A Composite Fabry-Perot Interferometric Sensor with the Dual-Cavity Structure for Simultaneous Measurement of High Temperature and Strain

Abstract

:1. Introduction

2. Sensor Fabrication and Operating Principle

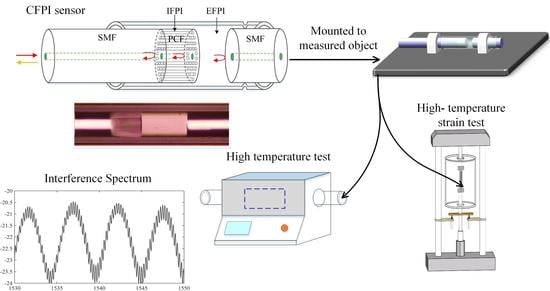

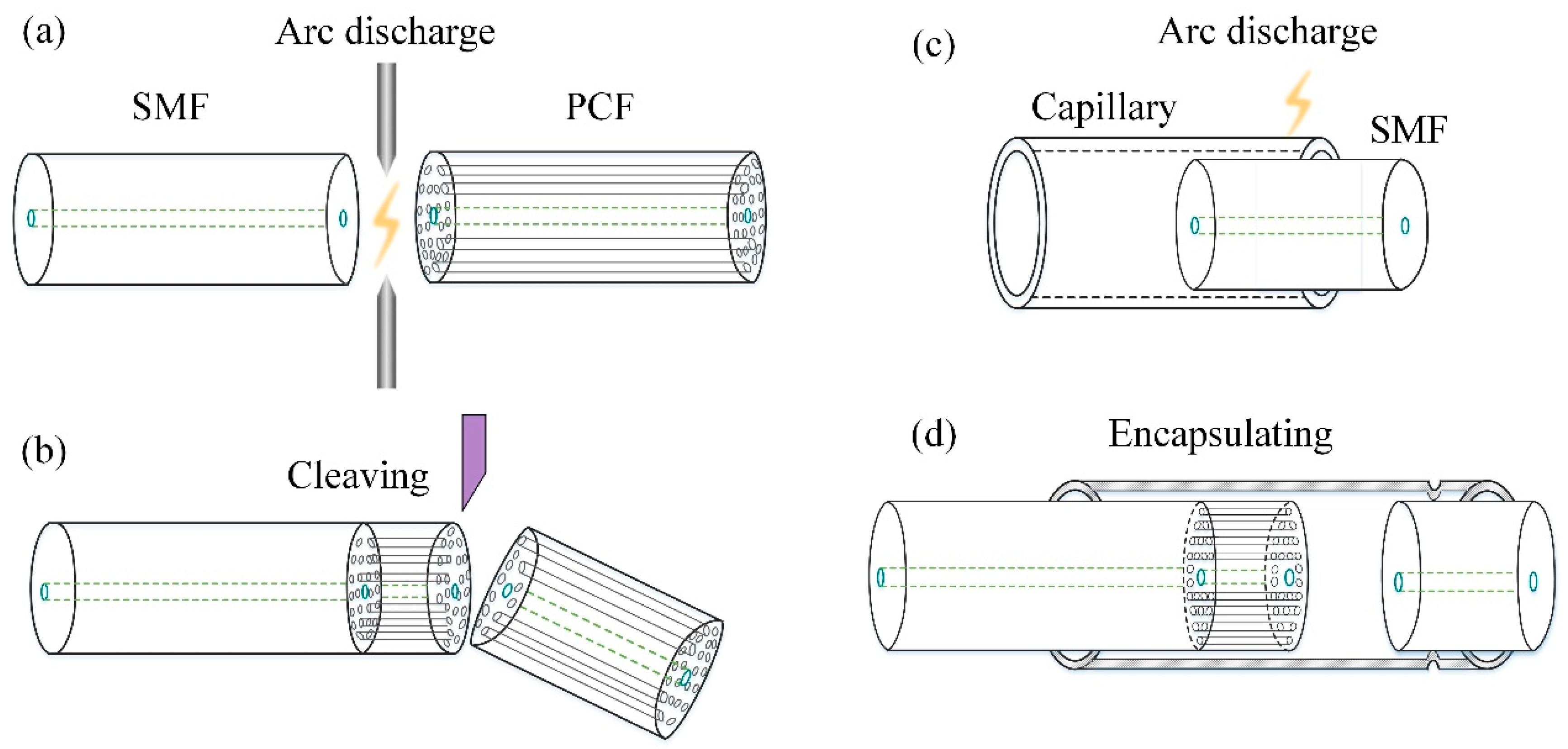

2.1. Sensor Design, Fabrication and Signal Demodulation

2.2. Sensor Installation and Measurement Principle

3. Experiments

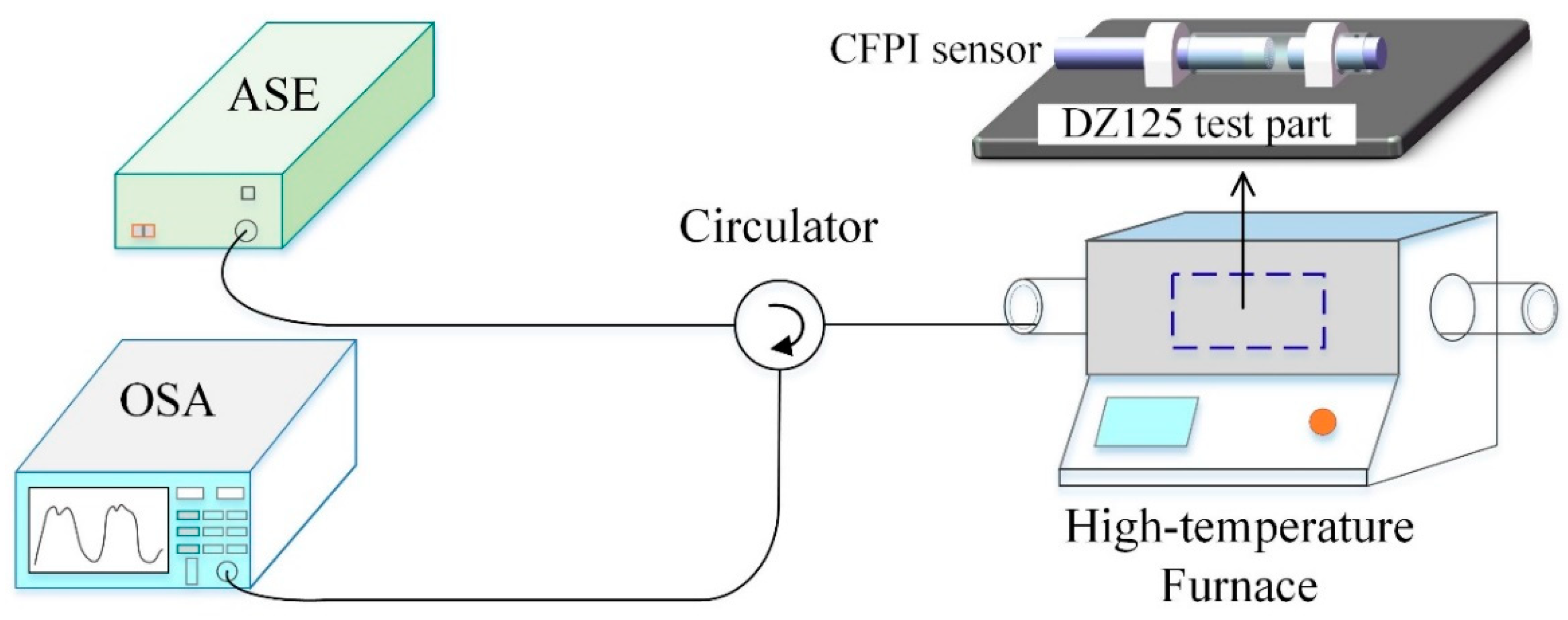

3.1. High-Temperature Test

3.2. Strain Measurement and Calibration at Room Temperature

3.3. Strain Measurement under High Temperatures

4. Experimental Results and Discussion

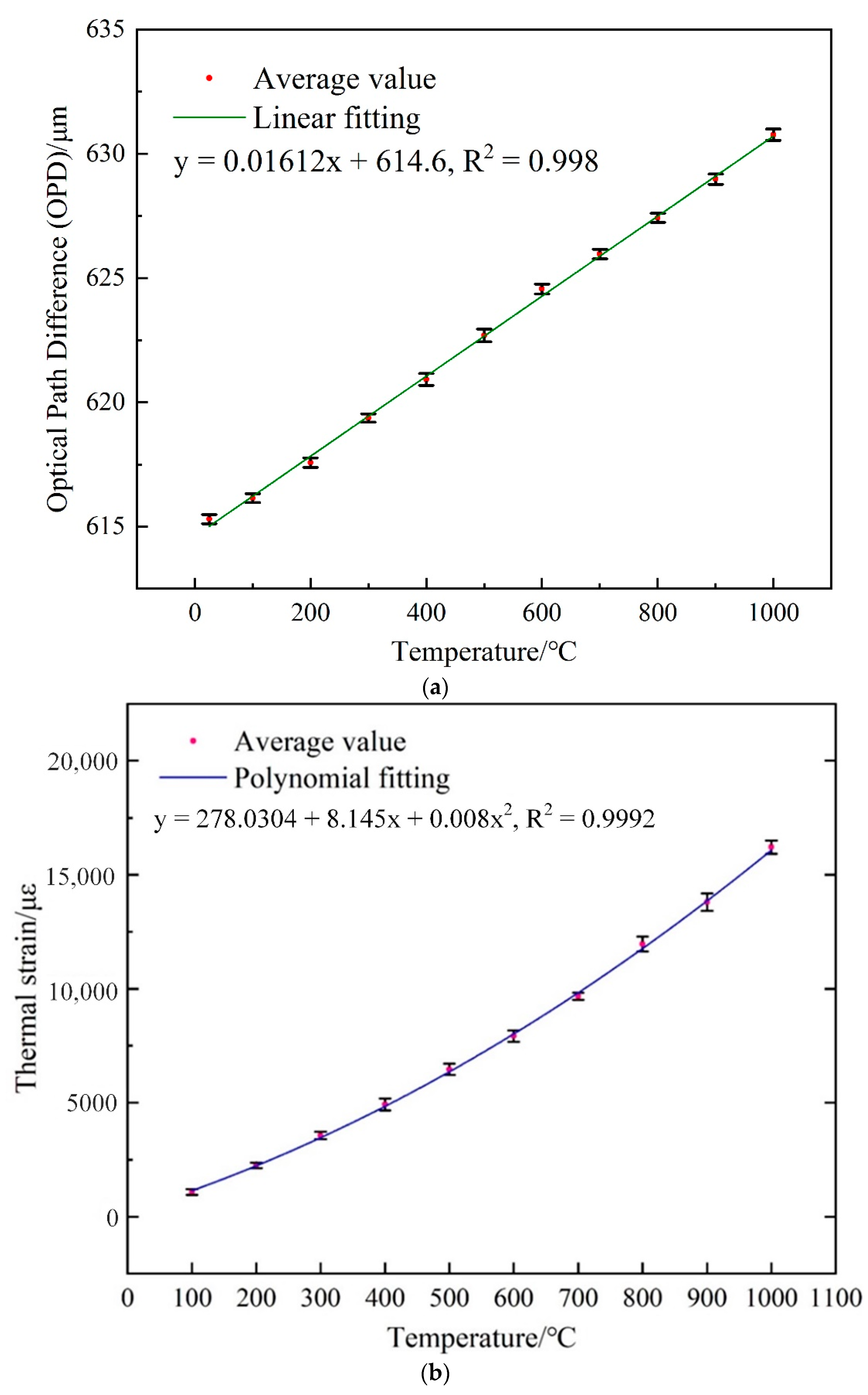

4.1. Results of Temperature Testing Experiments

4.2. Results of Strain Measurement and Calibration at Room Temperature

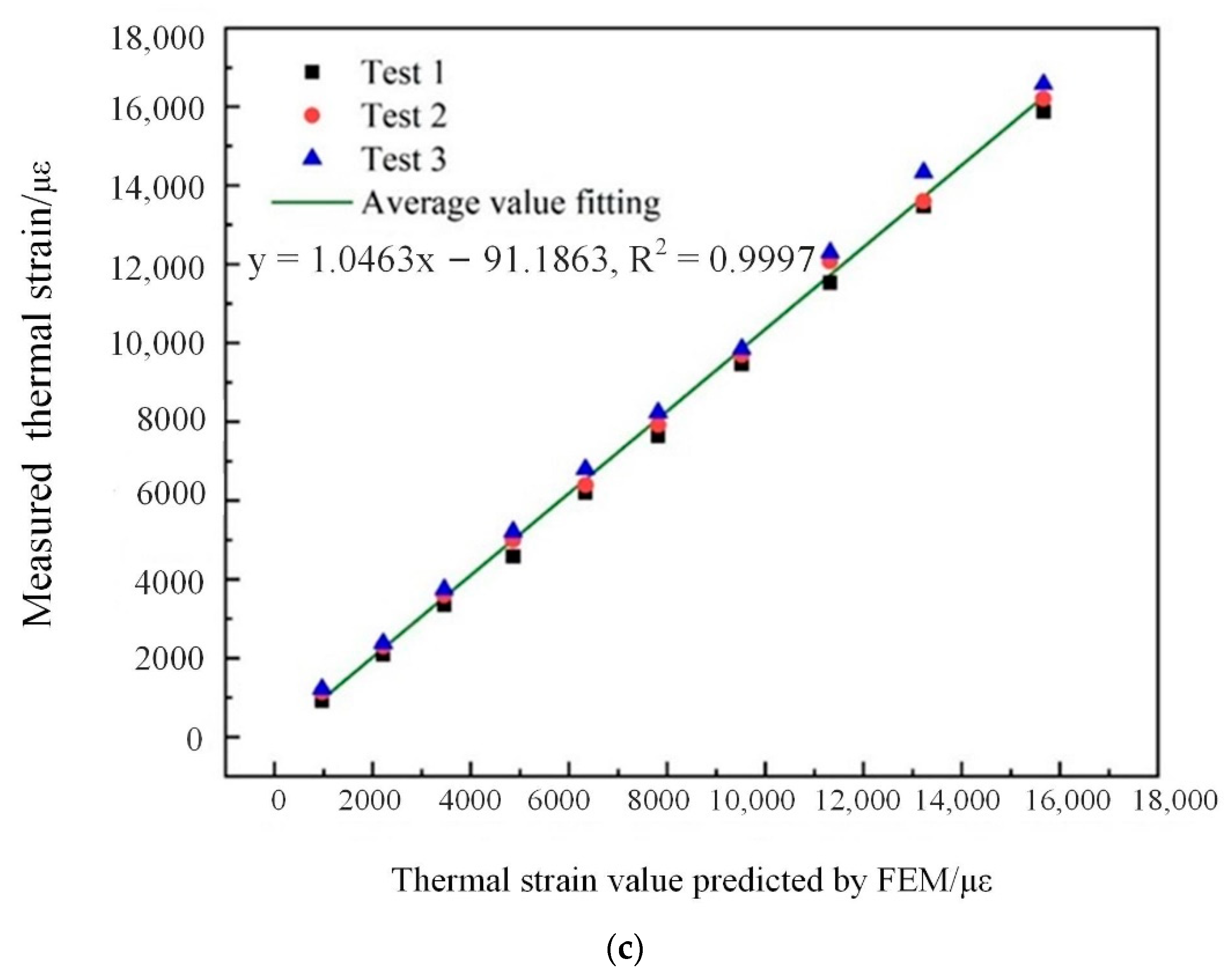

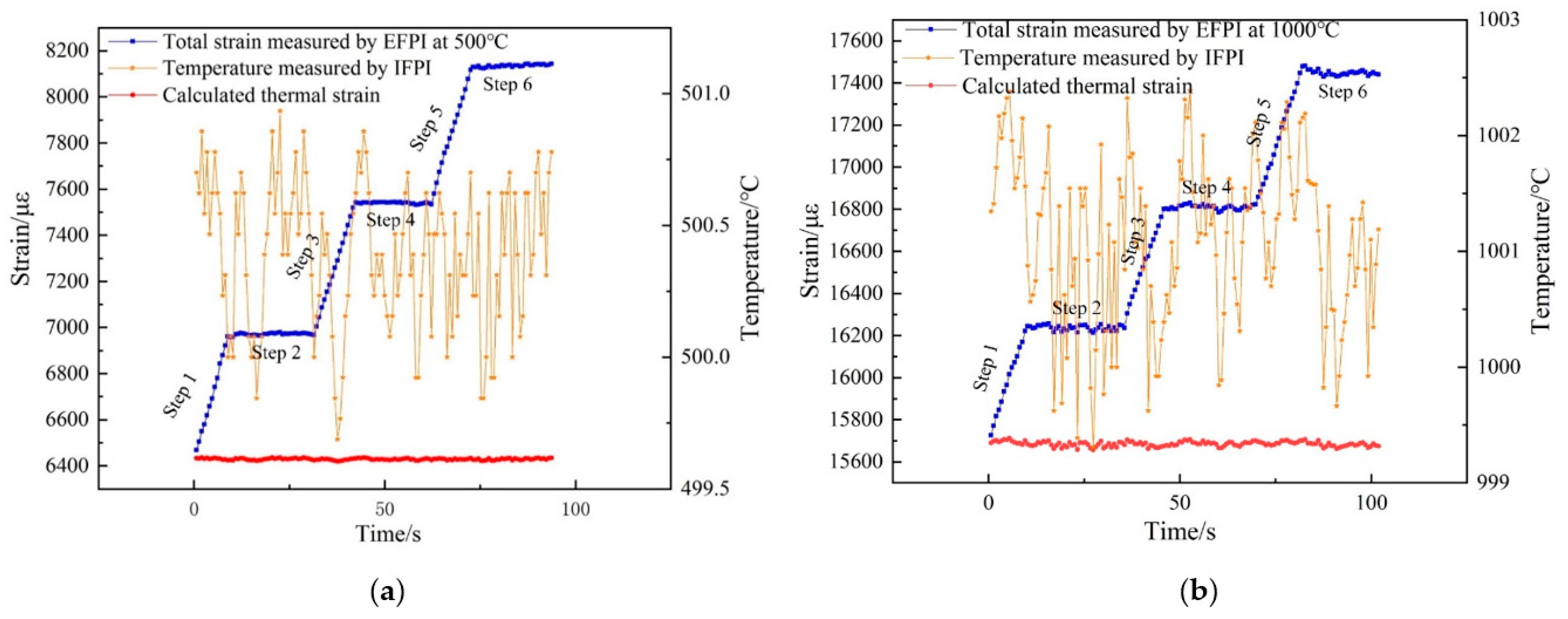

4.3. Results of Strain Measurement at High Temperatures

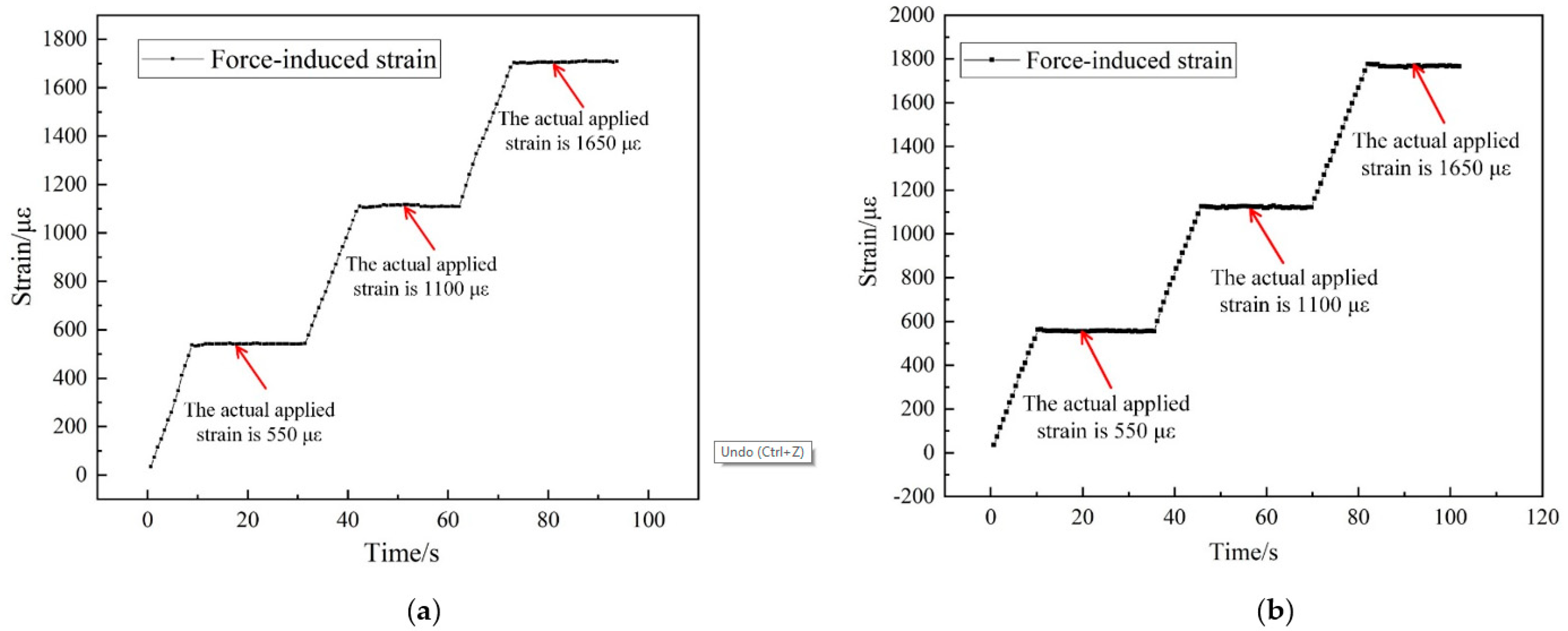

4.4. Results of Strain Measurement with Temperature Compensation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, C.; Chen, Y.; Zhuang, Y.; Huang, J. Displacement and Strain Measurement up to 1000 °C Using a Hollow Coaxial Cable Fabry-Perot Resonator. Sensors 2018, 18, 1304. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ye, X.W.; Su, Y.H.; Han, J.P. Structural Health Monitoring of Civil Infrastructure Using Optical Fiber Sensing Technology: A Comprehensive Review. Sci. World J. 2014, 2014, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Maskay, A.; da Cunha, M.P. High-temperature static strain langasite SAWR sensor: Temperature compensation and numerical calibration for direct strain reading. Sensor Actuat A-Phys 2017, 259, 34–43. [Google Scholar] [CrossRef] [Green Version]

- Pollak, R.T.; Lambros, J. Special issue on strain measurement in extreme environments. J. Strain Anal. Eng. Des. 2014, 49, 202–203. [Google Scholar] [CrossRef] [Green Version]

- Nan, J.; Zhang, D.; Wen, X.; Li, M.; Lv, H.; Su, K. Elimination of Thermal Strain Interference in Mechanical Strain Measurement at High Temperature Using an EFPI-RFBG Hybrid Sensor with Unlimited Cavity Length. IEEE Sens. J. 2020, 20, 5270–5276. [Google Scholar] [CrossRef]

- Xiong, L.; Guo, Y.; Jiang, G.; Zhou, X.; Jiang, L.; Liu, H. Six-Dimensional Force/Torque Sensor Based on Fiber Bragg Gratings with Low Coupling. IEEE Trans. Ind. Electron. 2021, 68, 4079–4089. [Google Scholar] [CrossRef]

- Li, T.; Tan, Y.; Xia, P.; Zhou, Z. Paralleled Structure-Based String-Type Fiber Bragg Grating Acceleration Sensor. IEEE Sens. J. 2016, 17, 1325–1332. [Google Scholar] [CrossRef]

- Dvorak, M.; Chlup, H.; Horny, L.; Ruzicka, M. Comparison of strain measurement methods: Optical FBG sensors, strain gages & digital image correlation. In Proceedings of the 50th Annual Conference on Experimental Stress Analysis, EAN 2012, Tabor, Czechia, 4–7 June 2012. [Google Scholar]

- Xia, P.; Tan, Y.G.; Li, T.L.; Zhou, Z.D.; Lv, W.Q. A High-temperature Resistant Photonic Crystal Fiber Sensor with Single-side Sliding Fabry-Perot Cavity for Super-large Strain Measurement. Sens. Actuat A-Phys 2021, 318, 112492. [Google Scholar] [CrossRef]

- Deng, M.; Tang, C.-P.; Zhu, T.; Rao, Y.-J. PCF-Based Fabry–Pérot Interferometric Sensor for Strain Measurement at High Temperatures. IEEE Photonics Technol. Lett. 2011, 23, 700–702. [Google Scholar] [CrossRef]

- Liu, Y.; Lang, C.; Wei, X.; Qu, S. Strain force sensor with ultra-high sensitivity based on fiber inline Fabry-Perot micro-cavity plugged by cantilever taper. Opt. Express 2017, 25, 7797–7806. [Google Scholar] [CrossRef]

- Mokhtar, M.R.; Sun, T.; Grattan, K.T.V. Two-dimensional fibre grating packaging design for simultaneous strain and temperature measurement. In Proceedings of the Fourth European Workshop on Optical Fibre, Porto, Portugal, 8–10 September 2010; p. 7653. [Google Scholar]

- Ferna´ndez-Valdivielso, C.; Matı´as, I.R.; Arregui, F. Simultaneous measurement of strain and temperature using a fiber Bragg grating and a thermochromic material. Sens. Actuat A-Phys 2002, 101, 107–116. [Google Scholar] [CrossRef]

- Song, M.; Lee, B.; Lee, S.B.; Choi, S.S. Interferometric temperature-insensitive strain measurement with different-diameter fiber Bragg gratings. Opt. Lett. 1997, 22, 790–792. [Google Scholar] [CrossRef]

- Triollet, S.; Robert, L.; Marin, E.; Ouerdane, Y. Discriminated measures of strain and temperature in metallic specimen with embedded superimposed long and short fibre Bragg gratings. Meas. Sci. Technol. 2010, 22, 015202. [Google Scholar] [CrossRef] [Green Version]

- Patrick, H.; Williams, G.; Kersey, A.; Pedrazzani, J.; Vengsarkar, A. Hybrid fiber Bragg grating/long period fiber grating sensor for strain/temperature discrimination. IEEE Photon. Technol. Lett. 1996, 8, 1223–1225. [Google Scholar] [CrossRef]

- Kanellopoulos, S.E.; Handerek, V.A.; Rogers, A.J. Simultaneous strain and temperature sensing with photogenerated in-fibre gratings. Opt. Lett. 1995, 20, 333–335. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yu, C.Y. Highly stretchable hybrid silica/polymer optical fiber sensors for large-strain and high-temperature application. Opt. Express 2019, 27, 20107–20116. [Google Scholar]

- Lancry, M.; Cook, K.; Cao, J.; Billotte, T.; Poumellec, B.; Canning, J. Study of stress relaxation in UV regenerated fiber Bragg gratings. In Proceedings of the 2017 Conference on Lasers and Electro-Optics Europe & European Quantum Electronics Conference (CLEO/Europe-EQEC), Munich, Germany, 25–29 June 2017. [Google Scholar]

- Zhang, L.; Jiang, Y.; Gao, H.; Jia, J.; Cui, Y.; Wang, S.; Hu, J. Simultaneous Measurements of Temperature and Pressure with a Dual-Cavity Fabry-Perot Sensor. IEEE Photon. Technol. Lett. 2018, 31, 106–109. [Google Scholar] [CrossRef]

- Lee, C.E.; Alcoz, J.J.; Yeh, Y.; Gibler, W.N.; Atkins, R.A.; Taylor, H.F. Optical fiber Fabry-Perot sensors for smart structures. Smart Mater. Struct. 1992, 1, 123–127. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Avellar, L.; Diaz, C.A.R.; Frizera, A.; Marques, C.; Pontes, M.J. Fabry-Perot Curvature Sensor with Cavities Based on UV-Curable Resins: Design, Analysis, and Data Integration Approach. IEEE Sens. J. 2019, 19, 9798–9805. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Diaz, C.; Marques, C.; Frizera, A.; Pontes, M.J. Analysis of viscoelastic properties influence on strain and temperature responses of Fabry-Perot cavities based on UV-curable resins. Opt. Laser Technol. 2019, 120, 105743. [Google Scholar] [CrossRef]

- Tian, Q.; Xin, G.G.; Lim, K.S.; He, Y.D.; Liu, J.; Ahmad, H.; Liu, X.C.; Yang, H.Z. Cascaded Fabry-Perot interferometer-regenerated fiber Bragg grating structure for temperature-strain measurement under extreme temperature conditions. Opt. Express 2020, 28, 30478–30488. [Google Scholar] [CrossRef] [PubMed]

- Murphy, K.A.; Gunther, M.F.; Vengsarkar, A.M.; Claus, R.O. Fabry-Perot fiber-optic sensors in full-scale fatigue testing on an F-15 aircraft. Appl. Opt. 1992, 31, 431–433. [Google Scholar] [CrossRef]

- Xiao, H.; May, R.G.; Wang, J.; Zhao, W.; Deng, J.; Zhang, P.; Pickrell, G.R. Optical fiber sensors for harsh environments. In Proceedings of the SPIE-The International Society for Optical Engineering, San Jose, CA USA, 24–25 January 2000. [Google Scholar] [CrossRef] [Green Version]

- Villatoro, J.; Finazzi, V.; Coviello, G.; Pruneri, V. Photonic-crystal-fiber-enabled micro-Fabry-Perot interferometer. Opt. Lett. 2009, 34, 2441–2443. [Google Scholar] [CrossRef]

- Liu, S.; Yang, K.; Wang, Y.; Qu, J.; Liao, C.; He, J.; Li, Z.; Yin, G.; Sun, B.; Zhou, J.; et al. High-sensitivity strain sensor based on in-fiber rectangular air bubble. Sci. Rep. 2015, 5, 1–7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Favero, F.C.; Araujo, L.; Bouwmans, G.; Finazzi, V.; Villatoro, J.; Pruneri, V. Spheroidal Fabry-Perot microcavities in optical fibers for high-sensitivity sensing. Opt. Express 2012, 20, 7112–7118. [Google Scholar] [CrossRef]

- Ma, Z.; Cheng, S.; Kou, W.; Chen, H.; Wang, W.; Zhang, X.; Guo, T. Sensitivity-Enhanced Extrinsic Fabry-Perot Interferometric Fiber-Optic Microcavity Strain Sensor. Sensors 2019, 19, 4097. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, G.; Han, M.; Hou, W. High-resolution and fast-response fiber-optic temperature sensor using silicon Fabry-Pérot cavity. Opt. Express 2015, 23, 7237–7247. [Google Scholar] [CrossRef] [Green Version]

- Coviello, G.; Finazzi, V.; Villatoro, J.; Pruneri, V. Thermally stabilized PCF-based sensor for temperature measurements up to 1000 °C. Opt. Express 2009, 17, 21551–21559. [Google Scholar] [CrossRef] [Green Version]

- Huang, Z.; Zhu, Y.; Chen, X.; Wang, A. Intrinsic Fabry-Pe/spl acute/rot fiber sensor for temperature and strain measurements. IEEE Photon. Technol. Lett. 2005, 17, 2403–2405. [Google Scholar] [CrossRef]

- Wu, D.; Zhu, T.; Wang, G.-Y.; Fu, J.-Y.; Lin, X.-G.; Gou, G.-L. Intrinsic fiber-optic Fabry-Perot interferometer based on arc discharge and single-mode fiber. Appl. Opt. 2013, 52, 2670–2675. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Xiong, S.; Gao, S.; Zhang, H.; Wan, L.; Huang, X.; Huang, B.; Feng, Y.; Liu, W.; Li, Z. High-Temperature Sensor Based on Fabry-Perot Interferometer in Microfiber Tip. Sensors 2018, 18, 202. [Google Scholar] [CrossRef] [Green Version]

- Sun, H.; Tian, S.; Tian, N.; Yu, H.; Meng, X. Microstructure heterogeneity and creep damage of DZ125 nickel-based superalloy. Prog. Nat. Sci. Mater. Int. 2014, 24, 266–273. [Google Scholar] [CrossRef] [Green Version]

| Research Group | Sensor Structure | Sensing Principle | Maximum Working Temperature/ Strain Measurement Range |

|---|---|---|---|

| Nan et al. [5] | EFPI-RFBG hybrid sensor | EFPI for strain measurement, RFBG for temperature measurement | 800 °C/ 6500 με |

| Tian et al. [24] | FPI-RFBG hybrid sensor | FPI for strain measurement, RFBG for temperature measurement | 1000 °C/ 450 με |

| This paper | EFPI-IFPI composite sensor | EFPI for strain measurement, IFPI for temperature measurement | 1000 °C/ 17,480 με |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, P.; Tan, Y.; Yang, C.; Zhou, Z.; Yun, K. A Composite Fabry-Perot Interferometric Sensor with the Dual-Cavity Structure for Simultaneous Measurement of High Temperature and Strain. Sensors 2021, 21, 4989. https://doi.org/10.3390/s21154989

Xia P, Tan Y, Yang C, Zhou Z, Yun K. A Composite Fabry-Perot Interferometric Sensor with the Dual-Cavity Structure for Simultaneous Measurement of High Temperature and Strain. Sensors. 2021; 21(15):4989. https://doi.org/10.3390/s21154989

Chicago/Turabian StyleXia, Ping, Yuegang Tan, Caixia Yang, Zude Zhou, and Kang Yun. 2021. "A Composite Fabry-Perot Interferometric Sensor with the Dual-Cavity Structure for Simultaneous Measurement of High Temperature and Strain" Sensors 21, no. 15: 4989. https://doi.org/10.3390/s21154989

APA StyleXia, P., Tan, Y., Yang, C., Zhou, Z., & Yun, K. (2021). A Composite Fabry-Perot Interferometric Sensor with the Dual-Cavity Structure for Simultaneous Measurement of High Temperature and Strain. Sensors, 21(15), 4989. https://doi.org/10.3390/s21154989