Design and Evaluation of Magnetic Hall Effect Tactile Sensors for Use in Sensorized Splints

Abstract

1. Introduction

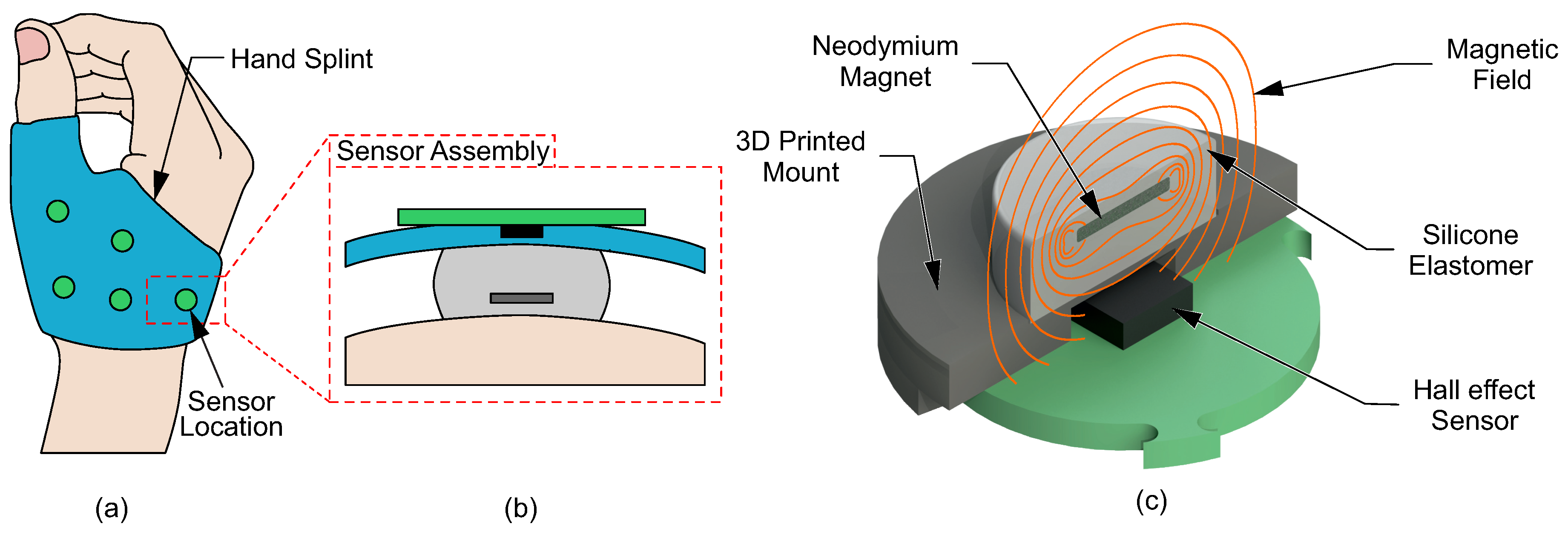

2. System Description

3. System Design

3.1. Sensor Requirements

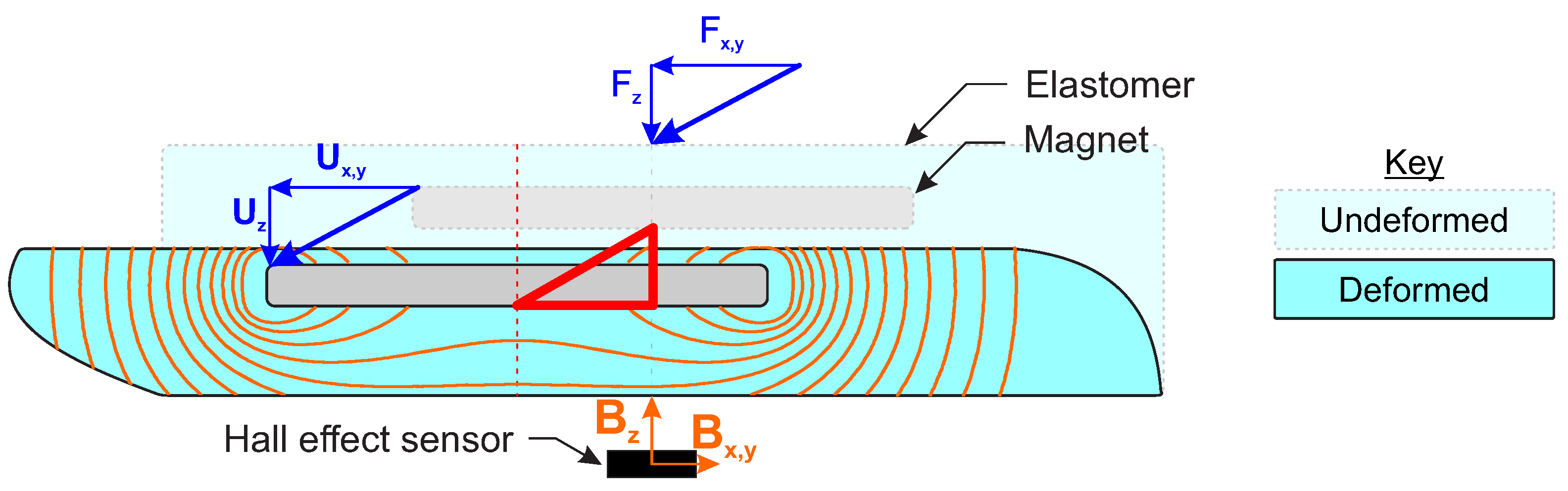

3.2. Identifying Sensor Design Parameters

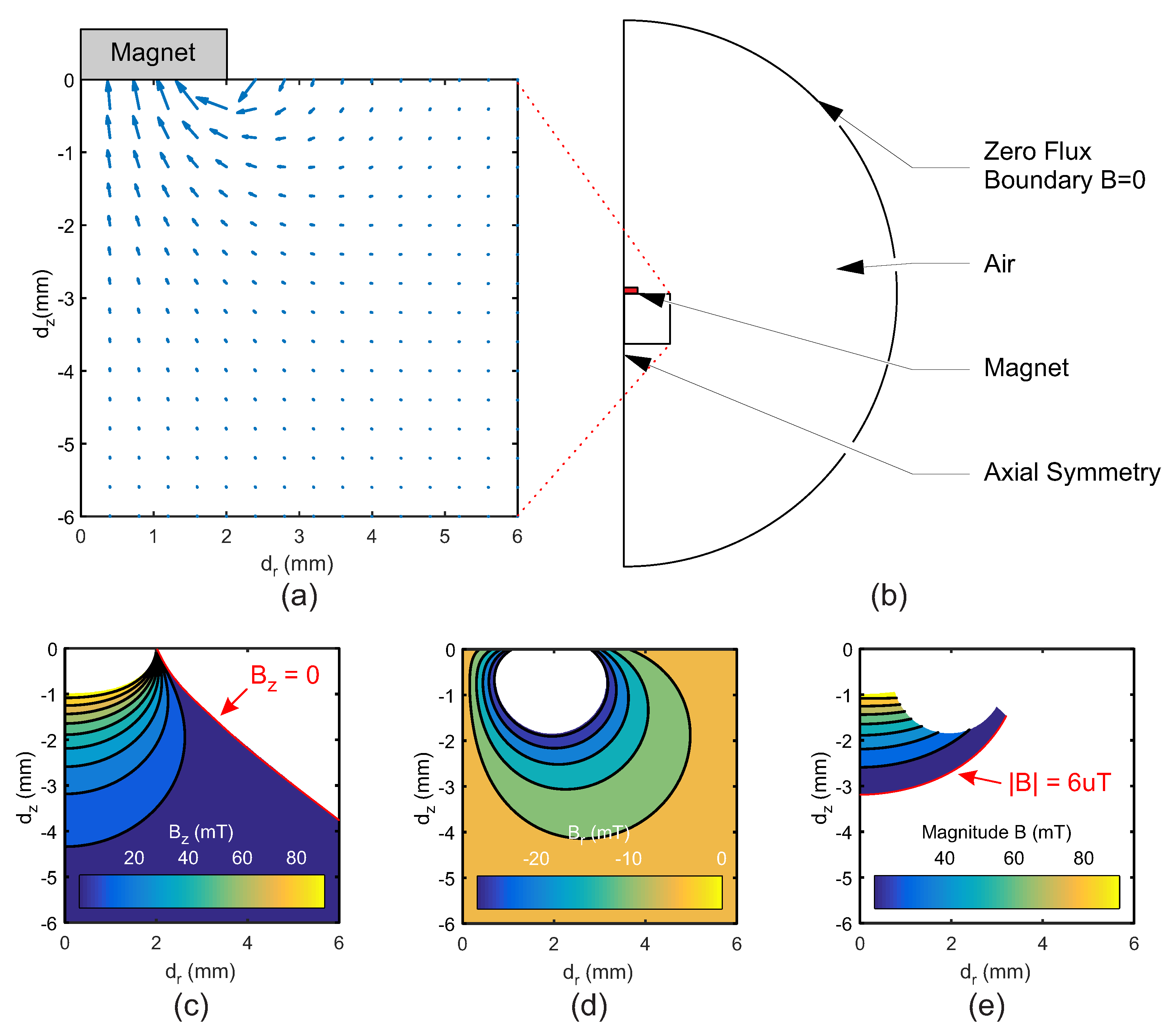

3.3. Investigation of Magnetic Design Parameters

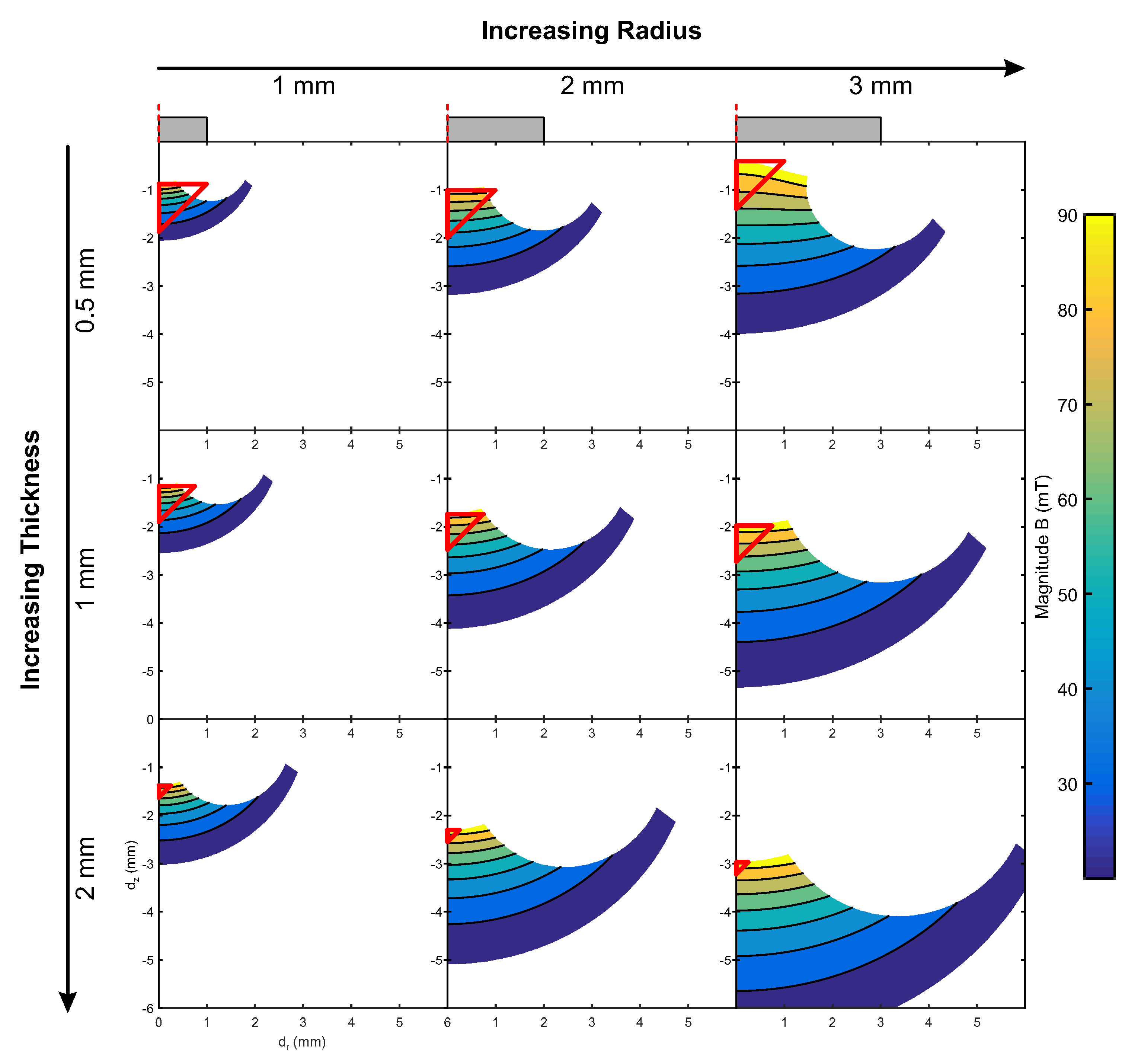

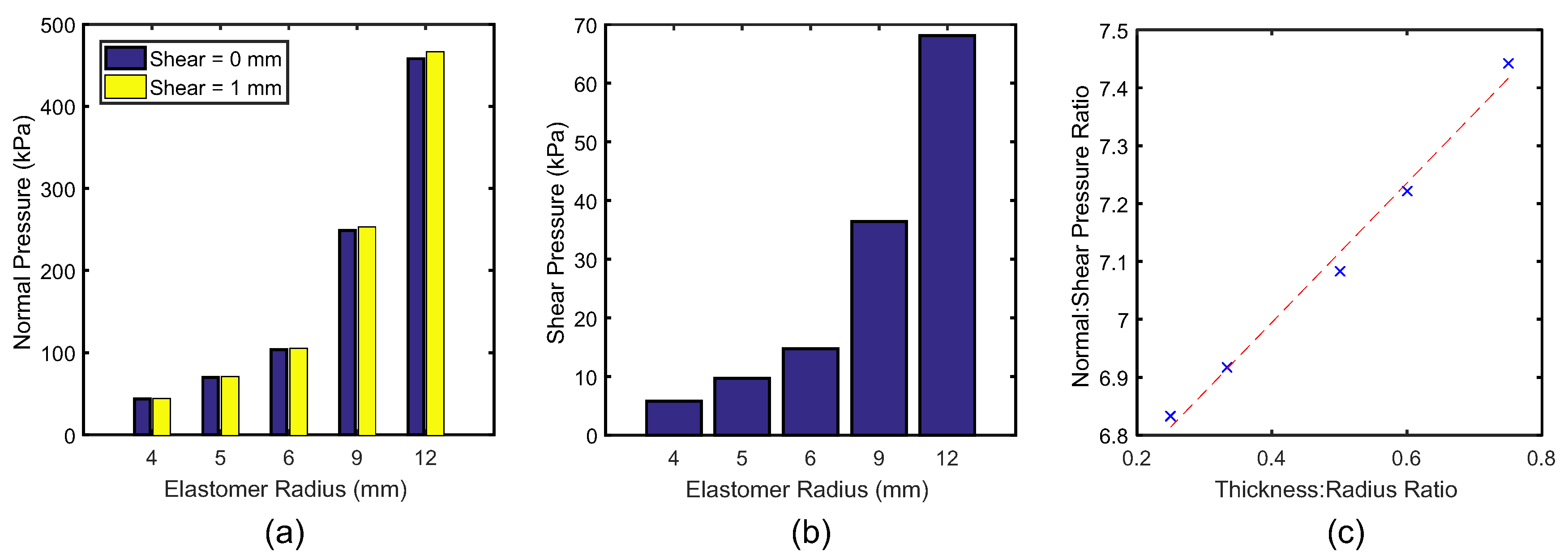

3.4. Investigation of Physical Design Parameters

4. System Evaluation

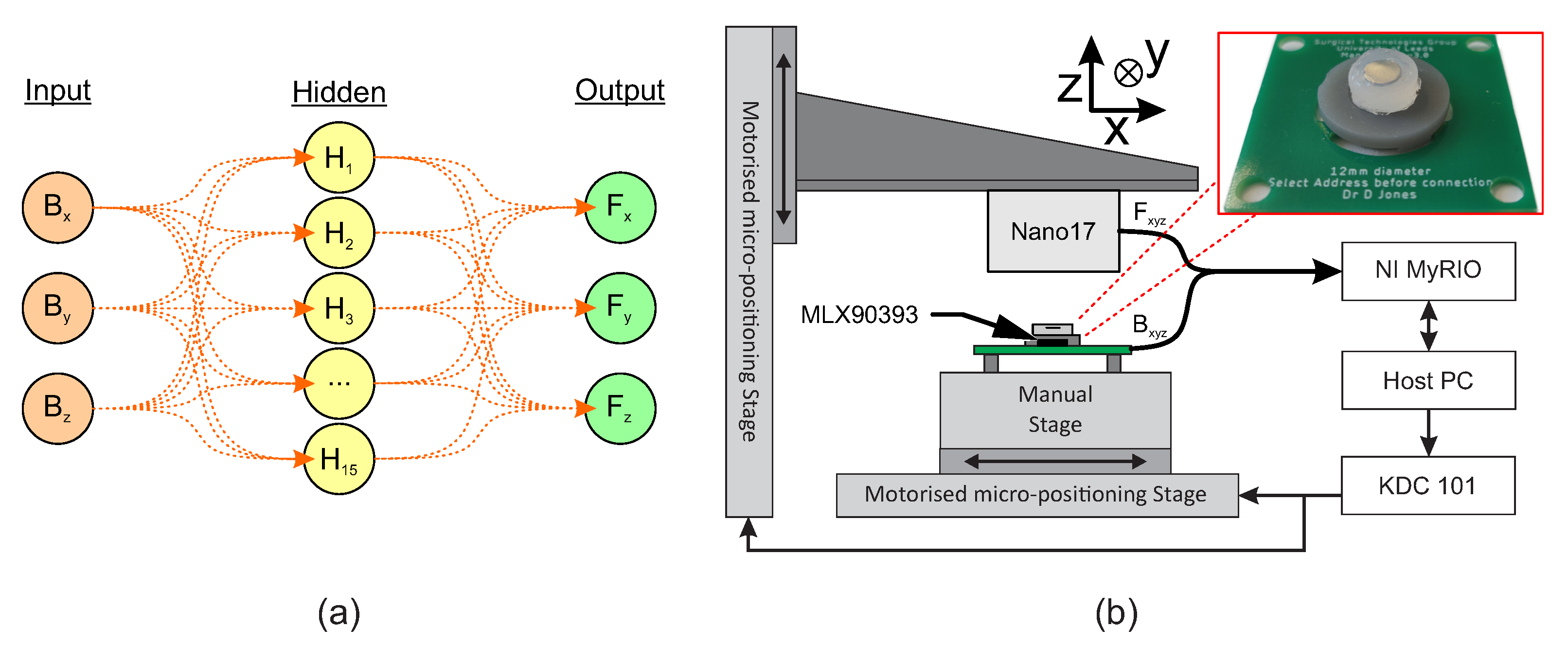

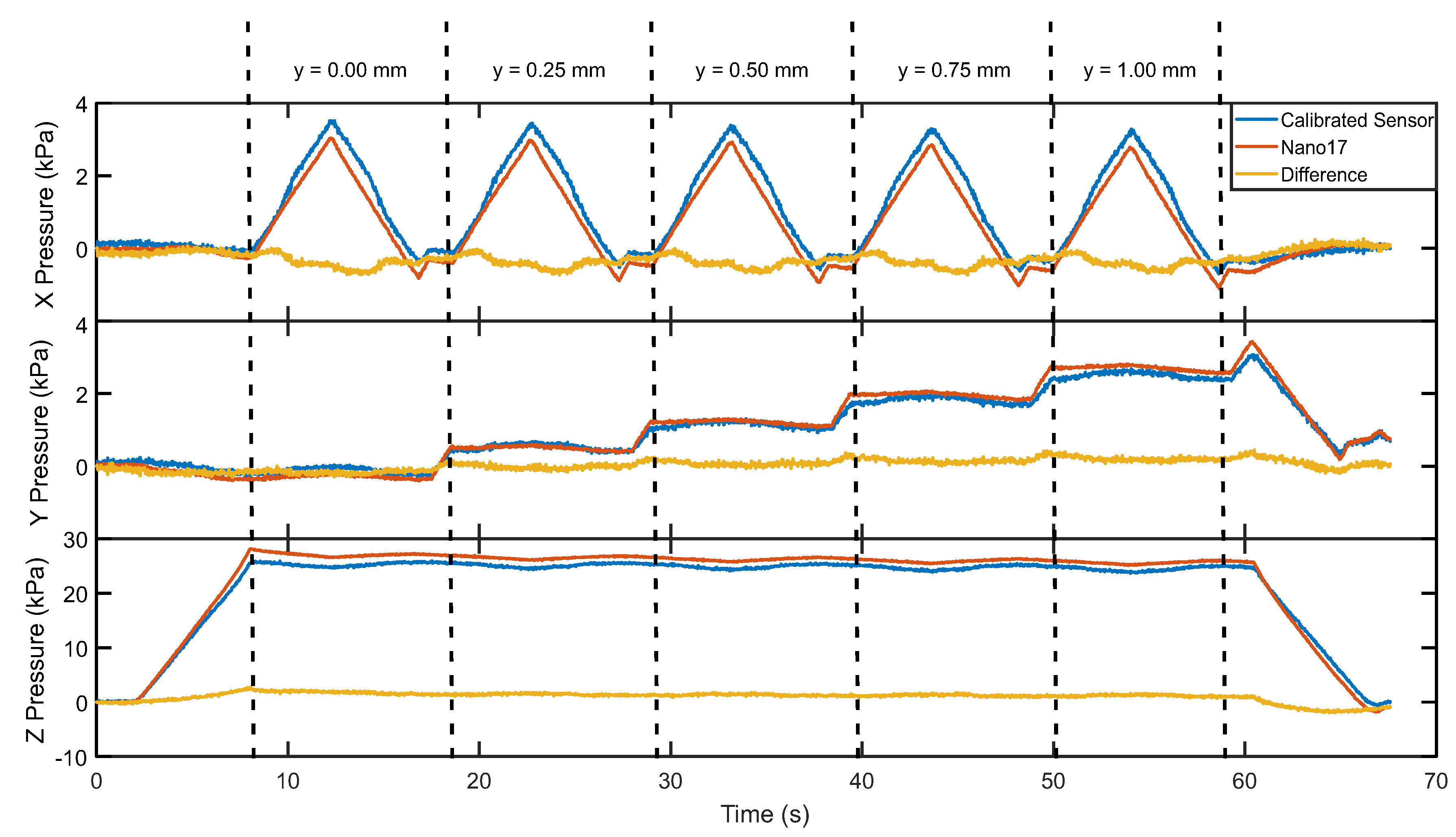

4.1. Sensor Calibration

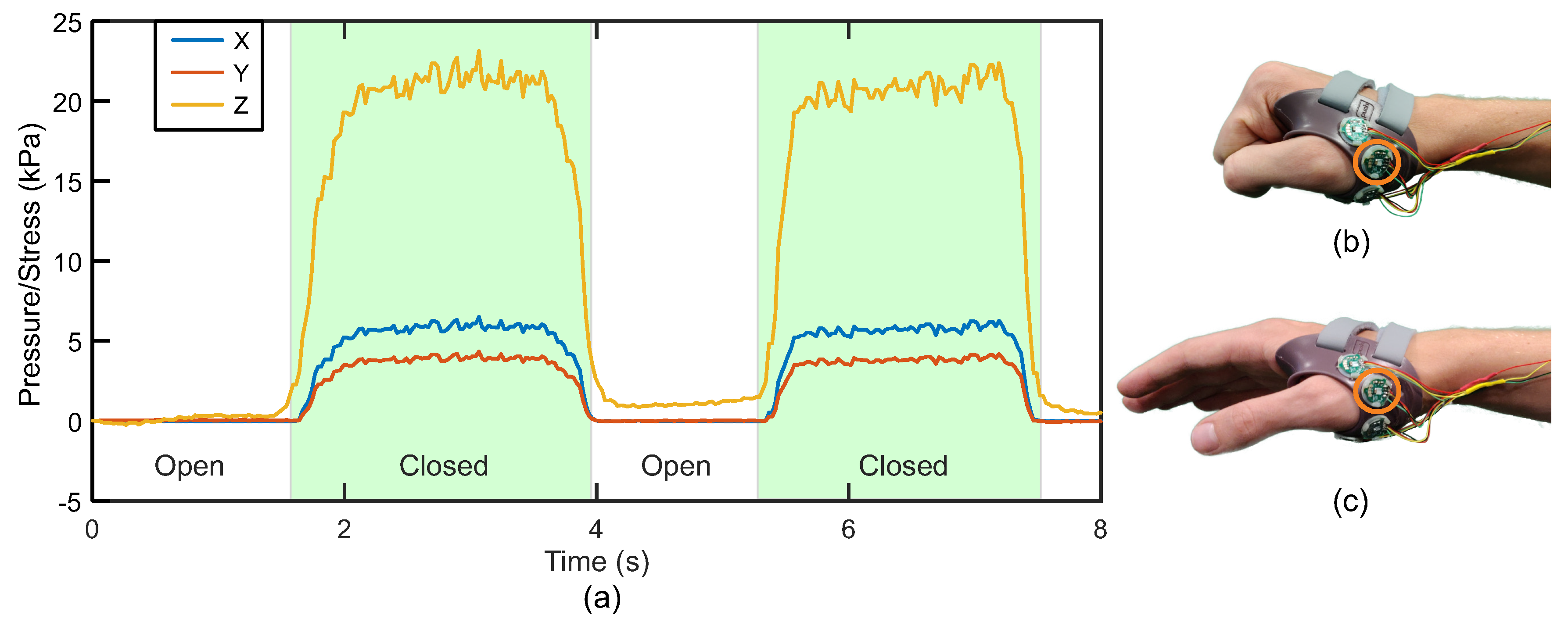

4.2. Splint Sensor Prototype

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gravlee, J.R.; Van Durme, D.J. Braces and splints for musculoskeletal conditions. Am. Fam. Physician 2007, 75, 342–348. [Google Scholar] [PubMed]

- Gerritsen, A.A.; de Vet, H.C.; Scholten, R.J.; Bertelsmann, F.W.; de Krom, M.C.; Bouter, L.M. Splinting vs surgery in the treatment of carpal tunnel syndrome: A randomized controlled trial. JAMA 2002, 288, 1245–1251. [Google Scholar] [CrossRef] [PubMed]

- Gottschalk, M.B.; Patel, N.N.; Boden, A.L.; Kakar, S. Treatment of basilar thumb arthritis: A critical analysis review. JBJS Rev. 2018, 6, 4. [Google Scholar] [CrossRef] [PubMed]

- Andreu-Perez, J.; Leff, D.R.; Ip, H.M.; Yang, G.Z. From wearable sensors to smart implants—Toward pervasive and personalized healthcare. IEEE Trans. Biomed. Eng. 2015, 62, 2750–2762. [Google Scholar] [CrossRef] [PubMed]

- Laufer, S.; Calvin, K.; Cohen, E.R.; Lenhart, R.L.; Stork, N.C.; Halanski, M.A.; Pugh, C.M. Sensor-based assessment of cast placement and removal. Stud. Health Technol. Inform. 2014, 196, 259–261. [Google Scholar]

- Tuan, C.C.; Lu, C.H.; Wu, Y.C.; Yeh, W.L.; Chen, M.C.; Lee, T.F.; Chen, Y.J.; Kao, H.K. Development of a System for Real-Time Monitoring of Pressure, Temperature, and Humidity in Casts. Sensors 2019, 19, 2417. [Google Scholar] [CrossRef] [PubMed]

- Giesberts, R.B.; Hekman, E.E.G.; Verkerke, G.J.; Maathuis, P.G.M. Rapid decrease of cast-induced forces during the treatment of clubfoot using the Ponseti method. Bone Jt. J. 2018, 100, 1655–1660. [Google Scholar] [CrossRef] [PubMed]

- Giesberts, R.B.; ter Haar, A.M.; Sanderman, G.M.; Hekman, E.E.G.; Verkerke, G.J. Tissue adaptation rate in the treatment of Dupuytren contracture. J. Hand Therapy 2019, in press. [Google Scholar] [CrossRef] [PubMed]

- Tiwana, M.I.; Redmond, S.J.; Lovell, N.H. A review of tactile sensing technologies with applications in biomedical engineering. Sens. Actuators A 2012, 179, 17–31. [Google Scholar] [CrossRef]

- Casey, V.; Grace, P.; Clarke-Moloney, M. Pressure measurement at biomedical interfaces. In Applied Biomedical Engineering; IntechOpen: London, UK, 2010; pp. 243–264. [Google Scholar]

- Zhang, M.; Turner-Smith, A.; Roberts, V. The reaction of skin and soft tissue to shear forces applied externally to the skin surface. Proc. Inst. Mech. Eng. H J. Eng. Med. 1994, 208, 217–222. [Google Scholar] [CrossRef]

- Hanson, D.; Langemo, D.K.; Anderson, J.; Thompson, P.; Hunter, S. Friction and shear considerations in pressure ulcer development. Adv. Skin Wound Care 2010, 23, 21–24. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; De Boer, G.; Kow, J.; Alazmani, A.; Ghajari, M.; Hewson, R.; Culmer, P. Design methodology for magnetic field-based soft tri-axis tactile sensors. Sensors 2016, 16, 1356. [Google Scholar] [CrossRef] [PubMed]

- Boer, G.D.; Raske, N.; Wang, H.; Kow, J.; Alazmani, A.; Ghajari, M.; Culmer, P.; Hewson, R. Design optimisation of a magnetic field based soft tactile sensor. Sensors 2017, 17, 2539. [Google Scholar] [CrossRef] [PubMed]

- Colditz, J.C. The biomechanics of a thumb carpometacarpal immobilization splint: Design and fitting. J. Hand Therapy 2000, 13, 228–235. [Google Scholar] [CrossRef]

- Wei, P.; Yang, X.; Cao, Z.; Guo, X.L.; Jiang, H.; Chen, Y.; Morikado, M.; Qiu, X.; Yu, D. Flexible and stretchable electronic skin with high durability and shock resistance via embedded 3D printing technology for human activity monitoring and personal healthcare. Adv. Mater. Technol. 2019, 4, 1900315. [Google Scholar] [CrossRef]

- Chen, J.S.; Wu, C.T.; Pan, C. A pressure projection method for nearly incompressible rubber hyperelasticity, part II: Applications. J. Appl. Mech. 1996, 63, 869–876. [Google Scholar] [CrossRef]

- Paterno, L.; Tortora, G.; Menciassi, A. Hybrid soft–rigid actuators for minimally invasive surgery. Soft Robot. 2018, 5, 783–799. [Google Scholar] [CrossRef] [PubMed]

- First4Magnets. Neodymium Magnet Grades. Available online: https://www.first4magnets.com/tech-centre-i61/information-and-articles-i70/neodymium-magnet-information-i82/grades-of-neodymium-magnets-i92 (accessed on 30 September 2019).

- Yu, H.; Wilamowski, B.M. Levenberg-marquardt training. In The Industrial Electronics Handbook, 2nd ed.; Intelligent Systems; CRC Press: Boca Raton, FL, USA, 2011; Volume 5, Available online: http://www.eng.auburn.edu/~wilambm/pap/2011/K10149_C012.pdf (accessed on 17 February 2020).

| Magnet Radius (mm) | Magnet Thicknesses (mm) |

|---|---|

| 1 | 0.5 |

| 2 | 1 |

| 3 | 2 |

| Elastomer Radius (mm) | Total Thickness (mm) | Thickness:Radius Ratio |

|---|---|---|

| 4 | 3 | 0.75 |

| 5 | 3 | 0.6 |

| 6 | 3 | 0.5 |

| 9 | 3 | 0.33 |

| 12 | 3 | 0.25 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jones, D.; Wang, L.; Ghanbari, A.; Vardakastani, V.; Kedgley, A.E.; Gardiner, M.D.; Vincent, T.L.; Culmer, P.R.; Alazmani, A. Design and Evaluation of Magnetic Hall Effect Tactile Sensors for Use in Sensorized Splints. Sensors 2020, 20, 1123. https://doi.org/10.3390/s20041123

Jones D, Wang L, Ghanbari A, Vardakastani V, Kedgley AE, Gardiner MD, Vincent TL, Culmer PR, Alazmani A. Design and Evaluation of Magnetic Hall Effect Tactile Sensors for Use in Sensorized Splints. Sensors. 2020; 20(4):1123. https://doi.org/10.3390/s20041123

Chicago/Turabian StyleJones, Dominic, Lefan Wang, Ali Ghanbari, Vasiliki Vardakastani, Angela E. Kedgley, Matthew D. Gardiner, Tonia L. Vincent, Peter R. Culmer, and Ali Alazmani. 2020. "Design and Evaluation of Magnetic Hall Effect Tactile Sensors for Use in Sensorized Splints" Sensors 20, no. 4: 1123. https://doi.org/10.3390/s20041123

APA StyleJones, D., Wang, L., Ghanbari, A., Vardakastani, V., Kedgley, A. E., Gardiner, M. D., Vincent, T. L., Culmer, P. R., & Alazmani, A. (2020). Design and Evaluation of Magnetic Hall Effect Tactile Sensors for Use in Sensorized Splints. Sensors, 20(4), 1123. https://doi.org/10.3390/s20041123