Velocity Sensor for Real-Time Backstepping Control of a Multirotor Considering Actuator Dynamics

Abstract

1. Introduction

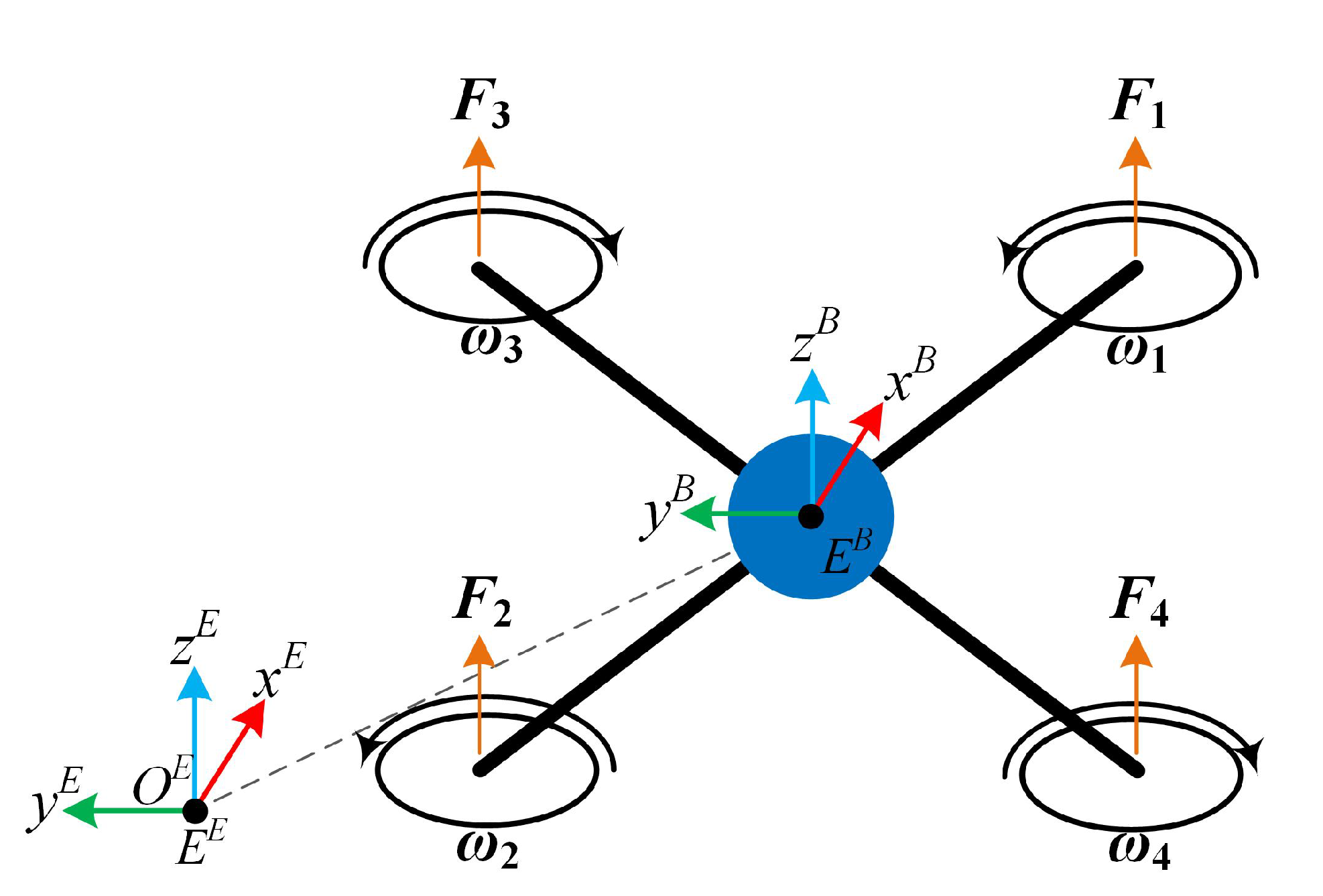

2. UAV’S Dynamical Model

2.1. Actuators Dynamical Model

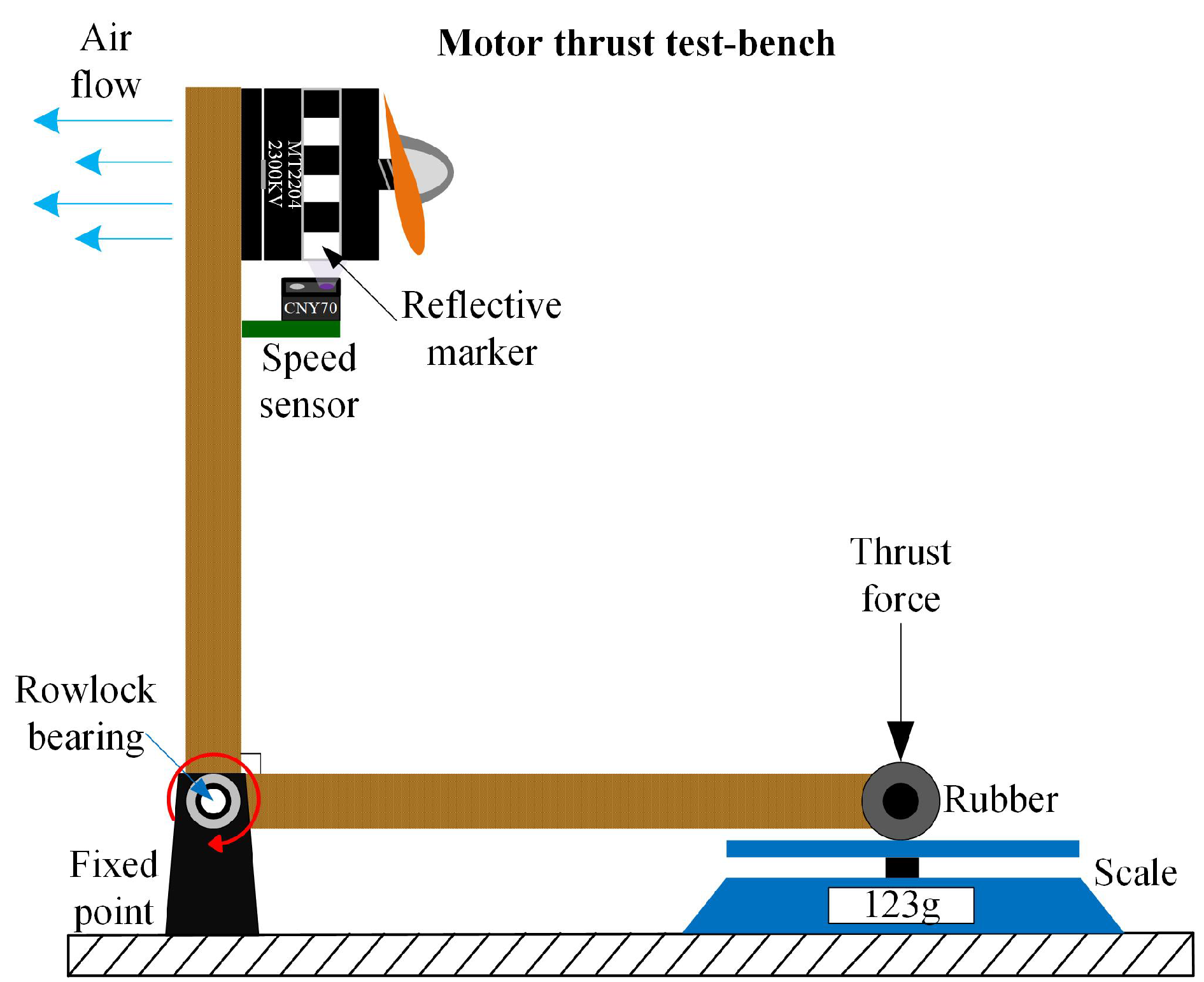

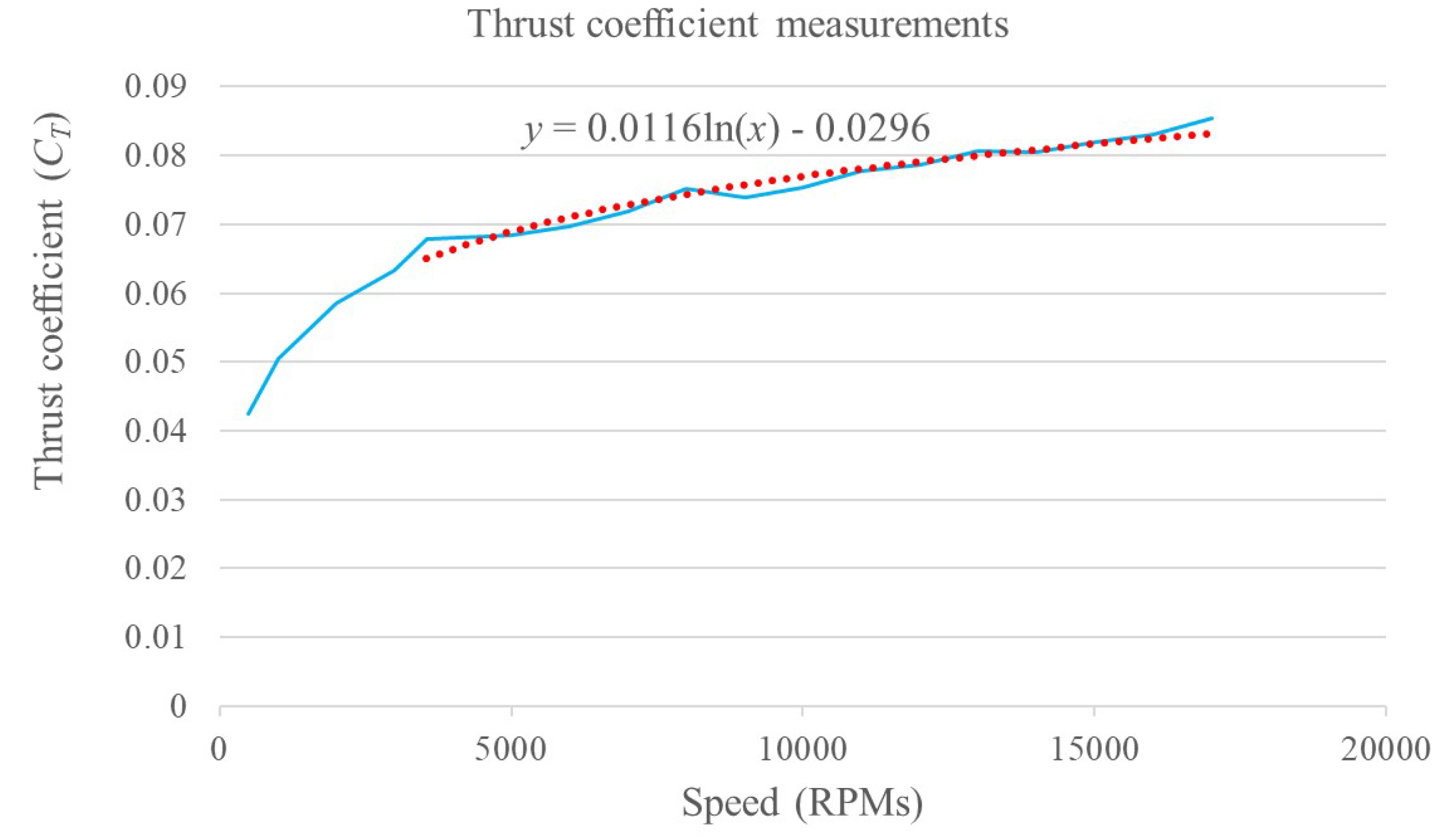

2.2. Dynamical Parameter Characterization

3. Controller Design

3.1. UAV Controller

3.2. Levant’s Differentiator

3.3. Actuator Controller

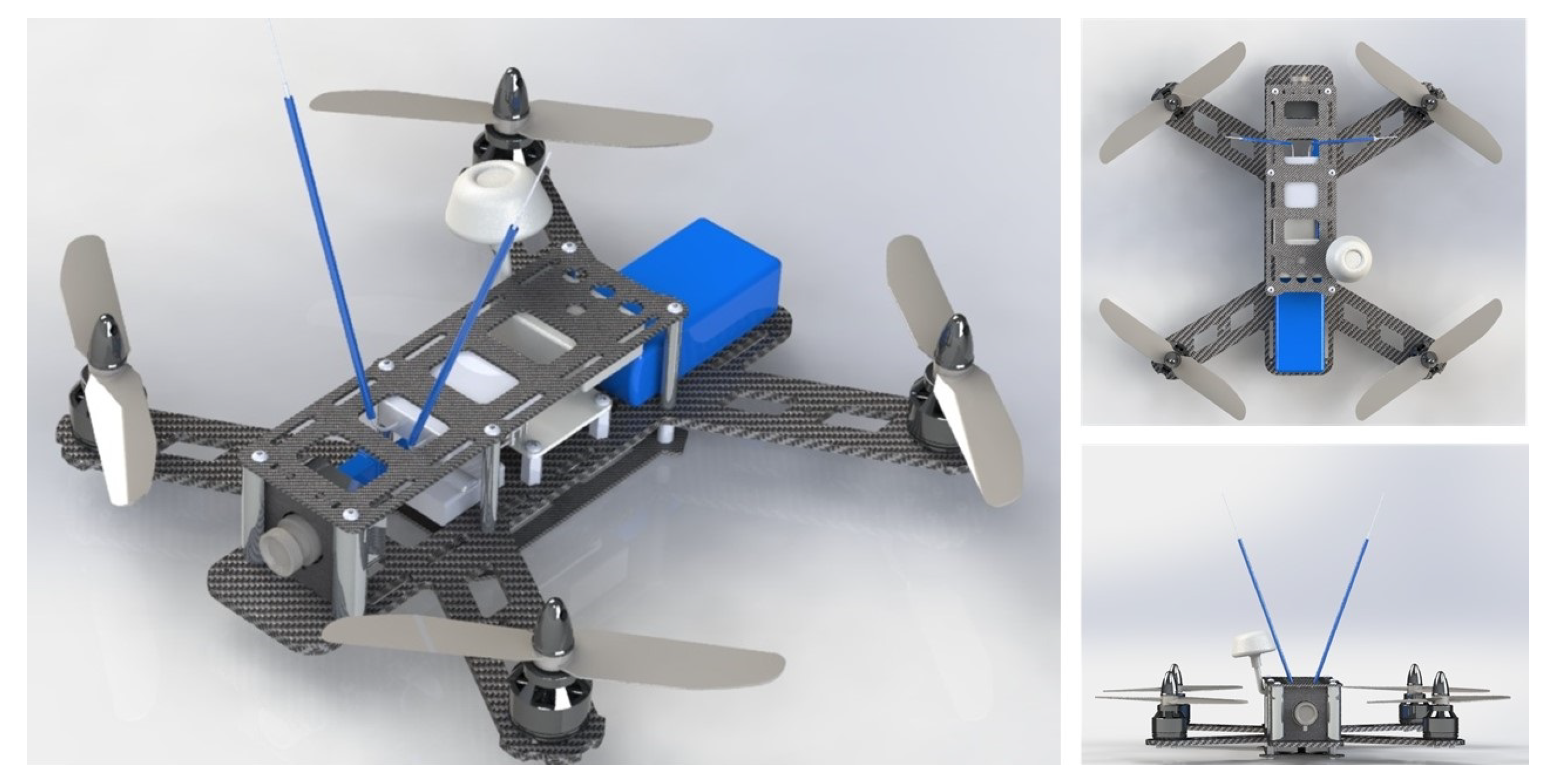

4. Experimental Setup

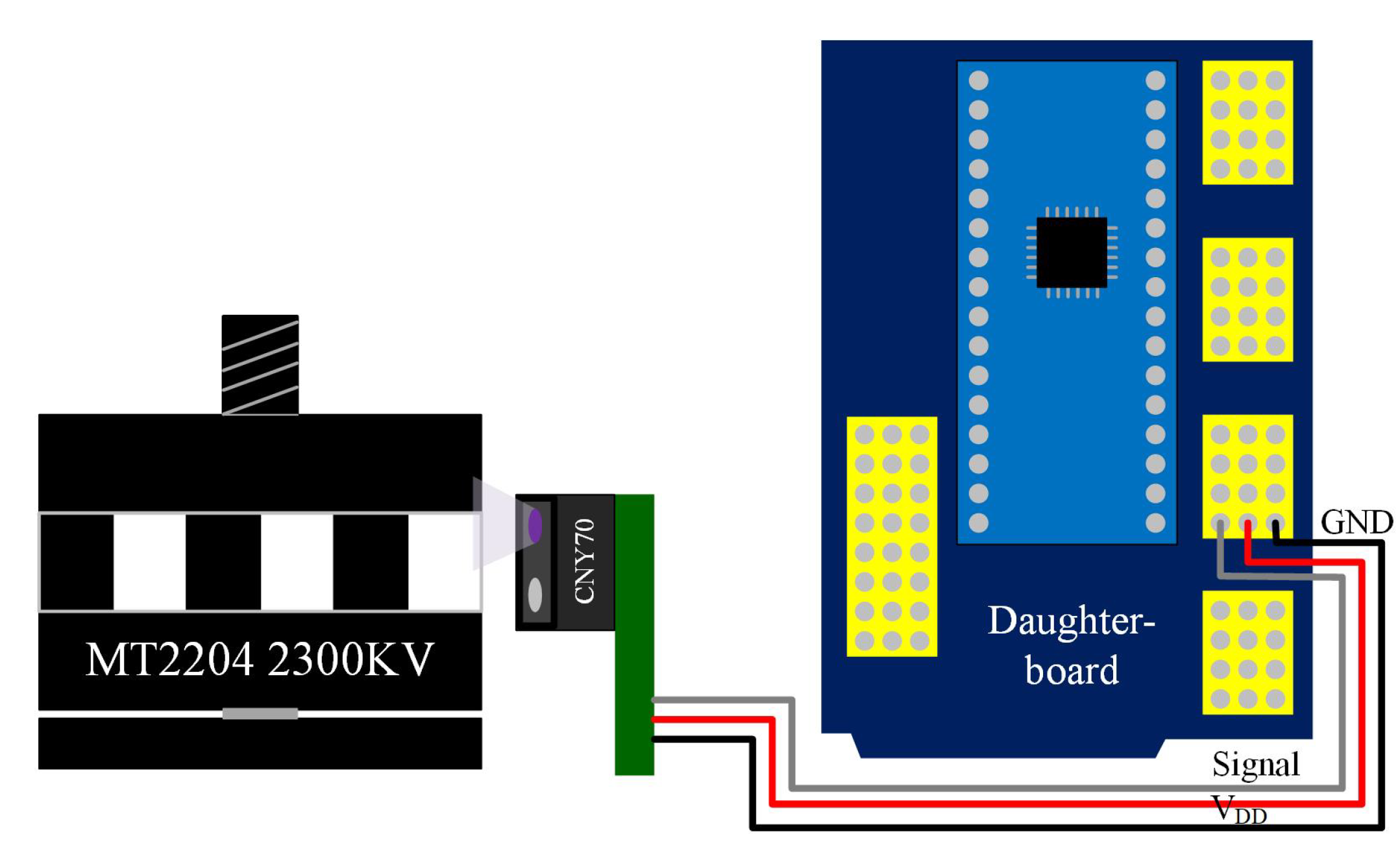

4.1. Angular Velocity Sensor for the UAV Rotors

4.2. Velocity Sensor’s Signal Conditioning

4.3. Overall Controller Implementation

| Algorithm 1: Overall Controller Execution. |

|

5. Results

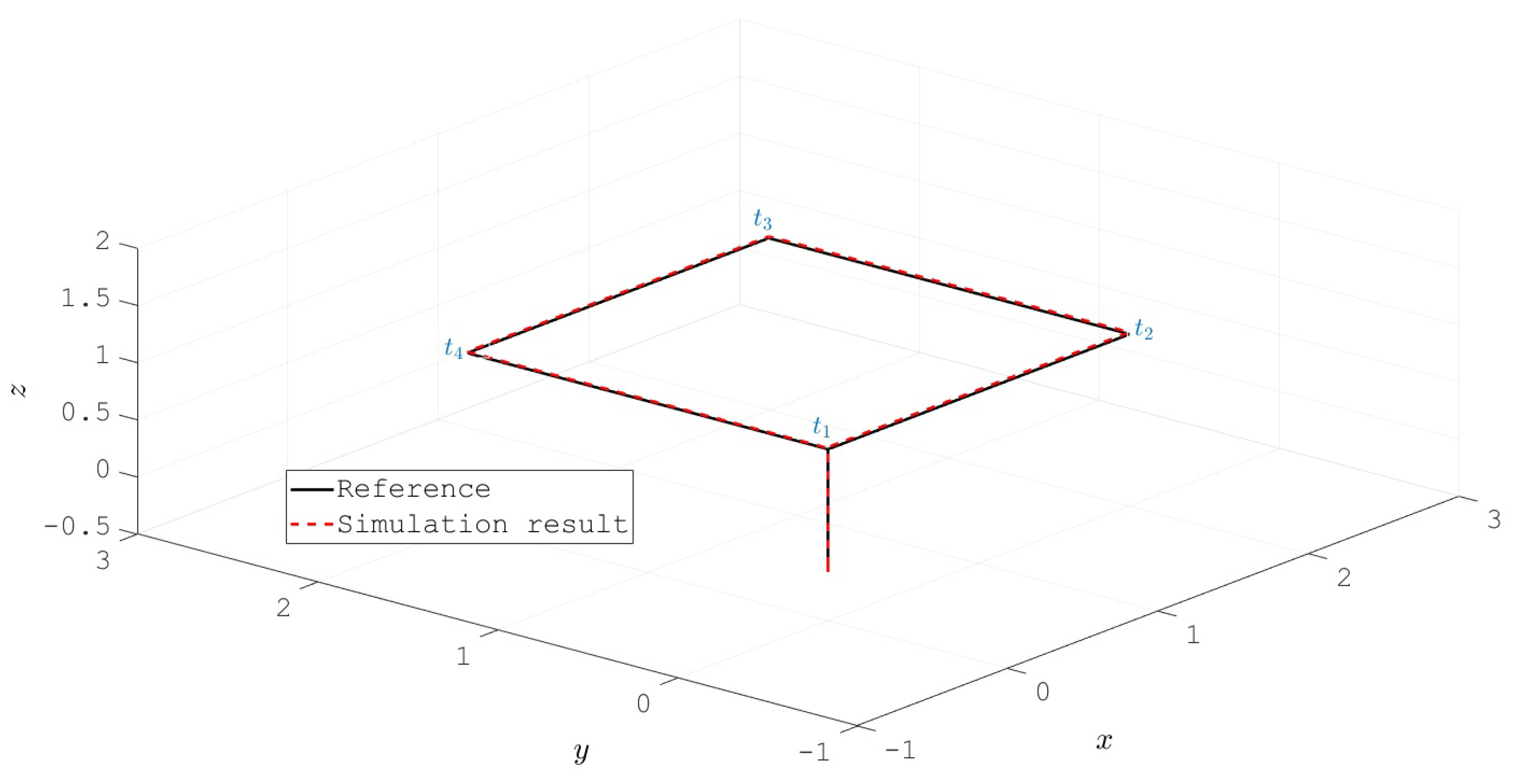

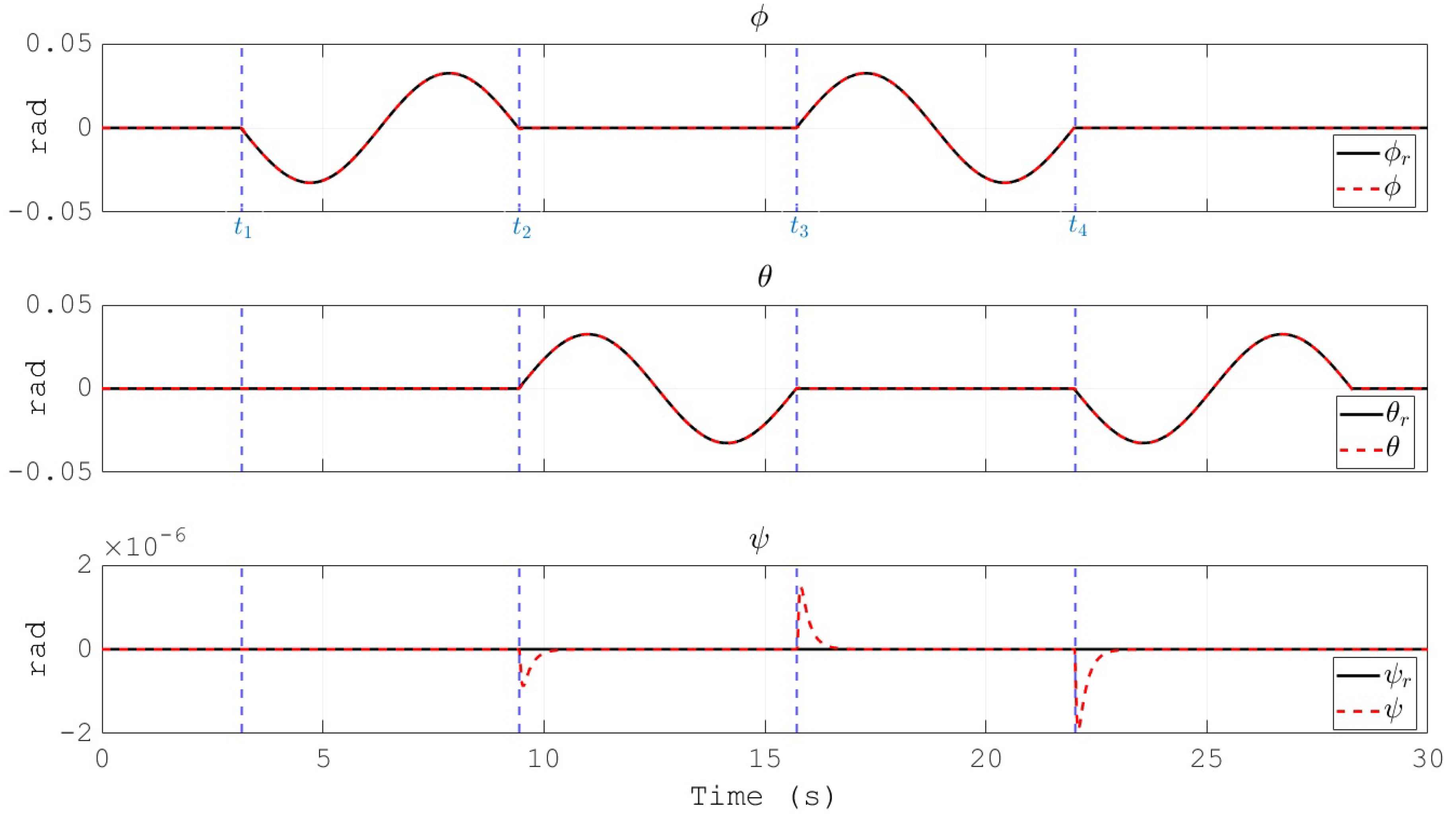

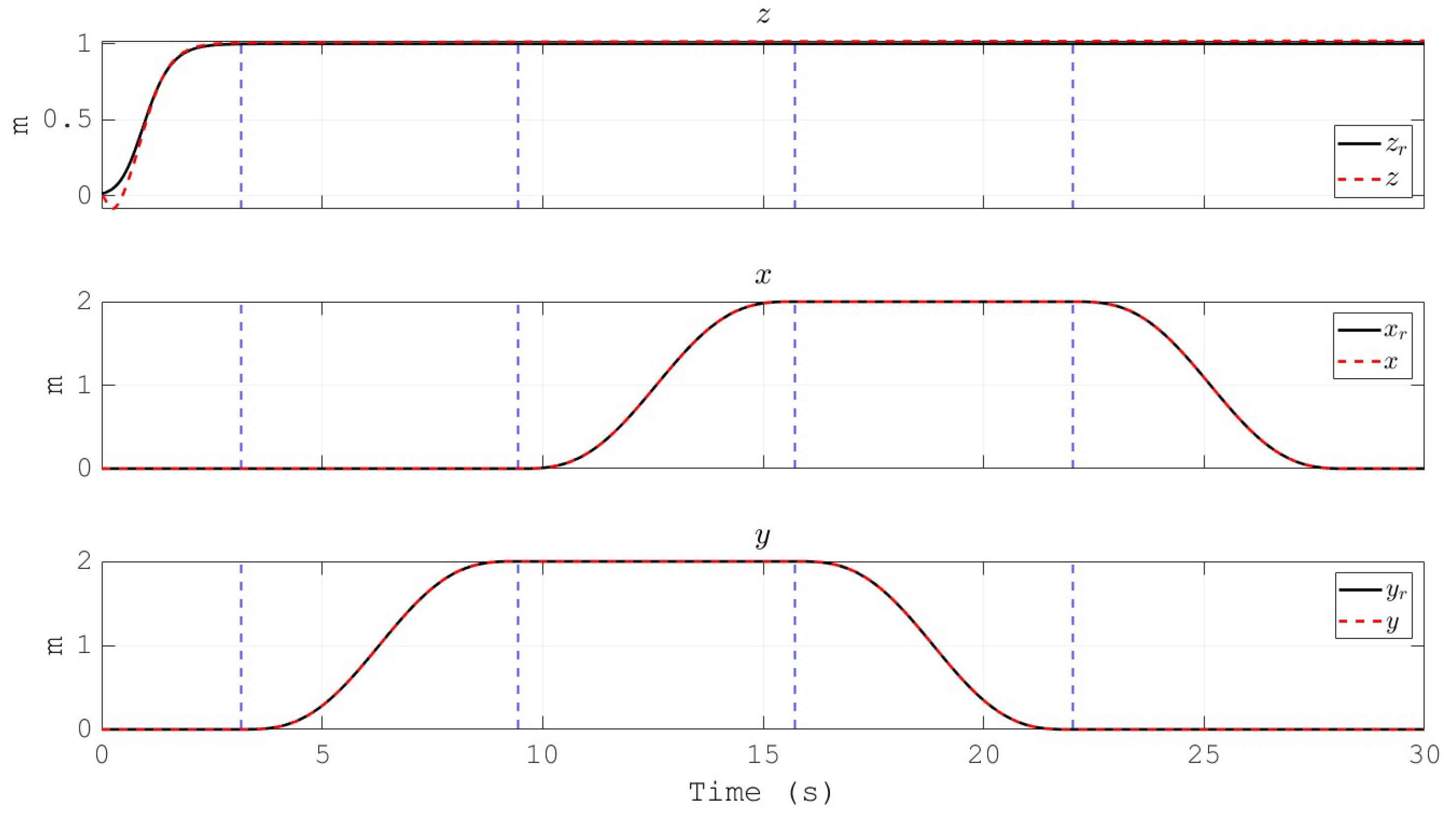

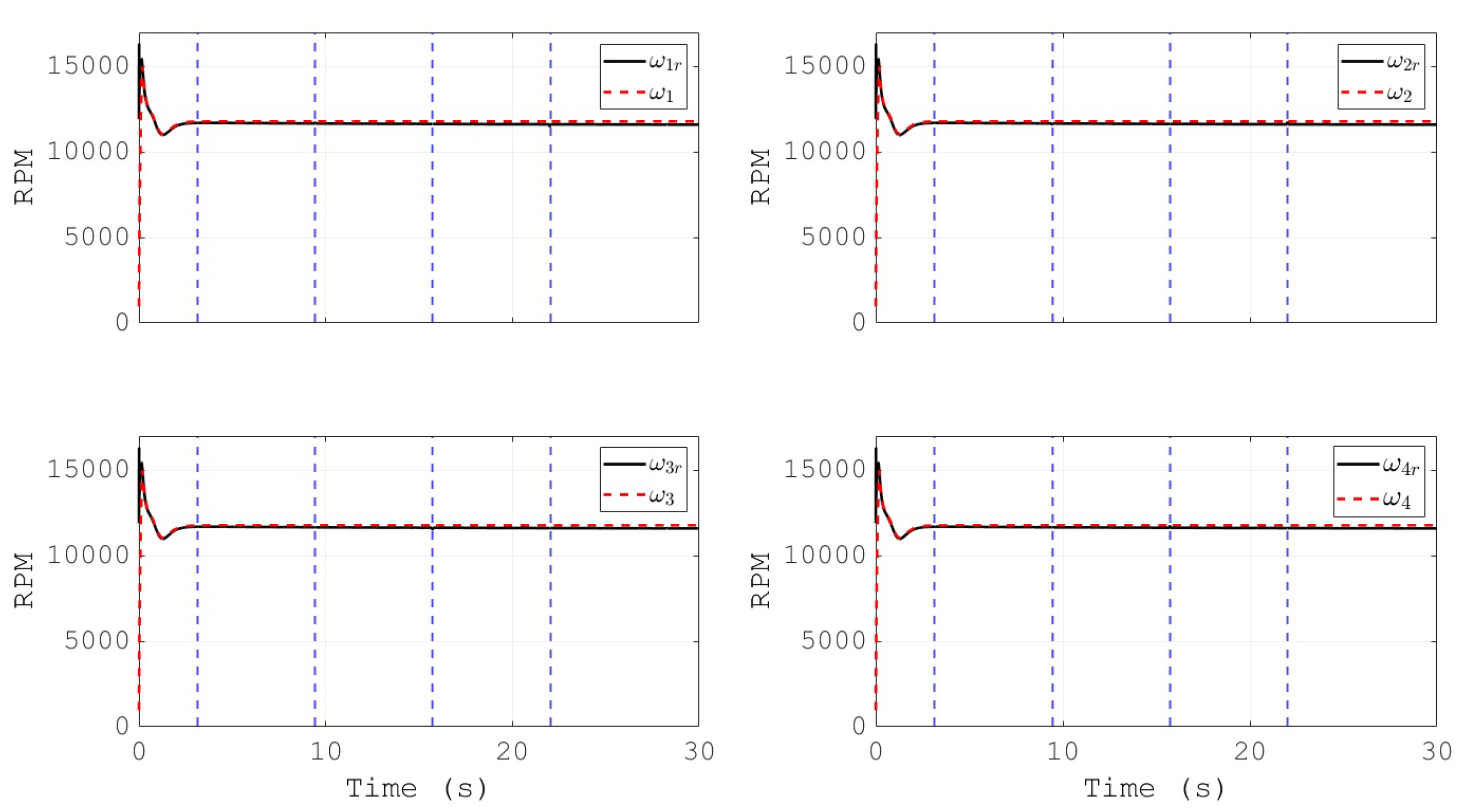

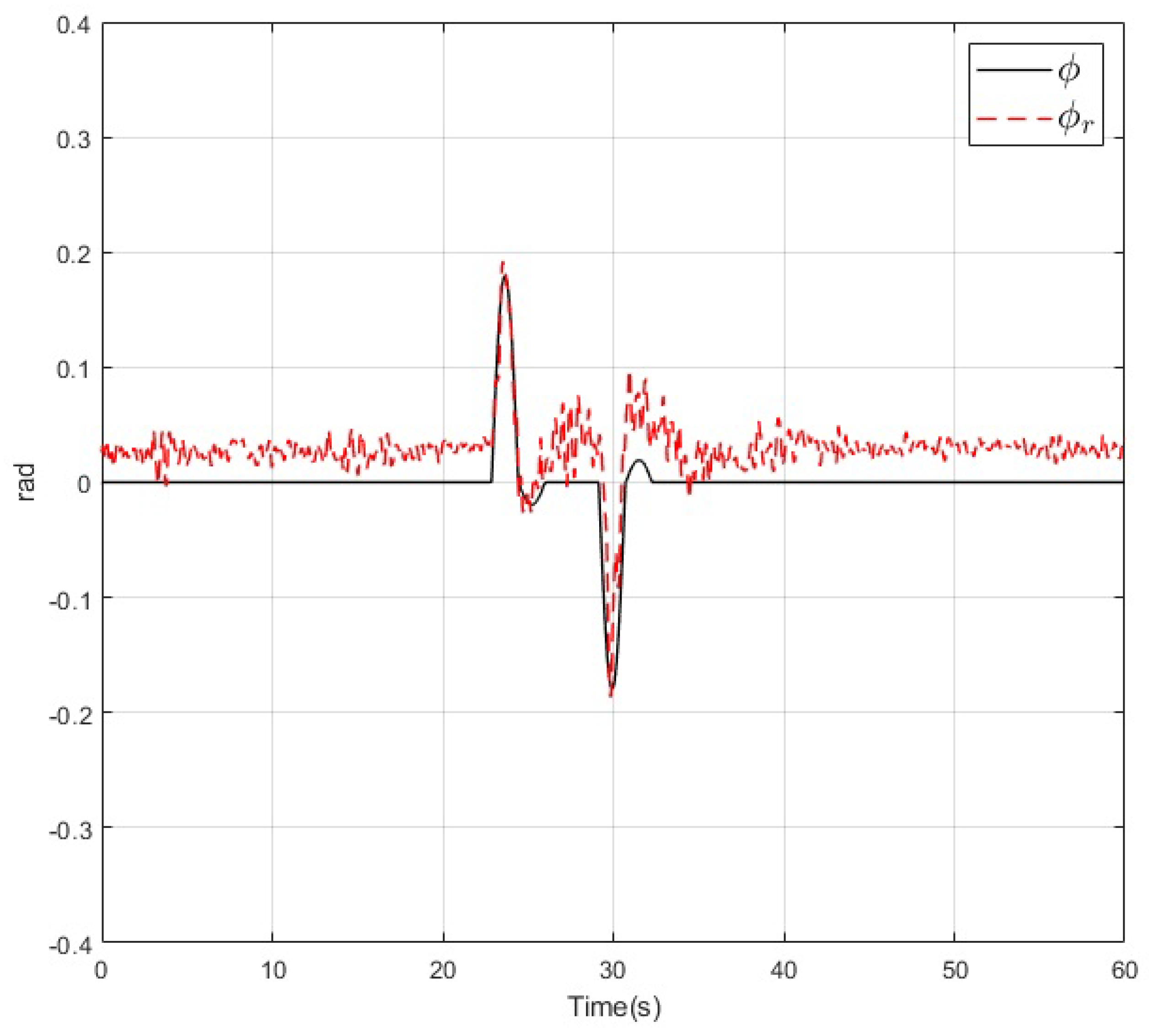

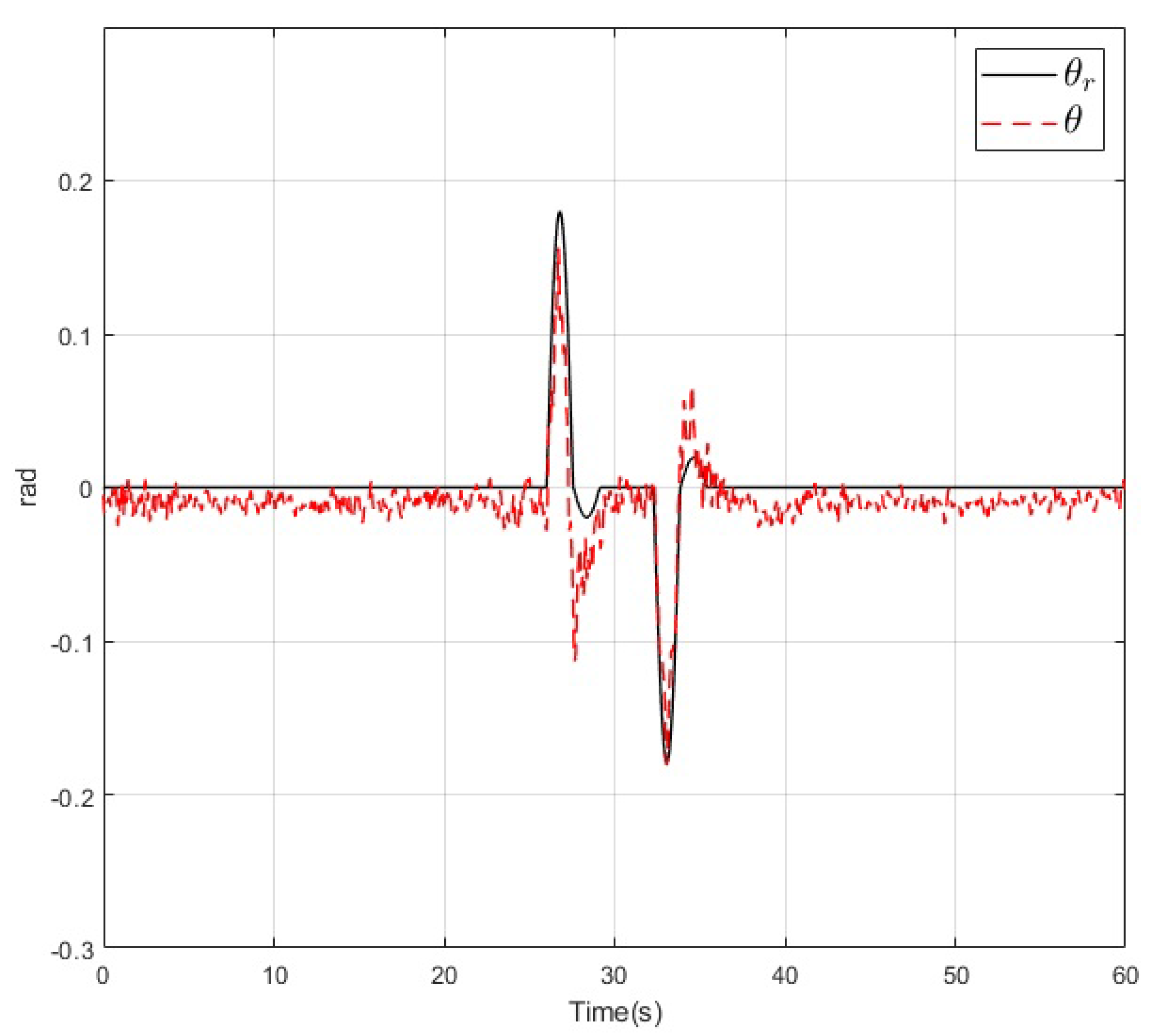

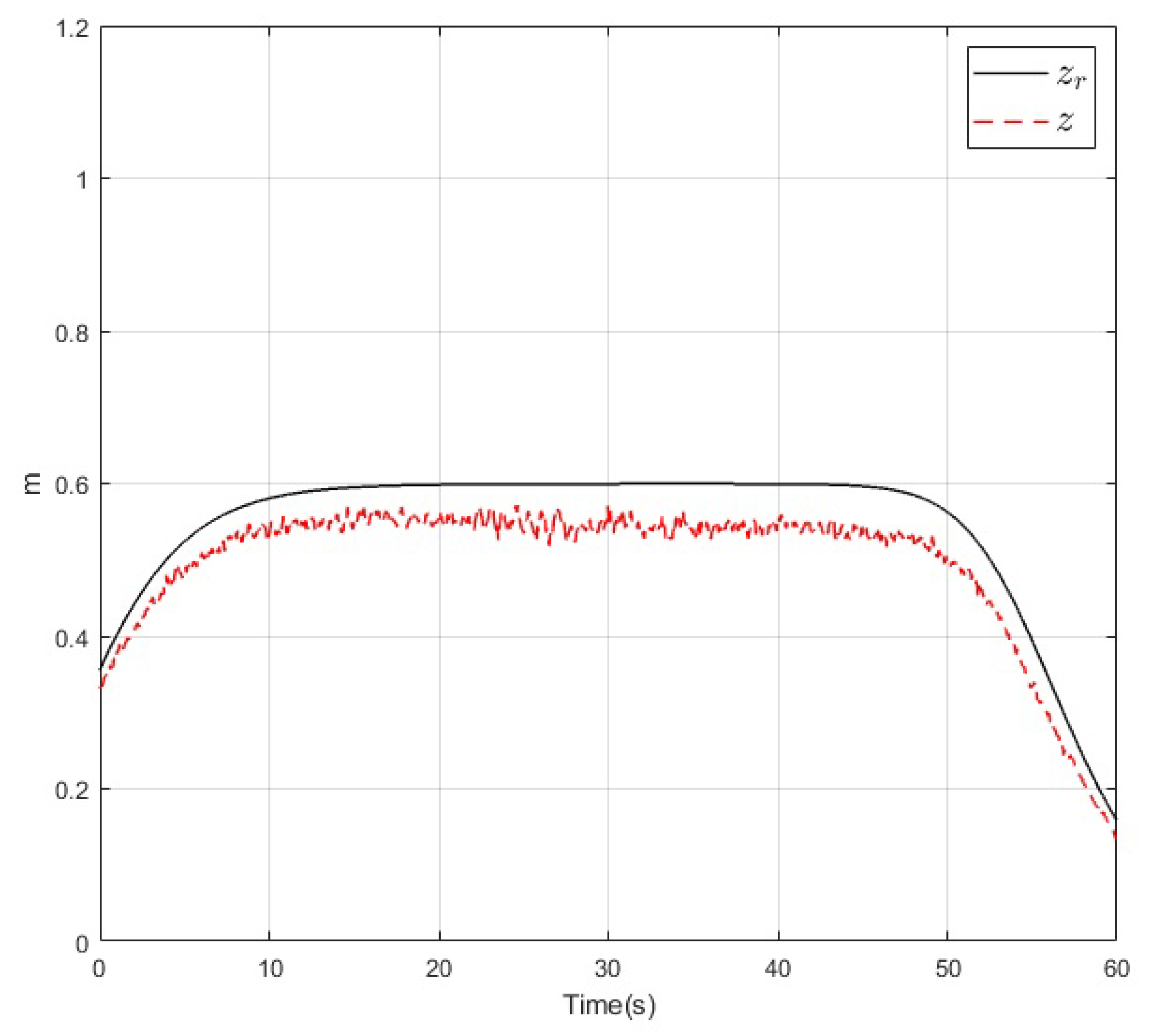

5.1. Simulation Results

5.2. Experimental Results

6. Discussion

7. Materials and Methods

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | Three Dimensional |

| BLDC | Brushless Direct Current |

| CAD | Computer-Aided Design |

| EMF | Electro-Mechanical Force |

| ESC | Electronic Speed Controller |

| GPS | Global Positioning System |

| IMU | Inertial Measurement Unit |

| LQR | Linear Quadratic Regulator |

| MPC | Model Predictive Control |

| PID | Proportional-Integral-Derivative |

| PWM | Pulse-Width Modulation |

| RMSE | Root Mean Squared Error |

| UAV | Unmanned Aerial Vehicle |

References

- Kim, J.; Gadsden, S.; Wilkerson, S. A Comprehensive Survey of Control Strategies for Autonomous Quadrotors. Can. J. Electr. Comput. Eng. 2020, 43, 3–16. [Google Scholar]

- Rubí, B.; Pérez, R.; Morcego, B. A Survey of Path Following Control Strategies for UAVs Focused on Quadrotors. J. Intell. Robot. Syst. 2020, 98, 241–265. [Google Scholar] [CrossRef]

- Li, J.; Li, Y. Dynamic analysis and PID control for a quadrotor. In Proceedings of the 2011 IEEE International Conference on Mechatronics and Automation, Beijing, China, 7–10 August 2011; pp. 573–578. [Google Scholar]

- Surya, Y.; Pitowarno, E. Robust adaptive proportional derivative-active force control for unmanned hexacopter. In Proceedings of the 2016 International Electronics Symposium (IES), Denpasar, Indonesia, 29–30 September 2016; pp. 1–6. [Google Scholar]

- Kukreti, S.; Kumar, M.; Cohen, K. Genetically tuned Lqr based path following for UAVs under wind disturbance. In Proceedings of the 2016 International Conference on Unmanned Aircraft Systems (ICUAS), Arlington, VA, USA, 7–10 June 2016; pp. 267–274. [Google Scholar]

- Alexis, K.; Papachristos, C.; Siegwart, R.; Tzes, A. Robust model predictive flight control of unmanned rotorcrafts. J. Intell. Robot. Syst. 2016, 81, 443–469. [Google Scholar] [CrossRef]

- Bangura, M.; Mahony, R. Real-time model predictive control for quadrotors. IFAC Proc. Vol. 2014, 47, 11773–11780. [Google Scholar] [CrossRef]

- Bouabdallah, S.; Siegwart, R. Backstepping and sliding-mode techniques applied to an indoor micro quadrotor. In Proceedings of the 2005 IEEE International Conference on Robotics and Automation, Barcelona, Spain, 18–22 April 2005; pp. 2247–2252. [Google Scholar]

- Arellano-Muro, C.; Luque-Vega, L.; Castillo-Toledo, B.; Loukianov, A. Backstepping control with sliding mode estimation for hexacopter. In Proceedings of the 2013 10th International Conference on Electrical Engineering, Computing Science and Automatic Control (CCE), Mexico City, Mexico, 30 September–4 October 2013; pp. 31–36. [Google Scholar]

- Lippiello, V.; Ruggiero, F.; Serra, D. Emergency landing for a quadrotor in case of a propeller failure: A backstepping approach. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Chicago, IL, USA, 14–18 September 2014; pp. 4782–4788. [Google Scholar]

- Toledo, M.; Sanchez, E.; Alanis, A.; Flórez, J.; Perez-Cisneros, M. Real-Time Integral Backstepping with Sliding Mode Control for a Quadrotor UAV. IFAC-PapersOnLine 2018, 51, 549–554. [Google Scholar] [CrossRef]

- Dierks, T.; Jagannathan, S. Output feedback control of a quadrotor UAV using neural networks. IEEE Trans. Neural Netw. 2010, 21, 50–66. [Google Scholar] [CrossRef] [PubMed]

- Rosales, C.; Rossomando, C.; Soria, C.; Carelli, R. Neural control of a Quadrotor: A state-observer based approach. In Proceedings of the 2018 International Conference on Unmanned Aircraft Systems (ICUAS), Dallas, TX, USA, 12–15 June 2018; pp. 647–653. [Google Scholar]

- Lee, H.; Kim, H.J. Robust control of a quadrotor using takagi-sugeno fuzzy model and an lmi approach. In Proceedings of the International Conference on Control, Automation and Systems, Seoul, Korea, 22–25 October 2014; pp. 370–374. [Google Scholar]

- Santos, M.; López, V.; Morata, F. Intelligent fuzzy controller of a quadrotor. In Proceedings of the 2010 IEEE International Conference on Intelligent Systems and Knowledge Engineering, Hangzhou, China, 15–16 November 2010; pp. 141–146. [Google Scholar]

- Zhou, B.; Satyavada, H.; Baldi, S. Adaptive path following for unmanned aerial vehicles in time-varying unknown wind environments. In Proceedings of the 2017 American Control Conference (ACC), Seattle, WA, USA, 24–26 May 2017; pp. 1127–1132. [Google Scholar]

- Lou, W.; Guo, X. Adaptive trajectory tracking control using reinforcement learning for quadrotor. Int. J. Adv. Robot. Syst. 2016, 13, 1–10. [Google Scholar] [CrossRef]

- Utkin, V.; Guldner, J.; Shi, J. Sliding Mode Control in Electro-Mechanical Systems, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Basci, A.; Can, K.; Orman, K.; Derdiyok, A. Trajectory tracking control of a four rotor unmanned aerial vehicle based on continuous sliding mode controller. Elektron. Elektrotechnika 2017, 23, 12–19. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Zhao, S.; Shen, L. Vector field based sliding mode control of curved path following for miniature unmanned aerial vehicles in winds. J. Syst. Sci. Complex. 2018, 31, 302–324. [Google Scholar] [CrossRef]

- Coates, E.; Wenz, A.; Gryte, K.; Johansen, T. Propulsion System Modeling for Small Fixed-Wing UAVs. In Proceedings of the 2019 International Conference on Unmanned Aircraft Systems (ICUAS), Atlanta, GA, USA, 11–14 June 2019; pp. 748–757. [Google Scholar]

- Davis, E.; Pounds, P. Direct Sensing of Thrust and Velocity for a Quadrotor Rotor Array. IEEE Robot. Autom. Lett. 2017, 2, 1360–1366. [Google Scholar] [CrossRef]

- Bronz, M.; de Marina, H.G.; Hattenberger, G. In-Flight Thrust Measurement using On-Board Force Sensor. In Proceedings of the AIAA Atmospheric Flight Mechanics Conference, Grapevine, TX, USA, 9–13 January 2017; pp. 1–11. [Google Scholar]

- Gong, A.; Maunder, H.; Verstraete, D. Development of an in-flight thrust measurement system for UAVs. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10–12 July 2017; pp. 1–10. [Google Scholar]

- Safi’i, I.; Nurohman, C.; Hardy, D.; Rifianto, O.; Muhammad, H. Thrust modelling for a small UAV. AIP Conf. Proc. 2020, 2226, 030015. [Google Scholar]

- González-Hernández, I. Attitude stabilization of a Quad-rotor UAV based on rotor speed sensing with accelerometer data estimation via Kalman filtering. In Proceedings of the 31st Chinese Control Conference, Hefei, China, 25–27 July 2012; pp. 5123–5128. [Google Scholar]

- Parvathy, T.; Abraham, P. Fast response antiwindup self tuning fuzzy PID speed control of brushless DC motor drive. AIP Conf. Proc. 2020, 2222, 040014. [Google Scholar]

- Jaya, A.; Purwanto, E.; Fauziah, M.; Murdianto, F.; Prabowo, G.; Rusli, G. Design of PID-fuzzy for speed control of brushless DC motor in dynamic electric vehicle to improve steady-state performance. In Proceedings of the 2017 International Electronics Symposium on Engineering Technology and Applications (IES-ETA), Surabaya, Indonesia, 26–27 September 2017; pp. 179–184. [Google Scholar]

- Rif’an, M.; Yusivar, F.; Putro, B. Adaptive PID controller based on additional error of an inversed-control signal for improved performance of brushless DC motor. In Proceedings of the 2017 15th International Conference on Quality in Research, Nusa Dua, Indonesia, 24–27 July 2017; pp. 315–320. [Google Scholar]

- Kandiban, R.; Arulmozhiyal, R. Speed control of BLDC motor using adaptive fuzzy PID controller. Procedia Eng. 2012, 38, 306–313. [Google Scholar] [CrossRef]

- Gobinath, S.; Madheswaran, M. Deep perceptron neural network with fuzzy PID controller for speed control and stability analysis of BLDC motor. Soft Comput. 2020, 24, 10161–10180. [Google Scholar] [CrossRef]

- MATLAB, version 9.6.0.1072779 (R2019a); The MathWorks Inc.: Natick, MA, USA, 2019.

- GRABCAD COMMUNITY. ZMR250 Quadcopter Frame (rev. 2015). Available online: https://grabcad.com/library/zmr250-quadcopter-frame-1 (accessed on 21 August 2019).

- Levant, A. Higher-order sliding modes, differentiation and output-feedback control. Int. J. Control. 2003, 76, 924–941. [Google Scholar] [CrossRef]

- Levant, A. Robust exact differentiation via sliding mode technique. Automatica 1998, 34, 379–384. [Google Scholar] [CrossRef]

- Milosavljević, Č.; Peruničić, B.; Veselić, B. A new real differentiator with low-pass filter in control loop. Electronics 2010, 14, 27–32. [Google Scholar]

- Forrai, A. Embedded Control System Design: A Model Based Approach, 1st ed.; Springer: Berlin, Germany, 2013. [Google Scholar]

- Lozano, R. Unmanned Aerial Vehicles: Embedded Control, 1st ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Video Recording of the Real Time Experimental Results. Available online: https://youtu.be/RdDv3WunO1Y (accessed on 20 June 2020).

- Project’s Embedded Code Repository. Available online: https://drive.google.com/folderview?id=1YXmv2AeCgNLX_RdopMzKAezgqCmBPBDX (accessed on 27 March 2020).

| Parameter | Description | Value |

|---|---|---|

| m | Mass of the vehicle | 0.85 kg |

| g | Gravity force | 9.80665 m/s |

| l | Arm length | 0.1272 m |

| Thrust coefficient | 81.7445 × 10 | |

| Drag coefficient | 45 × | |

| Moment of inertia in the x-axis | 2.14571 × m | |

| Moment of inertia in the y-axis | 3.28887 × m | |

| Moment of inertia in the z-axis | 4.94533 × m | |

| Back EMF constant | 6.4 × | |

| Torque constant | 0.432140018 | |

| Motor inertia resistance | 0.05 | |

| Coefficient of viscous friction | 341.336 × | |

| Rotor inertia | 1.47106 × kg·m | |

| Inductance | 0.012 H |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mayorga-Macías, W.A.; González-Jiménez, L.E.; Meza-Aguilar, M.A.; Luque-Vega, L.F. Velocity Sensor for Real-Time Backstepping Control of a Multirotor Considering Actuator Dynamics. Sensors 2020, 20, 4229. https://doi.org/10.3390/s20154229

Mayorga-Macías WA, González-Jiménez LE, Meza-Aguilar MA, Luque-Vega LF. Velocity Sensor for Real-Time Backstepping Control of a Multirotor Considering Actuator Dynamics. Sensors. 2020; 20(15):4229. https://doi.org/10.3390/s20154229

Chicago/Turabian StyleMayorga-Macías, Walter Alejandro, Luis Enrique González-Jiménez, Marco Antonio Meza-Aguilar, and Luis Fernando Luque-Vega. 2020. "Velocity Sensor for Real-Time Backstepping Control of a Multirotor Considering Actuator Dynamics" Sensors 20, no. 15: 4229. https://doi.org/10.3390/s20154229

APA StyleMayorga-Macías, W. A., González-Jiménez, L. E., Meza-Aguilar, M. A., & Luque-Vega, L. F. (2020). Velocity Sensor for Real-Time Backstepping Control of a Multirotor Considering Actuator Dynamics. Sensors, 20(15), 4229. https://doi.org/10.3390/s20154229