Weakly Coupled Piezoelectric MEMS Resonators for Aerosol Sensing

Abstract

:1. Introduction

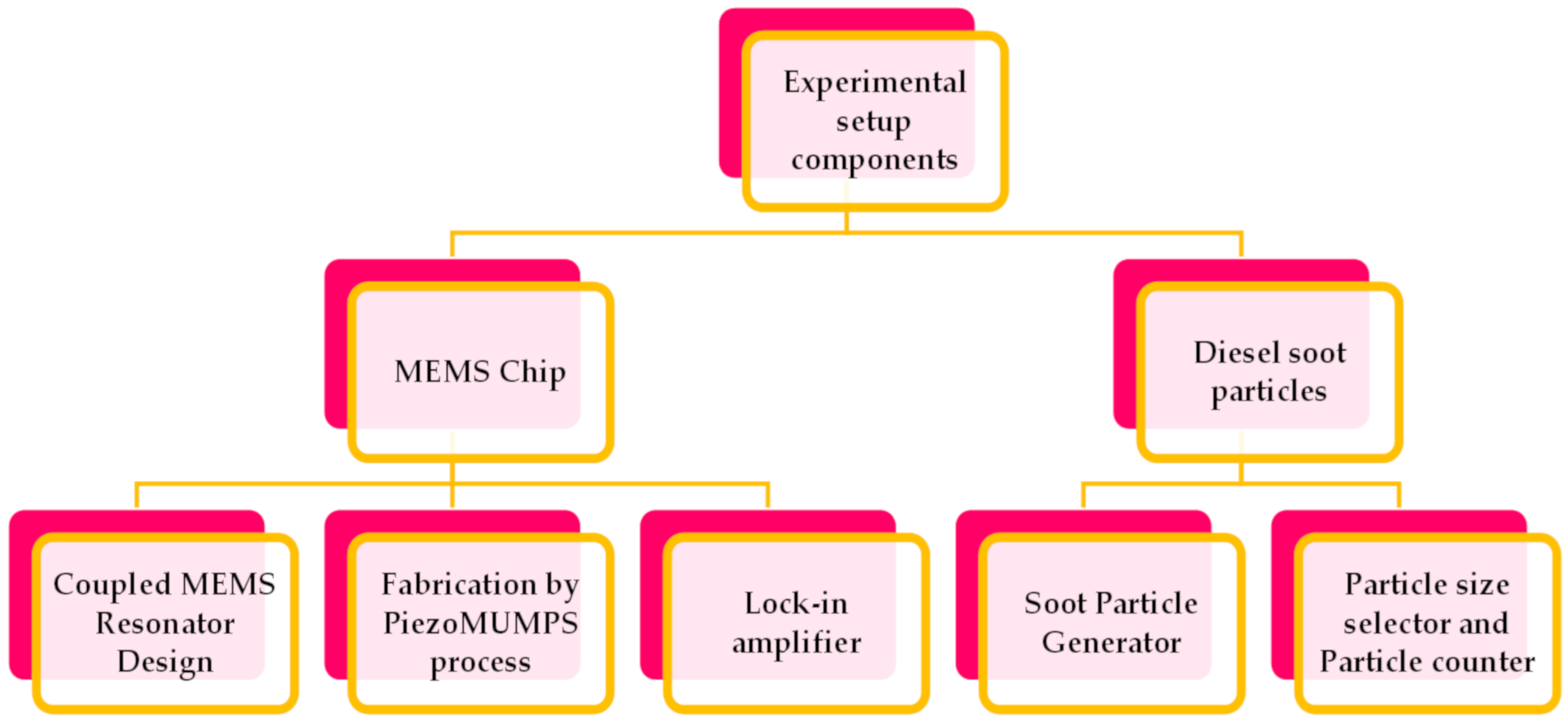

2. Materials and Methods

- (a)

- Coupled MEMS resonator design.

- (b)

- Fabrication of designed MEMS resonators and transduction.

- (c)

- Construction of soot particle generator.

- (d)

- Differential mobility analyser (DMA) and condensation particle counter (CPC).

- (e)

- MEMS Impactor Stage and Measurement electronics.

2.1. Coupled MEMS Resonator Design

2.2. Fabrication of Designed MEMS Resonators and Transduction

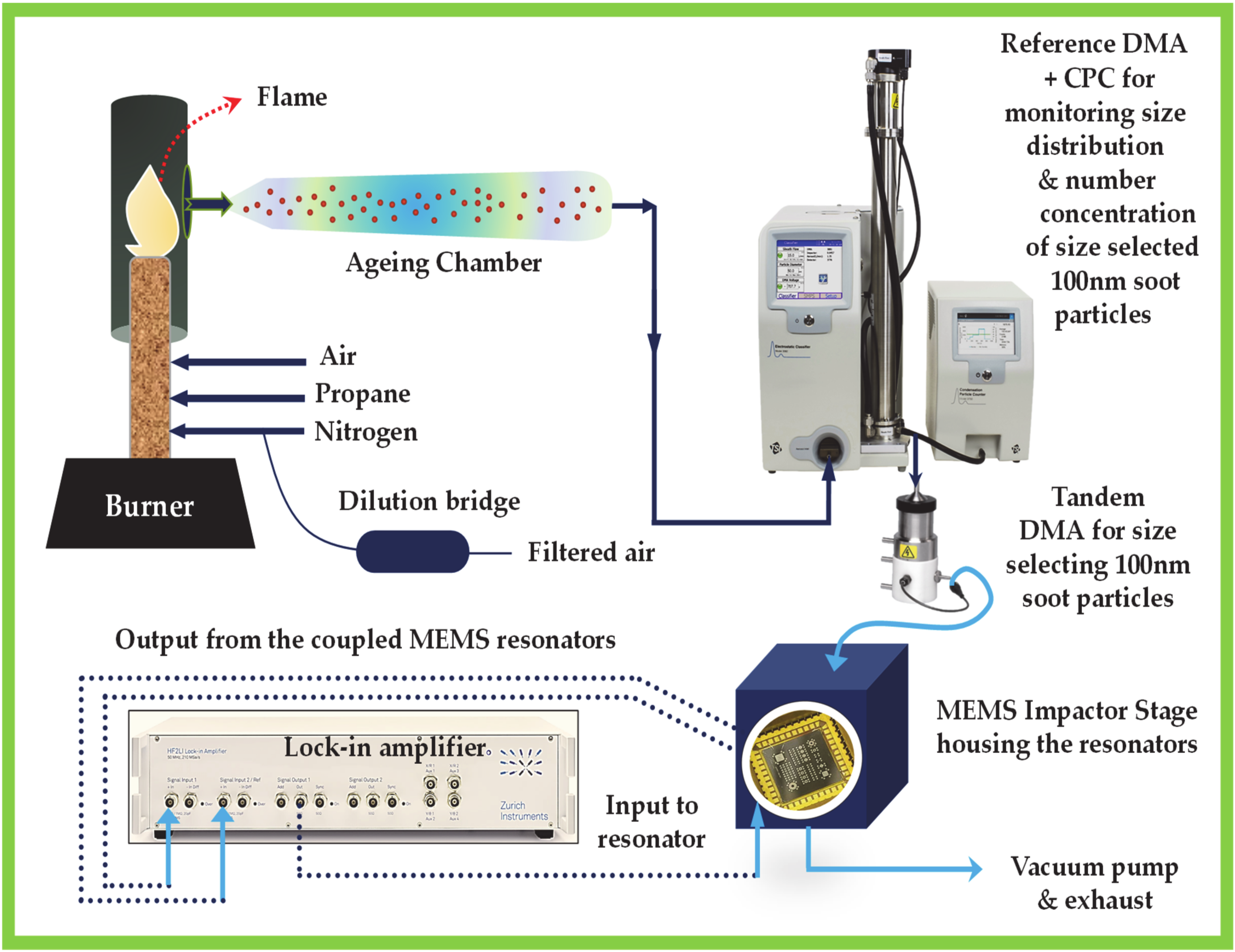

2.3. Construction of Soot Particle Generator

2.4. Differential Mobility Analyser and Condensation Particle Counter

2.5. MEMS Impactor Stage and Measurement Electronics

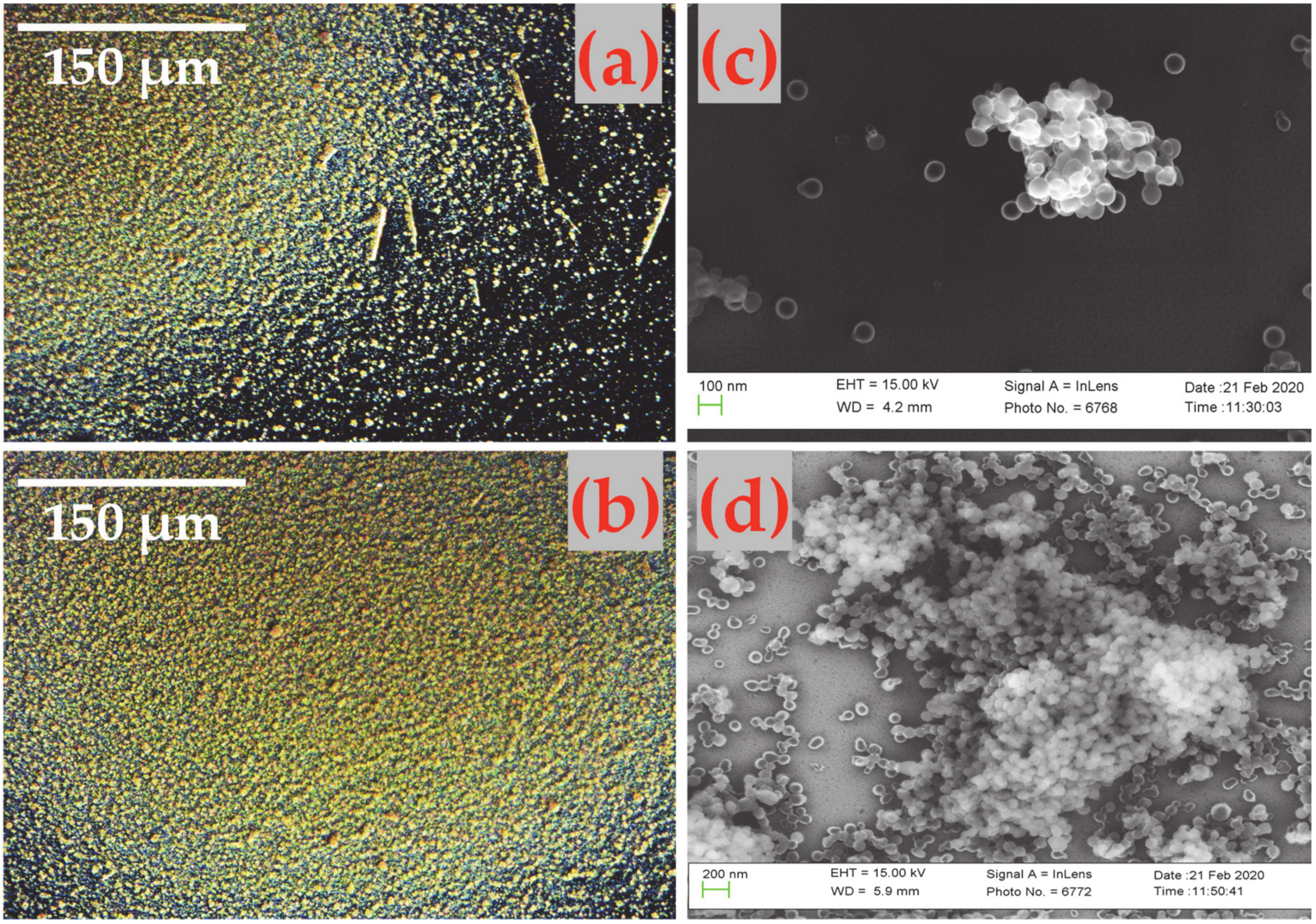

2.6. Soot Particle Impaction and Resonator Stability—Experiment

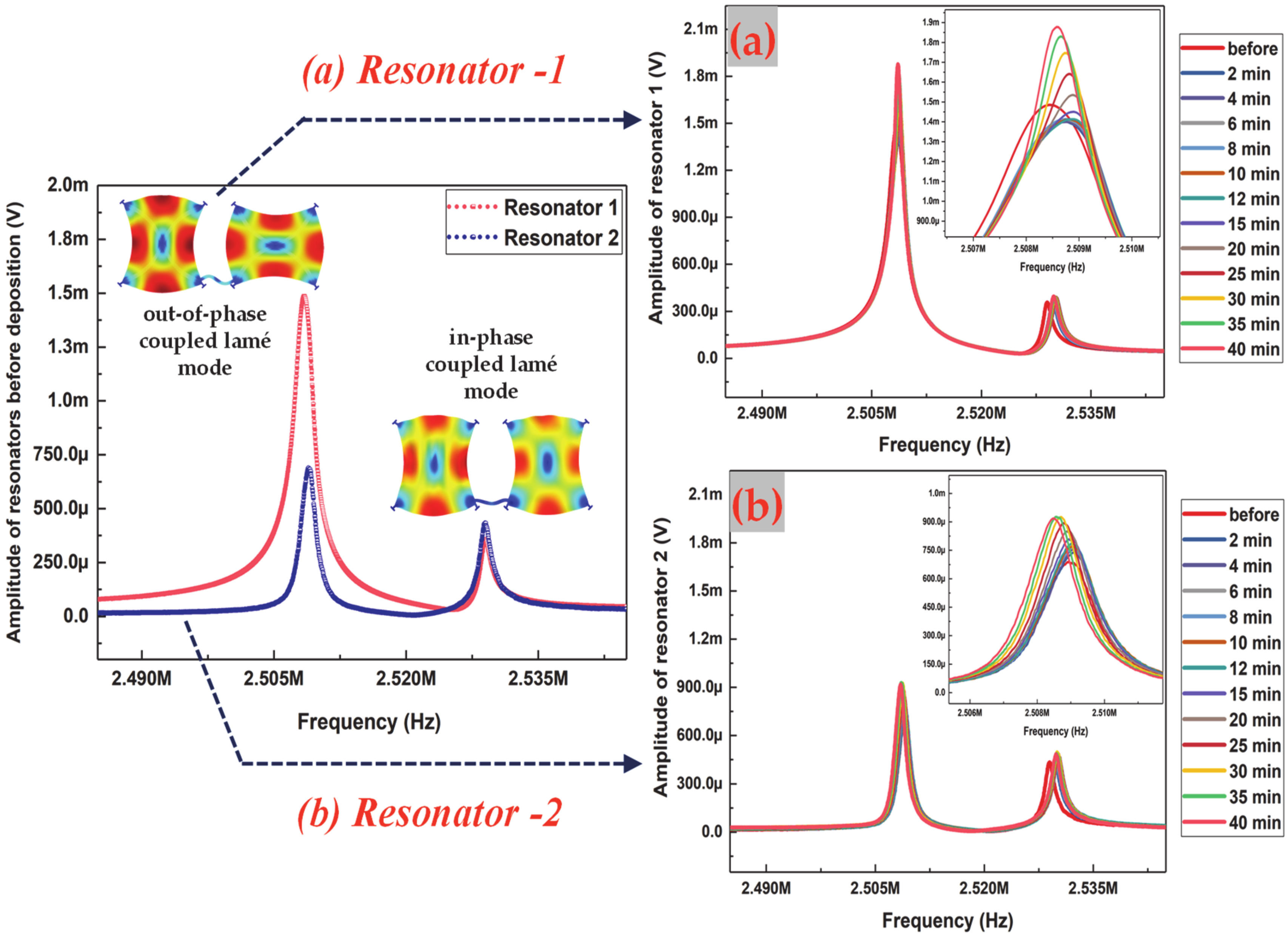

3. Theory and Modelling of the Coupled MEMS Resonators

4. Results

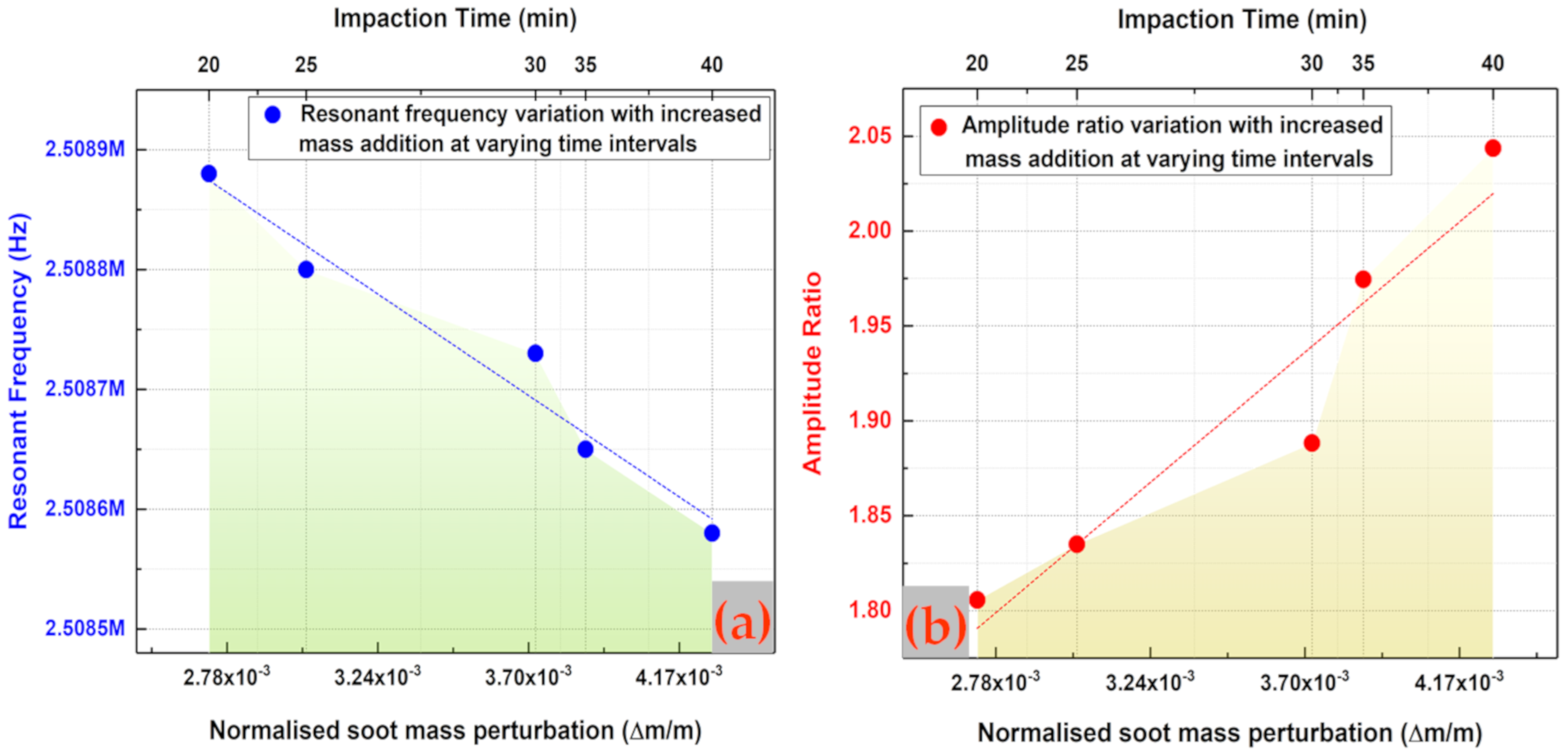

4.1. Sensitivity Analysis

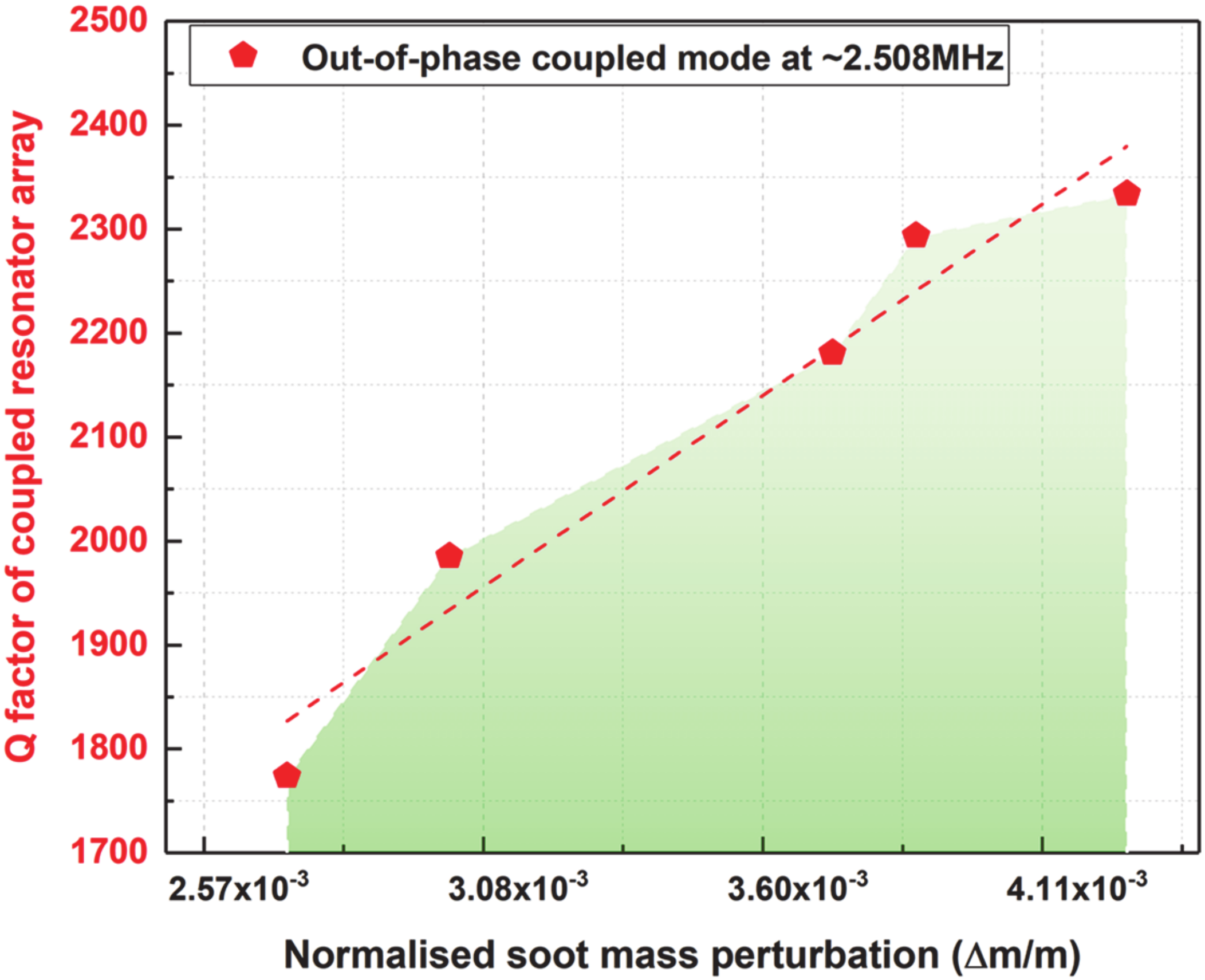

4.2. Quality Factor of the Coupled MEMS Resonator Array

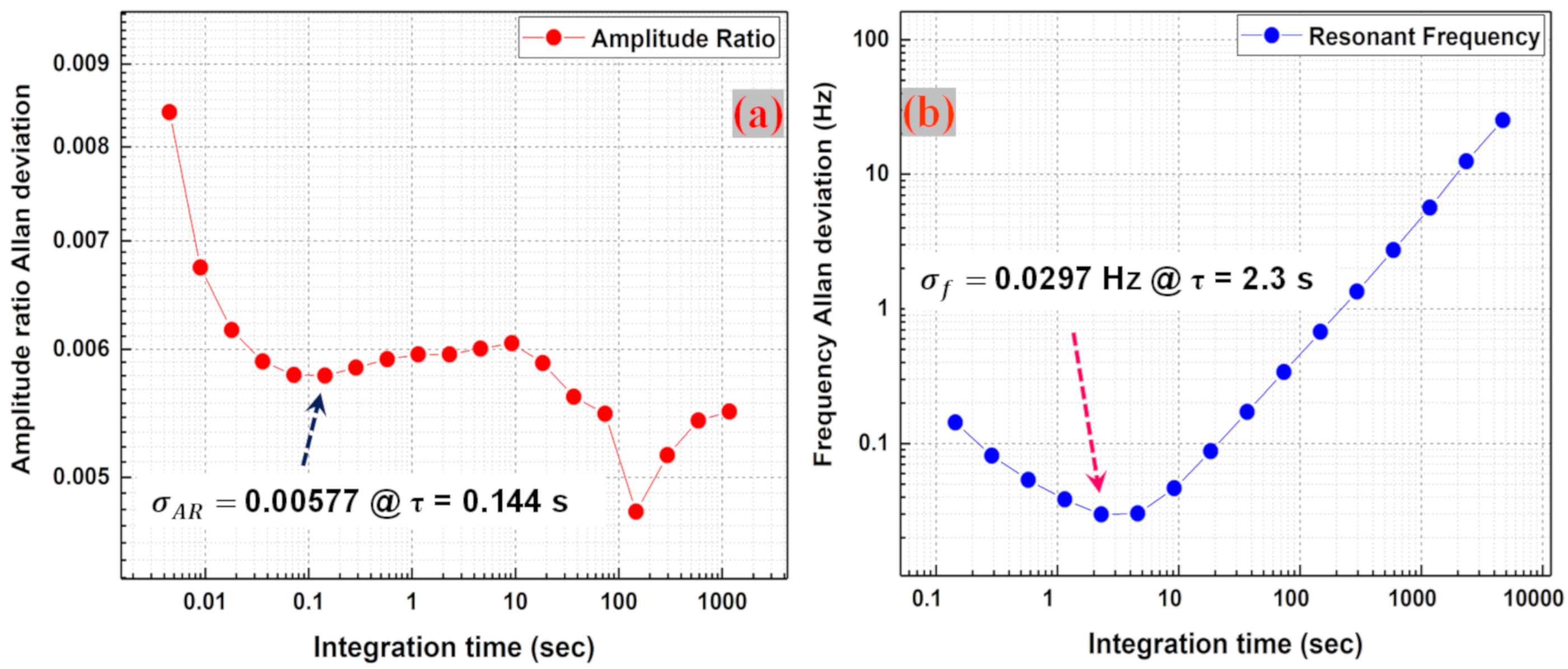

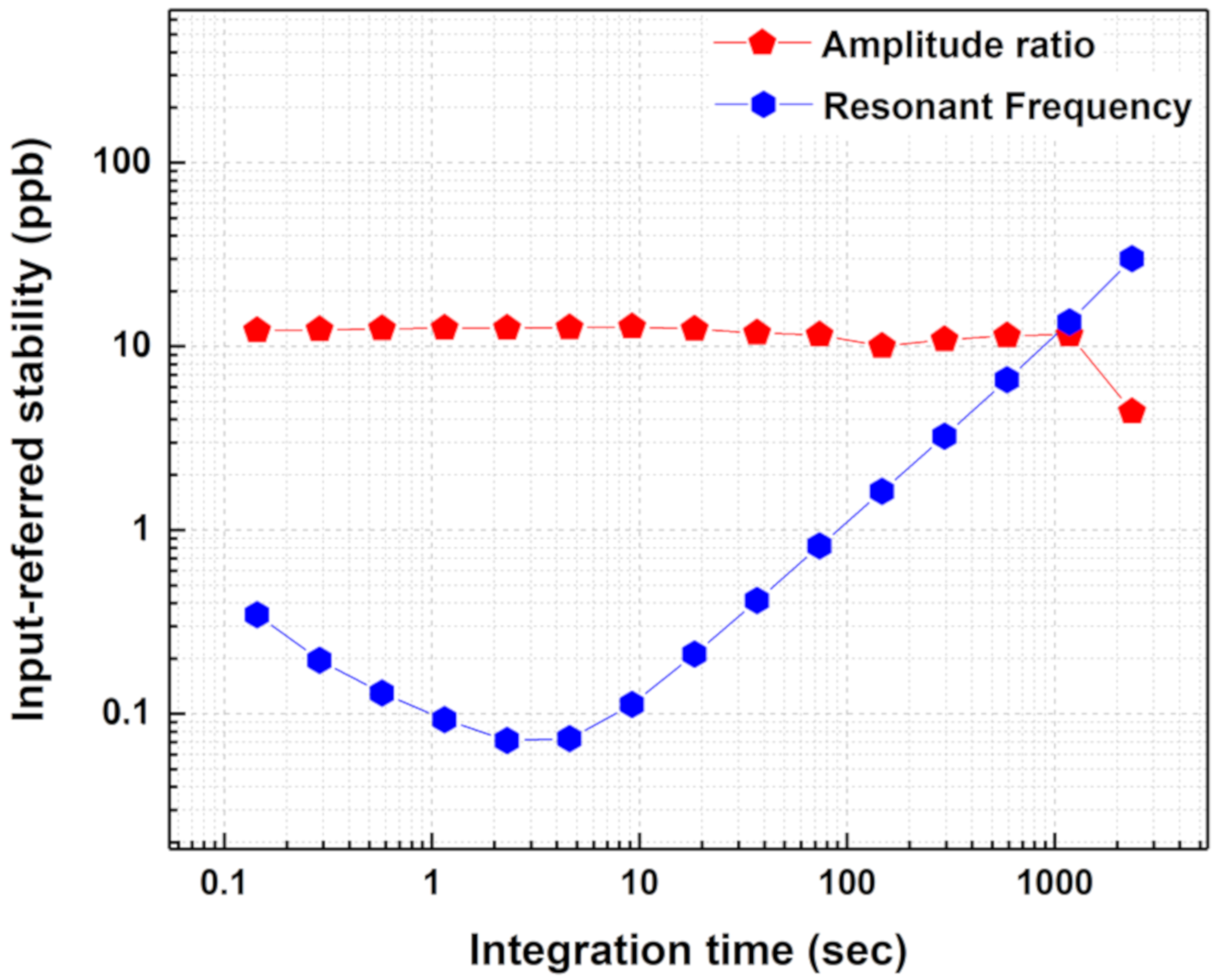

4.3. Stability Analysis

5. Discussion

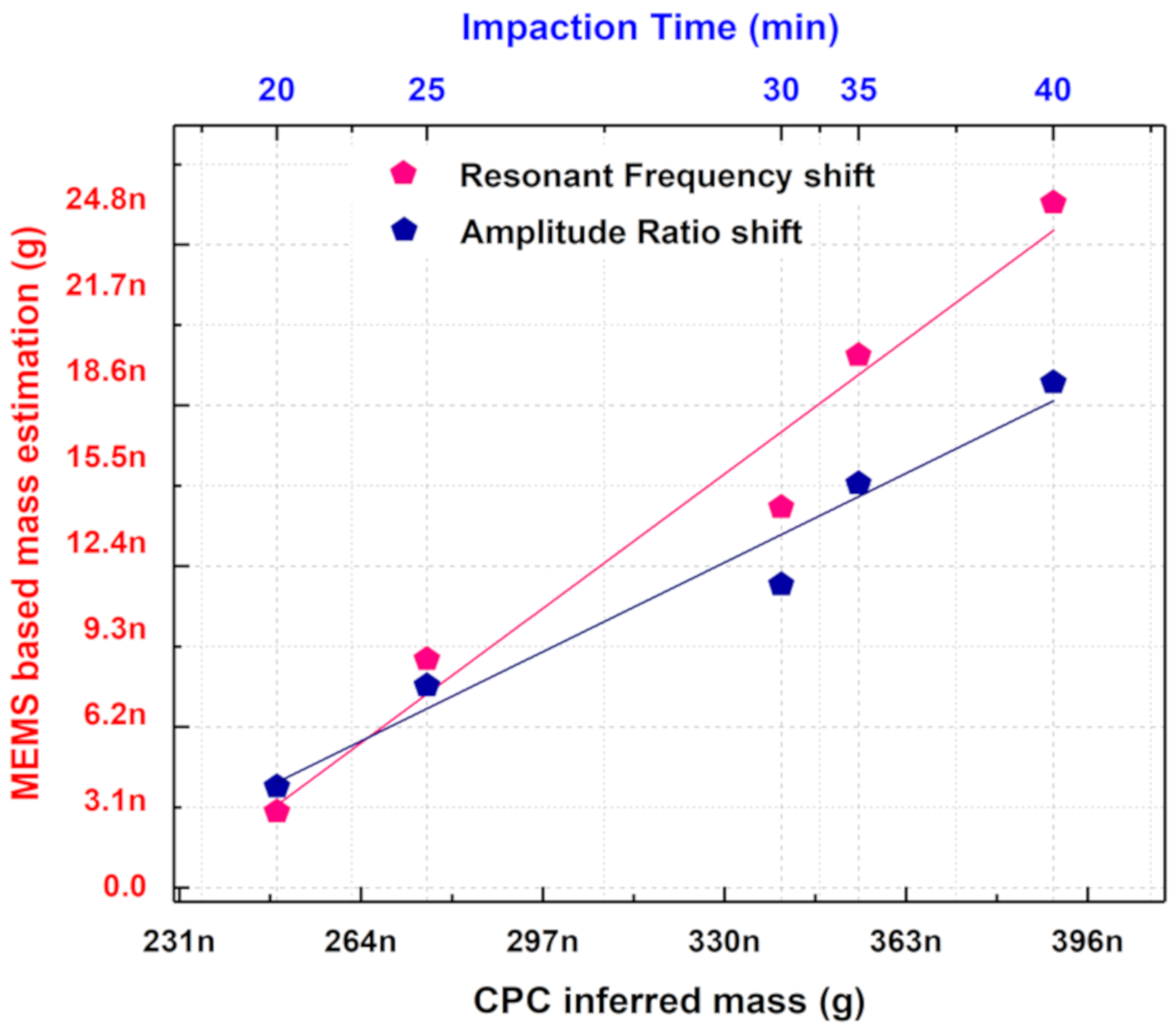

5.1. Comparison of Amplitude Ratio Shift and Resonant Frequency Shift Output Metrics

5.2. Comparison of MEMS-Based Mass Estimation With the CPC Inferred Mass

5.3. Limitations of the MEMS Sensor

5.4. Improving the MEMS Sensor Parameters

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rinaldi, M.; Duick, B.; Zuniga, C.; Zuo, C.; Piazza, G. SS-DNA functionalized ultra-thin-film ALN Contour-mode Resonators with self-sustained oscillator for volatile organic chemical detection. In Proceedings of the 2010 IEEE 23rd International Conference on Micro Electro Mechanical Systems (MEMS), Hong Kong, China, 24–28 January 2010; pp. 132–135. [Google Scholar]

- Harrington, B.; Shahmohammadi, M.; Abdolvand, R. Toward ultimate performance in GHZ MEMS resonators: Low impedance and high Q. In Proceedings of the 2010 IEEE 23rd International Conference on Micro Electro Mechanical Systems (MEMS), Hong Kong, China, 24–28 January 2010; pp. 707–710. [Google Scholar]

- Mehdizadeh, E.; Chapin, J.C.; Gonzales, J.M.; Rahafrooz, A.; Abdolvand, R.; Purse, B.W.; Pourkamali, S. Microelectromechanical disk resonators for direct detection of liquid-phase analytes. Sens. Actuators A Phys. 2014, 216, 136–141. [Google Scholar] [CrossRef]

- Aigner, R.; Ella, J.; Timme, H.-J.; Elbrecht, L.; Nessler, W.; Marksteiner, S. Advancement of MEMS into RF-filter applications. In Proceedings of the Digest. International Electron Devices Meeting, San Francisco, CA, USA, 8–11 December 2002; pp. 897–900. [Google Scholar] [CrossRef]

- Hung, L.-W.; Nguyen, C. Capacitive-Piezoelectric Transducers for High- QQ Micromechanical AlN Resonators. J. Microelectromech. Syst. 2014, 24, 458–473. [Google Scholar] [CrossRef]

- Hui, Y.; Gomez-Diaz, J.S.; Qian, Z.; Alu, A.; Rinaldi, M. Plasmonic piezoelectric nanomechanical resonator for spectrally selective infrared sensing. Nat. Commun. 2016, 7, 11249. [Google Scholar] [CrossRef] [PubMed]

- Black, J.P.; Elium, A.; White, R.M.; Apte, M.G.; Gundel, L.A.; Cambie, R. 6D-2 MEMS-Enabled Miniaturized Particulate Matter Monitor Employing 1.6 GHz Aluminum Nitride Thin-Film Bulk Acoustic Wave Resonator (FBAR) and Thermophoretic Precipitator. In Proceedings of the 2007 IEEE Ultrasonics Symposium, New York, NY, USA, 28–31 October 2007; pp. 476–479. [Google Scholar]

- Zielinski, A.T.; Kalberer, M.; Jones, R.; Prasad, A.; Seshia, A.A. Particulate mass sensing with piezoelectric bulk acoustic mode resonators. In Proceedings of the 2016 IEEE International Frequency Control Symposium (IFCS), New Orleans, LA, USA, 9–12 May 2016. [Google Scholar] [CrossRef] [Green Version]

- Mehdizadeh, E.; Kumar, V.; Wilson, J.C.; Pourkamali, S. Inertial Impaction on MEMS Balance Chips for Real-Time Air Quality Monitoring. IEEE Sensors J. 2017, 17, 2329–2337. [Google Scholar] [CrossRef]

- Toledo, J.; Ruiz-Díez, V.; Bertke, M.; Wasisto, H.S.; Peiner, E.; Sánchez-Rojas, J.L. Piezoelectric MEMS Resonators for Cigarette Particle Detection. Micromachines 2019, 10, 145. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jung, H.; Kittelson, D.B.; Zachariah, M.R. The influence of a cerium additive on ultrafine diesel particle emissions and kinetics of oxidation. Combust. Flame 2005, 142, 276–288. [Google Scholar] [CrossRef]

- Wang, C.; Xu, H.; Herreros, J.; Wang, J.; Cracknell, R. Impact of fuel and injection system on particle emissions from a GDI engine. Appl. Energy 2014, 132, 178–191. [Google Scholar] [CrossRef] [Green Version]

- Oberdörster, G.; Sharp, Z.; Atudorei, V.; Elder, A.; Gelein, R.; Kreyling, W.G.; Cox, C. Translocation of Inhaled Ultrafine Particles to the Brain. Inhal. Toxicol. 2004, 16, 437–445. [Google Scholar] [CrossRef]

- Chiriacò, M.S.; Rizzato, S.; Primiceri, E.; Spagnolo, S.; Monteduro, A.G.; Ferrara, F.; Maruccio, G. Optimization of SAW and EIS sensors suitable for environmental particulate monitoring. Microelectron. Eng. 2018, 202, 31–36. [Google Scholar] [CrossRef]

- Apte, J.S.; Kirchstetter, T.W.; Reich, A.H.; Deshpande, S.J.; Kaushik, G.; Chel, A.; Marshall, J.D.; Nazaroff, W.W. Concentrations of fine, ultrafine, and black carbon particles in auto-rickshaws in New Delhi, India. Atmos. Environ. 2011, 45, 4470–4480. [Google Scholar] [CrossRef]

- European Environment Agency. Available online: https://www.eea.europa.eu/data-and-maps/figures/world-premature-deaths-due-to (accessed on 27 April 2020).

- Beelen, R.; Raaschou-Nielsen, O.; Stafoggia, M.; Andersen, Z.J.; Weinmayr, G.; Hoffmann, B.; Wolf, K.; Samoli, E.; Fischer, P.; Nieuwenhuijsen, M.; et al. Effects of long-term exposure to air pollution on natural-cause mortality: An analysis of 22 European cohorts within the multicentre ESCAPE project. Lancet 2014, 383, 785–795. [Google Scholar] [CrossRef]

- Chong, U.; Yim, S.H.L.; Barrett, S.R.H.; Boies, A.M. Air Quality and Climate Impacts of Alternative Bus Technologies in Greater London. Environ. Sci. Technol. 2014, 48, 4613–4622. [Google Scholar] [CrossRef]

- Kittelson, D.B. Engines and nanoparticles. J. Aerosol Sci. 1998, 29, 575–588. [Google Scholar] [CrossRef]

- Paprotny, I.; Doering, F.; White, R.M. MEMS Particulate Matter (PM) monitor for cellular deployment. 2010 IEEE Sens. 2010, 2435–2440. [Google Scholar] [CrossRef]

- Zampetti, E.; Macagnano, A.; Papa, P.; Bearzotti, A.; Petracchini, F.; Paciucci, L.; Pirrone, N. Exploitation of an integrated microheater on QCM sensor in particulate matter measurements. Sens. Actuators A Phys. 2017, 264, 205–211. [Google Scholar] [CrossRef]

- Paprotny, I.; Doering, F.; Solomon, P.A.; White, R.M.; Gundel, L. Microfabricated air-microfluidic sensor for personal monitoring of airborne particulate matter: Design, fabrication, and experimental results. Sens. Actuators A Phys. 2013, 201, 506–516. [Google Scholar] [CrossRef]

- Zielinski, A.T.; Gallimore, P.J.; Griffiths, P.T.; Jones, R.; Seshia, A.A.; Kalberer, M. Measuring Aerosol Phase Changes and Hygroscopicity with a Microresonator Mass Sensor. Anal. Chem. 2018, 90, 9716–9724. [Google Scholar] [CrossRef] [PubMed]

- Zielinski, A.T.; Prasad, A.; Seshia, A.A.; Kalberer, M.; Jones, R. Effects of spatial sensitivity on mass sensing with bulk acoustic mode resonators. Sens. Actuators A Phys. 2015, 236, 369–379. [Google Scholar] [CrossRef] [Green Version]

- Thomas, S.; Cole, M.; Villa-López, F.H.; Gardner, J. High frequency surface acoustic wave resonator-based sensor for particulate matter detection. Sens. Actuators A Phys. 2016, 244, 138–145. [Google Scholar] [CrossRef] [Green Version]

- Hao, W.-C.; Liu, J.-L.; Liu, M.-H.; He, S.-T. Development of a new surface acoustic wave based PM2.5 monitor. In Proceedings of the 2014 Symposium on Piezoelectricity, Acoustic Waves, and Device Applications, Beijing, China, 30 October–2 November 2014; pp. 52–55. [Google Scholar]

- Carminati, M.; Ferrari, G.; Sampietro, M. Emerging miniaturized technologies for airborne particulate matter pervasive monitoring. Measurement 2017, 101, 250–256. [Google Scholar] [CrossRef]

- Carminati, M.; Pedalà, L.; Bianchi, E.; Nason, F.; Dubini, G.; Cortelezzi, L.; Ferrari, G.; Sampietro, M. Capacitive detection of micrometric airborne particulate matter for solid-state personal air quality monitors. Sens. Actuators A Phys. 2014, 219, 80–87. [Google Scholar] [CrossRef]

- Li, X.; Iervolino, E.; Santagata, F.; Wei, J.; Yuan, C.A.; Sarro, P.; Zhang, G.Q. Miniaturized particulate matter sensor for portable air quality monitoring devices. In Proceedings of the IEEE SENSORS 2014, Valencia, Spain, 2–5 November 2014; pp. 2151–2154. [Google Scholar]

- Chellasivalingam, M.; Pandit, M.; Kalberer, M.; Seshia, A.A. Ultra-fine Particulate Detection using Mode-localized MEMS Resonators. In Proceedings of the 2019 Joint Conference of the IEEE International Frequency Control Symposium and European Frequency and Time Forum (EFTF/IFC), Orlando, FL, USA, 14–18 April 2019; pp. 1–5. [Google Scholar]

- Chellasivalingam, M.; Graves, B.; Boies, A.; Seshia, A.A. Mass Tuning in Weakly Coupled Low-Q Piezoelectric MEMS Resonator Arrays for Particulate Sensing. In Proceedings of the 2020 IEEE 33rd International Conference on Micro Electro Mechanical Systems (MEMS), Vancouver, BC, Canada, 18–22 January 2020; pp. 761–764. [Google Scholar]

- Pandit, M.; Zhao, C.; Sobreviela, G.; Mustafazade, A.; Du, S.; Zou, X.; Seshia, A.A. Closed-Loop Characterization of Noise and Stability in a Mode-Localized Resonant MEMS Sensor. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2018, 66, 170–180. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, K.; Kumasaka, K. Lame-mode piezoelectric resonators and transformers using LiNbO/sub 3/ crystals. In Proceedings of the 1995 IEEE Ultrasonics Symposium. An International Symposium, Seattle, WA, USA, 7–10 November 1995; pp. 999–1002. [Google Scholar]

- Thakar, V.; Rais-Zadeh, M. Temperature-compensated piezoelectrically actuated Lamé-mode resonators. In Proceedings of the 2014 IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 January 2014; pp. 214–217. [Google Scholar]

- Ali, A.; Lee, J.E.-Y. Fully Differential Piezoelectric Button-Like Mode Disk Resonator for Liquid Phase Sensing. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2018, 66, 600–608. [Google Scholar] [CrossRef] [PubMed]

- Prasad, A.; Charmet, J.; Seshia, A.A. Simultaneous interrogation of high-Q modes in a piezoelectric-on-silicon micromechanical resonator. Sensors Actuators A Phys. 2016, 238, 207–214. [Google Scholar] [CrossRef]

- Zhao, C.; Wood, G.S.; Xie, J.; Chang, H.; Pu, S.H.; Kraft, M. A Comparative Study of Output Metrics for an MEMS Resonant Sensor Consisting of Three Weakly Coupled Resonators. J. Microelectromechanical Syst. 2016, 25, 626–636. [Google Scholar] [CrossRef]

- Zotov, S.A.; Simon, B.R.; Prikhodko, I.P.; Trusov, A.A.; Shkel, A.M. Quality Factor Maximization Through Dynamic Balancing of Tuning Fork Resonator. IEEE Sensors J. 2014, 14, 2706–2714. [Google Scholar] [CrossRef]

- Kazemimanesh, M.; Moallemi, A.; Thomson, K.; Smallwood, G.; Lobo, P.; Olfert, J. A novel miniature inverted-flame burner for the generation of soot nanoparticles. Aerosol Sci. Technol. 2018, 53, 184–195. [Google Scholar] [CrossRef]

- Nishida, R.T.; Boies, A.M.; Hochgreb, S. Measuring ultrafine aerosols by direct photoionization and charge capture in continuous flow. Aerosol Sci. Technol. 2018, 52, 546–556. [Google Scholar] [CrossRef] [Green Version]

- Fahimi, D.; Mahdavipour, O.; Sabino, J.; White, R.M.; Paprotny, I. Vertically-stacked MEMS PM2.5 sensor for wearable applications. Sens. Actuators A Phys. 2019, 299, 111569. [Google Scholar] [CrossRef]

- Liu, T.-Y.; Sung, C.-A.; Weng, C.-H.; Chu, C.-C.; Zope, A.A.; Pillai, G.; Li, S.-S. Gated CMOS-MEMS thermal-piezoresistive oscillator-based PM2.5 sensor with enhanced particle collection efficiency. In Proceedings of the 2018 IEEE Micro Electro Mechanical Systems (MEMS), Belfast, UK, 21–25 January 2018; pp. 75–78. [Google Scholar] [CrossRef]

- Thiruvenkatanathan, P.; Yan, J.; Woodhouse, J.; Aziz, A.; Seshia, A.A. Ultrasensitive mode-localized mass sensor with electrically tunable parametric sensitivity. Appl. Phys. Lett. 2010, 96, 81913. [Google Scholar] [CrossRef] [Green Version]

- Wood, G.S.; Zhao, C.; Pu, S.H.; Boden, S.A.; Sari, I.; Kraft, M. Mass sensor utilizing the mode-localisation effect in an electrostatically-coupled MEMS resonator pair fabricated using an SOI process. Microelectron. Eng. 2016, 159, 169–173. [Google Scholar] [CrossRef] [Green Version]

- Lin, Y.-W.; Hung, L.-W.; Li, S.-S.; Ren, Z.; Nguyen, C.T.-C. Quality Factor Boosting via Mechanically-Coupled Arraying. In Proceedings of the TRANSDUCERS 2007—2007 International Solid-State Sensors, Actuators and Microsystems Conference, Lyon, France, 10–14 June 2007; pp. 2453–2456. [Google Scholar]

- Northcross, A.L.; Edwards, R.D.; Johnson, M.A.; Wang, Z.-M.; Zhu, K.; Allen, T.; Smith, K.R. A low-cost particle counter as a realtime fine-particle mass monitor. Environ. Sci. Process. Impacts 2013, 15, 433–439. [Google Scholar] [CrossRef] [PubMed]

- Charmet, J.; Daly, R.; Thiruvenkatanathan, P.; Woodhouse, J.; Seshia, A.A. Observations of modal interaction in lateral bulk acoustic resonators. Appl. Phys. Lett. 2014, 105, 13502. [Google Scholar] [CrossRef]

- Charmet, J.; Daly, R.; Thiruvenkatanathan, P.; Seshia, A.A. The effect of mass loading on spurious modes in micro-resonators. Appl. Phys. Lett. 2015, 107, 043502. [Google Scholar] [CrossRef] [Green Version]

- Hao, Z.; Abdolvand, R.; Ayazi, F. A High-Q Length-Extensional Bulk-Modemass Sensor with Annexed Sensing Platforms. In Proceedings of the 19th IEEE International Conference on Micro Electro Mechanical Systems, Istanbul, Turkey, 22–26 January 2006; pp. 598–601. [Google Scholar]

- Pulskamp, J.S.; Bedair, S.S.; Polcawich, R.G.; Smith, G.L.; Martin, J.; Power, B.; Bhave, S.A. Electrode-shaping for the excitation and detection of permitted arbitrary modes in arbitrary geometries in piezoelectric resonators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2012, 59, 1043–1060. [Google Scholar] [CrossRef]

- Lee, J.E.-Y.; Bahreyni, B.; Zhu, Y.; Seshia, A.A. Ultrasensitive mass balance based on a bulk acoustic mode single-crystal silicon resonator. Appl. Phys. Lett. 2007, 91, 234103. [Google Scholar] [CrossRef] [Green Version]

- Demirci, M.; Abdelmoneum, M.; Nguyen, C.-C. Mechanically corner-coupled square microresonator array for reduced series motional resistance. In Proceedings of the TRANSDUCERS ‘03. 12th International Conference on Solid-State Sensors, Actuators and Microsystems. Digest of Technical Papers (Cat. No.03TH8664), Boston, MA, USA, 8–12 June 2003; pp. 955–958. [Google Scholar]

- Xu, Y.; Lee, J.E.-Y. Mechanically coupled SOI Lamé-mode resonator-arrays: Synchronized oscillations with high quality factors of 1 million. In Proceedings of the 2013 Joint European Frequency and Time Forum & International Frequency Control Symposium (EFTF/IFC), Prague, Czech Republic, 21–25 July 2013; pp. 133–136. [Google Scholar] [CrossRef]

- Spletzer, M.; Raman, A.; Sumali, H.; Sullivan, J.P. Highly sensitive mass detection and identification using vibration localization using vibration localization in coupled microcantilever arrays. Appl. Phys. Lett. 2008, 92, 114102. [Google Scholar] [CrossRef] [Green Version]

- DeMartini, B.E.; Rhoads, J.F.; Zielke, M.A.; Owen, K.G.; Shaw, S.W.; Turner, K.L. A single input-single output coupled microresonator array for the detection and identification of multiple analytes. Appl. Phys. Lett. 2008, 93, 54102. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Value |

|---|---|

| Side length of the square resonator | L = 1400 µm |

| Thickness of the square resonator | h = 10 µm |

| Mass of the resonator array | marray = 91.336 µg |

| Stiffness of the resonator array | karray = 14.61 MN/m |

| Thickness of the AlN film | hAlN = 500 nm |

| Thickness of the Al film | hAl = 1 μm |

| Unloaded Q of the resonator array | Qarray = 1773.8 (out-of-phase) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chellasivalingam, M.; Imran, H.; Pandit, M.; Boies, A.M.; Seshia, A.A. Weakly Coupled Piezoelectric MEMS Resonators for Aerosol Sensing. Sensors 2020, 20, 3162. https://doi.org/10.3390/s20113162

Chellasivalingam M, Imran H, Pandit M, Boies AM, Seshia AA. Weakly Coupled Piezoelectric MEMS Resonators for Aerosol Sensing. Sensors. 2020; 20(11):3162. https://doi.org/10.3390/s20113162

Chicago/Turabian StyleChellasivalingam, Malar, Hassan Imran, Milind Pandit, Adam M. Boies, and Ashwin A. Seshia. 2020. "Weakly Coupled Piezoelectric MEMS Resonators for Aerosol Sensing" Sensors 20, no. 11: 3162. https://doi.org/10.3390/s20113162

APA StyleChellasivalingam, M., Imran, H., Pandit, M., Boies, A. M., & Seshia, A. A. (2020). Weakly Coupled Piezoelectric MEMS Resonators for Aerosol Sensing. Sensors, 20(11), 3162. https://doi.org/10.3390/s20113162