An all-Optical Photoacoustic Sensor for the Detection of Trace Gas

Abstract

1. Introduction

2. Design of the Photoacoustic Sensor

2.1. Description of the System

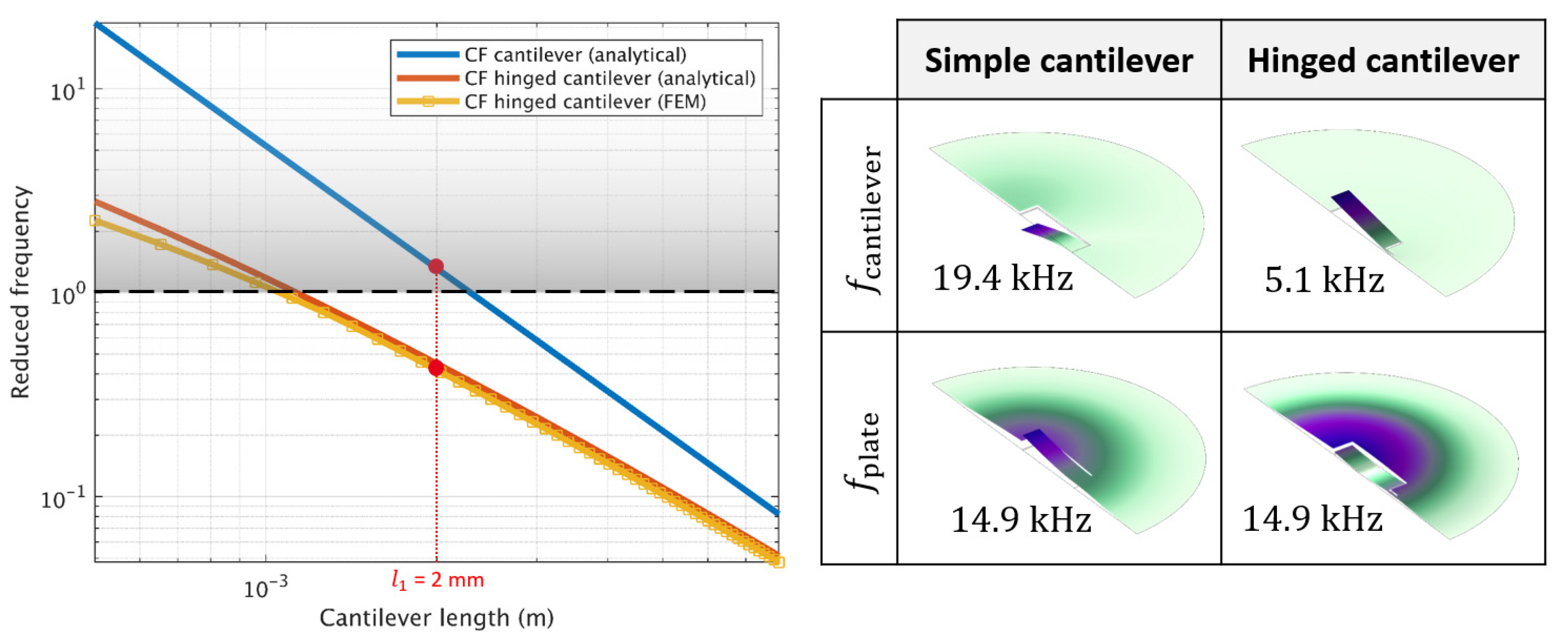

2.2. Mechanical Model

2.3. Photoacoustic Model

2.3.1. Heat Source

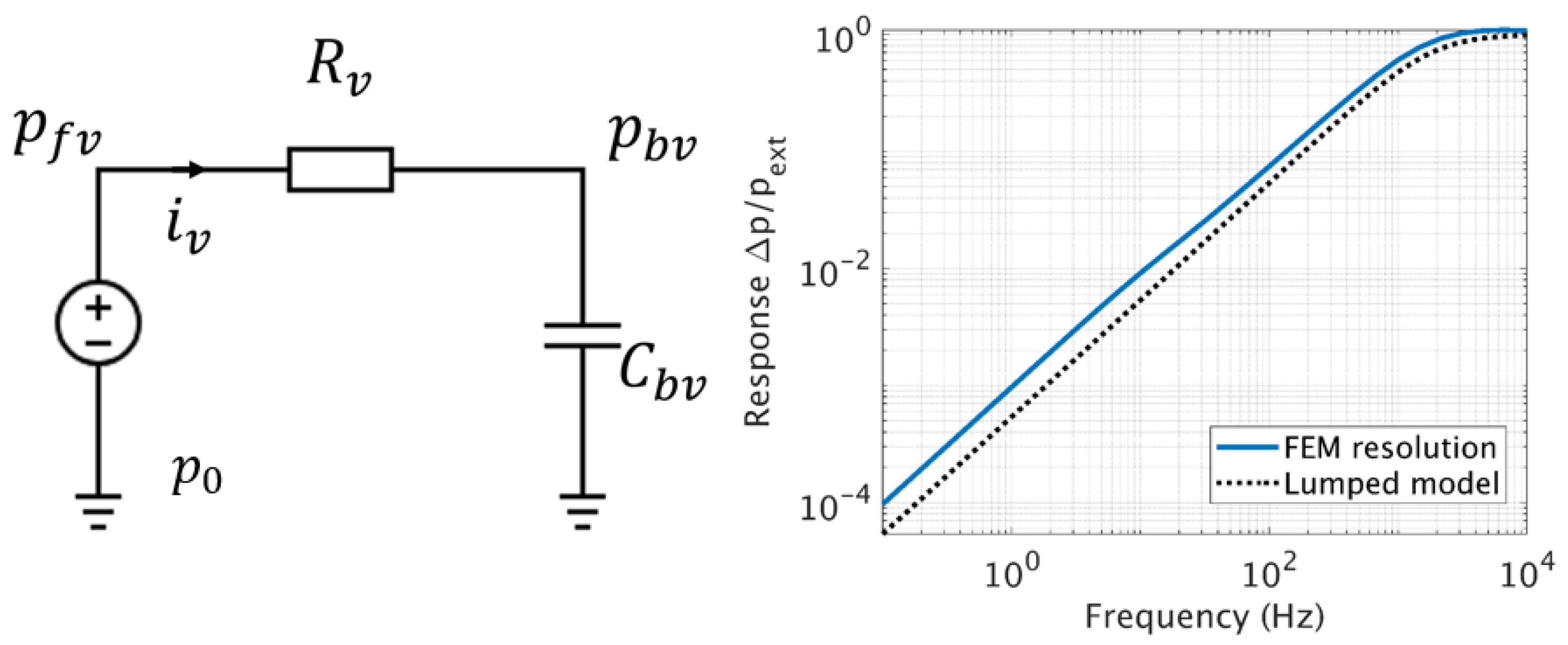

2.3.2. Acoustic Coupling

2.4. Global Resolution of the System

3. Fabrication and Experimental Set-Up

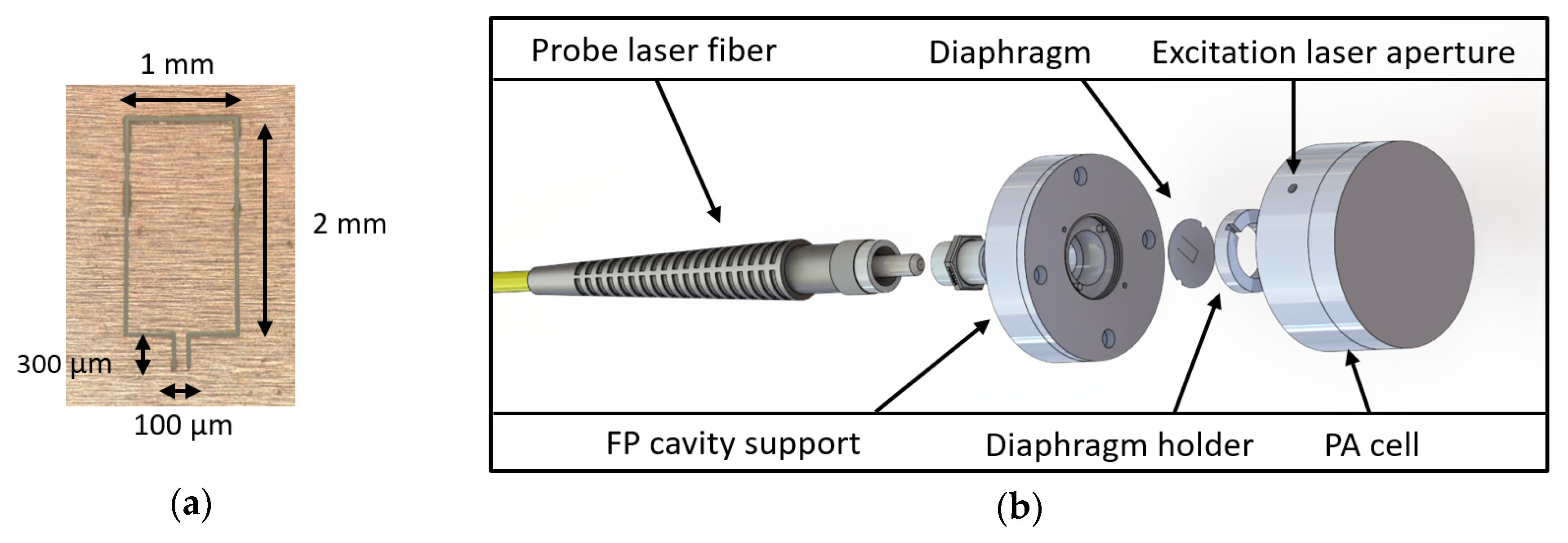

3.1. Acoustic Transducer

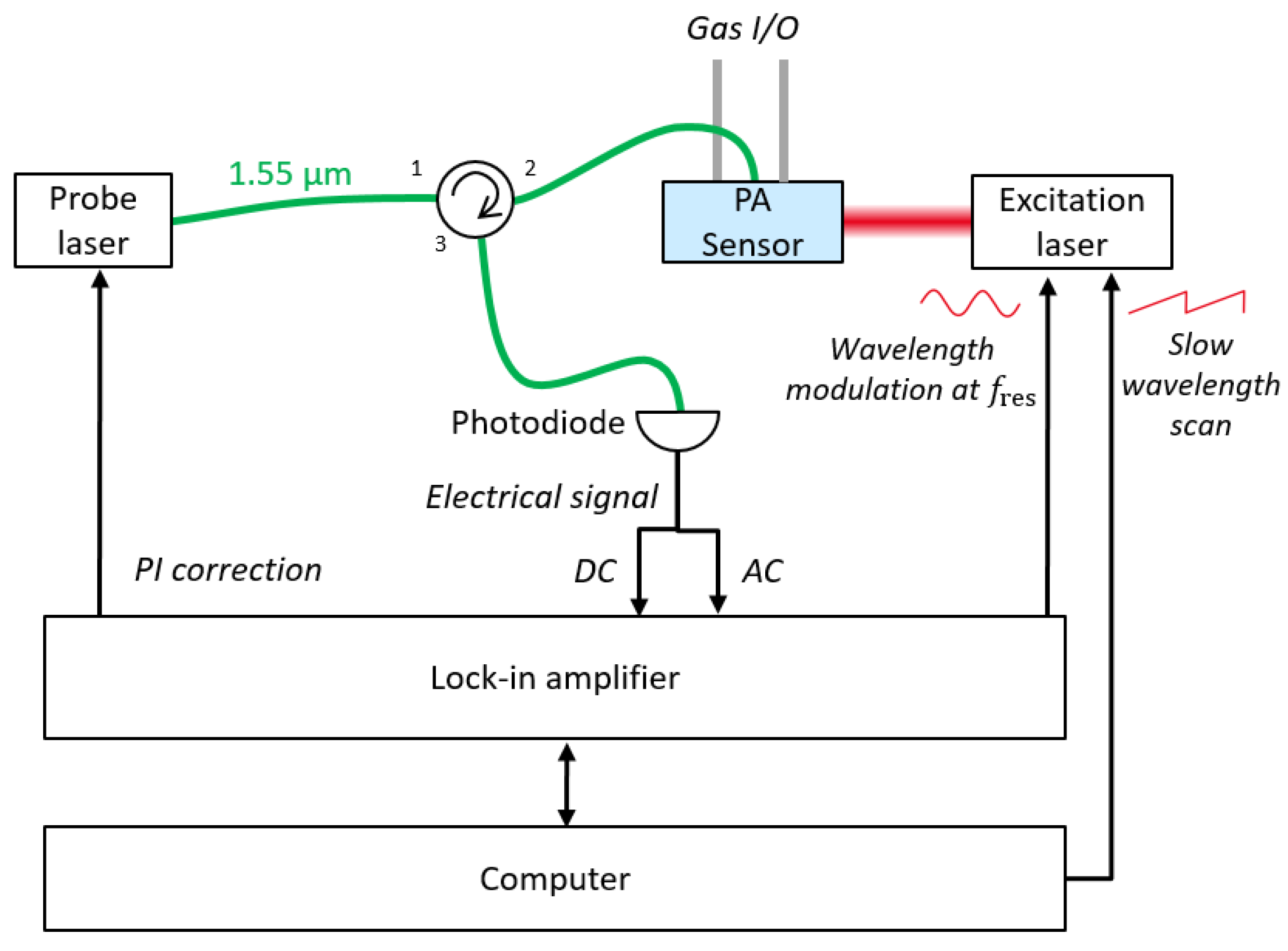

3.2. Experimental Bench Set-Up

4. Experimental Results

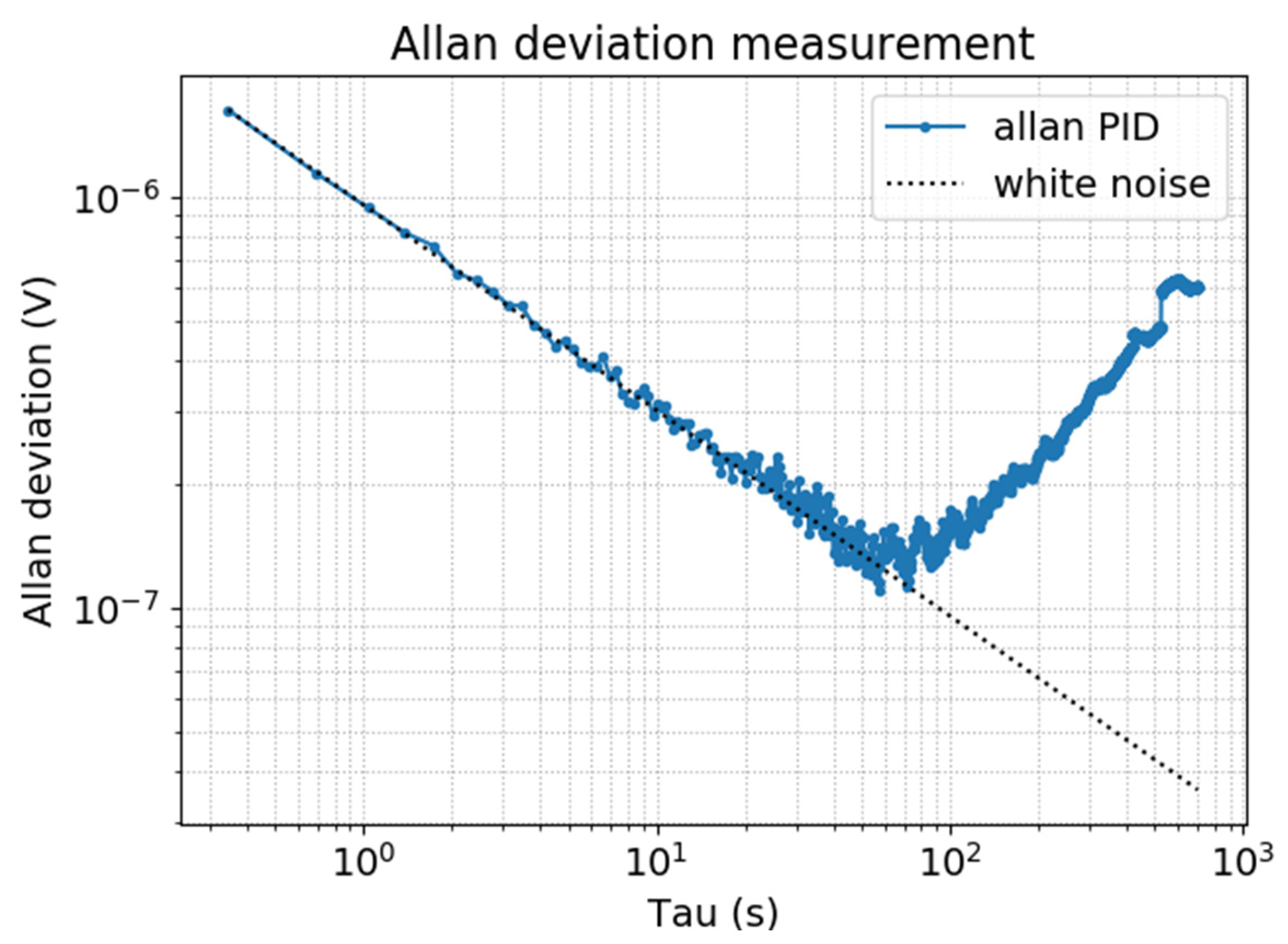

4.1. Microphone Characterization

4.2. Photoacoustic Measurements

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Hinged Cantilever Effective Mass and Stiffness

Appendix B. Lumped Model for the Heat Source

References

- Zhang, P.; Li, L.; Lin, L.; Shi, J.; Wang, L.V. In vivo superresolution photoacoustic computed tomography by localization of single dyed droplets. Light Sci. Appl. 2019, 8, 36. [Google Scholar] [CrossRef]

- Wissmeyer, G.; Pleitez, M.A.; Rosenthal, A.; Ntziachristos, V. Looking at sound: Optoacoustics with all-optical ultrasound detection. Light Sci. Appl. 2018, 7, 1–16. [Google Scholar] [CrossRef]

- Zheng, H.; Dong, L.; Patimisco, P.; Wu, H.; Sampaolo, A.; Yin, X.; Li, S.; Ma, W.; Zhang, L.; Yin, W.; et al. Double antinode excited quartz-enhanced photoacoustic spectrophone. Appl. Phys. Lett. 2017, 110, 021110. [Google Scholar] [CrossRef]

- Chen, K.; Yu, Q.; Gong, Z.; Guo, M.; Qu, C. Ultra-high sensitive fiber-optic Fabry-Perot cantilever enhanced resonant photoacoustic spectroscopy. Sens. Actuators B Chem. 2018, 268, 205–209. [Google Scholar] [CrossRef]

- Rouxel, J.; Coutard, J.-G.; Gidon, S.; Lartigue, O.; Nicoletti, S.; Parvitte, B.; Vallon, R.; Zéninari, V.; Glière, A. Miniaturized differential Helmholtz resonators for photoacoustic trace gas detection. Sens. Actuators B Chem. 2016, 236, 1104–1110. [Google Scholar] [CrossRef]

- Kosterev, A.A.; Tittel, F.K.; Serebryakov, D.V.; Malinovsky, A.L.; Morozov, I.V. Applications of quartz tuning forks in spectroscopic gas sensing. Rev. Sci. Instrum. 2005, 76, 043105. [Google Scholar] [CrossRef]

- Patimisco, P.; Borri, S.; Sampaolo, A.; Beere, H.E.; Ritchie, D.A.; Vitiello, M.S.; Scamarcio, G.; Spagnolo, V. A quartz enhanced photo-acoustic gas sensor based on a custom tuning fork and a terahertz quantum cascade laser. Analyst 2014, 139, 2079–2087. [Google Scholar] [CrossRef] [PubMed]

- Patimisco, P.; Borri, S.; Galli, I.; Mazzotti, D.; Giusfredi, G.; Akikusa, N.; Yamanishi, M.; Scamarcio, G.; De Natale, P.; Spagnolo, V. High finesse optical cavity coupled with a quartz-enhanced photoacoustic spectroscopic sensor. Analyst 2015, 140, 736–743. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Q.; Zhang, W.; Wei, H.; Li, Y.; Ren, W. Ultrasensitive photoacoustic detection in a high-finesse cavity with Pound—Drever—Hall locking. Opt. Lett. 2019, 44, 1924. [Google Scholar] [CrossRef]

- Dostál, M.; Suchánek, J.; Válek, V.; Blatoňová, Z.; Nevrlý, V.; Bitala, P.; Kubát, P.; Zelinger, Z. Cantilever-Enhanced Photoacoustic Detection and Infrared Spectroscopy of Trace Species Produced by Biomass Burning. Energy Fuels 2018, 32, 10163–10168. [Google Scholar] [CrossRef]

- Gallego, D.; Lamela, H. High-sensitivity ultrasound interferometric single-mode polymer optical fiber sensors for biomedical applications. Opt. Lett. 2009, 34, 1807. [Google Scholar] [CrossRef] [PubMed]

- Kuusela, T.; Kauppinen, J. Photoacoustic Gas Analysis Using Interferometric Cantilever Microphone. Appl. Spectrosc. Rev. 2007, 42, 443–474. [Google Scholar] [CrossRef]

- Murray, M.J.; Davis, A.; Redding, B. Fiber-Wrapped Mandrel Microphone for Low-Noise Acoustic Measurements. J. Lightwave Technol. 2018, 36, 3205–3210. [Google Scholar] [CrossRef]

- Yu, Q.; Zhou, X. Pressure sensor based on the fiber-optic extrinsic Fabry-Perot interferometer. Photonic Sens. 2011, 1, 72–83. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.; Li, L.; Yu, Q. An all-optical photoacoustic spectrometer for trace gas detection. Sens. Actuators B Chem. 2011, 153, 214–218. [Google Scholar] [CrossRef]

- Chen, K.; Guo, M.; Liu, S.; Zhang, B.; Deng, H.; Zheng, Y.; Chen, Y.; Luo, C.; Tao, L.; Lou, M.; et al. Fiber-optic photoacoustic sensor for remote monitoring of gas micro-leakage. Opt. Express 2019, 27, 4648. [Google Scholar] [CrossRef]

- Liu, B.; Lin, J.; Liu, H.; Jin, A.; Jin, P. Extrinsic Fabry-Perot fiber acoustic pressure sensor based on large-area silver diaphragm. Microelectron. Eng. 2016, 166, 50–54. [Google Scholar] [CrossRef]

- Tan, Y.; Zhang, C.; Jin, W.; Yang, F.; Ho, H.L.; Ma, J. Optical Fiber Photoacoustic Gas Sensor With Graphene Nano-Mechanical Resonator as the Acoustic Detector. IEEE J. Sel. Top. Quantum Electron 2017, 23, 199–209. [Google Scholar] [CrossRef]

- Gong, Z.; Zhou, X.; Chen, K.; Zhou, X.; Yu, Q. Parylene-C diaphragm-based fiber-optic Fabry-Perot acoustic sensor for trace gas detection. In Proceedings of the 2017 International Conference on Optical Instruments and Technology: Advanced Optical Sensors and Applications, Beijing, China, 28–30 October 2017; Dong, L., Zhang, X., Xiao, H., Arregui, F.J., Eds.; SPIE: Bellingham, WA, USA, 2018; p. 5. [Google Scholar]

- Chen, K.; Gong, Z.; Guo, M.; Yu, S.; Qu, C.; Zhou, X.; Yu, Q. Fiber-optic Fabry-Perot interferometer based high sensitive cantilever microphone. Sens. Actuators A Phys. 2018, 279, 107–112. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, K.; Chen, Y.; Yang, B.; Guo, M.; Deng, H.; Ma, F.; Zhu, F.; Gong, Z.; Peng, W.; et al. High-sensitivity photoacoustic gas detector by employing multi-pass cell and fiber-optic microphone. Opt. Express 2020, 28, 6618. [Google Scholar] [CrossRef]

- Lauwers, T.; Glière, A.; Basrour, S. Resonant optical transduction for photoacoustic detection. In Proceedings of the Photonic Instrumentation Engineering VII, San Francisco, CA, USA, 4–6 February 2020; Soskind, Y., Busse, L.E., Eds.; SPIE: Bellingham, WA, USA, 2020; p. 25. [Google Scholar]

- Glière, A.; Rouxel, J.; Brun, M.; Parvitte, B.; Zéninari, V.; Nicoletti, S. Challenges in the Design and Fabrication of a Lab-on-a-Chip Photoacoustic Gas Sensor. Sensors 2014, 14, 957–974. [Google Scholar] [CrossRef] [PubMed]

- Lobontiu, N. Dynamics of Microelectromechanical Systems; Microsystems: Santa Clara, CA, USA; Springer: New York, NY, USA, 2007; ISBN 978-0-387-36800-9. [Google Scholar]

- Benade, A.H. On the propagation of sound waves in a cylindrical conduit. J. Acoust. Soc. Am. 1968, 44, 616–623. [Google Scholar] [CrossRef]

- Kampinga, W.R. Viscothermal Acoustics Using Finite Elements—Analysis Tools for Engineers. Ph.D. Thesis, University of Twente, Enschede, The Netherlans, 2010. [Google Scholar] [CrossRef]

- Schilt, S.; Thévenaz, L. Wavelength modulation photoacoustic spectroscopy: Theoretical description and experimental results. Infrared Phys. Technol. 2006, 48, 154–162. [Google Scholar] [CrossRef]

- Mao, X.; Yuan, S.; Zheng, P.; Wang, X. Stabilized Fiber-Optic Fabry–Perot Acoustic Sensor Based on Improved Wavelength Tuning Technique. J. Lightwave Technol. 2017, 35, 2311–2314. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lauwers, T.; Glière, A.; Basrour, S. An all-Optical Photoacoustic Sensor for the Detection of Trace Gas. Sensors 2020, 20, 3967. https://doi.org/10.3390/s20143967

Lauwers T, Glière A, Basrour S. An all-Optical Photoacoustic Sensor for the Detection of Trace Gas. Sensors. 2020; 20(14):3967. https://doi.org/10.3390/s20143967

Chicago/Turabian StyleLauwers, Thomas, Alain Glière, and Skandar Basrour. 2020. "An all-Optical Photoacoustic Sensor for the Detection of Trace Gas" Sensors 20, no. 14: 3967. https://doi.org/10.3390/s20143967

APA StyleLauwers, T., Glière, A., & Basrour, S. (2020). An all-Optical Photoacoustic Sensor for the Detection of Trace Gas. Sensors, 20(14), 3967. https://doi.org/10.3390/s20143967