A New Stitching Method for Dark-Field Surface Defects Inspection Based on Simplified Target-Tracking and Path Correction

Abstract

1. Introduction

- This stitching method is effective for reducing mismatches, even if there are only a few defects.

- This stitching method can make corrections on the scanning path deviation from the designed path. This scanning path deviation is usually one of the main sources resulting in location deviation of defects. Therefore, it is possible to reduce the location deviation of defects by eliminating the bad effects of the scanning path deviation.

- This stitching method has potential for improving the performance of weak defects detection while maintaining low false-alarm rates.

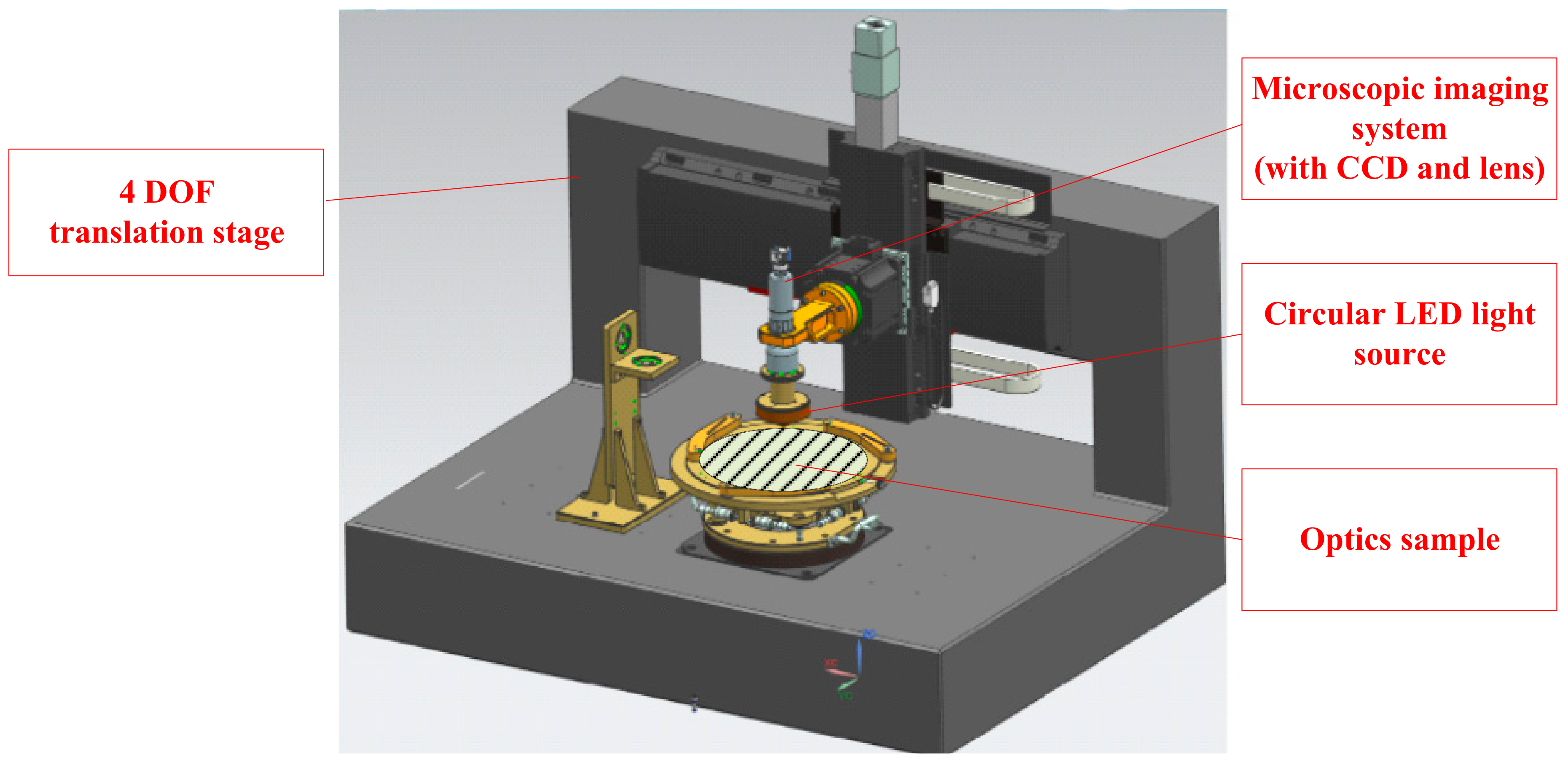

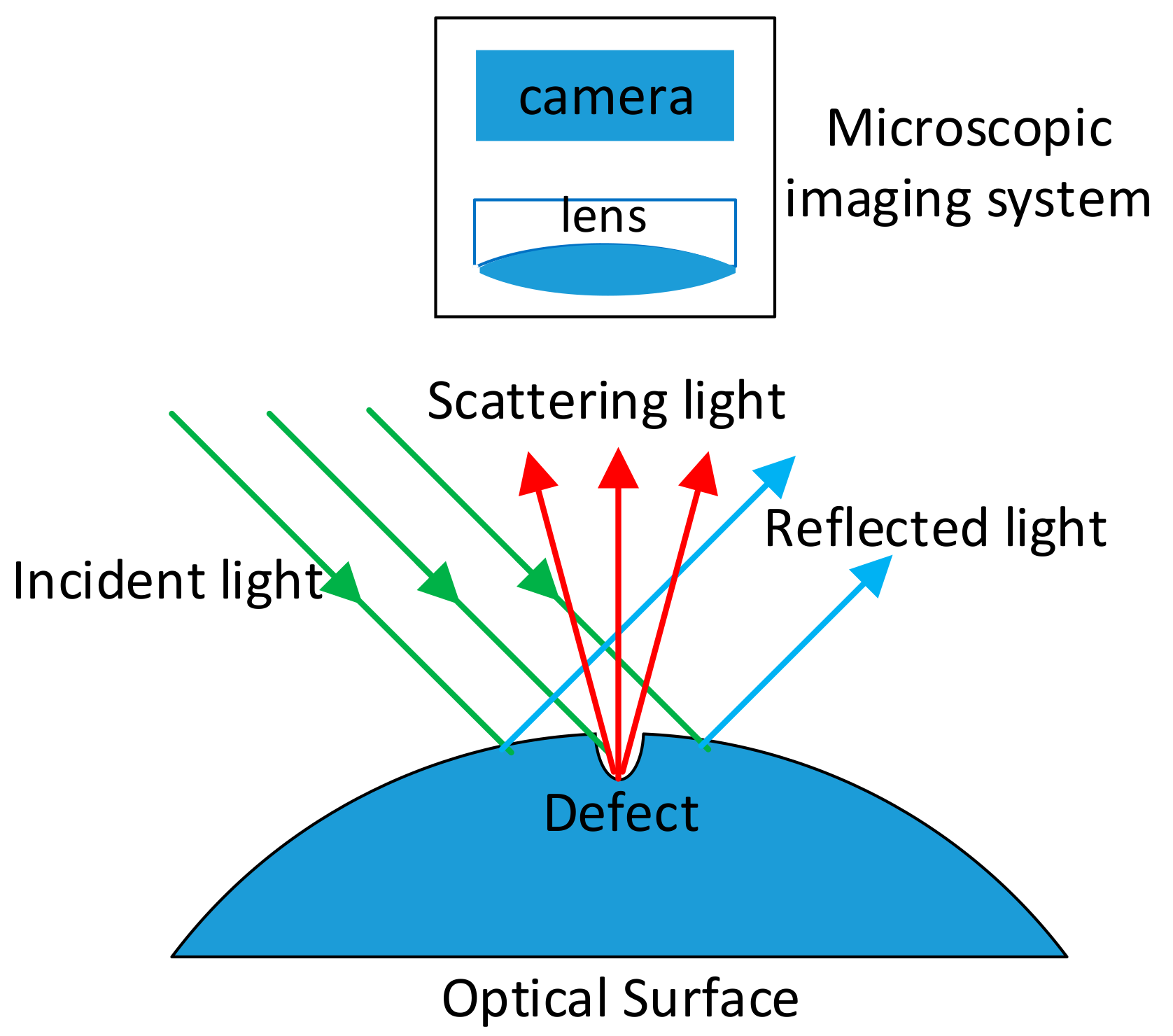

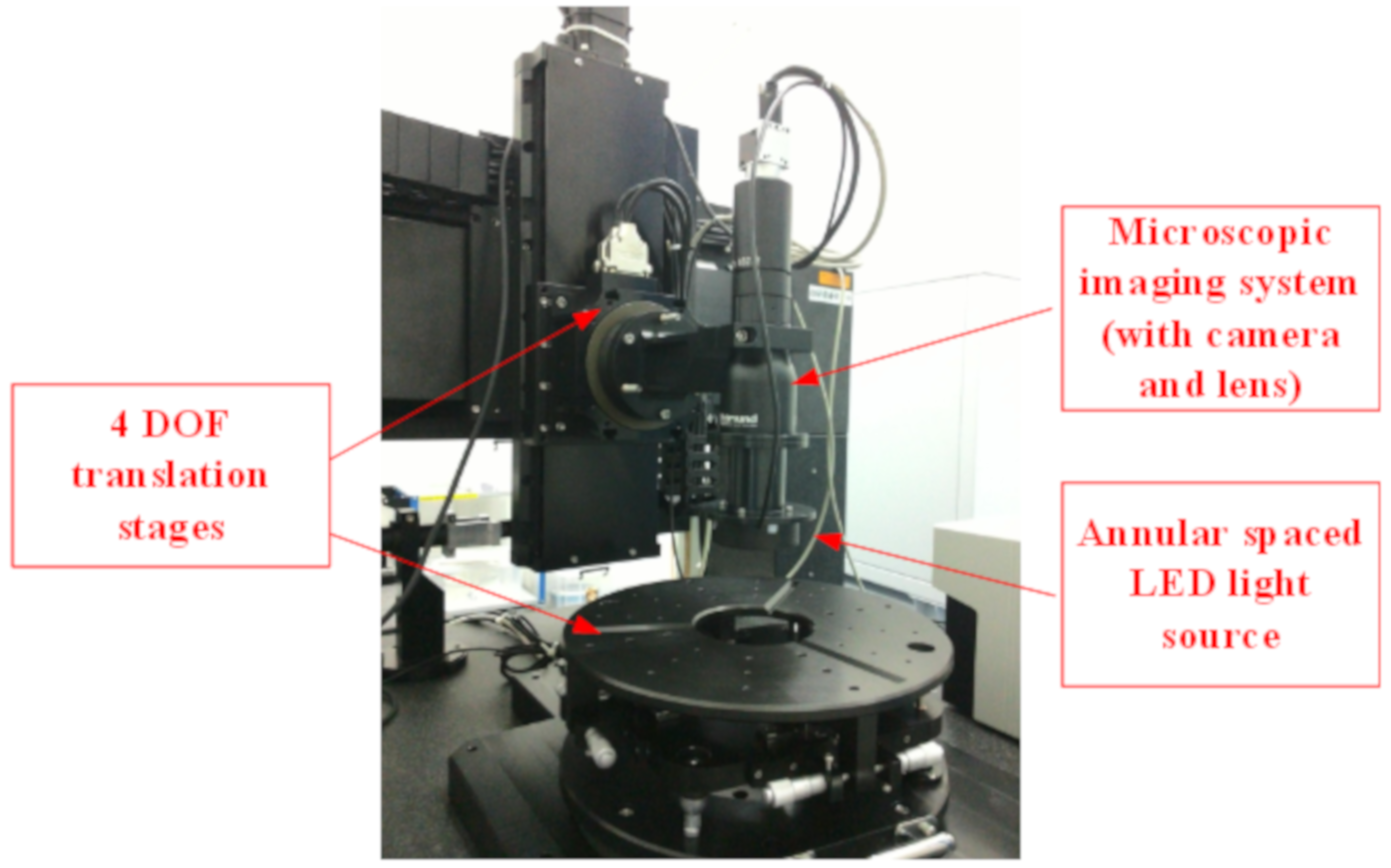

2. Dark-Field Microscopic Imaging System

2.1. System Layout

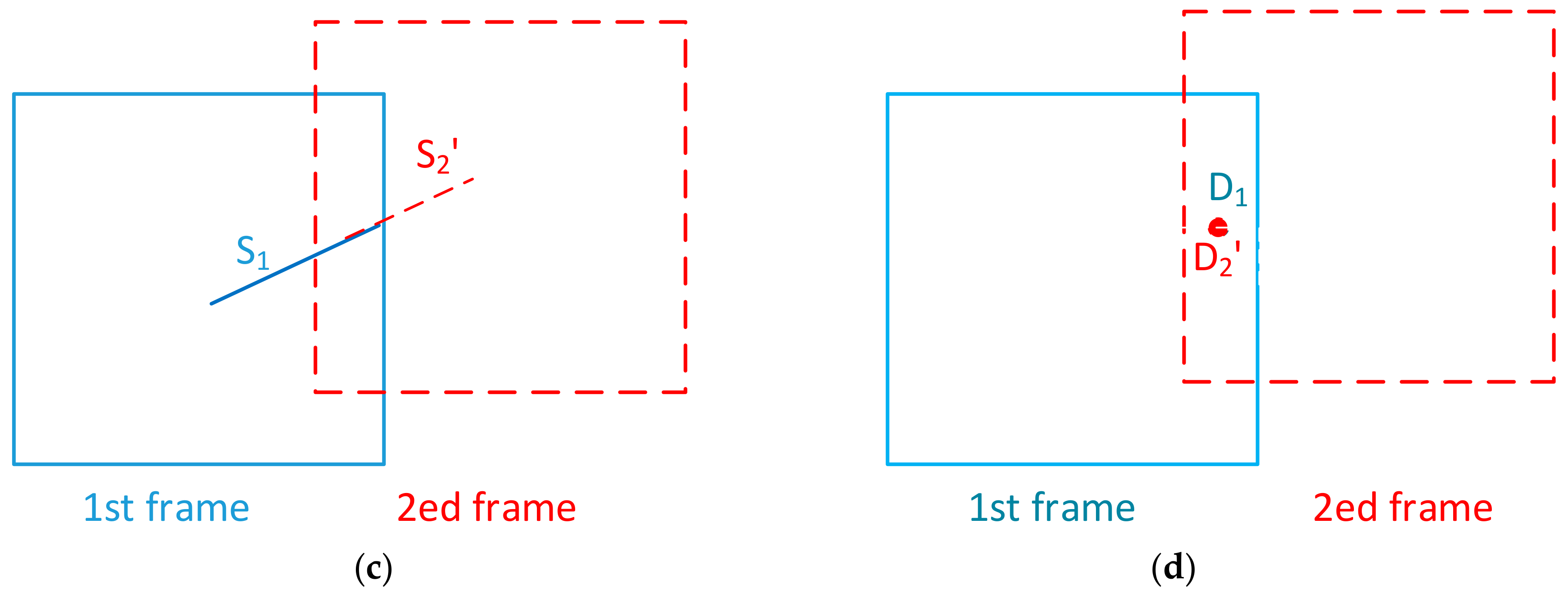

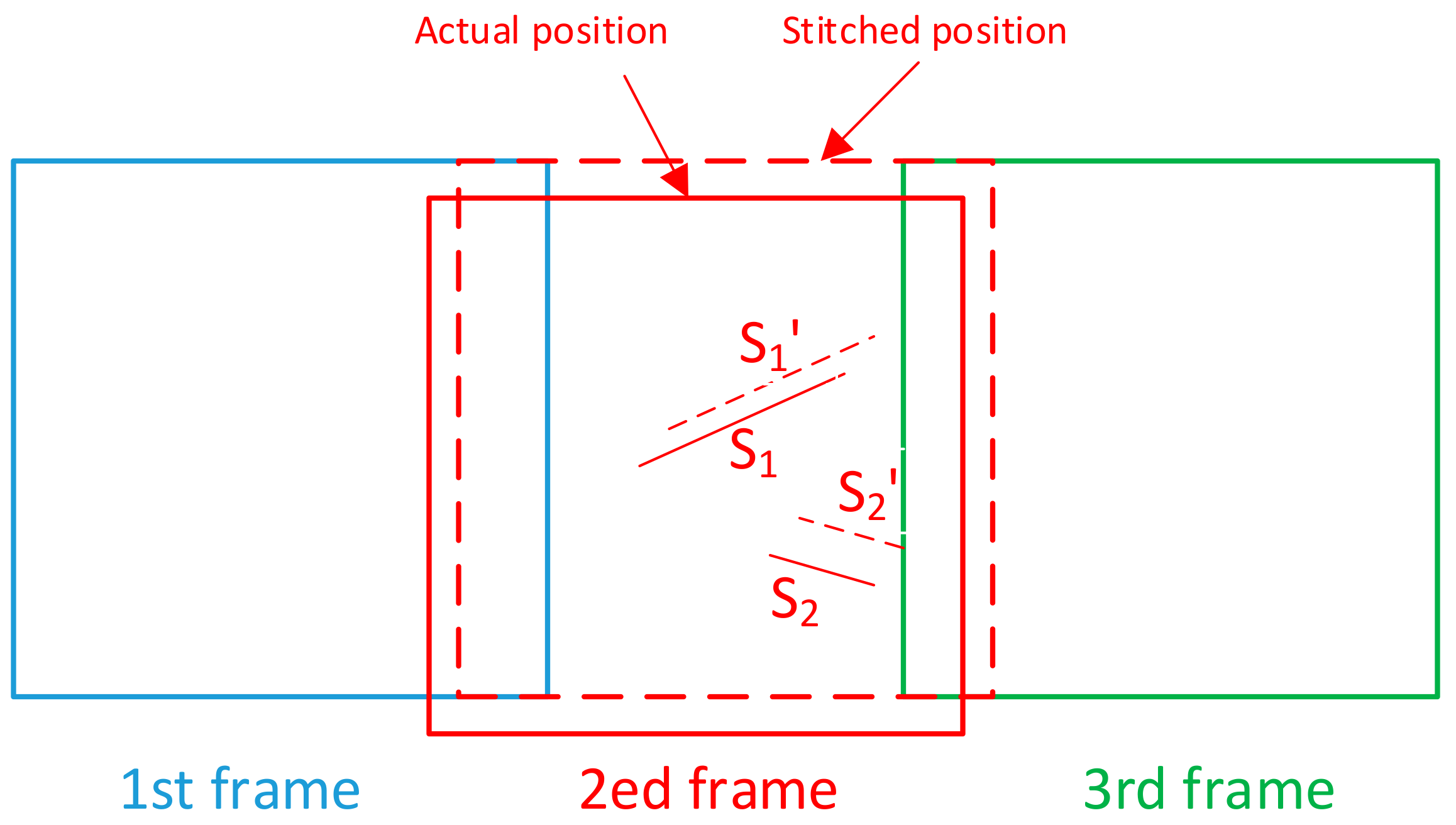

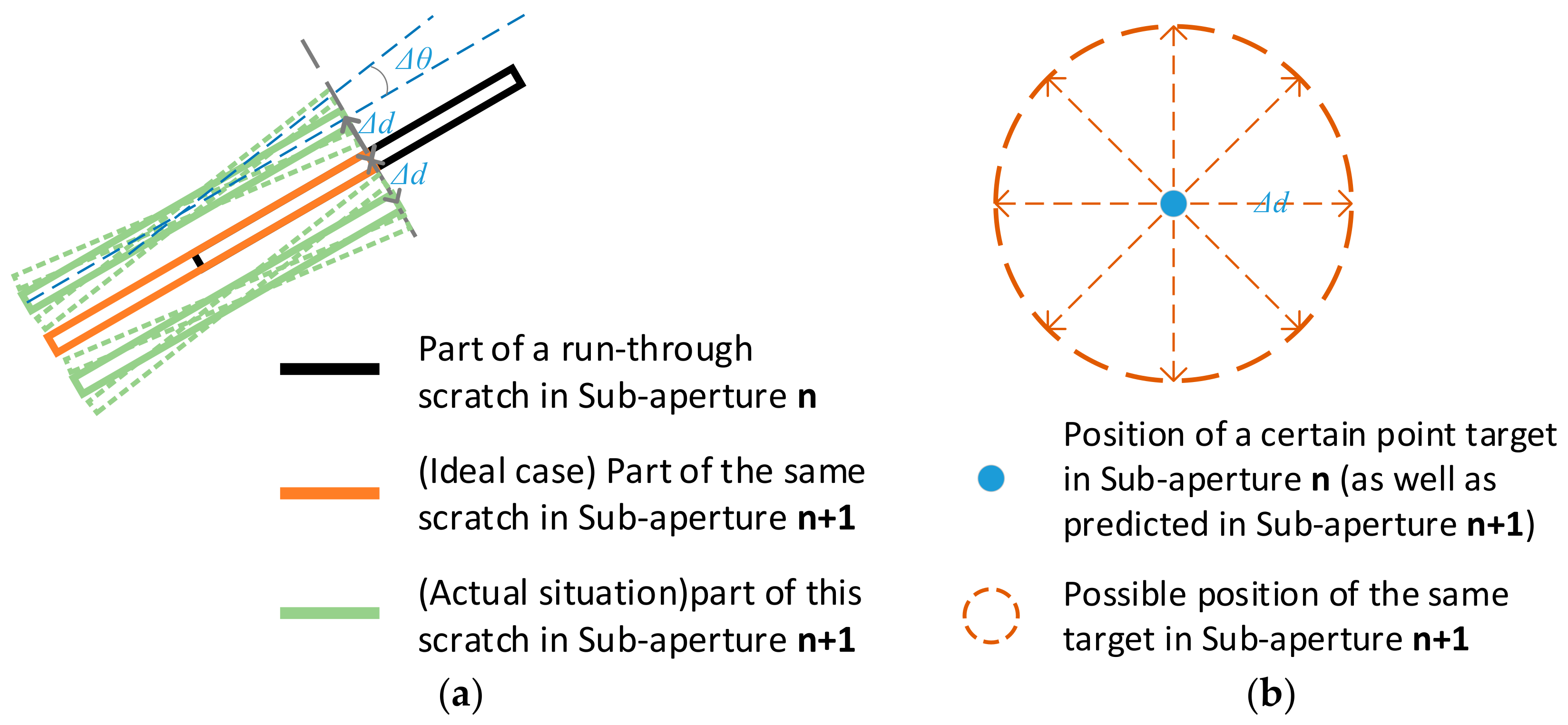

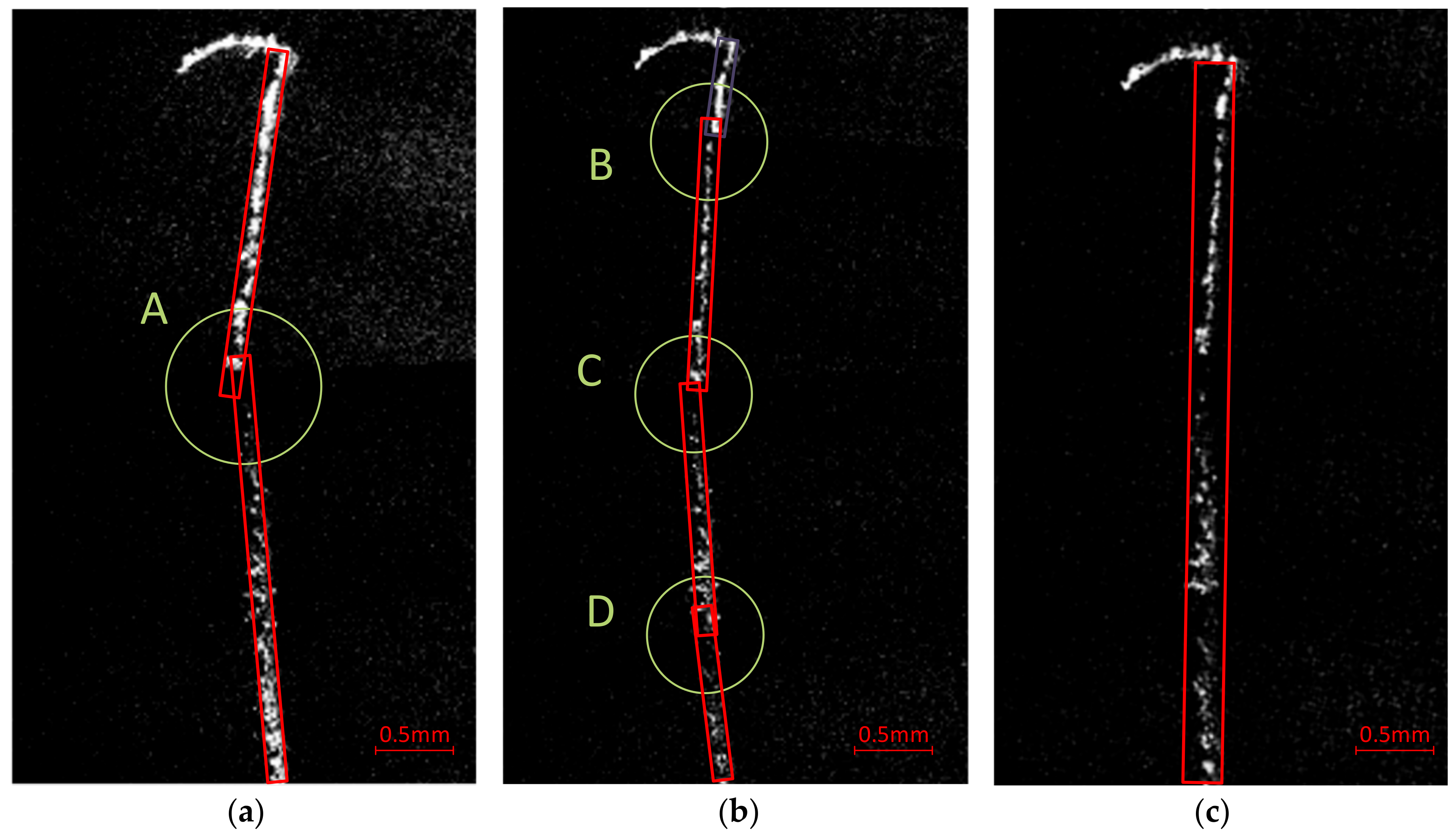

2.2. Mismatch of Sub-Stitching

- Mismatch that increases the number of defects;

- Mismatch that decreases the number of defects.

2.2.1. Mismatch That Increases the Number of Defects

2.2.2. Mismatch That Decreases the Number of Defects

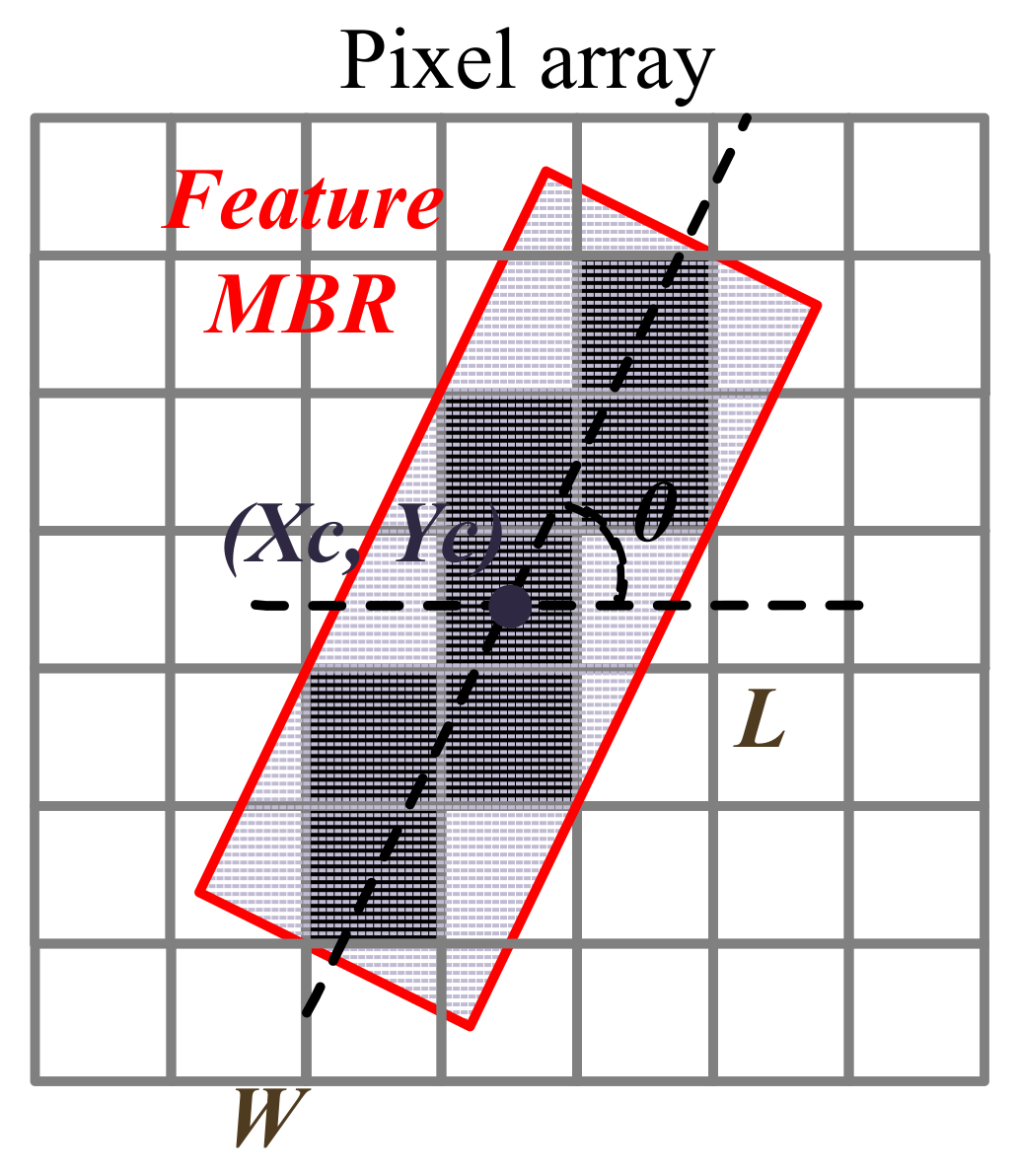

2.3. Location Deviation of Defects

- (1)

- The center coordinates of the target ;

- (2)

- The area of the target S.

- (1)

- The center coordinates of the MBR in the camera coordinate system, presenting the global location of the scratch;

- (2)

- The length and width of the MBR, L and W, presenting the size of the scratch;

- (3)

- The angle between length of MBR and x axis, , presenting the orientation of the scratch.

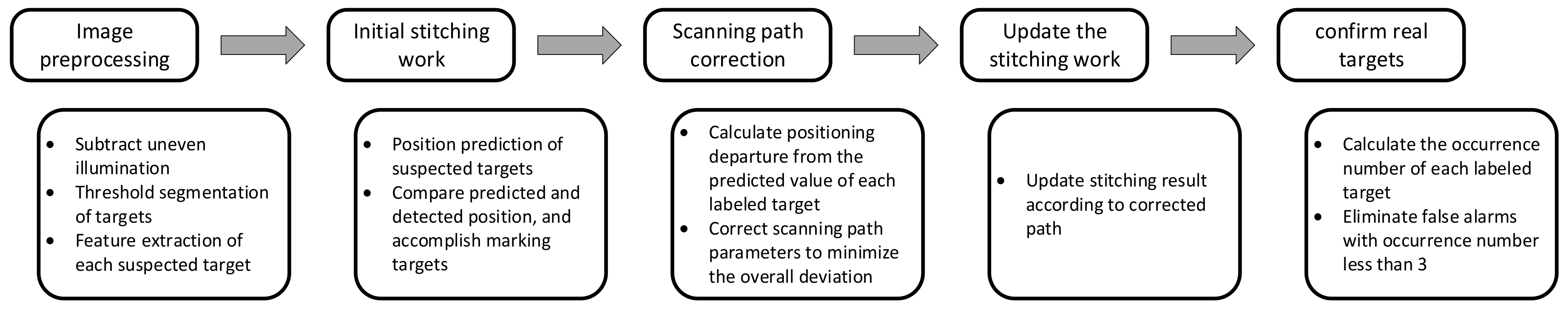

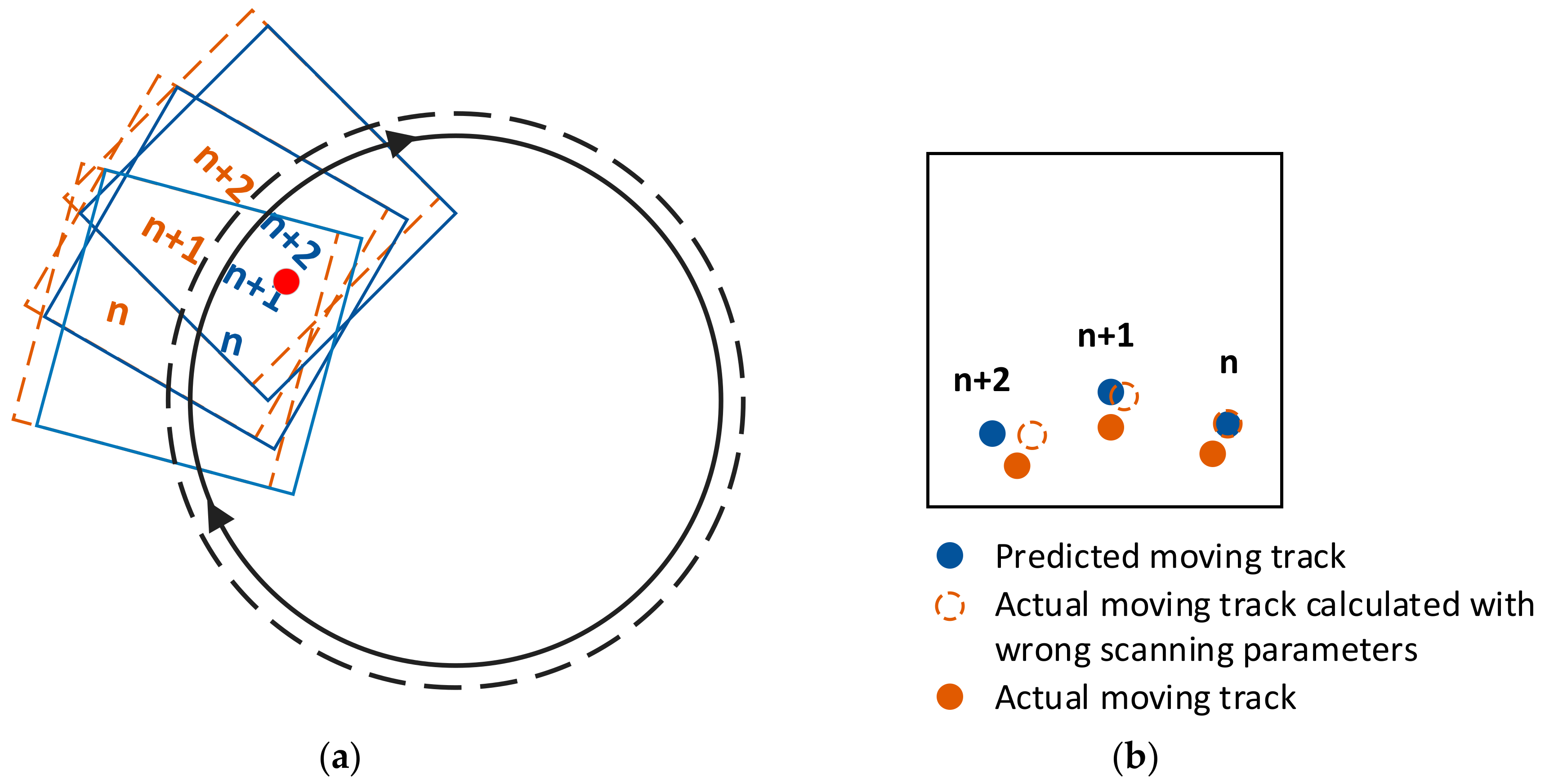

3. Stitching Method for Dark-Field Surface Defects Inspection

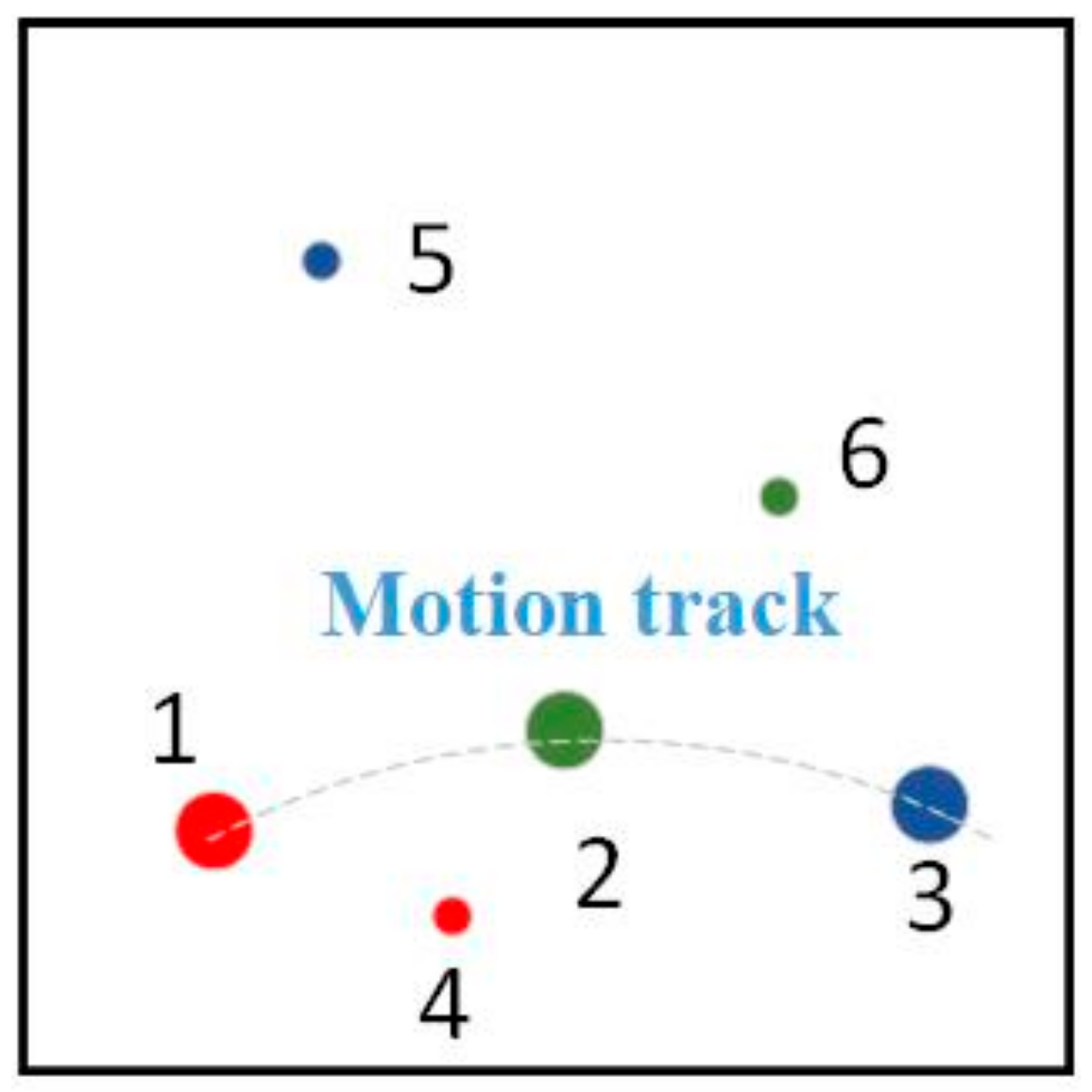

3.1. Basic Principle of the Simplified Target-Tracking Algorithm

3.2. Modified Feature-Based Target-Tracking-Like Stitching Method

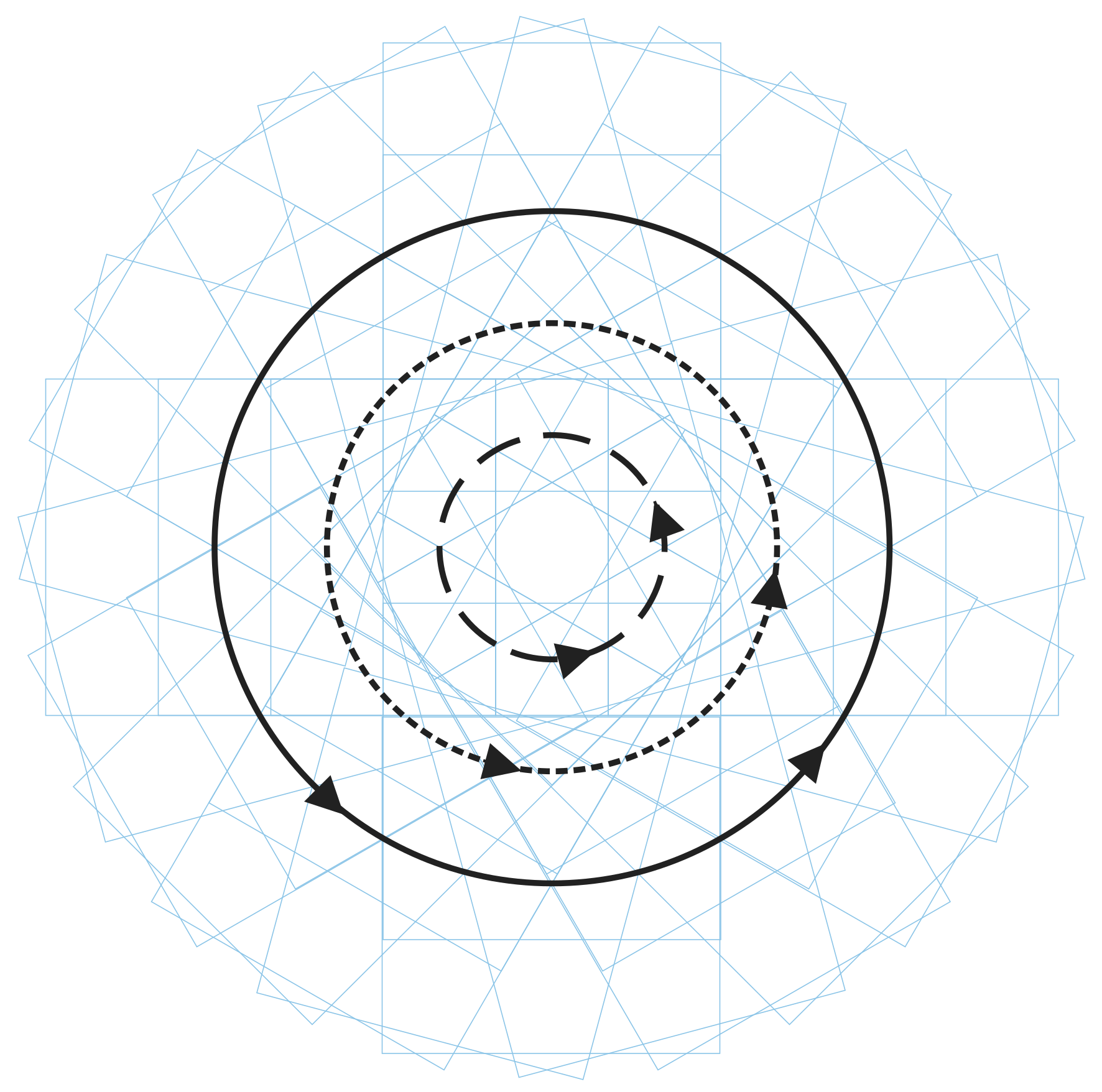

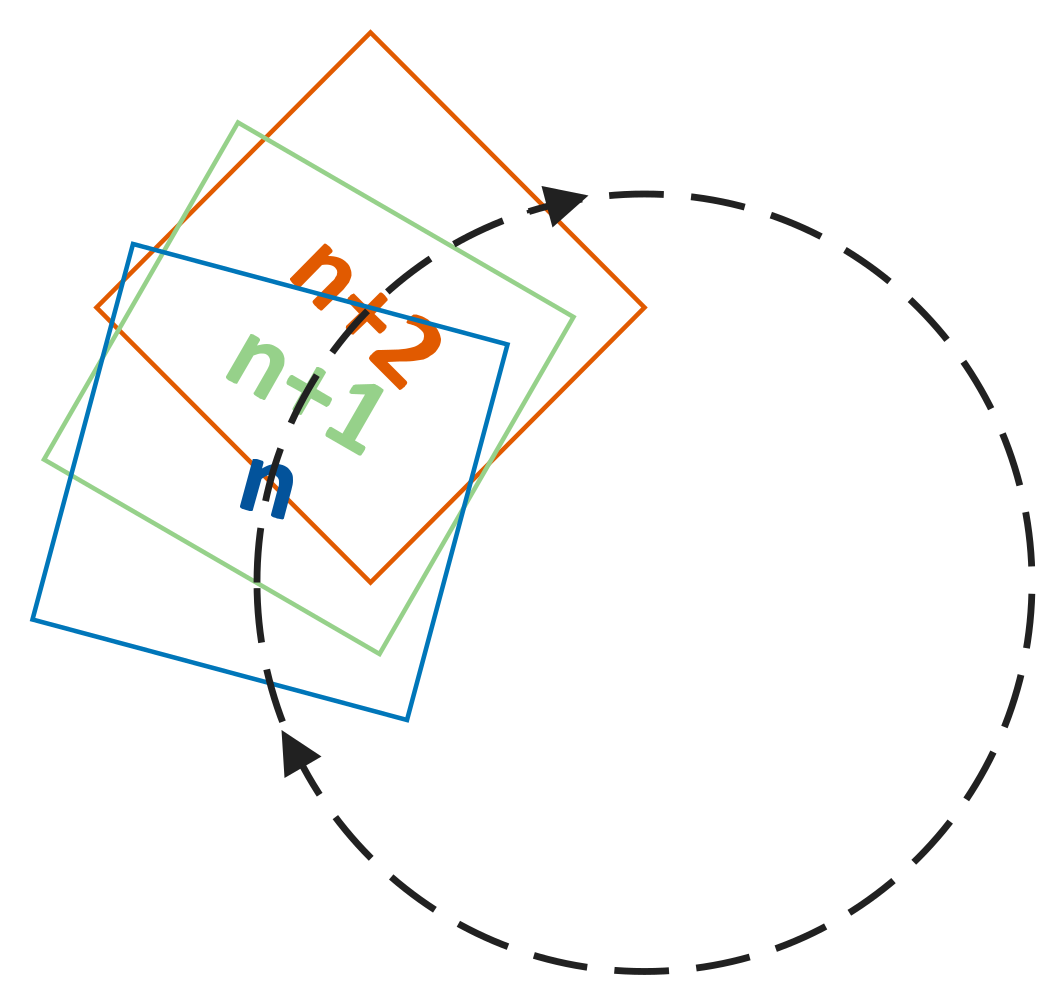

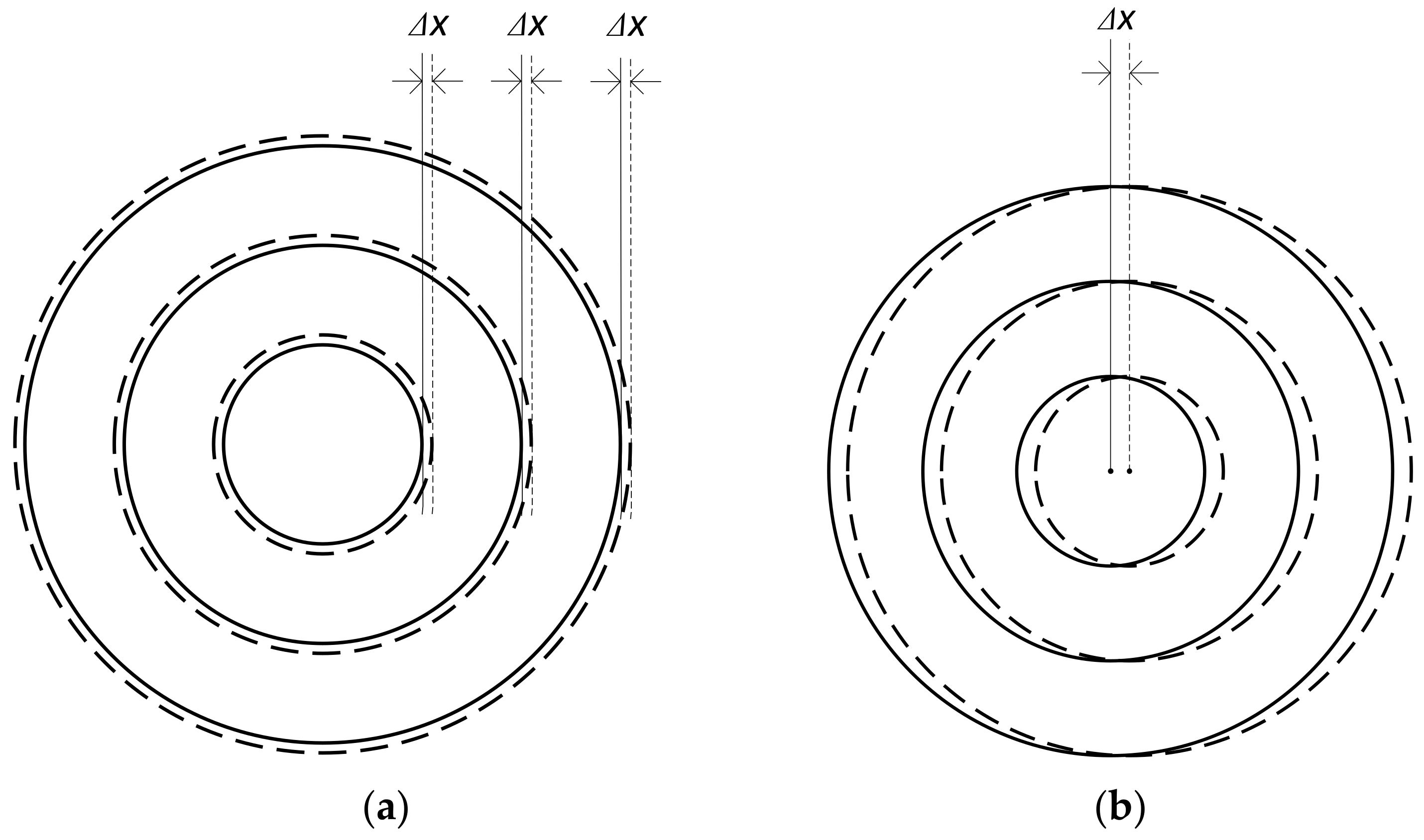

3.3. Scanning Path Correction

- Under the situation where the position of the starting point of the scanning has a deviation apart from the ideal position, which often happened in our practical works, the actual path scanning by the system is another set of concentric circles, as shown by the dashed lines in Figure 11a;

- The centers of scanning circles do not coincide with the rotation center of the tested surface, as shown in Figure 11b. Compared with the ideal scanning path, the actual position of every sub-aperture departs from its nominal position.

3.4. Potential Enhancement of Weak Defect Detection through Target Reconfirming

4. Experiment

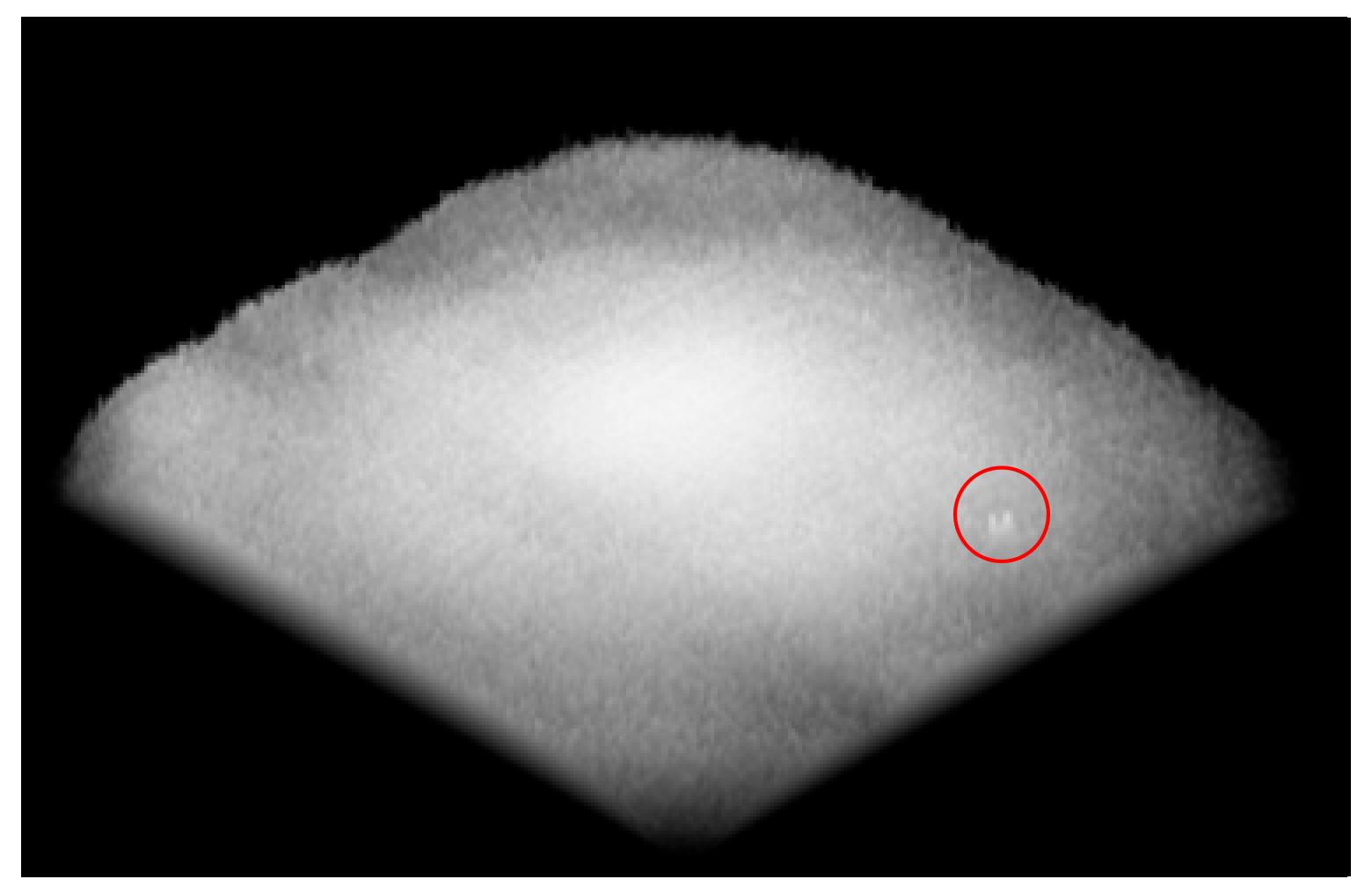

4.1. Experiment System

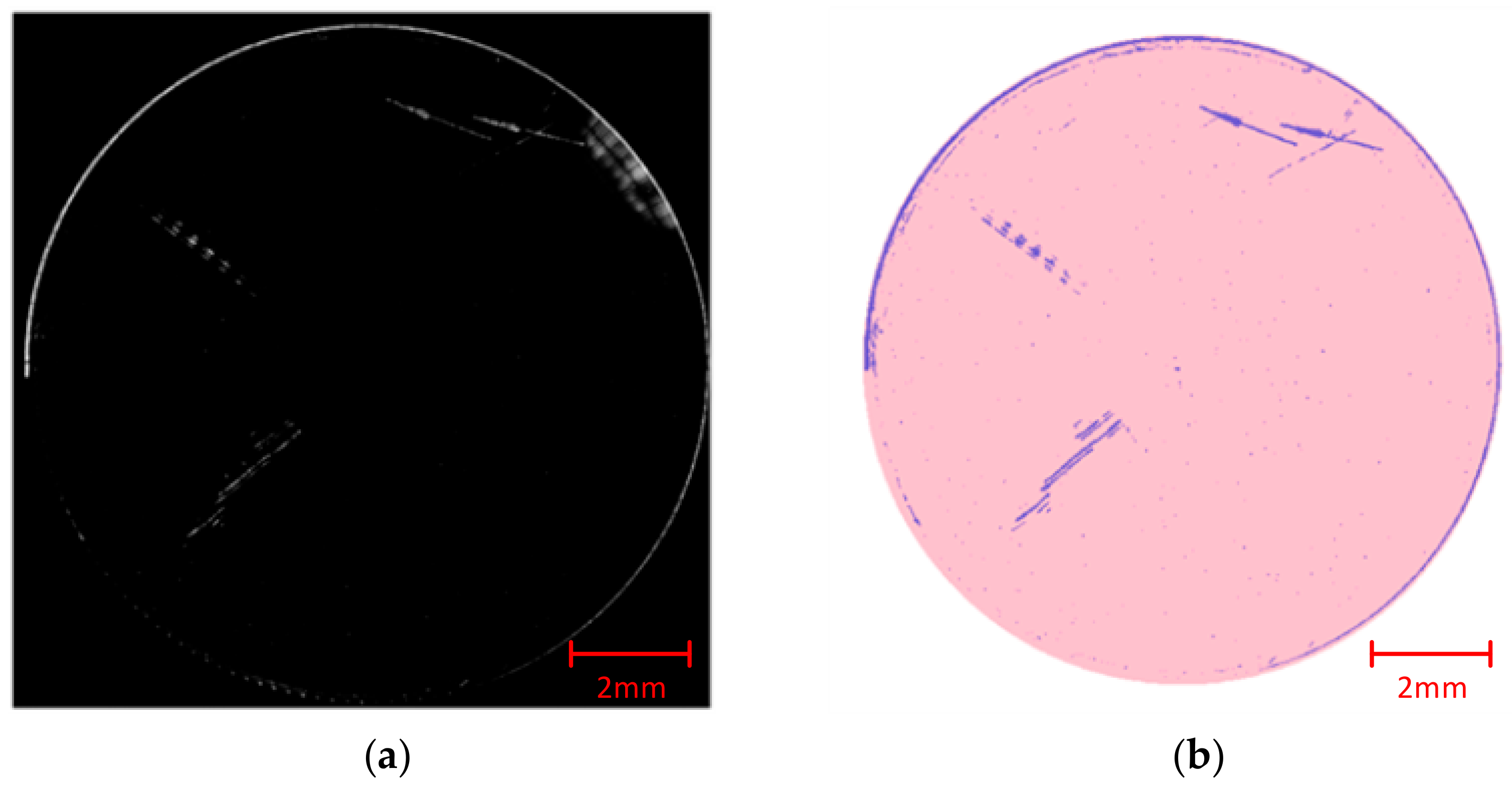

4.2. Defect Distribution Map for Sample Surface

4.3. Stitching Performance against Sub-Aperture Mismatches

4.4. Contrast Experiment

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Baisden, P.A.; Atherton, L.J.; Hawley, R.A.; Land, T.A.; Menapace, J.A.; Miller, P.E.; Runkel, M.J.; Spaeth, M.L.; Stolz, C.J.; Suratwala, T.I.; et al. Large optics for the national ignition facility. Fusion Sci. Technol. 2016, 69, 295–351. [Google Scholar] [CrossRef]

- Ota, H.; Hachiya, M.; Ichiyasu, Y.; Kurenuma, T. Scanning surface inspection system with defect-review SEM and analysis system solutions. Hatachi Rev. 2006, 55, 78–82. [Google Scholar]

- Brunton, G.; Abed, Y.; Fedorov, M.; Fishler, B.; Larson, D.; Ludwigsen, A.P.; Mathisen, D.; Miller-Kamm, V.; Paul, M.; Reed, R.; et al. Status of the national ignition facility (NIF) integrated computer control and information systems. In Proceedings of the 16th Int Conf on Accelerator and Large Experimental Control Systems (ICALEPCS), Barcelona, Spain, 8–13 October 2017; pp. 14–18. [Google Scholar]

- Casner, A.; Caillaud, T.; Darbon, S.; Duval, A.; Thfouin, I.; Jadaud, J.P.; LeBreton, J.P.; Reverdin, C.; Rosse, B.; Rosch, R.; et al. LMJ/PETAL laser facility: Overview and opportunities for laboratory astrophysics. High Energy Density Phys. 2015, 17, 2–11. [Google Scholar] [CrossRef]

- Germer, T.A.; Wolters, C.; Brayton, D. Calibration of wafer surface inspection systems using spherical silica nanoparticles. Opt. Exp. 2008, 16, 4698–4705. [Google Scholar] [CrossRef]

- Liu, D.; Yang, Y.; Wang, L.; Zhuo, Y.; Lu, C.; Yang, L.; Li, R. Microscopic scattering imaging measurement and digital evaluation system of defects for fine optical surface. Opt. Commun. 2007, 278, 240–246. [Google Scholar] [CrossRef]

- Tao, X.; Zhang, Z.; Zhang, F.; Xu, D. A Novel and Effective Surface Flaw Inspection Instrument for Large-Aperture Optical Elements. IEEE Trans. Instrum. Meas. 2015, 64, 2530–2540. [Google Scholar]

- Yang, Y.; Chai, H.; Li, C.; Zhang, Y.; Wu, F.; Bai, J.; Shen, Y. Surface defects evaluation system based on electromagnetic model simulation and inverse-recognition calibration method. Opt. Commun. 2017, 390, 88–98. [Google Scholar] [CrossRef]

- Cao, P.; Yang, Y.; Li, C.; Chai, H.; Li, Y.; Xie, S.; Liu, B. Alignment methods for micron-scale surface defects automatic evaluation of large-aperture fine optics. Chin. Opt. Lett. 2015, 13, 041102. [Google Scholar]

- Li, L.; Liu, D.; Cao, P.; Xie, S.; Li, Y.; Chen, Y.; Yang, Y. Automated discrimination between digs and dust particles on optical surfaces with dark-field scattering microscopy. Appl. Opt. 2014, 53, 5131–5140. [Google Scholar] [CrossRef]

- Gomez, S.; Hale, K.; Burrows, J.; Griffiths, B. Measurements of surface defects on optical components. Meas. Sci. Technol. 1998, 9, 607–616. [Google Scholar] [CrossRef]

- Ding, W.D.; Zhang, Z.T.; Zhang, D.P.; Xu, L.; Lv, H.B.; Miao, X.X.; Zhou, G.R.; Liu, H. An Effective On-line Surface Particles Inspection Instrument for Large Aperture Optical Element. Int. J. Autom. Comput. 2017, 14, 420–431. [Google Scholar] [CrossRef]

- Wang, S.; Liu, D.; Yang, Y.; Chen, X.; Cao, P.; Li, L.; Yan, L.; Cheng, Z.; Shen, Y. Distortion correction in surface defects evaluating system of large fine optics. Opt. Commun. 2014, 312, 110–116. [Google Scholar] [CrossRef]

- Liu, D.; Wang, S.; Cao, P.; Li, L.; Cheng, Z.; Gao, X.; Yang, Y. Dark-field microscopic image stitching method for surface defects evaluation of large fine optics. Opt. Express 2013, 21, 5974–5987. [Google Scholar] [CrossRef] [PubMed]

- Neubecker, R.; Hon, J.E. Automatic inspection for surface imperfections: Requirements, potentials and limits. Third Eur. Semin. Precis. Opt. Manuf. 2016, 10009, 1000907. [Google Scholar]

- Li, X.R.; Jilkov, V.P. Survey of maneuvering target tracking. Part I. Dynamic models. IEEE Trans. Aerosp. Electron. Syst. 2003, 39, 1333–1364. [Google Scholar]

- Blackman, S. Multiple hypothesis tracking for multiple target tracking. IEEE Aerosp. Electron. Syst. Mag. 2004, 19, 5–18. [Google Scholar] [CrossRef]

- Gao, J.; Du, J.; Wang, W. Radar Detection of Fluctuating Targets under Heavy-Tailed Clutter Using Track-Before-Detect. Sensors 2018, 18, 2241. [Google Scholar] [CrossRef]

- Li, C.; Wang, W. Detection and Tracking of Moving Targets for Thermal Infrared Video Sequences. Sensors 2018, 18, 3944. [Google Scholar] [CrossRef]

- Gebhardt, M.; Truckenbrodt, H.; Harnisch, B. Surface defect detection and classification with light scattering. Proc. SPIE 1991, 1500, 135–143. [Google Scholar]

- Dong, J. Line-scanning laser scattering system for fast defect inspection of a large aperture surface. Appl. Opt. 2017, 56, 7089. [Google Scholar] [CrossRef]

- Li, C.; Yang, Y.; Chai, H.; Zhang, Y.; Wu, F.; Zhou, L.; Yan, K.; Bai, J.; Shen, Y.; Xu, Q.; et al. Dark-field detection method of shallow scratches on the super-smooth optical surface based on the technology of adaptive smoothing and morphological differencing. Chin. Opt. Lett. 2017, 15, 081202. [Google Scholar]

- Zhang, Y.; Yang, Y.; Li, C.; Wu, F.; Chai, H.; Yan, K.; Zhou, L.; Li, Y.; Liu, D.; Bai, J.; et al. Defects evaluation system for spherical optical surfaces based on microscopic scattering dark-field imaging method. Appl. Opt. 2016, 55, 6162–6170. [Google Scholar] [CrossRef] [PubMed]

- Optics and Photonics—Preparation of Drawings for Optical Elements and Systems—Part7: Surface Imperfection Tolerances. Available online: https://www.en-standard.eu/iso-10110-7-optics-and-photonics-preparation-of-drawings-for-optical-elements-and-systems-part-7-surface-imperfections/ (accessed on 10 January 2020).

- Tao, X.; Xu, D.; Zhang, Z.; Zhang, F.; Liu, X.; Zhang, D. Weak scratch detection and defect classification methods for a large-aperture optical element. Opt. Commun. 2017, 387, 390–400. [Google Scholar] [CrossRef]

| Stitching Method | Nominal Position Stitching | Template Match Stitching | Multi-Cycle Stitching | Our Method |

|---|---|---|---|---|

| Mismatches of sub-stitching | 25 | 8 | 2 | 0 |

| Mean location deviation (μm) | 68.46 | 27.86 | 18.52 | 10.67 |

| The number of defects identified | 110 | 110 | 110 | 118 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Li, J.; Sui, Y. A New Stitching Method for Dark-Field Surface Defects Inspection Based on Simplified Target-Tracking and Path Correction. Sensors 2020, 20, 448. https://doi.org/10.3390/s20020448

Chen X, Li J, Sui Y. A New Stitching Method for Dark-Field Surface Defects Inspection Based on Simplified Target-Tracking and Path Correction. Sensors. 2020; 20(2):448. https://doi.org/10.3390/s20020448

Chicago/Turabian StyleChen, Xue, Jiaqi Li, and Yongxin Sui. 2020. "A New Stitching Method for Dark-Field Surface Defects Inspection Based on Simplified Target-Tracking and Path Correction" Sensors 20, no. 2: 448. https://doi.org/10.3390/s20020448

APA StyleChen, X., Li, J., & Sui, Y. (2020). A New Stitching Method for Dark-Field Surface Defects Inspection Based on Simplified Target-Tracking and Path Correction. Sensors, 20(2), 448. https://doi.org/10.3390/s20020448