High-Sensitivity Whispering Gallery Mode Humidity Sensor Based on Glycerol Microdroplet Volumetric Expansion

Abstract

1. Introduction

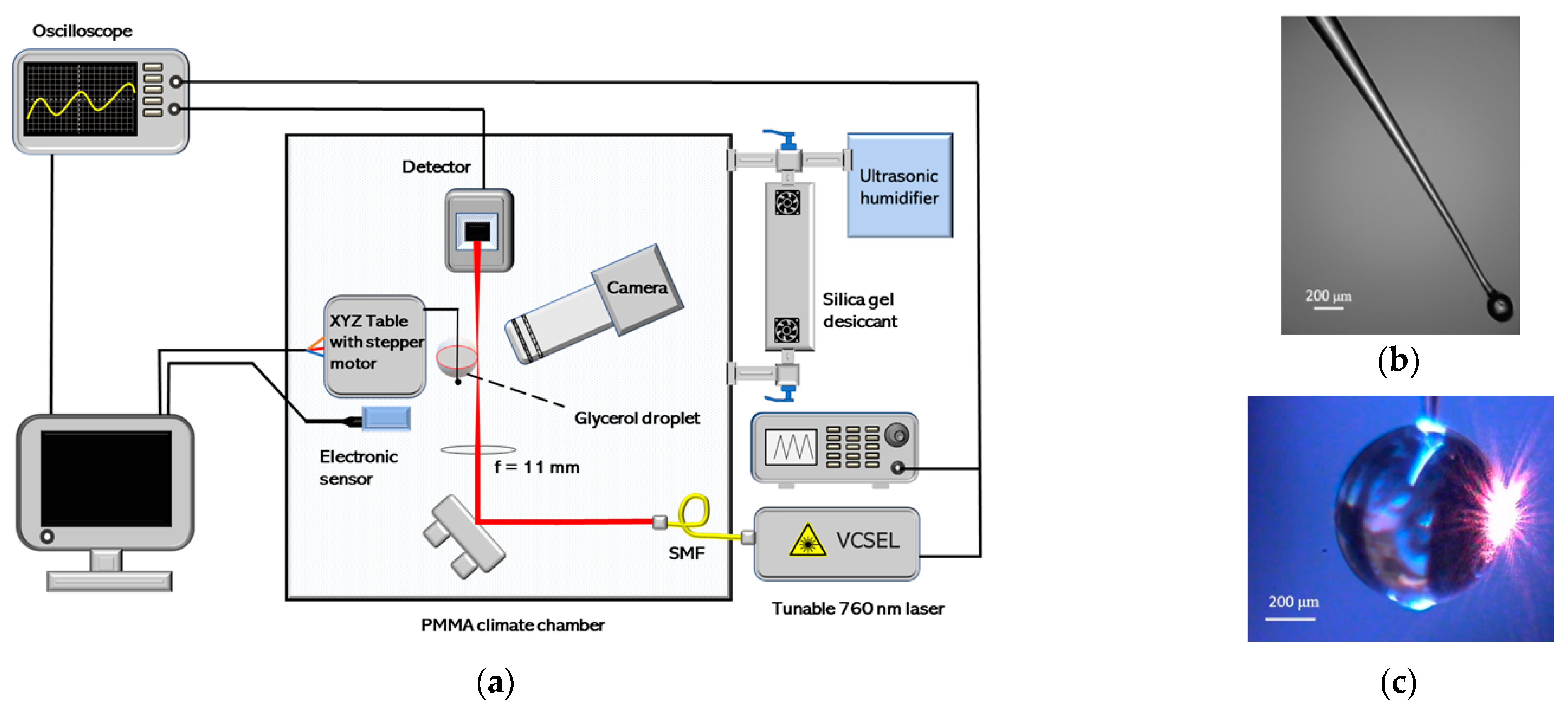

2. Materials and Methods

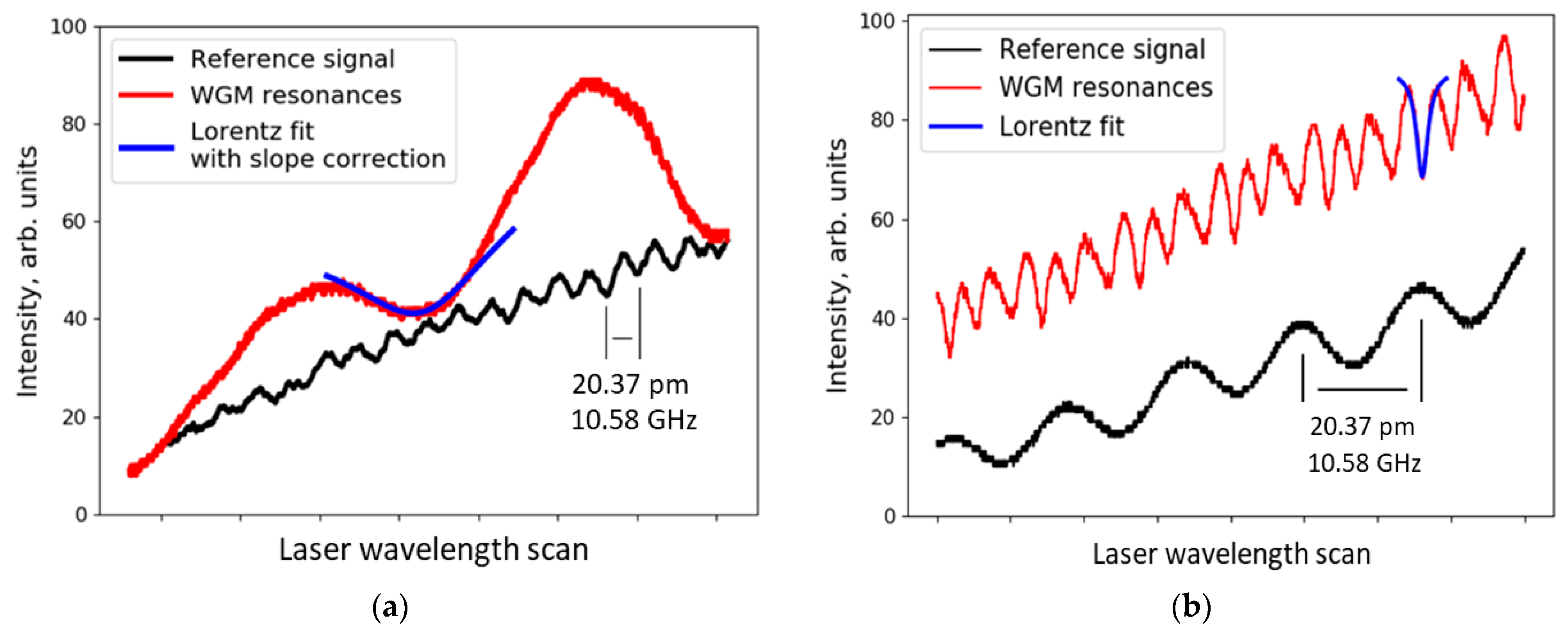

3. WGM Spectra Measurements

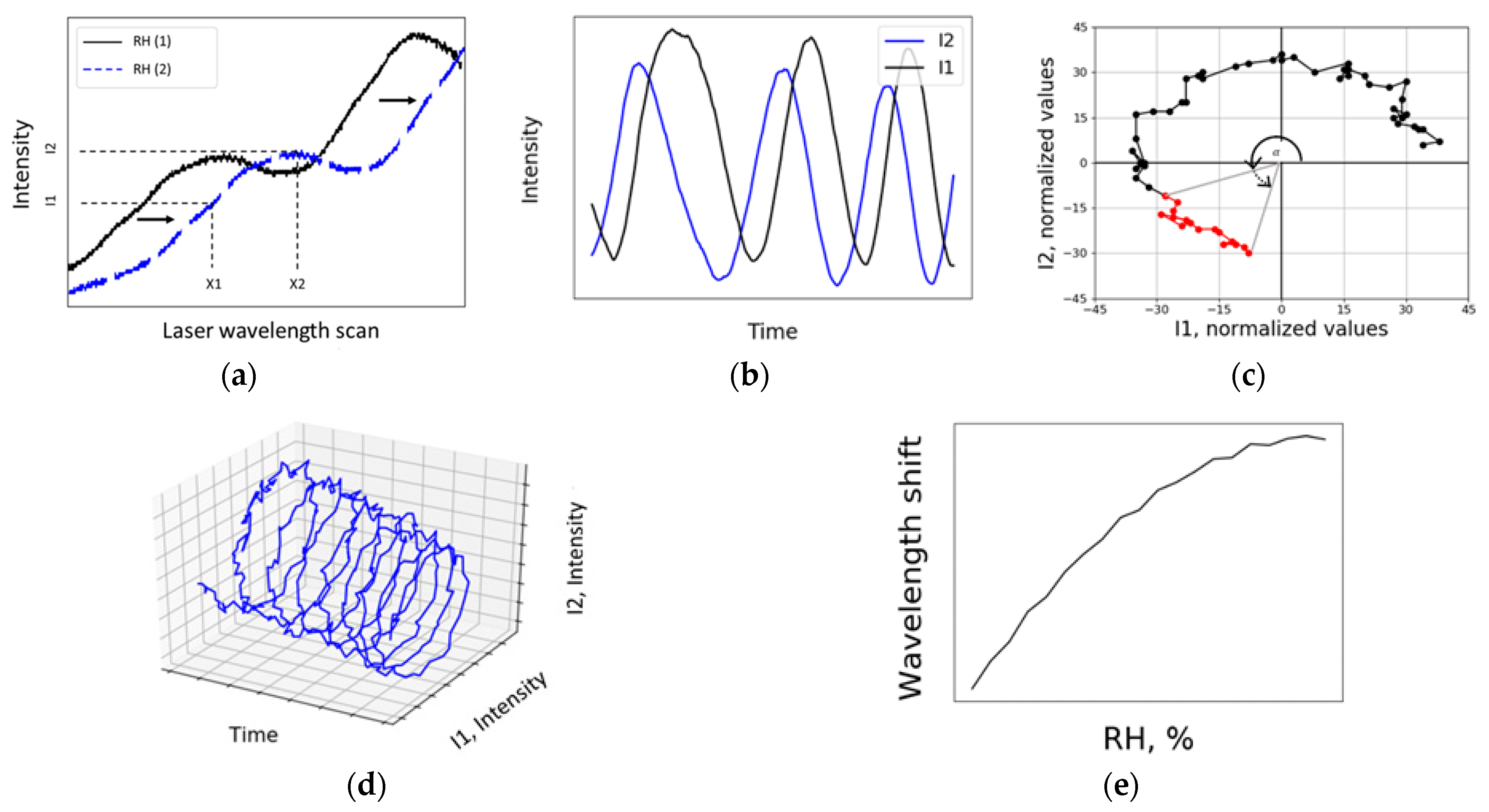

4. Results

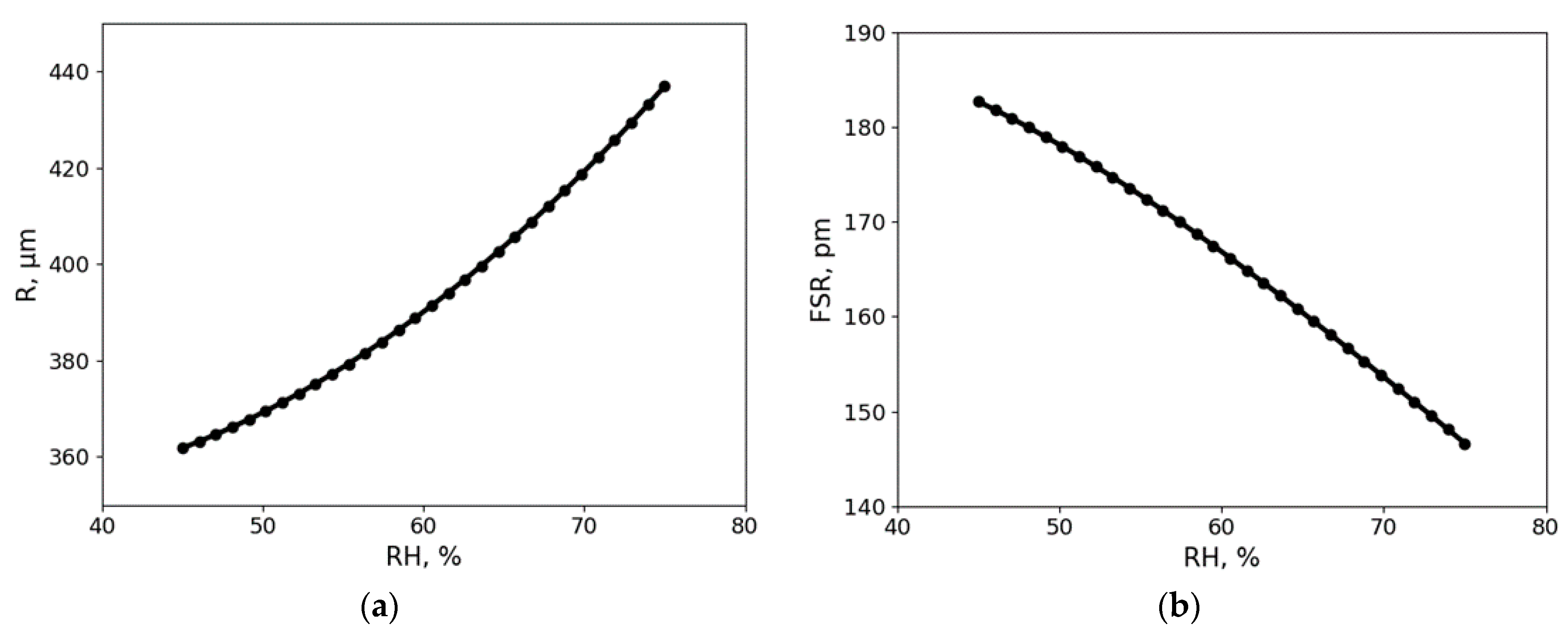

4.1. Sensitivity and Resolution

4.2. Hysteresis, Repeatability and Stability

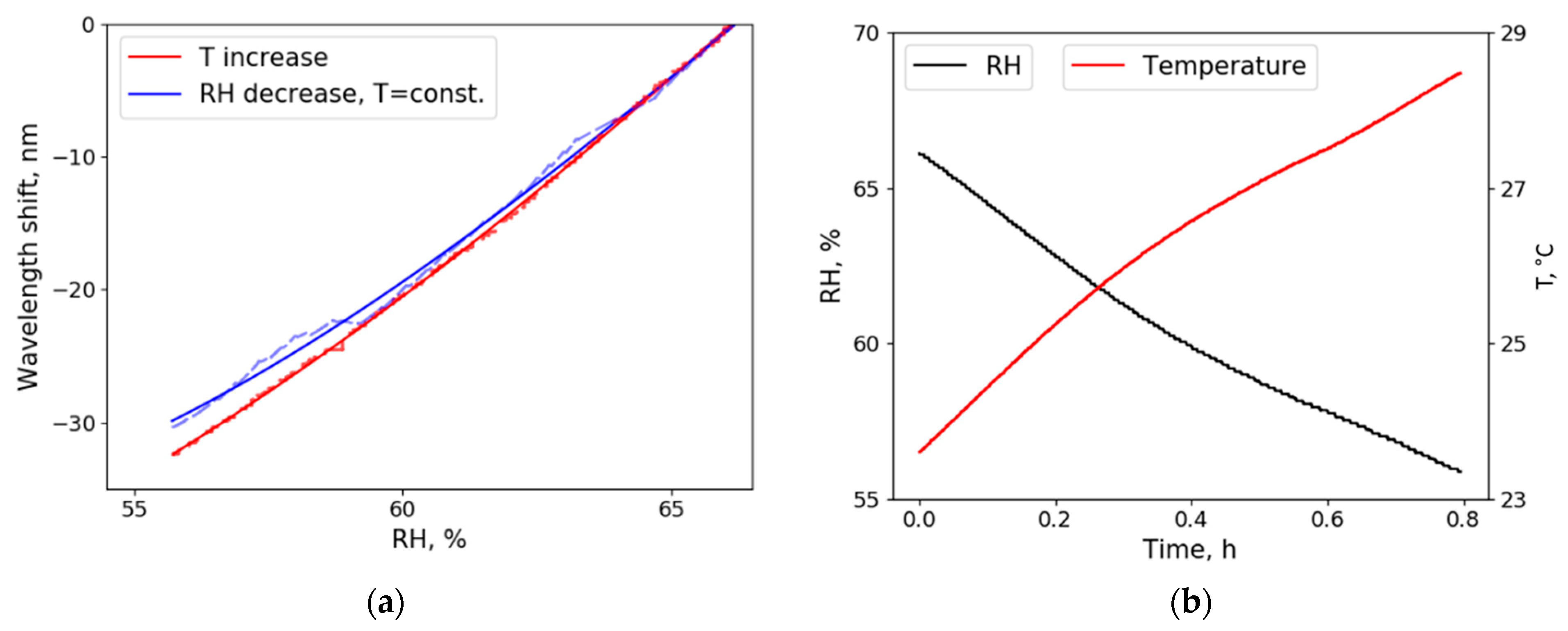

4.3. Temperature Dependence

4.4. COMSOL Simulations

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Z.; Lu, C. Humidity sensors: A review of materials and mechanisms. Sens. Lett. 2005, 3, 274–295. [Google Scholar] [CrossRef]

- Tan, E.L.; Ng, W.N.; Shao, R.; Pereles, B.D.; Ong, K.G. A wireless, passive sensor for quantifying packaged food quality. Sensors 2007, 7, 1747–1756. [Google Scholar] [CrossRef]

- Rudmann, L.; Langenmair, M.; Hahn, B.; Ordonez, J.S.; Stieglitz, T. Novel desiccant-based very low humidity indicator for condition monitoring in miniaturized hermetic packages of active implants. Sens. Actuators B Chem. 2020, 322, 128555. [Google Scholar] [CrossRef]

- Scott, C.; Cameron, S.; Cundell, J.; Mathur, A.; Davis, J. Adapting resistive sensors for monitoring moisture in smart wound dressings. Curr. Opin. Electrochem. 2020, 23, 31–35. [Google Scholar] [CrossRef]

- Funk, T.L.; Robert, M.J.; Appleford, J.M.; Chen, Y. Two Novel Sensor Systems for Monitoring Moisture Content in Biofilters Treating Exhaust Ventilation Air from Livestock Production Facilities. In Proceedings of the International Symposium on Air Quality and Waste Management for Agriculture (ASABE), Broomfield, CO, USA, 16–19 September 2007. [Google Scholar] [CrossRef]

- Toggweiler, J.; Key, R. Clean laboratories and clean rooms for analysis of radionuclides and trace elements. At. Energy 2003, 4, 1549–1555. [Google Scholar]

- Lee, C.Y.; Lee, G. Bin Humidity sensors: A review. Sens. Lett. 2005, 3, 1–14. [Google Scholar] [CrossRef]

- Ascorbe, J.; Corres, J.M.; Arregui, F.J.; Matias, I.R. Recent developments in fiber optics humidity sensors. Sensors 2017, 17, 893. [Google Scholar] [CrossRef]

- Mallik, A.K.; Farrell, G.; Liu, D.; Kavungal, V.; Wu, Q.; Semenova, Y. A coated spherical microresonator for measurement of water vapor concentration at PPM levels in very low humidity environments. J. Light. Technol. 2018, 36, 2667–2674. [Google Scholar] [CrossRef]

- Foreman, M.R.; Swaim, J.D.; Vollmer, F. Whispering gallery mode sensors. Adv. Opt. Photonics 2015, 7, 168–240. [Google Scholar] [CrossRef]

- Righini, G.C.; Dumeige, Y.; Féron, P.; Ferrari, M.; Conti, G.N.; Ristic, D.; Soria, S. Whispering gallery mode microresonators: Fundamentals and applications. La Riv. del Nuovo Cim. 2011, 34, 435–488. [Google Scholar] [CrossRef]

- Jiang, X.; Qavi, A.J.; Huang, S.H.; Yang, L. Whispering gallery microsensors: A review. arXiv 2018, arXiv:1805.00062. [Google Scholar]

- Rayleigh, L. The problem of the whispering gallery. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1910, 20, 1001–1004. [Google Scholar] [CrossRef]

- Gomilšek, M. Whispering Gallery Modes; University of Ljubljana: Ljubljana, Slovenia, 2011. [Google Scholar]

- Labrador-Páez, L.; Soler-Carracedo, K.; Hernández-Rodríguez, M.; Martín, I.R.; Carmon, T.; Martin, L.L. Liquid whispering-gallery-mode resonator as a humidity sensor. Opt. Express 2017, 25, 1165–1172. [Google Scholar] [CrossRef]

- Glycerine Producers’ Association. Physical Properties of Glycerine and Its Solutions; Glycerine Producers’ Association: New York, NY, USA, 1963. [Google Scholar]

- Farahani, H.; Wagiran, R.; Hamidon, M.N. Humidity sensors principle, mechanism, and fabrication technologies: A comprehensive review. Sensors (Switzerland) 2014, 14, 7881–7939. [Google Scholar] [CrossRef]

- Johari, M.A.M.J.; Khudus, M.I.M.A.; Jali, M.H.B.; Noman, A.A.; Harun, S.W. Whispering gallery modes on optical micro-bottle resonator for humidity sensor application. Optik 2019, 185, 558–565. [Google Scholar] [CrossRef]

- Mallik, A.K.; Liu, D.; Kavungal, V.; Wu, Q.; Farrell, G.; Semenova, Y. Agarose coated spherical micro resonator for humidity measurements. Opt. Express 2016, 24, 21216–21227. [Google Scholar] [CrossRef] [PubMed]

- Petermann, A.B.; Hildebrandt, T.; Morgner, U.; Roth, B.W.; Meinhardt-Wollweber, M. Polymer based whispering gallery mode humidity sensor. Sensors 2018, 18, 2383. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhong, J.; Fang, Y.F.; Wang, J.; Huang, G.S.; Cui, X.G.; Mei, Y.F. Roll up polymer/oxide/polymer nanomembranes as a hybrid optical microcavity for humidity sensing. Nanoscale 2014, 6, 13646–13650. [Google Scholar] [CrossRef]

- Eryürek, M.; Tasdemir, Z.; Karadag, Y.; Anand, S.; Kilinc, N.; Alaca, B.E.; Kiraz, A. Integrated humidity sensor based on SU-8 polymer microdisk microresonator. Sens. Actuators B Chem. 2017, 242, 1115–1120. [Google Scholar] [CrossRef]

- Bhola, B.; Nosovitskiy, P.; Mahalingam, H.; Steier, W.H. Sol-gel-based integrated optical microring resonator humidity sensor. IEEE Sens. J. 2009, 9, 740–747. [Google Scholar] [CrossRef]

- Mehrabani, S.; Kwong, P.; Gupta, M.; Armani, A.M. Hybrid microcavity humidity sensor. Appl. Phys. Lett. 2013, 102, 241101. [Google Scholar] [CrossRef]

- Liang, L.; Li, M.; Liu, N.; Sun, H.; Rong, Q.; Hu, M. A high-sensitivity optical fiber relative humidity sensor based on microsphere WGM resonator. Opt. Fiber Technol. 2018, 45, 415–418. [Google Scholar] [CrossRef]

- Giorgini, A.; Avino, S.; Malara, P.; De Natale, P.; Gagliardi, G. Fundamental limits in high-Q droplet microresonators. Sci. Rep. 2017, 7, 41997. [Google Scholar] [CrossRef] [PubMed]

- Ren, H.; Xu, S.; Liu, Y.; Wu, S.T. Liquid-based infrared optical switch. Appl. Phys. Lett. 2012, 101, 041104. [Google Scholar] [CrossRef]

- Kudryashova, O.; Pavlenko, A.; Vorozhtsov, B.; Titov, S.; Arkhipov, V.; Bondarchuk, S.; Maksimenko, E.; Akhmadeev, I.; Muravlev, E. Remote Optical Diagnostics of Nonstationary Aerosol Media in a Wide Range of Particle Sizes. In Photodetectors; Gateva, S., Ed.; InTech: London, UK, 2012; pp. 341–364. [Google Scholar]

- Wang, Y.; Li, H.; Zhao, L.; Wu, B.; Liu, S.; Liu, Y.; Yang, J. A review of droplet resonators: Operation method and application. Opt. Laser Technol. 2016, 86, 61–68. [Google Scholar] [CrossRef]

- Tang, J.; Liu, J.; Shang, C.; Xie, C.; Guo, H.; Qian, K.; Xue, C.; Liu, J. Fabrication and spectral characterizations of high Q asymmetric resonant cavities. Opt. Commun. 2015, 355, 269–273. [Google Scholar] [CrossRef]

- Samusenko, A.; Gandolfi, D.; Pucker, G.; Chalyan, T.; Guider, R.; Ghulinyan, M.; Pavesi, L. A SiON microring resonator-based platform for biosensing at 850 nm. J. Light. Technol. 2016, 34, 969–977. [Google Scholar] [CrossRef]

- Gu, Y.; Jérôme, F. Glycerol as a sustainable solvent for green chemistry. Green Chem. 2010, 12, 1127–1138. [Google Scholar] [CrossRef]

- Wernke, M.J. Glycerol. In Encyclopedia of Toxicology: Third Edition; Academic Press: Cambridge, MA, USA, 2014; Volume 2, pp. 754–756. [Google Scholar]

- Quincot, G.; Azenha, M.; Barros, J.; Faria, R. Use of Salt Solutions for Assuring Constant Relative Humidity Conditions in Contained Environments; University of Minho: Guimaraes, Portugal, 2011. [Google Scholar]

- Brachmann, J.F.S.; Kinder, T.; Dieckmann, K. Calibrating an interferometric laser frequency stabilization to megahertz precision. Appl. Opt. 2012, 51, 5517–5521. [Google Scholar] [CrossRef]

- Kim, K.T.; Kim, I.S.; Lee, C.H.; Lee, J. A temperature-insensitive cladding-etched fiber bragg grating using a liquid mixture with a negative thermo-optic coefficient. Sensors 2012, 12, 7886–7892. [Google Scholar] [CrossRef]

- Yan, Y.-Z.; Zou, C.-L.; Yan, S.-B.; Sun, F.-W.; Ji, Z.; Liu, J.; Zhang, Y.-G.; Wang, L.; Xue, C.-Y.; Zhang, W.-D.; et al. Packaged silica microsphere-taper coupling system for robust thermal sensing application. Opt. Express 2011, 19, 5753. [Google Scholar] [CrossRef] [PubMed]

- Brice, I.; Viter, R.; Draguns, K.; Grundsteins, K.; Atvars, A.; Alnis, J.; Coy, E.; Iatsunskyi, I. Whispering gallery mode resonators covered by a ZnO nanolayer. Optik 2020, 219, 165296. [Google Scholar] [CrossRef]

- Li, J.; Tong, Z.; Jing, L.; Zhang, W.; Qin, J.; Liu, J. Fiber temperature and humidity sensor based on photonic crystal fiber coated with graphene oxide. Opt. Commun. 2020, 467, 125707. [Google Scholar] [CrossRef]

- Kell, G.S. Precise representation of volume properties of water at one atmosphere. J. Chem. Eng. Data 1967, 12, 66–69. [Google Scholar] [CrossRef]

- Berkis, R.; Alnis, J.; Atvars, A.; Brice, I.; Draguns, K.; Grundsteins, K. Quality Factor Measurements for PMMA WGM Microsphere Resonators Using Fixed Wavelength Laser and Temperature Changes. In Proceedings of the 2019 IEEE 9th International Conference on Nanomaterials, Odesa, Ukraine, 15–20 September 2019. [Google Scholar] [CrossRef]

- Yang, Y.E.; Liu, Y.; Sun, S.; Li, W.; Zhu, N.; Li, M. Optical phase matching of high-order azimuthal WGM in a water droplet resonator. Opt. Express 2019, 27, 33436–33444. [Google Scholar] [CrossRef]

| Sensing Material/Type | Sensitivity | Q Factor, Wavelength, Type of Measurement | Precision and Resolution, Detection Limit | Ref. |

|---|---|---|---|---|

| Silica microbottle (Figure 1a) | 0.049 dB/% RH | Q = 104, excitation by tunable laser (1551–1559 nm), transmission spectrum | - | [18] |

| Silica microsphere coated with a layer of Agarose hydrogel (Figure 1b) | 518 pm/% RH (30–70% RH) | Q = 104, excitation by a broadband superluminescent light source, spectrum analysed with OSA | 2.0227 pm (resolution) 1.15 × 10−1% RH (det. limit) | [19] |

| PMMA microspheres with different diameters (Figure 1c) | 47 pm/% RH | Q–N/A, excitation by tunable laser (centered at 635.5 nm), mode map of many spheres (intensity pattern) | - | [20] |

| Glycerol microsphere doped with rhodamine 6G dye (Figure 1d) | 2 nm/% RH (45–65% RH) | Q = 103, excitation 532 nm, rhodamine 6G spectrum (550–650 nm) | 3 × 10−3% RH (detection limit from COMSOL simulation proposed prototype) | [15] |

| Roll up polymer/oxide/polymer nanomembranes | 130 pm/% RH (5–97% RH) | Excitation 514.5 nm, photoluminescence spectrum (650–675 nm) | - | [21] |

| SU-8 polymer microdisk | 78.4 pm/% RH (0–5% RH); 23.5 pm/% RH (45–50% RH) | Q = 103, excitation by tunable laser (1500–1620 nm), transmission spectrum | 0.03% RH (detection limit) | [22] |

| Sol-gel-based integrated microring | 16 pm/% RH | Q = 104, excitation by tunable laser (2 nm range), sol-gel clad spectrum (1310–1311 nm) | 0.16% RH (detection limit) | [23] |

| Silica microtoroid coated with nm-scale polymer (pNIPAAm) | 12.98 pm/% RH | Q = 105, excitation by tunable laser (centered at 980 nm), transmission spectrum | - | [24] |

| Silica microsphere coated with a thin layer of Agarose hydrogel (Figure 1b) | 0.71 pm/% RH (1–25% RH) | Q = 106, excitation by tunable laser (1490–1640 nm), transmission spectrum (oscilloscope) | 43.58 fm (resolution) 6.13 × 10−2% RH (detection limit) | [9] |

| Silica microsphere (WGM excited using a tapered fiber) | 0.11 dB/% RH (20–70% RH); 0.21 dB/% RH (70–90% RH) | Q = 104, broadband source (centered at 1550 nm), transmission spectrum (OSA) | 0.02 nm and 0.001 dB (resolution) | [25] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reinis, P.K.; Milgrave, L.; Draguns, K.; Brice, I.; Alnis, J.; Atvars, A. High-Sensitivity Whispering Gallery Mode Humidity Sensor Based on Glycerol Microdroplet Volumetric Expansion. Sensors 2021, 21, 1746. https://doi.org/10.3390/s21051746

Reinis PK, Milgrave L, Draguns K, Brice I, Alnis J, Atvars A. High-Sensitivity Whispering Gallery Mode Humidity Sensor Based on Glycerol Microdroplet Volumetric Expansion. Sensors. 2021; 21(5):1746. https://doi.org/10.3390/s21051746

Chicago/Turabian StyleReinis, Pauls Kristaps, Lase Milgrave, Kristians Draguns, Inga Brice, Janis Alnis, and Aigars Atvars. 2021. "High-Sensitivity Whispering Gallery Mode Humidity Sensor Based on Glycerol Microdroplet Volumetric Expansion" Sensors 21, no. 5: 1746. https://doi.org/10.3390/s21051746

APA StyleReinis, P. K., Milgrave, L., Draguns, K., Brice, I., Alnis, J., & Atvars, A. (2021). High-Sensitivity Whispering Gallery Mode Humidity Sensor Based on Glycerol Microdroplet Volumetric Expansion. Sensors, 21(5), 1746. https://doi.org/10.3390/s21051746