Design and Analysis of a 6-DOF Magnetic Suspension Platform with an Improved Permanent Magnetic Array

Abstract

1. Introduction

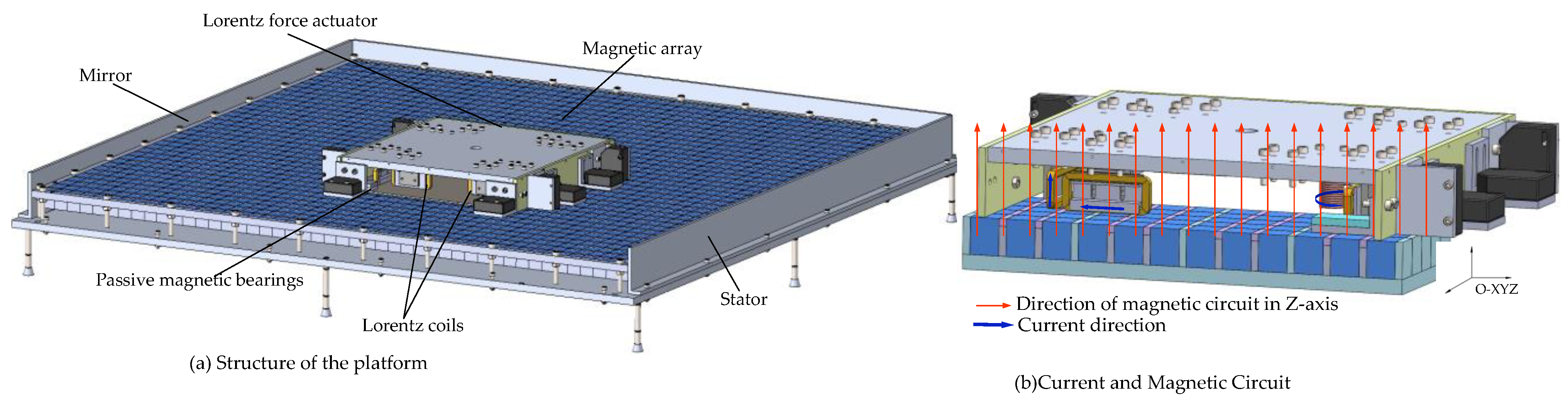

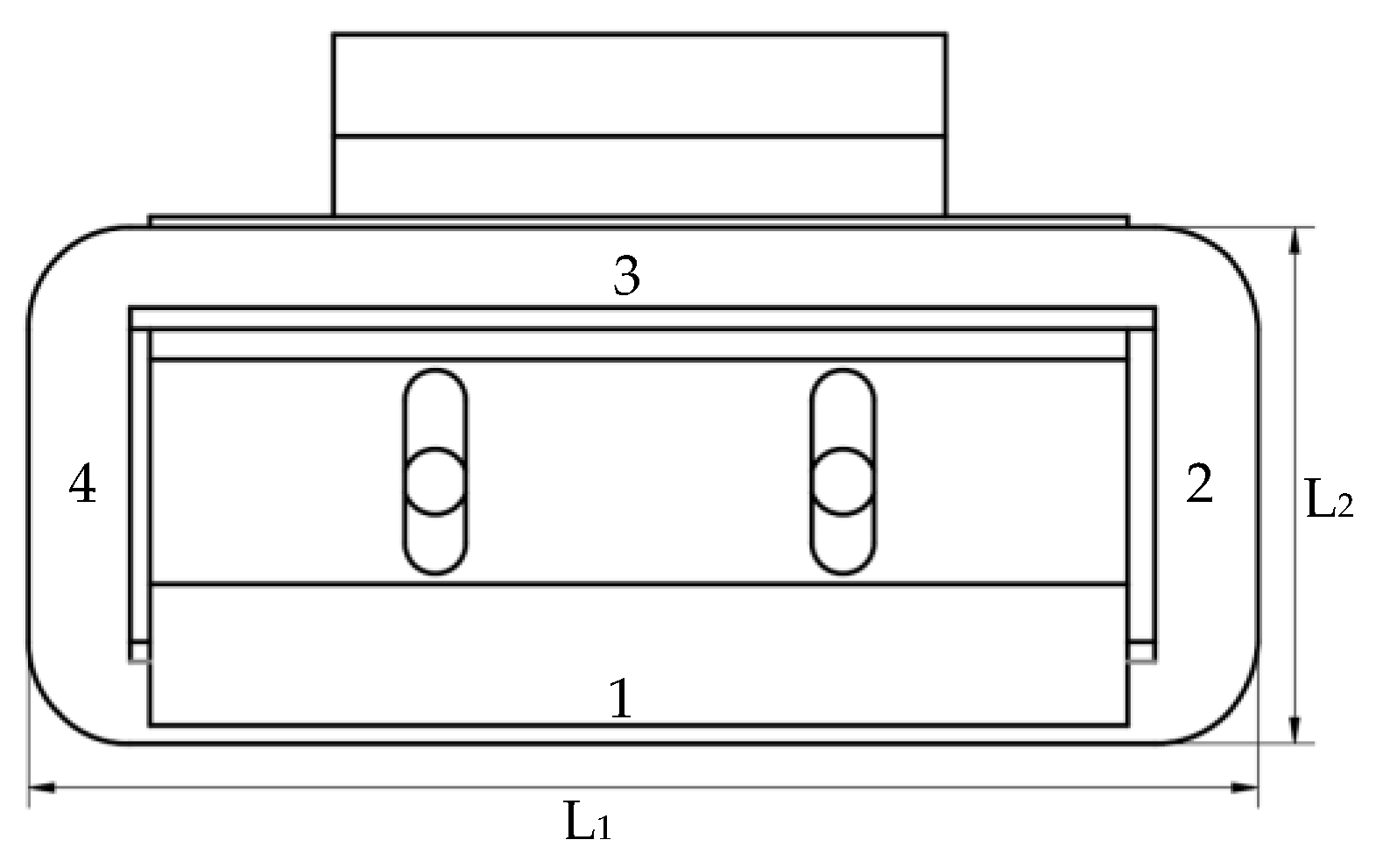

2. Structure and Working Principle

3. Force Model

3.1. Suspension Force Model

3.2. Driving Force Model

4. Measurement Model of Actuator

4.1. Position Measurement Model for the Actuator

4.2. Acceleration Model of Actuator

5. Suspension Force and Driving Force Analysis

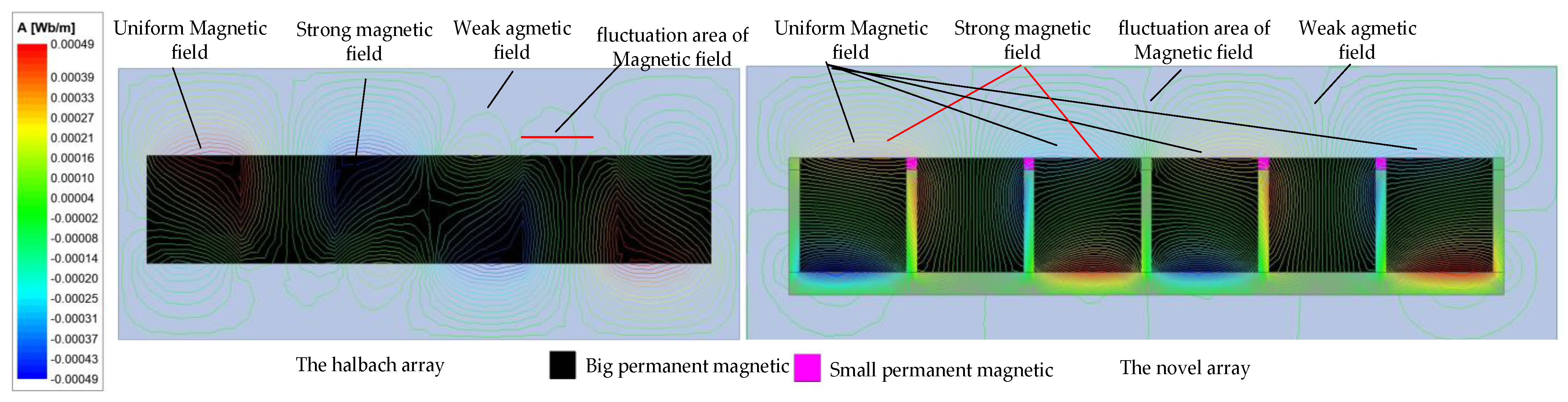

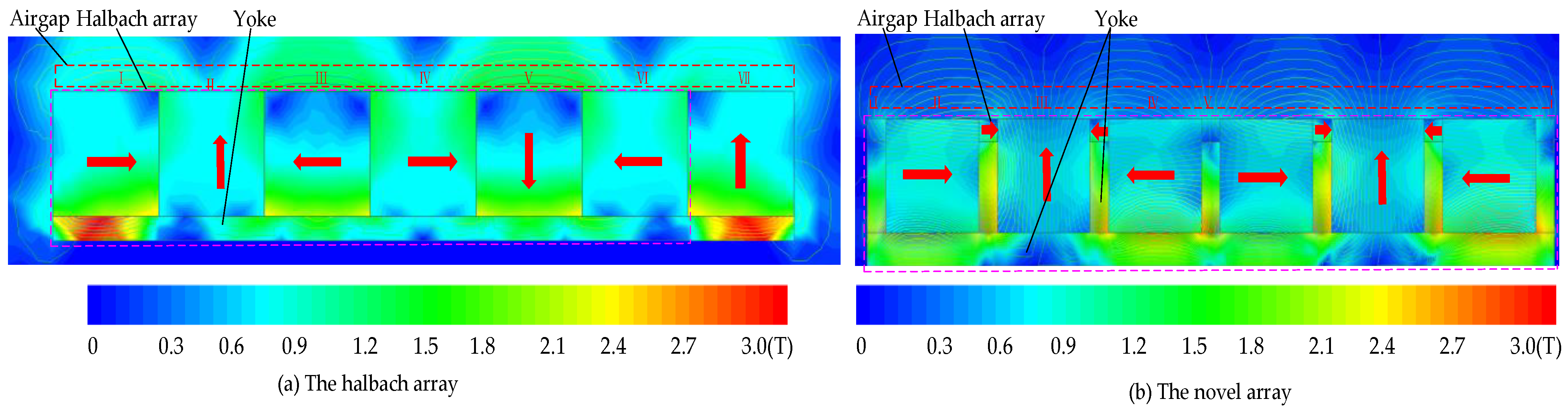

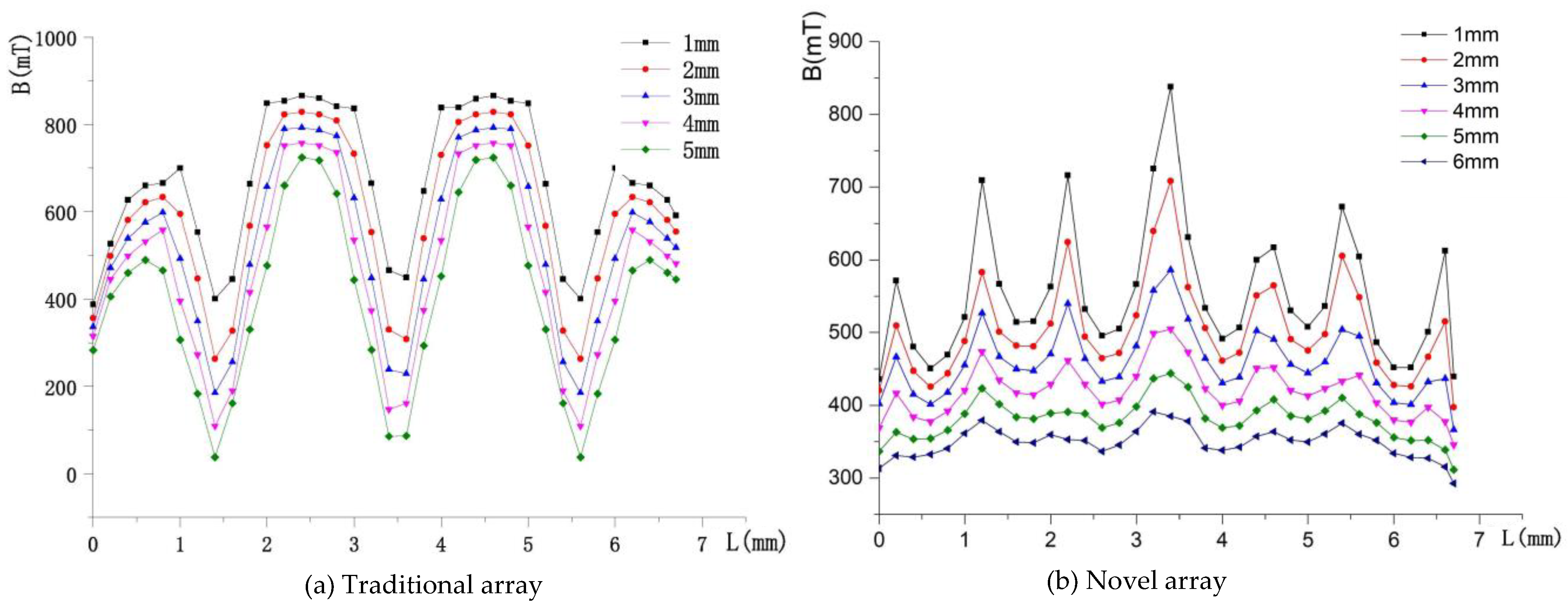

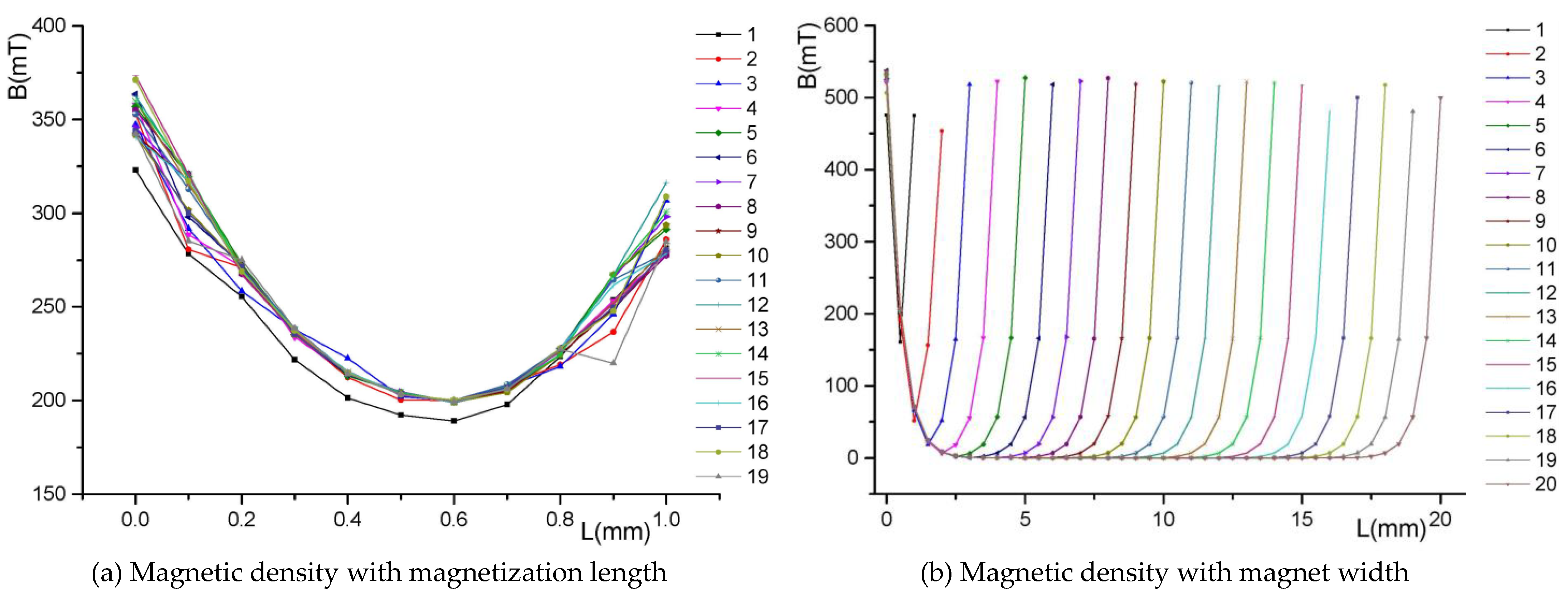

5.1. Analysis of the Magnetic Flux Density

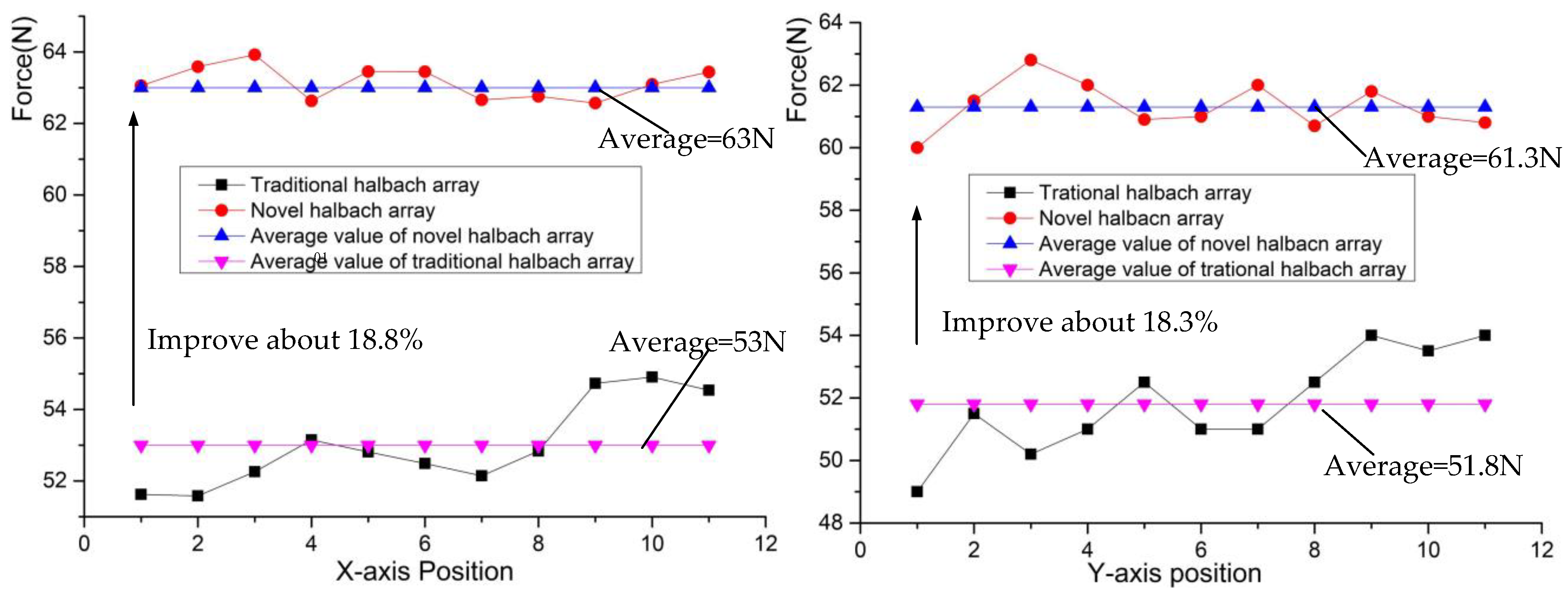

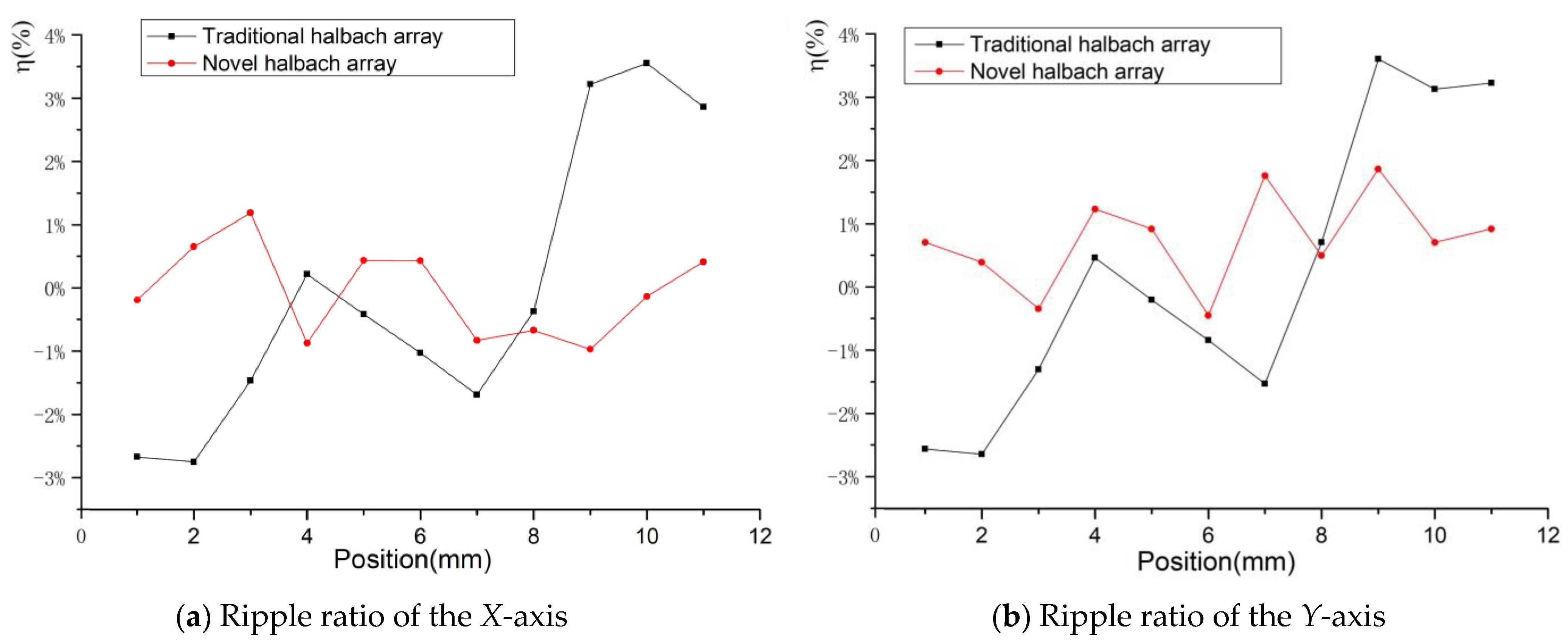

5.2. Analysis of the Force

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Choi, K.B.; Lee, J.J.; Kim, G.H.; Lim, H.J. A compliant parallel mechanism with flexure-based joint chains for two translations. Int. J. Precis. Eng. Manuf. 2012, 13, 1625–1632. [Google Scholar] [CrossRef]

- Colic, M.; Lechter, A.; Morse, W.; Miller, J.D. The Development and Application of the Hybrid Centrifugal-Dissolved Air Flotation System for Wastewater Treatment. In Proceedings of the 21st Filtration and Separation Society Meeting, Valley Forge, PA, USA, 19–22 May 2008. [Google Scholar]

- Nassar, S. Improving the Inertial Navigation System (INS) Error Model for INS and INS/DGPS Applications [Microform]. Ph.D. Thesis, The University of Calgary, Calgary, AB, Canada, 2003. [Google Scholar]

- Tanaka, K. Development of 6DOF Magnetic Levitation Stage for Lithography Tool-Proof of Concept (Second Report). J. Jpn. Soc. Precis. Eng. 2009, 75, 605–611. [Google Scholar] [CrossRef]

- Kim, W.J.; Trumper, D.L. High-precision magnetic levitation stage for photolithography. Precis. Eng. 1998, 22, 66–77. [Google Scholar] [CrossRef]

- Kim, W.J.; Bhat, N.; Hu, T. Integrated multidimensional positioner for precision manufacturing. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2004, 218, 431–442. [Google Scholar] [CrossRef]

- Verma, S.; Shakir, H.; Kim, W.J. Novel Electromagnetic Actuation Scheme for Multiaxis Nanopositioning. IEEE Trans. Magn. 2006, 42, 2052–2062. [Google Scholar] [CrossRef]

- Estevez, P.; Mulder, A.; Schmidt, R. 6-DoF miniature maglev positioning stage for application in haptic micro-manipulation. Mechatronics 2012, 22, 1015–1022. [Google Scholar] [CrossRef]

- Deng, R.; Zhao, Y.; Fang, J. Disturbance characteristics analysis of magnetically suspended and mechanical flywheel. J. Astronaut. 2016, 37, 917–923. [Google Scholar]

- Zhang, Z.; Menq, C.H. Six-axis magnetic levitation and motion control. IEEE Trans. Robot. 2007, 23, 196–205. [Google Scholar] [CrossRef]

- Wei, G.; Dejima, S.; Yanai, H.; Katakura, K.; Tomita, Y. A surface motor-driven planar motion stage integrated with an XYθ Z surface encoder for precision positioning. Precis. Eng. 2004, 28, 329–337. [Google Scholar]

- Dejima, S.; Wei, G.; Shimizu, H.; Kiyono, S.; Tomita, Y. Precision positioning of a five degree-of-freedom planar motion stage. Mechatronics 2005, 15, 969–987. [Google Scholar] [CrossRef]

- Lee, D.J.; Lee, K.N.; Park, N.C.; Park, Y.P.; Lee, D.J. Development of 3-Axis Nano Stage for Precision Positioning in Lithography System. In Proceedings of the Mechatronics & Automation, IEEE International Conference, Niagara Falls, ON, Canada, 29 July–1 August 2005. [Google Scholar]

- Xu, F.; Xu, X.; Chen, M. Prototype of 6-DOF Magnetically Levitated Stage Based on Single Axis Lorentz force Actuator. J. Electr. Eng. Technol. 2016, 11, 1216–1228. [Google Scholar] [CrossRef]

- Yang, F.; Zhao, Y.; Li, H.; Mu, X.; Zhang, W.; Yue, H.; Liu, R. Design and Analysis of a 2-DOF Electromagnetic Actuator with an Improved Halbach Array for the Magnetic Suspension Platform. Sensors 2022, 22, 790. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.; Gweon, D. A High-Precision Dual-Servo Stage Using Halbach Linear Active Magnetic Bearings. IEEE/ASME Trans. Mechatron. 2011, 16, 925–931. [Google Scholar] [CrossRef]

- Britcher, C.P.; Ghofrani, M. A magnetic suspension system with a large angular range. Rev. Sci. Instrum. 1993, 64, 1910–1917. [Google Scholar] [CrossRef]

- Choi, Y.M.; Lee, M.G.; Gweon, D.G.; Jeong, J. A new magnetic bearing using Halbach magnet arrays for a magnetic levitation stage. Rev. Sci. Instrum. 2009, 80, 045106. [Google Scholar] [CrossRef]

- Molenaar, L.; Zaaijer, E. A Novel Long Stroke Planar Magnetic Bearingactuator. In Proceedings of the 4th International Conference on Motion and Vibration Control, Zurich, Switzerland, 3 August 1998; pp. 1071–1076. [Google Scholar]

- Jabben, L.; Overschie, P.M.; Molenaar, A. Lorentz Motor with Stationary Magnets and Coils Applied in a 6DOF Contactless Motion Stage; American Society for Precision Engineering Net: Washington, DC, USA, 2014. [Google Scholar]

- Rovers, J.; Jansen, J.W.; Compter, J.C.; Lomonova, E.A. Analysis Method of the Dynamic Force and Torque Distribution in the Magnet Array of a Commutated Magnetically Levitated Planar Actuator. IEEE Trans. Ind. Electron. 2012, 59, 2157–2166. [Google Scholar] [CrossRef]

- Jansen, J.W.; Lierop, C.V.; Lomonova, E.A.; Vandenput, A. Modeling of Magnetically Levitated Planar Actuators with Moving Magnets. IEEE Trans. Magn. 2006, 43, 15–25. [Google Scholar] [CrossRef]

- Schaeffel, C.; Katzschmann, M.; Mohr, H.; Gloess, R.; Rudolf, C.; Mock, C.; Walenda, C. 6D planar magnetic levitation system-PIMag 6D. Mech. Eng. J. 2016, 3, 15-00111. [Google Scholar] [CrossRef][Green Version]

- Takahashi, M. Design Concept and Structural Configuration of Magnetic Levitation Stage with Z-Assist System. Int. J. Autom. Technol. 2021, 15, 706–714. [Google Scholar] [CrossRef]

- Torralba, M.; Valenzuela, M.; Yagüe-Fabra, J.A.; Albajez, J.A.; Aguilar, J.J. Large range nanopositioning stage design: A three-layer and two-stage platform. Measurement 2016, 89, 55–71. [Google Scholar] [CrossRef]

- Berkelman, P.; Lu, Y.S. Long Range Six Degree-of-Freedom Magnetic Levitation Using Low Cost Sensing and Control. J. Robot. Mechatron. 2020, 32, 683–691. [Google Scholar] [CrossRef]

- Marta, T.; José, Y.; José, A.; Juan, A. Design Optimization for the Measurement Accuracy Improvement of a Large Range Nanopositioning Stage. Sensors 2016, 16, 84. [Google Scholar] [CrossRef]

| Movement of the Platform | Driving Force/Torque |

|---|---|

| Translation in X-axis direction of O-XYZ | Driving coils 1 and 7 or 4 and 11 |

| Translation in Y-axis direction of O-XYZ | Driving coils 5 and 10 or 2 and 8 |

| Translation in Z-axis direction of O-XYZ | Suspension coils 3, 6, 9, 12 |

| Rotate around X-axis of O-XYZ | Suspension coils 3, 6 and 9, 12 |

| Rotate around Y-axis of O-XYZ | Suspension coils 3 12 and 6, 9 |

| Rotate around Z-axis of O-XYZ | Driving coils 1 and 7 or 4 and 11 or 5 and 10 or 2 and 8 |

| The Halbach Array | The Novel Array | |

|---|---|---|

| Value | 6.5 N*cm | 7.4 N*cm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, S.; Niu, P.; Bai, J.; Wang, W.; Liu, Q.; Sheng, S.; Li, J. Design and Analysis of a 6-DOF Magnetic Suspension Platform with an Improved Permanent Magnetic Array. Sensors 2022, 22, 4067. https://doi.org/10.3390/s22114067

Cao S, Niu P, Bai J, Wang W, Liu Q, Sheng S, Li J. Design and Analysis of a 6-DOF Magnetic Suspension Platform with an Improved Permanent Magnetic Array. Sensors. 2022; 22(11):4067. https://doi.org/10.3390/s22114067

Chicago/Turabian StyleCao, Shinan, Pingjuan Niu, Jie Bai, Wei Wang, Qiang Liu, Sha Sheng, and Jing Li. 2022. "Design and Analysis of a 6-DOF Magnetic Suspension Platform with an Improved Permanent Magnetic Array" Sensors 22, no. 11: 4067. https://doi.org/10.3390/s22114067

APA StyleCao, S., Niu, P., Bai, J., Wang, W., Liu, Q., Sheng, S., & Li, J. (2022). Design and Analysis of a 6-DOF Magnetic Suspension Platform with an Improved Permanent Magnetic Array. Sensors, 22(11), 4067. https://doi.org/10.3390/s22114067