A Bond-Wire Drift Offset Minimized Capacitance-to-Digital Interface for MEMS Accelerometer with Gain-Enhanced VCO-Based Quantization and Nested Digital Chopping Feedback Loops

Abstract

1. Introduction

2. The Proposed Interface Principle

2.1. Challenges Based on MEMS Characteristics

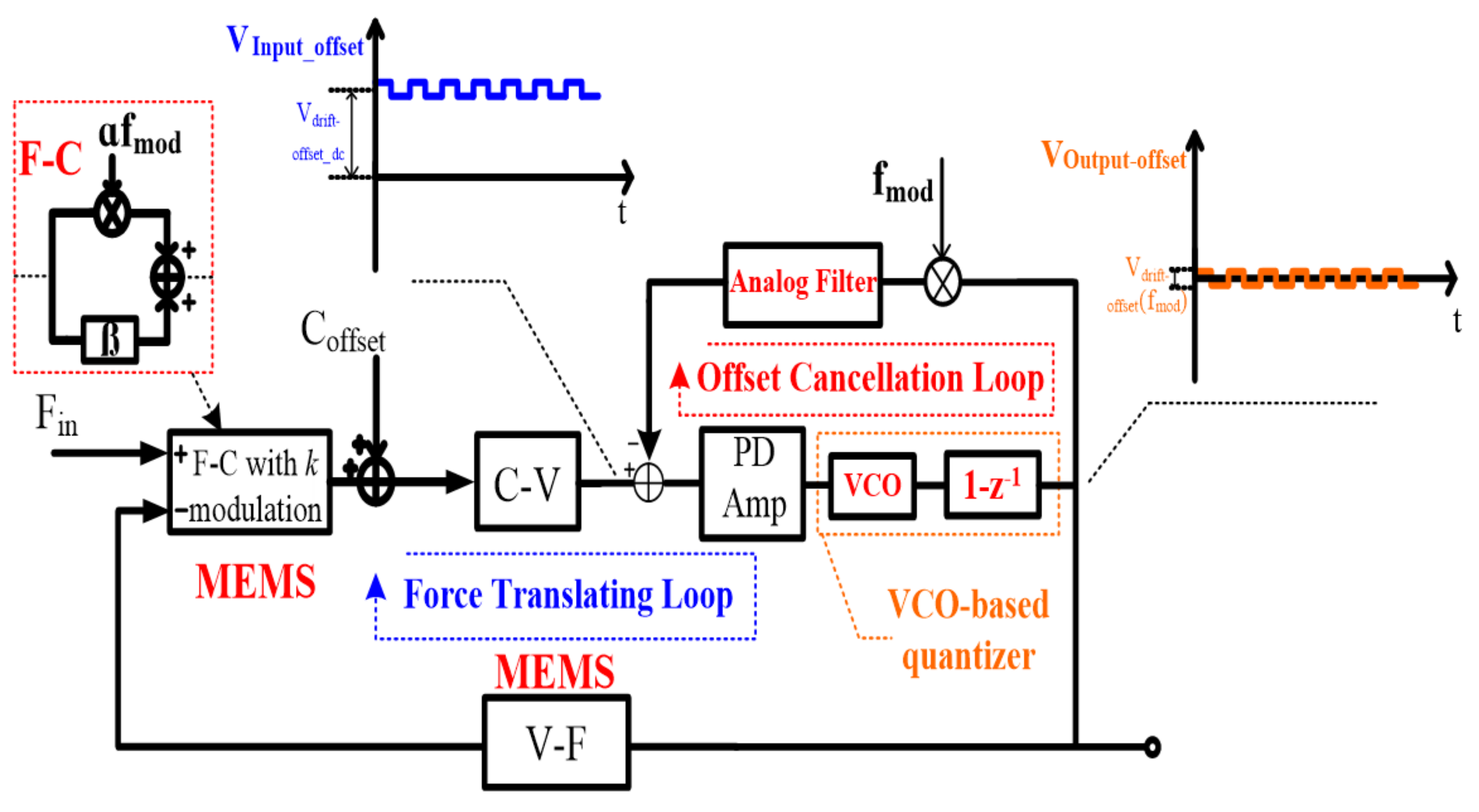

2.2. The Proposed Interface

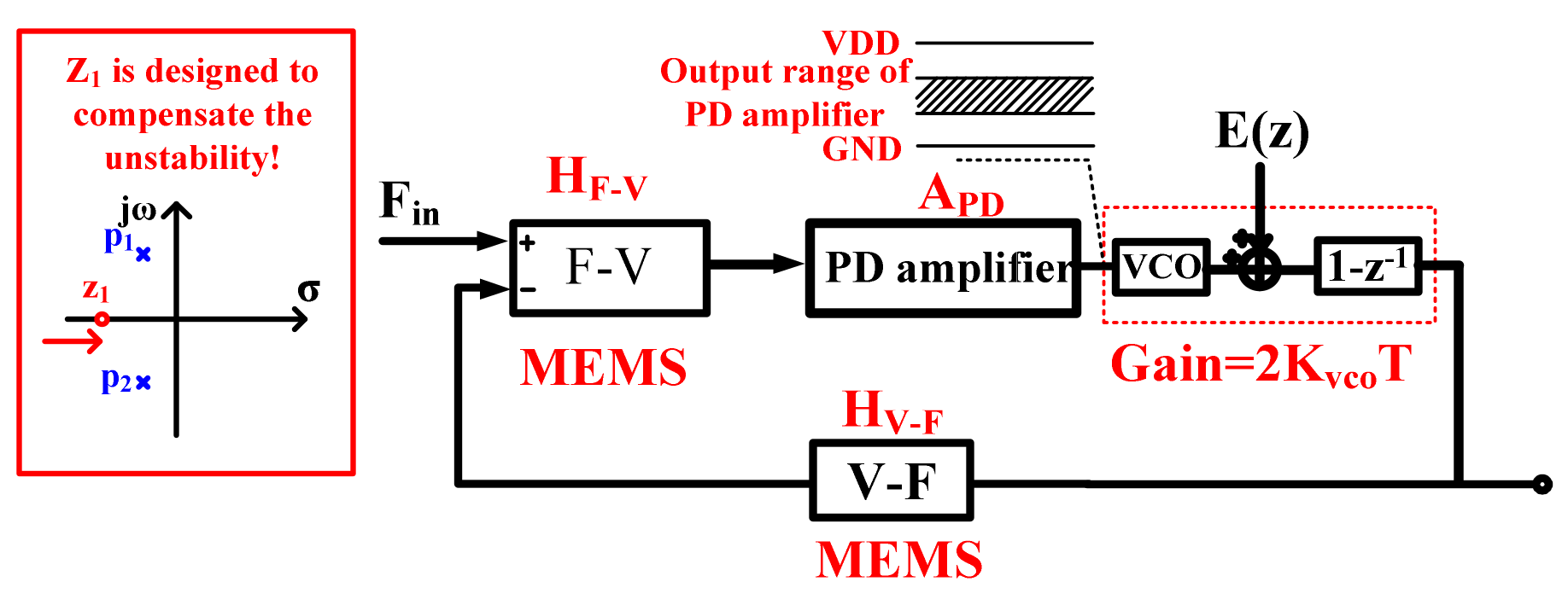

2.3. The Gain-Enhanced VCO-Based Quantization Loop

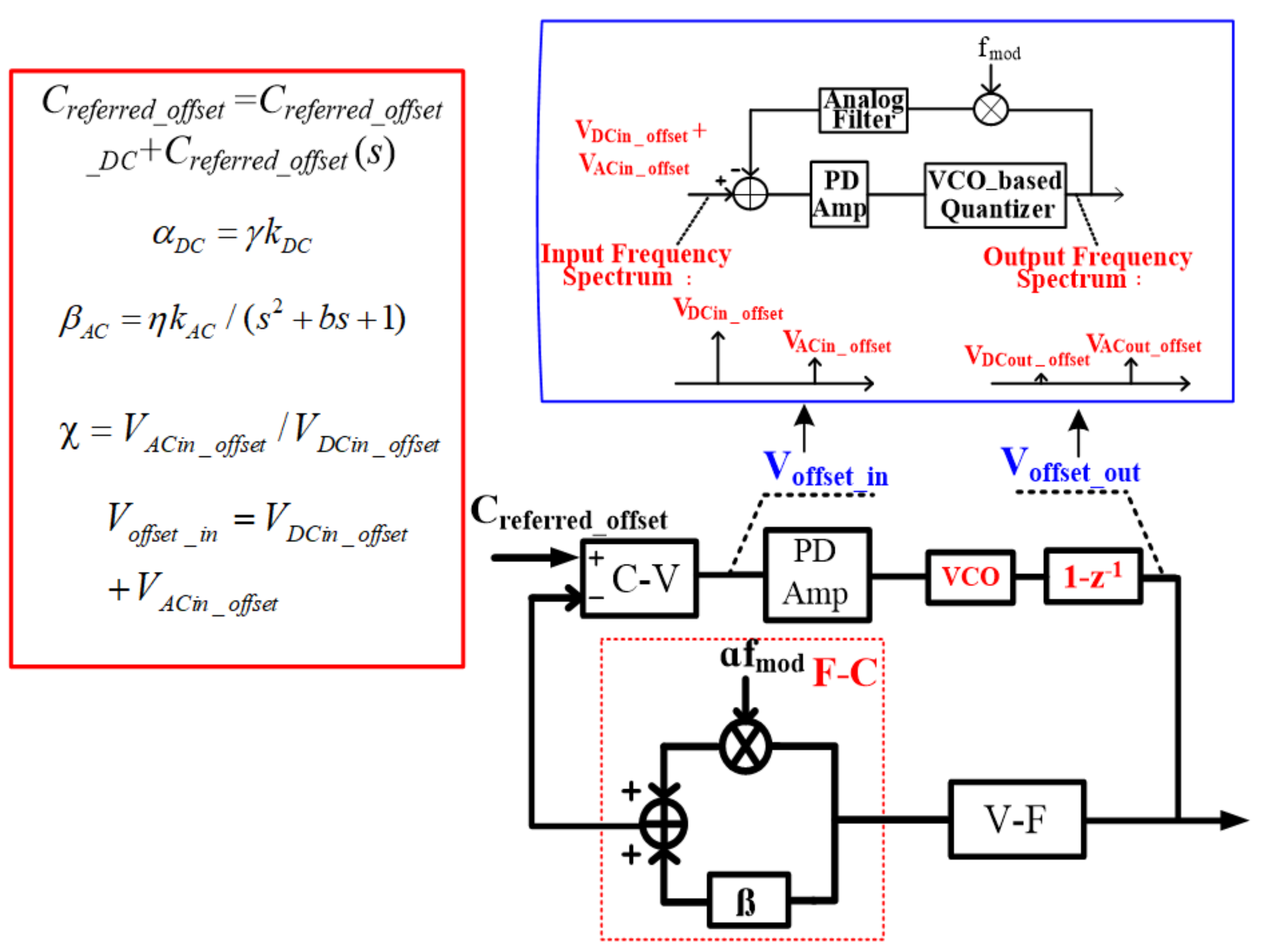

2.4. The Nested Digital Chopping Feedback Loop

3. Circuit Implementation

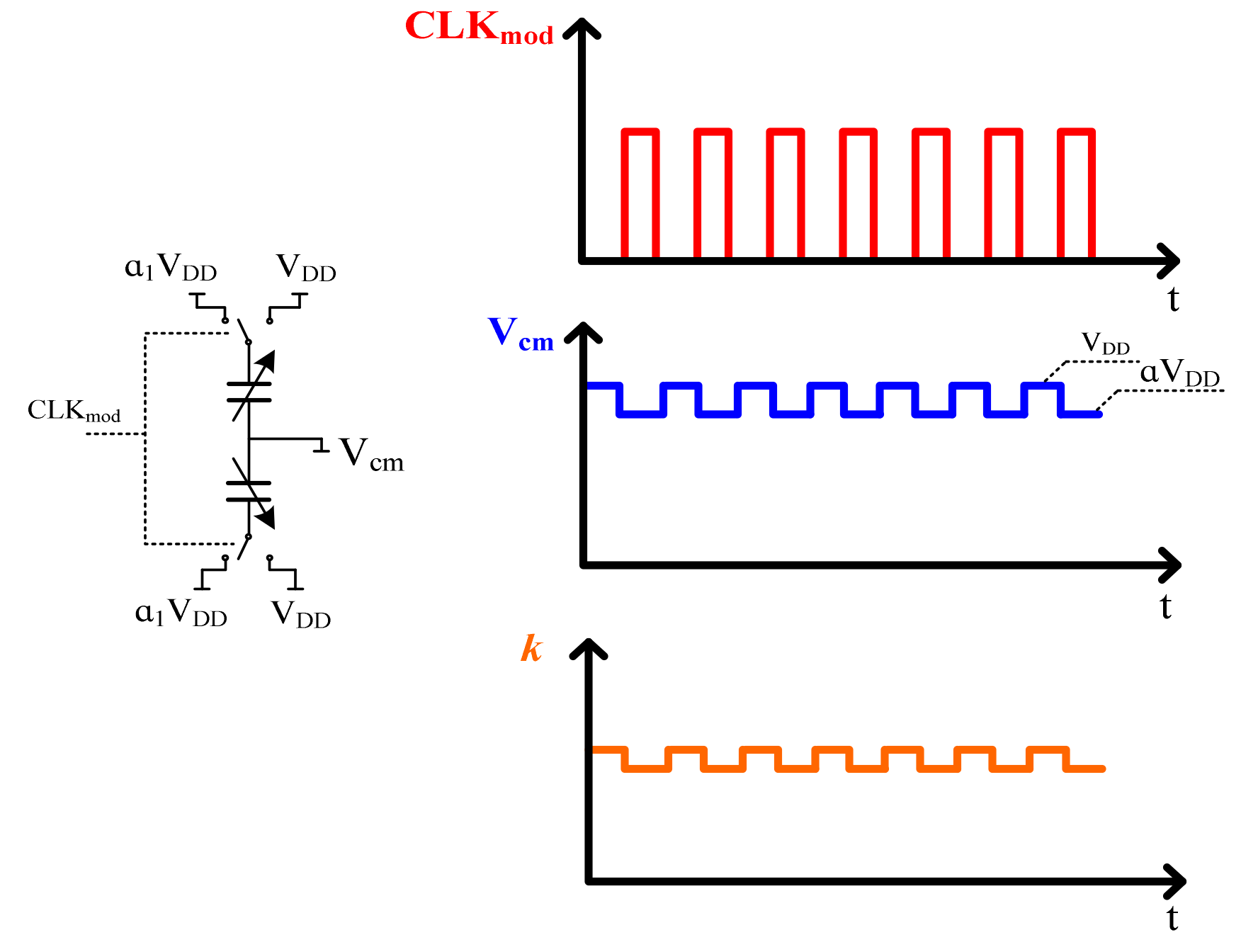

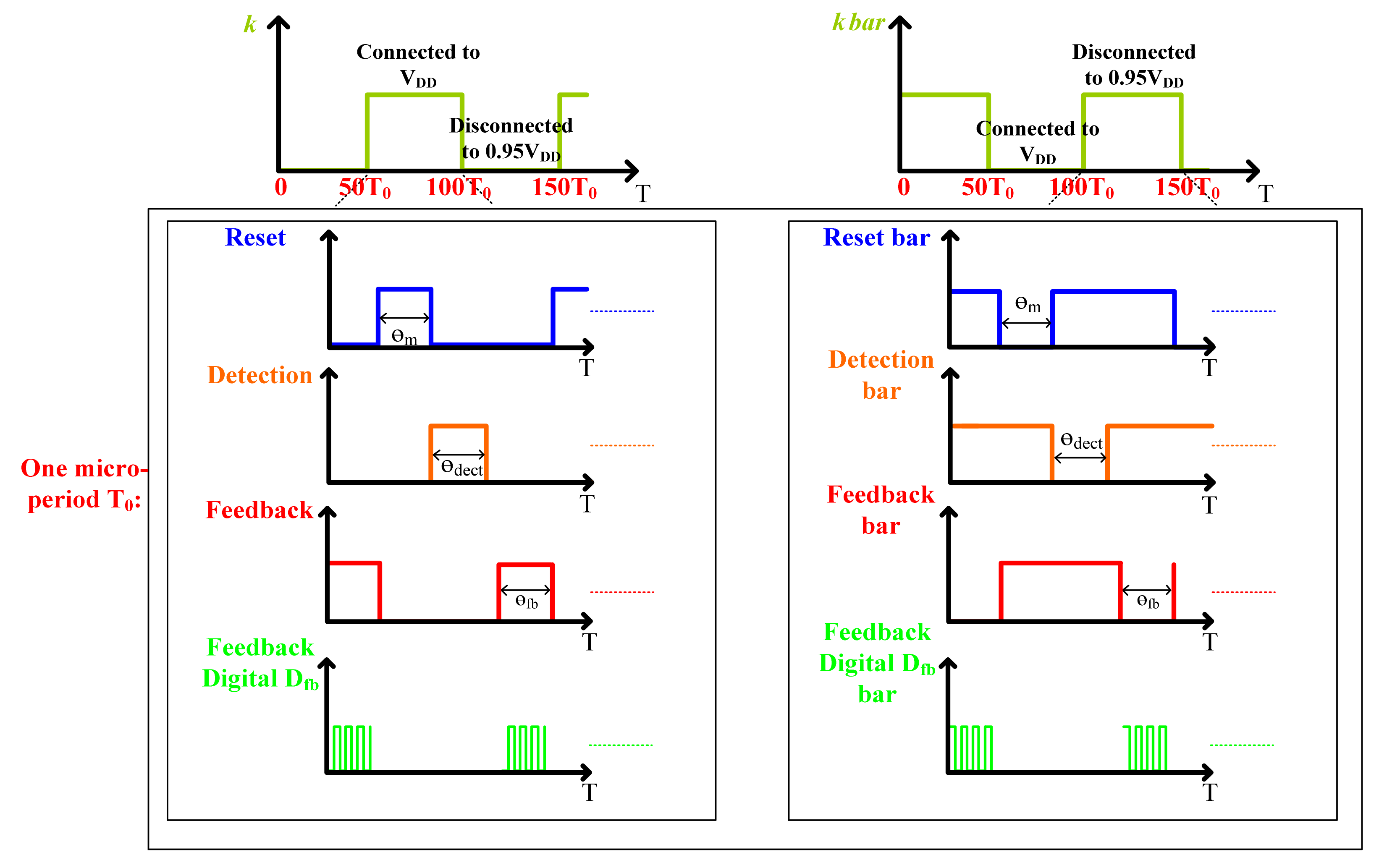

3.1. Circuit Implementation of k Modulation

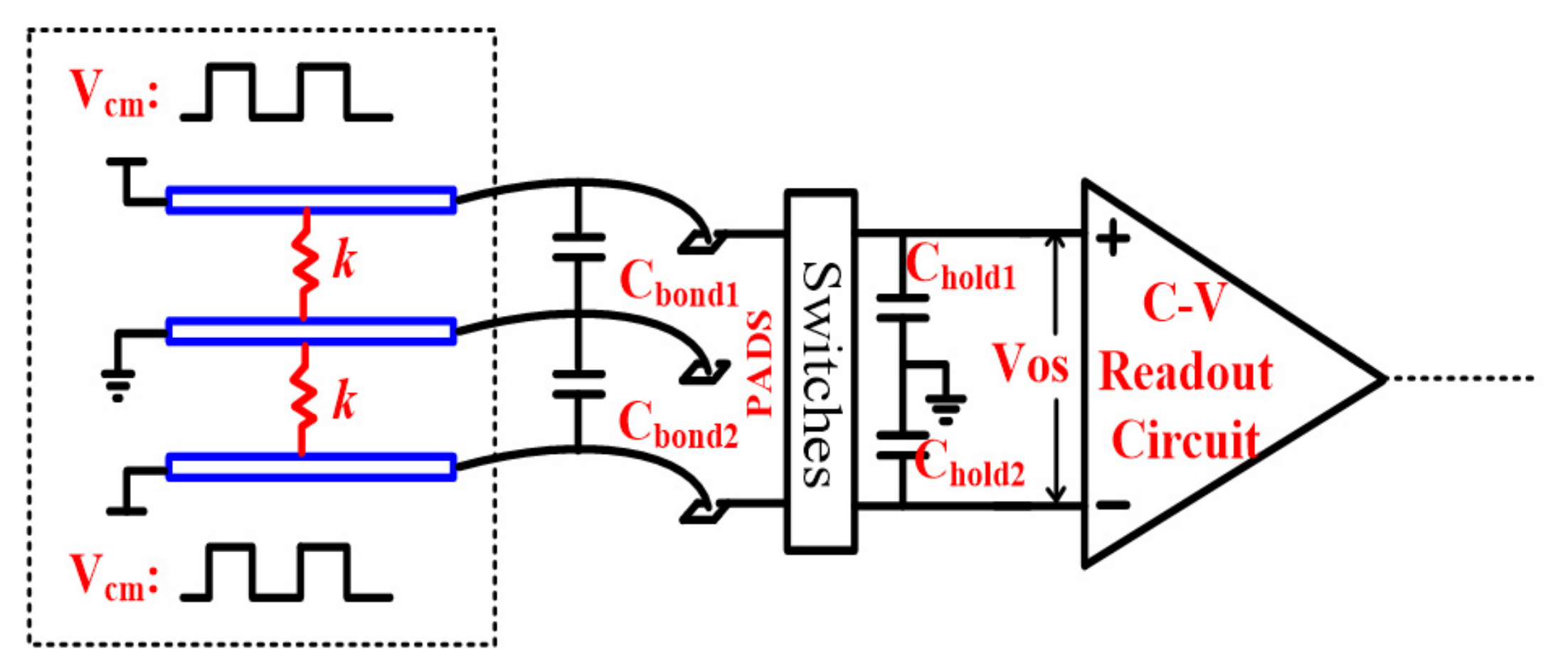

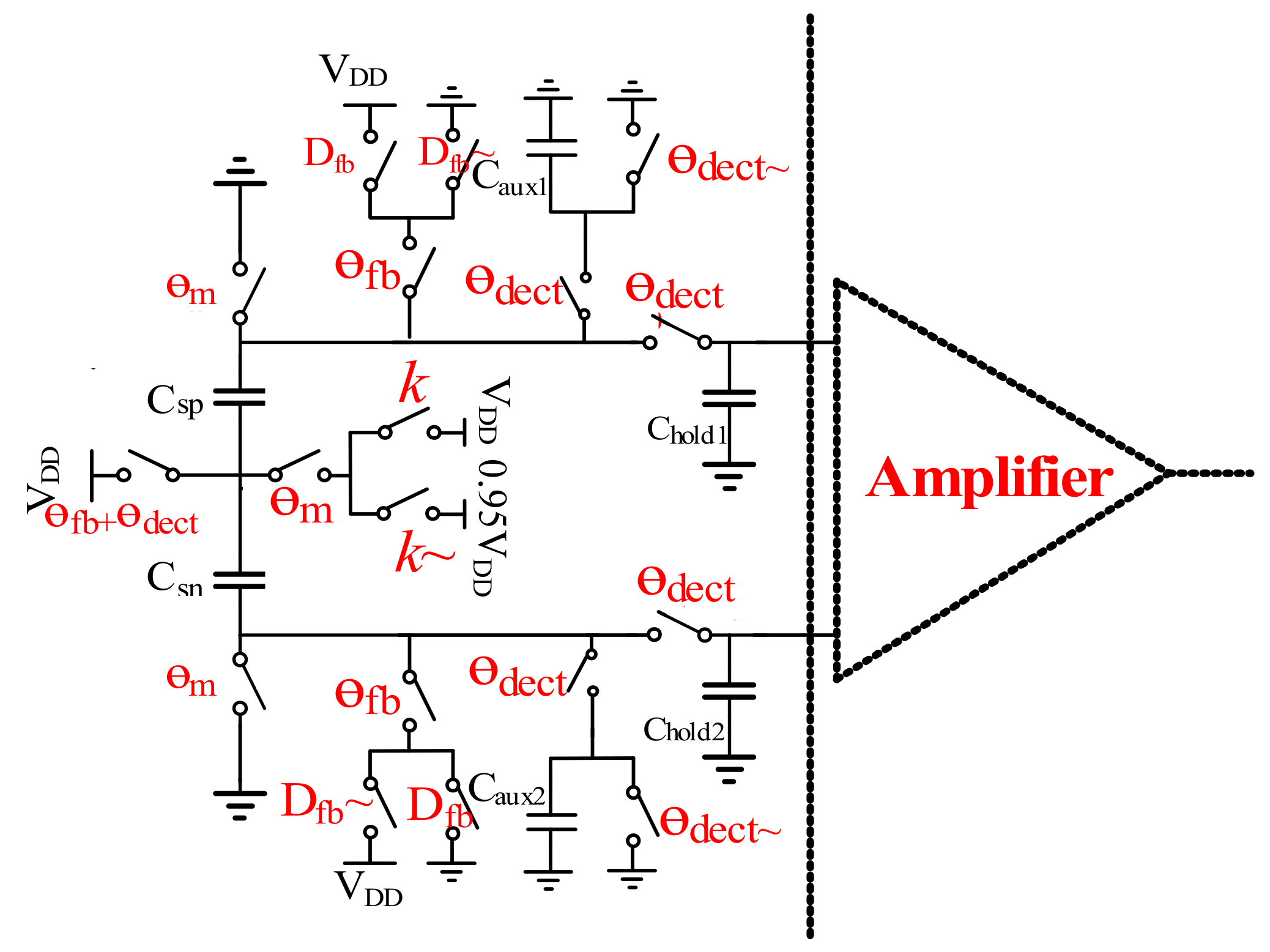

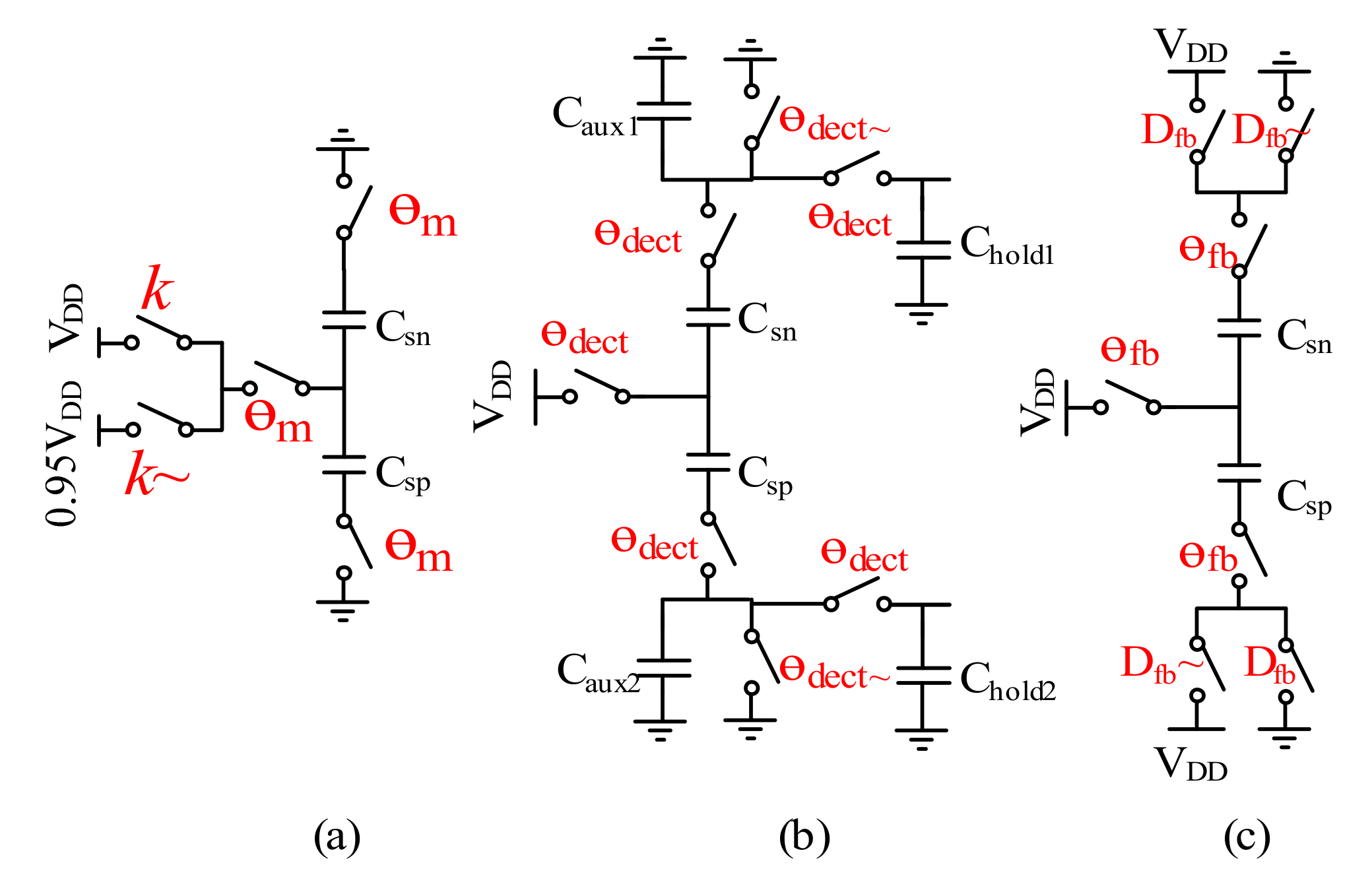

3.2. Implementation of C-V Switched Capacitors

3.3. The Readout Circuit

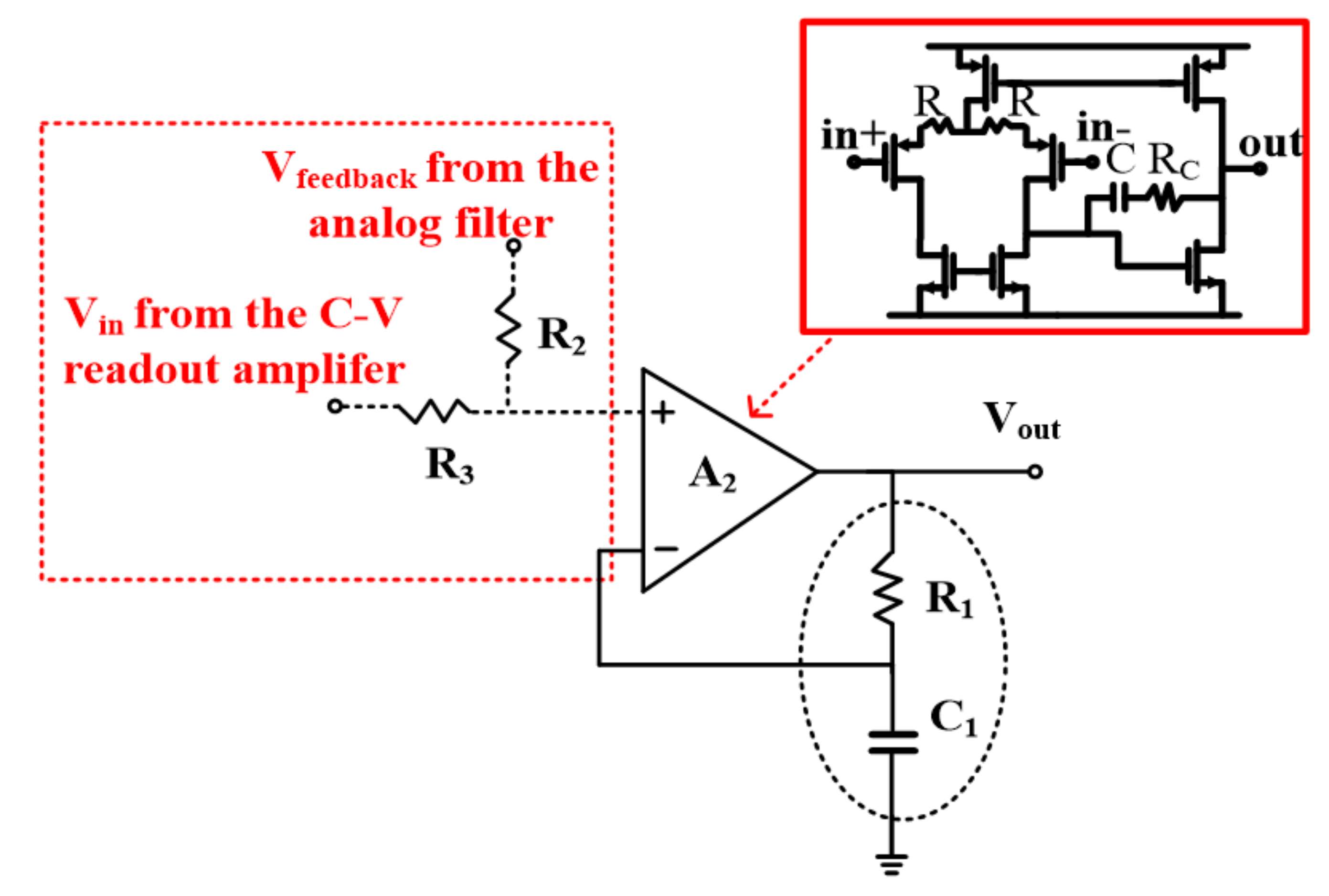

3.4. The PD Amplifier

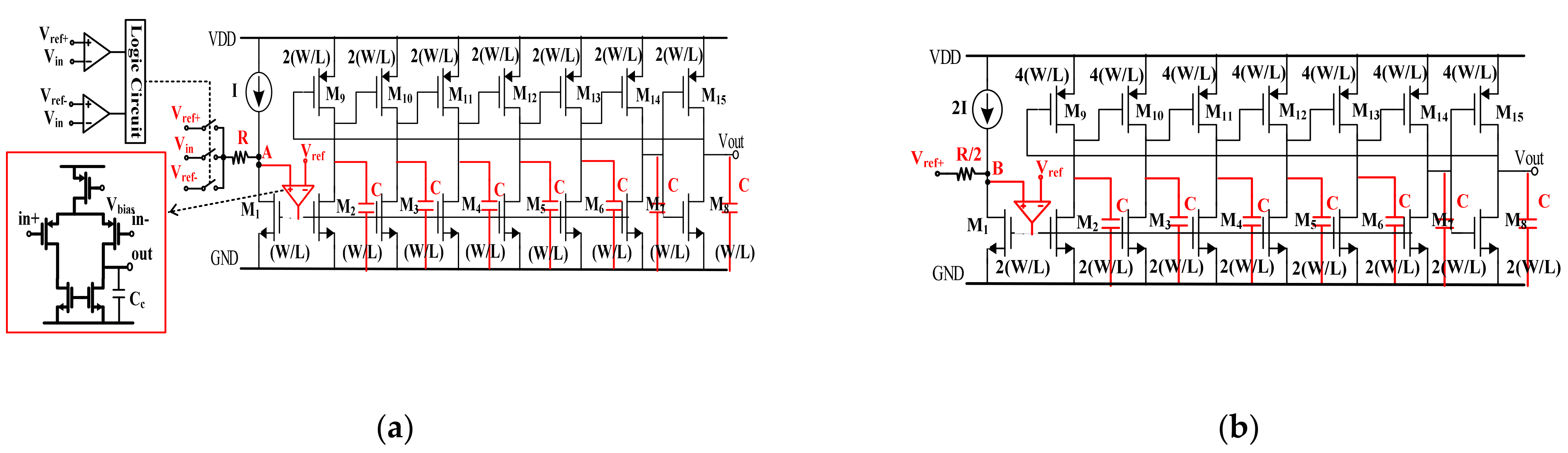

3.5. Gain-Enhanced VCO-Based Quantizer

3.6. Analog Filtering in the Proposed Digital Chopping Feedback Loop

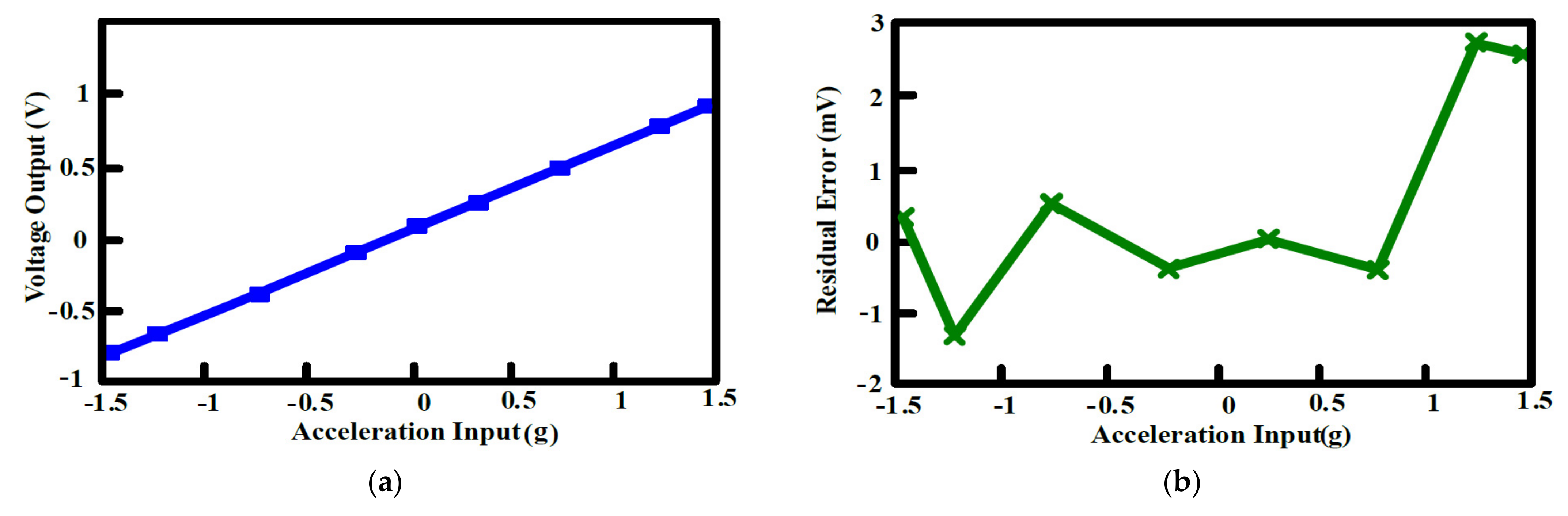

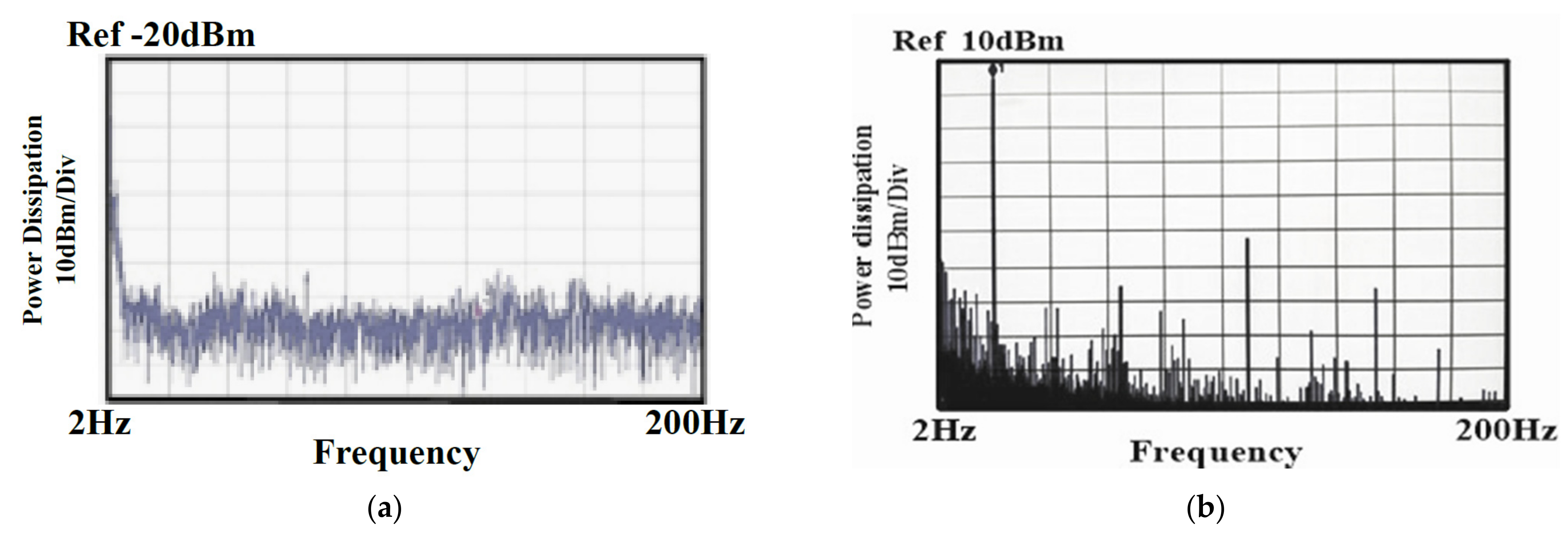

4. Measurement Results and Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Boser, B.E.; Howe, R.T. Surface Micromachined Accelerometers. IEEE J. Solid State Circuits 1996, 31, 366–375. [Google Scholar] [CrossRef]

- Lemkin, M.; Boser, B. A three-axis micromachined accelerometer with a CMOS position-sense interface and digital offset-trim electronics. IEEE J. Solid State Circuits 1999, 34, 456–468. [Google Scholar] [CrossRef]

- Yeh, C.Y.; Huang, J.T.; Tseng, S.H.; Wu, P.C.; Tsai, H.H.; Juang, Y.Z. A low-power monolithic three-axis accelerometer with automatically sensor offset compensated and interface circuit. Microelectron. J. 2019, 86, 150–160. [Google Scholar] [CrossRef]

- Petkov, V.P.; Balachandran, G.K.; Beintner, J. A fully differential charge-balanced accelerometer for electronic stability control. IEEE J. Solid State Circuits 2014, 49, 262–270. [Google Scholar] [CrossRef]

- Marx, M.; Rombach, S.; Nessler, S.; De Dorigo, D.; Manoli, Y. A 141μW high-voltage MEMS gyroscope drive interface circuit based on flying capacitors. IEEE J. Solid State Circuits 2019, 54, 511–523. [Google Scholar] [CrossRef]

- García, J.A.; Lara, E.; Aguilar, L. Low-cost calibration method for low-cost MEMS accelerometers based on 3D printing. Sensors 2020, 20, 6454. [Google Scholar] [CrossRef] [PubMed]

- Jun, J.; Rhee, C.; Kim, S.; Kim, S. An SC interface wih programmable-gain embedded ΔΣ ADC for monolithic three-axis 3-D stacked capacitve MEMS accelerometer. IEEE Sens. J. 2017, 17, 5558–5568. [Google Scholar]

- Jiangfeng, W.; Carley, L.R. Electromechanical delta sigma modulation with high-Q micromechanical accelerometers and pulse density modulated force feedback. IEEE J. Solid State Circuits 2006, 53, 274–287. [Google Scholar] [CrossRef]

- Xu, H.; Liu, X.; Yin, L. A closed-loop interface for a high-Q micromechanical capacitive accelerometer with 200 ng/√Hz input noise density. IEEE J. Solid State Circuits 2015, 50, 2102–2112. [Google Scholar] [CrossRef]

- Li, X.; Chen, W.; Liu, X.; Ren, M. A high-order sigma-delta accelerometer interface circuit. IEICE Electron. Express 2015, 12, 1–6. [Google Scholar] [CrossRef]

- Di, X.; Chen, W.; Liu, X.; Yin, L.; Fu, Q. A high performance with low harmonic distortion interface circuit of sigma-delta accelerometer. IEICE Electron. Express 2016, 13, 1–8. [Google Scholar] [CrossRef][Green Version]

- Kulah, H.; Chae, J.; Yazdi, N.; Najafi, K. Noise analysis and characterization of a sigma-delta capacitive microaccelerometer. IEEE J. Solid State Circuits 2006, 41, 352–361. [Google Scholar] [CrossRef]

- Ye, Z.; Yang, H.; Yin, T.; Huang, G.; Liu, F. High-performance closed loop interface circuit for high-Q capacitive microaccelerometers. IEEE Sens. J. 2013, 13, 1425–1433. [Google Scholar] [CrossRef]

- Meng, Z.; Jingqing, H.; Tingting, Z.; Lichen, H.; Yacong, Z.; Wengao, L.; Zhongjian, C. Research on nonlinearity of closed-loop capacitive accelerometer resulting from time-division force feedback. In Proceedings of the IEEE International Conference on Electron Devices and Solid State Circuit (EDSSC), Bangkok, Thailand, 3–5 December 2012; pp. 1–4. [Google Scholar]

- Yin, T.; Ye, Z.; Huang, G.; Wu, H.; Yang, H. A closed-loop interface for capacitive micro-accelerometers with pulse-width-modulation force feedback. Analog. Integr. Circ. Sig. Process. 2018, 94, 195–204. [Google Scholar] [CrossRef]

- Lajevardi, P.; Petkov, V.P.; Murmann, B. A interface for MEMS accelerometers using electrostatic spring constant modulation for cancellation of bondwire capacitance drift. IEEE J. Solid State Circuits 2013, 48, 265–275. [Google Scholar] [CrossRef]

- Zhao, M.; Chen, Z.; Lu, W.; Zhang, Y.; Niu, Y.; Chen, G. A high-voltage closed-loop sc interface for a±50 g capacitive micro-accelerometer with 112.4 db dynamic range. IEEE Trans. Cir. Syst. I Regul. Pap. 2017, 64, 1328–1341. [Google Scholar]

- Tseng, S.H.; Yeh, C.Y.; Chang, A.Y.; Wang, Y.J.; Chen, P.C.; Tsai, H.H.; Juang, Y.Z. A monolithic three-axis accelerometer with wafer-level package by CMOS MEMS process. Proc. Eurosensors 2017, 1, 337. [Google Scholar] [CrossRef]

- Colibrys-SF1500S Single Axis Best in Class Seimic Accelerometer Product Datasheet. Available online: www.colibrys.com (accessed on 5 May 2019).

| [3] | [8] | [10] | [14] | [16] | This Work | |

|---|---|---|---|---|---|---|

| Process (μm) | 0.35 | 0.18 | 0.35 | 0.5 | 0.18 | 0.18 |

| Supply (V) | 3.3/15 | 1.8/3.3 | 5 | 7 | 3 | 2 |

| Power (mW) | 198 | 0.88 | 35 | 23 | 3 | 6.5 |

| Nonlinearity | 0.06% | 1.09% | 0.16% | 0.16% | / | 0.38% |

| Signal Bandwidth (Hz) | / | / | 1.2 k | 0.3 k | 1 k | 4 k |

| Full Range | +/−50 g | 0–3 g | +/−1.4 g | +/−1.2 g | +/−9 g | +/−1.5 g |

| Noise Floor (μg/sqr Hz) | 12.7 | 197 | 10 | 0.2 | 220 | 18 |

| Dynamic Range@ (<200 Hz) | 112 dB | 64 dB | 83 dB | 118 dB | 75 dB | 78 dB |

| FoM | / | / | 40 | 64 | 59 | 68 |

| Drift Offset Suppression | No | No | No | No | Yes | Yes without Complicated Digital Filters |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Yin, T.; Yang, H. A Bond-Wire Drift Offset Minimized Capacitance-to-Digital Interface for MEMS Accelerometer with Gain-Enhanced VCO-Based Quantization and Nested Digital Chopping Feedback Loops. Sensors 2021, 21, 4627. https://doi.org/10.3390/s21144627

Li F, Yin T, Yang H. A Bond-Wire Drift Offset Minimized Capacitance-to-Digital Interface for MEMS Accelerometer with Gain-Enhanced VCO-Based Quantization and Nested Digital Chopping Feedback Loops. Sensors. 2021; 21(14):4627. https://doi.org/10.3390/s21144627

Chicago/Turabian StyleLi, Fanyang, Tao Yin, and Haigang Yang. 2021. "A Bond-Wire Drift Offset Minimized Capacitance-to-Digital Interface for MEMS Accelerometer with Gain-Enhanced VCO-Based Quantization and Nested Digital Chopping Feedback Loops" Sensors 21, no. 14: 4627. https://doi.org/10.3390/s21144627

APA StyleLi, F., Yin, T., & Yang, H. (2021). A Bond-Wire Drift Offset Minimized Capacitance-to-Digital Interface for MEMS Accelerometer with Gain-Enhanced VCO-Based Quantization and Nested Digital Chopping Feedback Loops. Sensors, 21(14), 4627. https://doi.org/10.3390/s21144627