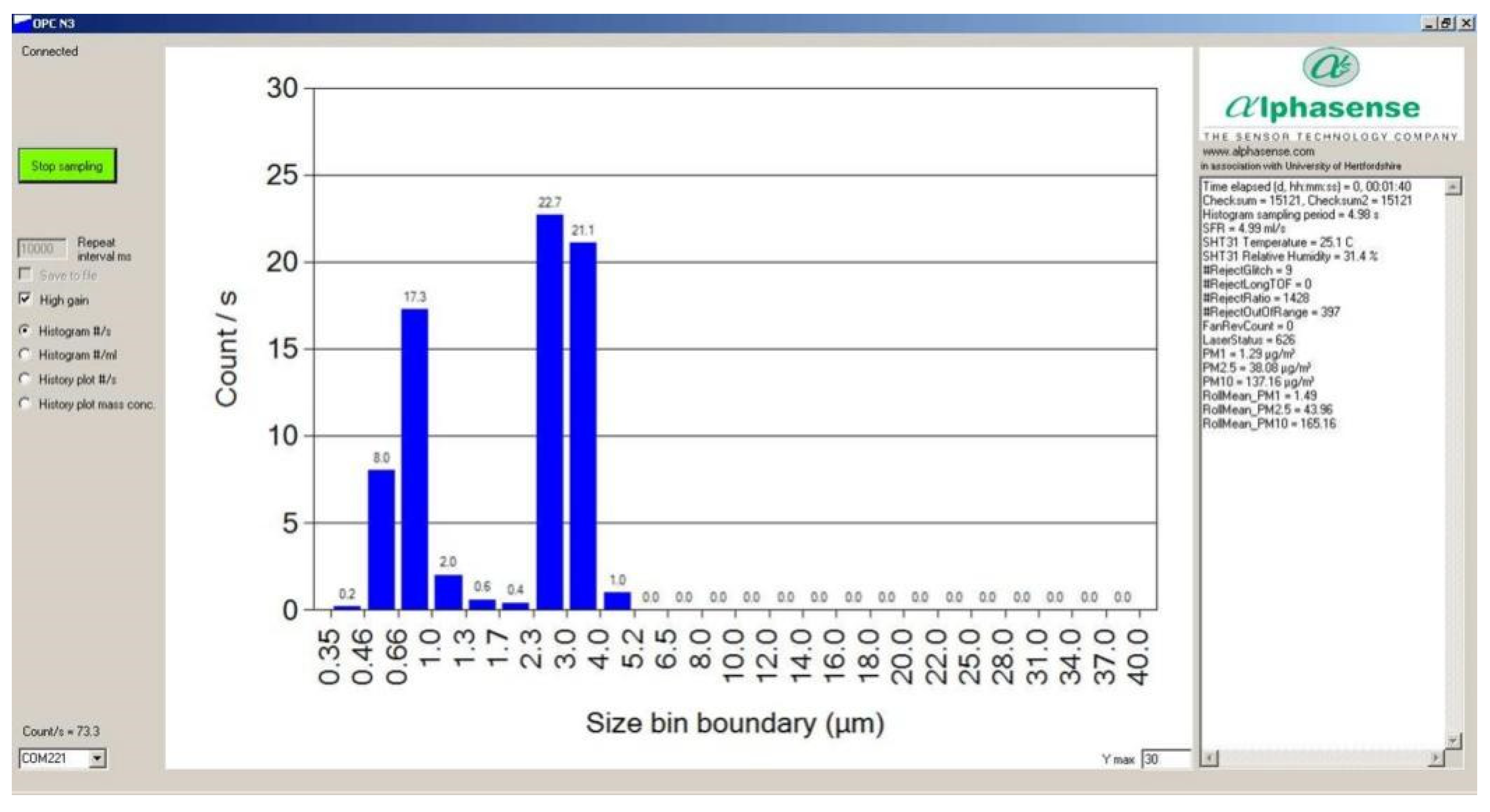

2.2. PM Detectors and UAV

2.3. Experimental Process

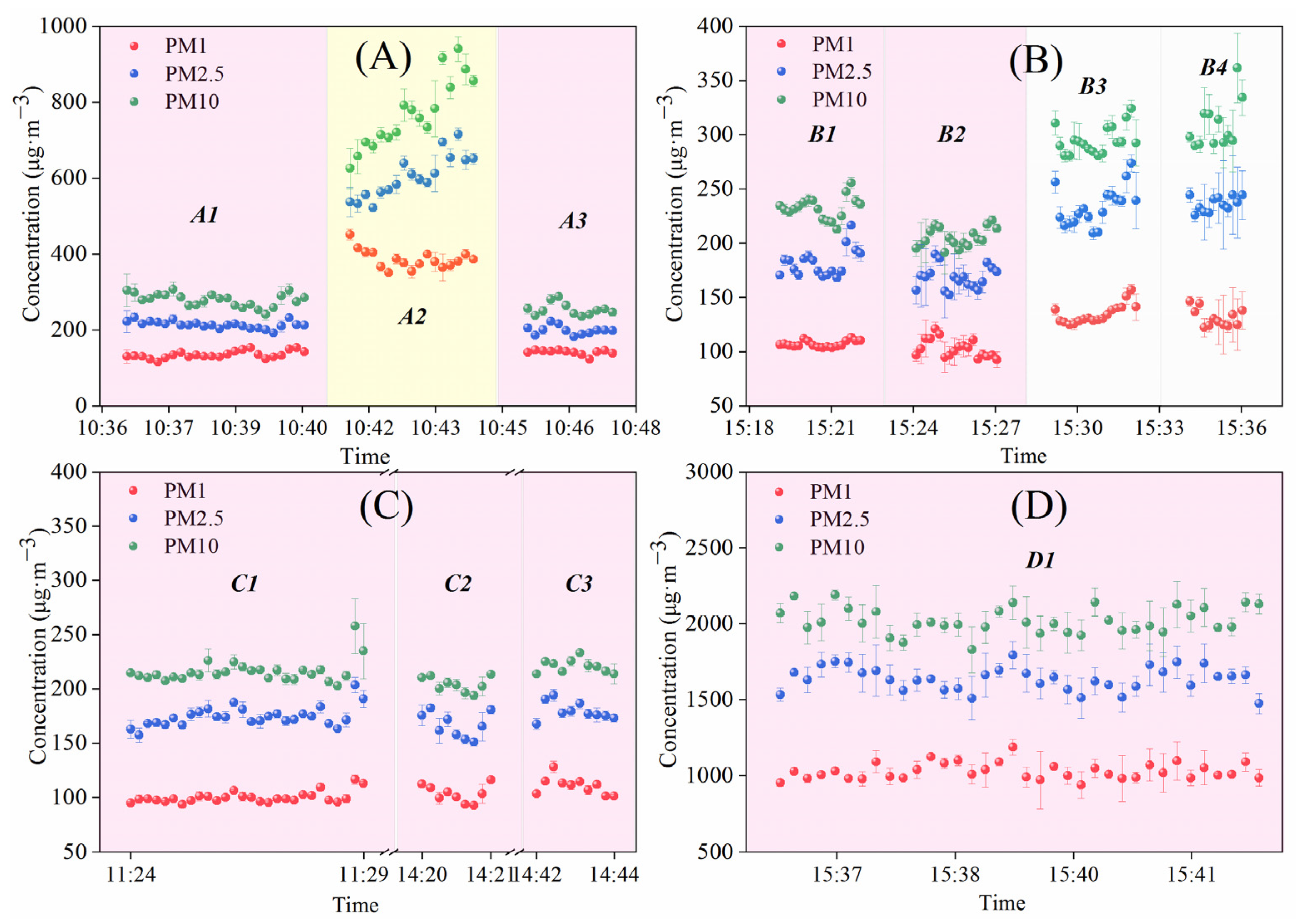

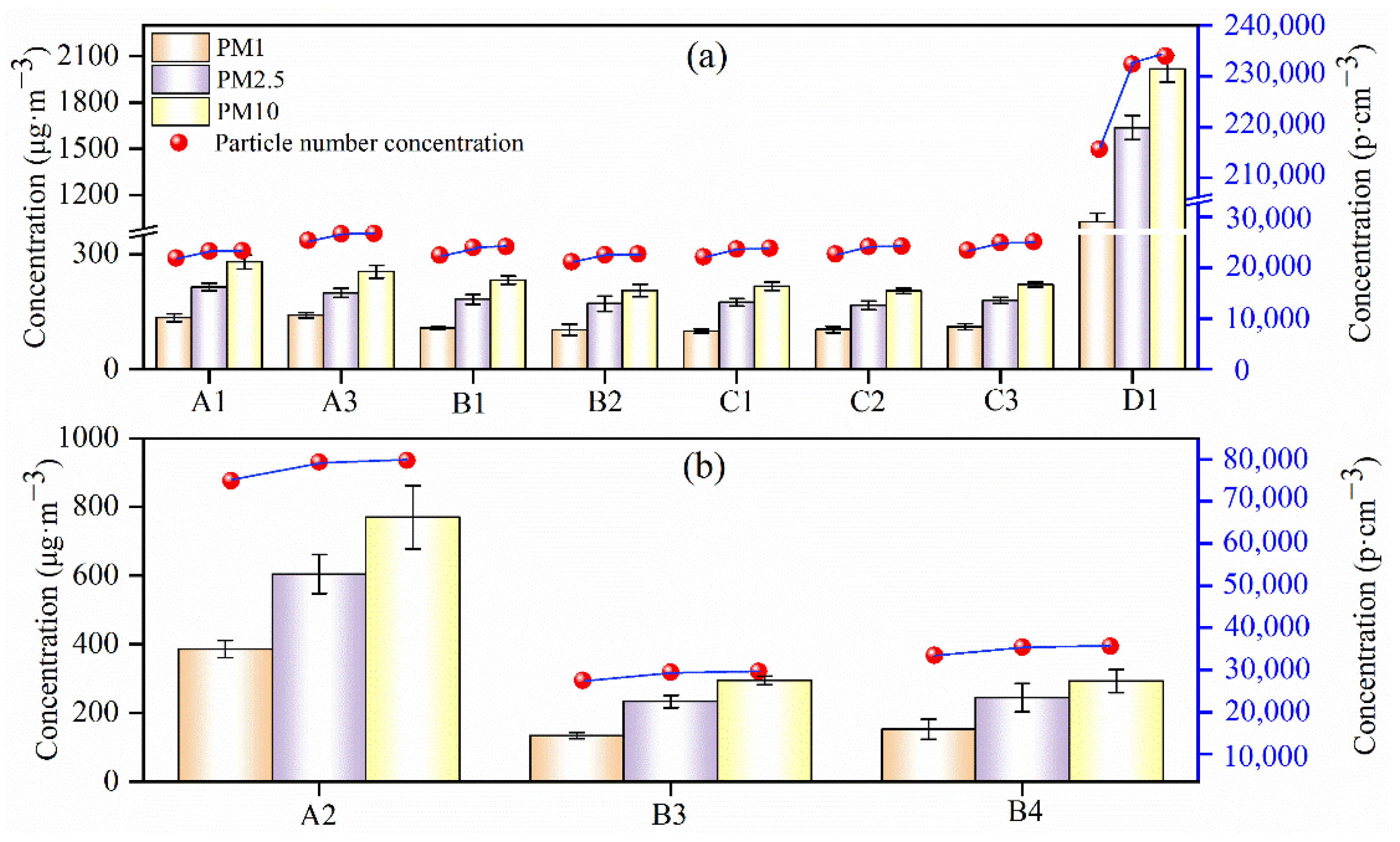

3. Results and Discussion

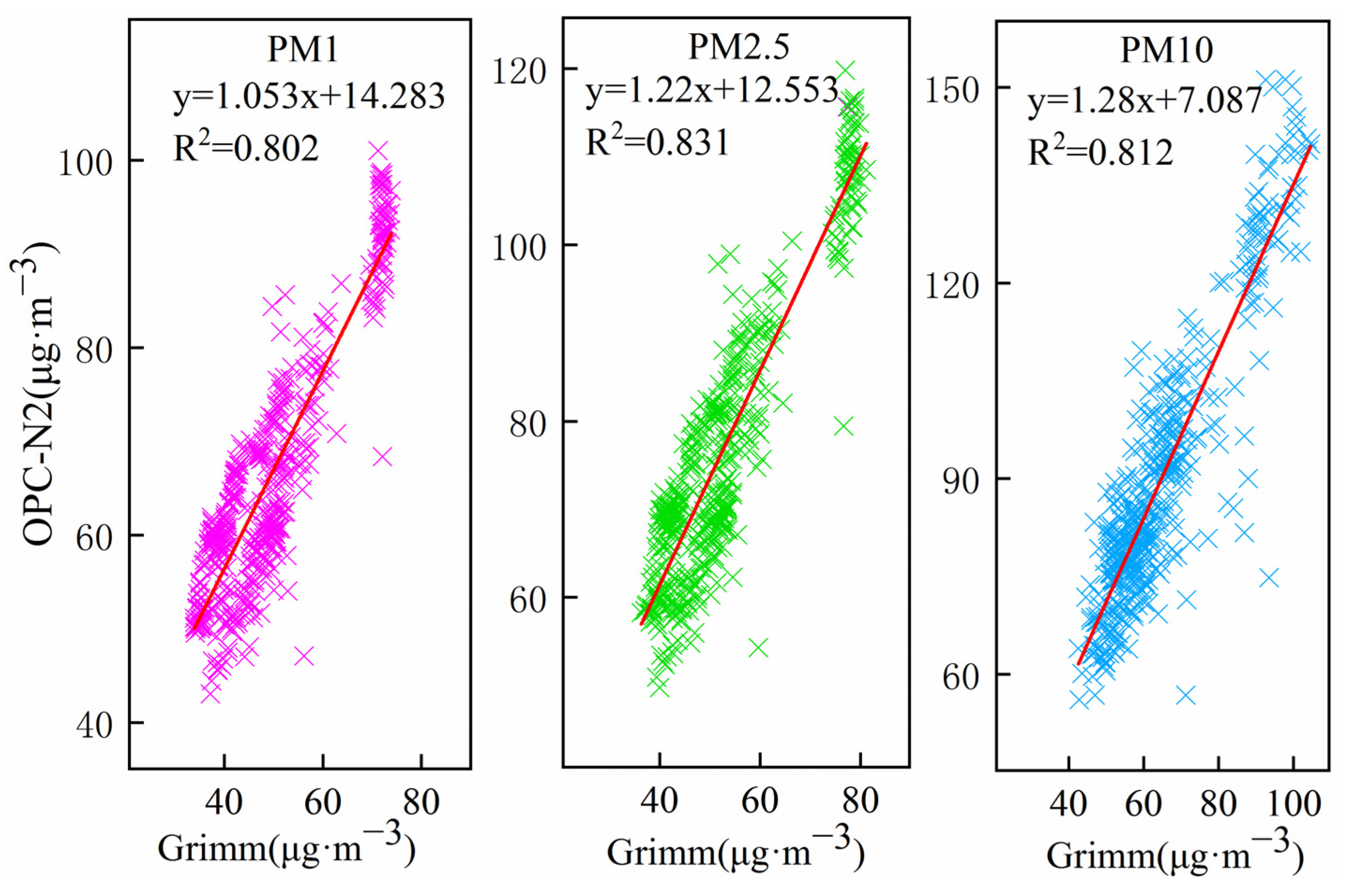

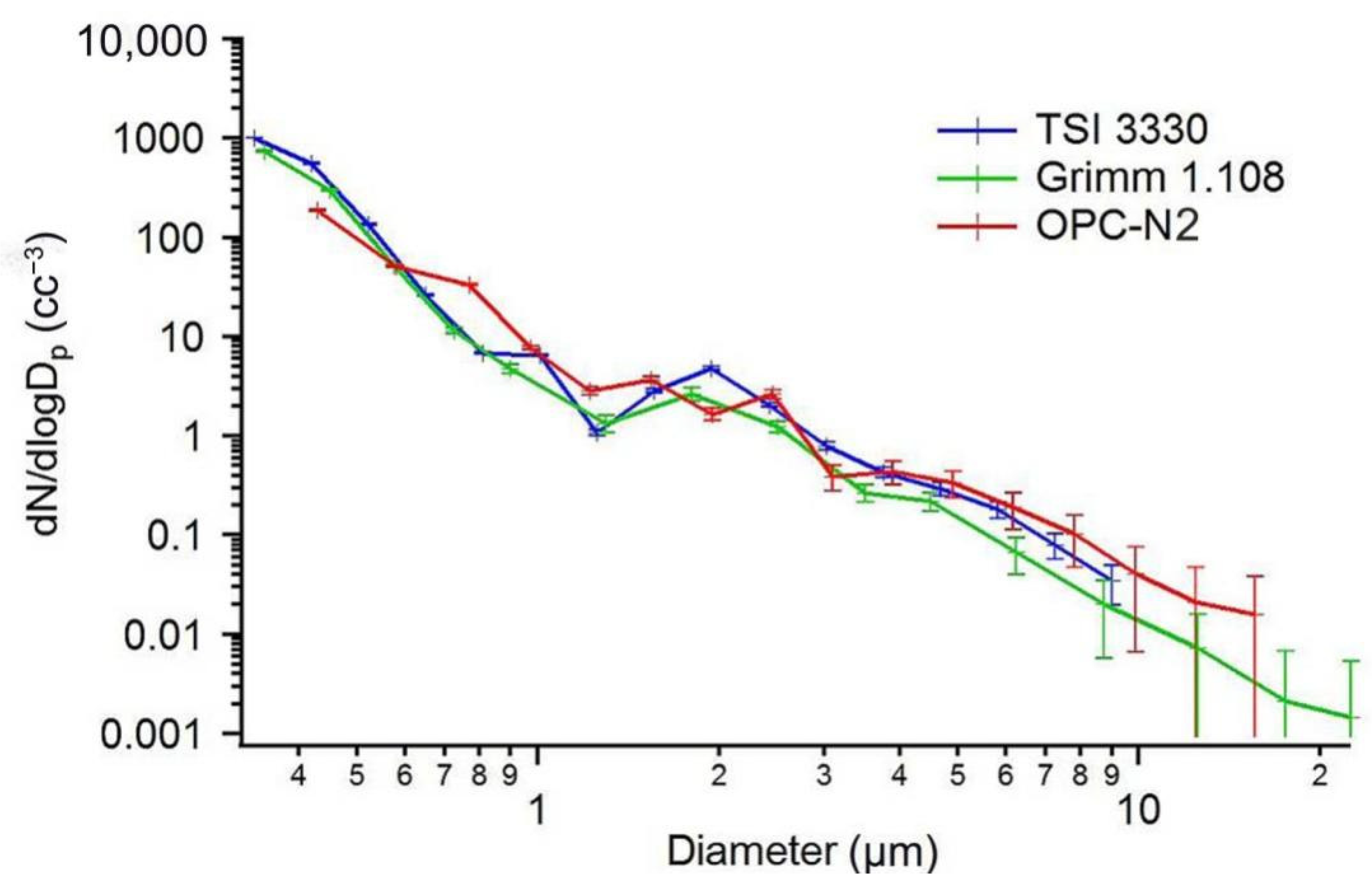

3.1. Comparison with Self-Developed PM Detector and Commercial Device

3.2. PM Concentrations and Size Distribution in Dyeing or Printing Process

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Aldalbahi, A.; El-Naggar, M.E.; El-Newehy, M.H.; Rahaman, M.; Hatshan, M.R.; Khattab, T.A. Effects of Technical Textiles and Synthetic Nanofibers on Environmental Pollution. Polymers 2021, 13, 155. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhu, L.B.; Zhang, C.; Ren, F.Y.; Huang, H.H.; Liu, Z.F. Life cycle assessment of melange yarns from the manufacturer perspective. Int. J. Life Cycle Assess. 2020, 25, 588–599. [Google Scholar] [CrossRef]

- Rovira, J.; Domingo, J.L. Human health risks due to exposure to inorganic and organic chemicals from textiles: A review. Environ. Res. 2019, 168, 62–69. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Li, Y.; Lou, Z.; Xie, H. Problems and countermeasures of wastewater treatment in Shaoxing’s textile printing and dyeing industry. J. Silk 2016, 53, 45–51. [Google Scholar]

- Zhang, L.; Wang, J.; Hu, X.; Zhou, J.; Zhao, M.; Zhang, J.; Bo, Y.; Huang, Y.; Zhang, Y. VOCs and PM concentrations in underground parking garages of the commercial center and high-rise residential buildings. Air Qual. Atmos. Health 2021, 14, 1117–1131. [Google Scholar] [CrossRef]

- Feng, Y.-Y.; Shi, J.-W.; Zhong, Y.-Q.; Han, X.-Y.; Feng, Y.-C.; Ren, L. Pollution Characteristics and Health Risk Assessment of Heavy Metals in Road Dust from Non-ferrous Smelting Parks. J. Environ. Sci. 2020, 41, 3547–3555. [Google Scholar]

- He, L.; Jin, H.; Wang, J.; Li, J.; Yu, Q.; Ma, W. Zero-impact emission limits of enterprise-scale air pollutants-a case study of a typical petrochemical enterprise in Shanghai Chemical Industry Park. J. Air Waste Manag. Assoc. 2022, 72, 98–115. [Google Scholar] [CrossRef]

- Mu, Y.; Zheng, X.; Li, W.; Xie, F.; Mao, P.; Li, Z.; Wang, Y. Development of an Industrial Air Pollutants Emission Inventory of Nanjing City. Environ. Sci. Technol. 2017, 40, 204–210. [Google Scholar]

- Zhuo, M.; Ma, S.; Li, G.; Yu, Y.; An, T. Chlorinated paraffins in the indoor and outdoor atmospheric particles from the Pearl River Delta: Characteristics, sources, and human exposure risks. Sci. Total Environ. 2019, 650, 1041–1049. [Google Scholar] [CrossRef]

- Miller, A.J.; Raduma, D.M.; George, L.A.; Fry, J.L. Source apportionment of trace elements and black carbon in an urban industrial area (Portland, Oregon). Atmos. Pollut. Res. 2019, 10, 784–794. [Google Scholar] [CrossRef]

- Senthilkumar, S.; Manju, A.; Muthuselvam, P.; Shalini, D.; Indhumathi, V.; Kalaiselvi, K.; Palanivel, M.; Chandrasekar, P.P.; Rajaguru, P. Characterization and genotoxicity evaluation of particulate matter collected from industrial atmosphere in Tamil Nadu State, India. J. Hazard. Mater. 2014, 274, 392–398. [Google Scholar] [CrossRef] [PubMed]

- Sahin, U.A.; Kurutas, B. Assessment of Fine Particulate Matter and Gaseous Pollutants in Workplace Atmosphere of Metallic Industry. Bull. Environ. Contam. Toxicol. 2012, 89, 898–904. [Google Scholar] [CrossRef] [PubMed]

- Strbova, K.; Raclavska, H.; Bilek, J. Impact of fugitive sources and meteorological parameters on vertical distribution of particulate matter over the industrial agglomeration. J. Environ. Manag. 2017, 203, 1190–1198. [Google Scholar] [CrossRef] [PubMed]

- Aurell, J.; Mitchell, W.; Chirayath, V.; Jonsson, J.; Tabor, D.; Gullett, B. Field Determination of Multipollutant, Open Area Combustion Source Emission Factors with a Hexacopter Unmanned Aerial Vehicle. Atmos. Environ. 2017, 166, 433–440. [Google Scholar] [CrossRef] [PubMed]

- Gullett, B.; Aurell, J.; Mitchell, W.; Richardson, J. Use of an unmanned aircraft system to quantify NOx emissions from a natural gas boiler. Atmos. Meas. Tech. 2021, 14, 975–981. [Google Scholar] [CrossRef]

- Zhou, F.; Gu, J.; Chen, W.; Ni, X. Measurement of SO2 and NO2 in Ship Plumes Using Rotary Unmanned Aerial System. Atmosphere 2019, 10, 657. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Huang, J.; Wang, Y.; Tao, X.; Hu, C.; Deng, L.; Xu, J.; Xiao, H.W.; Luo, L.; Xiao, H.Y.; et al. Vertical distribution of PM2.5 and interactions with the atmospheric boundary layer during the development stage of a heavy haze pollution event. Sci. Total Environ. 2020, 704, 135329. [Google Scholar] [CrossRef]

- Rautenberg, A.; Allgeier, J.; Jung, S.; Bange, J. Calibration Procedure and Accuracy of Wind and Turbulence Measurements with Five-Hole Probes on Fixed-Wing Unmanned Aircraft in the Atmospheric Boundary Layer and Wind Turbine Wakes. Atmosphere 2019, 10, 124. [Google Scholar] [CrossRef] [Green Version]

- Jumaah, H.J.; Kalantar, B.; Halin, A.A.; Mansor, S.; Ueda, N.; Jumaah, S.J. Development of UAV-Based PM2.5 Monitoring System. Drones 2021, 5, 60. [Google Scholar] [CrossRef]

- Madokoro, H.; Kiguchi, O.; Nagayoshi, T.; Chiba, T.; Inoue, M.; Chiyonobu, S.; Nix, S.; Woo, H.; Sato, K. Development of Drone-Mounted Multiple Sensing System with Advanced Mobility for In Situ Atmospheric Measurement: A Case Study Focusing on PM2.5 Local Distribution. Sensors 2021, 21, 4881. [Google Scholar] [CrossRef]

- Wang, T.H.; Han, W.T.; Zhang, M.F.; Yao, X.M.; Zhang, L.Y.; Peng, X.S.; Li, C.Q.; Dan, X.J. Unmanned Aerial Vehicle-Borne Sensor System for Atmosphere-Particulate-Matter Measurements: Design and Experiments. Sensors 2020, 20, 57. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sheng, Q.Q.; Zhang, Y.L.; Zhu, Z.L.; Li, W.Z.; Xu, J.Y.; Tan, R. An experimental study to quantify road greenbelts and their association with PM2.5 concentration along city main roads in Nanjing, China. Sci. Total Environ. 2019, 667, 710–717. [Google Scholar] [CrossRef] [PubMed]

- Villa, T.F.; Jayaratne, E.R.; Gonzalez, L.F.; Morawska, L. Determination of the vertical profile of particle number concentration adjacent to a motorway using an unmanned aerial vehicle. Environ. Pollut. 2017, 230, 134–142. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, Q.; Gao, Z.; Zhu, W.; Chen, J.; An, T. Underestimated contribution of fugitive emission to VOCs in pharmaceutical industry based on pollution characteristics, odorous activity and health risk assessment. J. Environ. Sci. 2022. [Google Scholar] [CrossRef]

- Pang, X.; Chen, L.; Shi, K.; Wu, F.; Chen, J.; Fang, S.; Wang, J.; Xu, M. A lightweight low-cost and multipollutant sensor package for aerial observations of air pollutants in atmospheric boundary layer. Sci. Total Environ. 2021, 764, 142828. [Google Scholar] [CrossRef]

- Ziegler, J.; Wachtel, H. Comparison of cascade impaction and laser diffraction for particle size distribution measurements. J. Aerosol Med. Depos. Clear. Eff. Lung 2005, 18, 311–324. [Google Scholar] [CrossRef]

- Duran, J.Z.; Caldona, E.B. Design of an activated carbon equipped-cyclone separator and its performance on particulate matter removal. Part. Sci. Technol. 2020, 38, 694–702. [Google Scholar] [CrossRef]

- Yang, Y.; Li, M.; Fu, S. Use of highly-stable and covalently bonded polymer colorant on binder-free pigment printing of citric acid treated cotton fabric. Cellulose 2021, 28, 1843–1856. [Google Scholar] [CrossRef]

- Sahin, U.K.; Tufan, H.A. Effects of Binder Solution on Color Fastness of Digital Printed Cotton Fabric. In Proceedings of the 18th World Textile Conference (AUTEX), Istanbul, Turkey, 20–22 June 2018. [Google Scholar]

- Ketema, A.; Worku, A. Review on Intermolecular Forces between Dyes Used for Polyester Dyeing and Polyester Fiber. J. Chem. 2020, 2020, 6628404. [Google Scholar] [CrossRef]

- Rastogi, D.; Sen, K.; Gulrajani, M. Photofading of reactive dyes on silk and cotton: Effect of dye-fibre interactions. Color. Technol. 2001, 117, 193–198. [Google Scholar] [CrossRef]

- Aspland, J.R. Chapter 5—Reactive Dyes and Their Application. Text. Chem. Color. 1992, 24, 31–36. [Google Scholar]

- Li, C.; Xiao, H.; Wang, X.; Zhao, T. Development of green waterborne UV-curable vegetable oil-based urethane acrylate pigment prints adhesive: Preparation and application. J. Clean. Prod. 2018, 180, 272–279. [Google Scholar] [CrossRef]

- Seemork, K.; Setthayanond, J.; Suwanruji, P.; Tooptompong, P. Utilization of Spent Coffee Ground Oil in Eco-Friendly Scouring and Reactive Dyeing Processes for Cotton. Mater. Sci. Forum 2020, 1005, 85–92. [Google Scholar] [CrossRef]

- Kim, M.-K.; Jang, Y.; Park, D. Determination of the Optimum Removal Efficiency of Fine Particulate Matter Using Activated Carbon Fiber (ACF). Int. J. Environ. Res. Public Health 2020, 17, 8230. [Google Scholar] [CrossRef]

| Chimney No. | Process | Process Description | Exhaust Treatment |

|---|---|---|---|

| A1, A3, B1, B2, C1, C2 and C3 | Dyeing | coloring fiber with dyes | Electrostatic precipitation |

| A2 | Pigment printing | printing fiber with pigments and adhesives | Electrostatic precipitation |

| B3 and B4 | Digital printing | printing disperse dyes onto fabric by digital technology | Electrostatic precipitation |

| D1 | Dyeing | coloring fiber with dyes | Activated carbon adsorption |

| Sites | C1 | C2 | C3 | D1 |

|---|---|---|---|---|

| LD-5R | 161 ± 10 (n = 28 ) | 195 ± 50 (n = 10) | 197 ± 15 (n = 10) | 1676 ± 97 (n = 36) |

| PM detector | 150 ± 15 (n = 28) | 178 ± 36 (n = 10) | 189 ± 37 (n = 10) | 1537 ± 110 (n = 36) |

| RPD (%) | 6.8 | 8.7 | 3.9 | 8.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Pang, X.; Han, Z.; Yuan, K.; Dai, S.; Li, J.; Chen, J.; Xing, B. Direct Measuring Particulate Matters in Smoke Plumes from Chimneys in a Textile Dyeing Industrial Park by a Self-Developed PM Detector on an UAV in Yangtze River Delta of China. Sensors 2022, 22, 4330. https://doi.org/10.3390/s22124330

Wu Z, Pang X, Han Z, Yuan K, Dai S, Li J, Chen J, Xing B. Direct Measuring Particulate Matters in Smoke Plumes from Chimneys in a Textile Dyeing Industrial Park by a Self-Developed PM Detector on an UAV in Yangtze River Delta of China. Sensors. 2022; 22(12):4330. https://doi.org/10.3390/s22124330

Chicago/Turabian StyleWu, Zhentao, Xiaobing Pang, Zhangliang Han, Kaibin Yuan, Shang Dai, Jingjing Li, Jianmeng Chen, and Bo Xing. 2022. "Direct Measuring Particulate Matters in Smoke Plumes from Chimneys in a Textile Dyeing Industrial Park by a Self-Developed PM Detector on an UAV in Yangtze River Delta of China" Sensors 22, no. 12: 4330. https://doi.org/10.3390/s22124330

APA StyleWu, Z., Pang, X., Han, Z., Yuan, K., Dai, S., Li, J., Chen, J., & Xing, B. (2022). Direct Measuring Particulate Matters in Smoke Plumes from Chimneys in a Textile Dyeing Industrial Park by a Self-Developed PM Detector on an UAV in Yangtze River Delta of China. Sensors, 22(12), 4330. https://doi.org/10.3390/s22124330