Vehicular Sensor Network and Data Analytics for a Health and Usage Management System

Abstract

:1. Introduction

1.1. Scope and Structure of the Article

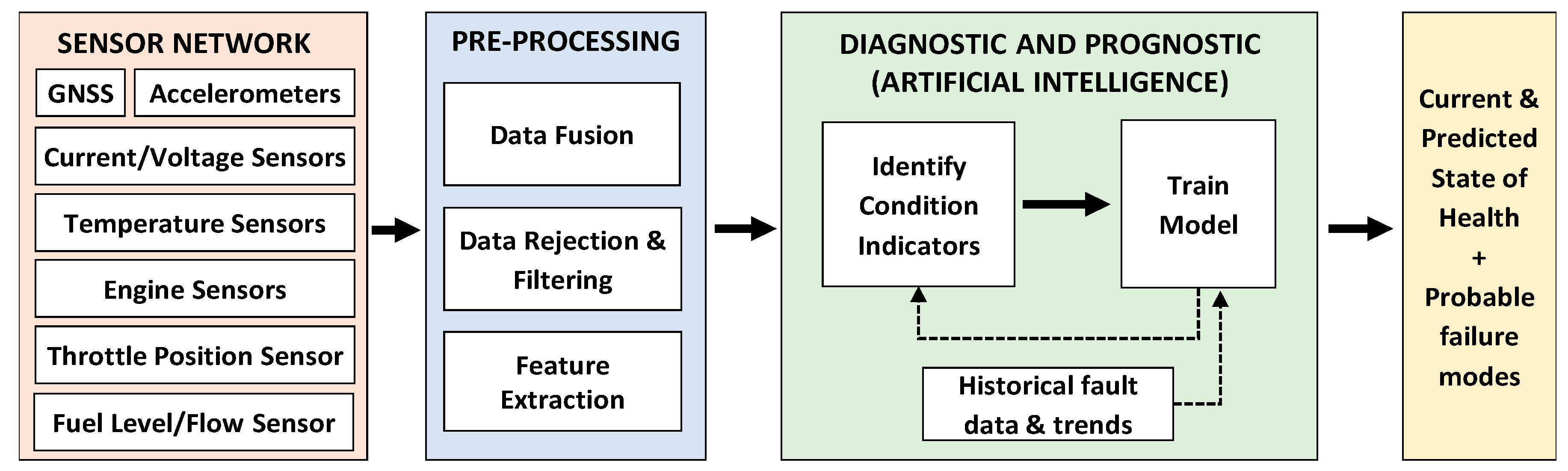

1.2. HUMS Concept

1.3. Role of Artificial Intelligence Techniques in Intelligent HUMS

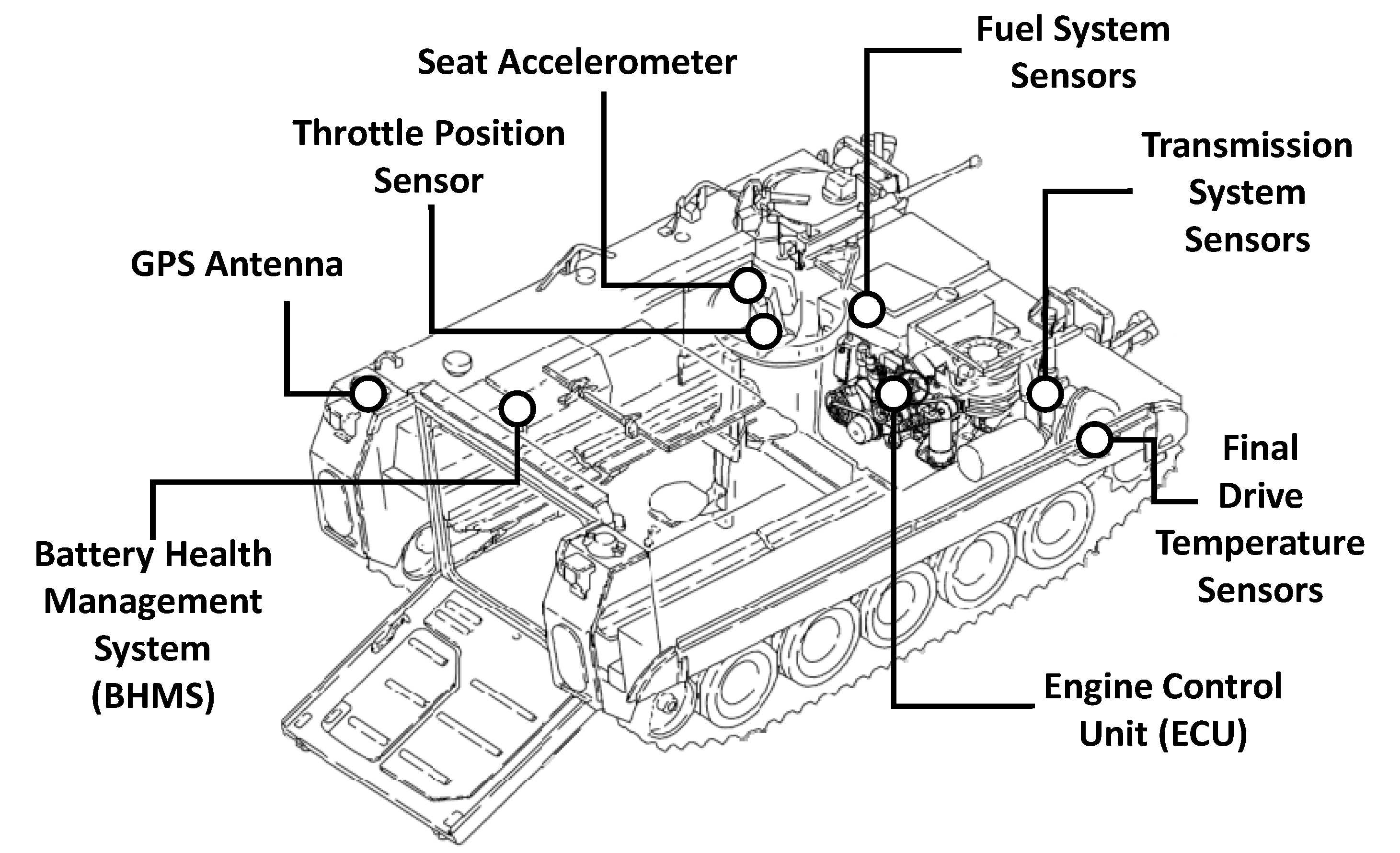

2. APC Sensor Network

3. Methodology

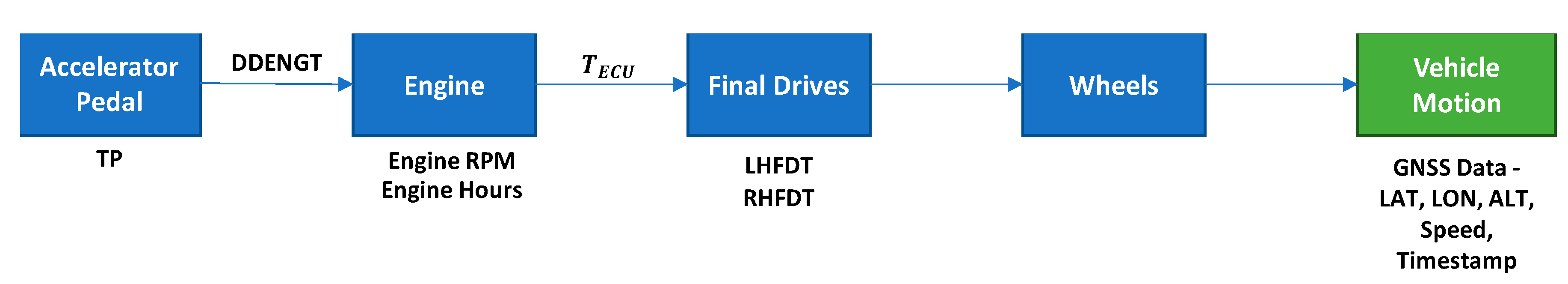

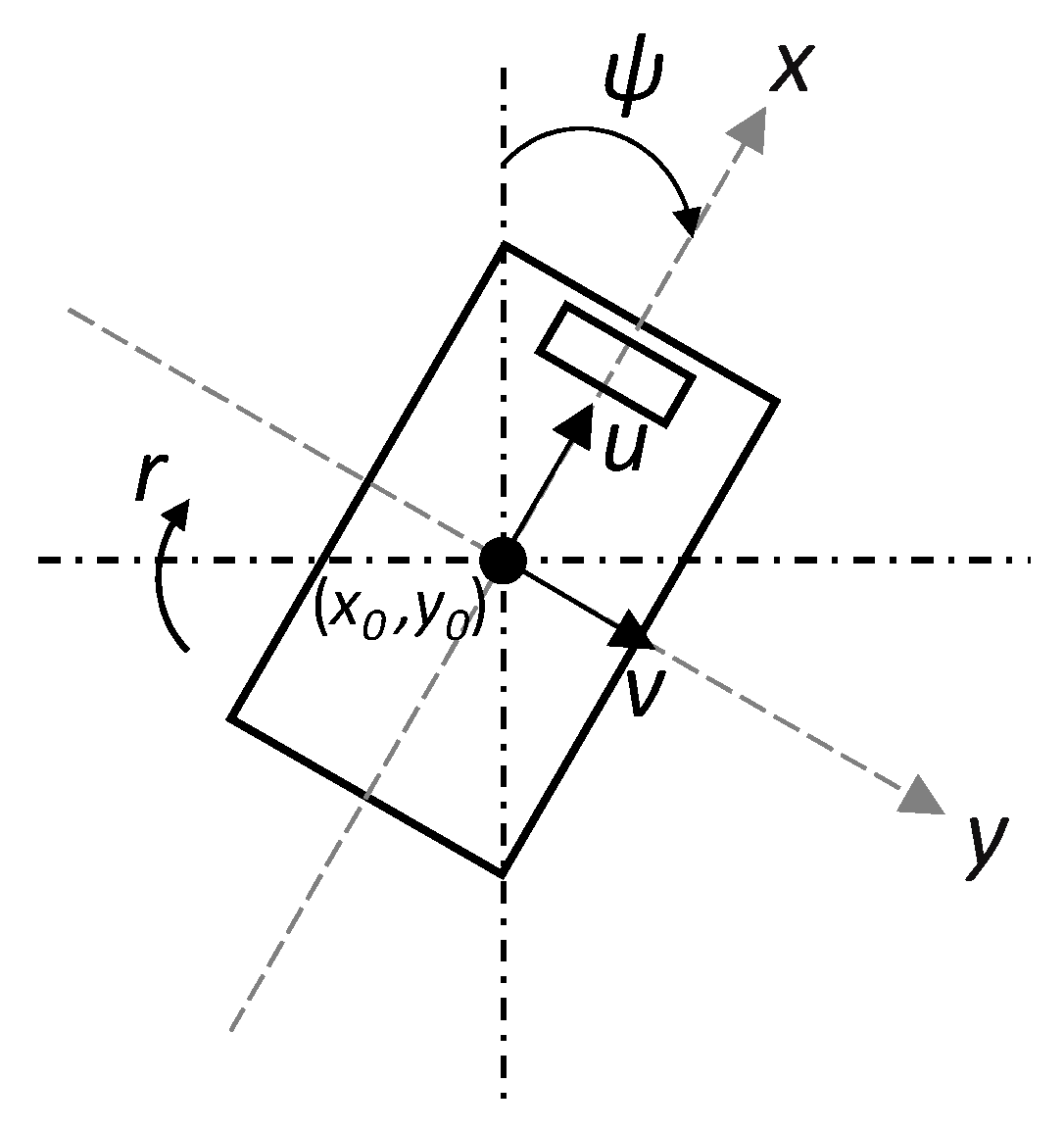

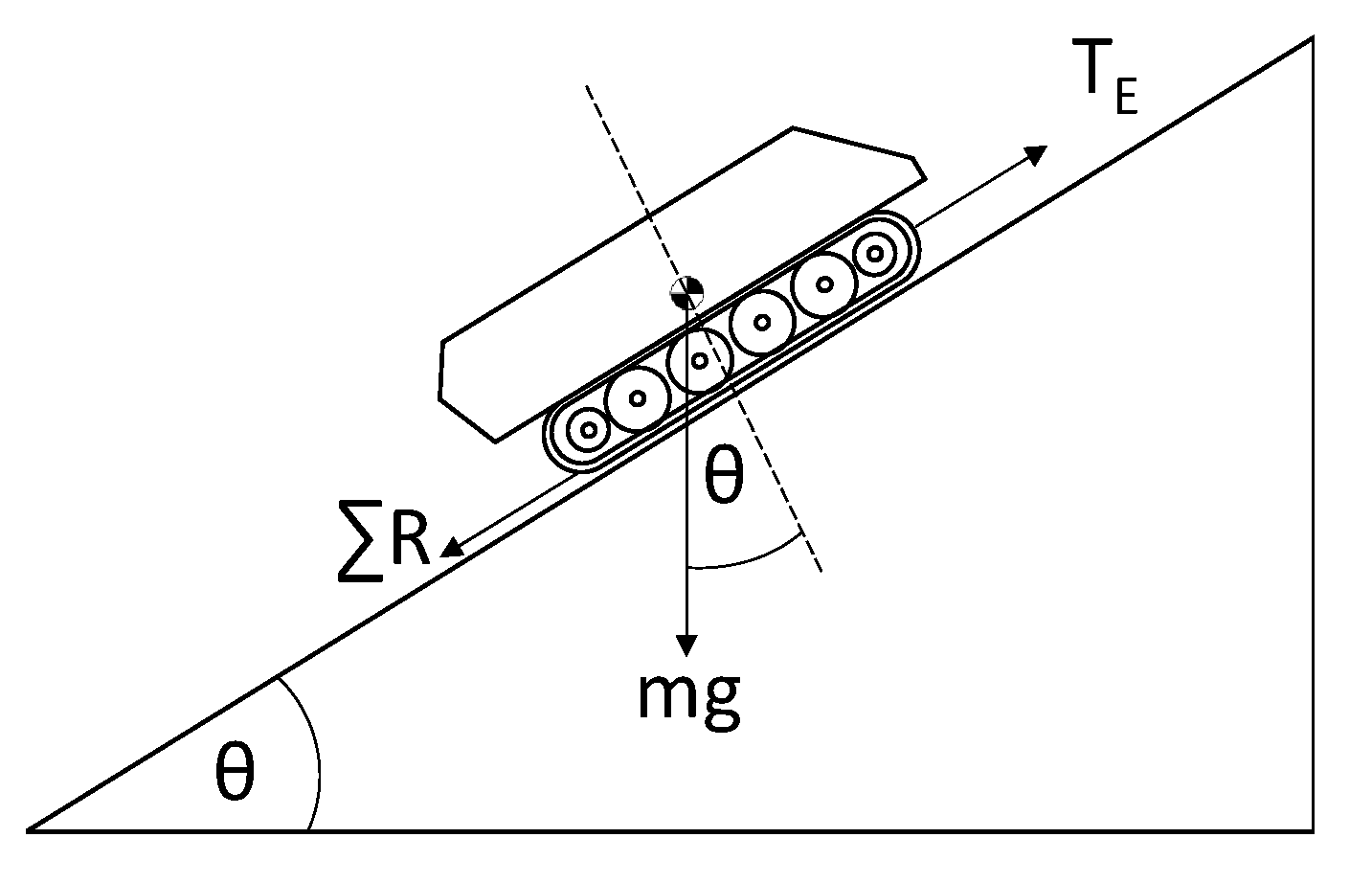

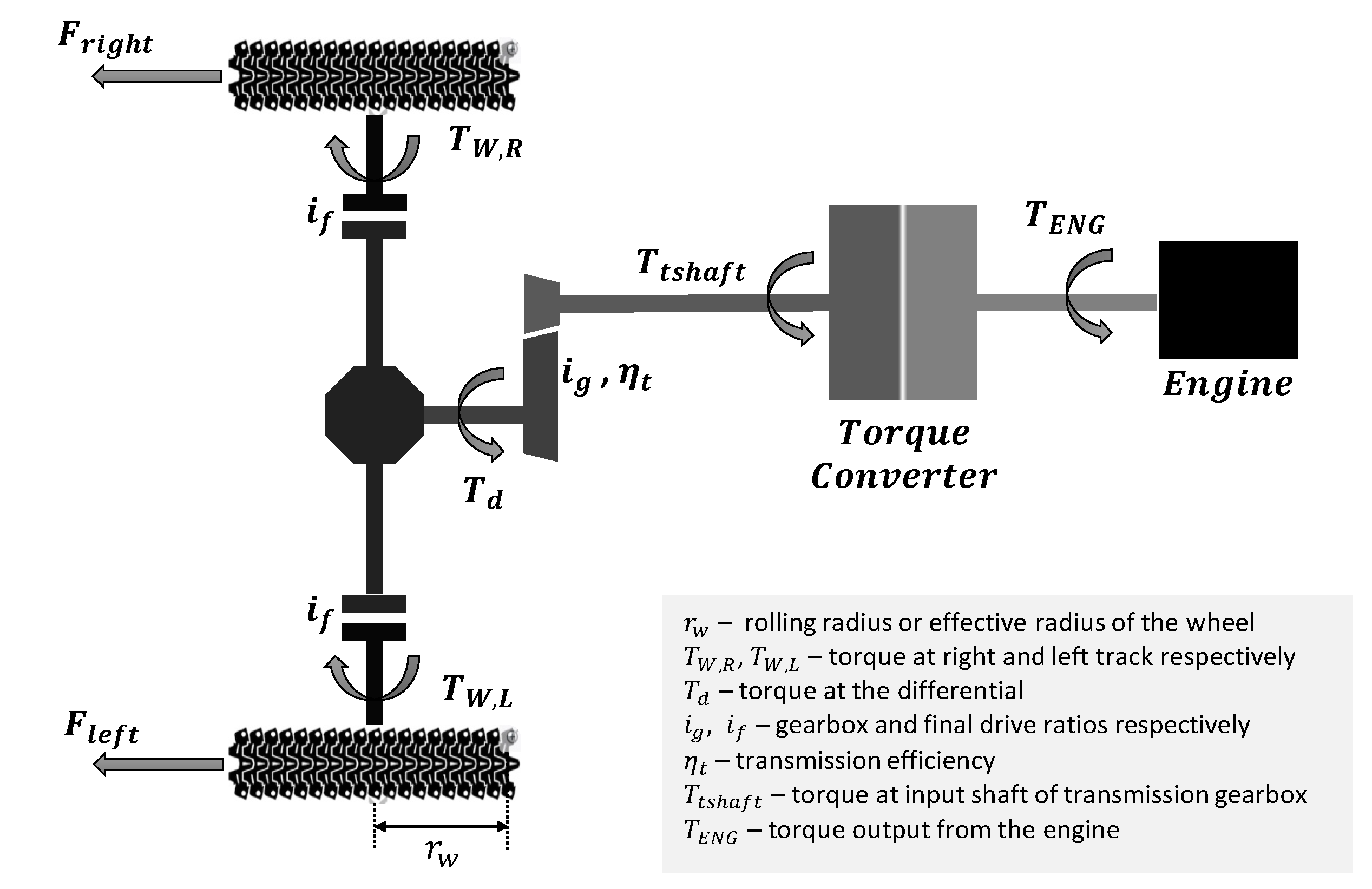

3.1. Virtual Dynamometer

- , —position of vehicle centre of mass in the road (inertial) axes.

- —yaw angle (between longitudinal axis and north)., —velocity in the longitudinal and lateral body axes, respectively.

- —yaw rate.

- , —mass and inertia of the vehicle, respectively.

- —longitudinal acceleration (obtained from GNSS data).

- , —tractive effort produced by right and left tracks, respectively.

- , —gravitational and resistance forces (comprised of aerodynamic resistance and rolling resistance ).

- —perpendicular distance between tracks and centre of moment

3.1.1. Resistances

3.1.2. Gravitational Force Component

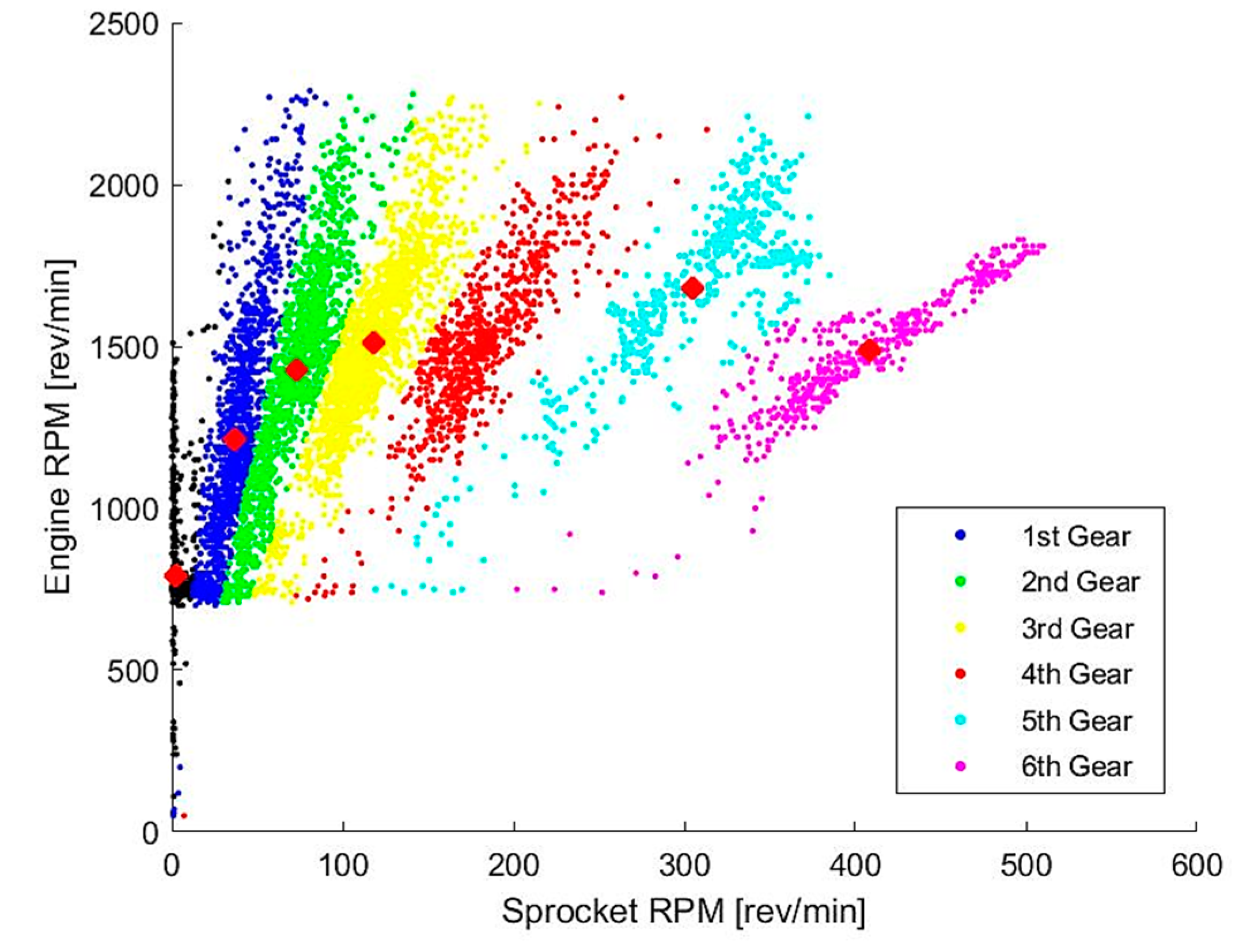

3.1.3. Gear Setting Identification

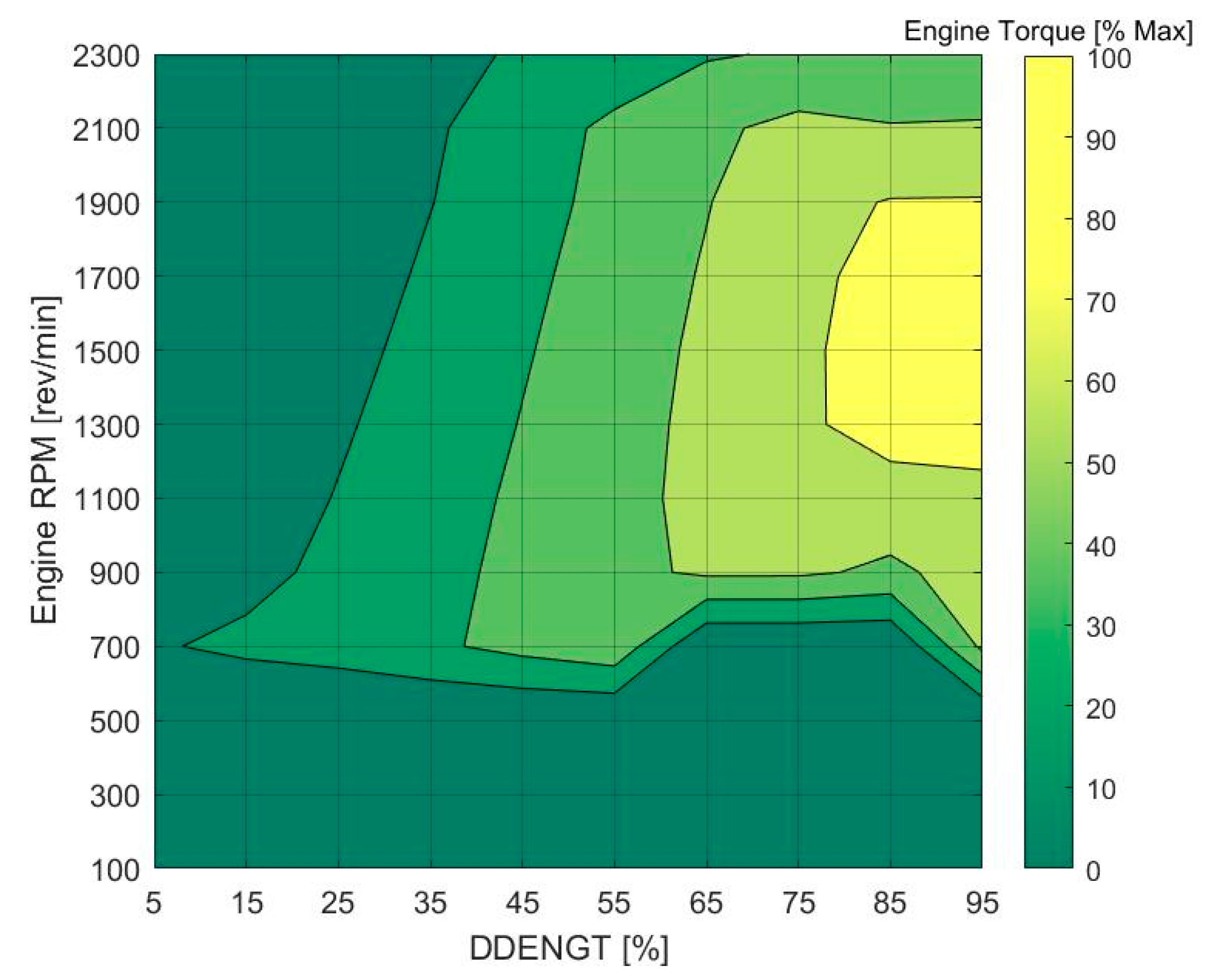

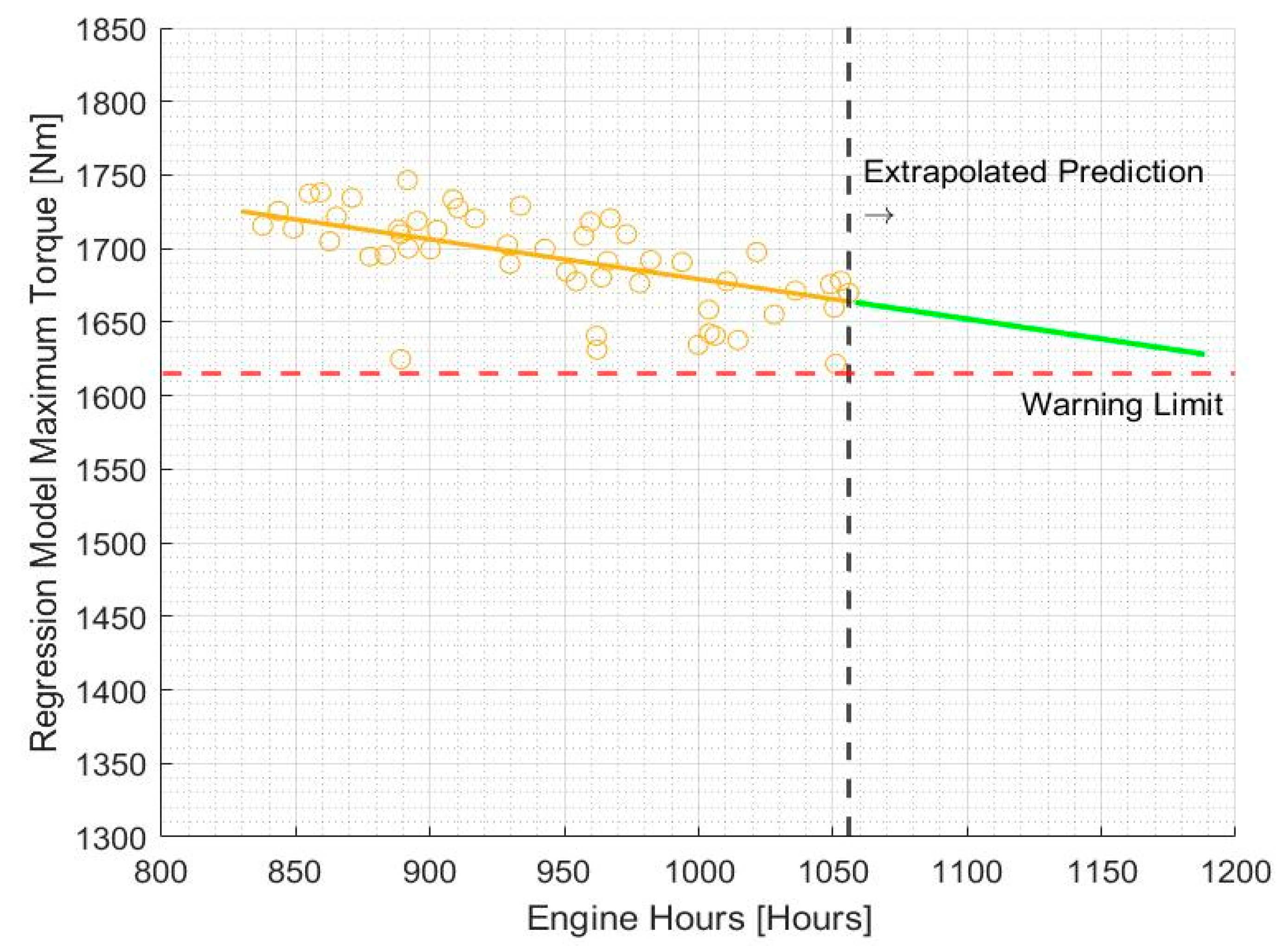

3.2. Maximum Torque Degradation of Engine

- % time with throttle > 70%—extended periods of time with high driver demand engine torque in a single operation puts more strain on the engine;

- Engine oil temperature—lower engine oil temperature leads to higher viscosity and the engine running less efficiently;

- Engine coolant temperature—inefficient cooling will affect engine performance;

- Ambient temperature—internal combustion engines develop more power in cold conditions (along with high barometric pressure) when the charge air density is high.

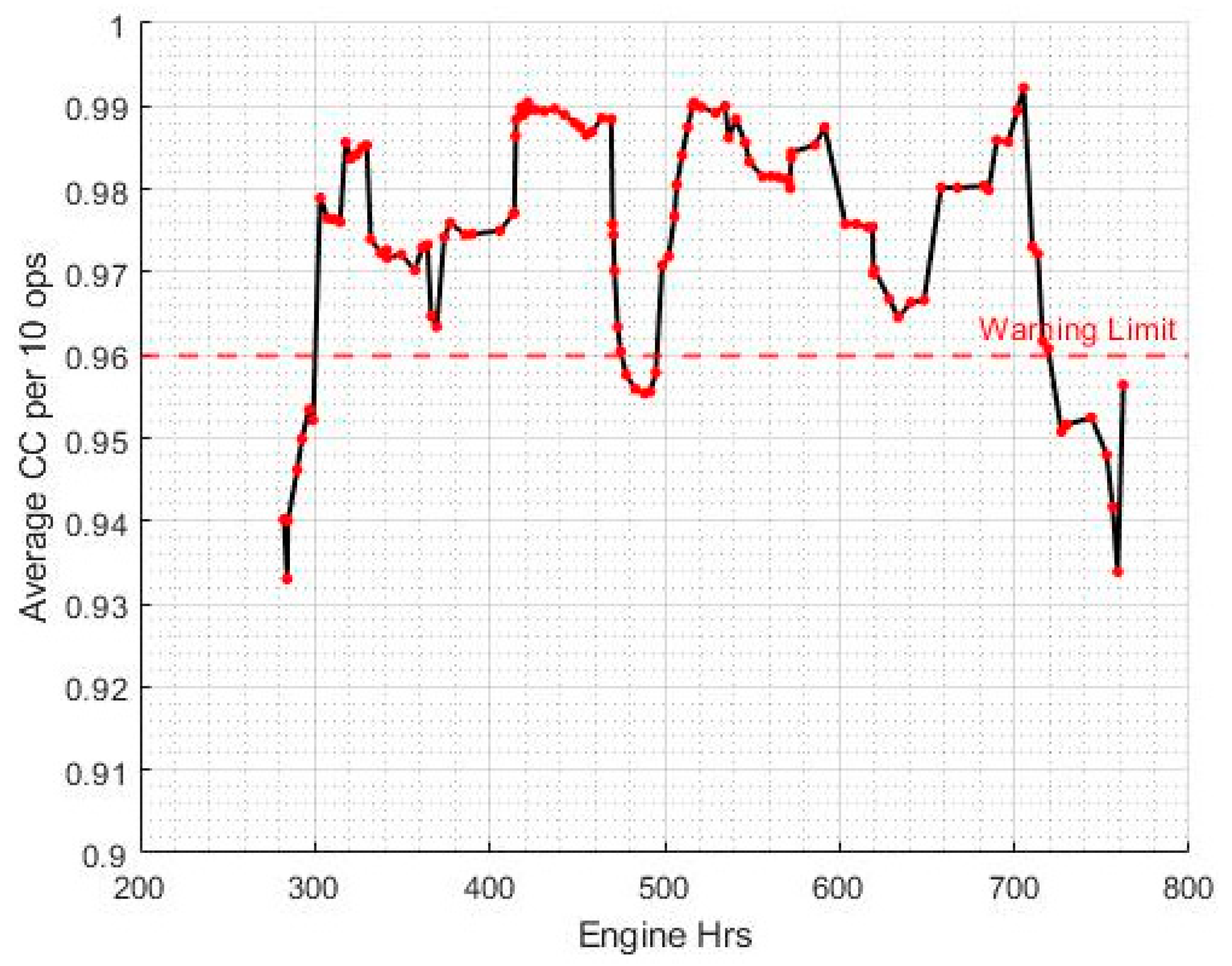

3.3. Degradation of Final Drives

4. Results, Data Analysis, and Discussion

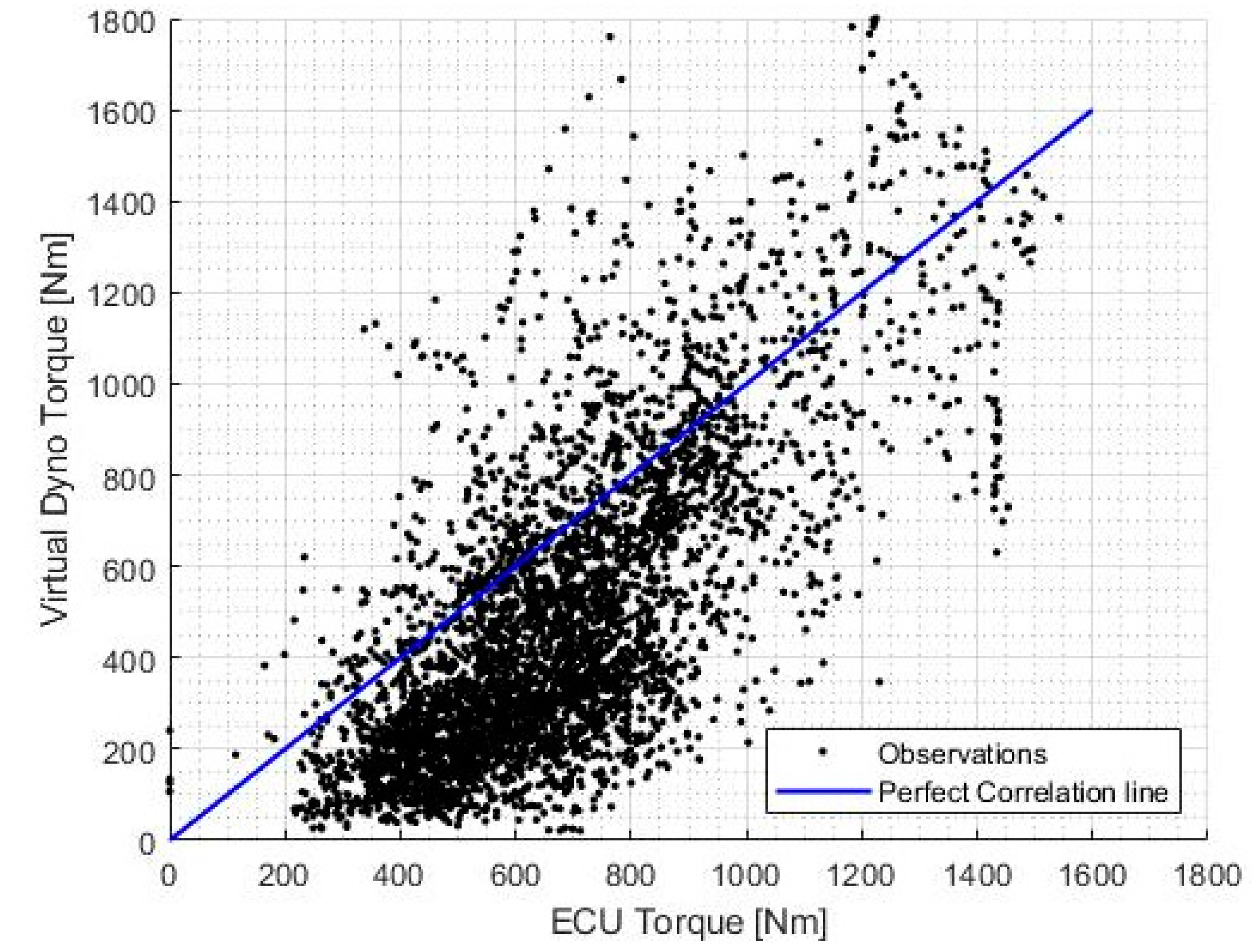

4.1. Virtual Dynamometer

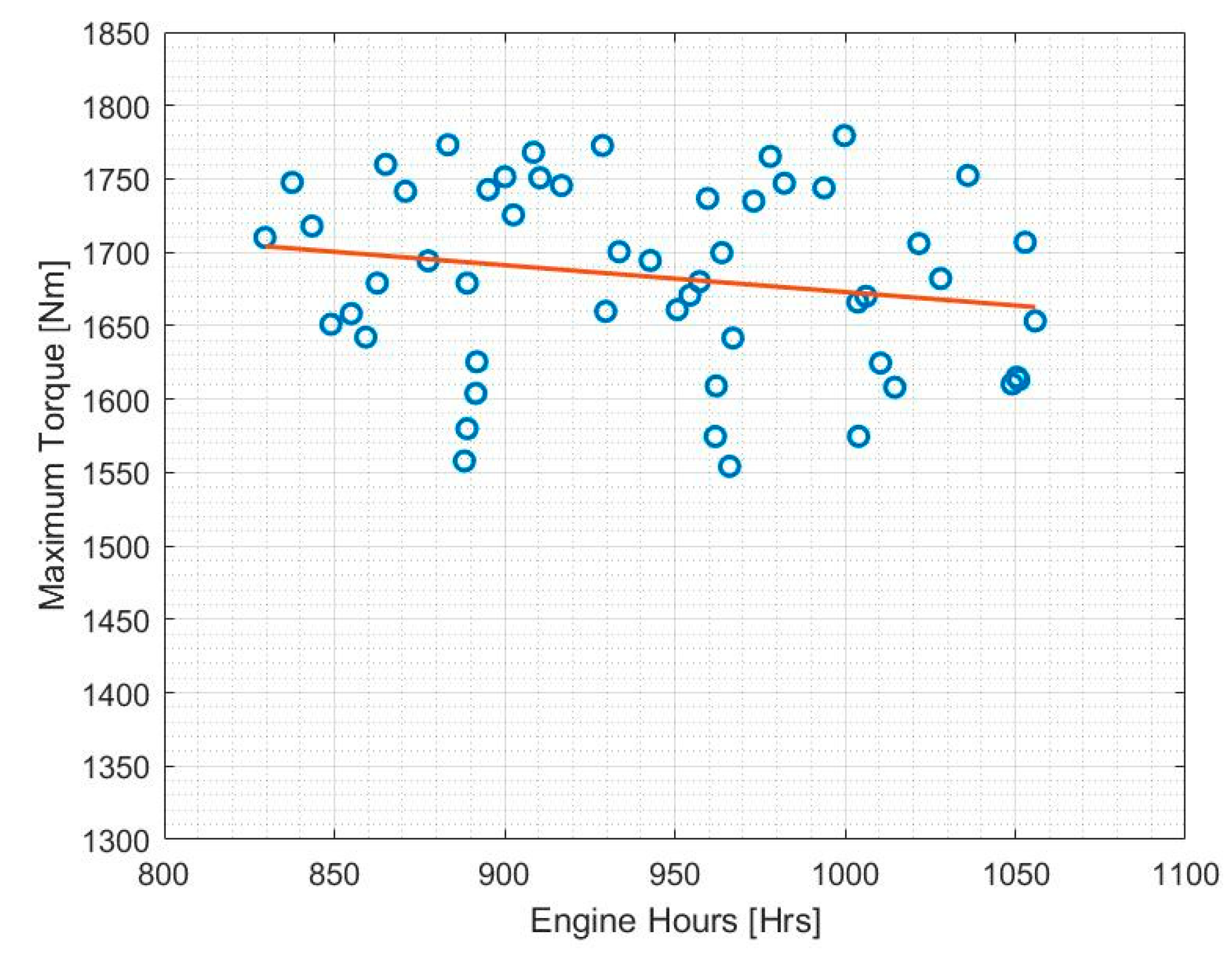

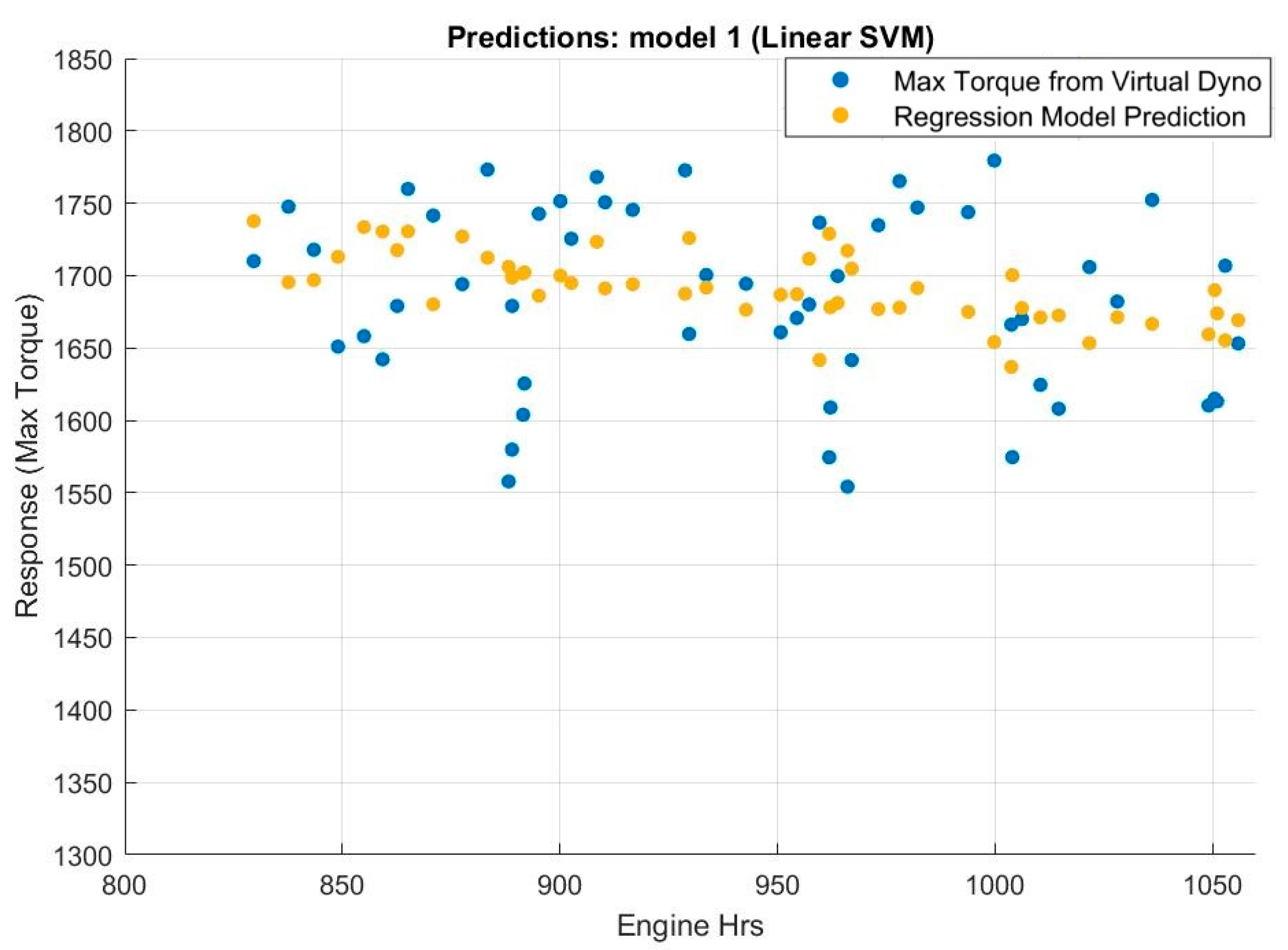

4.2. Maximum Torque Degradation of Engine

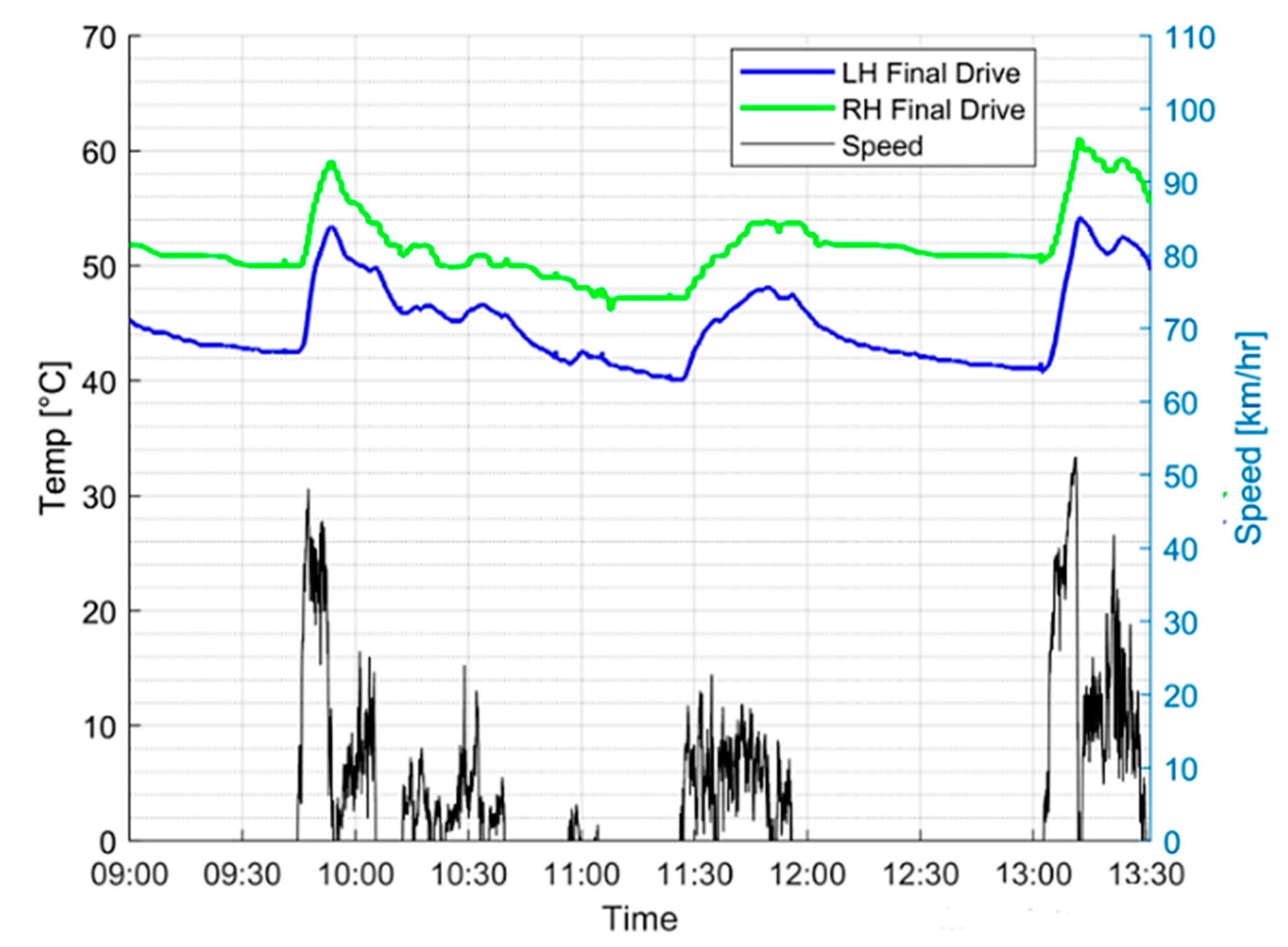

4.3. Degradation of Final Drives

5. Conclusions

- a virtual dynamometer, which acts as a model-based virtual sensor that fuses multiple sensor measurements to calculate the output torque of the engine based on the motion of the vehicle.

- an engine performance degradation model based on regression analysis of the maximum torque output over time.

- a health assessment of the final drives based on the difference between temperature variation of the left- and right-hand final drives.

Author Contributions

Funding

Conflicts of Interest

References

- Jardine, A.K.S.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Benedettini, O.; Baines, T.S.; Lightfoot, H.W.; Greenough, R.M. State-of-the-art in integrated vehicle health management. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2008, 223, 157–170. [Google Scholar] [CrossRef] [Green Version]

- Song, Y.; Li, B.; Ye, H.; Cao, Y. Application of prognostics and health management in armored equipment maintenance based on afmea. Energy Procedia 2011, 11, 1510–1516. [Google Scholar]

- Redding, L.; Jennions, I.K. An introduction to integrated vehicle health management—A perspective from the literature. In Integrated Vehicle Health Management: Perspectives on an Emerging Field; SAE International: Warrendale, PA, USA, 2011; pp. 17–26. [Google Scholar]

- Turo, T.; Neumann, V.; Krobot, Z. Health and usage monitoring system assestment. In Proceedings of the 2019 International Conference on Military Technologies (ICMT), Brno, Czech Republic, 30–31 May 2019; pp. 1–4. [Google Scholar]

- Hess, A.; Calvello, G.; Dabney, T. Phm a key enabler for the jsf autonomic logistics support concept. In Proceedings of the 2004 IEEE Aerospace Conference Proceedings (IEEE Cat. No. 04TH8720), Big Sky, MT, USA, 6–13 March 2004; Volume 3546, pp. 3543–3550. [Google Scholar]

- Tiddens, W.; Braaksma, J.; Tinga, T. Exploring predictive maintenance applications in industry. J. Qual. Maint. Eng. 2020. [Google Scholar] [CrossRef]

- Elattar, H.M.; Elminir, H.K.; Riad, A.M. Prognostics: A literature review. Complex Intell. Syst. 2016, 2, 125–154. [Google Scholar] [CrossRef] [Green Version]

- Bernardo, J.T.; Reichard, K.M. Trends in research techniques of prognostics for gas turbines and diesel engines. In Proceedings of the 2017 Annual Conference of the Prognostics and Health Management Society, St. Petersburg, FL, USA, 2–5 October 2017; pp. 2–5. [Google Scholar]

- Kulkarni, C.; Corbetta, M. Health management and prognostics for electric aircraft powertrain. In Proceedings of the 2019 AIAA/IEEE Electric Aircraft Technologies Symposium (EATS), Indianapolis, IN, USA, 22–24 August 2019; pp. 1–13. [Google Scholar]

- Zhao, W.; Siegel, D.; Lee, J.; Su, L. An integrated framework of drivetrain degradation assessment and fault localization for offshore wind turbines. Int. J. Progn. Health Manag. 2013, 4, 46. [Google Scholar]

- Xiong, Y.; Zhong, Z.; Sun, Z. An online fault diagnosis method based on object oriented modeling for fcv power train system. In Proceedings of the IEEE Vehicle Power Propulsion Conference, Harbin, China, 3–5 September 2008; pp. 1–6. [Google Scholar]

- Dong, X.; Dong, H.; Yi, X.; Hou, P.; Ren, C.; Tao, Y. Sensors for prognostic and health management of armored vehicles. In Proceedings of the 2019 Prognostics and System Health Management Conference), Paris, France, 2–5 May 2019; pp. 57–63. [Google Scholar]

- Ezhilarasu, C.M.; Skaf, Z.; Jennions, I.K. The application of reasoning to aerospace integrated vehicle health management (IVHM): Challenges and opportunities. Prog. Aerosp. Sci. 2019, 105, 60–73. [Google Scholar] [CrossRef]

- Pecht, M.G.; Kang, M. Machine learning: Diagnostics and Prognostics. In Prognostics and Health Management of Electronics: Fundamentals, Machine Learning, and the Internet of Things; Wiley-IEEE Press: Piscataway, NJ, USA, 2019; pp. 163–191. [Google Scholar]

- Medjaher, K.; Zerhouni, N. Residual-based failure prognostic in dynamic systems. IFAC Proc. Vol. 2009, 42, 716–721. [Google Scholar] [CrossRef] [Green Version]

- Mba, D.; Reuben, L. Diagnostics and prognostics using switching kalman filters. Struct. Health Monit. 2014, 13, 296–306. [Google Scholar]

- Julier, S.J.; Uhlmann, J.K. Unscented filtering and nonlinear estimation. Proc. IEEE 2004, 92, 401–422. [Google Scholar] [CrossRef] [Green Version]

- Rozas, H.; Jaramillo, F.; Perez, A.; Jimenez, D.; Orchard, M.E.; Medjaher, K. A method for the reduction of the computational cost associated with the implementation of particle-filter-based failure prognostic algorithms. Mech. Syst. Signal Process. 2020, 135, 106421. [Google Scholar] [CrossRef]

- Coppe, A.; Haftka, R.T.; Kim, N.H. Uncertainty identification of damage growth parameters using nonlinear regression. AIAA J. 2011, 49, 2818–2821. [Google Scholar] [CrossRef]

- Zheng, B.; Huang, H.-Z.; Guo, W.; Li, Y.-F.; Mi, J. Fault diagnosis method based on supervised particle swarm optimization classification algorithm. Intell. Data Anal. 2018, 22, 191–210. [Google Scholar] [CrossRef]

- Samantaray, S.; Kamwa, I.; Joos, G. Decision tree based fault detection and classification in distance relaying. Int. J. Eng. Intell. Syst. Electr. Eng. Commun. 2011, 19, 139. [Google Scholar]

- Yu, W.; Kim, I.; Mechefske, C. Time series reconstruction using a bidirectional recurrent neural network based encoder-decoder scheme. In Proceedings of the AIAC18: 18th Australian International Aerospace Congress (2019): HUMS-11th Defence Science and Technology (DST) International Conference on Health and Usage Monitoring (HUMS 2019): ISSFD-27th International Symposium on Space Flight Dynamics (ISSFD), Melbourne, Australia, 24–26 February 2019; p. 876. [Google Scholar]

- Che, C.; Wang, H.; Fu, Q.; Ni, X. Combining multiple deep learning algorithms for prognostic and health management of aircraft. Aerosp. Sci. Technol. 2019, 94, 105423. [Google Scholar] [CrossRef]

- Widodo, A.; Yang, B.-S. Support vector machine in machine condition monitoring and fault diagnosis. Mech. Syst. Signal Process. 2007, 21, 2560–2574. [Google Scholar] [CrossRef]

- Tobon-Mejia, D.A.; Medjaher, K.; Zerhouni, N.; Tripot, G. Hidden markov models for failure diagnostic and prognostic. In Proceedings of the 2011 Prognostics and System Health Managment Conference, Shenzen, China, 24–25 May 2011; pp. 1–8. [Google Scholar]

- Lee, E. Using k-nearest-neighbours (knn) machine learning technique to classify archived helicopter wear debris data. In Proceedings of the AIAC18: 18th Australian International Aerospace Congress (2019): HUMS-11th Defence Science and Technology (DST) International Conference on Health and Usage Monitoring (HUMS 2019): ISSFD-27th International Symposium on Space Flight Dynamics (ISSFD), Melbourne, Australia, 24–26 February 2019; p. 816. [Google Scholar]

- Ezhilarasu, C.M.; Jennions, I.K. A system-level failure propagation detectability using anfis for an aircraft electrical power system. Appl. Sci. 2020, 10, 2854. [Google Scholar] [CrossRef] [Green Version]

- Bae Systems Demos Autonomous Armoured Vehicles for Australian Army. Army Technology. 2019. Available online: https://www.army-technology.com/news/bae-autonomous-armoured-vehicles/ (accessed on 18 September 2020).

- Road vehicles—Controller area network (can)—Part 1: Data link layer and physical signalling. In ISO 11898-1:2015; ISO: Geneva, Switzerland, 2015.

- Bray, M. Optimising land vehicle life cycle cost through health and usage monitoring systems. In Proceedings of the Ninth DSTO International Conference on Health and Usage Monitoring, Melbourne, Australia, 23–24 February 2015. [Google Scholar]

- Berntorp, K. Derivation of a Six Degrees-of-Freedom Ground-Vehicle Model for Automotive Applications; Lund University: Lund, Sweden, 2013. [Google Scholar] [CrossRef]

- Ingole, P.; Nichat, M.M.K. Landmark based shortest path detection by using dijkestra algorithm and haversine formula. Int. J. Eng. Res. Appl. 2013, 3, 162–165. [Google Scholar]

- Bezdek, J.C.; Ehrlich, R.; Full, W. Fcm: The fuzzy c-means clustering algorithm. Comput. Geosci. 1984, 10, 191–203. [Google Scholar] [CrossRef]

- Abdullah, N.; Shahruddin, N.; Mamat, R.; Bin Mamat, A.; Zulkifli, A. Effects of air intake pressure on the engine performance, fuel economy and exhaust emissions of a small gasoline engine. J. Mech. Eng. Sci. 2014, 6, 949–958. [Google Scholar] [CrossRef]

- Ting, L.L.; Mayer, J.E., Jr. Piston ring lubrication and cylinder bore wear analysis, part i—Theory. J. Lubr. Technol. 1974, 96, 305–313. [Google Scholar] [CrossRef]

- Greitzer, F.; Pawlowski, R. Embedded prognostics health monitoring. Int. Instrum. Symp. 2002, 48, 301–310. [Google Scholar]

- Montgomery, D.C.; Peck, E.A.; Vining, G.G. Introduction to Linear Regression Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2012; Volume 821. [Google Scholar]

- Wold, S.; Esbensen, K.; Geladi, P. Principal component analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Basak, D.; Pal, S.; Patranabis, D.C. Support vector regression. Neural Inf. Process. 2007, 11, 203–224. [Google Scholar]

- Gunn, S.R. Support vector machines for classification and regression. ISIS Tech. Rep. 1998, 14, 5–16. [Google Scholar]

- American Society for Testing and Materials. ASTM D7720-11(2017) Standard Guide for Statistically Evaluating Measurand Alarm Limits When Using Oil Analysis to Monitor Equipment and Oil for Fitness and Contamination; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

| Time Trends | Aggregated Analysis | |

|---|---|---|

| Reliability-based | Group A | - |

| Physics-model-based | Group B | Group C |

| Data-driven | Group D | Group E |

| Hybrid | Group F | |

| Subsystem | Sensor Variable | Range/Units | Measurement |

|---|---|---|---|

| Accelerator Pedal | Throttle Position (TP) | 0 to 100% | Ratio of actual position of accelerator pedal to maximum position |

| Engine | Driver demand Engine Torque (DDENGT) | 0 to 100% | Instantaneous engine torque demanded by driver. Calculated by engine control unit (ECU) |

| Actual Percent Engine Torque () | 0 to 100% | Output torque of engine calculated by ECU | |

| Engine RPM | 0 to 3000 rev/m | Operating speed of engine calculated by ECU | |

| Total Engine Hours (ECU + HUMS) | N/A h | Aggregate vehicle engine hours incremented when the condition (engine RPM >= 200 for 0.1 s) is satisfied | |

| Final Drives | Left-Hand Final Drive Temperature (LHFDT) | −10 to 150 °C | Temperature of LH final drive measured by k-type stick on thermocouples |

| Right-Hand Final Drive Temperature (RHFDT) | −10 to 150 °C | Temperature of RH final drive measured by k-type stick on thermocouples | |

| Vehicle (GNSS) | GNSS Altitude | 0 to 8000 m | Height above sea level |

| GNSS Latitude | −90 to 90 degrees | Latitude co-ordinate of vehicle | |

| GNSS Longitude | −180 to 180 degrees | Longitudinal co-ordinate of vehicle | |

| GNSS Speed | km/h | Vehicle speed derived from GNSS data | |

| GNSS Time | N/A | Timestamp determined by GNSS | |

| Vehicle (Totals) | Vehicle Distance | N/A km | Total distance travelled (generated from GNSS data) |

| Vehicle Hours | N/A h | Aggregate vehicle hours incremented when the condition (alternator voltage output >= 5 volts for 1 s) is satisfied |

| Terrain Class | Average Speed [km/h] | Coefficient of Rolling Resistance φ |

|---|---|---|

| First Class | > 58.1 | 0.024 |

| Second Class | 30.9 < < 58.1 | 0.08 |

| Cross Country | < 30.9 | 0.17 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ranasinghe, K.; Kapoor, R.; Gardi, A.; Sabatini, R.; Wickramanayake, V.; Ludovici, D. Vehicular Sensor Network and Data Analytics for a Health and Usage Management System. Sensors 2020, 20, 5892. https://doi.org/10.3390/s20205892

Ranasinghe K, Kapoor R, Gardi A, Sabatini R, Wickramanayake V, Ludovici D. Vehicular Sensor Network and Data Analytics for a Health and Usage Management System. Sensors. 2020; 20(20):5892. https://doi.org/10.3390/s20205892

Chicago/Turabian StyleRanasinghe, Kavindu, Rohan Kapoor, Alessandro Gardi, Roberto Sabatini, Vishwanath Wickramanayake, and David Ludovici. 2020. "Vehicular Sensor Network and Data Analytics for a Health and Usage Management System" Sensors 20, no. 20: 5892. https://doi.org/10.3390/s20205892