1. Introduction

Transparent polymer-based delivery devices often contain a solid lubricant coating of a substance such as polyethylene glycol (PEG), poly(hydroxyethyl methacrylate) (PHM), poly(styrene-b-isobutylene-b-styrene) (PSIT), or poly(vinylpyrrolidone) (PVP), on a stronger bulk polymer material, such as such as poly(ethylene) (PE), poly(carbonate) (PC), or poly(propylene) (PP) [

1,

2]. The coating may also have antimicrobial, water-repellent, or adhesive functions [

1,

2]. The distribution of lubricant, by spraying, dipping, brushing, and/or chemical/physical vapor deposition [

3,

4], must be monitored during device optimisation appraisals and to ensure consistency during mass production.

PP, the bulk material of the delivery device presented, is the second most widely produced commodity polymer plastic. PP’s main application is in packaging of consumer products; however, applications can be found in most commercial fields [

5]. In delivery devices, its mechanical stability, transparency, bio-compatibility, functionality, durability, and safety make it a popular component [

6]. The PP bulk material is coated with PU- and PVP-based films for lubrication. PVP’s diverse properties, including chemical stability, non-toxicity, adhesive, electrical, solubility in water and organic solvents, and high capacity to form interpolymer complexes, make it a highly versatile product. The capability to form complexes with many active substances has made it a common component in tablets, granules, pellets, soft gelatine capsules, gels, hydrogels, films, and coatings. In the case of coatings, its hydrophobic properties make it a popular lubricant [

7]. PU forms the cross-linker between the mechanically stable PP and PVP lubricant. Commercially, foam is the most common form of PU manufactured and can be easily tailored to be rigid or flexible. As a binder, PU offers good adhesion, low chemical reactivity, efficient drying, low temperature flexibility, and adequate scratch tolerance [

8].

An abundance of thin film coating evaluation techniques for presence, thickness, and density are available [

9]. Scanning electron microscopy (SEM) or transmission electron microscopy (TEM) can have sub-micrometer resolution and clear results, using such add-ons as energy-dispersive X-ray spectroscopy (EDX), but a cross-section of the sample is required and thickness can only be measured in one dimension [

10]. Profilometry, either stylus or optical, contains high spatial resolution, but recording a thickness requires a full-depth step in the coating [

11]. Gravimetric measurements can measure the total quantity of coating, but they do not contain any coverage detail. Acoustic wave techniques can be employed, but they are limited due to the similar mechanical properties of the plastics involved. Similarly, magnetic techniques cannot be used on plastics.

Optical techniques are popular, as they offer non-destructive characterisation. Raman and fluorescence microscopy [

12,

13] use laser excitation and spectroscopic molecular fingerprints to identify samples. Surface imaging can be made by placing the sample on a three-axis translation stage and an image is formed in a stepwise manner, with spatial resolution at the micron level. However, depth analysis to measure coating thickness is difficult and depends on many factors, such as the opaqueness and Raman/fluorescence quenching properties of the different materials. Even with satisfactory optical properties of the sample, the stepwise approach makes the measurement time-consuming and not suitable for high-quantity industry allotments. Similarly, FTIR microscopes use a three-axis translation stage and have even lower temporal resolution due to the translation of interferometer mirrors/beamsplitters [

14]. Other spectroscopic techniques include optical coherence tomography (OCT) and reflective techniques, attenuated total reflection (ATR) and ellipsometry [

9,

15]. A limitation of spectroscopic techniques is the requirement of direct access/sight of the coating. In reflective techniques, thin films concealed beneath the bulk are not observable without destroying the sample and disjointed surfaces require time-consuming sample re-alignment. In the case of a delivery interface, such as a duct with a bevel tip, both concealed and disjointed surfaces are present.

Dye stain test methods can evaluate coating coverage over a large area and in combination with microscopy can have high spatial resolution [

16,

17,

18]. The technique is destructive, so lot quality assurance sampling must be used during manufacturing. Concealed surfaces can be studied, if the bulk sample is transparent in the visible. The technique has several limitations; it is destructive, time-consuming, and reveals little detail, and some dyes are carcinogenic. However, the simple visible identification of the presence of coating on a non-planar sample make it a useful tool, especially where samples are easily disposed. Dye stain testing is regularly applied to devices containing transparent thin film coatings, such as PEG, PHM, PSIT, PVP, and polyurethane (PU), and can be considered the industrial standard. Although transparent in the visible, these thin films have molecular absorption fingerprints in the IR, where commonly used bulk materials, such as PE, PC, PP, and polystyrene (PS) are transparent. Consequently, a transmission microscope in the IR has the advantages of dye stain testing without the destructive, time-consuming, and hazardous dye deterrents. Measurement of the absorption of thin film coating also provides more qualitative and/or quantitative information.

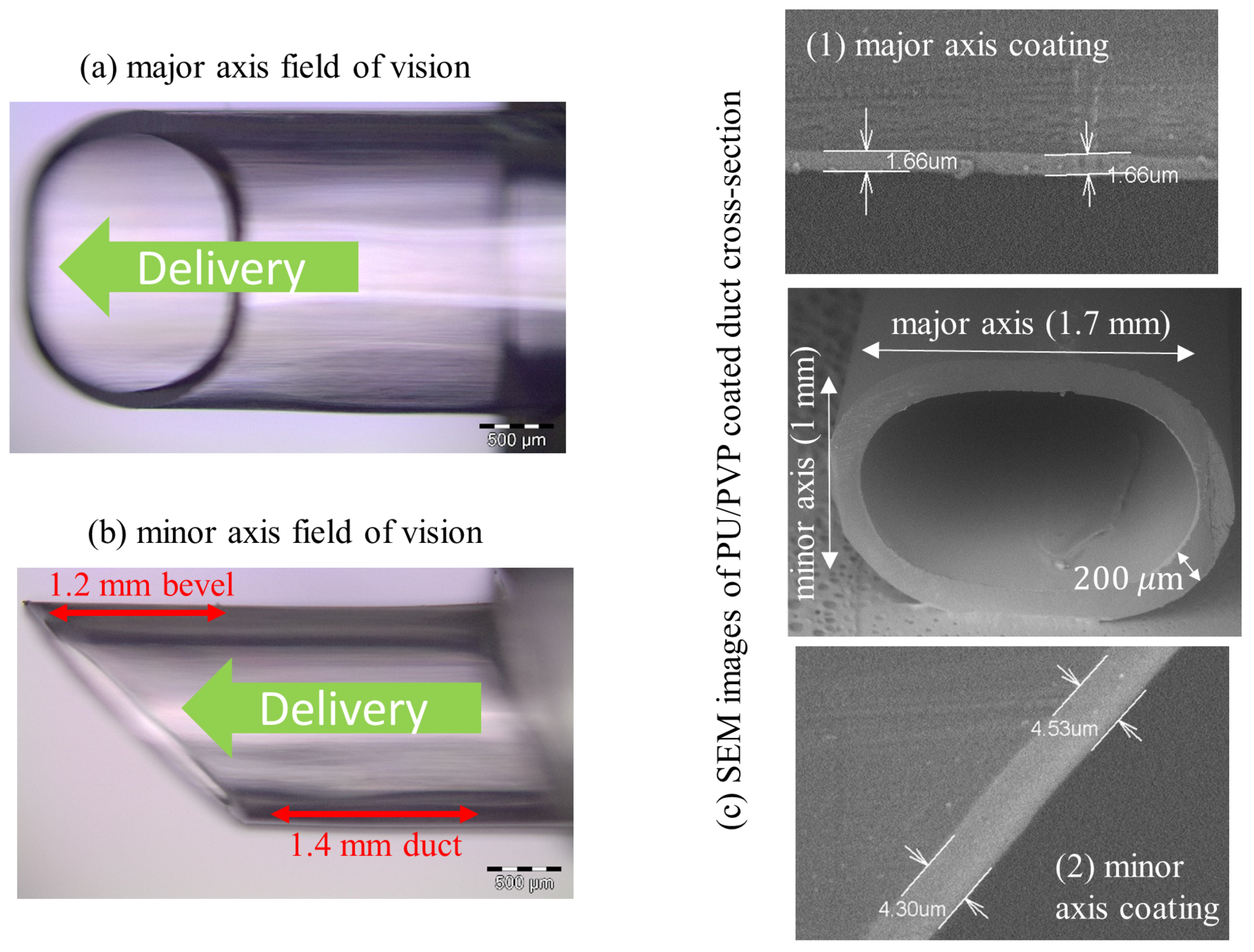

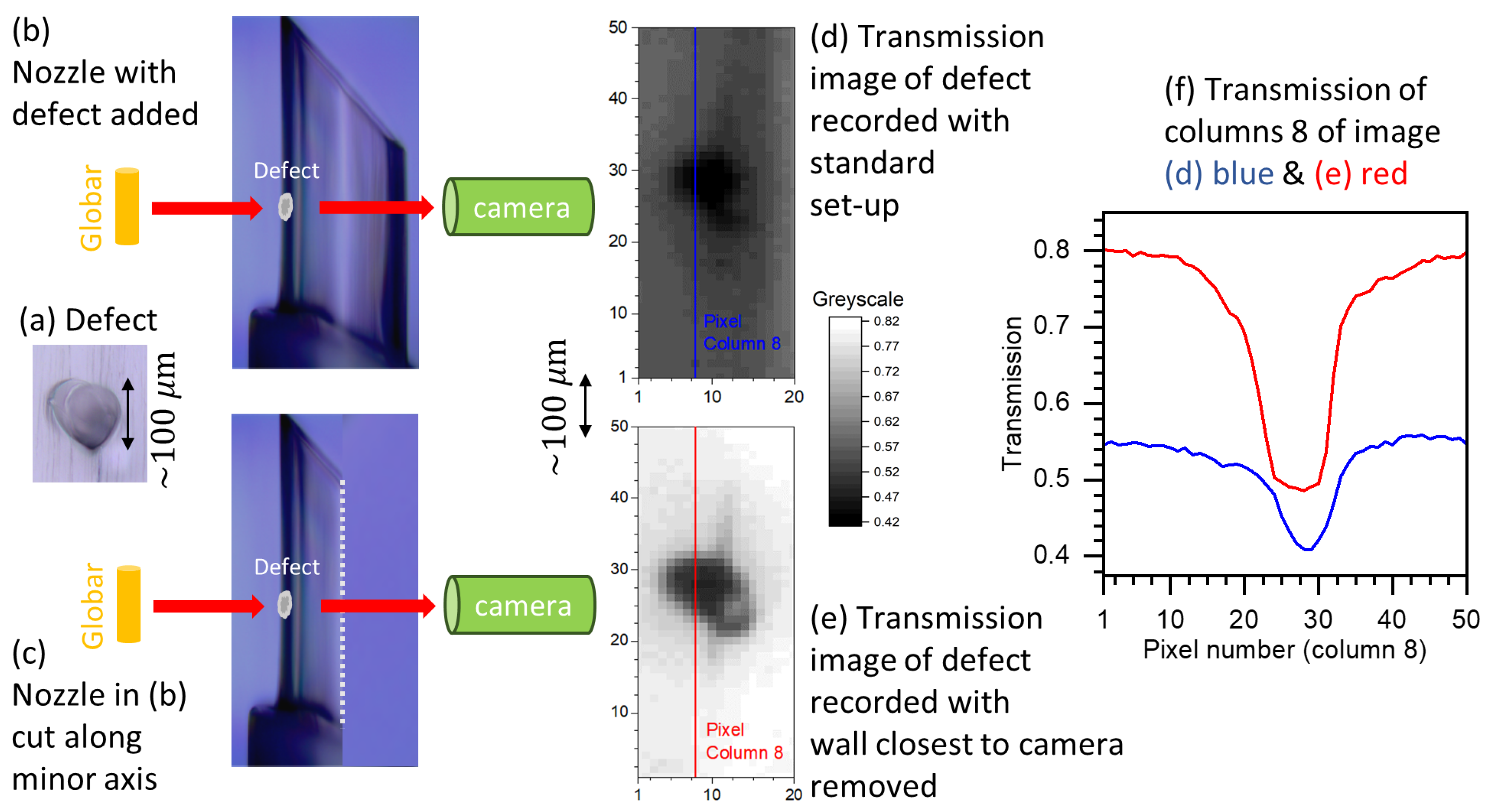

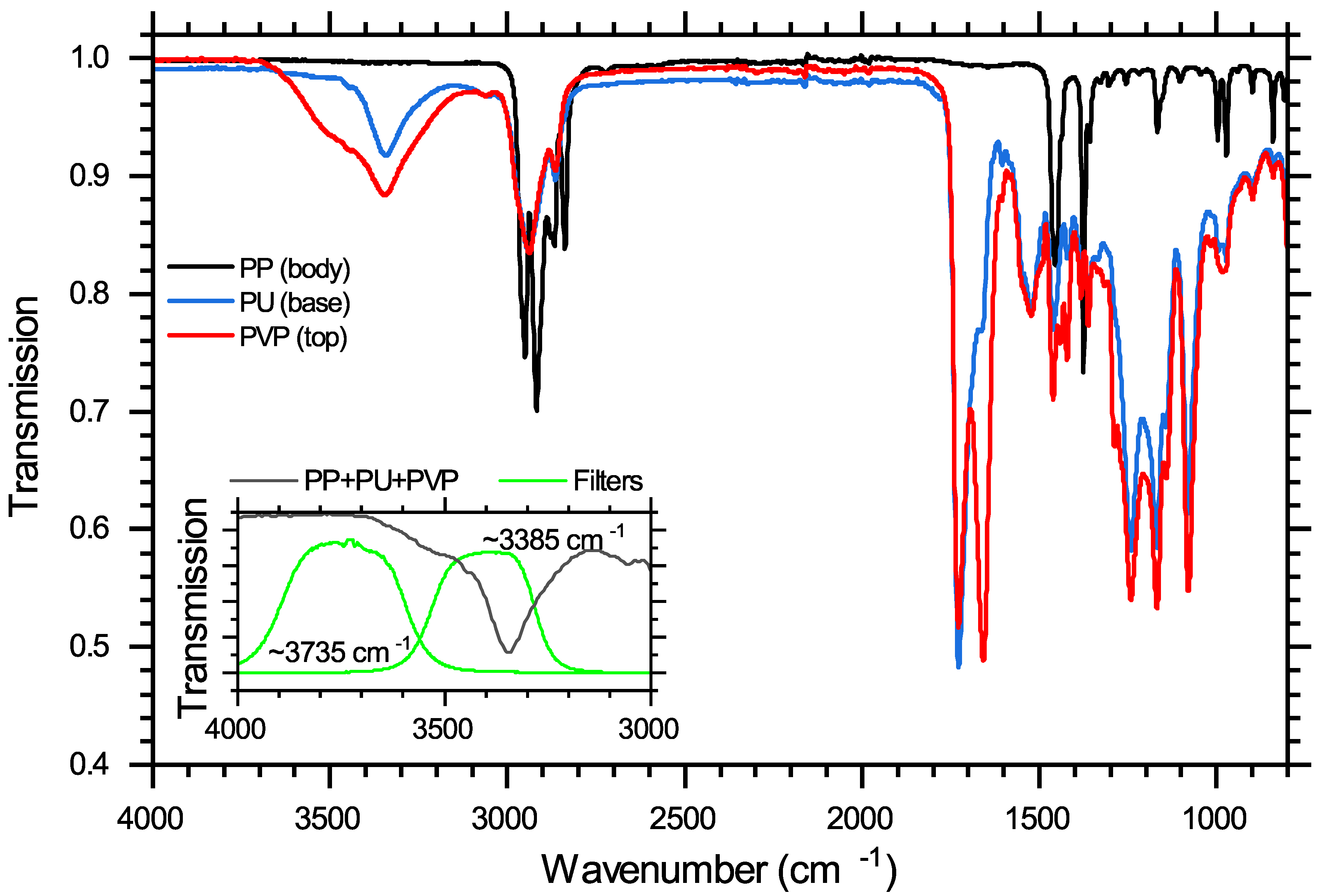

We describe an IR transmission set-up which interrogates coating coverage on a nozzle with a common configuration for a delivery device head, an elliptical duct with a bevel tip. The nozzle contains coating on both concealed and disjointed surfaces, demonstrating the technique can be easily expanded to other delivery device shapes. The PU/PVP coatings employed and PP bulk material of the sample are commonly used in industry. Their IR absorption properties are shared with other polymer coatings, such as PEG, PHM, and PSIT, and bulk materials, such as PE, PC, and PS, and so the technique can easily be expanded to include other common materials.

The sample delivery device interface is described in full in

Section 2.1. The transmission microscope, consisting of a SiC globar, filter wheel, imaging optics, and microbolometer array detector, is described in

Section 2.2. IR absorption/scattering fingerprints are used to identify bulk and coating transmission independently. The process of separating bulk and coating transmission properties on the duct and bevel of the sample is given in

Section 2.3. Measurements of coating coverage on samples are compared with dye stain and SEM measurements in

Section 3. In

Section 4, the applicability of the set-up to industrial samples is discussed. Tests for coating coverage, water dilution, and machine malfunction identification are made using the set-up.

The set-up combines multispectral imaging, IR absorption spectroscopy, and machine vision to measure sub-micron level coating coverage of PVP and PU on the surface of a 200

m thick PP wall. Coating coverage on concealed and disjointed surfaces are identified on a single image, without the need for re-alignment of the sample, with a spatial resolution of ≈50

m. A conclusion and outlook for the technique is presented in

Section 5.

3. Results

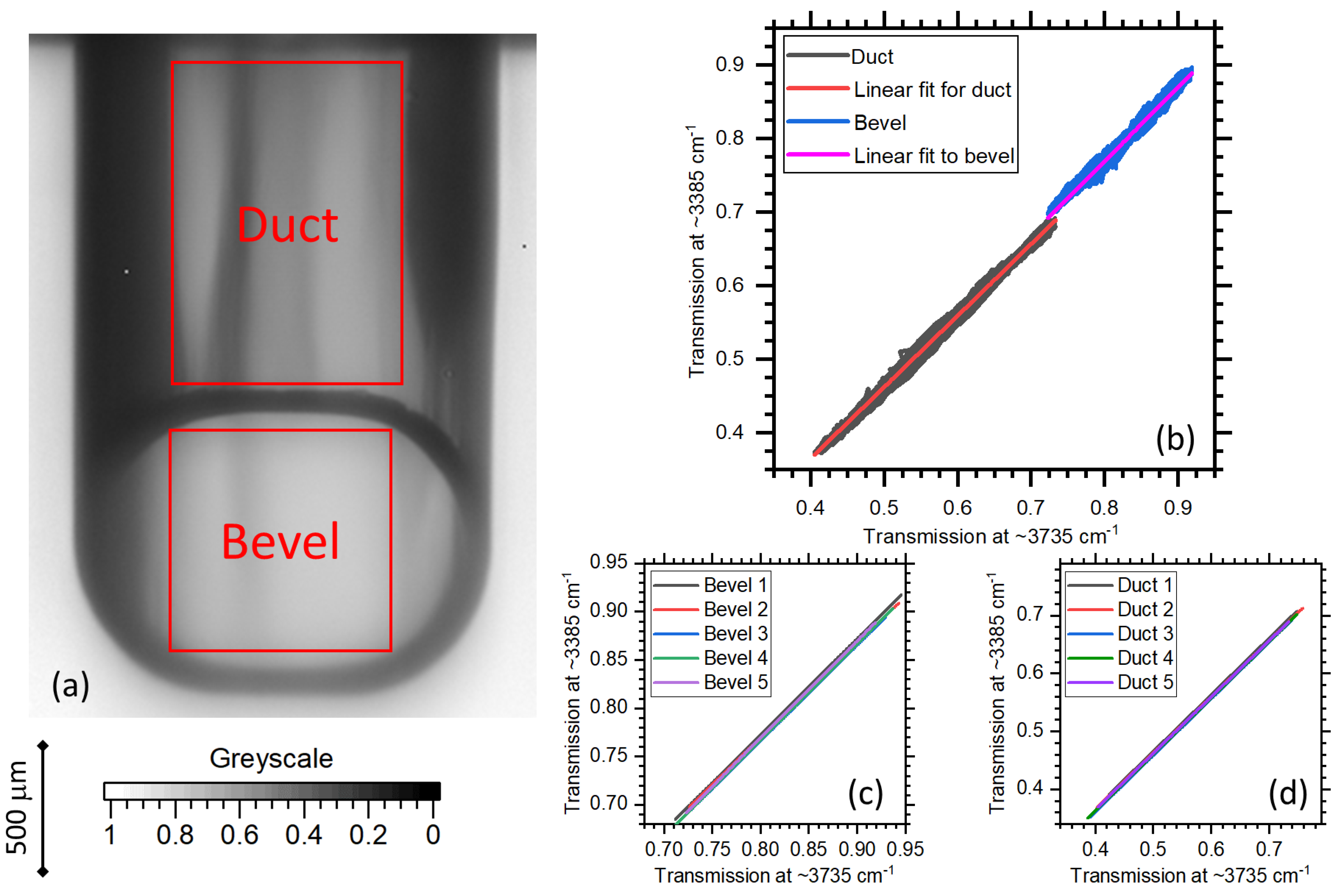

A machine vision Python 2.7 algorithm, employing the OpenCV package [

22], is used to identify nozzle boundaries in ≈3385 cm

and ≈3735 cm

transmission images, such as

Figure 4a, in order to extract duct and bevel components. The OpenCV

canny edge detection function is applied to the U16 greyscale ≈3735 cm

transmission images to find the outlines of the nozzle. The subsequent application of

findContours function provides an array of contours which form the outline. The algorithm calls the

drawContours function to draw the contours on the U16 greyscale image with a 3-pixel-wide line. Subsequently, the algorithm finds coordinates for the borders by doing a horizontal and vertical scan of the image. From border coordinates, it calculates the centers of the nozzle’s bevel and duct. The size of the areas of interest are determined during calibration and the algorithm forms a rectangular crop based on the calculated centers and the width and height provided as input parameters. The parameters determined using ≈3735 cm

transmission image are subsequently used to crop the ≈3385 cm

transmission image. The full version of the code can be found in the

Supplementary Material, along with sample ≈3735 cm

transmission images,

Figure S1, of before and after cropping, and of contour outlines. A custom 3D printed mounting device was crucial to ensure the nozzle edges were perpendicular and alignment within <50

m was reproducible.

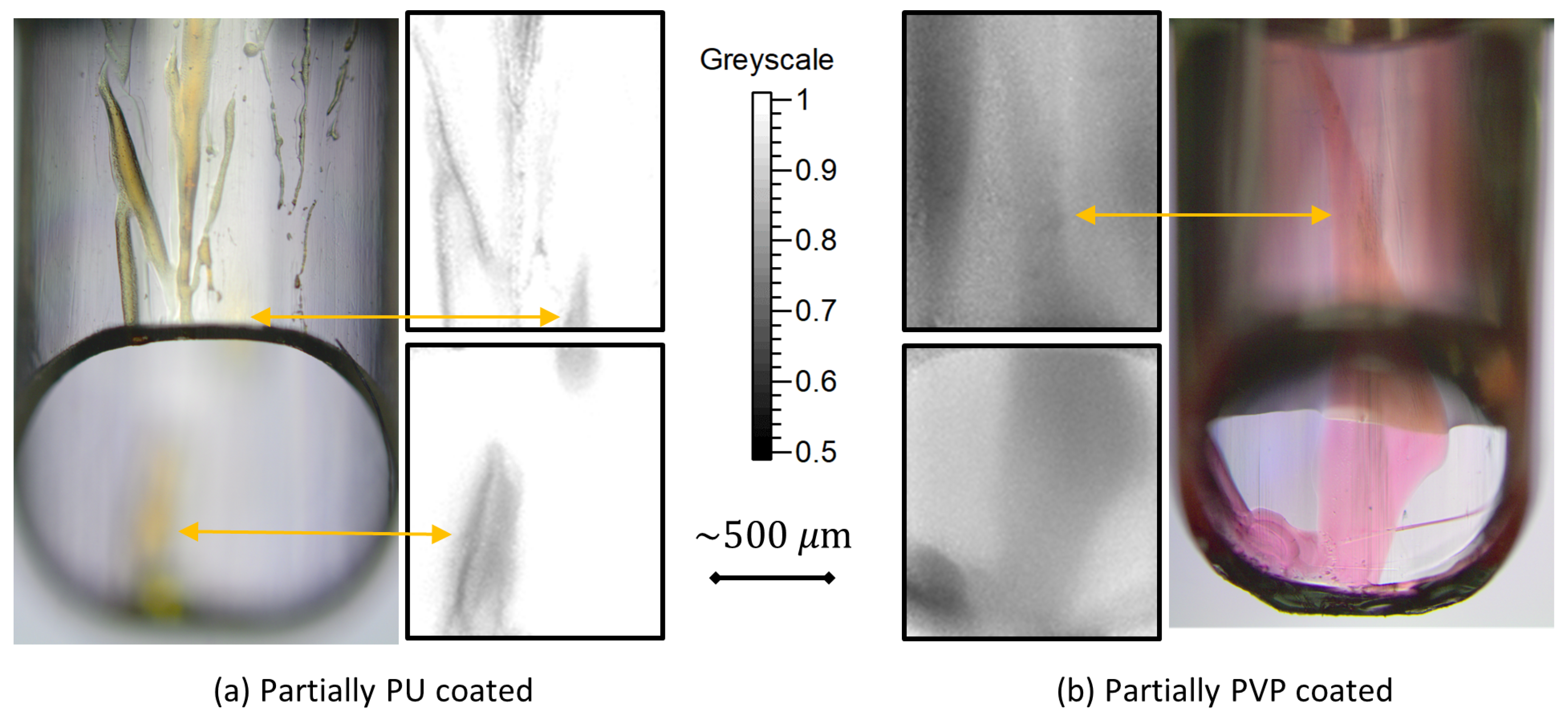

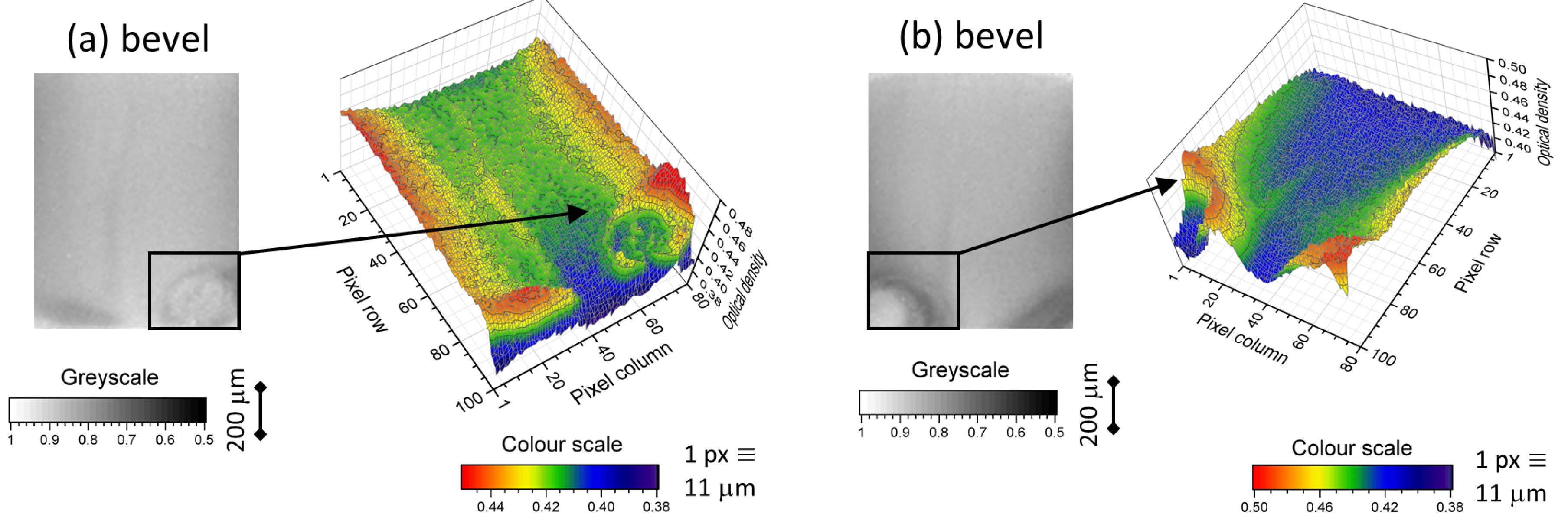

Figure 5a shows images from a nozzle partially coated with PU. The greyscale image shows coating transmission measured using the IR transmission microscope. After measurement, a Cresol dye solution was used to test for the presence of PU [

23] and a visible image of the dyed nozzle is also shown. Patterns in coating identified using the dye stain are matched in the transmission greyscale images. The dye stain images were recorded using a

magnification and a DOF less than the width of the nozzle. Consequently, the sample position must be adjusted to identify patterns on opposing wall surfaces. For the IR image, in contrast, patterns on both inner walls of the major axis of the duct and on the surface of the bevel can be measured with the single sample position.

Figure 5b contains images from a nozzle partially coated with PVP. The nozzle was coated with PU beforehand using a standard industrial process. Similar to

Figure 5a, an IR transmission image of coating was measured first, followed by a dye stain analysis. A Congo red solution was employed to identify the presence of PVP [

24]. The presence of coating is seen throughout the IR greyscale images, due to the presence of the PU base coating. The pattern in PVP coating can be identified by gradients in the reduction of transmission, which is relatively constant for purely PU coated industrial samples. These patterns are matching with patterns observed in the dye stain image.

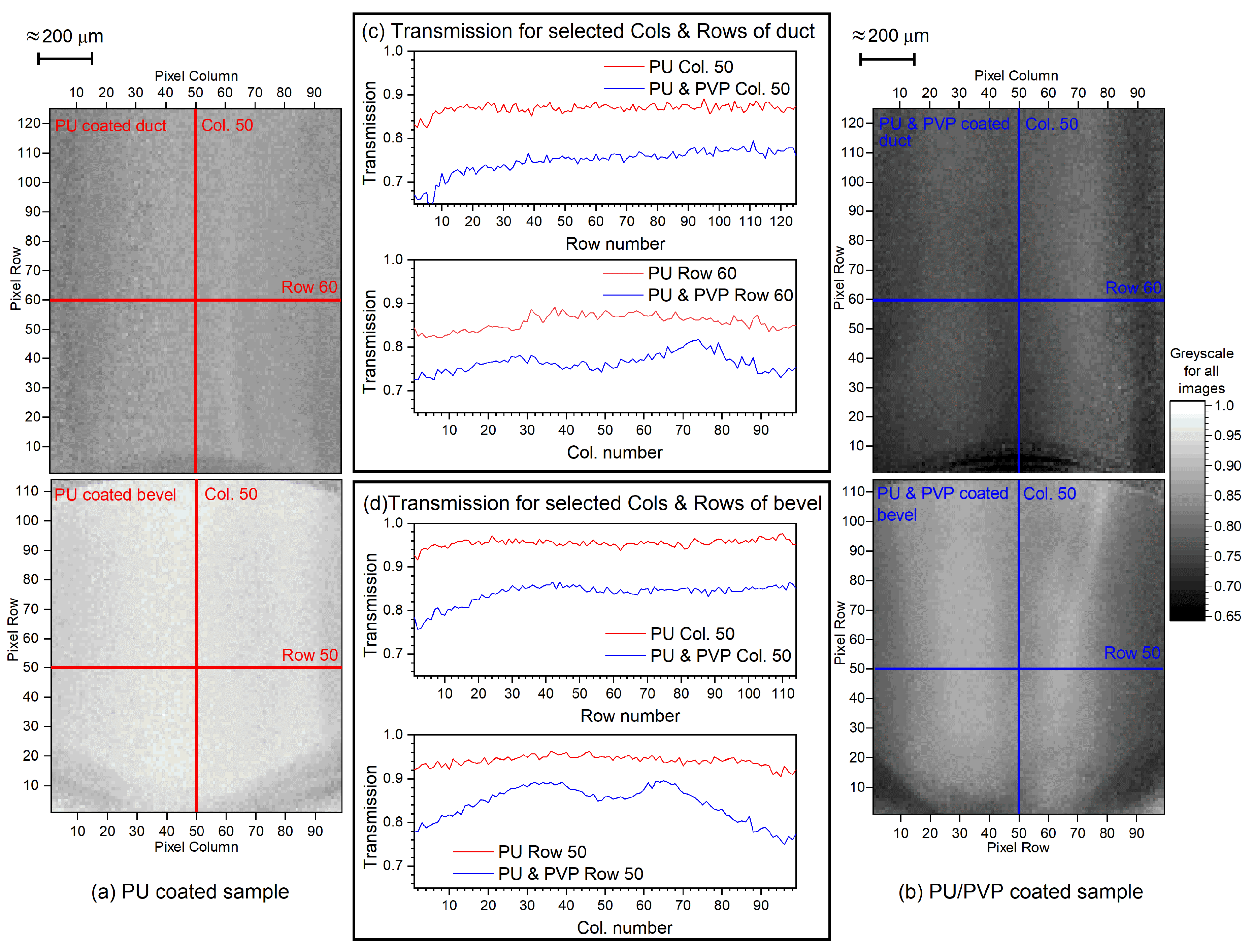

Figure 6a shows PU samples and

Figure 6b shows PU/PVP samples where coating was applied using standard industrial processes. Coating coverage has several treatment parameters, including pre-plasma treatment, PU and PVP quantities, dispersion mechanism and curing. Comparisons between coating properties measured using IR transmission and other techniques, SEM and dye stain, are the focus of the present work and no discussion of coating treatment performance will be made.

Figure 6c,d contains plots of coating transmission as a function of pixel number along selected columns and rows, in approximately the center of the axes. For purely PU-coated samples, the transmission for selected columns/rows are relatively consistent, varying by only 3–4%. The only exception being approaching the rims of the bevel and duct, where decreases in transmission occur, see col. 50 coating transmission plots for duct and bevel. There were no resolvable differences in coating thickness on SEM measurements of solely PU-coated samples. Thickness of <1

m was found [

19].

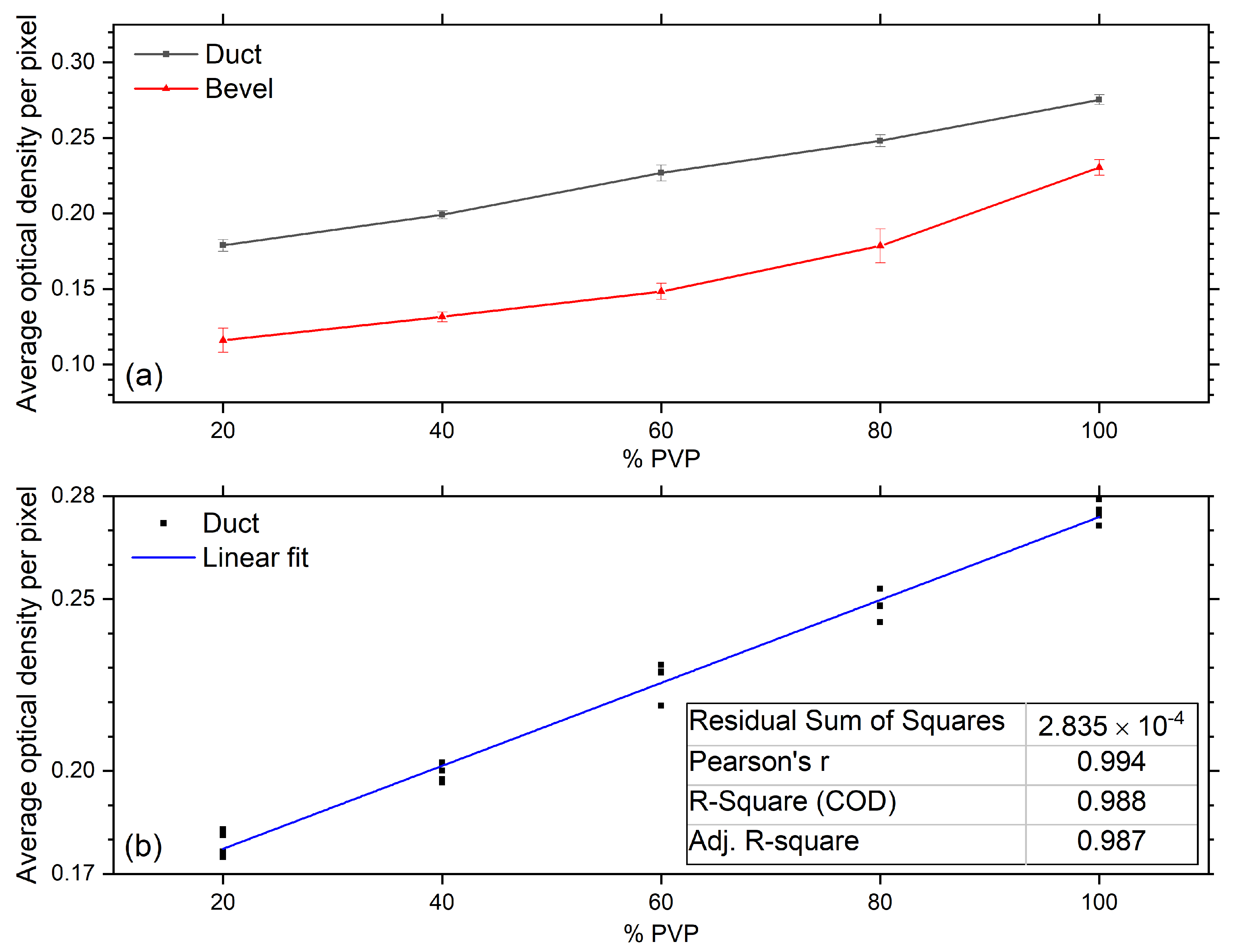

Reduction in transmission from PU- to PU/PVP-coated samples was observed as expected. Compared to solely PU-coated nozzles, general features in PU/PVP coating were seen. A gradual decrease in transmission along the delivery axis towards the bevel was observed in the duct and, similar to the PU-coated samples, a further increase in coating thickness was seen towards the rim; see col. 50 coating transmission plot for duct. An increase in coating thickness along the delivery axis was also seen from SEM imaging. Slight patterns were seen perpendicular to the delivery axis on the duct, as well as transmission decreases towards both sides, and, at the centre, a shallow hollow in the coating exists; see row 60 coating transmission plot for duct. The increase in thickness towards the edges was confirmed by SEM images, where coating along the centre of the major axis is typically <2 m and on the centre of the minor axis is >4 m. The shallow hollow in coating was not observed from SEM imaging or in dye stain testing. This is not surprising for dye stain testing, as only the presence of coating can be measured. For SEM imaging, the nozzle must be sliced. Cutting the nozzle along the delivery axis is relatively smooth and the risk of damage to the coating is slight. Cutting perpendicular to the axis is more difficult and damage to the coating is more likely. Consequently, the slight hollows observed in the IR images would be hard to reproduce using SEM.

The bevel showed more pronounced patterns than the duct for PU/PVP-coated samples. The patterns were similar as a function of position to the duct, with increased coating towards the rim of the bevel along the delivery axis, as well as increased coating towards both edges perpendicular to the delivery axis. The increase in coating thickness along the delivery axis matched SEM imaging, where coating up to ≈5 m can be measured at the outer rim. The hollow at the centre of the major axis is more pronounced on the bevel.

SEM imaging of the surface morphology of industry standard coated samples identified area roughness at sizes below ≈50

m, our determined resolution, down to features encompassing a few micron. Estimating the associated profile roughness of coated samples with SEM imaging is difficult, as the sample must be cut to observe a cross-section. Random cross-sections of coated nozzles revealed continual fluctuations of coating thickness of up to ≈0.2

m on cross-section lengths of ≈50–60

m; see

Figure S2 of the Supplementary Material. Fluctuations in coverage on this scale are not identifiable with the present configuration of the IR transmission microscope, as the smallest possible defect size detectable is ≈50

m. The smoothing of local defects, below the microscope resolution, is used to estimate a ≈0.01 noise level in transmission. Quantum statistics could not be used to determine noise in transmission, as the microbolometer camera does not measure light intensity directly, but a change in temperature. Instead, noise in transmission was estimated using areas where a low change in transmission, ≤0.2, is viewed over surface cross sections of >200

m, and fitting a low-order polynomial. The noise was then estimated from the residuals of the fit.

While other techniques, such as SEM imaging, optical profilometery, and Raman/fluorescence microscopy, can offer higher resolution coverage measurements, their limitations on quantifying coverage depth, added to their time constraints, make them inapplicable for bulk sample appraisals in an industrial setting. The industry standard dye stain technique, which the presented technique targeted for replacement, employs visible microscopes to manually scrutinize dyed samples. Using a standard laboratory microscope, a technician can identify defects down to a ≈5

m size. The higher resolution is compromised by the narrow DOF, compared to the presented IR transmission microscope, which increases the time required to scrutinise samples. We demonstrate for the ≈2 mm sized delivery device presented that the lower ≈50

m resolution is not needed to create a test equivalent to the dye stain test, which has superior resolution (see

Section 4.1). In some applications, minimum allowed size defects may not be established. More crucial is the relative thickness of the coating, above or below the optimum, which cannot be easily identified using dye staining testing and can be easily identified with the IR transmission microscope.

5. Conclusions and Outlook

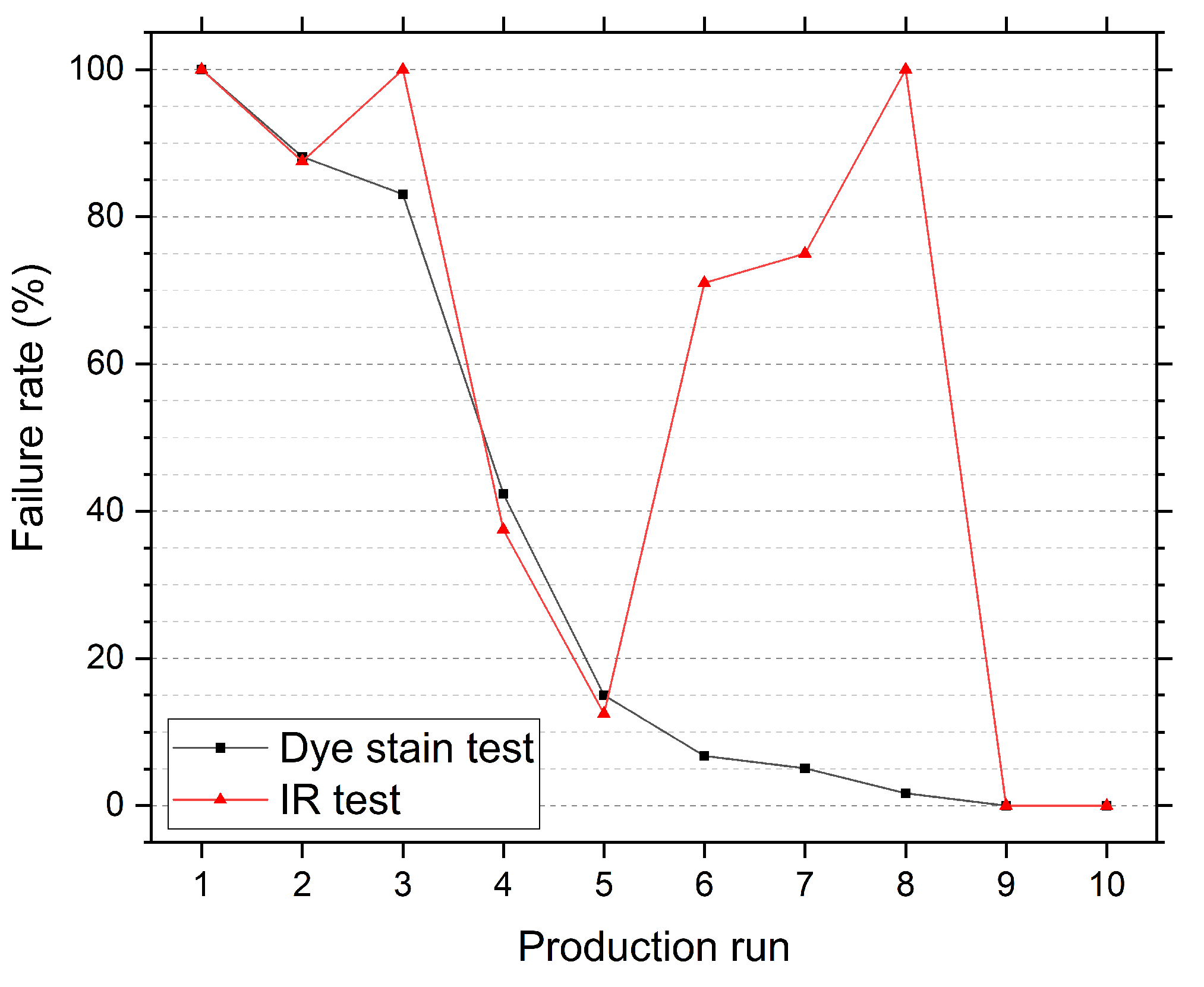

We measured the coverage of common thin film coating products, PVP and PU, on 200 m thick walls of a PP-based delivery device. The device has a common configuration, composing of an elliptical duct and bevel. The transparency of PP at ≈3385 cm enables the study of PU/PVP coverage on concealed surfaces inside the tube, and a long DOF enables the imaging of opposing inner surfaces on a single camera array, along with the surface of the bevel. Coating thickness of <1 m was observed and ≈50 m sized defects on the inner surfaces of the duct and on the bevel were identified. An IR transmission microscope set-up, which is automated to measure eight nozzles in ≈3 min, was constructed to measure coating coverage. The set-up offers a significant improvement in temporal resolution compared to the greater than ≈20 min needed for dye stain testing of a similar sized sample.

A test was developed to replace the standard industrial dye stain technique for identifying deficient coating. Inferior coating processes were used to produce consignments of samples with dye stain fail rates between 5% and 100%. These consignments were mixed with consignments containing zero dye stain fails. The IR transmission test was able to identify all consignments which produced failed samples and passed all the consignments of adequately coated samples. The two testing techniques had at times large discrepancies in the fail rate, with the IR test generally being higher. As dye stain testing is subjective, matching fail rates is difficult. A quantitative technique for measuring water dilution of the coating solution was also demonstrated and use of machine vision to identify machine malfunction was proposed.

Future work includes moving to the ≈1700 cm region, where the PU cross-linker and PVP lubricant can be identified separately. Identification of separate absorption features also opens the prospect of measuring absolute coating thickness on the bevel. However, moving into the ≈1700 cm region may require a cooled detector and/or a laser source, greatly increasing the cost of the set-up. Up-scaling the present set-up to efficiently measure coating coverage on increased quantities of nozzles, ≈10,000 per day, will be investigated and could enable movement away from random lot assurance sampling to entire product testing. Further adaption of the set-up can be made to measure coverage of other lubricants, such as PEG, PHM, and PSIT, as well as other bulk materials, such as PE and PC.