Data Handling in Industry 4.0: Interoperability Based on Distributed Ledger Technology

Abstract

1. Introduction

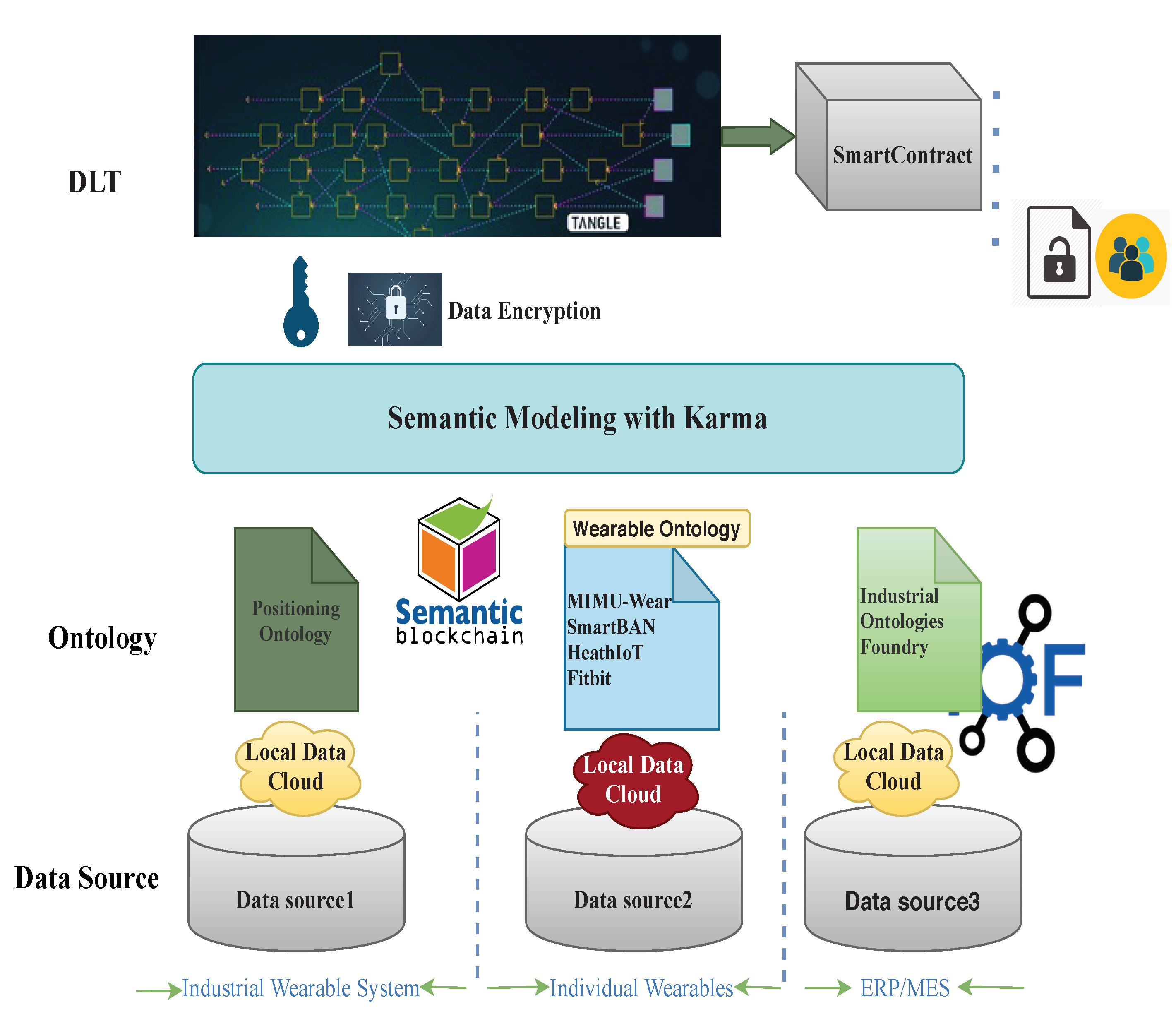

- An enhanced framework providing flexibility to accommodate different data sources and digital twin, as well as an integrated mechanism to disseminate the desired content while limiting exposition of the related IT systems. This creates a common understanding of interoperability.

- Integration of ontologies with the data sets, enabling data fusion techniques and a higher degree of flexibility for data manipulation, enabling automation in machine learning applications.

- Integration of data dissemination in an encrypted way which is immutable and isolated from other IT areas of the company, through the usage of Distributed Ledger Technology (DLT) solutions. Such automation accounts for the transparency principle. Obviously, its contribution must be understood as not being attached to the any particular DLT ledgers, but as a convenient data management approach to show its capabilities.

- Validation of the proposal through Proof of Concept, as deployed in an industrial case involving a real manufacturing company.

2. Literature review

- Data silos. At present, data produced by IIoT deployment devices and wearable devices are controlled or owned by different device manufacturers. Most of the existing value proposals for the IIoT deployment or wearable devices include one platform to manage the physical devices in an integrated way, as well as collecting the data from them by placing it into a private cloud for processing [32,33]. Benefiting from Radio-frequency identification (RFID) and sensor network technologies, common physical objects can be connected and are able to be monitored and managed by a single system [34]. However, as increasing types of IIoT and wearable devices from different vendors become available, more data silos are generated. The existence of such data silos not only jeopardize potential data-driven services and applications; the limited and restricted features provided also dramatically hinder the learning and inference capability derived from the higher requirements of data integration. Most importantly, all related stakeholders in I4.0 are looking forward to a transparent and shared information platform including production and operator data, which is difficult to realize due to the security constraints when passing between various data silos.

- Data ownership. It is an additional challenge for data producers (normally referred to as operators) to reuse (e.g., monetize) their data outside the data provider’s environments. The data producer cannot benefit from the data they generate, as the data is locked inside of the internal data environment of the enterprise. They lose their data ownership and the business opportunities stemming from those data are outside of the data owner’s control. Under this perspective, when referring to data related to humans, the EU General Data Protection Regulation (GDPR) is as effective tool to add significant trust to this dimension, as users are now able to understand their rights and privacy.

- Privacy. When data are related to people, such as devices which are linked to apps by bluetooth, the apps are mostly designed to present the data to users and upload summaries to the cloud manufacturer [35]. However, data integration (especially when related to people) has limitations related to privacy and misuse [36,37]. Cyber security is vulnerable, as wearable device manufacturers have reduced their safety protocols and safety stack layers to enable cheap products, as they have been understood as only serving the end user in a local context. Therefore, there is a clear demand regarding the concept of building and embedding security and privacy controls into connected products, as well as the infrastructure itself. This is one of the implementations of the Privacy by Design (PbD) concept [38,39].

- Interoperability. IIoT devices, including wearable devices, are highly heterogeneous in terms of the underlying communication protocols, data formats, and technologies from different vendors. Such heterogeneous infrastructures, devices, and configurations have becomes a strong limitation for data integration and interoperability. By 2021, 25 billion sensor-enabled objects are expected to be connected to the IIoT, as reported by Gartner [40].

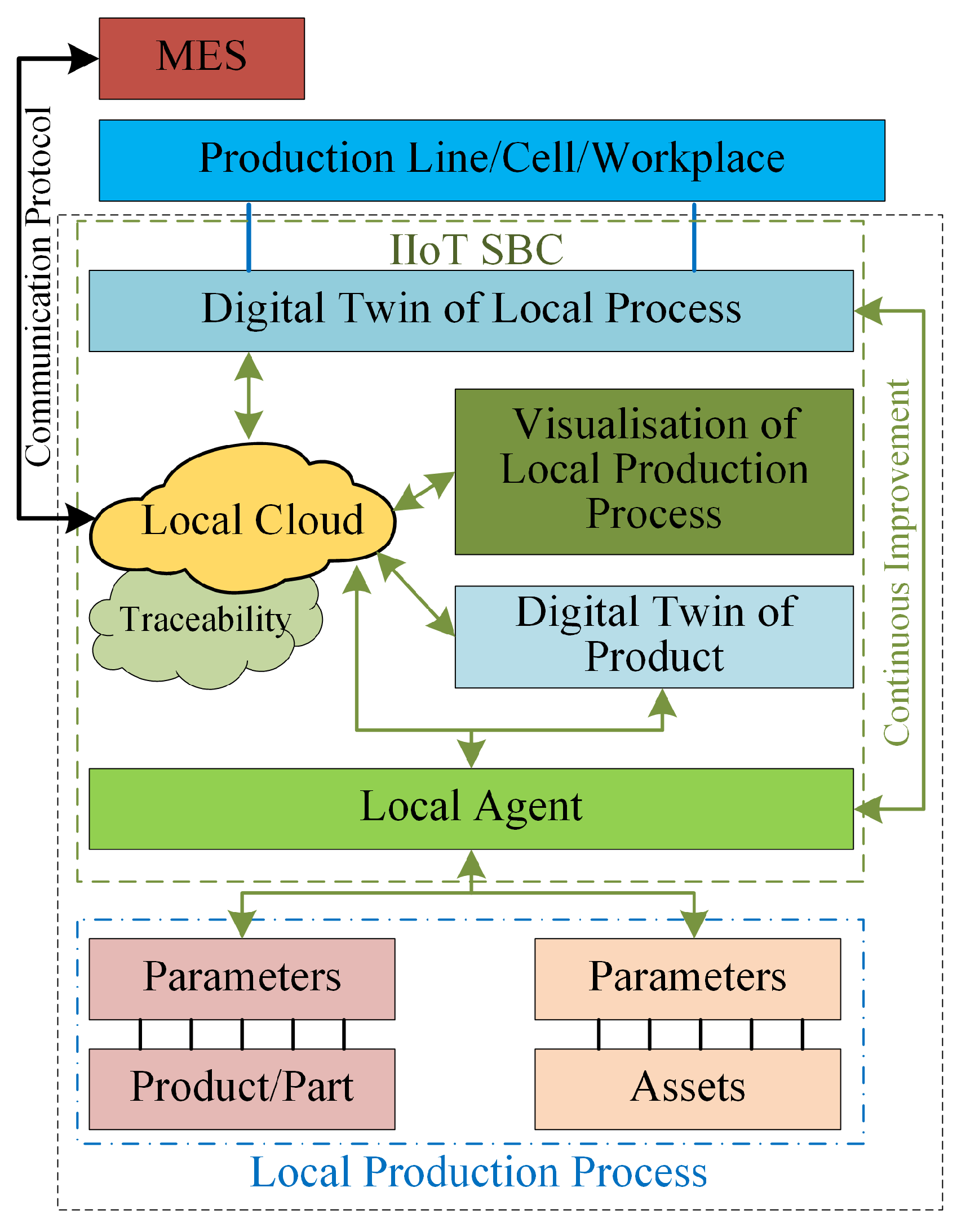

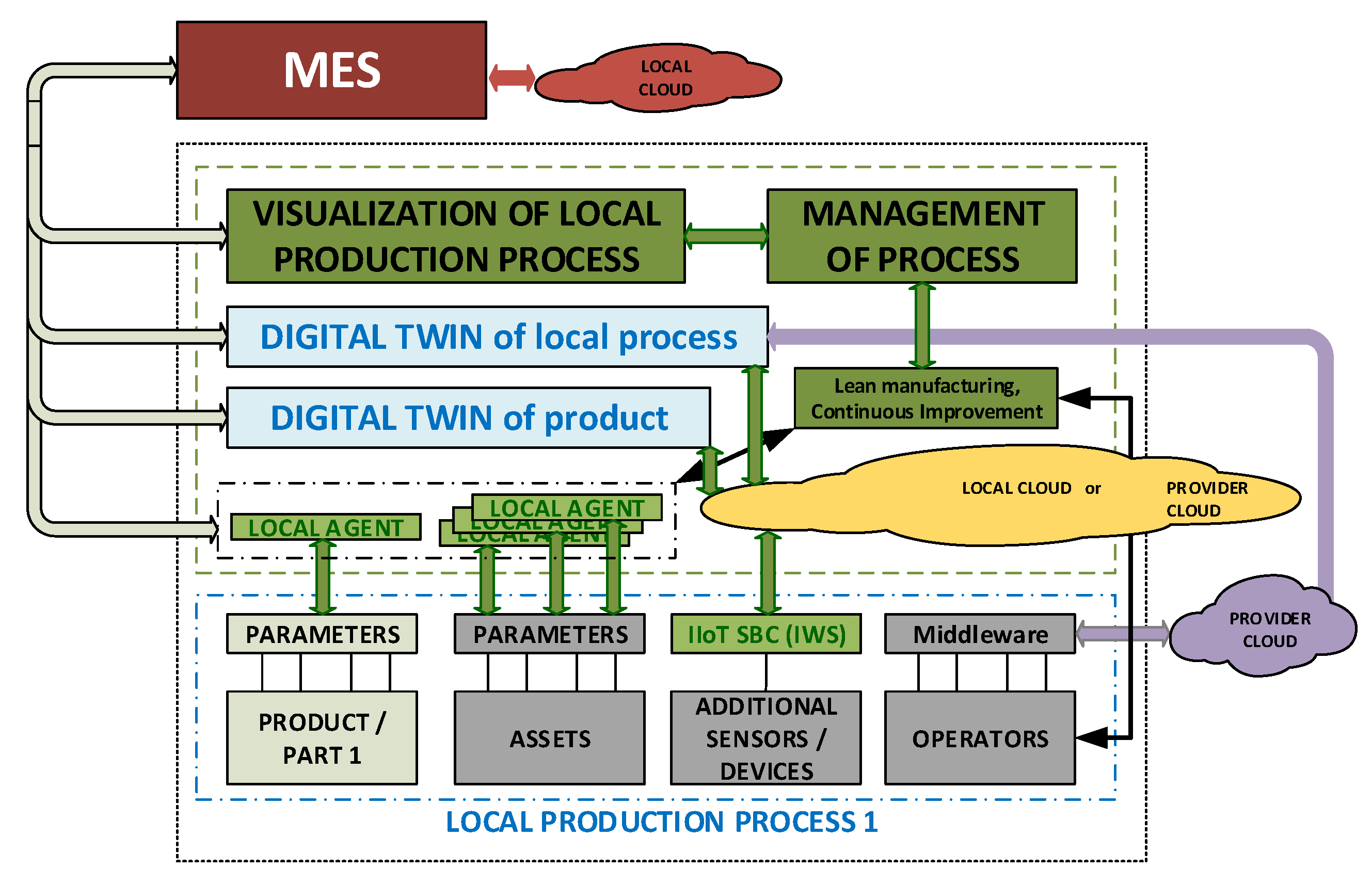

3. Proposed Architecture

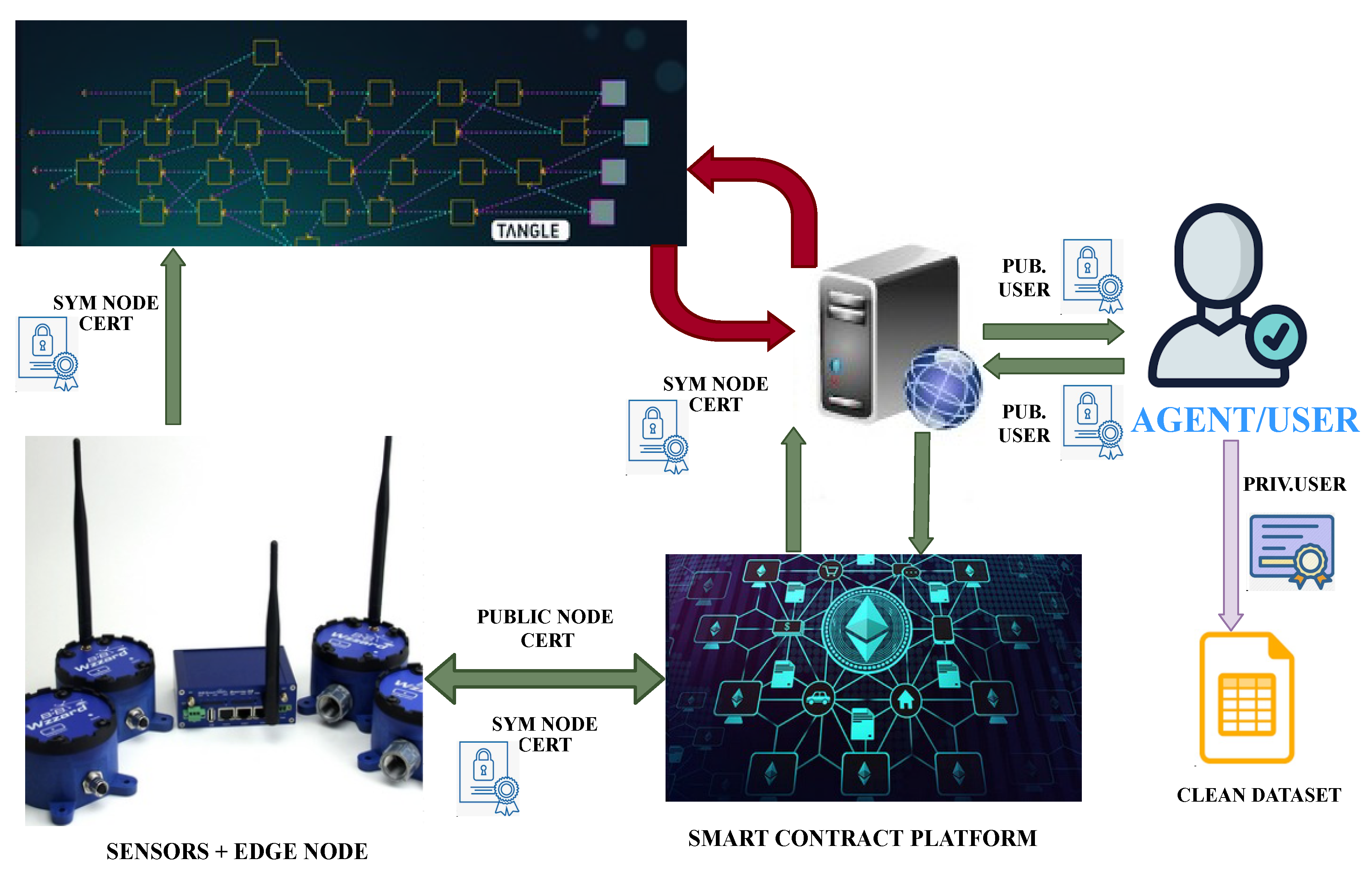

- Public. This is the already-described mechanism, where anyone knowing the address of the receiver has the right to freely access to the content.

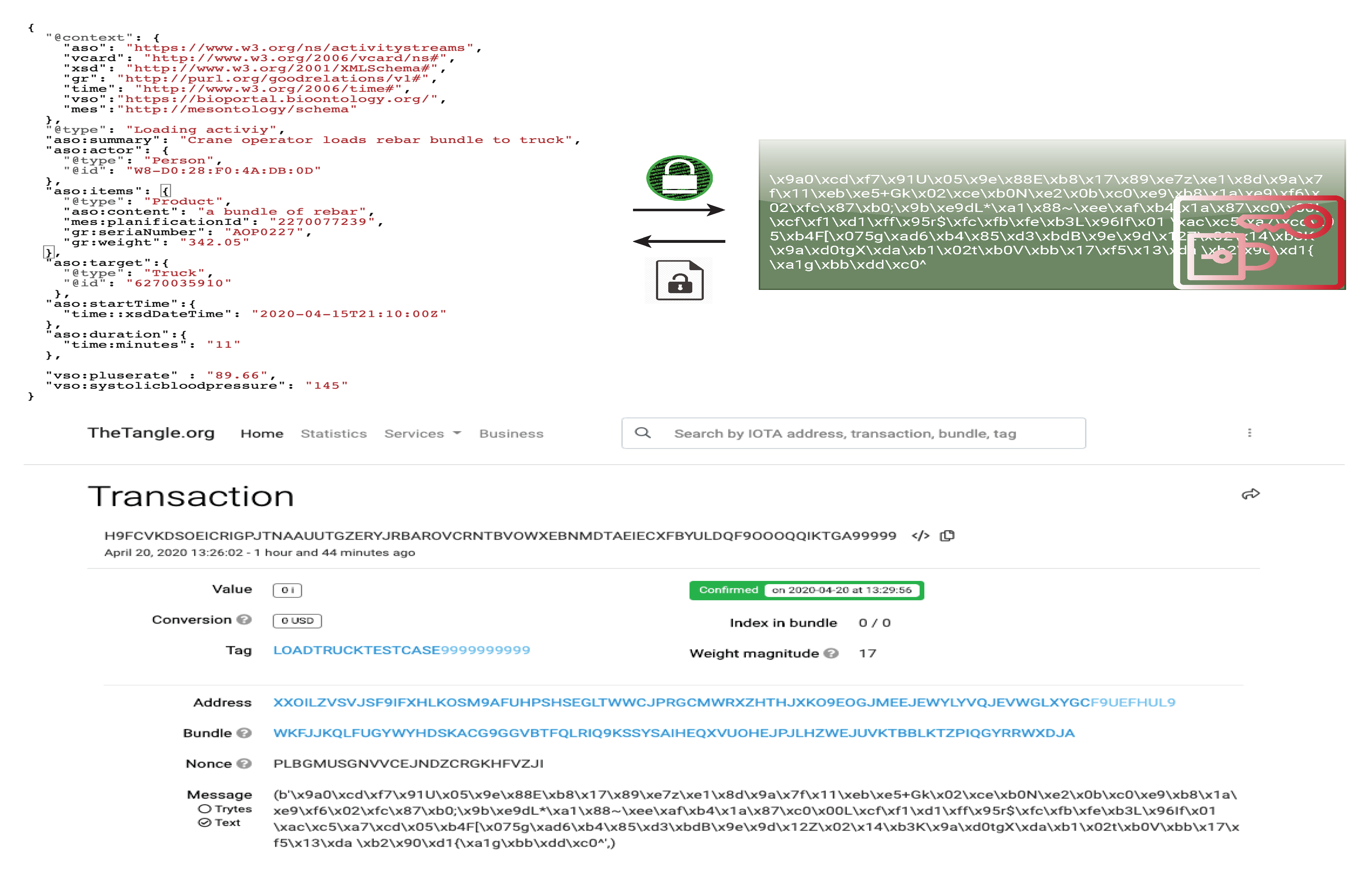

- Restricted. This is the case where sensitive information needs to be shared among only a limited number of stakeholders. To prevent unauthorized entities from reading the data, the message content is obfuscated by encrypting it before uploading it to the Tangle. DLT access at message level, including the encryption/decryption process, is demonstrated in Figure 3.

- Private. In this case, due to the specific content of the data, to prevent unauthorized entities from reading the data and to respect the GDPR enforcement rules, the message content is obfuscated by encrypting it before uploading it to the Tangle by using a private certificate, making it Private by Design (PbD).

- The DLT address, representing the interested entity or device;

- The DLT tag, representing the interested data set;

- The public key, for the user requesting the access to the DLT stored data;

- Selection criteria for the required data, such as from [DateTime] to [DateTime]; and

- Proof of worth for accessing the data.

4. Proof of Concept: An Industrial Scenario

- Production related information from ERP/MES/PLM system;

- Ultra wide band (UWB) indoor positioning system (IPS) to track crane position and crane operator movements, to better define the location for rebar bundles; and

- Smart band to monitor crane operator’s heart rate and blood pressure.

5. Discussion

- Data consistency and the use of different sources of information and/or different time periods or geographical positions;

- Data storage: although properly scrambled, masked, or blurred, the related persons probably are not aware such pieces of information do exist related to them; and

- Problems related to EU citizens when requesting products or services outside of the EU.

- Accountability regarding users; but also,

- Accountability within the organization.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| DAG | Directed Acyclic Graph |

| DL | Deep Learning |

| DLT | Distributed Ledger Technology |

| ERP | Enterprise Resource Planning |

| GDPR | General Data Protection Regulation |

| I4.0 | Industry 4.0 paradigm |

| IIoT | Industrial Internet of Things |

| IoT | Internet of Things |

| IPS | Indoor Positioning System |

| IT | Information Technology |

| IWS | Industrial Wearable System |

| JSON | JavaScript Object Notation |

| JSON-LD | JavaScript Object Notation for Linked Data |

| KPI | Key Performance Indicator |

| LASFA | Lasim Smart Factory reference model |

| MES | Manufacturing Execution System |

| ML | Machine Learning Techniques |

| OPC UA | Open Platform Communications Unified Architecture |

| PbD | Privacy by Design |

| PLM | Product Lifecycle Management |

| UWB | Ultra Wide Band |

References

- Piccarozzi, M.; Aquilani, B.; Gatti, C. Industry 4.0 in management studies: A systematic literature review. Sustainability 2018, 10, 3821. [Google Scholar] [CrossRef]

- Maresova, P.; Soukal, I.; Svobodova, L.; Hedvicakova, M.; Javanmardi, E.; Selamat, A.; Krejcar, O. Consequences of industry 4.0 in business and economics. Economies 2018, 6, 46. [Google Scholar] [CrossRef]

- Villalba-Díez, J.; Molina, M.; Ordieres-Meré, J.; Sun, S.; Schmidt, D.; Wellbrock, W. Geometric Deep Lean Learning: Deep Learning in Industry 4.0 Cyber–Physical Complex Networks. Sensors 2020, 20, 763. [Google Scholar] [CrossRef]

- Grangel-González, I.; Halilaj, L.; Coskun, G.; Auer, S.; Collarana, D.; Hofmeister, M. Towards a Semantic Administrative Shell for Industry 4.0 Components. In Proceedings of the 2016 IEEE Tenth International Conference on Semantic Computing (ICSC), Laguna Hills, CA, USA, 4–6 February 2016; pp. 230–237. [Google Scholar]

- Scheuermann, C.; Heinz, F.; Bruegge, B.; Verclas, S. Real-Time Support During a Logistic Process Using Smart Gloves. In Proceedings of the Smart SysTech 2017; European Conference on Smart Objects, Systems and Technologies, Munich, Germany, 20–21 June 2017; pp. 1–8. [Google Scholar]

- Hao, Y.; Helo, P. The role of wearable devices in meeting the needs of cloud manufacturing: A case study. Robot. Cim.-Int. Manuf. 2017, 45, 168–179. [Google Scholar] [CrossRef]

- Vrchota, J.; Pech, M. Readiness of Enterprises in Czech Republic to Implement Industry 4.0: Index of Industry 4.0. Appl. Sci. 2019, 9, 5405. [Google Scholar] [CrossRef]

- Neumann, W.; Kolus, A.; Wells, R. Human Factors in Production System Design and Quality Performance - A Systematic Review. IFAC-PapersOnLine 2016, 49, 1721–1724. [Google Scholar] [CrossRef]

- Sun, S.; Zheng, X.; Gong, B.; Paredes, J.G.; Ordieres-Meré, J. Healthy Operator 4.0: A Human Cyber–Physical System Architecture for Smart Workplaces. Sensors 2020, 20, 2011. [Google Scholar] [CrossRef]

- Kong, X.T.R.; Yang, X.; Huang, G.Q.; Luo, H. The impact of industrial wearable system on industry 4.0. In Proceedings of the 2018 IEEE 15th International Conference on Networking, Sensing and Control (ICNSC), Zhuhai, China, 27–29 March 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Zvei, E. Plattform Industrie 4.0: The reference Architecture Model of Industrie 4.0 (2015). Available online: https://www.zvei.org/en/subjects/industrie-4-0/the-reference-architectural-model-rami-40-and-the-industrie-40-component/ (accessed on 25 April 2020).

- Lee, J.; Bagheri, B.; Kao, H.A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Resman, M.; Pipan, M.; Simic, M.; Herakovic, N. A new architecture model for smart manufacturing: A performance analysis and comparison with the RAMI 4.0 reference model. Adv. Prod. Eng. Manag. 2019, 14, 153–165. [Google Scholar] [CrossRef]

- Wiemann, S.; Bernard, L. Spatial data fusion in spatial data infrastructures using linked data. Int. J. Geogr. Inf. Sci. 2016, 30, 613–636. [Google Scholar] [CrossRef]

- Gagnon, M. Ontology-based integration of data sources. In Proceedings of the 10th IEEE International Conference on Information Fusion, Quebec, QC, Canada, 9–12 July 2007; pp. 1–8. [Google Scholar]

- Noura, M.; Atiquzzaman, M.; Gaedke, M. Interoperability in Internet of Things Infrastructure: Classification, Challenges, and Future Work. In IoT as a Service; Lin, Y.B., Deng, D.J., You, I., Lin, C.C., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 11–18. [Google Scholar]

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and US Air Force vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1818. [Google Scholar]

- Boschert, S.; Rosen, R. Digital twin—The simulation aspect. In Mechatronic Futures; Hehenberger, P., Bradley, D., Eds.; Springer: Cham, Switzerland, 2016; pp. 59–74. [Google Scholar]

- Kagermann, H. Change through digitization—Value creation in the age of Industry 4.0. In Management of Permanent Change; Springer: Cham, Switzerland, 2015; pp. 23–45. [Google Scholar]

- Groopman, J. Circles of Trust for Smart Devices for US citizens. Source: Privacy & The Internet of Things: The Importance of Transparency in Accounting for What We Can’t See. Available online: https://www.trustarc.com/blog/tag/iot-summit/ (accessed on 25 April 2020).

- Frysak, J.; Krenn, F.; Kaar, C.; Stary, C. Decision-Making Support for View-Oriented I4.0 System Architecture Design. In Proceedings of the 2018 IEEE 20th Conference on Business Informatics (CBI), Vienna, Austria, 11–14 July 2018; Volume 1, pp. 186–195. [Google Scholar]

- Bakhshandeh, M.; Antunes, G.; Mayer, R.; Borbinha, J.; Caetano, A. A Modular Ontology for the Enterprise Architecture Domain. In Proceedings of the 17th IEEE International Enterprise Distributed Object Computing Conference Workshops, Vancouver, BC, Canada, 9–13 September 2013; pp. 5–12. [Google Scholar]

- Zhu, K. Information transparency in electronic marketplaces: Why data transparency may hinder the adoption of B2B exchanges. Electron. Mark. 2002, 12, 92–99. [Google Scholar] [CrossRef]

- Flatt, H.; Schriegel, S.; Jasperneite, J.; Trsek, H.; Adamczyk, H. Analysis of the Cyber-Security of industry 4.0 technologies based on RAMI 4.0 and identification of requirements. In Proceedings of the 2016 IEEE 21st International Conference on Emerging Technologies and Factory Automation (ETFA), Berlin, Germany, 6–9 September 2016; pp. 1–4. [Google Scholar]

- Müller, J.M.; Kiel, D.; Voigt, K.I. What Drives the Implementation of Industry 4.0? The Role of Opportunities and Challenges in the Context of Sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Villalba-Diez, J.; Ordieres-Meré, J. Improving manufacturing performance by standardization of interprocess communication. IEEE Trans. Eng. Manag. 2015, 62, 351–360. [Google Scholar] [CrossRef]

- Villalba-Diez, J.; Ordieres-Meré, J.; Nuber, G. The HOSHIN KANRI TREE. Cross-Plant Lean Shopfloor Management. Procedia CIRP 2015, 32, 150–155. [Google Scholar] [CrossRef][Green Version]

- Villalba-Diez, J.; Ordieres-Mere, J.; Chudzick, H.; Lopez-Rojo, P. NEMAWASHI: Attaining Value Stream alignment within Complex Organizational Networks. Procedia CIRP 2015, 37, 134–139. [Google Scholar] [CrossRef]

- Villalba-Diez, J. The Lean Brain Theory. Complex Networked Lean Strategic Organizational Design; CRC Press. Taylor and Francis Group LLC: Boca Raton, FL, USA, 2017. [Google Scholar]

- Villalba-Diez, J. The HOSHIN KANRI FOREST. Lean Strategic Organizational Design, 1st ed.; CRC Press, Taylor and Francis Group LLC: Boca Raton, FL, USA, 2017. [Google Scholar]

- Lee, J.; Ardakani, H.D.; Yang, S.; Bagheri, B. Industrial Big Data Analytics and Cyber-physical Systems for Future Maintenance & Service Innovation. Procedia CIRP 2015, 38, 3–7. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, X. Industry 4.0 and Cloud Manufacturing: A Comparative Analysis. J. Manuf. Sci. Eng. 2016, 139. [Google Scholar] [CrossRef]

- Jiang, L.; Da Xu, L.; Cai, H.; Jiang, Z.; Bu, F.; Xu, B. An IoT-oriented data storage framework in cloud computing platform. IEEE Trans. Ind. Inf. 2014, 10, 1443–1451. [Google Scholar] [CrossRef]

- Stergiou, C.; Psannis, K.E.; Kim, B.G.; Gupta, B. Secure integration of IoT and cloud computing. Future Gener. Comp. Syst. 2018, 78, 964–975. [Google Scholar] [CrossRef]

- D’Antrassi, P.; Prenassi, M.; Rossi, L.; Ferrucci, R.; Barbieri, S.; Priori, A.; Marceglia, S. Personally Collected Health Data for Precision Medicine and Longitudinal Research. Front. Med. 2019, 6, 125. [Google Scholar] [CrossRef] [PubMed]

- Antón, M.Á.; Ordieres-Meré, J.; Saralegui, U.; Sun, S. Non-Invasive Ambient Intelligence in Real Life: Dealing with Noisy Patterns to Help Older People. Sensors 2019, 19, 3113. [Google Scholar] [CrossRef]

- Bednar, K.; Spiekermann, S.; Langheinrich, M. Engineering Privacy by Design: Are engineers ready to live up to the challenge? Inf. Soc. 2019, 35, 122–142. [Google Scholar] [CrossRef]

- Cavoukian, A. Privacy by Design: The 7 Foundational Principles. Available online: https://www.ipc.on.ca/wp-content/uploads/resources/7foundationalprinciples.pdf (accessed on 25 April 2020).

- Gartner. Gartner Identifies Top 10 Strategic IoT Technologies and Trends. Available online: https://gtnr.it/2JLiEbA (accessed on 6 February 2020).

- OPC Foundation. OPC UA Specification: Part 1–Concepts, Version 1.04. OPC Foundation 2017. Available online: https://opcfoundation.org/developer-tools/specifications-unified-architecture/part-1-overview-and-concepts/ (accessed on 25 April 2020).

- Fraile, F.; Sanchis, R.; Poler, R.; Ortiz, A. Reference Models for Digital Manufacturing Platforms. Appl. Sci. 2019, 9, 4433. [Google Scholar] [CrossRef]

- Glebke, R.; Henze, M.; Wehrle, K.; Niemietz, P.; Trauth, D.; Mattfeld, M.; Bergs, T. A Case for Integrated Data Processing in Large-Scale Cyber-Physical Systems. In Proceedings of the 52nd Hawaii International Conference on System Sciences, Wailea, HI, USA, 8 August–1 November 2019. [Google Scholar]

- Al-Jabri, I.M.; Roztocki, N. Adoption of ERP systems: Does information transparency matter? Telemat. Inf. 2015, 32, 300–310. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, M.; Li, J.; Au, M.H.; Choo, K.K.R.; Chen, T.; Tian, S. Blockchain based secure data sharing system for Internet of vehicles: A position paper. Veh. Commun. 2019, 16, 85–93. [Google Scholar] [CrossRef]

- Wang, L.; Guo, S. Blockchain Based Data Trust Sharing Mechanism in the Supply Chain. In Security with Intelligent Computing and Big-data Services; Yang, C.N., Peng, S.L., Jain, L.C., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 43–53. [Google Scholar]

- Shen, B.; Guo, J.; Yang, Y. MedChain: Efficient Healthcare Data Sharing via Blockchain. Appl. Sci. 2019, 9, 1207. [Google Scholar] [CrossRef]

- Zheng, X.; Sun, S.; Mukkamala, R.R.; Vatrapu, R.; Ordieres-Meré, J. Accelerating Health Data Sharing: A Solution Based on the Internet of Things and Distributed Ledger Technologies. J. Med. Internet Res. 2019, 21, e13583. [Google Scholar] [CrossRef]

- Ledwaba, L.P.I.; Hancke, G.P.; Isaac, S.J.; Venter, H.S. Developing a Secure, Smart Microgrid Energy Market using Distributed Ledger Technologies. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019; Volumes 1, pp. 1725–1728. [Google Scholar] [CrossRef]

- Nikander, P.; Autiosalo, J.; Paavolainen, S. Interledger for the Industrial Internet of Things. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019; Volume 1, pp. 908–915. [Google Scholar] [CrossRef]

- Gomes, P.; Cavalcante, E.; Batista, T.; Taconet, C.; Conan, D.; Chabridon, S.; Delicato, F.C.; Pires, P.F. A semantic-based discovery service for the Internet of Things. J. Internet Serv. Appl. 2019, 10, 10. [Google Scholar] [CrossRef]

- Delicato, F.C.; Pires, P.F.; Batista, T. Resource Management for the Internet of Things; Springer International Publishing AG: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Popov, S. The Tangle. Available online: https://assets.ctfassets.net/r1dr6vzfxhev/2t4uxvsIqk0EUau6g2sw0g/45eae33637ca92f85dd9f4a3a218e1ec/iota1_4_3.pdf (accessed on 25 April 2020).

- Sahinel, D.; Akpolat, C.; Görür, O.C.; Sivrikaya, F. Integration of Human Actors in IoT and CPS Landscape. In Proceedings of the 2019 IEEE 5th World Forum on Internet of Things (WF-IoT), Limerick, Ireland, 15–18 April 2019; pp. 485–490. [Google Scholar]

- Zezulka, F.; Marcon, P.; Vesely, I.; Sajdl, O. Industry 4.0 —An Introduction in the phenomenon. IFAC-PapersOnLine 2016, 49, 8–12. [Google Scholar] [CrossRef]

- Giannetti, C.; Ransing, M.R.; Ransing, R.S.; Bould, D.C.; Gethin, D.T.; Sienz, J. Organisational Knowledge Management for Defect Reduction and Sustainable Development in Foundries. Int. J. Knowl. Syst. Sci. 2015, 6, 18–37. [Google Scholar] [CrossRef]

- Cheng, H.; Zeng, P.; Xue, L.; Shi, Z.; Wang, P.; Yu, H. Manufacturing Ontology Development Based on Industry 4.0 Demonstration Production Line. In Proceedings of the 2016 Third International Conference on Trustworthy Systems and Their Applications (TSA), Wuhan, China, 18–22 September 2016; pp. 42–47. [Google Scholar] [CrossRef]

- Blockchain Ontology with Dynamic Extensibility. Available online: https://github.com/hedugaro/Blondie (accessed on 6 February 2020).

- Smith, B.; Grenon, P.; Goldberg, L. Biodynamic Ontology: Applying BFO in the Biomedical Domain. Stud. Health Technol. Inf. 2004, 102, 20–38. [Google Scholar]

- Gangemi, A.; Guarino, N.; Masolo, C.; Oltramari, A.; Schneider, L. Sweetening Ontologies with DOLCE. In Proceedings of the EKAW: International Conference on Knowledge Engineering and Knowledge Management, Sigüenza, Spain, 1–4 October 2002; pp. 166–181. [Google Scholar]

- Industrial Ontologies Foundry (IOF). Available online: https://sites.google.com/view/industrialontologies/home (accessed on 25 April 2020).

- Yun, J.; Ahn, I.Y.; Song, J.; Kim, J. Implementation of Sensing and Actuation Capabilities for IoT Devices Using oneM2M Platforms. Sensors 2019, 19, 4567. [Google Scholar] [CrossRef] [PubMed]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comput. Ind. 2019, 113, 103130. [Google Scholar] [CrossRef]

- Jha, S.B.; Babiceanu, R.F.; Seker, R. Formal modeling of cyber-physical resource scheduling in IIoT cloud environments. J. Int. Manuf. 2019, 1–16. [Google Scholar] [CrossRef]

- Ikävalko, H.; Turkama, P.; Smedlund, A. Value creation in the internet of things: Mapping business models and ecosystem roles. Technol. Innov. Manag. Rev. 2018, 8. [Google Scholar] [CrossRef]

- Zhang, Y.; Wen, J. The IoT electric business model: Using blockchain technology for the internet of things. Peer Peer Netw. Appl. 2017, 10, 983–994. [Google Scholar] [CrossRef]

- D’Antonio, G.; Macheda, L.; Sauza Bedolla, J.; Chiabert, P. PLM-MES Integration to Support Industry 4.0. In Proceedings of the PLM: IFIP International Conference on Product Lifecycle Management, Seville, Spain, 10–12 July 2017; pp. 129–137. [Google Scholar]

- Carbonera, J.L.; Fiorini, S.R.; Prestes, E.; Jorge, V.A.M.; Abel, M.; Madhavan, R.; Locoro, A.; Gonçalves, P.; Haidegger, T.; Barreto, M.E.; et al. Defining positioning in a core ontology for robotics. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 1867–1872. [Google Scholar]

- Kun, D.P.; Varga, E.B.; Toth, Z. Ontology based navigation model of the ILONA system. In Proceedings of the 2017 IEEE 15th International Symposium on Applied Machine Intelligence and Informatics (SAMI), Herl’any, Slovakia, 26–28 January 2017; pp. 479–484. [Google Scholar] [CrossRef]

- Villalonga, C.; Pomares, H.; Rojas, I.; Banos Legran, O. MIMU-Wear: Ontology-based sensor selection for real-world wearable activity recognition. Neurocomputing 2017, 1–25. [Google Scholar] [CrossRef]

- Long, W. Construct MES Ontology with OWL. In Proceedings of the 2008 ISECS International Colloquium on Computing, Communication, Control, and Management, Guangzhou, China, 3–4 August 2008; Volume 1, pp. 614–617. [Google Scholar]

- Khedher, A.B.; Henry, S.; Bouras, A. Integration between MES and Product Lifecycle Management. In Proceedings of the ETFA2011, Toulouse, France, 5–9 September 2011. [Google Scholar] [CrossRef]

- Fumagalli, L.; Pala, S.; Garetti, M.; Negri, E. Ontology-Based Modeling of Manufacturing and Logistics Systems for a New MES Architecture. In Advances in Production Management Systems. Innovative and Knowledge-Based Production Management in a Global-Local World; Grabot, B., Vallespir, B., Gomes, S., Bouras, A., Kiritsis, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 192–200. [Google Scholar]

- OGC. OGC® IndoorGML. Available online: https://www.ogc.org/standards/indoorgml (accessed on 6 February 2020).

- ETSI. Smart Body Area Networks (SmartBAN) Unified data representation formats, semantic and open data model. Available online: https://www.etsi.org/deliver/etsi_ts/103300_103399/103378/01.01.01_60/ts_103378v010101p.pdf (accessed on 25 April 2020).

- Nach, H.; Lejeune, A. Implementing ERP in SMEs: Towards an Ontology Supporting Managerial Decisions. In Proceedings of the 2008 International MCETECH Conference on e-Technologies (Mcetech 2008), Montreal, QC, Canada, 23–25 Janauary 2008; pp. 223–226. [Google Scholar]

- Hepp, M.; Wechselberger, A. OntoNaviERP: Ontology-Supported Navigation in ERP Software Documentation. In The Semantic Web-ISWC 2008; Sheth, A., Staab, S., Dean, M., Paolucci, M., Maynard, D., Finin, T., Thirunarayan, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 764–776. [Google Scholar]

- Dudas, P.M.; Ghafourian, M.; Karimi, H.A. ONALIN: Ontology and Algorithm for Indoor Routing. In Proceedings of the 2009 Tenth International Conference on Mobile Data Management: Systems, Services and Middleware, Taipei, Taiwan, 18–20 May 2009; pp. 720–725. [Google Scholar]

- Stevenson, G.; Ye, J.; Dobson, S.; Nixon, P. LOC8: A Location Model and Extensible Framework for Programming with Location. IEEE Pervas. Comp. 2010, 9, 28–37. [Google Scholar] [CrossRef]

- Rhayem, A.; Mhiri, M.B.A.; Gargouri, F. HealthIoT Ontology for Data Semantic Representation and Interpretation Obtained from Medical Connected Objects. In Proceedings of the 2017 IEEE/ACS 14th International Conference on Computer Systems and Applications (AICCSA), Hammamet, Tunisia, 30 October–3 November 2017; pp. 1470–1477. [Google Scholar]

- Maheshwari, N.; Srivastava, S.; Rajan, K.S. Development of an Indoor Space Semantic Model and Its Implementation as an IndoorGML Extension. ISPRS Int. J. Geo Inf. 2019, 8, 333. [Google Scholar] [CrossRef]

- Khruahong, S.; Kong, X.; Sandrasegaran, K.; Liu, L. Develop An Indoor Space Ontology For Finding Lost Properties for Location-Based Service of Smart City. In Proceedings of the 2018 18th International Symposium on Communications and Information Technologies (ISCIT), Bangkok, Thailand, 26–29 September 2018; pp. 54–59. [Google Scholar]

- universAAL IoT. Fitbit Ontology. Unified Data Representation Formats, Semantic and Open Data Model. Available online: https://github.com/universAAL/ontology/issues/479 (accessed on 25 April 2020).

- Goldfain, A.; Smith, B.; Arabandi, S.; Brochhausen, M.; Hogan, W. Vital Sign Ontology. In Proceedings of the Workshop on Bio-Ontologies, Vienna, Austria, June 2011; pp. 71–74. [Google Scholar]

- Sun, S. Interoperable Data Handling for Industry 4.0. Available online: https://gitlab.com/sunshengjing/interoperable-data-usage-for-industry-4.0 (accessed on 25 April 2020).

- Longo, F.; Nicoletti, L.; Padovano, A. Smart operators in industry 4.0: A human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context. Comp. Ind. Eng. 2017, 113, 144–159. [Google Scholar] [CrossRef]

- Aehnelt, M.; Urban, B. Follow-Me: Smartwatch Assistance on the Shop Floor. In HCI in Business; Nah, F.F.H., Ed.; Springer International Publishing: Cham, Switzerland, 2014; pp. 279–287. [Google Scholar]

- Chapin, F.S.; Folke, C.; Kofinas, G.P. A framework for understanding change. In Principles of Ecosystem Stewardship; Springer: Berlin/Heidelberg, Germany, 2009; pp. 3–28. [Google Scholar]

- Kharlamov, E.; Martin-Recuerda, F.; Perry, B.; Cameron, D.; Fjellheim, R.; Waaler, A. Towards semantically enhanced digital twins. In Proceedings of the 2018 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA, 10–13 December 2018; pp. 4189–4193. [Google Scholar]

- Gómez-Berbís, J.M.; de Amescua-Seco, A. SEDIT: Semantic Digital Twin Based on Industrial IoT Data Management and Knowledge Graphs. In International Conference on Technologies and Innovation; Springer: Cham, Switzerland, 2019; pp. 178–188. [Google Scholar]

- Lu, J.; Zheng, X.; Gharaei, A.; Kalaboukas, K.; Kiritsis, D. Cognitive Twins for Supporting Decision-Makings of Internet of Things Systems. arXiv 2019, arXiv:1912.08547. [Google Scholar]

- Zhou, J.; Zhou, Y.; Wang, B.; Zang, J. Human-Cyber-Physical Systems (HCPSs) in the Context of New-Generation Intelligent Manufacturing. Engineering 2019, 5, 624–636. [Google Scholar] [CrossRef]

- Roda-Sanchez, L.; Garrido-Hidalgo, C.; Hortelano, D.; Olivares, T.; Ruiz, M.C. OperaBLE: An IoT-Based Wearable to Improve Efficiency and Smart Worker Care Services in Industry 4.0. J. Sens. 2018, 2018, 1–12. [Google Scholar] [CrossRef]

- Awolusi, I.; Marks, E.; Hallowell, M. Wearable technology for personalized construction safety monitoring and trending: Review of applicable devices. Automat. Constr. 2018, 85, 96–106. [Google Scholar] [CrossRef]

| Ontology List | ||

|---|---|---|

| IPS | Wearable | Production System |

| Positioning Ontology [69,70] | MIMU-Wear Ontology [71] | MES ontology [72,73,74] |

| IndoorGML [75] | SmartBAN Ontology [76] | ERP ontology [77,78] |

| Navigation ontology [70,79,80] | HealthIoT Ontology [81] | PLM ontology [73] |

| Indoor space ontology [82,83] | Fitbit Ontology [84] | |

| Vital Sign Ontology [85] | ||

| Semantic Modeling | |||

|---|---|---|---|

| Data Source | Data Storage | Ontology | JSON-LD |

| MES (ISA-95) | Microsoft SQL database | MES ontology [72] | {

"@context": { "mes":"http://mesontology/schema", "gr": "http://purl.org/goodrelations/v1#", "pto": "http://www.productontology.org/id/", "xsd": "http://www.w3.org/2001/XMLSchema#", "gr:seriaNumber": { "@type": "xsd:int" }, "gr:description": { "@type": "xsd: string" }, "gr:amountOfThisGood": { "@type": "xsd:int" }, "gr:eligibleRegions": { "@type": "xsd: string" }, "gr:weight": { "@type": "xsd:float" } "mes:planificationId": "2270077239", "gr:seriaNumber": "AAAEEE3452XX", "gr:description": "bundle of rebars", "gr:amountOfThisGood": "20", "gr:eligibleRegions": "DE(Germany)", "gr:weight": "300", "gr:includes": { "@type": [ "gr:Individual", "pto:Rebar" ]} } |

| Smart band | MongoDB | Vital Sign Ontology [85] | {

"@context": { "vso": "https://bioportal.bioontology.org/ ontologies/VSO", "xsd": "http://www.w3.org/2001/XMLSchema#", "vso: pulserate": { "@type": "xsd:int" }, "vso: systolicbloodpressure": { "@type": "xsd:int" }, "sumo": "http://www.adampease.org/OP/SUMO.owl", "sumo:timepoint": { "@type": "xsd:dateTime" }, "vso:pulserate" : "79", "vso:systolicbloodpressure": "111", "sumo:timepoint": "2020-04-08T11:20:00Z" } |

| IPS (tracktio) | CSV file | Positioning Ontology [69] | {

"@context": { "positionpoint": "http://positioningontology/schema", "xsd": "http://www.w3.org/2001/XMLSchema#", "axis": "http://data.ign.fr/def/ignf#CoordinateSystemAxis", "axis: listofaxes": { "@type": "xsd:list" }, "sumo": "http://www.adampease.org/OP/SUMO.owl", "sumo:timepoint": { "@type": "xsd:dateTime" }, "positionpoint": { "axis: listofaxes": "7.299998 1.140002 1.499998" }, "sumo:timepoint": "2020-04-09T10:00:00Z" } } |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, S.; Zheng, X.; Villalba-Díez, J.; Ordieres-Meré, J. Data Handling in Industry 4.0: Interoperability Based on Distributed Ledger Technology. Sensors 2020, 20, 3046. https://doi.org/10.3390/s20113046

Sun S, Zheng X, Villalba-Díez J, Ordieres-Meré J. Data Handling in Industry 4.0: Interoperability Based on Distributed Ledger Technology. Sensors. 2020; 20(11):3046. https://doi.org/10.3390/s20113046

Chicago/Turabian StyleSun, Shengjing, Xiaochen Zheng, Javier Villalba-Díez, and Joaquín Ordieres-Meré. 2020. "Data Handling in Industry 4.0: Interoperability Based on Distributed Ledger Technology" Sensors 20, no. 11: 3046. https://doi.org/10.3390/s20113046

APA StyleSun, S., Zheng, X., Villalba-Díez, J., & Ordieres-Meré, J. (2020). Data Handling in Industry 4.0: Interoperability Based on Distributed Ledger Technology. Sensors, 20(11), 3046. https://doi.org/10.3390/s20113046