IoT Platform for Seafood Farmers and Consumers

Abstract

1. Introduction

Research Method

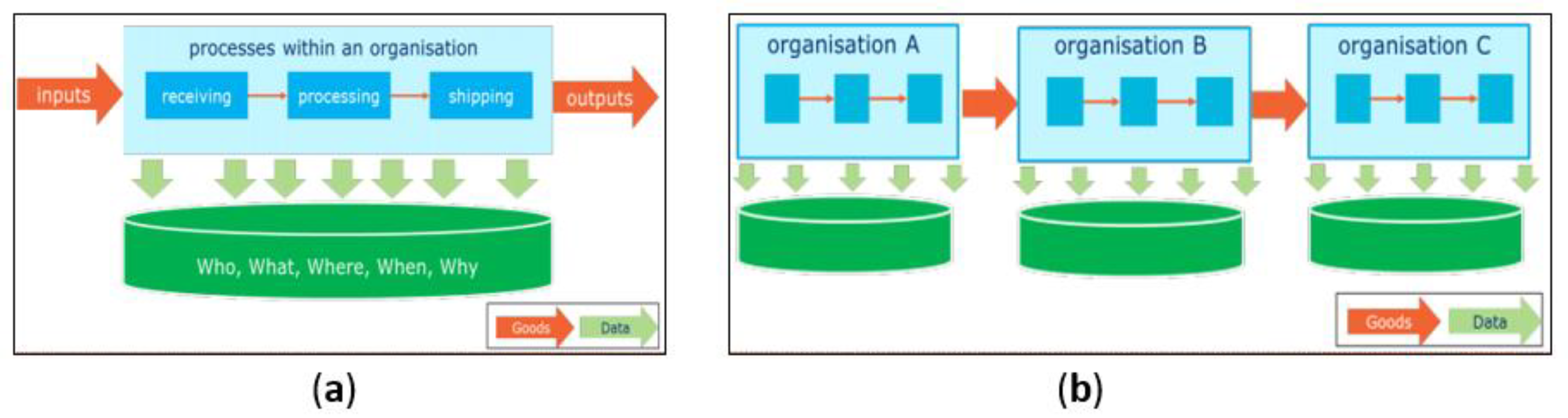

2. Background and Methods

3. Case Study of the IoT Platform for a Seafood Farmer

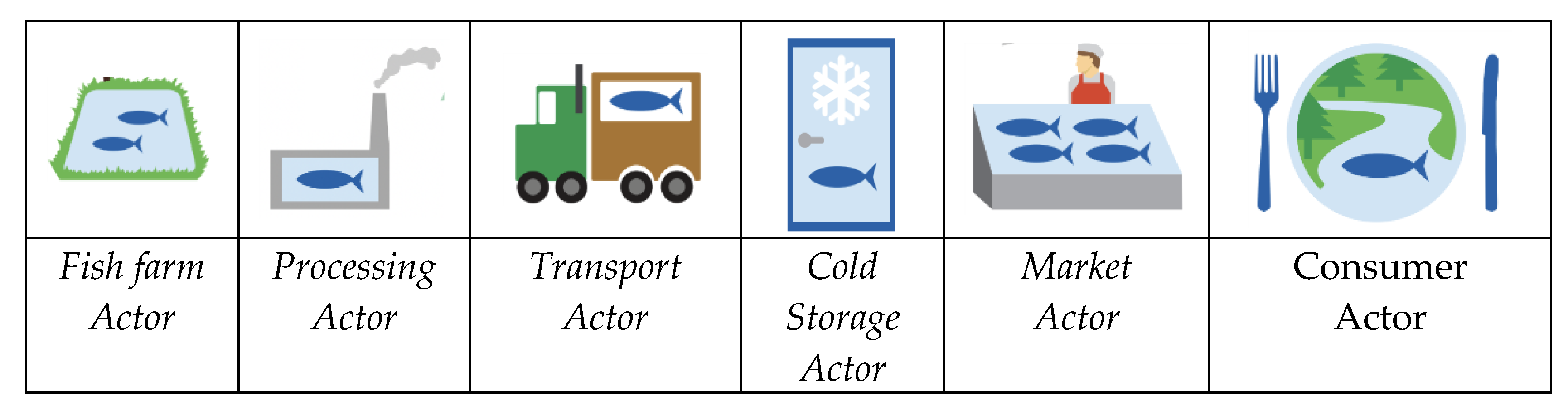

3.1. The Farmed Seafood Supply Chain

3.2. Seafood Farmer and the Seafood Supply Chain

3.2.1. Installation

3.2.2. Creating Traceability Events

3.2.3. Identification

3.2.4. Capturing

3.2.5. Sharing

3.2.6. Using

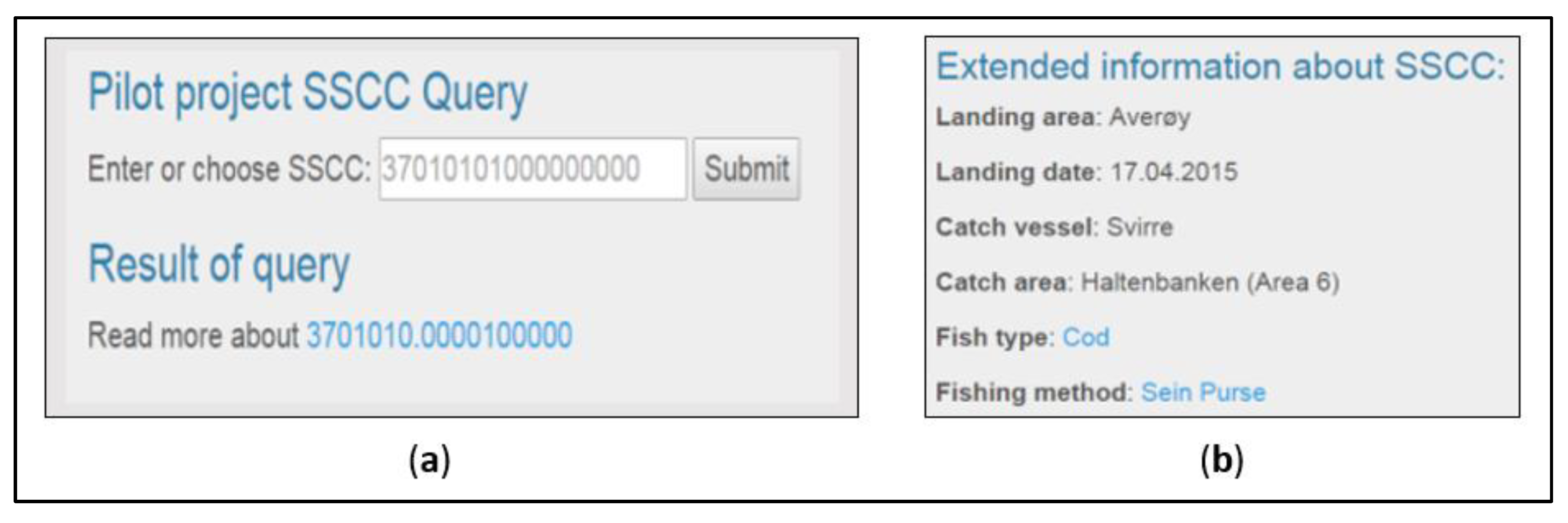

3.3. System Demonstration

Demonstrator Web GUI

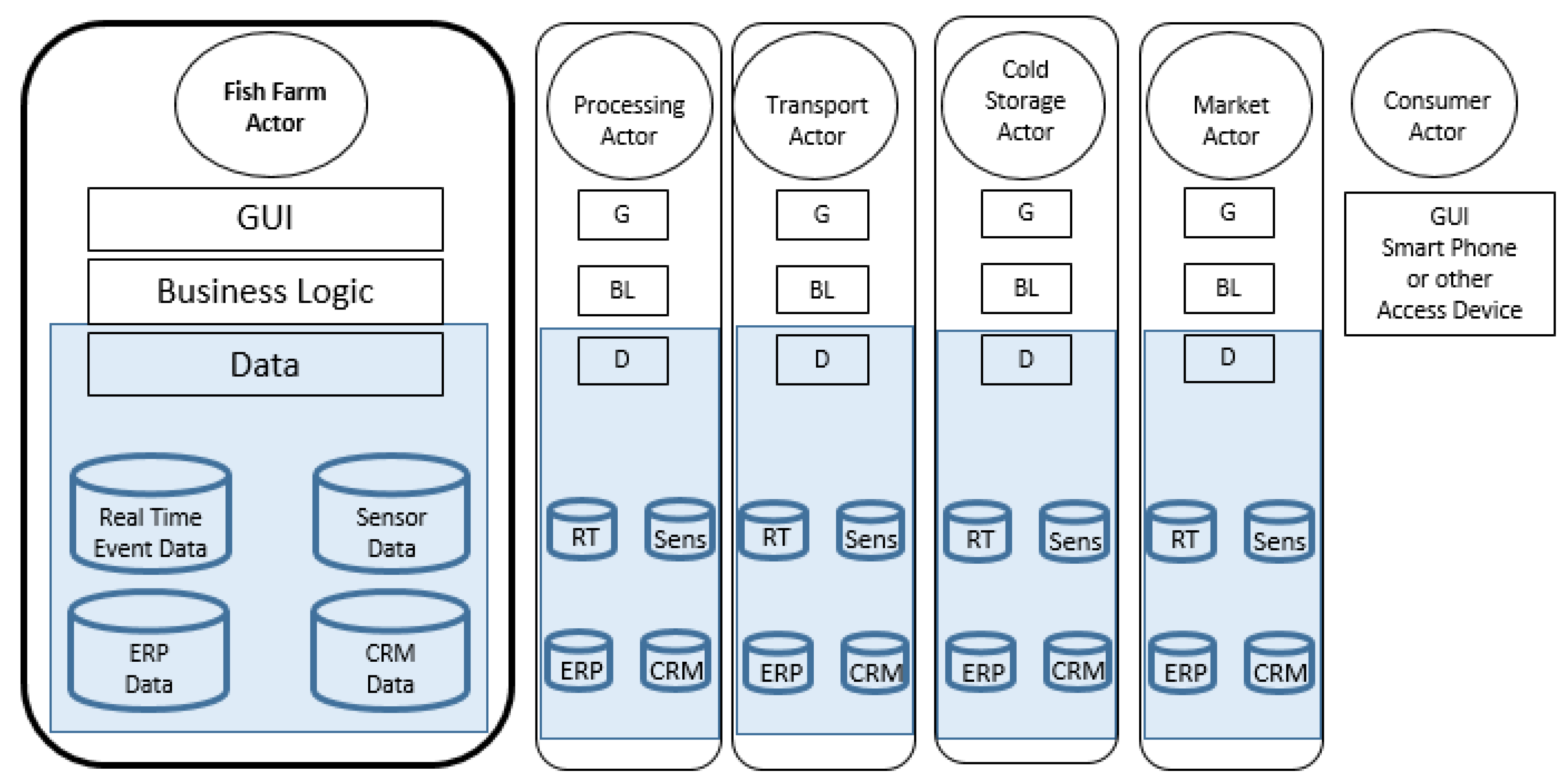

3.4. IoT platform with EPCIS, ERP, CRM, and Blockchain

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Who Conducted the Interviews? | Companies and Organization | Who Was Involved? | How Long Did They Last? |

|---|---|---|---|

| One of the authors and a researcher | GS1 Norway | Respondent 1, business development manager, GS1 Norway | Four interviews each of 20–30 min plus several e-mail interactions |

| A researcher | GS1 France | Respondent 2, chef de projets traçabilité, GS1 France | One interview by phone of 15 min plus several e-mail interactions |

| One of the authors and a researcher | Maritech Systems AS | Respondent 4, chief technical officer, IT provider | Six interviews each of 20–30 min plus several e-mail interactions |

| One of the authors and a researcher | Seminar by GS1 Norway on global seafood traceability standards with presenters from the authorities, retailers, fish farmers, GS1, and IT providers for the seafood industry | Interviews with each presenter

| Interviews each of 5–25 min face-to-face during the seminar |

References

- Cruz, E.F.; da Cruz, A.M.R.; Gomes, R. Analysis of a traceability and quality monitoring platform for the fishery and aquaculture value chain. In Proceedings of the 2019 14th Iberian Conference on Information Systems and Technologies (CISTI), IEEE, Coimbra, Portugal, 19–22 June 2019; pp. 1–6. [Google Scholar]

- Ullah, I.; Kim, D. An optimization scheme for water pump control in smart fish farm with efficient energy consumption. Processes 2018, 6, 65. [Google Scholar] [CrossRef]

- Zhou, L.; Chong, A.Y.; Ngai, E.W. Supply chain management in the era of the internet of things. Int. J. Prod. Econ. 2015, 159, 1–3. [Google Scholar] [CrossRef]

- Kang, Y.S.; Park, I.H.; Youm, S. Performance prediction of a MongoDB-based traceability system in smart factory supply chains. Sensors 2016, 16, 2126. [Google Scholar] [CrossRef] [PubMed]

- Jakkhupan, W.; Arch-Int, S.; Li, Y. An RFID-based traceability system. Telecommun. Syst. 2015, 58, 243–258. [Google Scholar] [CrossRef]

- da Cruz, A.M.R.; Cruz, E.F.; Moreira, P.; Carreira, R.; Gomes, J.; Oliveira, J.; Gomes, R. On the design of a platform for traceability in the fishery and aquaculture value chain. In Proceedings of the 2019 14th Iberian Conference on Information Systems and Technologies (CISTI), IEEE, Coimbra, Portugal, 19–22 June 2019; pp. 1–6. [Google Scholar]

- Dandage, K.; Badia-Melis, R.; Ruiz-García, L. Indian perspective in food traceability: A review. Food Control 2017, 71, 217–227. [Google Scholar] [CrossRef]

- Bhatt, T.; Cusack, C.; Dent, B.; Gooch, M.; Jones, D.; Newsome, R.; Stitzinger, J.; Sylvia, G.; Zhang, J. Project to develop an interoperable seafood traceability technology architecture: Issues brief. Compr. Rev. Food Sci. Food Saf. 2016, 15, 392–429. [Google Scholar] [CrossRef]

- GS1. GS1 Foundation for Fish, Seafood and Aquaculture Traceability Guideline. 2019. Available online: https://www.gs1.org/sites/default/files/docs/traceability/GS1_Foundation_for_Fish_Seafood_Aqu aculture_Traceability_Guideline.pdf (accessed on 28 July 2020).

- Klievink, B.; Van Stijn, E.; Hesketh, D.; Aldewereld, H.; Overbeek, S.; Heijmann, F.; Tan, Y.H. Enhancing visibility in international supply chains: The data pipeline concept. Int. J. Electron. Gov. Res. 2012, 8, 14–33. [Google Scholar] [CrossRef]

- Keogh, J.G.; Rejeb, A.; Khan, N.; Dean, K.; Hand, K.J. Blockchain and GS1 standards in the food chain: A review of the possibilities and challenges. In Building the Future of Food Safety Technology, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2020; Preprint. [Google Scholar]

- GS1. GS1 Global Traceability Standard. Release 2.0. Ratified 2017 (GS1′s Framework for the Design of Interoperable Traceability Systems for Supply Chains). 2017. Available online: https://www.gs1.org/sites/default/files/docs/traceability/GS1_Global_Traceability_Standard_i2.pdf (accessed on 28 July 2020).

- Berners-Lee, T. Axioms of Web Architecture: Metadata. 1997. Available online: www.w3.org/DesignIssues/Metadata.html (accessed on 28 July 2020).

- Zuboff, S. You Are Now Remotely Controlled. New York Times. 24 January 2020. Available online: www.nytimes.com/2020/01/24/opinion/sunday/surveillance-capitalism.html (accessed on 28 July 2020).

- Kembro, J.; Näslund, D.; Olhager, J. Information sharing across multiple supply chain tiers: A Delphi study on antecedents. Int. J. Prod. Econ. 2017, 193, 77–86. [Google Scholar] [CrossRef]

- Fawcett, S.E.; Osterhaus, P.; Magnan, G.M.; Brau, J.C.; McCarter, M.W. Information sharing and supply chain performance: The role of connectivity and willingness. Supply Chain Manag. Int. J. 2007, 12, 358–368. [Google Scholar] [CrossRef]

- Prajogo, D.; Olhager, J. Supply chain integration and performance: The effects of long-term relationships, information technology and sharing, and logistics integration. Int. J. Prod. Econ. 2012, 135, 514–522. [Google Scholar] [CrossRef]

- SeafoodChain Powered by UNISOT. Available online: https://seafoodchain.no/ (accessed on 28 July 2020).

- Wang, Y.; Singgih, M.; Wang, J.; Rit, M. Making sense of blockchain technology: How will it transform supply chains? Int. J. Prod. Econ. 2019, 211, 221–236. [Google Scholar] [CrossRef]

- Nakamoto, S. Bitcoin: A Peer-to-Peer Electronic Cash System. 2009. Available online: https://bitcoin.org/bitcoin.pdf (accessed on 28 July 2020).

- Dujak, D.; Sajter, D. Blockchain applications in supply chain. In SMART Supply Network; Springer: Cham, Switzerland, 2019; pp. 21–46. [Google Scholar]

- Zhao, J.L.; Fan, S.; Yan, J. Overview of business innovations and research opportunities in blockchain and introduction to the special issue. Financ. Innov. 2016, 2, 28. [Google Scholar] [CrossRef]

- Hughes, L.; Dwivedi, Y.K.; Misra, S.K.; Rana, N.P.; Raghavan, V.; Akella, V. Blockchain research, practice and policy: Applications, benefits, limitations, emerging research themes and research agenda. Int. J. Inf. Manag. 2019, 49, 114–129. [Google Scholar] [CrossRef]

- Chen, R.Y. An intelligent value stream-based approach to collaboration of food traceability cyber physical system by fog computing. Food Control 2017, 71, 124–136. [Google Scholar] [CrossRef]

- Introini, S.C.; Boza, A.; Alemany, M.D.M.E. Traceability in the Food Supply Chain: Review of the literature from a technological perspective. Dir. Organ. 2018, 64, 50–55. [Google Scholar]

- Directorate of Fisheries. 2010. Marine Life–Our Common Responsibility. Edited by Directorate of Fisheries. Available online: http://www.fiskeridir.no/english/publications: Directorate of fisheries (accessed on 12 May 2020).

- 9405. Norsk Standard NS 9405:2014. Available online: https://www.standard.no/no/Nettbutikk/produktkatalogen/Produktpresentasjon/?ProductID=682942 (accessed on 28 July 2020).

- EN 17099:2020. Information Technology-Fishery and Aquaculture Products-Requirements for Labelling of Distribution Units and Pallets in the Trade of Fishery and Aquaculture Products. 2020. Available online: https://standards.iteh.ai/catalog/standards/cen/311c418b-1bac-43db-8e14-b87c33bf0f01/en-17099-2020 (accessed on 28 July 2020).

- Mowi. Mowi Annual Report 2018. Available online: mowi.com/blog/2019/04/07/mowis-2018-annual-report/ (accessed on 28 July 2020).

- Xu, X. Quality and safety traceability system of aquatic products based on internet of things. Int. J. Online Biomed. Eng. 2017, 13, 132–139. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Ruiz-Garcia, L. Real-Time tracking and remote monitoring in food traceability. In Advances in Food Traceability Techniques and Technologies; Woodhead Publishing: Sawston, UK, 2016; pp. 209–224. [Google Scholar]

- Yin, R.K. Case Study Research: Design and Methods, 2nd ed.; Sage Publications: Thousand Oaks, CA, USA, 1994. [Google Scholar]

- GS1. 2020. Global Standards 1 (GS1). Available online: www.gs1-germany.de (accessed on 28 July 2020).

- Jonsson, P.; Holmström, J. Future of supply chain planning: Closing the gaps between practice and promise. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 62–81. [Google Scholar] [CrossRef]

- Wang, G.; Gunasekaran, A.; Ngai, E.W.; Papadopoulos, T. Big data analytics in logistics and supply chain management: Certain investigations for research and applications. Int. J. Prod. Econ. 2016, 176, 98–110. [Google Scholar] [CrossRef]

- Sanjay, S.; Brock, D.L.; Ashton, K. “The networked physical world.” Auto-ID Center White Pap (pp. 1–16). MIT-AUTOID-WH-001. Available online: https://www.semanticscholar.org/paper/white-paper-The-Networked-Physical-World-Proposals-Sarma-Brock/88b4a255082d91b3c88261976c85a24f2f92c5c3 (accessed on 22 April 2015).

- Cambridge Auto-ID Lab. History of Auto-ID Labs 2015. Available online: http://www.autoidlabs.org.uk/ (accessed on 22 April 2015).

- Atzori, L.; Iera, A.; Morabito, G. The internet of things: A survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Mai, N.; Bogason, S.G.; Arason, S.; Árnason, S.V.; Matthíasson, T.G. Benefits of traceability in fish supply chains–Case studies. Br. Food J. 2010, 112, 976–1002. [Google Scholar] [CrossRef]

- Moga, L.M. Cloud computing based solutions for monitoring the supply chain of fish and fishery products. In Proceedings of the 2017 Eighth International Conference on Intelligent Computing and Information Systems (ICICIS), IEEE, Cairo, Egypt, 5–7 December 2017; pp. 33–38. [Google Scholar]

- Yan, B.; Hu, D.; Shi, P. A traceable platform of aquatic foods supply chain based on RFID and EPC Internet of Things. Int. J. RF Technol. 2012, 4, 55–70. [Google Scholar] [CrossRef]

- Parreño-Marchante, A.; Alvarez-Melcon, A.; Trebar, M.; Filippin, P. Advanced traceability system in aquaculture supply chain. J. Food Eng. 2014, 122, 99–109. [Google Scholar] [CrossRef]

- Espinosa-Faller, F.J.; Rendón-Rodríguez, G.E. A ZigBee wireless sensor network for monitoring an aquaculture recirculating system. J. Appl. Res. Technol. 2012, 10, 380–387. [Google Scholar] [CrossRef]

- Qi, L.; Zhang, J.; Xu, M.; Fu, Z.; Chen, W.; Zhang, X. Developing WSN-based traceability system for recirculation aquaculture. Math. Comput. Model. 2011, 53, 2162–2172. [Google Scholar] [CrossRef]

- Shi, B.; Sreeram, V.; Zhao, D.; Duan, S.; Jiang, J. A wireless sensor network-based monitoring system for freshwater fishpond aquaculture. Biosyst. Eng. 2018, 172, 57–66. [Google Scholar] [CrossRef]

- Nicolae, C.G.; Moga, L.M.; Bahaciu, G.V.; Marin, M.P. Traceability System Structure Design for Fish and Fish Products Based on Supply Chain Actors Needs. Scientific Papers: Series D, Animal Science-the International Session of Scientific Communications of the Faculty of Animal Science, 60. 2017. Available online: http://animalsciencejournal.usamv.ro/index.php/scientific-papers/476-traceability-system-structure-design-for-fish-and-fish-products-based-on-supply-chain-actors-needs-742 (accessed on 28 July 2020).

- Cario, G.; Casavola, A.; Gjanci, P.; Lupia, M.; Petrioli, C.; Spaccini, D. Long lasting underwater wireless sensors network for water quality monitoring in fish farms. In Proceedings of the OCEANS 2017-Aberdeen, IEEE, Aberdeen, UK, 19–22 June 2017; pp. 1–6. [Google Scholar]

- Tai, H.; Liu, S.; Li, D.; Ding, Q.; Ma, D. A multi-environmental factor monitoring system for aquiculture based on wireless sensor networks. Sens. Lett. 2012, 10, 265–270. [Google Scholar] [CrossRef]

- Folinas, D.; Vlachopoulou, M.; Manthou, V.; Manos, B. A web-based integration of data and processes in the agribusiness supply chain. In Proceedings of the EFITA 2003 Conference, Debrecen, Hungary, 5–9 July 2003. [Google Scholar]

- Regattieri, A.; Gamberi, M.; Manzini, R. Traceability of food products: General framework and experimental evidence. J. Food Eng. 2007, 81, 347–356. [Google Scholar] [CrossRef]

- EU. Mandatory Origin-Labelling Schemes in Member States. 2018. Available online: https://www.europarl.europa.eu/RegData/etudes/BRIE/2018/625182/EPRS_BRI(2018)625182_EN.pdf (accessed on 28 July 2020).

- Gao, G.; Xiao, K.; Chen, M. An intelligent IoT-based control and traceability system to forecast and maintain water quality in freshwater fish farms. Comput. Electron. Agric. 2019, 166, 105013. [Google Scholar] [CrossRef]

- Dlodlo, N.; Kalezhi, J. The internet of things in agriculture for sustainable rural development. In Proceedings of the 2015 International Conference on Emerging Trends in Networks and Computer Communications (ETNCC), IEEE, Otjozondjupa, Namibia, 17–20 May 2015; pp. 13–18. [Google Scholar]

- Domingo, M.C. An overview of the internet of underwater things. J. Netw. Comput. Appl. 2012, 35, 1879–1890. [Google Scholar] [CrossRef]

- IoT-based Fish Farm Management System. 2014. SK Telecom. Available online: http://en.c114.com.cn/576/a855896.html (accessed on 28 July 2020).

- Zhang, Y.; Hua, J.; Wang, Y.B. Application effect of aquaculture IOT system. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Baech, Switzerland, 2013; Volume 303, pp. 1395–1401. [Google Scholar]

- Zhang, Y.; Wang, W.; Yan, L.; Glamuzina, B.; Zhang, X. Development and evaluation of an intelligent traceability system for waterless live fish transportation. Food Control 2019, 95, 283–297. [Google Scholar] [CrossRef]

- Fan, B.; Qian, J.; Wu, X.; Du, X.; Li, W.; Ji, Z.; Xin, X. Improving continuous traceability of food stuff by using barcode-RFID bidirectional transformation equipment: Two field experiments. Food Control 2019, 98, 449–456. [Google Scholar] [CrossRef]

- What the Global Supply Chain Needs is Blockchain. 2020. Available online: https://www.foodlogistics.com/technology/press-release/21135570/unisot-what-the-global-supply-chain-needs-is-blockchain (accessed on 28 July 2020).

- How SeafoodChain Uses Blockchain Tech to Provide Transparency for Seafood Products. Available online: https://www.zdnet.com/article/how-seafoodchain-uses-blockchain-tech-to-provide-transparency-for-seafood-products/ (accessed on 28 July 2020).

- SeafoodChain. Blockchain Powered Supply Chain by UNISOT. 2020. Available online: seafoodchain.no/about/ (accessed on 28 July 2020).

- fTrace. Available online: https://web.ftrace.com/en/ (accessed on 28 July 2020).

- Buttle, F.; Maklan, S. Customer Relationship Management: Concepts and Technologies; Routledge: Abingdon-on-Thames, UK, 2019; Available online: ec.europa.eu/digital-single-market/en/trust-services-and-eid (accessed on 28 July 2020).

- GS1 Query. Available online: http://www.gs1.org/sites/default/files/docs/epc/ons_2_0_1-standard-20130131.pdf (accessed on 28 July 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jæger, B.; Mishra, A. IoT Platform for Seafood Farmers and Consumers. Sensors 2020, 20, 4230. https://doi.org/10.3390/s20154230

Jæger B, Mishra A. IoT Platform for Seafood Farmers and Consumers. Sensors. 2020; 20(15):4230. https://doi.org/10.3390/s20154230

Chicago/Turabian StyleJæger, Bjørn, and Alok Mishra. 2020. "IoT Platform for Seafood Farmers and Consumers" Sensors 20, no. 15: 4230. https://doi.org/10.3390/s20154230

APA StyleJæger, B., & Mishra, A. (2020). IoT Platform for Seafood Farmers and Consumers. Sensors, 20(15), 4230. https://doi.org/10.3390/s20154230