Application of Pyroelectric Sensors Based on PVDF Films for EPR Spectra Detection by Heat Release

Abstract

:1. Introduction

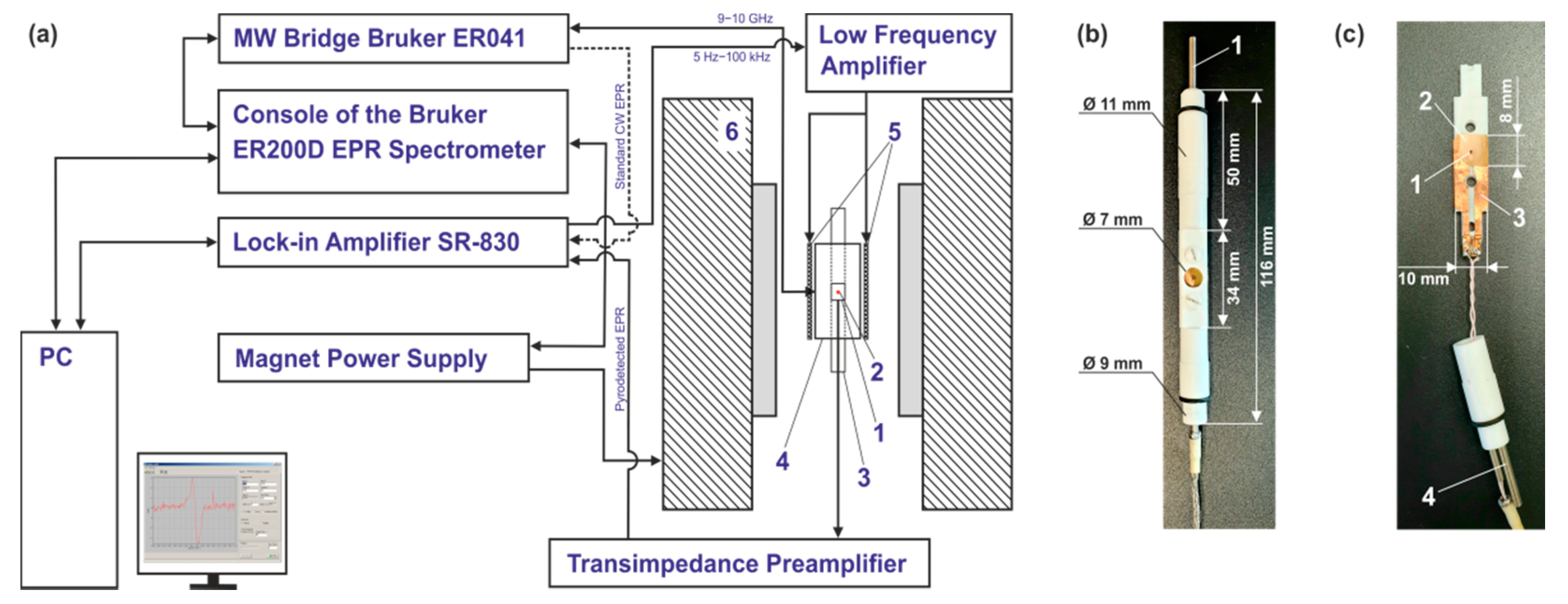

2. Materials and Methods

3. Results

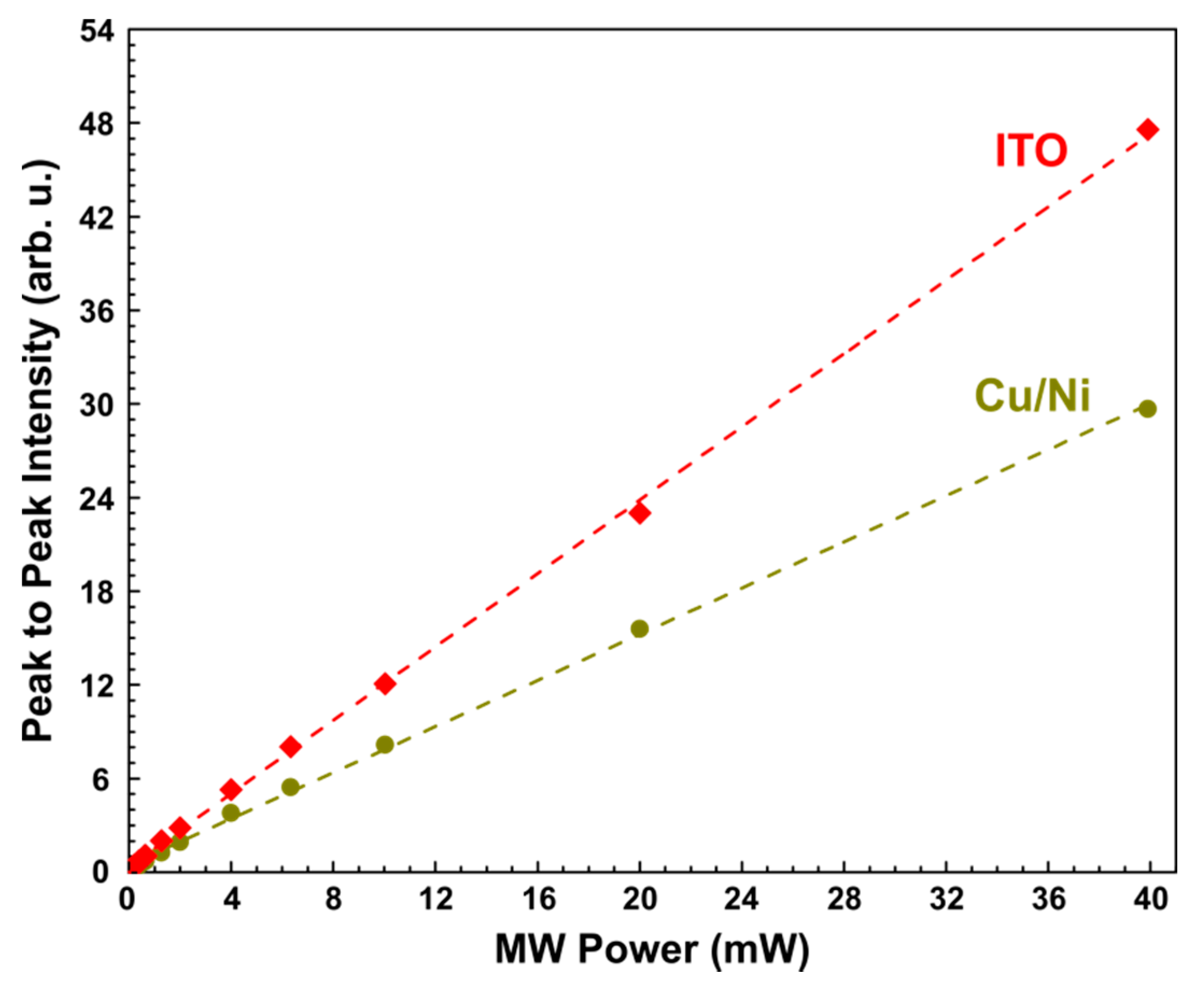

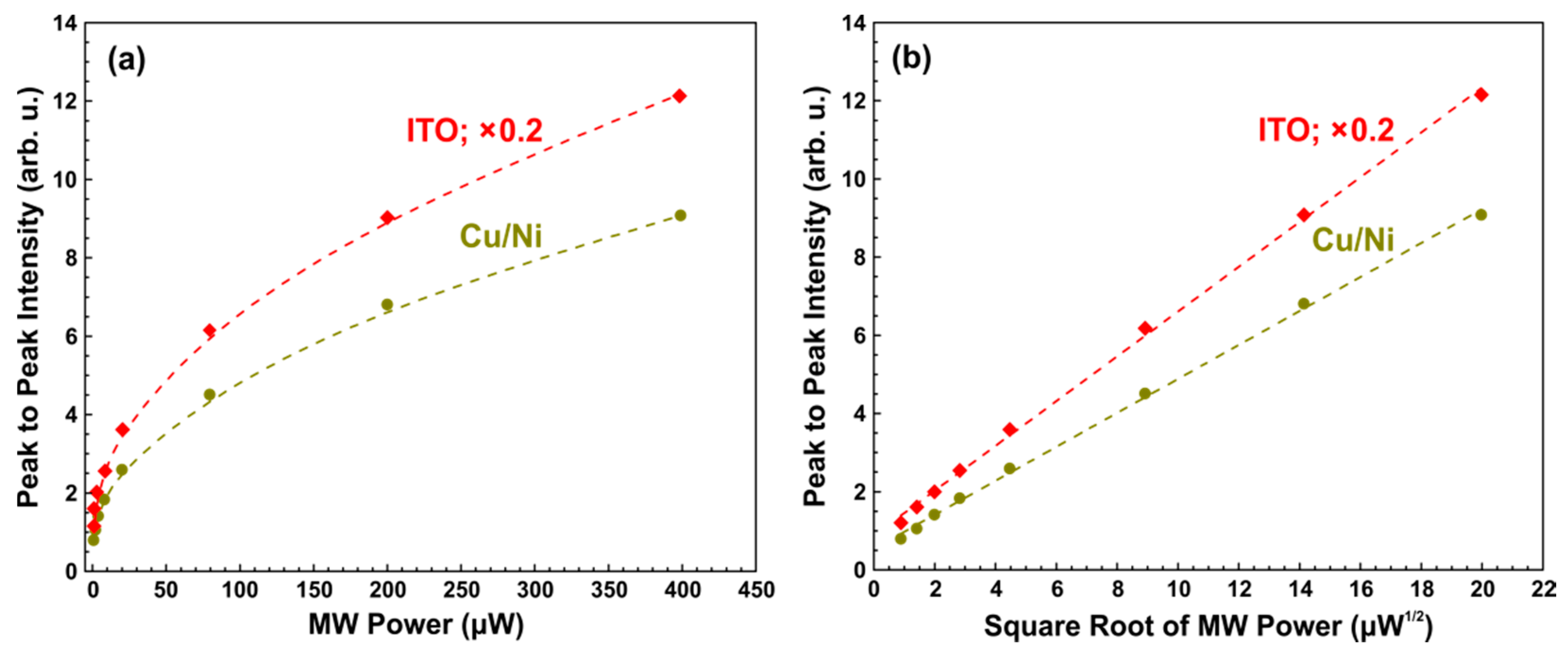

3.1. Dependence of Pyrodetected and Standard CW EPR Signals on MW Power

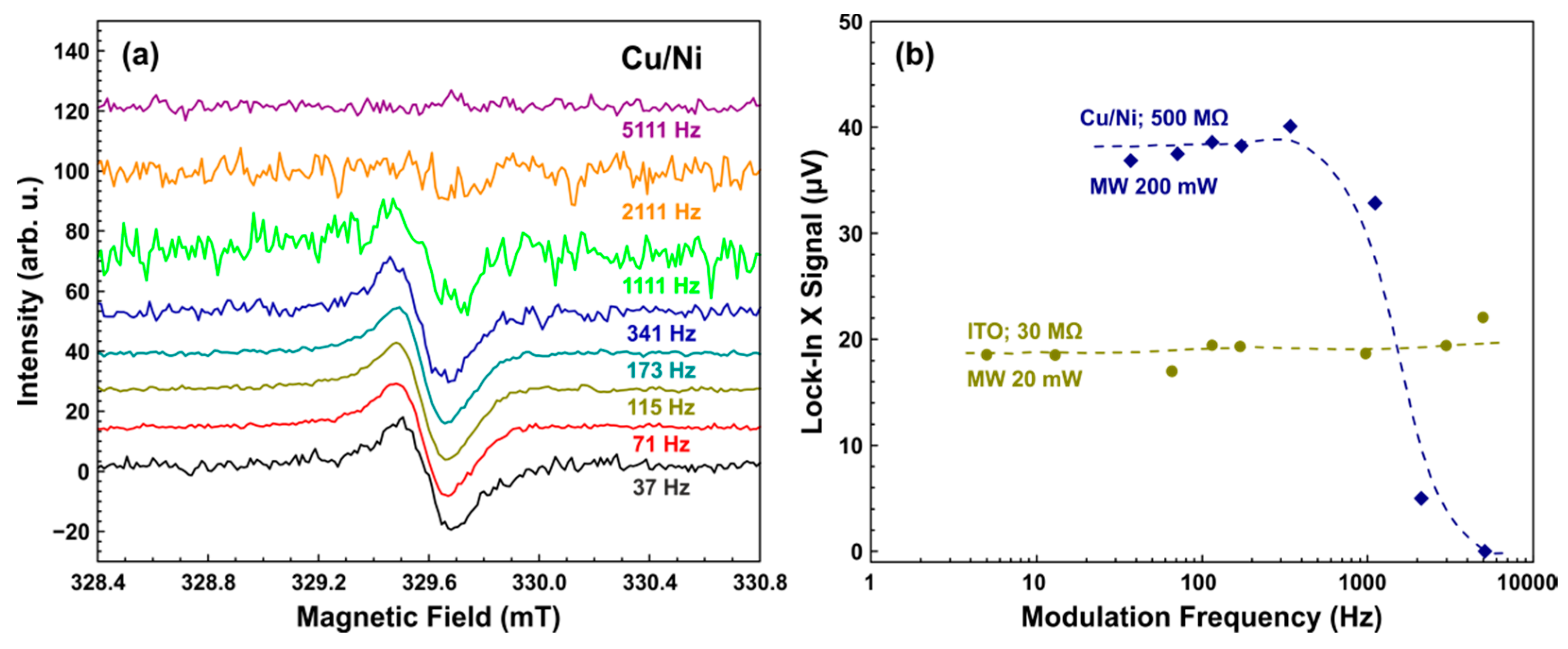

3.2. Dependence of Pyrodetected EPR Signals on Modulation Frequency

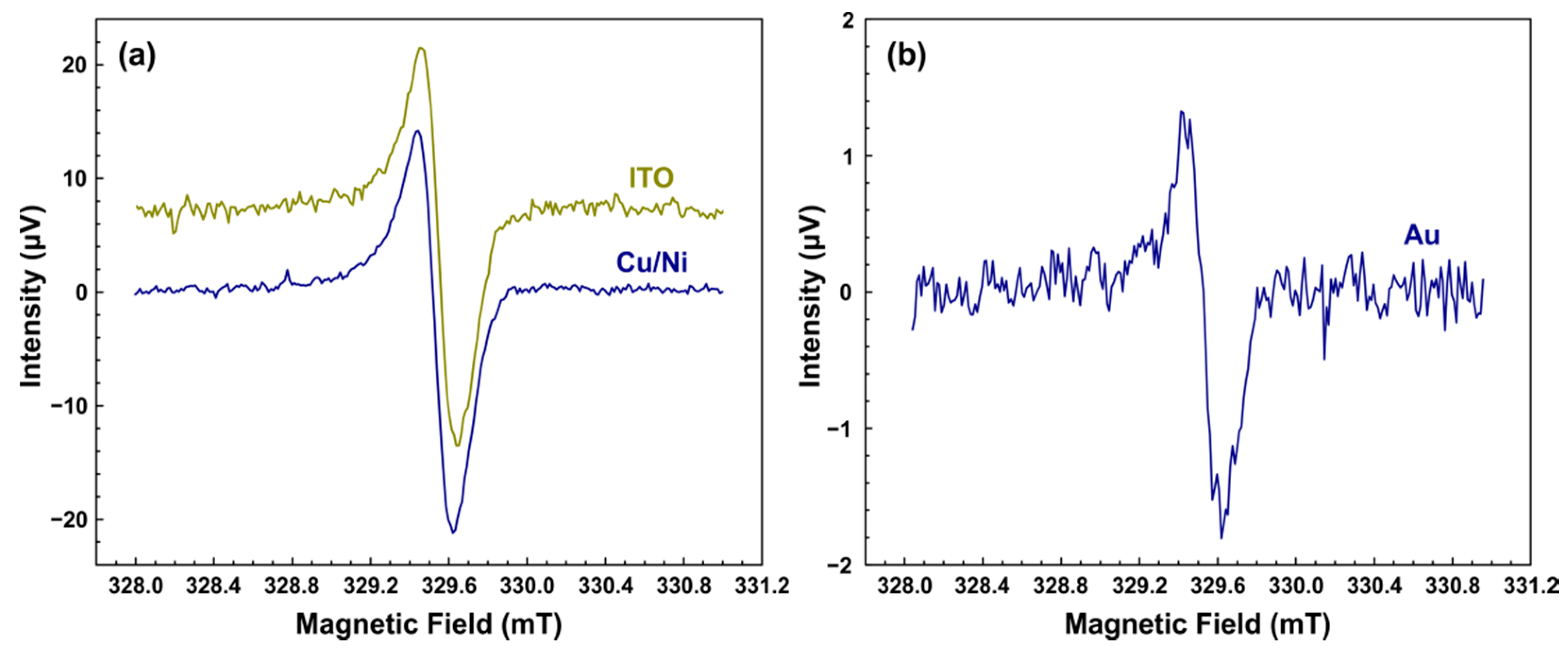

3.3. Sensitivity of Different Active Elements of the Pyrodetector

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fukada, E. History and recent progress in piezoelectric polymers. IEEE Trans. Ultrason. Ferro. Freq. Control 2000, 47, 1277–1290. [Google Scholar] [CrossRef] [PubMed]

- Bobinger, M.; Keddis, S.; Hinterleuthner, S.; Becherer, M.; Kluge, F.; Schwesinger, N.; Salmeron, J.F.; Lugli, P.; Rivadeneyra, A. Light and pressure sensors based on PVDF with sprayed and transparent electrodes for self-powered wireless sensor nodes. IEEE Sens. J. 2018, 19, 1114–1126. [Google Scholar] [CrossRef]

- Thakur, P.; Kool, A.; Hoque, N.A.; Bagchi, B.; Khatun, F.; Biswas, P.; Brahma, D.; Roy, S.; Banerjee, S.; Das, S. Superior performances of in situ synthesized ZnO/PVDF thin film based self-poled piezoelectric nanogenerator and self-charged photo-power bank with high durability. Nano Energy 2018, 44, 456–467. [Google Scholar] [CrossRef]

- Martins, P.; Lopes, A.C.; Lanceros-Mendez, S. Electroactive phases of poly(vinylidene fluoride): Determination, processing and applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- Salimi, A.; Yousefi, A.A. Analysis Method: FTIR studies of β-phase crystal formation in stretched PVDF films. Polym. Test. 2003, 22, 699–704. [Google Scholar] [CrossRef]

- Hujer, J.; Carrat, J.-B.; Müller, M.; Riondet, M. Impact load measurements with a PVDF pressure sensor in an erosive cavitating flow. J. Phys. Conf. Ser. 2015, 656, 012051. [Google Scholar] [CrossRef]

- Chang, Y.M.; Lee, J.S.; Kim, K.J. Heartbeat monitoring technique based on corona-poled PVDF film sensor for smart apparel application. Solid State Phenom. 2007, 124, 299–302. [Google Scholar] [CrossRef]

- Ronald, G.D.; Melvin, H.F.; Nichols, J. Introduction to Infrared and Electro-Optical Systems, 2nd ed.; Artech House: Norwood, MA, USA, 2012; pp. 126–128. [Google Scholar]

- Chirtoc, M.; Bentefour, E.H.; Antoniow, J.S.; Glorieux, C.; Thoen, J.; Delenclos, S.; Sahraoui, A.H.; Longuemart, S.; Kolinsky, C.; Buisine, J.M. Current mode versus voltage mode measurement of signals from pyroelectric sensors. Rev. Sci. Instrum. 2003, 74, 648–650. [Google Scholar] [CrossRef]

- Available online: https://www.planetanalog.com/using-pspice-to-analyze-amplifier-loop-stability-part-1-of-2 (accessed on 10 December 2021).

- Weil, J.A.; Bolton, J.R.; Wertz, J.E. Electron Paramagnetic Resonance—Elementary Theory and Practical Applications, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Schmidt, J.; Solomon, I. High-Sensitivity Magnetic Resonance by Bolometer Detection. J. Appl. Phys. 1966, 37, 3719–3724. [Google Scholar] [CrossRef]

- Melcher, R.L. Thermoacoustic detection of electron paramagnetic resonance. Appl. Lett. Phys. 1980, 37, 895–897. [Google Scholar] [CrossRef]

- Melcher, R.L.; Arbach, G.V. Pyroelectric detection of magnetic resonance. Appl. Phys. Lett. 1982, 40, 910–911. [Google Scholar] [CrossRef]

- Frankevich, E.L.; Pristupa, A.I.; Lesin, V.I. Magnetic resonance of short-lived triplet exciton pairs detected by fluorescence modulation at room temperature. Chem. Phys. Lett. 1977, 47, 304–308. [Google Scholar] [CrossRef]

- Anisimov, O.A.; Grigoryants, V.M.; Molchanov, V.K.; Molin, Y.N. Optical detection of ESR absorption of short-lived ion-radical pairs produced in solution by ionizing radiation. Chem. Phys. Lett. 1979, 66, 265–268. [Google Scholar] [CrossRef]

- Anisimov, O.A. Ion pairs in liquids. In Radical Ionic System; Lund, A., Shiotani, M., Eds.; Kluwer: Dordrecht, The Netherlands, 1991; pp. 285–309. [Google Scholar]

- Rolfe, J.; Moore, S.E. The Efficient Use of Photomultiplier Tubes for Recording Spectra. Appl. Opt. 1970, 9, 63–71. [Google Scholar] [CrossRef]

- Wei, X.B.; Hess, C.; Vardeny, Z.V.; Wudl, F. Studies of Photoexcited States in Polyacetylene and Poly(paraphenylenevinylene) by Absorption Detected Magnetic Resonance: The Case of Neutral Photoexcitations. Phys. Rev. Lett. 1992, 68, 666–669. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Itoh, T.; Matsuyama, A.; Maeda, K.; Murai, H. Validity and possibility of photoconductivity-detected magnetic resonance (PCDMR) method as one of reaction-yield-detected magnetic resonance (RYDMR) methods. Chem. Phys. Lett. 2001, 333, 242–247. [Google Scholar] [CrossRef]

- Yang, C.G.; Ehrenfreund, E.; Vardeny, Z.V. Polaron spin-lattice relaxation time in pi-conjugated polymers from optically detected magnetic resonance. Phys. Rev. Lett. 2007, 99, 157401. [Google Scholar] [CrossRef] [PubMed]

- McCamey, D.R.; Seipel, H.A.; Paik, S.-Y.; Walter, M.J.; Borys, N.J.; Lupton, J.M.; Boehme, C. Spin Rabi flopping in the photocurrent of a polymer light-emitting diode. Nat. Mater. 2008, 7, 723–728. [Google Scholar] [CrossRef] [PubMed]

- Boehme, C.; Lips, K. Theory of time-domain measurement of spin-dependent recombination with pulsed electrically detected magnetic resonance. Phys. Rev. B 2003, 68, 245105. [Google Scholar] [CrossRef]

- Castro, F.A.; Silva, G.B.; Santos, L.F.; Faria, R.M.; Nuesch, F.; Zuppiroli, L.; Graeff, C.F.O. Electrically detected magnetic resonance of organic and polymeric light emitting diodes. J. Non-Cryst. Solids 2004, 338, 622–625. [Google Scholar] [CrossRef]

- Lee, M.-K.; Segal, M.; Soos, Z.G.; Shinar, J.; Baldo, M.A. Yield of singlet excitons in organic light-emitting devices: A double modulation photoluminesence-detected magnetic resonance study. Phys. Rev. Lett. 2005, 94, 137403. [Google Scholar] [CrossRef] [PubMed]

- Milster, S.; Grünbaum, T.; Bange, S.; Kurrmann, S.; Kraus, H.; Stoltzfus, D.M.; Leung, A.E.; Darwish, T.A.; Burn, P.L.; Boehme, C.; et al. Perdeuterated conjugated polymers for ultralow-frequency magnetic resonance of OLEDs. Angew. Chem. 2020, 59, 9388–9392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ashton, J.P.; Lenahan, P.M.; Lichtenwalner, D.J.; Lelis, A.J.; Anders, M.A. Electrically detected magnetic resonance study of barium and nitric oxide treatments of 4H-SiC metal-oxide-semiconductor field-effect transistors. J. Appl. Phys. 2019, 126, 145702. [Google Scholar] [CrossRef]

- Ashton, J.P.; Lenahan, P.M. Multiple-photon transitions in electrically detected magnetic resonance measurements of 4H-SiC transistors. Phys. Rev. B 2020, 102, 020101. [Google Scholar] [CrossRef]

- Kraus, H.; Bange, S.; Frunder, F.; Scherf, U.; Boehme, C.; Lupton, J.M. Visualizing the radical-pair mechanism of molecular magnetic field effects by magnetic resonance induced electrofluorescence to electrophosphorescence interconversion. Phys. Rev. B 2017, 95, 241201. [Google Scholar] [CrossRef] [Green Version]

- Fukuda, K.; Asakawa, N. Electrically detected magnetic resonance observations of spin-dependent space-charge-limited conduction in regioregular poly(3-hexylthiophene). Macromol. Chem. Phys. 2018, 219, 1700395. [Google Scholar] [CrossRef]

- Yeh, T.-H.; Tsai, C.-K.; Chu, S.-Y.; Lee, H.-Y.; Lee, C.-T. Performance improvement of Y-doped VOX microbolometers with nanomesh antireflection layer. Opt. Exp. 2020, 28, 6433–6442. [Google Scholar] [CrossRef] [PubMed]

- Weller, H.J.; Setiadi, D.; Binnie, T.D. Low-noise charge sensitive readout for pyroelectric sensor arrays using PVDF thin films. Sens. Actuators A 2000, 85, 267–274. [Google Scholar] [CrossRef]

- Eaton, G.R.; Eaton, S.S.; Barr, D.P.; Weber, R.T. Quantitative EPR: A Practioners Guide; Springer: Wien, NY, USA, 2010. [Google Scholar]

- Miyagawa, I.; Sogabe, K.; Hossain, S.A. ESR modulation-spectrum from a DPPH crystal. Chem. Phys. Lett. 1991, 182, 265–268. [Google Scholar] [CrossRef]

- Lang, S.B. Pyroelectricity: From Ancient Curiosity to Modern Imaging Tool. Phys. Today 2005, 58, 31–36. [Google Scholar] [CrossRef] [Green Version]

| Active Element Coating | ||||||

|---|---|---|---|---|---|---|

| Cu/Ni | 3.1 | 17.2 | 1.6 | 13.6 | 230 | 4.2 |

| Au | 0.3 | 3.0 | 7.8 | 1.1 | 300 | 3.2 |

| ITO | 4.0 | 7.1 | 5.0 | 3.2 | 1260 | 0.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melnikov, A.R.; Zikirin, S.B.; Kalneus, E.V.; Ivannikov, V.I.; Grishin, Y.A.; Anisimov, O.A. Application of Pyroelectric Sensors Based on PVDF Films for EPR Spectra Detection by Heat Release. Sensors 2021, 21, 8426. https://doi.org/10.3390/s21248426

Melnikov AR, Zikirin SB, Kalneus EV, Ivannikov VI, Grishin YA, Anisimov OA. Application of Pyroelectric Sensors Based on PVDF Films for EPR Spectra Detection by Heat Release. Sensors. 2021; 21(24):8426. https://doi.org/10.3390/s21248426

Chicago/Turabian StyleMelnikov, Anatoly R., Samat B. Zikirin, Evgeny V. Kalneus, Vladimir I. Ivannikov, Yuri A. Grishin, and Oleg A. Anisimov. 2021. "Application of Pyroelectric Sensors Based on PVDF Films for EPR Spectra Detection by Heat Release" Sensors 21, no. 24: 8426. https://doi.org/10.3390/s21248426

APA StyleMelnikov, A. R., Zikirin, S. B., Kalneus, E. V., Ivannikov, V. I., Grishin, Y. A., & Anisimov, O. A. (2021). Application of Pyroelectric Sensors Based on PVDF Films for EPR Spectra Detection by Heat Release. Sensors, 21(24), 8426. https://doi.org/10.3390/s21248426