Toward the Use of Temporary Tattoo Electrodes for Impedancemetric Respiration Monitoring and Other Electrophysiological Recordings on Skin

Abstract

1. Introduction

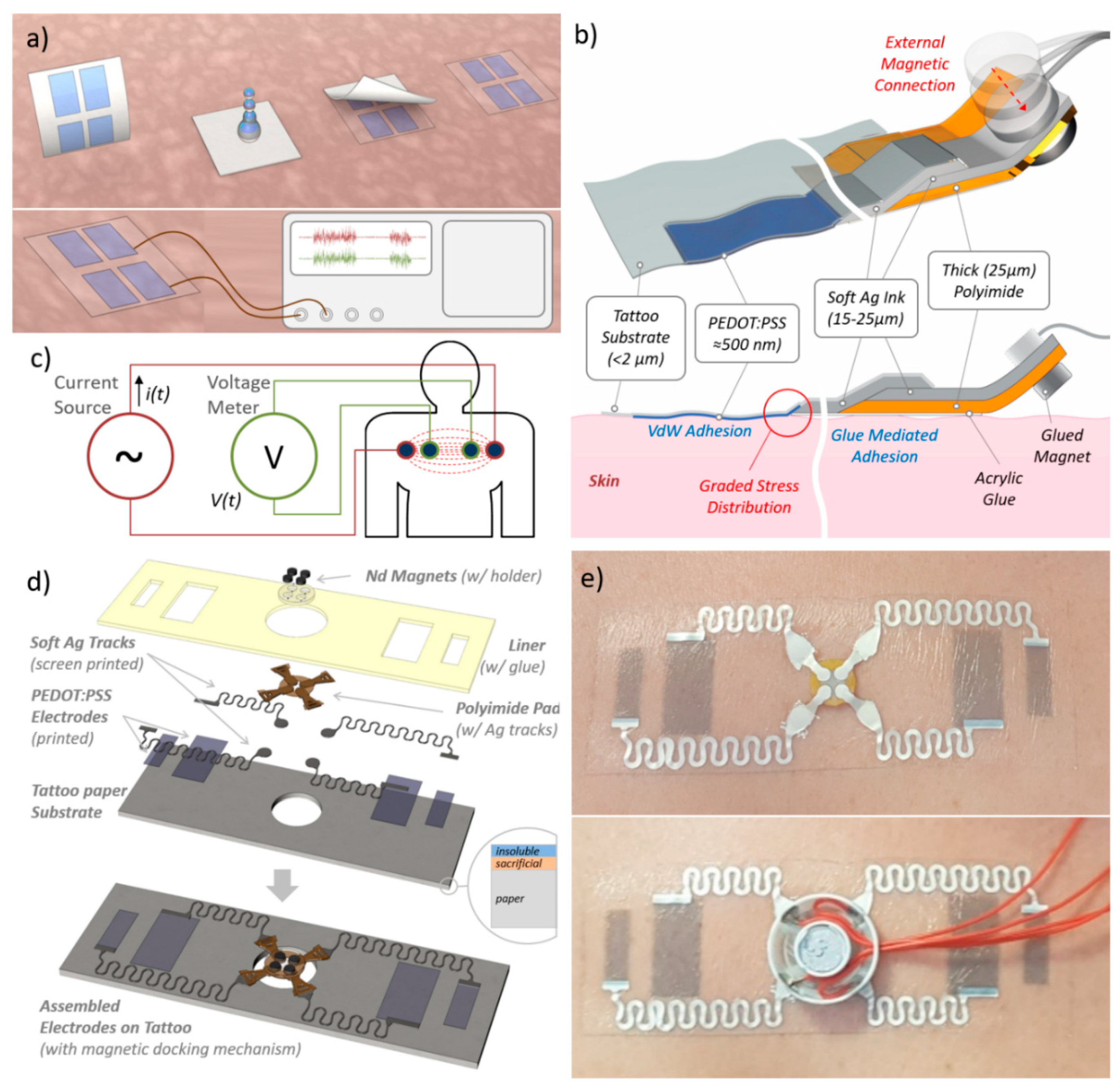

2. Case study, Ultrathin Films and Interconnection Technology

3. Materials and Methods

3.1. Tattoo Fabrication

3.2. Tattoo Characterization

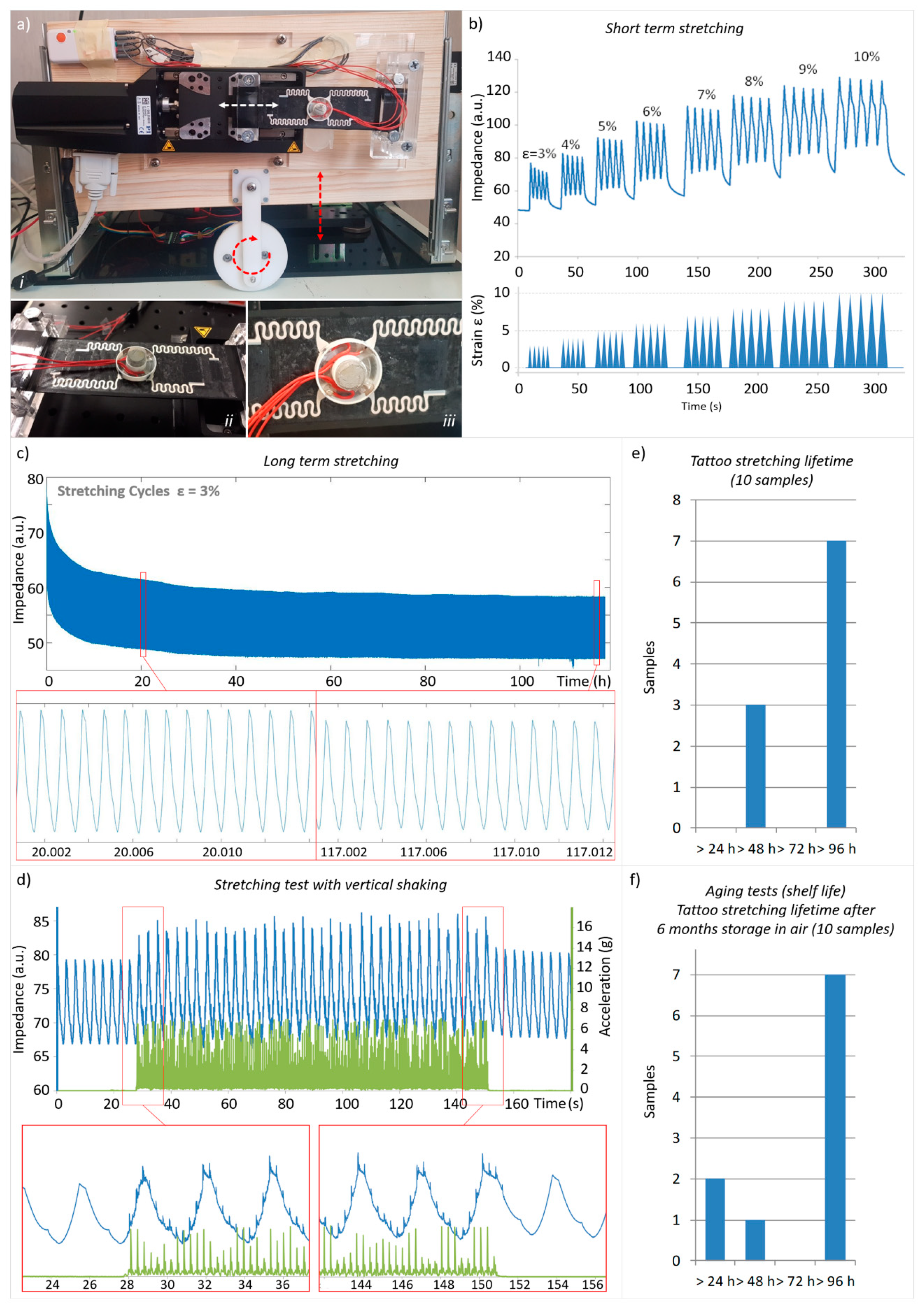

3.3. In-Lab Stretching Test to Evaluate the Connection Reliability

3.4. Tests on Volunteer

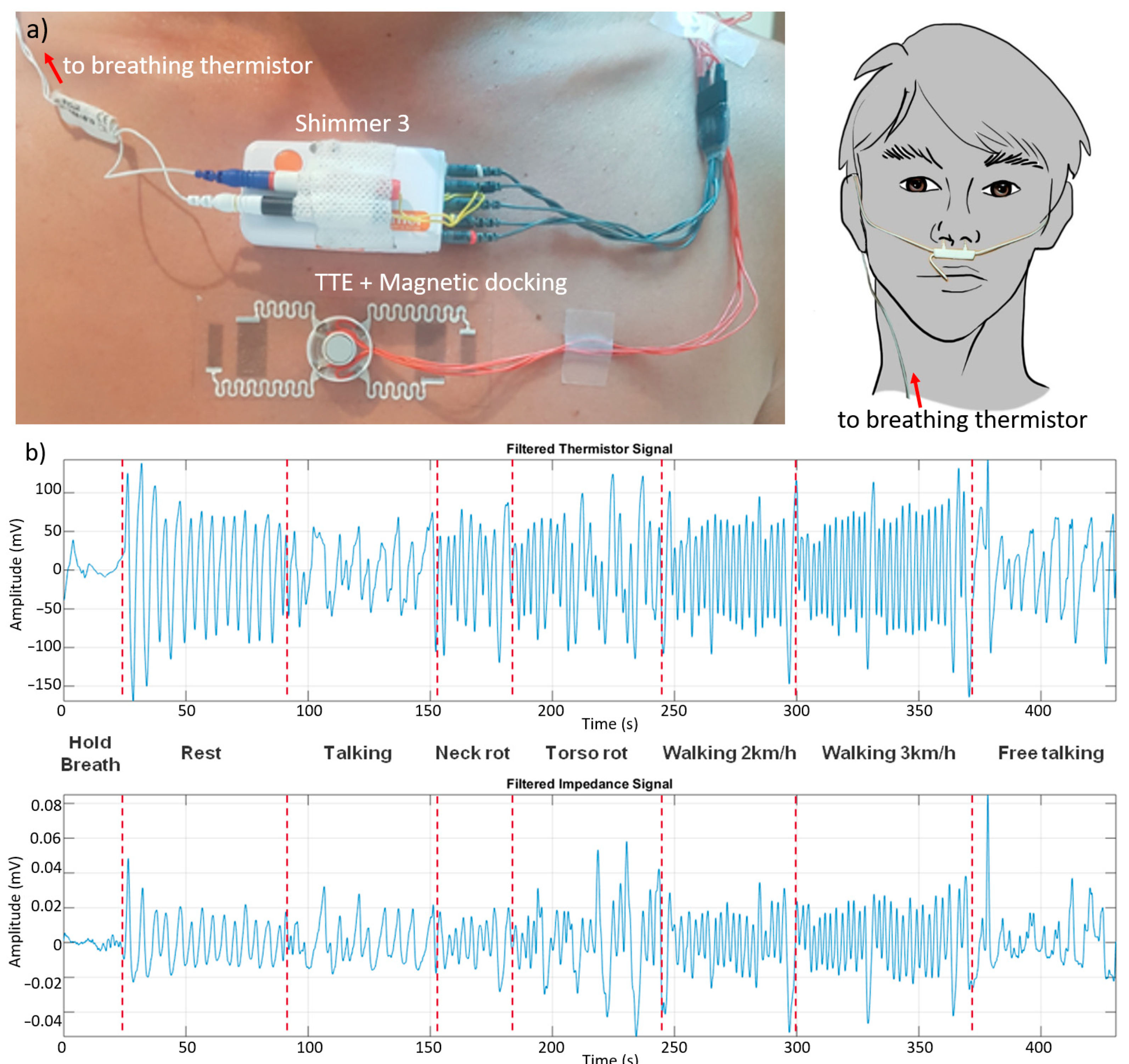

3.4.1. Transthoracic Impedance Measurement with Commercial Sensor Unit

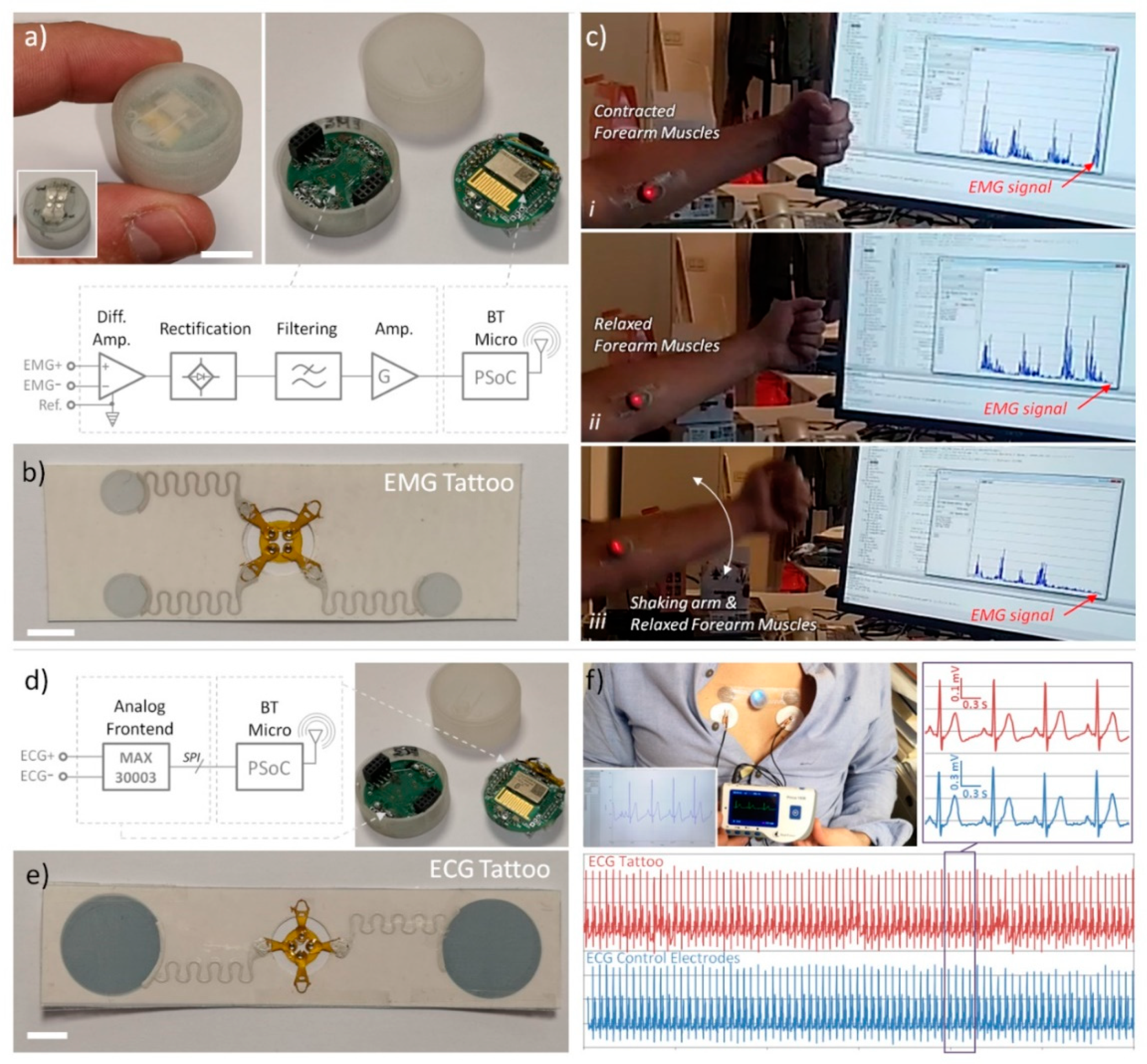

3.4.2. EMG Measurement with Miniaturised Standalone Devices

3.4.3. ECG Measurement with Miniaturised Standalone Devices

4. Results and Discussion

4.1. TTEs for Transthoracic Impedance Measurements Design

4.2. In Lab Stretching Test

4.3. Test on Subject

4.4. Other Use-Case Examples, with Miniaturised Standalone Device

4.4.1. EMG Measurement and Threshold Detection

4.4.2. ECG Recording

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, D.H.; Lu, N.S.; Ma, R.; Kim, Y.S.; Kim, R.H.; Wang, S.D.; Wu, J.; Won, S.M.; Tao, H.; Islam, A.; et al. Epidermal electronics. Science 2011, 333, 838. [Google Scholar] [CrossRef]

- Hammock, M.L.; Chortos, A.; Tee, B.C.; Tok, J.B.; Bao, Z. 25th anniversary article: The evolution of electronic skin (e-skin): A brief history, design considerations, and recent progress. Adv. Mater. 2013, 25, 5997. [Google Scholar] [CrossRef]

- Liu, Y.; Pharr, M.; Salvatore, G.A. Lab-on-Skin: A Review of Flexible and Stretchable Electronics for Wearable Health Monitoring. ACS Nano 2017, 11, 9614. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Akhtar, A.; Liu, Y.; Chen, H.; Yeo, W.H.; Park, S.I.; Boyce, B.; Kim, H.; Yu, J.; Lai, H.Y.; et al. An Epidermal Stimulation and Sensing Platform for Sensorimotor Prosthetic Control, Management of Lower Back Exertion, and Electrical Muscle Activation. Adv. Mater. 2016, 28, 4462. [Google Scholar] [CrossRef] [PubMed]

- Jeong, J.W.; Yeo, W.H.; Akhtar, A.; Norton, J.J.; Kwack, Y.J.; Li, S.; Jung, S.Y.; Su, Y.; Lee, W.; Xia, J.; et al. Materials and optimized designs for human-machine interfaces via epidermal electronics. Adv. Mater. 2013, 25, 6839. [Google Scholar] [CrossRef]

- Jin, H.; Nayeem, M.O.G.; Lee, S.; Matsuhisa, N.; Inoue, D.I.; Yokota, T.; Hashizume, D.; Someya, T. Highly Durable Nanofiber-Reinforced Elastic Conductors for Skin-Tight Electronic Textiles. ACS Nano 2019, 13, 7905. [Google Scholar] [CrossRef]

- Chandra, S.; Li, J.; Afsharipour, B.; Cardona, A.F.; Suresh, N.L.; Tian, L.; Deng, Y.; Zhong, Y.; Xie, Z.; Shen, H.; et al. Performance evaluation of a wearable tattoo electrode suitable for high-resolution surface electromyogram recording. IEEE Trans. Biomed. Eng. 2020. [Google Scholar] [CrossRef]

- Chung, H.U.; Rwei, A.Y.; Hourlier-Fargette, A.; Xu, S.; Lee, K.-H.; Dunne, E.C.; Xie, Z.; Liu, C.; Carlini, A.; Kim, D.H.; et al. Skin-interfaced biosensors for advanced wireless physiological monitoring in neonatal and pediatric intensive-care units. Nat. Med. 2020, 26, 418. [Google Scholar] [CrossRef]

- Wang, S.; Li, M.; Wu, J.; Kim, D.-H.; Lu, N.; Su, Y.; Kang, Z.; Huang, Y.; Rogers, J.A. Mechanics of Epidermal Electronics. J. Appl. Mech. 2012, 79, 031022. [Google Scholar] [CrossRef]

- Yamagishi, K.; Taccola, S.; Takeoka, S.; Fujie, T.; Mattoli, V.; Greco, F. Flexible and Stretchable Medical Devices; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2018. [Google Scholar]

- Wang, L.; Lu, N. Conformability of a thin elastic membrane laminated on a soft substrate with slightly wavy surface. J. Appl. Mech. 2016, 83, 041007. [Google Scholar] [CrossRef]

- Ferrari, L.M.; Keller, K.; Burtscher, B.; Greco, F. Temporary tattoo as unconventional substrate for conformable and transferable electronics on skin and beyond. Multifunct. Mater 2020, 3, 032003. [Google Scholar] [CrossRef]

- Zucca, A.; Cipriani, C.; Tarantino, S.; Ricci, D.; Mattoli, V.; Greco, F. Conformable Electronics: Tattoo Conductive Polymer Nanosheets for Skin-Contact Applications. Adv. Healthc. Mater. 2015, 4, 983. [Google Scholar] [CrossRef]

- Ferrari, L.M.; Sudha, S.; Tarantino, S.; Esposti, R.; Bolzoni, F.; Cavallari, P.; Cipriani, C.; Mattoli, V.; Greco, F. Ultraconformable temporary tattoo electrodes for electrophysiology. Adv. Sci. 2018, 5, 1700771. [Google Scholar] [CrossRef]

- Chortos, A.; Koleilat, G.I.; Pfattner, R.; Kong, D.; Lin, P.; Nur, R.; Lei, T.; Wang, H.; Liu, N.; Lai, Y.C.; et al. Mechanically durable and highly stretchable transistors employing carbon nanotube semiconductor and electrodes. Adv. Mater. 2016, 28, 4441. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; de Araujo, W.R.; Samek, I.A.; Bandodkar, A.J.; Jia, W.; Brunetti, B.; Paixão, T.R.L.C.; Wang, J. Wearable temporary tattoo sensor for real-time trace metal monitoring in human sweat. Electrochem. Commun. 2015, 51, 41. [Google Scholar] [CrossRef]

- Bandodkar, A.J.; Jia, W.; Yardimci, C.; Wang, X.; Ramirez, J.; Wang, J. Tattoo-based noninvasive glucose monitoring: A proof-of-concept study. Anal. Chem. 2015, 87, 394. [Google Scholar] [CrossRef]

- Bareket, L.; Inzelberg, L.; Rand, D.; David-Pur, M.; Rabinovich, D.; Brandes, B.; Hanein, Y. Temporary-tattoo for long-term high fidelity biopotential recordings. Sci. Rep. 2016, 6, 25727. [Google Scholar] [CrossRef] [PubMed]

- Bihar, E.; Roberts, T.; Zhang, Y.; Ismailova, E.; Hervé, T.; Malliaras, G.G.; de Graaf, J.B.; Inal, S.; Saadaoui, M. Fully printed all-polymer tattoo/textile electronics for electromyography. Flex. Print. Electron. 2018, 3, 034004. [Google Scholar] [CrossRef]

- Bonacchini, G.E.; Bossio, C.; Greco, F.; Mattoli, V.; Kim, Y.-H.; Lanzani, G.; Caironi, M. Tattoo-Paper Transfer as a Versatile Platform for All-Printed Organic Edible Electronics. Adv. Mater. 2018, 30, 1706091. [Google Scholar] [CrossRef]

- Piva, N.; Greco, F.; Garbugli, M.; Iacchetti, A.; Mattoli, V.; Caironi, M. Organic Photovoltaics: Tattoo-Like Transferable Hole Selective Electrodes for Highly Efficient, Solution-Processed Organic Indoor Photovoltaics. Adv. Electron. Mater. 2018, 4, 1700325. [Google Scholar] [CrossRef]

- Ferrari, L.M.; Ismailov, U.; Badier, J.-M.; Greco, F.; Ismailova, E. Conducting polymer tattoo electrodes in clinical electro-and magneto-encephalography. npj Flex. Electron. 2020, 4, 4. [Google Scholar] [CrossRef]

- Wagner, S.; Bauer, S. Materials for stretchable electronics. MRS Bull. 2012, 37, 207. [Google Scholar] [CrossRef]

- Gong, S.; Yap, L.W.; Zhu, B.; Cheng, W. Gas-permeable, ultrathin, stretchable epidermal electronics with porous electrodes. Adv. Mater. 2020, 32, 1902278. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Yan, Z.; Jang, K.-I.; Huang, W.; Fu, H.; Kim, J.; Wei, Z.; Flavin, M.; McCracken, J.; Wang, R.; et al. Assembly of micro/nanomaterials into complex, three-dimensional architectures by compressive buckling. Science 2015, 347, 154. [Google Scholar] [CrossRef]

- Sun, Y.; Choi, W.M.; Jiang, H.; Huang, Y.Y.; Rogers, J.A. Controlled buckling of semiconductor nanoribbons for stretchable electronics. Nat. Nanotechnol. 2006, 1, 201. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S.; Li, X.; Fan, J.A.; Xu, S.; Song, Y.M.; Choi, K.J.; Yeo, W.H.; Lee, W.; Nazaar, S.N.; et al. Experimental and theoretical studies of serpentine microstructures bonded to prestrained elastomers for stretchable electronics. Adv. Funct. Mater. 2014, 24, 2028. [Google Scholar] [CrossRef]

- Ling, Y.; Guo, K.; Zhu, B.; Prieto-Simon, B.; Voelcker, N.H.; Cheng, W. High-adhesion vertically aligned gold nanowire stretchable electrodes via a thin-layer soft nailing strategy. Nanoscale Horiz. 2019, 4, 1380–1387. [Google Scholar] [CrossRef]

- Cretikos, M.A.; Bellomo, R.; Hillman, K.; Chen, J.; Finfer, S.; Flabouris, A. Respiratory rate: The neglected vital sign. Med. J. Aust. 2008, 188, 657–659. [Google Scholar] [CrossRef]

- Massaroni, C.; Nicolò, A.; Lo Presti, D.; Sacchetti, M.; Silvestri, S.; Schena, E. Contact-based methods for measuring respiratory rate. Sensors 2019, 19, 908. [Google Scholar] [CrossRef] [PubMed]

- Vanegas, E.; Igual, R.; Plaza, I. Sensing systems for respiration monitoring: A technical systematic review. Sensors 2020, 20, 5446. [Google Scholar] [CrossRef] [PubMed]

- Chu, M.; Nguyen, T.; Pandey, V.; Zhou, Y.; Pham, H.N.; Bar-Yoseph, R.; Radom-Aizik, S.; Jain, R.; Cooper, D.M.; Khine, M. Respiration rate and volume measurements using wearable strain sensors. Npj Digit. Med. 2019, 2, 8. [Google Scholar] [CrossRef]

- Blanco-Almazán, D.; Groenendaal, W.; Catthoor, F.; Jané, R. Wearable bioimpedance measurement for respiratory monitoring during inspiratory loading. IEEE Access 2019, 7, 89487–89496. [Google Scholar] [CrossRef]

- Dinh, T.; Nguyen, T.; Phan, H.-P.; Nguyen, N.-T.; Dao, D.V.; Bell, J. Stretchable respiration sensors: Advanced designs and multifunctional platforms for wearable physiological monitoring. Biosens. Bioelectron. 2020, 166, 112460. [Google Scholar] [CrossRef]

- Blanco-Almazán, D.; Groenendaal, W.; Catthoor, F.; Jané, R. Chest movement and respiratory volume both contribute to thoracic bioimpedance during loaded breathing. Sci. Rep. 2019, 9, 20232. [Google Scholar] [CrossRef]

- Timoshenko, S.; Woinowsky-Krieger, S. Theory of Plates and Shells; McGraw-Hill: New York, NY, USA, 1987. [Google Scholar]

- Jang, K.-I.; Jung, H.N.; Lee, J.W.; Xu, S.; Liu, Y.H.; Ma, Y.; Jeong, J.-W.; Song, Y.M.; Kim, J.; Kim, B.H.; et al. Ferromagnetic, folded electrode composite as a soft interface to the skin for long-term electrophysiological recording. Adv. Funct. Mater. 2016, 26, 7281–7290. [Google Scholar] [CrossRef]

- Zucca, A.; Yamagishi, K.; Fujie, T.; Takeoka, S.; Mattoli, V.; Greco, F. Roll to roll processing of ultraconformable conducting polymer nanosheets. J. Mater. Chem. C 2015, 3, 6539. [Google Scholar] [CrossRef]

- Gupta, A.K. Application Report SBAA181; Texas Instruments: Dallas, TX, USA, 2011. [Google Scholar]

- Eom, S.H.; Senthilarasu, S.; Uthirakumar, P.; Yoon, S.C.; Lim, J.; Lee, C.; Lim, H.S.; Lee, J.; Lee, S.-H. Polymer solar cells based on inkjet-printed PEDOT: PSS layer. Org. Electron. 2009, 10, 536. [Google Scholar] [CrossRef]

- Pailler-Mattei, C.; Bec, S.; Zahouani, H. In vivo measurements of the elastic mechanical properties of human skin by indentation tests. Med. Eng. Phys. 2008, 30, 599–606. [Google Scholar] [CrossRef] [PubMed]

- Redmond, C. Transthoracic Impedance Measurements in Patient Monitoring. Available online: https://www.analog.com/en/technical-articles/transthoracic-impedance-measurements-in-patient-monitoring.html (accessed on 11 January 2021).

- Carlson, B. Normal chest excursion. Phys. Ther. 1973, 53, 10–14. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taccola, S.; Poliziani, A.; Santonocito, D.; Mondini, A.; Denk, C.; Ide, A.N.; Oberparleiter, M.; Greco, F.; Mattoli, V. Toward the Use of Temporary Tattoo Electrodes for Impedancemetric Respiration Monitoring and Other Electrophysiological Recordings on Skin. Sensors 2021, 21, 1197. https://doi.org/10.3390/s21041197

Taccola S, Poliziani A, Santonocito D, Mondini A, Denk C, Ide AN, Oberparleiter M, Greco F, Mattoli V. Toward the Use of Temporary Tattoo Electrodes for Impedancemetric Respiration Monitoring and Other Electrophysiological Recordings on Skin. Sensors. 2021; 21(4):1197. https://doi.org/10.3390/s21041197

Chicago/Turabian StyleTaccola, Silvia, Aliria Poliziani, Daniele Santonocito, Alessio Mondini, Christian Denk, Alessandro Noriaki Ide, Markus Oberparleiter, Francesco Greco, and Virgilio Mattoli. 2021. "Toward the Use of Temporary Tattoo Electrodes for Impedancemetric Respiration Monitoring and Other Electrophysiological Recordings on Skin" Sensors 21, no. 4: 1197. https://doi.org/10.3390/s21041197

APA StyleTaccola, S., Poliziani, A., Santonocito, D., Mondini, A., Denk, C., Ide, A. N., Oberparleiter, M., Greco, F., & Mattoli, V. (2021). Toward the Use of Temporary Tattoo Electrodes for Impedancemetric Respiration Monitoring and Other Electrophysiological Recordings on Skin. Sensors, 21(4), 1197. https://doi.org/10.3390/s21041197