An Integrated Deep Learning Method towards Fault Diagnosis of Hydraulic Axial Piston Pump

Abstract

1. Introduction

- (1)

- Known as one of the most widely-used rotating machinery in many fields, fault diagnosis of hydraulic axial piston pumps is considered to be necessary and significant in engineering applications. Moreover, the present intelligent fault diagnosis methods are mainly focused on the bearing, gearing and gearbox, the research on hydraulic axial piston pumps is lacking.

- (2)

- In consideration of the superiority of wavelet transform in nonlinear signal processing, CWT is integrated into the approach to achieve the transformation of the time-frequency representations from raw vibration signals.

- (3)

- The limitations of traditional diagnostic methods and common intelligent fault diagnosis approaches are effectively overcome, the proposed diagnosis method will provide an important concept for exploring the new diagnostic methods.

2. Basic Algorithm Theory

2.1. Brief Introduction to Convolutional Neural Network

2.2. Basic Principle of Continuous Wavelet Transform

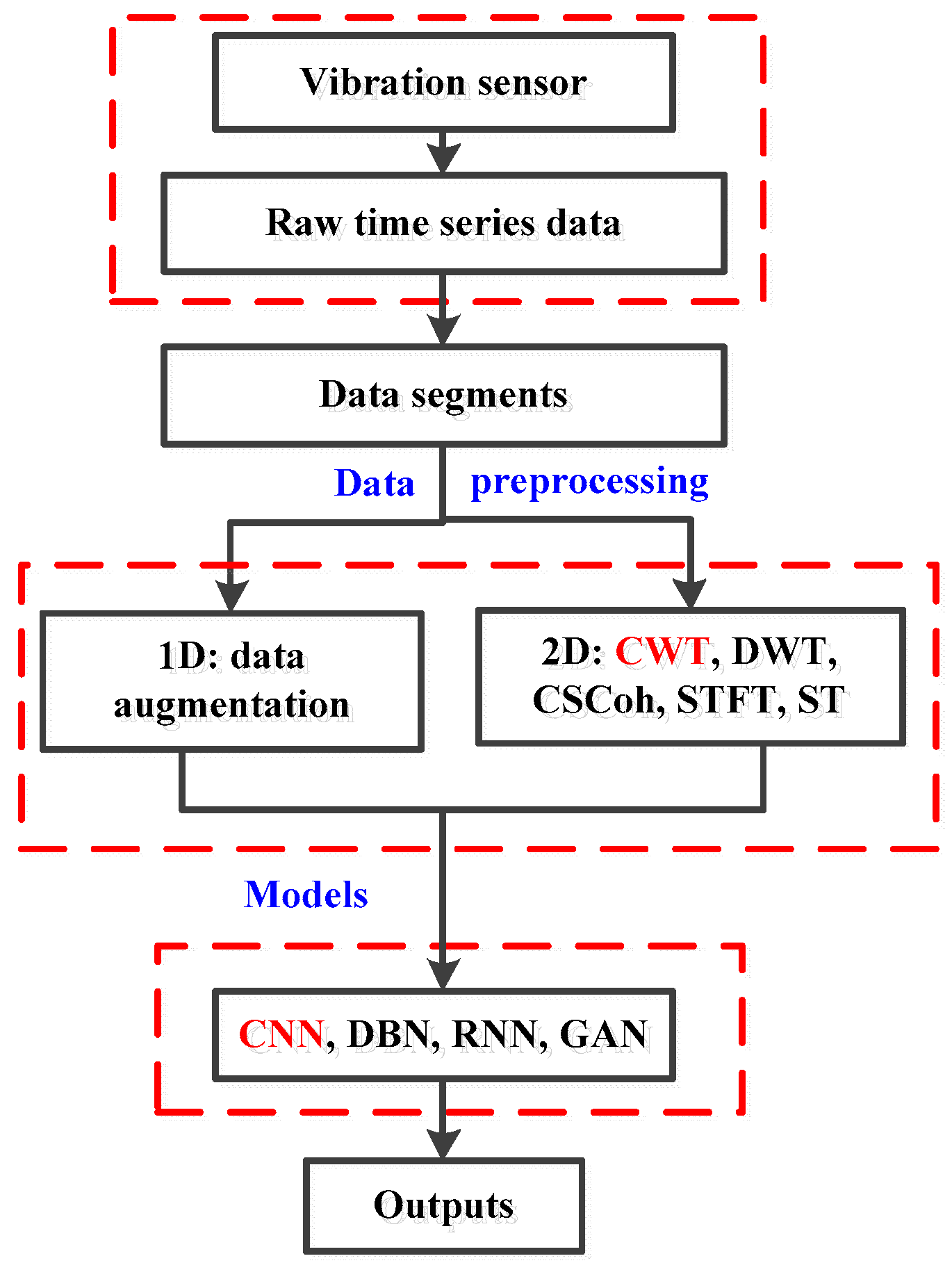

3. Proposed Intelligent Fault Diagnosis Method

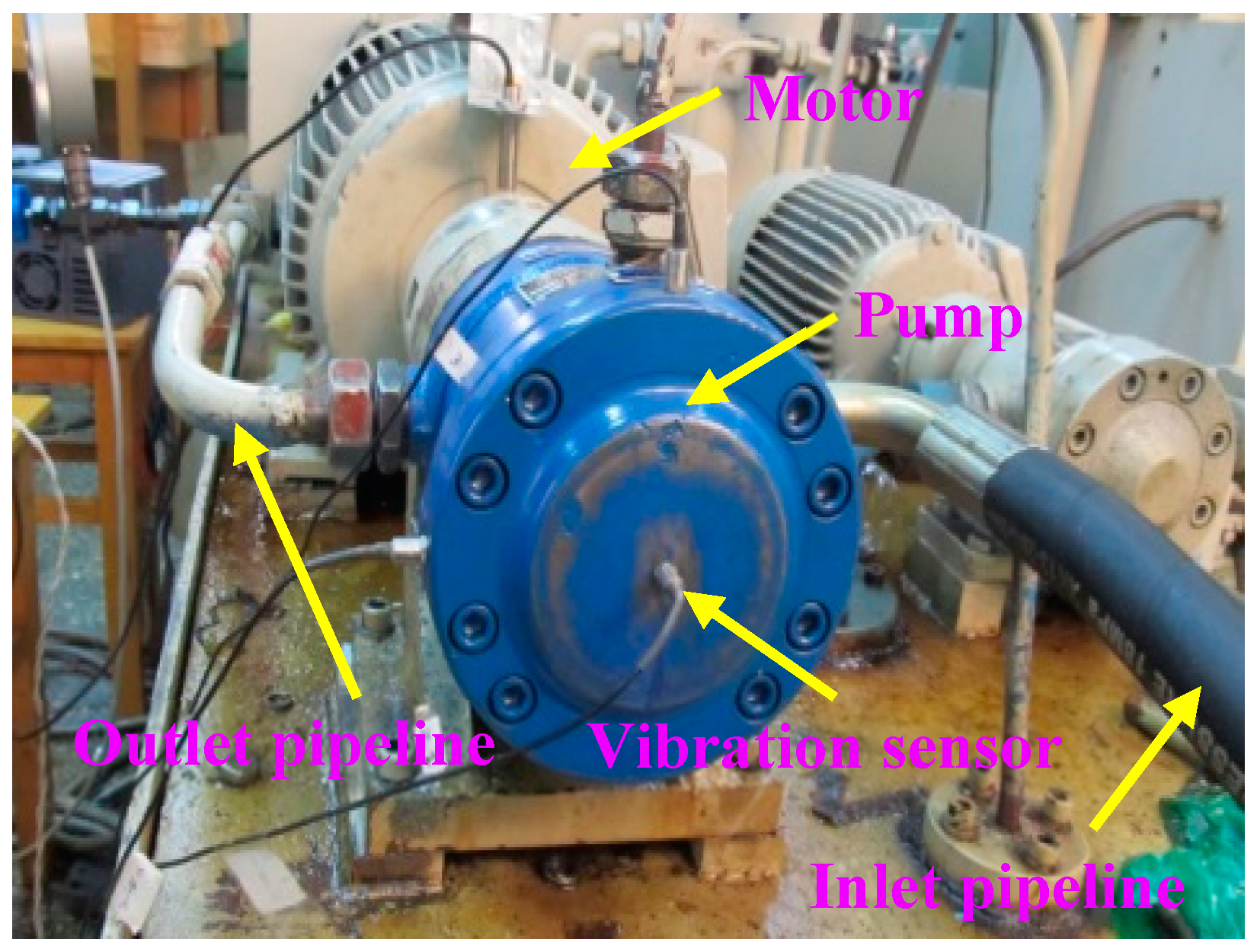

3.1. Data Description

3.2. Data Preprocessing

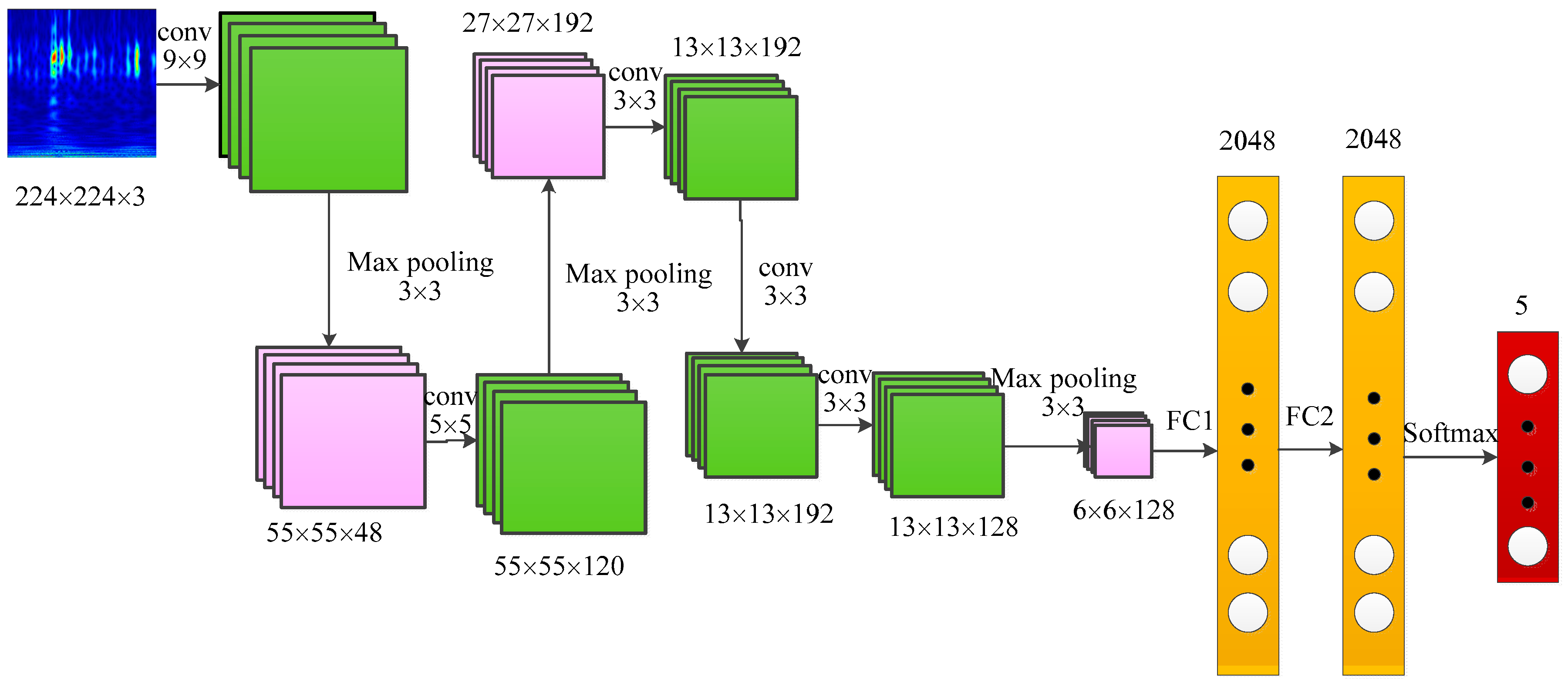

3.3. Proposed Intelligent Method

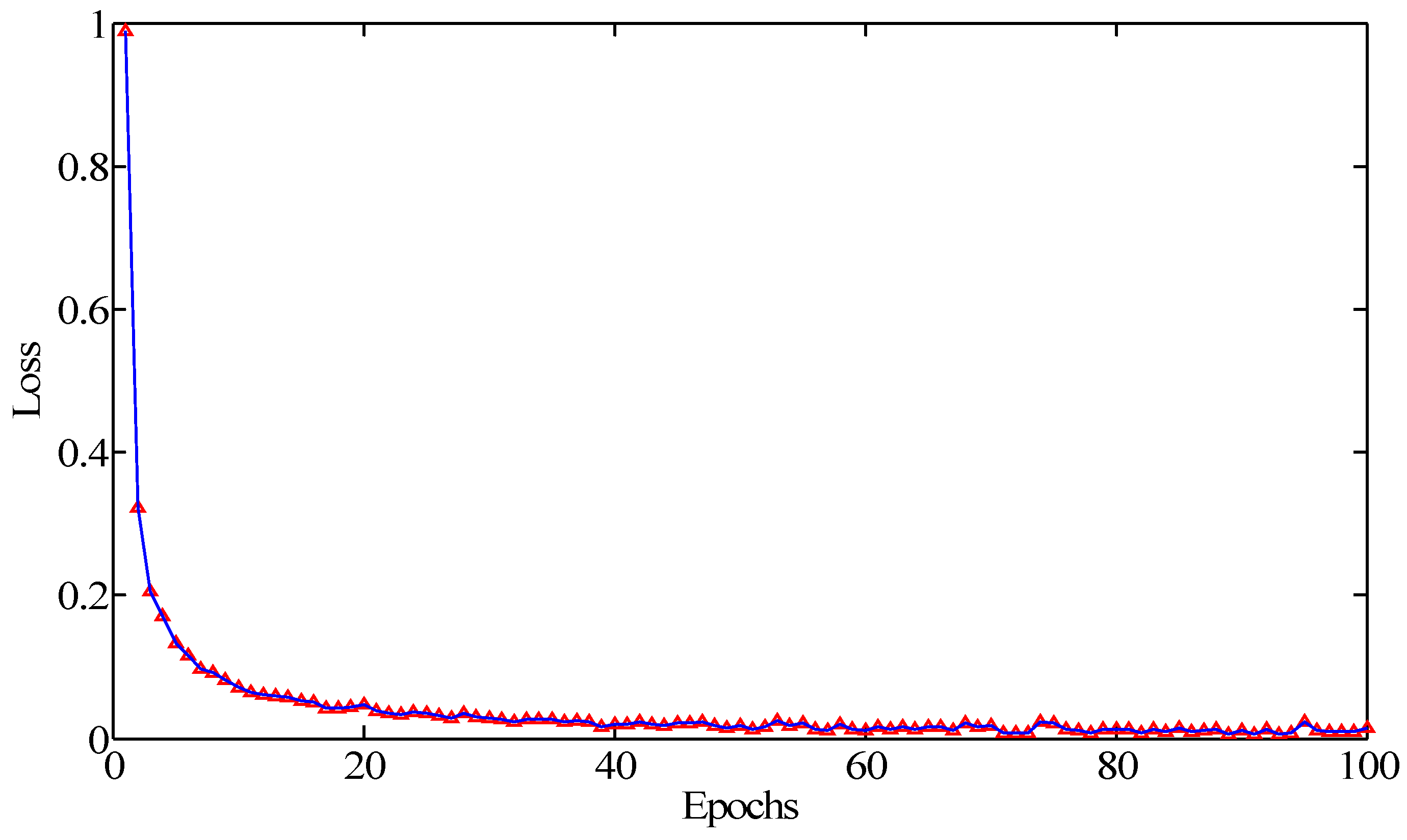

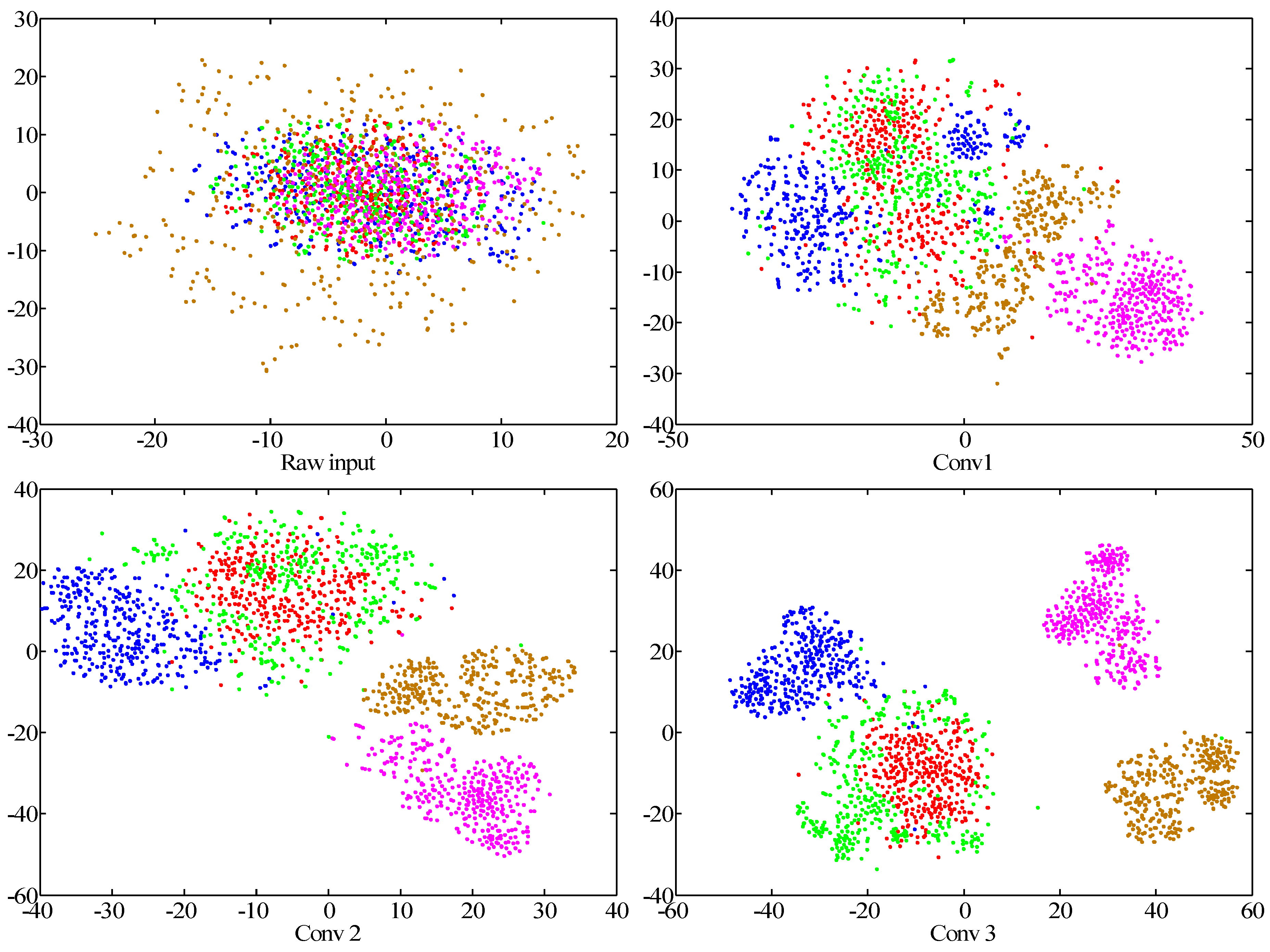

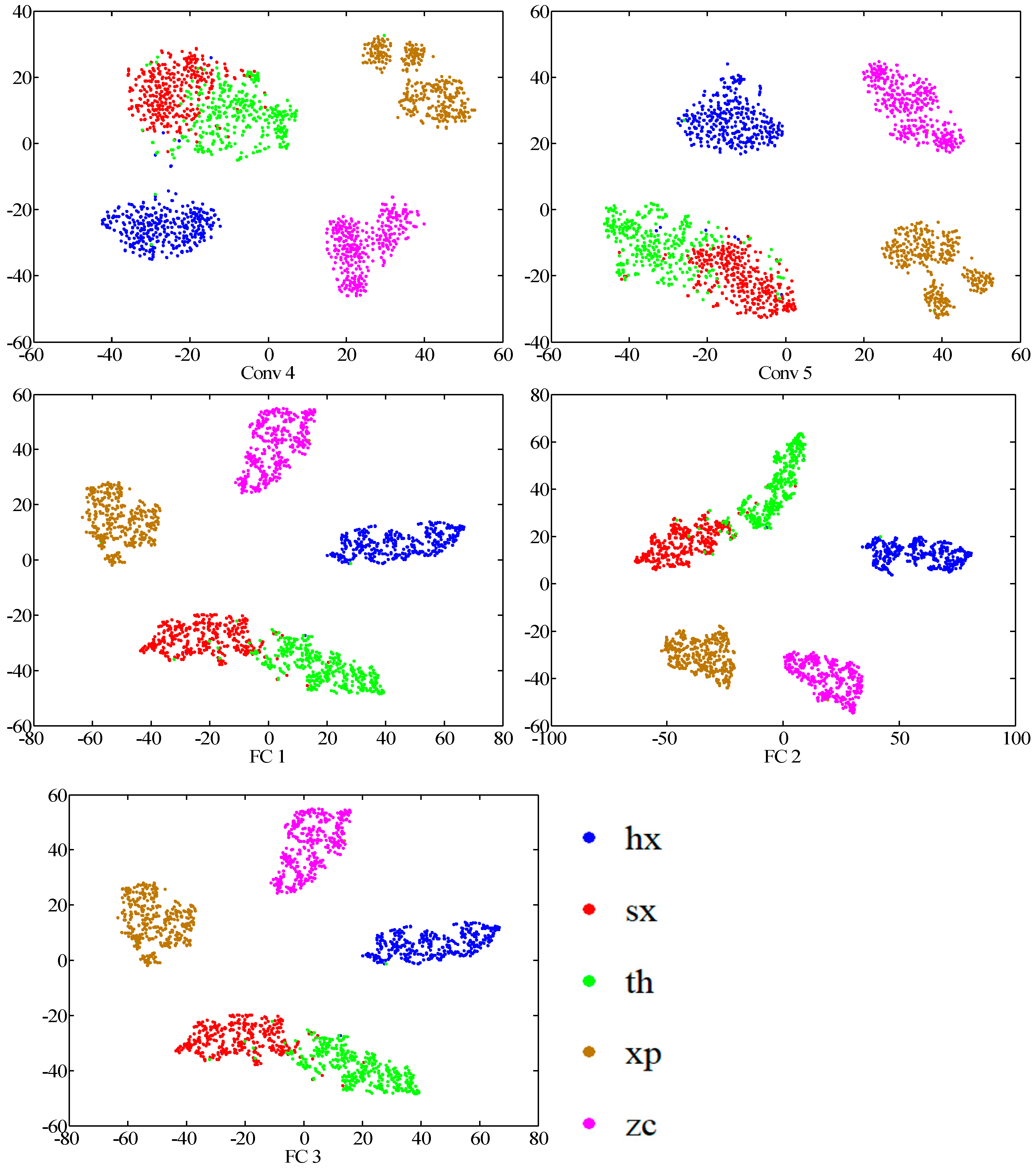

4. Validation of Proposed CNN Model

4.1. Input Data Description

4.2. Parameter Selection for the Proposed Model

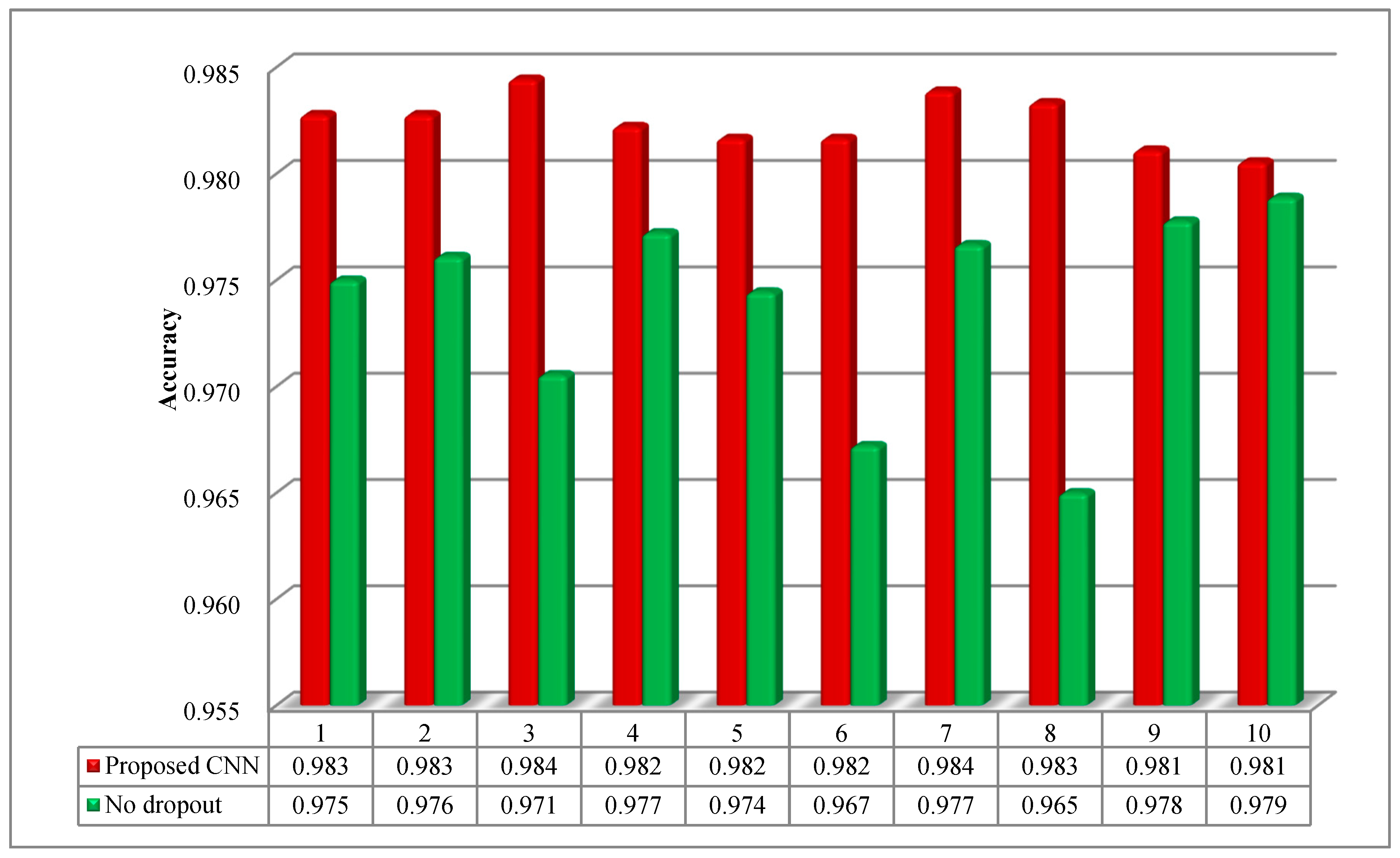

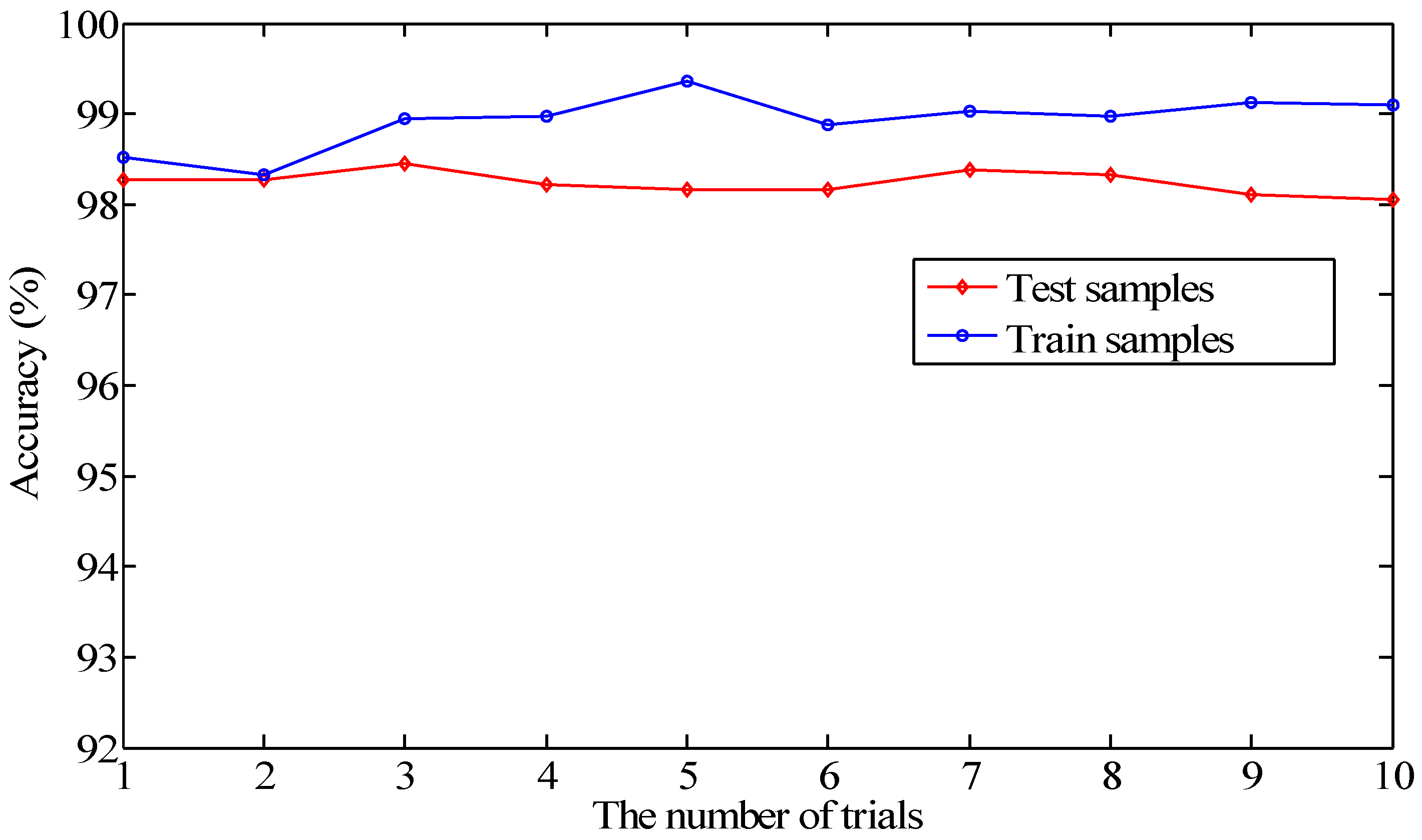

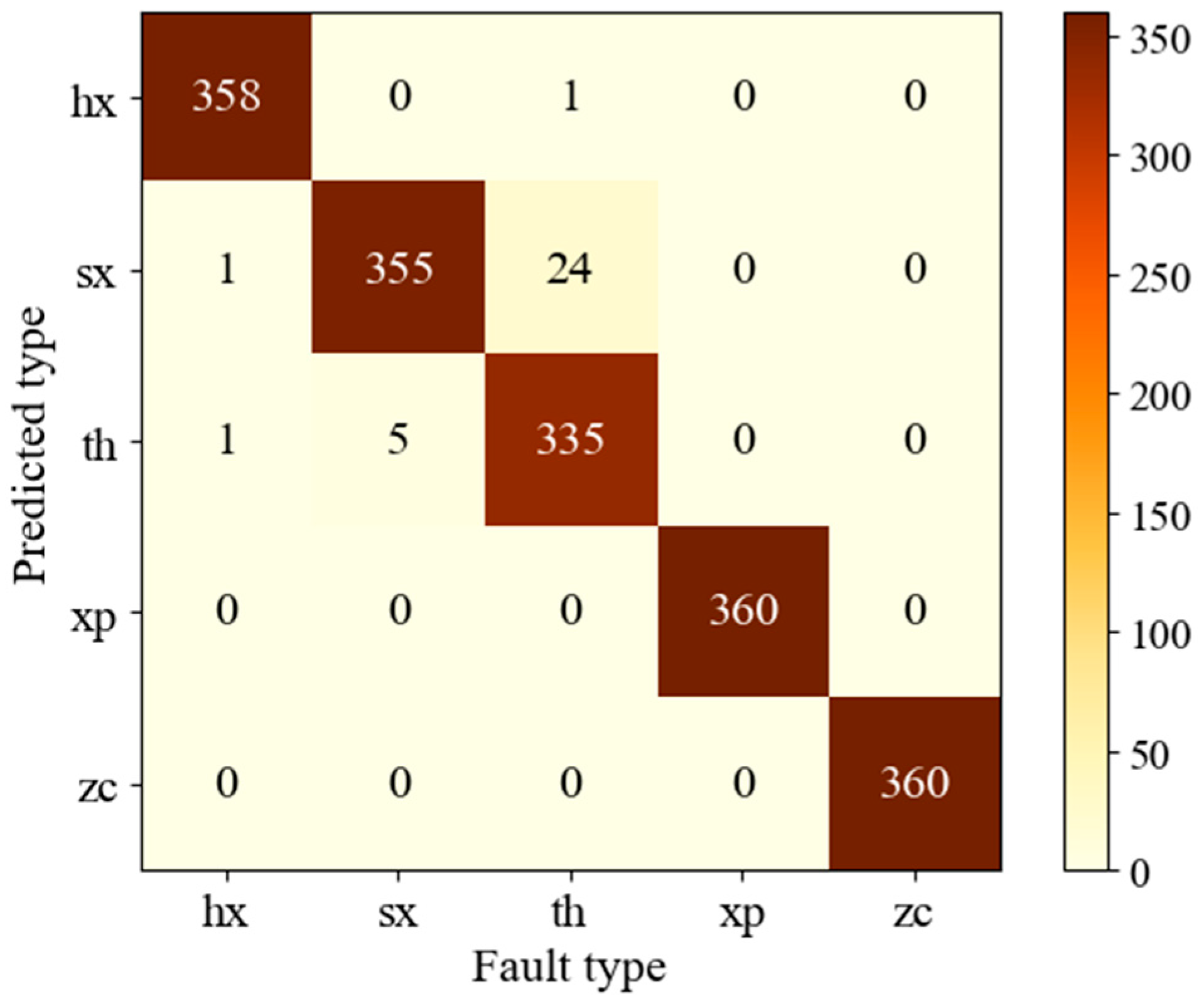

4.3. Performance Validation of the Proposed Model

4.4. Contrastive Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Du, J.; Wang, S.P.; Zhang, H.Y. Layered clustering multi-fault diagnosis for hydraulic piston pump. Mech. Syst. Signal Process. 2013, 36, 487–504. [Google Scholar] [CrossRef]

- Lan, Y.; Hu, J.; Huang, J.; Niu, L.; Zeng, X.; Xiong, X.; Wu, B. Fault diagnosis on slipper abrasion of axial piston pump based on Extreme Learning Machine. Measurement 2018, 124, 378–385. [Google Scholar] [CrossRef]

- Wang, S.; Xiang, J.; Tang, H.; Liu, X.; Zhong, Y. Minimum entropy deconvolution based on simulation–determined band pass filter to detect faults in axial piston pump bearings. ISA Trans. 2019, 88, 186–198. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Bergada, J.M. The effect of piston grooves performance in an axial piston pumps via CFD analysis. Int. J. Mech. Sci. 2013, 66, 168–179. [Google Scholar] [CrossRef]

- Kumar, S.; Bergada, J.M.; Watton, J. Axial piston pump grooved slipper analysis by CFD simulation of three dimensional NVS equation in cylindrical coordinates. Comput. Fluids 2009, 38, 648–663. [Google Scholar] [CrossRef]

- Bergada, J.M.; Kumar, S.; Watton, J. Axial Piston Pumps, New Trends and Development; Nova Science Publishers: New York, NY, USA, 2012. [Google Scholar]

- Lu, C.Q.; Wang, S.P.; Zhang, C. Fault diagnosis of hydraulic piston pumps based on a two-step EMD method and fuzzy C-means clustering. Inst. Mech. Eng. C- J. Mech. Eng. Sci. 2016, 230, 2913–2928. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, Q.; Kong, X. Wavelet-based pressure analysis for hydraulic pump health diagnosis. Trans. ASAE 2003, 46, 969–976. [Google Scholar]

- Hoang, D.T.; Kang, H.J. A survey on deep learning based bearing fault diagnosis. Neurocomputing 2019, 335, 327–335. [Google Scholar] [CrossRef]

- Zhang, F.; Appiah, D.; Hong, F.; Zhang, J.; Yuan, S.; Adu-Poku, K.A.; Wei, X. Energy loss evaluation in a side channel pump under different wrapping angles using entropy production method. Int. Commun. Heat Mass. 2020, 113, 104526. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, T.; Chu, F. Deep convolutional neural network based planet bearing fault classification. Comput. Ind. 2019, 107, 59–66. [Google Scholar] [CrossRef]

- Amar, M.; Gondal, I.; Wilson, C. Vibration spectrum imaging: A novel bearing fault classification approach. IEEE Trans. Int. Electron. 2015, 62, 494–502. [Google Scholar] [CrossRef]

- Wendy, F.F.; Moises, R.-L.; Oleg, S.; Felix, F.G.-N.; Javier, R.-C.; Daniel, H.-B.; Julio, C.R.-Q. Combined application of power spectrum centroid and support vector machines for measurement improvement in optical scanning systems. Signal Process. 2014, 9, 37–51. [Google Scholar]

- Jacob, F.T.; Landen, D.B.; Kody, M.P. On-line classification of coal combustion quality using nonlinear SVM for improved neural network NOx emission rate prediction. Comput. Chem. Eng. 2020, 141, 106990. [Google Scholar]

- Kouziokas, G.N. SVM kernel based on particle swarm optimized vector and Bayesian optimized SVM in atmospheric particulate matter forecasting. Appl. Soft Comput. 2020, 93, 106410. [Google Scholar] [CrossRef]

- Tang, B.; Song, T.; Li, F.; Deng, L. Fault diagnosis for a wind turbine transmission system based on manifold learning and Shannon wavelet support vector machine. Renew. Energy 2014, 62, 1–9. [Google Scholar] [CrossRef]

- Ren, L.; Lv, W.; Jiang, S.; Xiao, Y. Fault diagnosis using a joint model based on sparse representation and SVM. IEEE Trans. Instrum. Meas. 2016, 65, 2313–2320. [Google Scholar] [CrossRef]

- Han, T.; Jiang, D.; Zhao, Q.; Wang, L.; Yin, K. Comparison of random forest, artificial neural networks and support vector machine for intelligent diagnosis of rotating machinery. Trans. Inst. Meas. Control 2018, 40, 2681–2693. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, H.; Zhang, H.; Liang, T. Electric locomotive bearing fault diagnosis using a novel convolutional deep belief network. IEEE Trans. Ind. Electron. 2018, 65, 2727–2736. [Google Scholar] [CrossRef]

- Xiong, S.; Zhou, H.; He, S.; Zhang, L.; Xia, Q.; Xuan, J.; Shi, T. A novel end-to-end fault diagnosis approach for rolling bearings by integrating wavelet packet transform into convolutional neural network structures. Sensors 2020, 20, 4965. [Google Scholar] [CrossRef]

- Wen, L.; Li, X.; Gao, L.; Zhang, Y. A new convolutional neural network-based data-driven fault diagnosis method. IEEE Trans. Ind. Electron. 2018, 65, 5990–5998. [Google Scholar] [CrossRef]

- Pan, J.; Zi, Y.; Chen, J.; Zhou, Z.; Wang, B. LiftingNet: A novel deep learning network with layerwise feature learning from noisy mechanical data for fault classification. IEEE Trans. Ind. Electron. 2018, 65, 4973–4982. [Google Scholar] [CrossRef]

- Liang, P.; Deng, C.; Wu, J.; Yang, Z.; Zhu, J.; Zhang, Z. Compound fault diagnosis of gearboxes via multi-label convolutional neural network and wavelet transform. Comput. Ind. 2019, 113, 103132. [Google Scholar] [CrossRef]

- Luo, H.; Bo, L.; Peng, C.; Hou, D. Fault Diagnosis for High-Speed Train Axle-Box Bearing Using Simplified Shallow Information Fusion Convolutional Neural Network. Sensors 2020, 20, 4930. [Google Scholar] [CrossRef] [PubMed]

- Gao, T.; Sheng, W.; Zhou, M.; Fang, B.; Luo, F.; Li, J. Method for Fault Diagnosis of Temperature-Related MEMS Inertial Sensors by Combining Hilbert–Huang Transform and Deep Learning. Sensors 2020, 20, 5633. [Google Scholar] [CrossRef] [PubMed]

- Jia, F.; Lei, Y.; Lu, N.; Xing, S. Deep normalized convolutional neural network for imbalanced fault classification of machinery and its understanding via visualization. Mech. Syst. Signal Process. 2018, 110, 349–367. [Google Scholar] [CrossRef]

- Xu, G.; Liu, M.; Jiang, Z.; Shen, W.; Huang, C. Online fault diagnosis method based on transfer convolutional neural networks. IEEE Trans. Instrum. Meas. 2020, 69, 509–520. [Google Scholar] [CrossRef]

- Shenfield, A.; Howarth, M. A novel deep learning model for the detection and identification of rolling element-bearing faults. Sensors 2020, 20, 5112. [Google Scholar] [CrossRef]

- Lia, F.; Tang, T.; Tang, B.; He, Q. Deep convolution domain-adversarial transfer learning for fault diagnosis of rolling bearings. Measurement 2021, 169, 108339. [Google Scholar] [CrossRef]

- Wang, X.; Shen, C.; Xia, M.; Wang, D.; Zhu, J.; Zhu, Z. Multi-scale deep intra-class transfer learning for bearing fault diagnosis. Reliab. Eng. Syst. Saf. 2020, 202, 107050. [Google Scholar] [CrossRef]

- Ye, Q.; Liu, S.; Liu, C. A deep learning model for fault diagnosis with a deep neural network and feature fusion on multi-channel sensory signals. Sensors 2020, 20, 4300. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Wang, S.; Li, W.; Sarkodie-Gyan, T.; Feng, S. A hybrid deep-learning model for fault diagnosis of rolling bearings. Measurement 2021, 169, 108502. [Google Scholar] [CrossRef]

- Zhou, Q.; Li, Y.; Tian, Y.; Jiang, L. A novel method based on nonlinear auto-regression neural network and convolutional neural network for imbalanced fault diagnosis of rotating machinery. Measurement 2020, 161, 107880. [Google Scholar] [CrossRef]

- Chen, Z.; Gryllias, K.; Li, W. Mechanical fault diagnosis using Convolutional Neural Networks and Extreme Learning Machine. Mech. Syst. Signal Process. 2019, 133, 106272. [Google Scholar] [CrossRef]

- Wang, H.; Xu, J.; Yan, R.; Gao, R.X. A new intelligent bearing fault diagnosis method using SDP representation and SE-CNN. IEEE Trans. Instrum. Meas. 2020, 69, 2377–2389. [Google Scholar] [CrossRef]

- Wang, R.; Liu, F.; Hou, F.; Jiang, W.; Hou, Q.; Yu, L. A non-contact fault diagnosis method for rolling bearings based on acoustic imaging and convolutional neural networks. IEEE Access 2020, 8, 132761–132774. [Google Scholar] [CrossRef]

- Kim, M.; Jung, J.H.; Ko, J.U.; Kong, H.B.; Lee, J.; Youn, B.D. Direct connection-based convolutional neural network (DC-CNN) for fault diagnosis of rotor systems. IEEE Access 2020, 8, 172043–172056. [Google Scholar] [CrossRef]

- Li, X.; Jiang, H.; Niu, M.; Wang, R. An enhanced selective ensemble deep learning method for rolling bearing fault diagnosis with beetle antennae search algorithm. Mech. Syst. Signal Process. 2020, 142, 106752. [Google Scholar] [CrossRef]

- Wendy, F.F.; Oleg, S.; Felix, F.G.-N.; Moises, R.-L.; Julio, C.R.-Q.; Daniel, H.-B.; Vera, T.; Lars, L. Multivariate outlier mining and regression feedback for 3D measurement improvement in opto-mechanical system. Opt. Quantum Electron. 2016, 48, 403. [Google Scholar]

- Shao, S.; Yan, R.; Lu, Y.; Wang, P.; Gao, R.X. DCNN-based multi-signal induction motor fault diagnosis. IEEE Trans. Instrum. Meas. 2020, 69, 2658–2669. [Google Scholar] [CrossRef]

- Tang, S.; Yuan, S.; Zhu, Y. Convolutional Neural Network in Intelligent Fault Diagnosis toward Rotatory Machinery. IEEE Access 2020, 8, 86510–86519. [Google Scholar] [CrossRef]

- Zhao, R.; Yan, R.; Chen, Z.; Mao, K.; Wang, P.; Gao, R.X. Deep learning and its applications to machine health monitoring. Mech. Syst. Signal Process. 2019, 115, 213–237. [Google Scholar] [CrossRef]

- Chen, Z.Q.; Li, C.; Sanchez, R.V. Gearbox fault identification and classification with convolutional neural networks. Shock Vib. 2015, 10–13, 1–10. [Google Scholar] [CrossRef]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; The MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Peng, Z.K.; Chu, F.L.; Tse, P.W. Singularity analysis of the vibration signals by means of wavelet modulus maximal method. Mech. Syst. Signal Process. 2007, 21, 780–794. [Google Scholar] [CrossRef]

- Tang, S.; Yuan, S.; Zhu, Y. Data Preprocessing Techniques in Convolutional Neural Network based on Fault Diagnosis towards Rotating Machinery. IEEE Access 2020, 8, 149487–149496. [Google Scholar] [CrossRef]

- Tang, S.; Yuan, S.; Zhu, Y. Deep learning-based intelligent fault diagnosis methods towards rotating machinery. IEEE Access 2020, 8, 9335–9346. [Google Scholar] [CrossRef]

- Liu, D.; Cheng, W.; Wen, W. Rolling bearing fault diagnosis via STFT and improved instantaneous frequency estimation method. Procedia Manuf. 2020, 49, 166–172. [Google Scholar] [CrossRef]

- Hajiabotorabi, Z.; Kazemi, A.; Samavati, F.F.; Ghaini, F.M.M. Improving DWT-RNN model via B-spline wavelet multiresolution to forecast a high-frequency time series. Expert Syst. Appl. 2019, 138, 112842. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Q.S.; Zhang, G.L.; Liu, W.; Chen, F.R. Adaptive S transform for feature extraction in voltage sags. Appl. Soft Comput. 2019, 80, 438–449. [Google Scholar] [CrossRef]

- Liu, C.; Gryllias, K. A semi-supervised Support Vector Data Description-based fault detection method for rolling element bearings based on cyclic spectral analysis. Mech. Syst. Signal Process. 2020, 140, 106682. [Google Scholar] [CrossRef]

- Liu, H.; Li, L.; Ma, J. Rolling bearing fault diagnosis based on STFT-deep learning and sound signals. Shock Vib. 2016, 2016, 1–12. [Google Scholar] [CrossRef]

- Zeng, X.; Liao, Y.; Li, W. Gearbox fault classification using S-transform and convolutional neural network. In Proceedings of the 10th International Conference on Sensing Technology (ICST), Nanjing, China, 11–13 November 2016; pp. 1–5. [Google Scholar]

- ALTobi, M.A.S.; Bevan, G.; Wallace, P.; Harrison, D.; Ramachandran, K.P. Fault diagnosis of a centrifugal pump using MLP-GABP and SVM with CWT. Eng. Sci. Technol. Int. J. 2019, 22, 854–861. [Google Scholar] [CrossRef]

- Chen, Z.; Mauricio, A.; Li, W.; Gryllias, K. A deep learning method for bearing fault diagnosis based on cyclic spectral coherence and convolutional neural networks. Mech. Syst. Signal Process. 2020, 140, 106683. [Google Scholar] [CrossRef]

- Kingma, D.; Ba, J. Adam: A method for Stochastic Optimization. In Proceedings of the 6th International Conference on Learning Representations (ICLR), San Diego, CA, USA, 7–9 May 2015; pp. 1–15. [Google Scholar]

- van der Maaten, L.J.P.; Hinton, G.E. Visualizing high-dimensional data using t-SNE. J. Mach. Learn. Res. 2008, 9, 2579–2605. [Google Scholar]

| Health Condition | Description | Index Names | Type Labels |

|---|---|---|---|

| Normal | no fault in hydraulic pump | zc | 0 |

| Faulty | swash plate wear | xp | 1 |

| loose slipper failure | sx | 2 | |

| slipper wear | hx | 3 | |

| central spring wear | th | 4 |

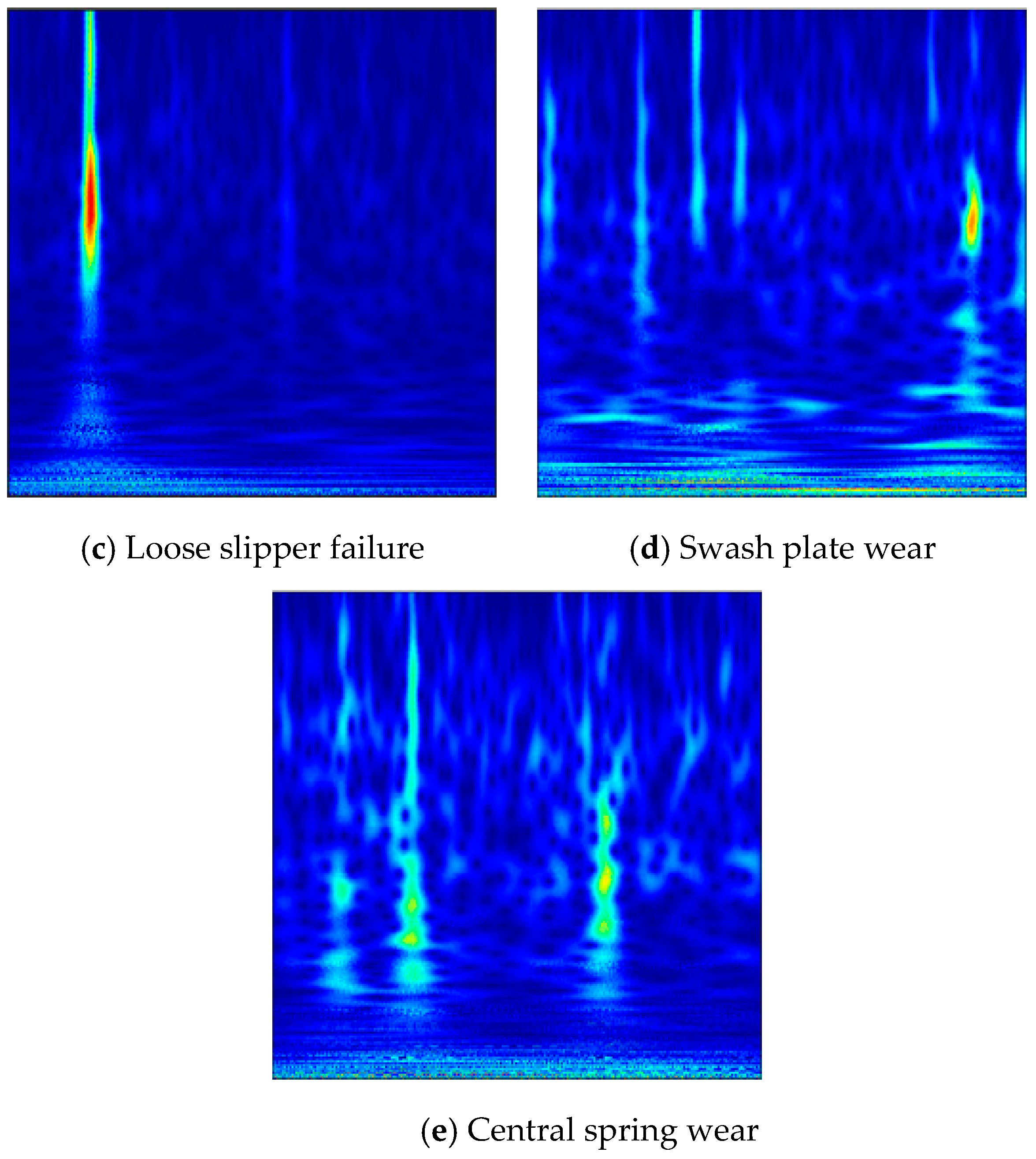

| Fault Type | Fault Description | Time-Frequency Image | Train Dataset | Test Dataset | Type Labels |

|---|---|---|---|---|---|

| hx | slipper wear |  | 840 | 360 | 0 |

| sx | loose slipper failure |  | 840 | 360 | 1 |

| th | central spring wear |  | 840 | 360 | 2 |

| xp | swash plate wear |  | 840 | 360 | 3 |

| zc | no fault in hydraulic pump |  | 840 | 360 | 4 |

| total | - | - | 4200 | 1800 | - |

| CNN Models | Average Accuracy (%) | STD |

|---|---|---|

| T-LeNet 5 | 95.22 | 0.007472 |

| I-LeNet 5 | 96.36 | 0.001172 |

| CNN-3 | 96.70 | 0.004603 |

| CNN-4 | 96.20 | 0.008946 |

| T-AlexNet | 95.87 | 0.003608 |

| Proposed CNN | 98.44 | 0.001171 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, S.; Yuan, S.; Zhu, Y.; Li, G. An Integrated Deep Learning Method towards Fault Diagnosis of Hydraulic Axial Piston Pump. Sensors 2020, 20, 6576. https://doi.org/10.3390/s20226576

Tang S, Yuan S, Zhu Y, Li G. An Integrated Deep Learning Method towards Fault Diagnosis of Hydraulic Axial Piston Pump. Sensors. 2020; 20(22):6576. https://doi.org/10.3390/s20226576

Chicago/Turabian StyleTang, Shengnan, Shouqi Yuan, Yong Zhu, and Guangpeng Li. 2020. "An Integrated Deep Learning Method towards Fault Diagnosis of Hydraulic Axial Piston Pump" Sensors 20, no. 22: 6576. https://doi.org/10.3390/s20226576

APA StyleTang, S., Yuan, S., Zhu, Y., & Li, G. (2020). An Integrated Deep Learning Method towards Fault Diagnosis of Hydraulic Axial Piston Pump. Sensors, 20(22), 6576. https://doi.org/10.3390/s20226576