Research on a Dynamic Algorithm for Cow Weighing Based on an SVM and Empirical Wavelet Transform

Abstract

1. Introduction

2. Materials and Methods

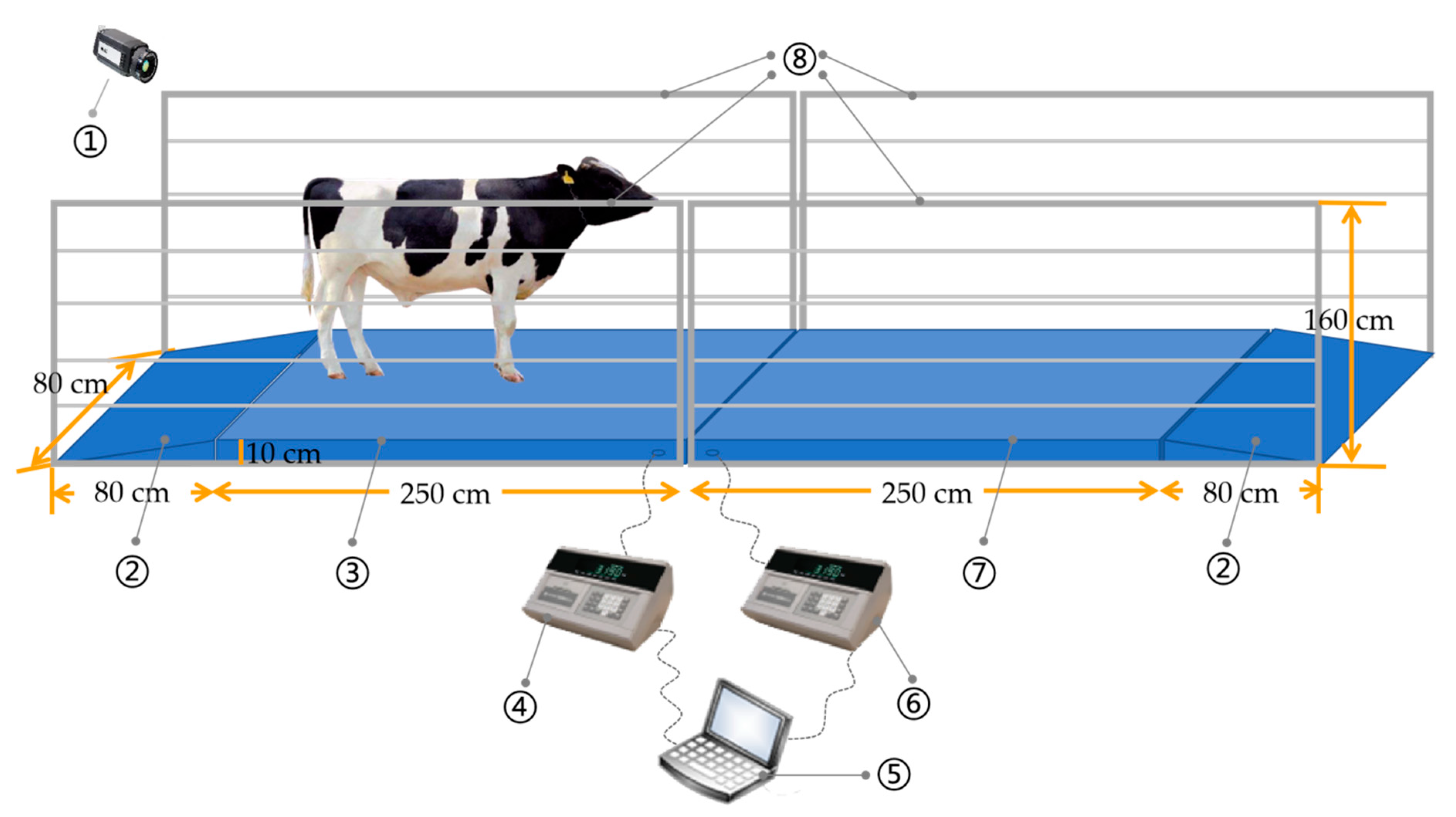

2.1. Dynamic Signal Acquisition

2.2. Dynamic Weighing Algorithm

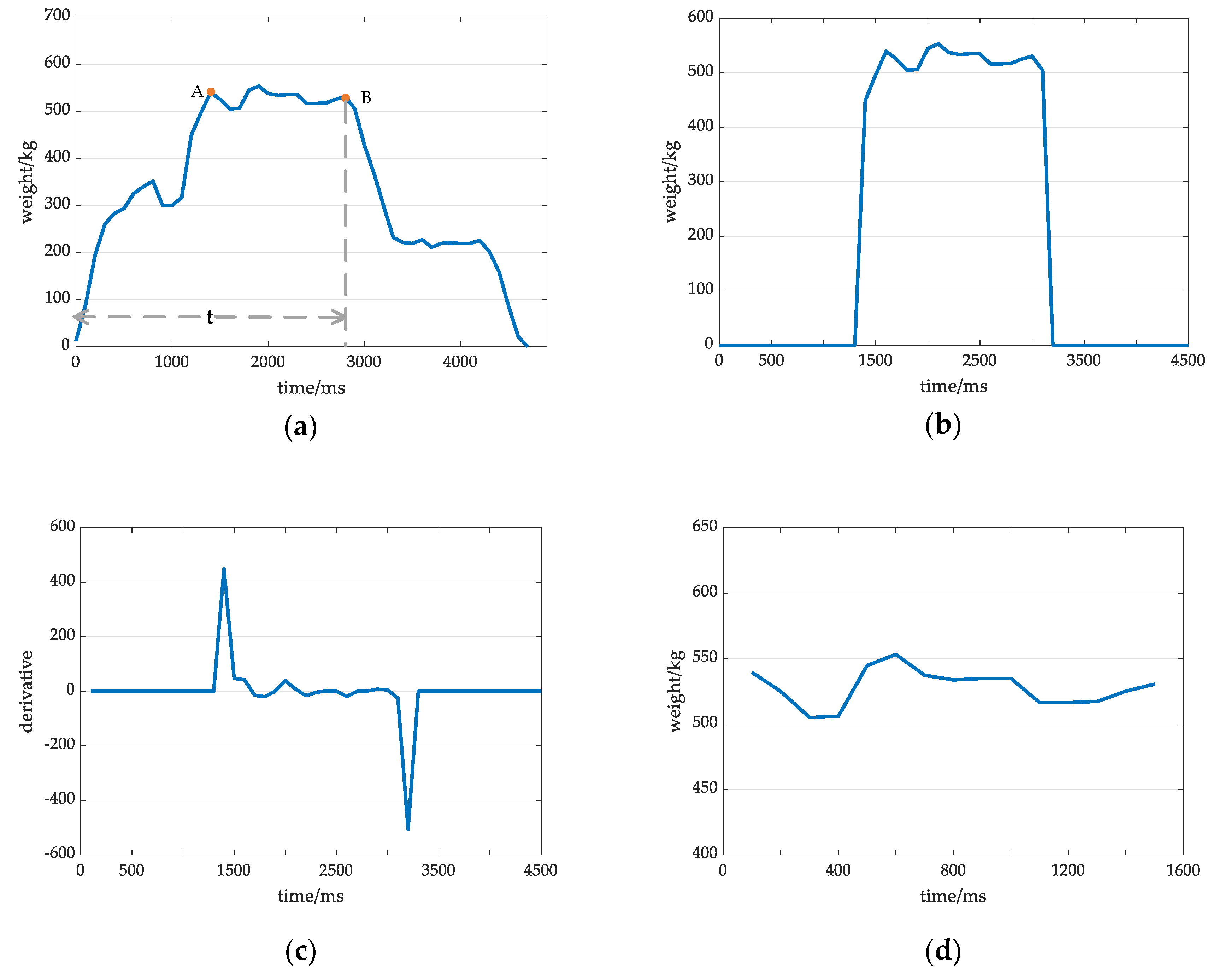

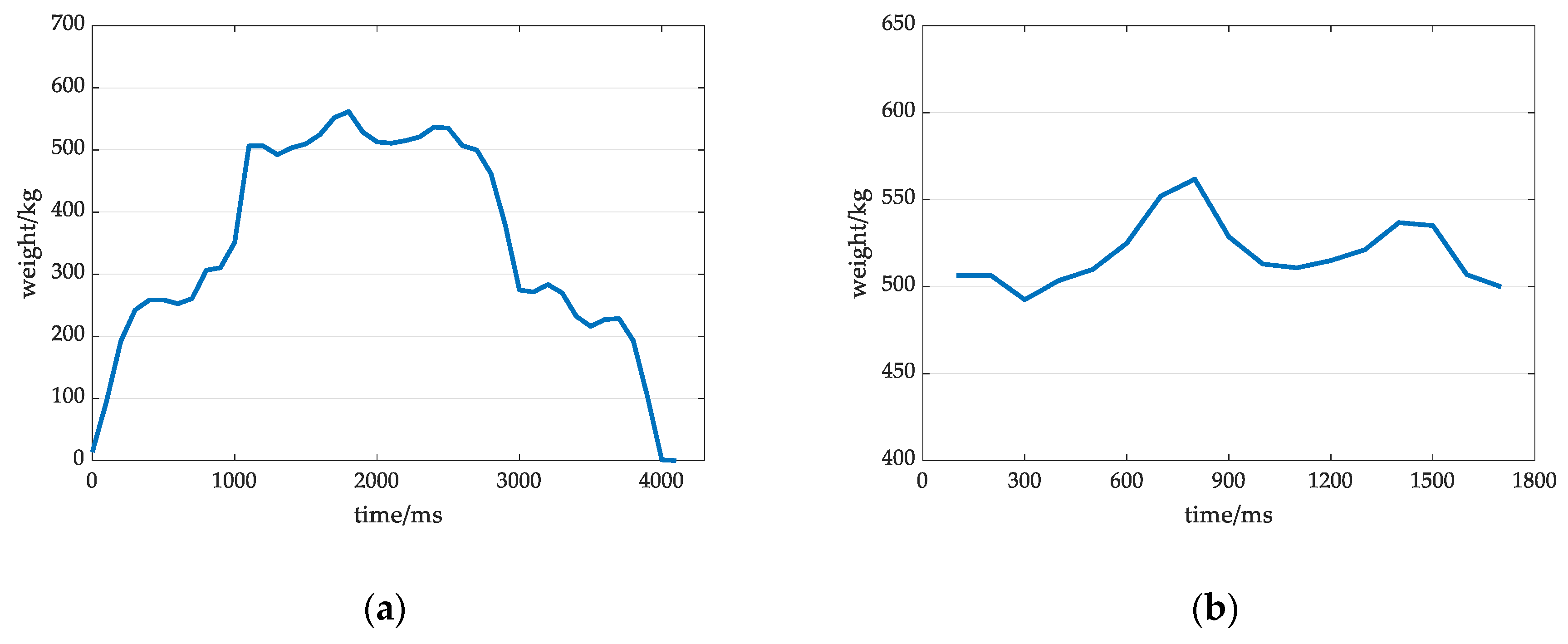

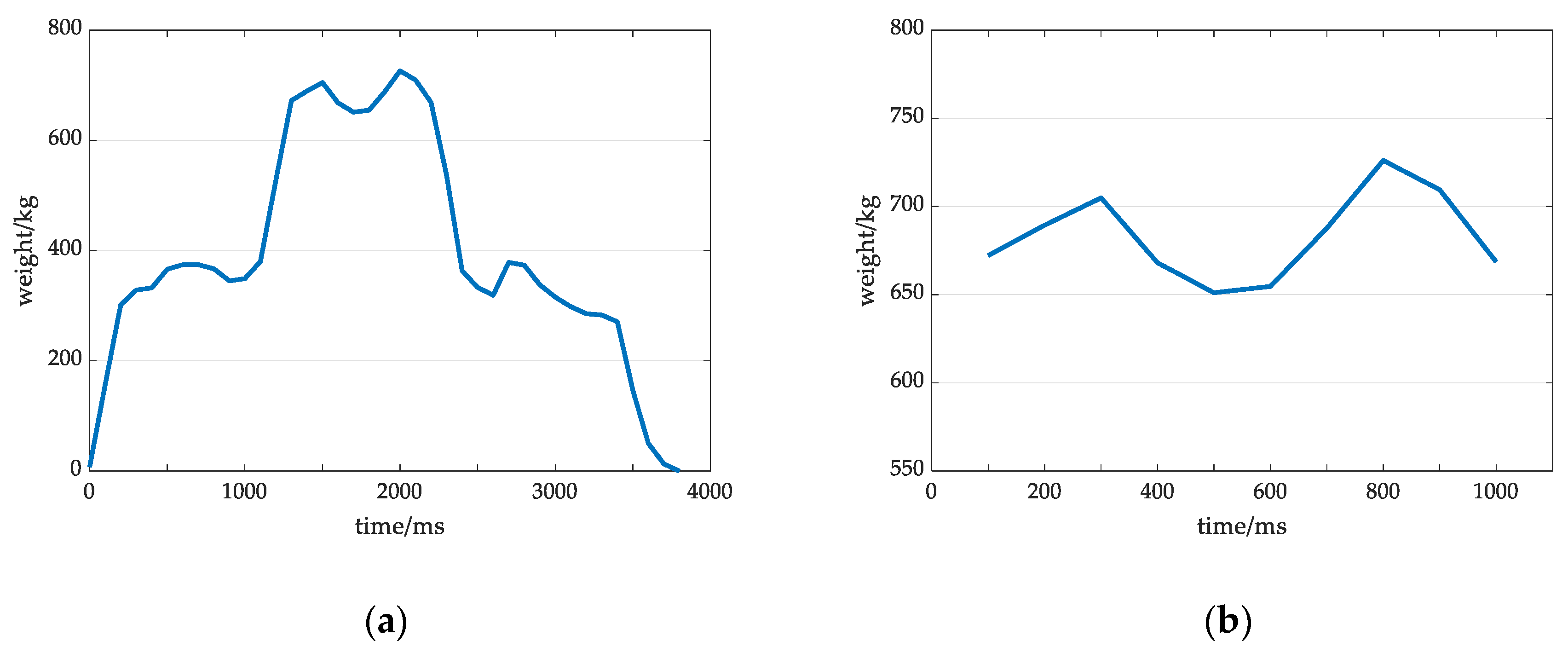

2.2.1. Preprocessing of the Dynamic Weight Signal

- Find the starting positions of the rising edge and the falling edge, i.e., points A and B; the data between A and B are valid data, as shown in Figure 3d.

2.2.2. SVM Classification

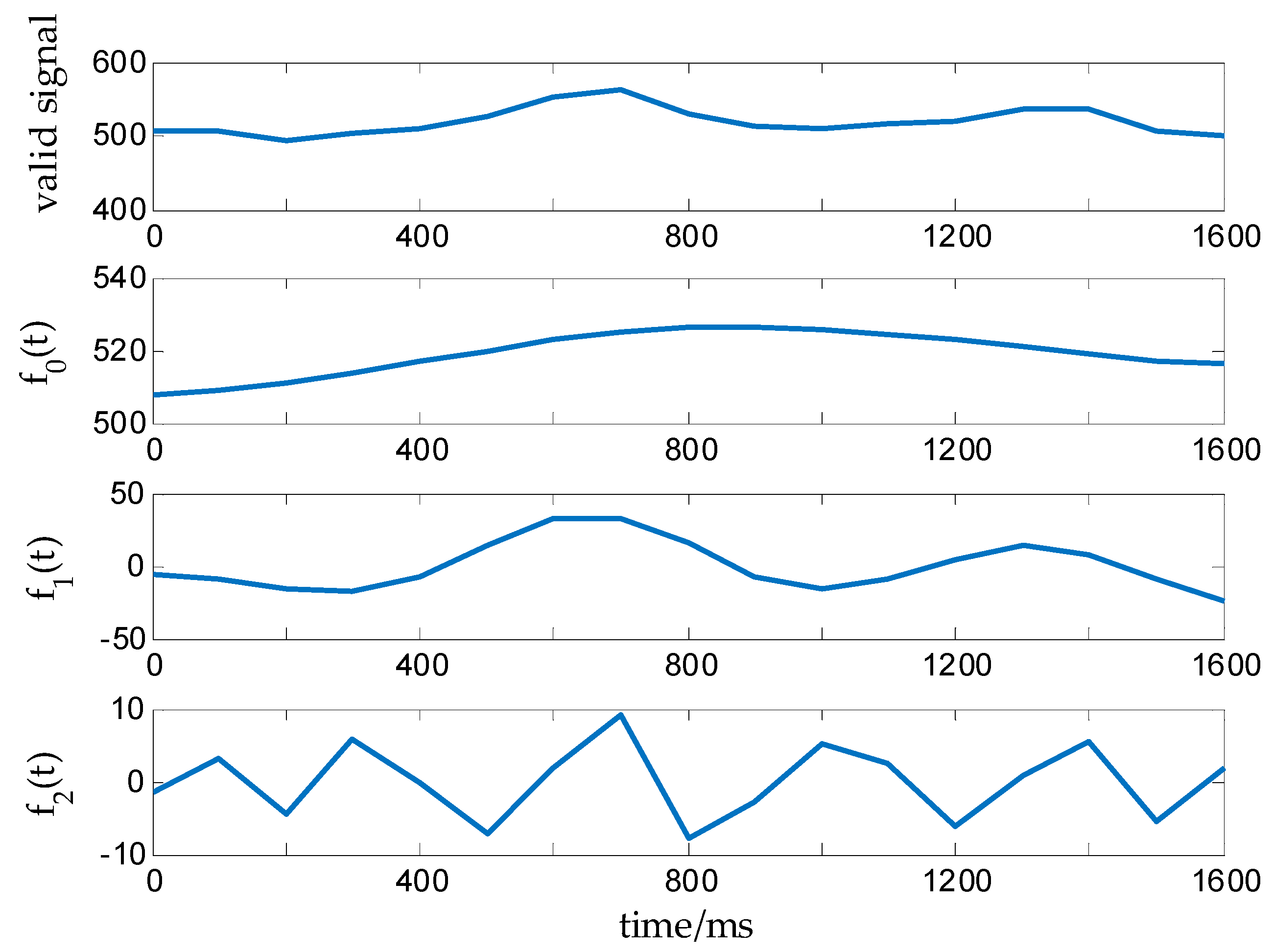

2.2.3. Dynamic Weight Value Calculation

- Calculate the Fourier spectrum of the effective signal .

- Normalize the Fourier spectrum to the interval [0,] and divide the spectrum into N intervals; in addition to the boundary value 0 and , there are N − 1 boundaries that need to be determined. is defined as a boundary, and the minimax method for spectral searches is used to determine the other boundaries. Then, each segment can be expressed as:

- The empirical wavelet is a band-pass filter defined on the interval based on the construction of Littlewood-Paley and Meyer theories, the wavelet scale function and wavelet function can be defined as follows:where and

- Calculate EWT through the construction method of another wavelet transform. The specific formulas of the detailed function and the approximate function are as follows:where represents the EWT; and are the Fourier transform of and ; and are the complex conjugate functions of and ; and <,> denotes an inner product operation.

- After obtaining the wavelet detail coefficient and approximate coefficient through the first four steps, for the effective signal , the mathematical expression after decomposition is as follows:where is the decomposed AM-FM component and N is the number of decomposed signal components. The expression of each component is shown in (18):

2.2.4. Evaluation

3. Results and Discussion

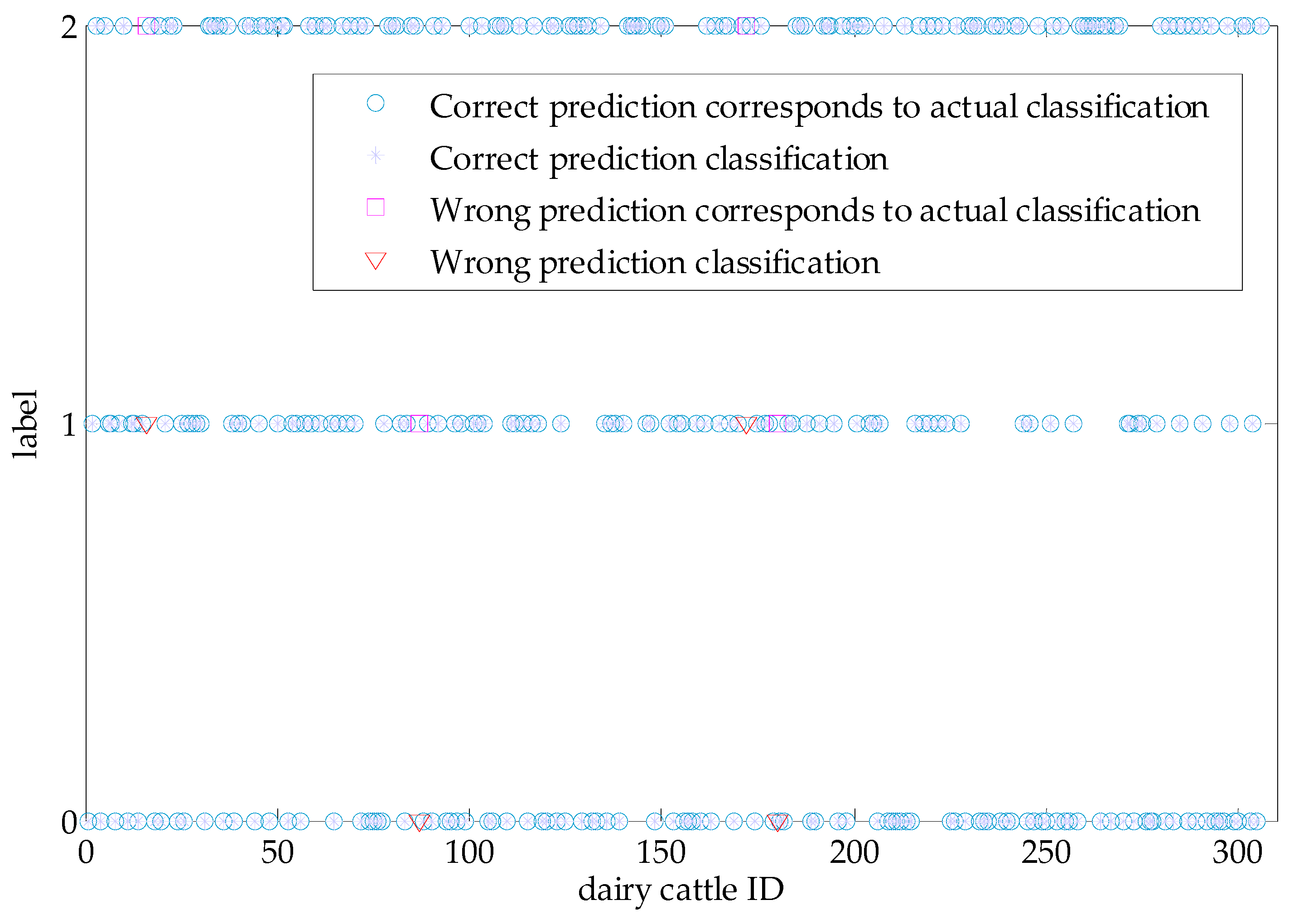

3.1. SVM Classification Results

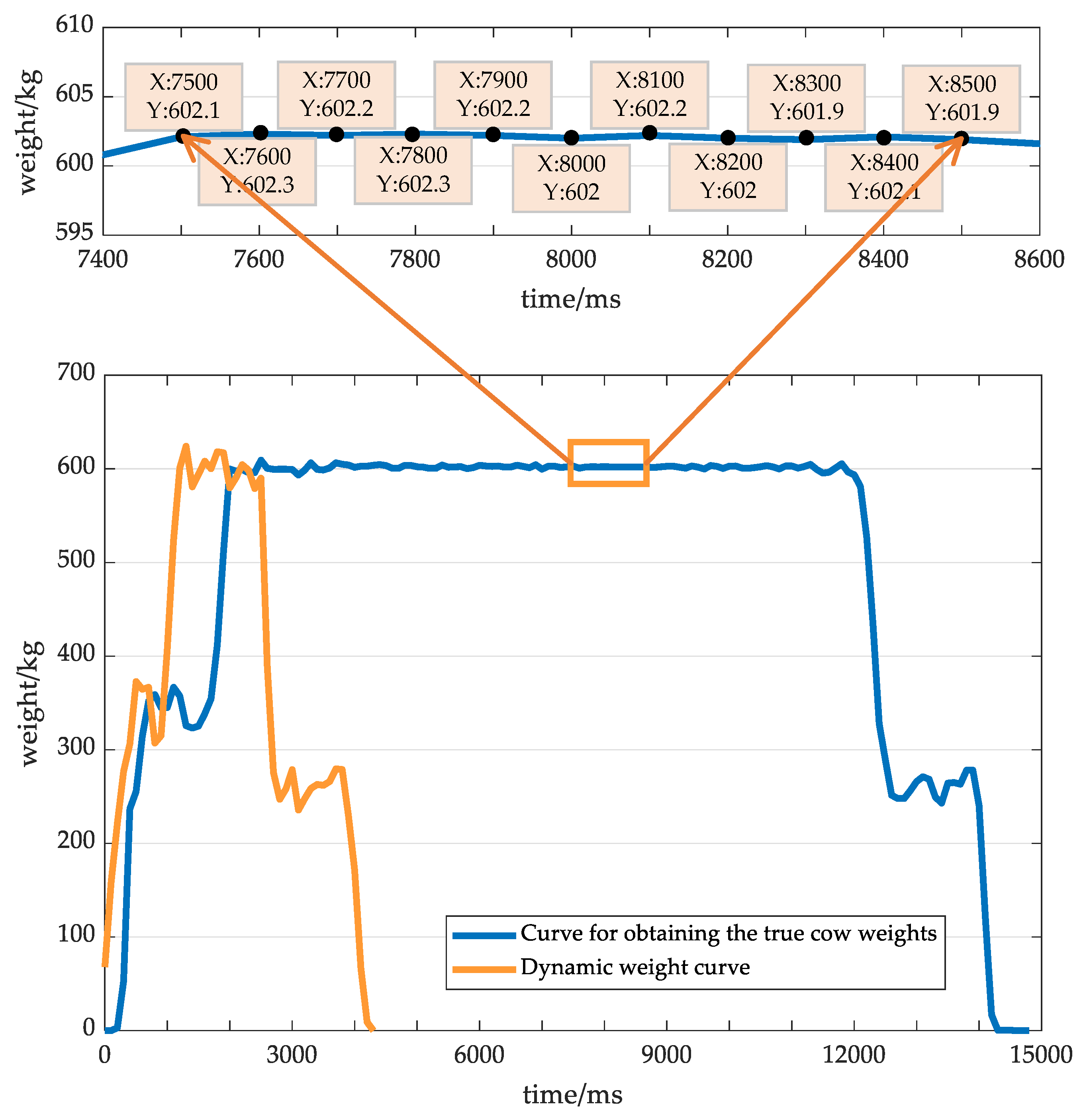

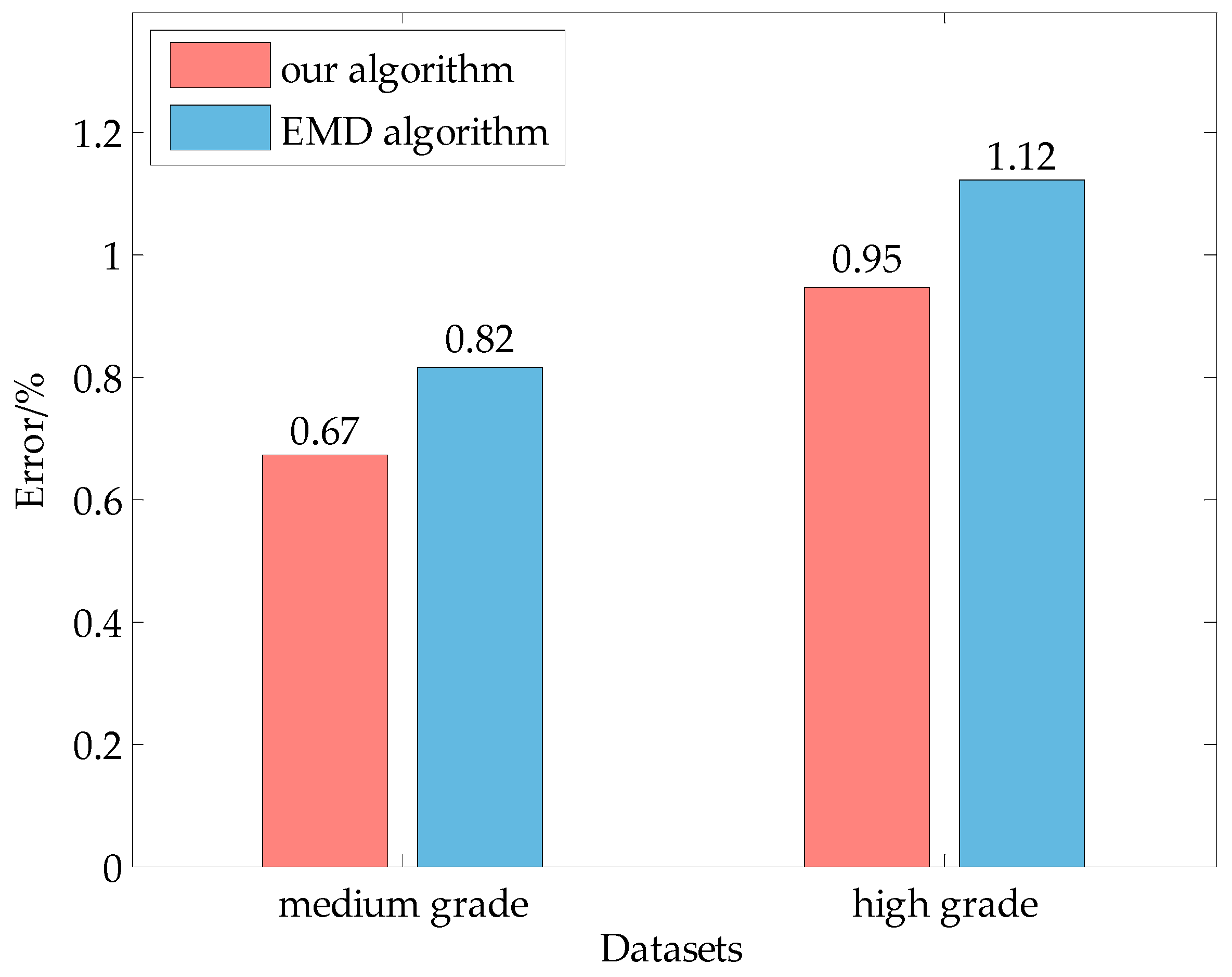

3.2. Dynamic Weighing Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Riley, D.G.; Burke, J.M.; Chase, C.C.; Coleman, S.W. Heterosis and direct effects for Charolais-sired calf weight and growth, cow weight and weight change, and ratios of cow and calf weights and weight changes across warm season lactation in Romosinuano, Angus, and F1 cows in Arkansas1. J. Anim. Sci. 2016, 94, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Mäntysaari, P.; Mäntysaari, E. Modeling of daily body weights and body weight changes of Nordic Red cows. J. Dairy Sci. 2015, 98, 6992–7002. [Google Scholar] [CrossRef] [PubMed]

- Pszczola, M.; Szalanski, M.; Rzewuska, K.; Strabel, T. Short communication: Improving repeatability of cows’ body weight recorded by an automated milking system. Livest. Sci. 2018, 214, 149–152. [Google Scholar] [CrossRef]

- Menezes, G.C.D.C.D.; Filho, S.V.; Lopez-Villalobos, N.; Ruas, J.R.M.; Detmann, E.; Zanetti, D.; Menezes, A.D.C.; Morris, S.; Mariz, L.D.S.; Duarte, M.D.S.D. Effect of feeding strategies on weaning weight and milk production of Holstein × Zebu calves in dual purpose milk production systems. Trop. Anim. Heal. Prod. 2015, 47, 1095–1100. [Google Scholar] [CrossRef]

- Bossen, D.; Weisbjerg, M.R.; Munksgaard, L.; Højsgaard, S. Allocation of feed based on individual dairy cow live weight changes. Livest. Sci. 2009, 126, 252–272. [Google Scholar] [CrossRef]

- Jensen, C.; Østergaard, S.; Bertilsson, J.; Weisbjerg, M.R. Responses in live weight change to net energy intake in dairy cows. Livest. Sci. 2015, 181, 163–170. [Google Scholar] [CrossRef]

- Podlahová, Š.; Smutný, L.; Šoch, M. Potential utilization of automatic cows weighing for evaluation of health and nutritional condition of herd. Lucr. Stiint. Zooteh. Si Biotehnol. 2011, 44, 308–314. [Google Scholar]

- Mulliniks, T.; Beard, J.; King, T. 108 impacts of dam age and milk production on cow/calf profitability. J. Anim. Sci. 2019, 97, 60–61. [Google Scholar] [CrossRef]

- Jones, F.M.; Accioly, J.M.; Copping, K.J.; Deland, M.P.B.; Graham, J.F.; Hebart, M.L.; Herd, R.M.; Laurence, M.; Lee, S.J.; Speijers, E.J.; et al. Divergent breeding values for fatness or residual feed intake in Angus cattle. 1. Pregnancy rates of heifers differed between fat lines and were affected by weight and fat. Anim. Prod. Sci. 2018, 58, 33–42. [Google Scholar] [CrossRef]

- Buckley, F.; O’Sullivan, K.; Mee, J.F.; Evans, R.D.; Dillon, P. Relationships among milk yield, body condition, cow weight, and reproduction in spring-calved Holstein-Friesians. J. Dairy Sci. 2003, 86, 2308–2319. [Google Scholar] [CrossRef]

- Aldridge, M.N.; Lee, S.J.; Taylor, J.D.; Popplewell, G.I.; Job, F.R.; Pitchford, W.S. The use of walk over weigh to predict calving date in extensively managed beef herds. Anim. Prod. Sci. 2017, 57, 583–591. [Google Scholar] [CrossRef]

- Menzies, D.; Patison, K.P.; Corbet, N.J.; Swain, D.L. Using walk-over-weighing technology for parturition date determination in beef cattle. Anim. Prod. Sci. 2018, 58, 1743–1750. [Google Scholar] [CrossRef]

- Segerkvist, K.A.; Höglund, J.; Österlund, H.; Wik, C.; Högberg, N.; Hessle, A. Automatic weighing as an animal health monitoring tool on pasture. Livest. Sci. 2020, 240, 104157. [Google Scholar] [CrossRef]

- Wangchuk, K.; Wangdi, J.; Mindu, M. Comparison and reliability of techniques to estimate live cattle body weight. J. Appl. Anim. Res. 2018, 46, 349–352. [Google Scholar] [CrossRef]

- Pezzuolo, A.; Milani, V.; Zhu, D.; Guo, H.; Guercini, S.; Marinello, F. On-barn pig weight estimation based on body measurements by structure-from-motion (SfM). Sensors 2018, 18, 3603. [Google Scholar] [CrossRef]

- Pastell, M.; Takko, H.; Gröhn, H.; Hautala, M.; Poikalainen, V.; Praks, J.; Veermäe, I.; Kujala, M.; Ahokas, J. Assessing cows’ welfare: Weighing the cow in a milking robot. Biosyst. Eng. 2006, 93, 81–87. [Google Scholar] [CrossRef]

- Liu, X.; Cai, Y. Design of automatic weighing system based on RFID and PLC. In Proceedings of the 2017 Chinese Automation Congress (CAC), Jinan, China, 20−22 October 2017; pp. 7020–7024. [Google Scholar]

- Dickinson, R.A.; Morton, J.M.; Beggs, D.S.; Anderson, G.A.; Pyman, M.F.; Mansell, P.D.; Blackwood, C.B. An automated walk-over weighing system as a tool for measuring liveweight change in lactating dairy cows. J. Dairy Sci. 2013, 96, 4477–4486. [Google Scholar] [CrossRef]

- Alawneh, J.I.; Stevenson, M.A.; Williamson, N.B.; Lopez-Villalobos, N.; Otley, T. Automatic recording of daily walkover liveweight of dairy cattle at pasture in the first 100 days in milk. J. Dairy Sci. 2011, 94, 4431–4440. [Google Scholar] [CrossRef]

- González-García, E.; Alhamada, M.; Pradel, J.; Douls, S.; Parisot, S.; Bocquier, F.; Menassol, J.B.; Llach, I.; González, L.A. A mobile and automated walk-over-weighing system for a close and remote monitoring of liveweight in sheep. Comput. Electron. Agric. 2018, 153, 226–238. [Google Scholar] [CrossRef]

- Cveticanin, D.; Wendl, G. Dynamic weighing of dairy cows: Using a lumped-parameter model of cow walk. Comput. Electron. Agric. 2004, 44, 63–69. [Google Scholar] [CrossRef]

- Wen, C.; Xie, Z.; Deng, Y. Portable dynamic weighing system of yak based on BP neural network. In Proceedings of the 2nd International Conference on Mechatronics Engineering and Information Technology (ICMEIT 2017), Dalian, China, 13–17 May 2017. [Google Scholar]

- Larios, D.F.; Rodríguez, C.; Barbancho, J.; Baena, M.; Leal, M.Á.; Marín, J.; Leon, C.; Bustamante, J. An Automatic Weighting System for Wild Animals Based in an Artificial Neural Network: How to Weigh Wild Animals without Causing Stress. Sensors 2013, 13, 2862–2883. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.W.; Zhang, H.J.; Lu, D.M.; Zhang, Z.M. Dynamic weighing of full-size wood composite panels based on wavelet denoising and empirical mode decomposition algorithm. Acta Metrol. Sin. 2017, 38, 300–303. [Google Scholar]

- Kedadouche, M.; Thomas, M.; Tahan, A. A comparative study between empirical wavelet transforms and empirical mode decomposition methods: Application to bearing defect diagnosis. Mech. Syst. Signal Process. 2016, 81, 88–107. [Google Scholar] [CrossRef]

- Long, J.; Takahata, H.; Umetsu, K.; Hoshiba, H.; Takeyama, I. A livestock walk-through scale system. J. Soc. Agric. Struct. Jpn. 1991, 21, 175–182. [Google Scholar]

- Ma, Y.; Zhang, S.; Qi, D.; Luo, Z.; Li, R.; Potter, T.; Zhang, Y. Driving drowsiness detection with EEG using a modified hierarchical extreme learning machine algorithm with particle swarm optimization: A pilot study. Electronics 2020, 9, 775. [Google Scholar] [CrossRef]

- Attal, F.; Mohammed, S.; Dedabrishvili, M.; Chamroukhi, F.; Oukhellou, L.; Amirat, Y. Physical human activity recognition using wearable sensors. Sensors 2015, 15, 31314–31338. [Google Scholar] [CrossRef]

- Wang, D.; Xie, L.; Yang, S.X.; Tian, F. Support Vector Machine Optimized by Genetic Algorithm for Data Analysis of Near-Infrared Spectroscopy Sensors. Sensors 2018, 18, 3222. [Google Scholar] [CrossRef]

- Gilles, J. Empirical wavelet transform. IEEE Trans. Signal Process. 2013, 61, 3999–4010. [Google Scholar] [CrossRef]

- Xu, X.; Liang, Y.; He, P.; Yang, J. Adaptive Motion Artifact Reduction Based on Empirical Wavelet Transform and Wavelet Thresholding for the Non-Contact ECG Monitoring Systems. Sensors 2019, 19, 2916. [Google Scholar] [CrossRef] [PubMed]

- Huang, N.; Qi, J.; Li, F.; Yang, D.; Cai, G.; Huang, G.; Zheng, J.; Li, Z. Short-Circuit Fault Detection and Classification Using Empirical Wavelet Transform and Local Energy for Electric Transmission Line. Sensors 2017, 17, 2133. [Google Scholar] [CrossRef] [PubMed]

- Taylor, W.; Shah, S.A.; Dashtipour, K.; Zahid, A.; Abbasi, Q.; Imran, M. An Intelligent Non-Invasive Real-Time Human Activity Recognition System for Next-Generation Healthcare. Sensors 2020, 20, 2653. [Google Scholar] [CrossRef] [PubMed]

- Chawla, N.V.; Bowyer, K.W.; Hall, L.O.; Kegelmeyer, W.P. SMOTE: Synthetic minority over-sampling technique. J. Artif. Intell. Res. 2002, 16, 321–357. [Google Scholar] [CrossRef]

- Zhu, T.; Weng, Z.; Chen, G.; Fu, L. A hybrid deep learning system for real-world mobile user authentication using motion sensors. Sensors 2020, 20, 3876. [Google Scholar] [CrossRef] [PubMed]

| Characteristic | Category | Average |

|---|---|---|

| range/kg | low grade | 24.3260 |

| medium grade | 59.7984 | |

| high grade | 107.9911 | |

| standard deviation | low grade | 10.5815 |

| medium grade | 19.5883 | |

| high grade | 37.8103 | |

| peak factor | low grade | 0.0650 |

| medium grade | 0.1090 | |

| high grade | 0.1901 | |

| waveform factor | low grade | 1.0002 |

| medium grade | 1.0006 | |

| high grade | 1.0022 | |

| speed/m/s | slow grade | 0.7525 |

| medium grade | 1.2500 | |

| high grade | 1.6685 |

| Evaluation Index | Computational Formula |

|---|---|

| Precision/% | |

| recall/% | |

| specificity/% | |

| Predicted Classification | Actual Classification | |||

|---|---|---|---|---|

| Low Grade | Medium Grade | High Grade | Total | |

| low grade | 101 | 2 | 0 | 103 |

| medium grade | 0 | 88 | 2 | 90 |

| high grade | 0 | 0 | 113 | 113 |

| total | 101 | 90 | 115 | 306 |

| Evaluation Index | Category | ||

|---|---|---|---|

| Low Grade | Medium Grade | High Grade | |

| accuracy/% | 98.6928 | ||

| precision/% | 98.0583 | 97.7778 | 100 |

| recall/% | 100 | 97.7778 | 98.2601 |

| specificity/% | 99.0244 | 99.0741 | 100 |

| 0.9902 | 0.9778 | 0.9912 | |

| Motion State | Mean Error Rate/% | Maximum Error Rate/% |

|---|---|---|

| low grade | 0.1838 | 0.5742 |

| medium grade | 0.6724 | 1.6924 |

| high grade | 0.9462 | 1.9696 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, N.; Kang, X.; Han, H.; Liu, G.; Zhang, Y.; Mei, S. Research on a Dynamic Algorithm for Cow Weighing Based on an SVM and Empirical Wavelet Transform. Sensors 2020, 20, 5363. https://doi.org/10.3390/s20185363

Feng N, Kang X, Han H, Liu G, Zhang Y, Mei S. Research on a Dynamic Algorithm for Cow Weighing Based on an SVM and Empirical Wavelet Transform. Sensors. 2020; 20(18):5363. https://doi.org/10.3390/s20185363

Chicago/Turabian StyleFeng, Ningning, Xi Kang, Haoyuan Han, Gang Liu, Yan’e Zhang, and Shuli Mei. 2020. "Research on a Dynamic Algorithm for Cow Weighing Based on an SVM and Empirical Wavelet Transform" Sensors 20, no. 18: 5363. https://doi.org/10.3390/s20185363

APA StyleFeng, N., Kang, X., Han, H., Liu, G., Zhang, Y., & Mei, S. (2020). Research on a Dynamic Algorithm for Cow Weighing Based on an SVM and Empirical Wavelet Transform. Sensors, 20(18), 5363. https://doi.org/10.3390/s20185363