Multi-Frequency Magnetic Induction Tomography System and Algorithm for Imaging Metallic Objects

Abstract

:1. Introduction

2. Principles of MIT Fundamentals

2.1. System Design

2.2. Forward and Inverse Problems

3. MIT Hardware Design

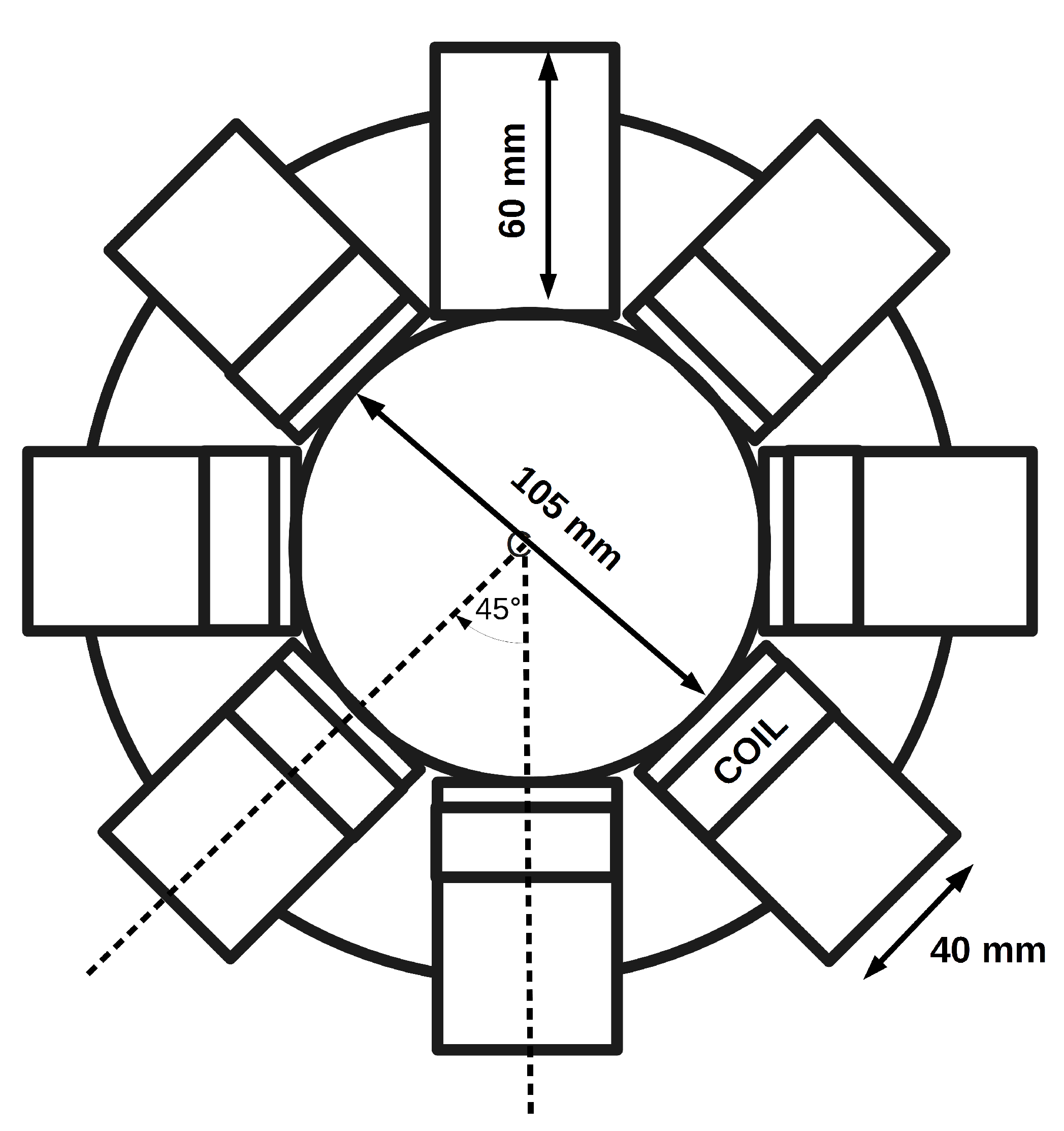

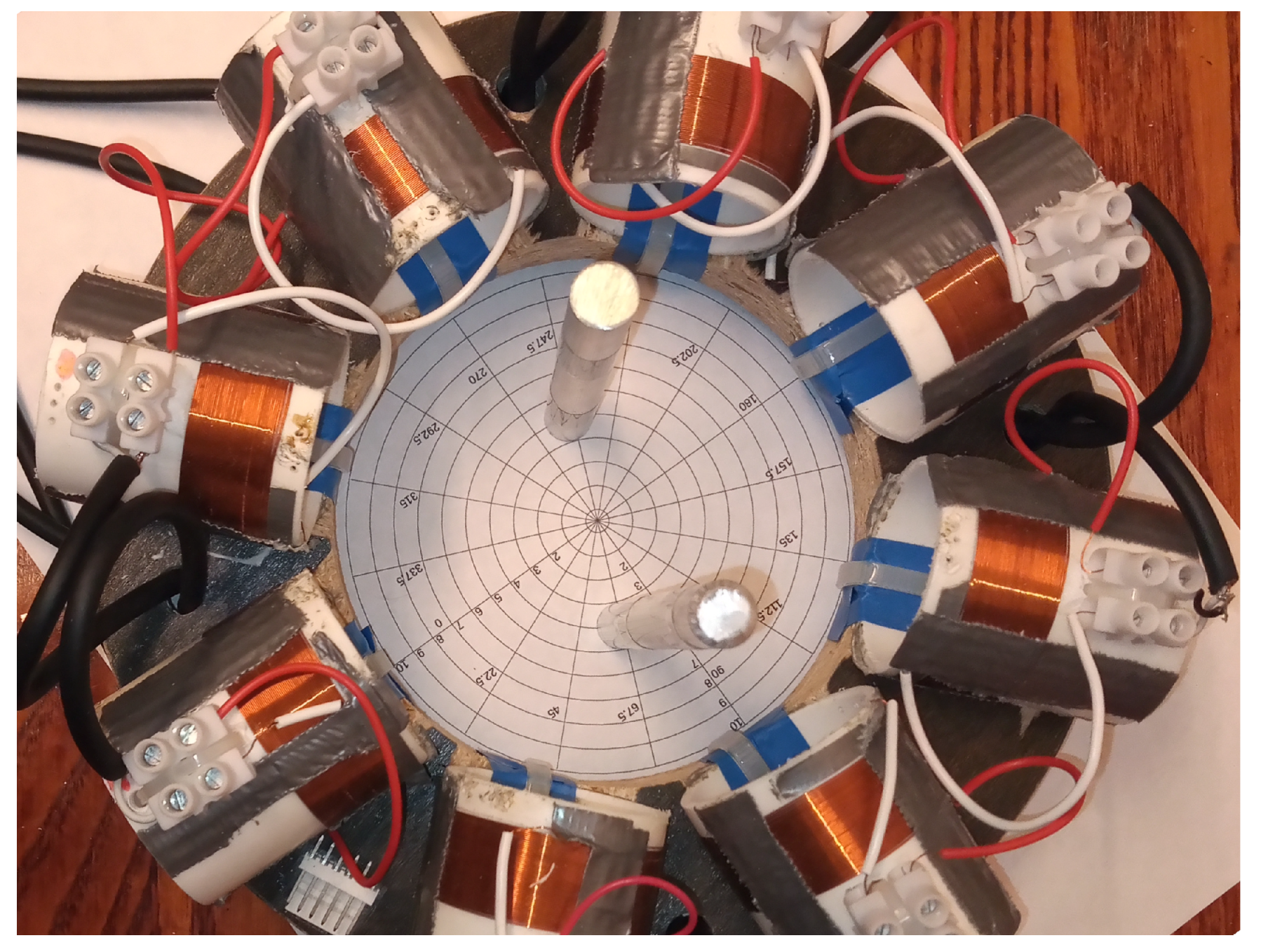

3.1. Description of Array

3.2. Hardware Description

4. Results and Discussion

4.1. SNR Measurements of Frame Data

4.2. Measurements of Reconstructed Images

4.3. Discussion of Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Ma, L.L.; Soleimani, M. Magnetic induction tomography methods and applications: A review. Meas. Sci. Technol. 2017, 28, 072001. [Google Scholar] [CrossRef] [Green Version]

- Wei, H.Y.; Soleimani, M. Electromagnetic Tomography for Medical and Industrial Applications: Challenges and Opportunities [Point of View]. Proc. IEEE 2013, 101, 559–565. [Google Scholar] [CrossRef]

- Griffiths, H. Magnetic induction tomography. Meas. Sci. Technol. 2001, 12, 1126–1131. [Google Scholar] [CrossRef]

- Igney, C.H.; Pinter, R.; Such, O. Magnetic Induction Tomography System and Method. U.S. 20080258717A1, 23 October 2008. [Google Scholar]

- Wei, H.Y.; Soleimani, M. Hardware and software design for a National Instrument-based magnetic induction tomography system for prospective biomedical applications. Physiol. Meas. 2012, 33, 863–879. [Google Scholar] [CrossRef]

- Watson, S.; Williams, R.J.; Gough, W.; Griffiths, H. A magnetic induction tomography system for samples with conductivities below 10 S/m. Meas. Sci. Technol. 2008, 19, 045501. [Google Scholar] [CrossRef]

- Terzija, N.; Yin, W.; Gerbeth, G.; Stefani, F.; Timmel, K.; Wondrak, T.; Peyton, A.J. Use of electromagnetic induction tomography for monitoring liquid metal/gas flow regimes on a model of an industrial steel caster. Meas. Sci. Technol. 2011, 22. [Google Scholar] [CrossRef]

- Ma, X.; Peyton, A.J.; Higson, S.R.; Drake, P. Development of multiple frequency electromagnetic induction systems for steel flow visualization. Meas. Sci. Technol. 2008, 19, 094008. [Google Scholar] [CrossRef]

- Wei, H.Y.H.Y.; Soleimani, M. A Magnetic Induction Tomography System for Prospective Industrial Processing Applications. Chin. J. Chem. Eng. 2012, 20, 406–410. [Google Scholar] [CrossRef]

- Bailey, J.; Long, N.; Hunze, A. Eddy Current Testing with Giant Magnetoresistance (GMR) Sensors and a Pipe-Encircling Excitation for Evaluation of Corrosion under Insulation. Sensors 2017, 17, 2229. [Google Scholar] [CrossRef] [Green Version]

- Guilizzoni, R.; Finch, G.; Harmon, S. Subsurface Corrosion Detection in Industrial Steel Structures. IEEE Magn. Lett. 2019, 10, 1–5. [Google Scholar] [CrossRef]

- De Alcantara, N.; da Silva, F.; Guimarães, M.; Pereira, M. Corrosion Assessment of Steel Bars Used in Reinforced Concrete Structures by Means of Eddy Current Testing. Sensors 2015, 16, 15. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Minesawa, G.V.; Sasaki, E. Eddy current inspection of corrosion defects for concrete embedded steel members. AIP Conf. Proc. 2014, 781, 781–786. [Google Scholar] [CrossRef]

- Frankowski, P.P.K. Corrosion detection and measurement using eddy current method. In Proceedings of the 2018 International Interdisciplinary PhD Workshop (IIPhDW), Swinoujscie, Poland, 9–12 May 2018; pp. 398–400. [Google Scholar] [CrossRef]

- Oka, M.; Yakushiji, T.; Tsuchida, Y.; Enokizono, M. Evaluation of fatigue damage in an austenitic stainless steel (SUS304) using the eddy current probe. In Proceedings of the INTERMAG Asia 2005, Digests of the IEEE International Magnetics Conference, Nagoya, Japan, 4–8 April 2005; pp. 427–428. [Google Scholar] [CrossRef]

- Oka, M.; Tsuchida, Y.; Yakushiji, T.; Enokizono, M. Fatigue Evaluation for a Ferritic Stainless Steel (SUS430) by the Eddy Current Method Using the Pancake-Type Coil. IEEE Trans. Magn. 2010, 46, 540–543. [Google Scholar] [CrossRef]

- Zheng, D.; Dong, Y. A Dual-parameter Oscillation Method for Eddy Current Testing with The Aid of Impedance Nonlinearity. IEEE Trans. Instrum. Meas. 2019, 69, 4476–4486. [Google Scholar] [CrossRef]

- Tsukada, K.; Tomioka, T.; Wakabayashi, S.; Sakai, K.; Kiwa, T. Magnetic detection of steel corrosion at a buried position near the ground level using a magnetic resistance sensor. IEEE Trans. Magn. 2018, 54, 1. [Google Scholar] [CrossRef]

- Gao, P.; Wang, X.; Han, D.; Zhang, Q. Eddy current testing for weld defects with different directions of excitation field of rectangular coil. In Proceedings of the 2018 4th International Conference on Control, Automation and Robotics (ICCAR), Auckland, New Zealand, 20–23 April 2018; pp. 486–491. [Google Scholar] [CrossRef]

- Uchanin, V.; Minakov, S.; Nardoni, G.; Ostash, O.; Fomichov, S. Nondestructive Determination of Stresses in Steel Components by Eddy Current Method. Strojniški Vestnik-J. Mech. Eng. 2018, 64, 690–697. [Google Scholar] [CrossRef]

- Charubin, T.; Nowicki, M.; Szewczyk, R. Spectral analysis of Matteucci effect based magnetic field sensor. AIP Conf. Proc. 1996, 2018, 020019. [Google Scholar] [CrossRef]

- Chady, T.; Sikora, R.; Psuj, G.; Enokizono, M.; Todaka, T. Fusion of electromagnetic inspection methods for evaluation of stress-loaded steel samples. IEEE Trans. Magn. 2005, 41, 3721–3723. [Google Scholar] [CrossRef]

- Lo, C.C.H.; Nakagawa, N. Evaluation of eddy current and magnetic techniques for inspecting rebars in bridge barrier rails. AIP Conf. Proc. 2013, 1511, 1371–1377. [Google Scholar] [CrossRef] [Green Version]

- Miller, G.; Gaydecki, P.; Quek, S.; Fernandes, B.T.; Zaid, M.A. Detection and imaging of surface corrosion on steel reinforcing bars using a phase-sensitive inductive sensor intended for use with concrete. NDT E Int. 2003, 36, 19–26. [Google Scholar] [CrossRef]

- Li, K.; Li, L.; Wang, P.; Liu, J.; Shi, Y.; Zhen, Y.; Dong, S. A fast and non-destructive method to evaluate yield strength of cold-rolled steel via incremental permeability. J. Magn. Magn. Mater. 2020, 498. [Google Scholar] [CrossRef]

- Postolache, O.; Pereira, M.D.; Ramos, H.G.; Ribeiro, A.L. NDT on Aluminum Aircraft Plates based on Eddy Current Sensing and Image Processing. In Proceedings of the 2008 IEEE Instrumentation and Measurement Technology Conference, Victoria, BC, Canada, 12–15 May 2008; pp. 1803–1808. [Google Scholar] [CrossRef]

- Bo, L.; Feilu, L.; Zhongqing, J.; Jiali, L. Eddy Current Array Instrument and Probe for Crack Detection of Aircraft Tubes. In Proceedings of the 2010 International Conference on Intelligent Computation Technology and Automation, Changsha, China, 11–12 May 2010; Volume 2, pp. 177–180. [Google Scholar] [CrossRef]

- Arismendi, N.; Pacheco, E.; Lopez, O.; Espina-Hernandez, J.; Benitez, J. Classification of artificial near-side cracks in aluminium plates using a GMR-based eddy current probe. In Proceedings of the 2018 28th International Conference on Electronics, Communications and Computers, CONIELECOMP 2018, Cholula, Mexico, 21–23 February 2018; pp. 31–36. [Google Scholar] [CrossRef]

- Li, F.; Spagnul, S.; Odedo, V.; Soleimani, M. Monitoring Surface Defects Deformations and Displacements in Hot Steel Using Magnetic Induction Tomography. Sensors 2019, 19, 3005. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peyton, A.J.; Beck, M.S.; Borges, A.R.; De Oliveira, J.E.; Lyon, G.M.; Yu, Z.Z.; Brown, M.W.; Ferrerra, J. Development of Electromagnetic Tomography (EMT) for Industrial Applications. Part 1: Sensor Design and Instrumentation. In Proceedings of the 1st World Congress on Industrial Process Tomography, Buxton, Greater Manchester, UK, 14–17 April 1999; pp. 306–312. [Google Scholar]

- Rubinacci, G.; Tamburrino, A.; Ventre, S. Concrete rebars inspection by eddy current testing. Int. J. Appl. Electromagn. Mech. 2007, 25, 333–339. [Google Scholar] [CrossRef]

- Borges, A.R.; de Oliveira, E.; Velez, J.; Peyton, A.J.; Tavares, C. Development of electromagnetic tomography (EMT) for industrial application: Part 2: Image reconstruction and software framework. World Congr. Ind. Process. Tomogr. 1999, 2, 219–225. [Google Scholar]

- Miller, G.; Gaydecki, P.; Quek, S.; Fernandes, B.; Zaid, M. A combined Q and heterodyne sensor incorporating real-time DSP for reinforcement imaging, corrosion detection and material characterisation. Sens. Actuators Phys. 2005, 121, 339–346. [Google Scholar] [CrossRef]

- Zheng, D.; Dong, Y. A Novel Eddy Current Testing Scheme by Transient Oscillation and Nonlinear Impedance Evaluation. IEEE Sens. J. 2018, 18, 4911–4919. [Google Scholar] [CrossRef]

- Muttakin, I.; Soleimani, M. Magnetic Induction Tomography Spectroscopy for Structural and Functional Characterization in Metallic Materials. Materials 2020, 13, 2639. [Google Scholar] [CrossRef] [PubMed]

- Schonekess, H.; Ricken, W.; Becker, W.J. Improved multi-sensor for force measurement on pre-stressed steel cables by means of eddy current technique. In Proceedings of the IEEE Sensors, 2004, Vienna, Austria, 24–27 October 2004; pp. 260–263. [Google Scholar] [CrossRef]

- Cao, B.; Iwamoto, T.; Bhattacharjee, P.P. An experimental study on strain-induced martensitic transformation behavior in SUS304 austenitic stainless steel during higher strain rate deformation by continuous evaluation of relative magnetic permeability. Mater. Sci. Eng. A 2020, 774, 138927. [Google Scholar] [CrossRef]

- Xu, H.; Lu, M.; Avila, J.R.S.; Zhao, Q.; Zhou, F.; Meng, X.; Yin, W. Imaging a weld cross-section using a novel frequency feature in multi-frequency eddy current testing. Insight-Non-Destr. Test. Cond. Monit. 2019, 61, 738–743. [Google Scholar] [CrossRef]

- Obeid, S.; Dogaru, T.; Tranjan, F.M. Rotational GMR magnetic sensor based eddy current probes for detecting buried corner cracks at the edge of holes in metallic structures. In Proceedings of the IEEE SoutheastCon 2008, Huntsville, AL, USA, 3–6 April 2008; pp. 314–317. [Google Scholar] [CrossRef]

- Dalal Radia, T.; Ahmed, D.; Bachir, H.; Khaldoun, L.I. Detection of Defects Using GMR and Inductive Probes. In Smart Energy Empowerment in Smart and Resilient Cities; Springer: Berlin/Heidelberg, Germany, 2020; Volume 102, pp. 617–622. [Google Scholar] [CrossRef]

- Sen, T.; Anoop, C.S.; Sen, S. Study and analysis of two GMR-based eddy-current probes for defect-detection. In Proceedings of the 2017 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Turin, Italy, 22–25 May 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Lopes Ribeiro, A.; Pasadas, D.; Ramos, H.; Rocha, T. Determination of crack depth in aluminum using eddy currents and GMR sensors. AIP Conf. Proc. 2015, 1650, 361–367. [Google Scholar] [CrossRef]

- Bernieri, A.; Betta, G.; Ferrigno, L.; Laracca, M. Multi-frequency ECT method for defect depth estimation. In Proceedings of the 2012 IEEE Sensors Applications Symposium Proceedings, Brescia, Italy, 7–9 February 2012; pp. 1–6. [Google Scholar] [CrossRef]

- Bernieri, A.; Betta, G.; Ferrigno, L.; Laracca, M. Crack Depth Estimation by Using a Multi-Frequency ECT Method. IEEE Trans. Instrum. Meas. 2013, 62, 544–552. [Google Scholar] [CrossRef]

- Neubauer, A. Tikhonov regularisation for non-linear ill-posed problems: Optimal convergence rates and finite-dimensional approximation. Inverse Probl. 1989, 5, 541–557. [Google Scholar] [CrossRef]

- Soleimani, M.; Mitchell, C.N.; Banasiak, R.; Wajman, R.; Adler, A. Four-Dimensional Electrical Capacitance Tomography Imaging Using Experimental Data. Prog. Electromagn. Res. 2009, 90, 171–186. [Google Scholar] [CrossRef] [Green Version]

- Adler, A.; Arnold, J.H.; Bayford, R.; Borsic, A.; Brown, B.; Dixon, P.; Faes, T.J.C.; Frerichs, I.; Gagnon, H.; Gärber, Y.; et al. GREIT: A unified approach to 2D linear EIT reconstruction of lung images. Physiol. Meas. 2009, 30, S35–S55. [Google Scholar] [CrossRef] [PubMed]

| Angle | Average k | STD k |

|---|---|---|

| 45° | 0.044 | 0.0037 |

| 90° | 0.0075 | 0.0029 |

| 135° | 0.0046 | 0.0023 |

| 180° | 0.0046 | 0.00218 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dingley, G.; Soleimani, M. Multi-Frequency Magnetic Induction Tomography System and Algorithm for Imaging Metallic Objects. Sensors 2021, 21, 3671. https://doi.org/10.3390/s21113671

Dingley G, Soleimani M. Multi-Frequency Magnetic Induction Tomography System and Algorithm for Imaging Metallic Objects. Sensors. 2021; 21(11):3671. https://doi.org/10.3390/s21113671

Chicago/Turabian StyleDingley, Gavin, and Manuchehr Soleimani. 2021. "Multi-Frequency Magnetic Induction Tomography System and Algorithm for Imaging Metallic Objects" Sensors 21, no. 11: 3671. https://doi.org/10.3390/s21113671

APA StyleDingley, G., & Soleimani, M. (2021). Multi-Frequency Magnetic Induction Tomography System and Algorithm for Imaging Metallic Objects. Sensors, 21(11), 3671. https://doi.org/10.3390/s21113671