1. Introduction

Single-photon (SP) imaging offers the ultimate performance in an imaging system due to its ability to capture and register each incoming photon [

1,

2]. This is particularly valuable in low light level conditions where every photon is precious, such as in astronomy, adaptive optics, night vision, surveillance and bio-imaging. In silicon (the most widely used semiconductor for image sensors), a single-photon with a wavelength between 300 and 1100 nm can generate only one electron–hole pair. Therefore, for visible and near-infrared light, the task of single-photon detection becomes a task of single-electron (or hole) detection. This is not easy due to the unavoidable readout noise of the sensor, which is usually too high for the reliable detection of a single electron. Another difficulty for room temperature applications are the thermal dark currents, because they are indistinguishable from photogenerated signals; however, dark signals can be reduced to negligible levels by cooling.

Two main methods for achieving SP sensitivity are used in semiconductor image sensors. In the first one, the photogenerated charge is amplified internally by a physical process before the conversion to voltage. In this way, the signal is lifted well above the noise floor, allowing reliable SP detection. Typical examples are single-photon avalanche photodiodes (SPAD) and electron multiplying CCDs (EMCCD), in which the primary photogenerated electron undergoes avalanche multiplication. Both can resolve single photons; however, they suffer from shortcomings such as high dark current rates and after-pulsing in SPADs [

3], and spurious charge and excess noise [

4] in EMCCDs due to traps and the use of high voltages.

The second method involves reducing the readout noise of a sensor to a fraction of one electron RMS equivalent noise charge (ENC). Studies have shown [

5] that for a practical single-photon imager with a negligible error rate that the ENC must be below 0.15 e- RMS. Recent advances in CMOS image sensor (CIS) technology have reduced readout noise significantly, and CISs with an ENC below 0.3 e- RMS have been reported [

6,

7,

8]. These developments are due to the increase of the conversion gain of the sensors above 200 µV/e- by the use of special design and processing techniques, as well as by improvements to the noise performance of MOSFETs. Further noise improvements using those methods are certainly possible, however difficulties increase as the noise approaches the required level of 0.15 e- RMS.

Recently, a new take on the well-known “skipper CCD” technique [

9,

10,

11] has demonstrated deep sub-electron readout noise [

12,

13]. In skipper CCDs, the charge is transferred under a floating gate in the buried channel (BC) multiple times and is measured after each transfer. Because the measurements are non-destructive and nearly statistically independent, averaging reduces the readout noise by the square root of the number of readouts. In [

13], readout noise of only 0.068 e- RMS has been achieved after 4000 measurements, using an amplifier exhibiting 3.55 e- ENC in a single measurement. A similar method has been used for DEPFETs [

14] to achieve 0.18 e- RMS noise in a sensor with inherent 3.1 e- ENC. The skipper technique is attractive because it can achieve sub-electron noise performance using the designs, processes and MOSFETs available today. However, a major disadvantage of the multiple readouts is the greatly increased readout time, which can take several hours for CCDs [

13]. For a more practical device, the readout time must be reduced to at least a few seconds (e.g., for slow astronomical imaging), and to few milliseconds for applications requiring a much higher frame rate.

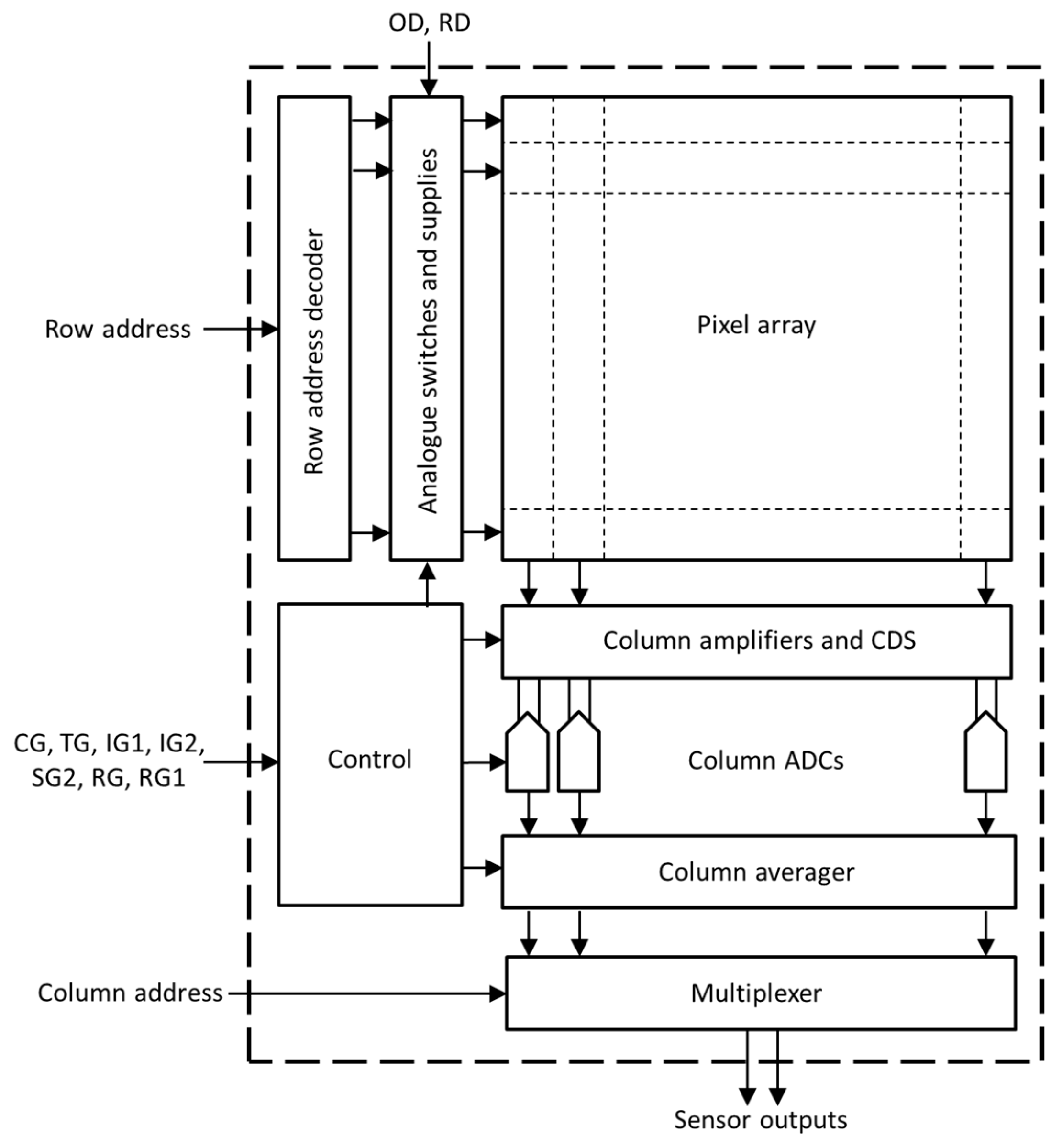

CMOS image sensors could potentially offer the needed increase in speed due to the inherent parallelism in their readout. In the vast majority of CISs, an entire row of pixels is read out simultaneously, which could reduce the readout time by three orders of magnitude compared to a sensor with a single or a smaller number of outputs such as the CCD. In addition, the finer feature size in modern CISs allows the conversion gain of a floating gate readout circuitry to be much higher than in CCDs. This finer feature size enables a substantial reduction of the readout noise in a single measurement, necessitating fewer signal samples to be averaged.

Sub-electron readout noise CMOS image sensors capable of high readout rates would be useful for many applications. In the field of astronomy, large-format sensors with a size of at least 4K x 4K pixels, readout at a rate of a few frames a second, would allow measurement of transient phenomena or observation techniques that require high time resolutions and low noise, such as speckle imaging. Lucky imaging [

15], for example, works best with noiseless image stacking, and could benefit from this development. Smaller sensors that can be readout at rates of 0.5–1 kHz would replace EMCCDs in adaptive optics applications. Similarly, in bio-imaging applications such as molecular fluorescence imaging, these larger format sensors would enable microscope images to cover a larger field with single-photon sensitivity.

In this paper we investigate the suitability of CIS-based skipper designs to achieving deep sub-electron readout noise for single-photon visible light imaging. The operating principles and TCAD simulations are presented in

Section 2, followed by a noise analysis in

Section 3 and a description of a proposed layout and its expected performance in

Section 4.

2. Operating Principles

The most widely used pixel architecture in modern CISs is based on the pinned photodiode (PPD) [

16]. The PPD achieves very low dark currents due to its pinning implant, low image lag and high conversion gain, which it achieves by using a small sense node separate from the charge collection region. The PPD relies on the efficient transfer of charge to the sense node, where the conversion to voltage occurs after the charge has been collected. Due to its excellent electro-optical characteristics and charge transfer capabilities, the PPD is one candidate for constructing a pixel capable of multiple-signal sampling.

Another possibility is a low-voltage CCD manufactured in a CMOS process, as used in time delay integration (TDI) image sensors. High-performance CCD-in-CMOS devices use buried channels to achieve efficient multiple charge transfers, and can have high conversion gain and low noise on a par with the PPD thanks to a small sense node. BC process modules are now routinely offered by several CIS foundries to help the design of TDI imagers. Buried channel CCD-in-CMOS devices have demonstrated charge transfer inefficiencies (CTIs) as low as 10

−5 per transfer [

17]. However, their dark currents are much higher than in PPDs because the Si–SiO

2 interface at the BC is not inverted.

Based on these considerations, we have chosen the PPD as the photosensitive element in this development due to its superior dark currents, and have combined it with a BC CCD-based structure for the multiple-signal sampling.

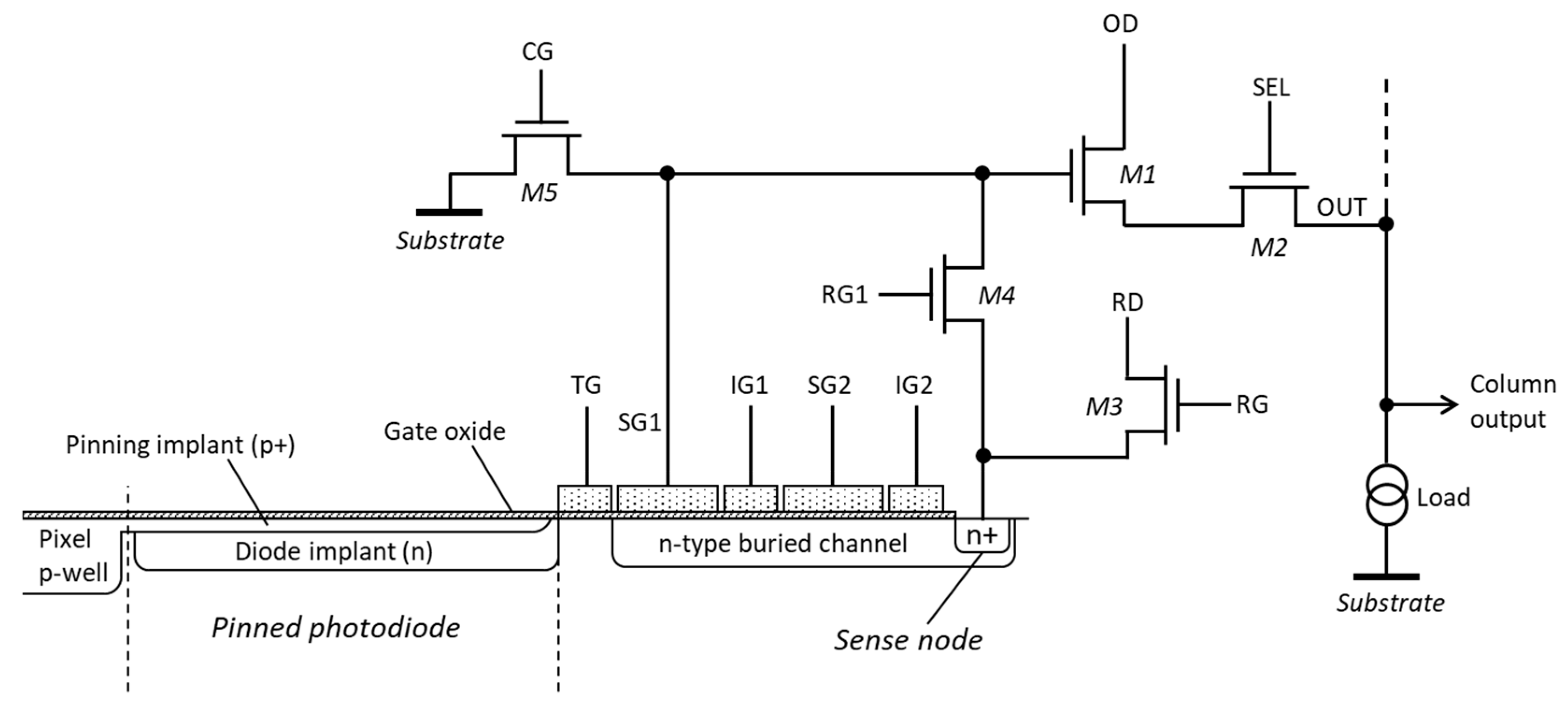

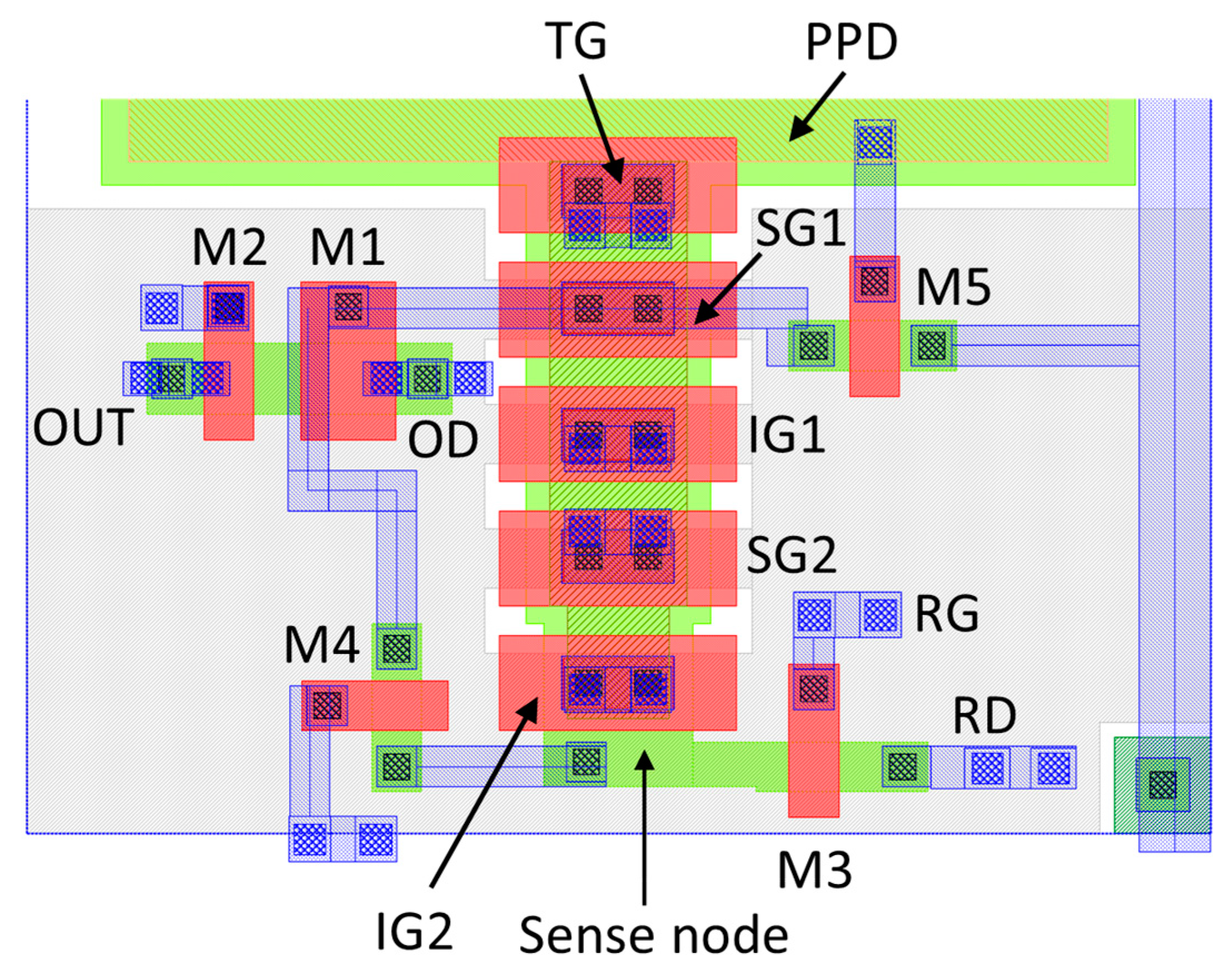

Figure 1 shows the simplified diagram of the proposed pixel. As performed normally, the charge is transferred from the PPD by the transfer gate (TG). Following the TG is a BC structure, where the charge is kept, transferred and sampled multiple times non-destructively.

The first sense gate (SG1) is used to capacitively measure the signal stored under it. The voltage on SG1 is buffered by the source follower M1, which connects to the column output line via the row select transistor M2. Here, output drain (OD) is the DC supply to the source follower and SEL is the control signal to the gate of the row select transistor. The transistor M5 is used to lower the potential on SG1 to substrate so that the charge can be transferred to SG2.

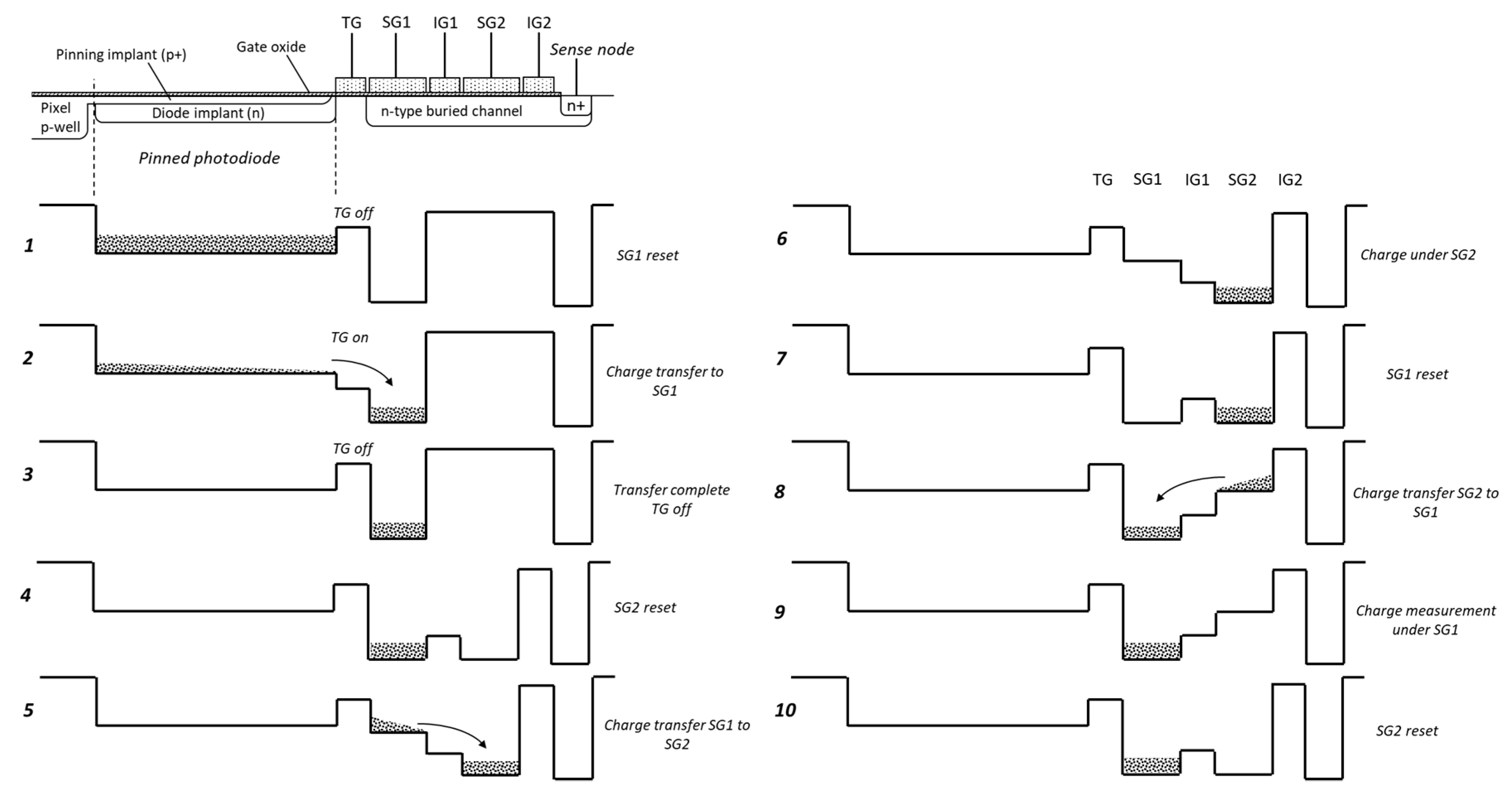

Figure 2 shows the potential diagrams of the pixel during its operation. Before the charge is transferred out of the PPD, in step 1 the voltage on SG1 is reset to the reset drain (RD) potential by turning both transistors M3 and M4 on. In step 2, the transfer gate (TG) is pulsed high and the charge stored under the PPD is transferred under SG1, followed by turning off the TG in step 3. In step 4, the storage gate SG2 is reset and the insulating gate (IG1) is biased in preparation for the charge transfer from SG1 to SG2 in step 5. SG1 is then lowered to substrate potential by applying a pulse to the CG of M5 while M3 and M4 are turned off, which makes the charge move under SG2.

Once the charge has been transferred, as shown in step 6, SG1 is reset by turning on M3 and M4, with M5 turned off (step 7). After this, the transistors M3 and M4 are turned off and the reset level on SG1 is read out via the source follower M1 as required to implement correlated double sampling (CDS). Next, the potential on SG2 is lowered so that the charge can be transferred back under SG1 (step 8). After the transfer is complete, the amount of charge under SG1 is measured by differencing the voltage level on SG1 and the previously taken reset sample. By repeating steps 4 to 10, it is possible to measure the signal charge under SG1 multiple times non-destructively.

Figure 1 shows SG1 as the floating gate used for the measurement; however, SG1 and SG2 are interchangeable and either can be used if they connect to M1. Furthermore, SG1 and SG2 can be connected to their own separate readout circuits, consisting of a source follower, row select and reset transistors.

Figure 2 shows that the reset and the signal time periods on SG1 and SG2 are in anti-phase, so that the reset level on SG1 can be measured simultaneously with the signal level on SG2 and vice versa, as in steps 7 and 10, respectively. This makes it possible to use both SG1 and SG2 for multiple-signal sampling, thus reaching the required number of samples in half the time. The downsides to this approach are the increased number of transistors, which occupy a larger area, and the need to have two outputs per pixel, since the signals from SG1 and SG2 appear concurrently. In addition, the gain difference between the two non-destructive readout paths would make the signal processing more challenging. In this work we have considered sampling only for SG1, as shown in

Figure 1.

After enough measurements have been made, the charge can be transferred out of the BC. This can be done by pulsing IG2 after the sense node has been reset in advance by the transistor M3 while M4 is turned on. This allows a conventional readout of the signal with CDS, after which the charge is destroyed. Alternatively, the charge can simply be dumped to the sense node without reading it. In any case, the charge in the BC must be cleared before the next charge is transferred from the PPD.

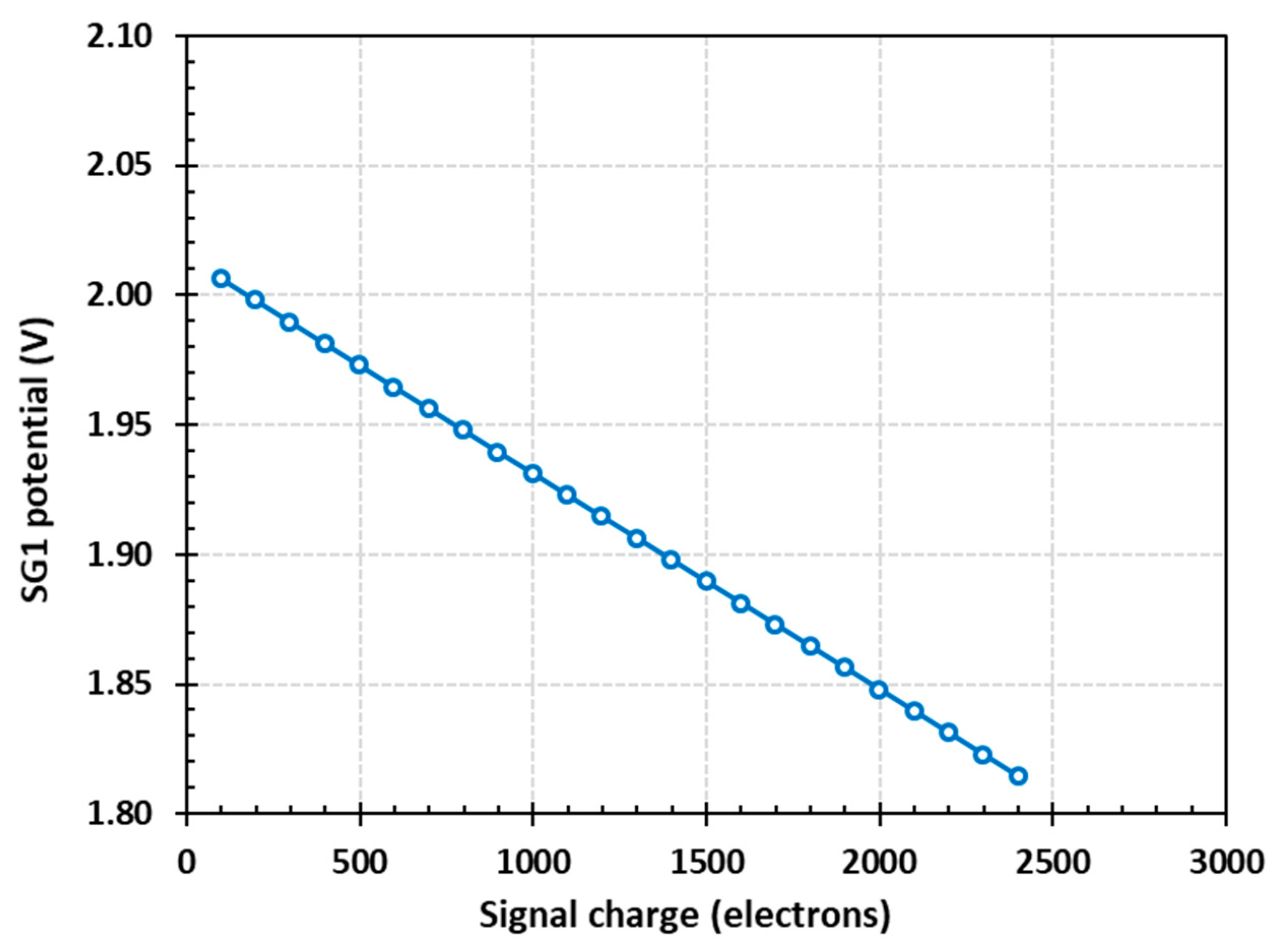

The pixel architecture relies on efficient multiple charge transfers in a BC CCD with low channel potential V

ch0. Typically, the PPD pinning voltage is in the range between 1.0 and 1.5 V, which implies that the CCD channel potential must be of a similar value. We performed TCAD simulations based on a 180-nm CIS process using a customized BC implant to achieve V

ch0 = 2 V. The simulations modeled a PPD and a BC with four gates, as shown in

Figure 2, using Athena (for process and device generation) and Atlas (for device simulation) commercial software from Silvaco Inc. Using simulated light, a charge was generated in the PPD and collected, then transferred out to the BC by pulsing the TG. This was not different from normal PPD operation.

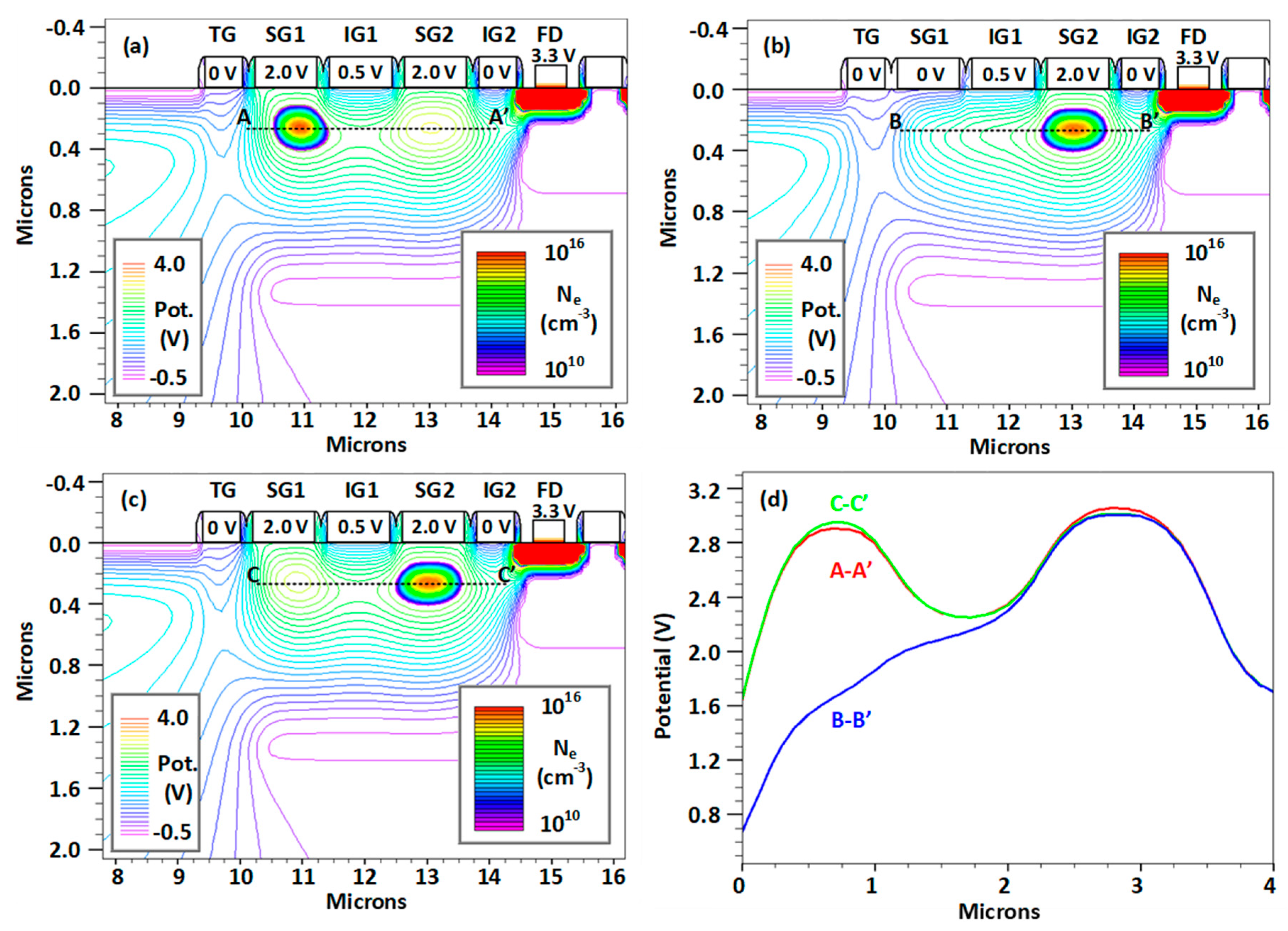

Figure 3a–c shows the potential in the BC and the size of the stored charge during transfer, demonstrating that the charge was stored away from the Si–SiO

2 interface, which is needed for a good CTI.

Figure 3d shows the potential along the middle of the buried channel when IG1 is biased to 0.5 V and acts as a potential barrier between SG1 and SG2, both biased at 2 V. During the charge transfer between SG1 and SG2, IG1 is held at an intermediate constant voltage in order to reduce the capacitive coupling to SG1 from the clock voltage on SG2. Simulations indicate that the charge transfer between SG1 and SG2 completes within 0.2 ns for signals of less than 100 electrons, which is to be expected considering the short gate length. Because of this, the charge transfer time is likely to be negligible compared to the signal sample time, which is in the range of few hundred nanoseconds.

5. Conclusions and Outlook

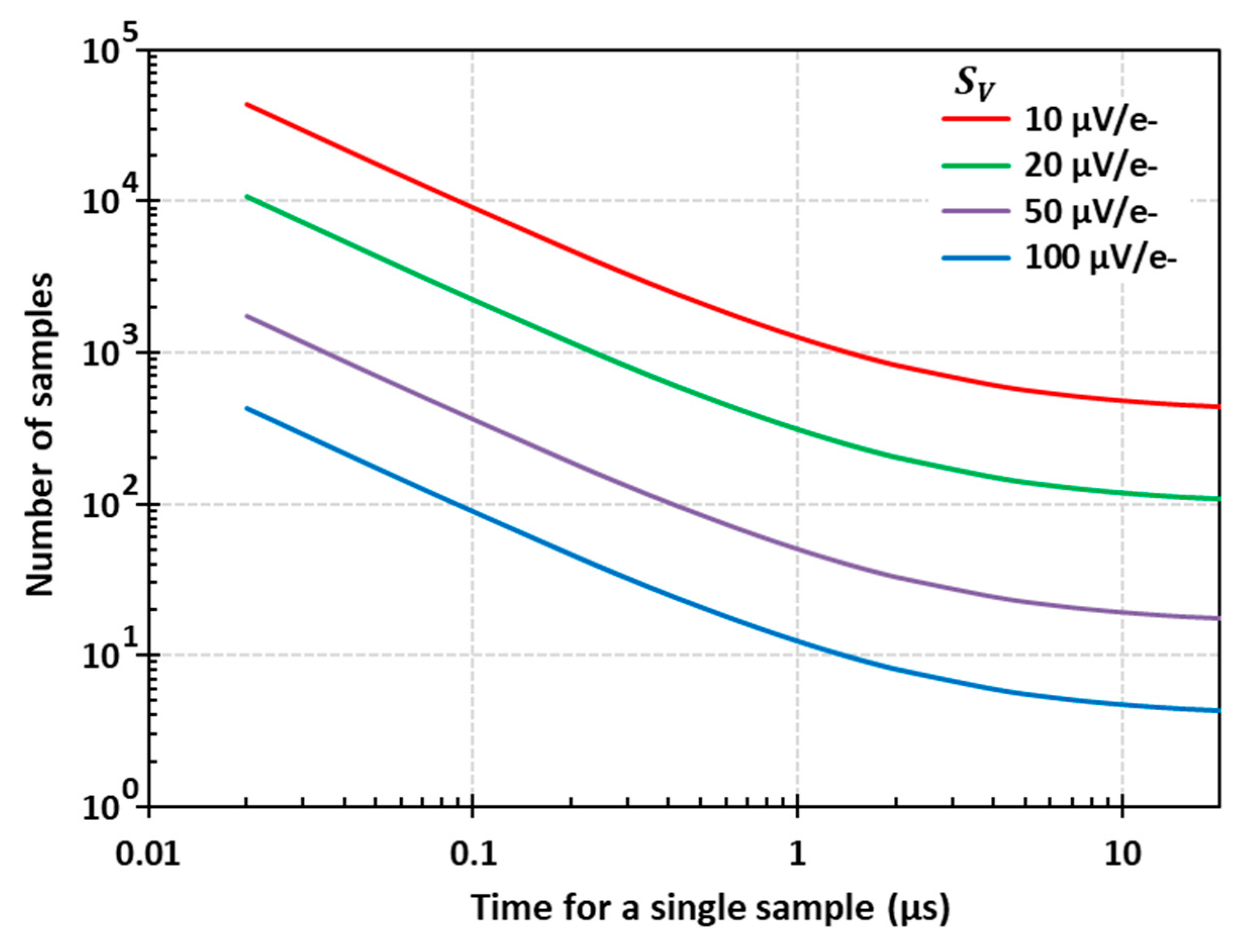

We have presented a concept for a single-photon image sensor using multiple non-destructive signal sampling in CMOS image sensor technology. By averaging multiple signal samples that are statistically independent, the readout electronic noise can be reduced by the square root of the number of samples. This allows the noise level to be reduced to ENC < 0.15 e- RMS, a level widely considered necessary for single electrons to be reliably distinguished. This will allow imaging to be limited only by the shot noise of the registered photons, and to be free from electronic noise.

The proposed pixel design uses a pinned photodiode as a photosensitive element, and a buried channel CCD per pixel for multiple charge transfer and non-destructive signal readouts via capacitive coupling between a sense gate and the signal charge. A pixel design using this method was simulated in TCAD, and several layouts were generated for a 180-nm CMOS image sensor process. Significant increases in the readout speed over the equivalent “skipper CCD” technique are possible due to the massive parallel readout in CMOS image sensors. Using simulations, the noise performance of the pixel was determined as a function of the number of samples, sense node capacitance, sampling rate and transistor characteristics.

The presented results show that single-photon imaging using multiple non-destructive signal sampling in CIS technology is viable. Our designs and simulations indicate that a megapixel-scale sensor operating at ~100 fps is feasible using present-day technology. Such a sensor could find numerous applications in science and technology in fields such as astronomy, adaptive optics, biological imaging, quantum technologies and autonomous systems.

Future work will involve the manufacturing of a prototype CIS using several variants of the described pixel design. Following that, a full-scale imager with digital signal averaging implemented on chip will be the next objective of our work.