Quantum Strategic Organizational Design: Alignment in Industry 4.0 Complex-Networked Cyber-Physical Lean Management Systems

Abstract

:1. Introduction

2. Background

- Industry 4.0. Industry 4.0 has gained a lot of attention since it was first released [26], claiming the necessity of a new paradigm shift in favour of a less centralized manufacture structure. It is regarded as the fourth industrial revolution, the first three being mechanization through the use of vapor energy, mass production through electricity generation, and ultimately the digital revolution through the integration of electronics and information technology. The industry 4.0 ought to allow for a larger independence of the manufacturing process, since technology is more interrelated and the machines can interact with each other creating a cyber-physical system [27,28,29,30,31,32].

- Cyber-Physical Systems. Cyber-physical system in the context of Industry 4.0 relates to the close bonding and alignment between computing and material resources. A new paradigm of technological systems that is based on embedded collaborative software is impacting the development of such systems [33,34,35].

- Lean Management. Lean management systems in a cyber-physical environment of Industry 4.0 are described as socio-technical structures that are designed to consistently reduce the variability of value creating processes and, therefore, increase their effectiveness and profitability [9,36,37,38,39,40,41,42,43,44,45,46].Variability in this context is understood as any deviation from the desired process state. In quantifiable terms, this work understands the variability of a process, as measured by the systematic reduction of the standard deviation that is associated with the indicators measuring its performance [9,47].

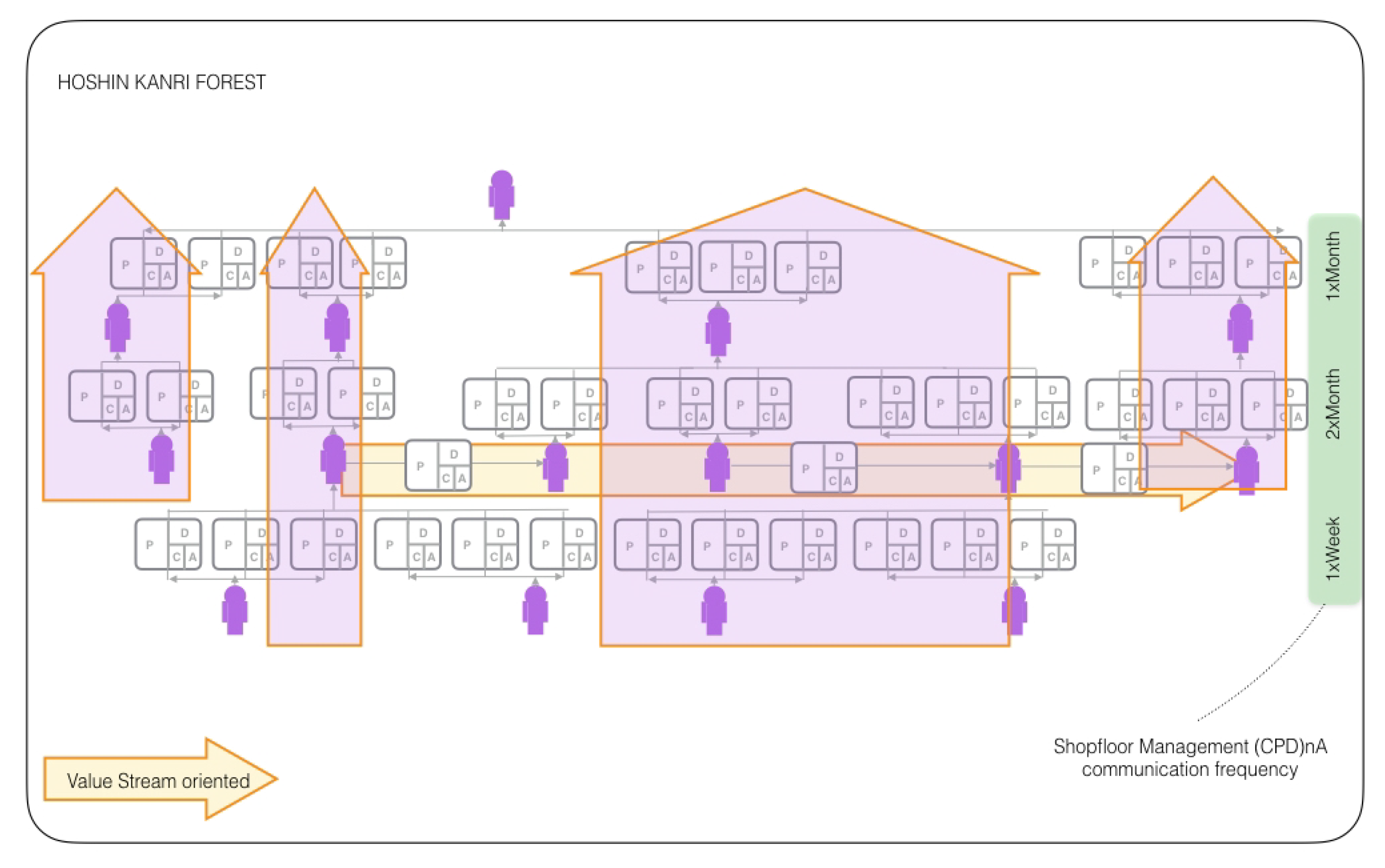

- Complex Networked Organizational Design. According to the network organizational paradigm, modern cyber-physical systems that are oriented to the lean management of Industry 4.0 can be seen as a socio-technical symbiotic ecosystem of human networks [5] interacting with distributed physical sensors interconnected in an increasingly complex network interconnected sensors [48], which readings are modeled as time-dependent signals at the vertices, human, or cyber-physical, respectively. That means that in the structure of the network nodes you can find characteristics that represent them in the form of a certain time series that describes the key performance indicators (KPIs).

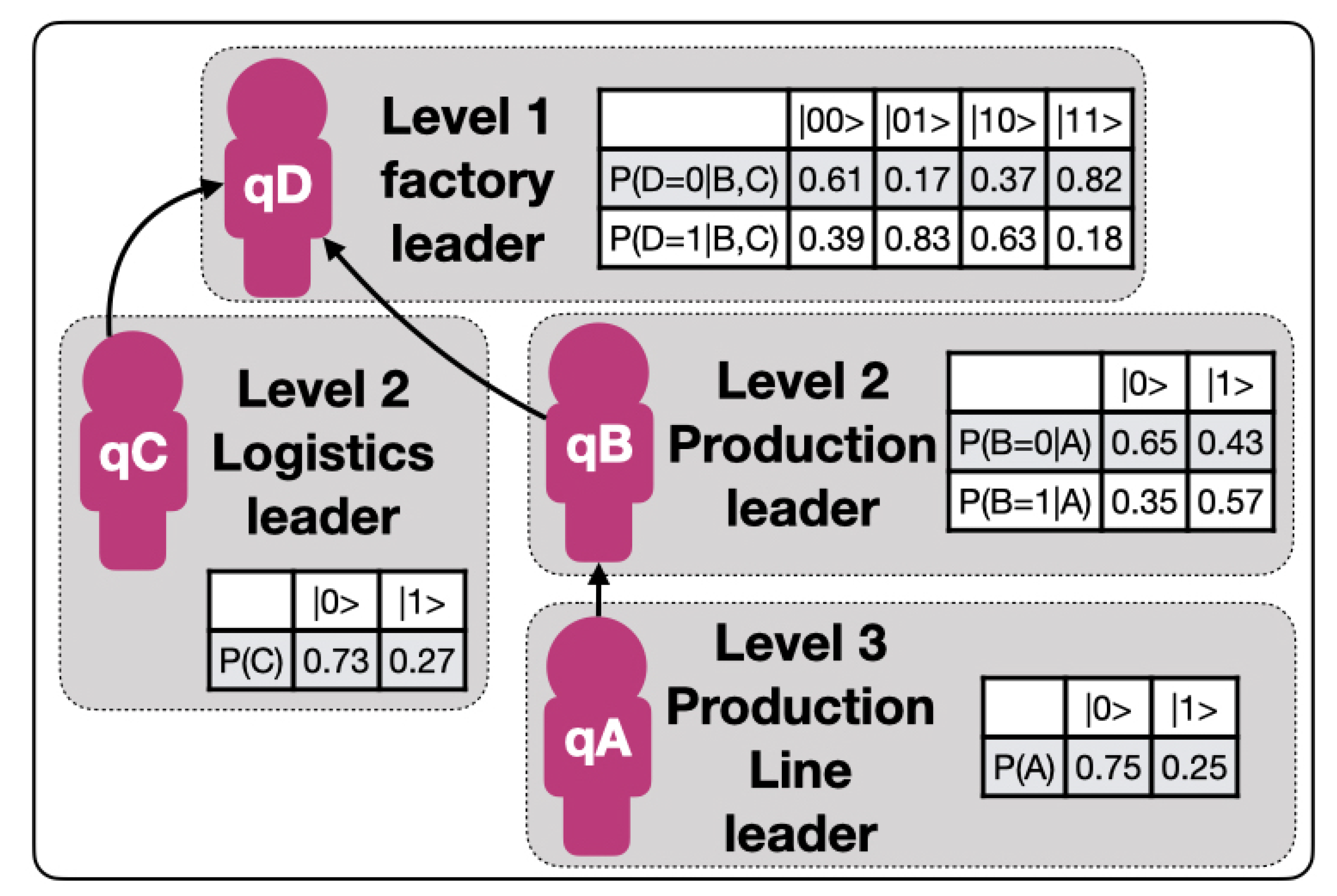

- Alignment. This information is typically described by a series of KPIs. Such KPIs are interdependent and they describe certain trajectories in node-related orthonormal bases [2]. These scholars define a node to be in alignment at any given moment in time if the KPI’s trajectory presents asymptotic stability at this point [49]. In other words, the condition for alignment at any given time interval t+ is given by Equation (2)where represents the euclidean distance between two points i and j in the KPI’s trajectory. Consequently, the probability that the node is not in alignment is given by Equation (3)where represents the euclidean distance between two points i and j in the KPI’s trajectory. Thus, alignment is a binary property of each node. Furthermore, since the trajectories are known , we can calculate the conditional probability that the nodes within the complex networked SOD are simultaneously in alignment or not, by the simple application of the well known Bayes theorems.In fact, within this time interval , the graph that is described in Equation (1) converts into a decision network formed by a set of nodes and edges, where represents the set of all the nodes being part of the network in , and the edges are determined by the known probabilistic dependence of alignment occurrence in a node , depending on the alignment occurrence on another . The node is thus called parent and node the child. The root nodes are those that do not depend on any other. Subsequently, as described by [50], the joint probability on the nodes can be decomposed into the product of the marginal probabilities that are given by Equation (4):where represents the set of parent nodes associated with . For the root nodes, becomes the marginal distribution . This property shall be used later on for a proper representation of lean complex cyber-physical networks through quantum circuits.

- QubitInformation may be represented in many different ways. Quantum computing uses quantum discrete units of information, the qubit (quantum bit) [51]. Qubits represent elementary units of information exchange in quantum computing, similar to the “bits” of classical computing. A bit is always in two basic states, 0 and 1, while a qubit can be in both bases of these states simultaneously. The characteristic is also known as superposition. Quantum computing normally uses the Dirac notation that represents the two bases of computing of these states and . The superposition of a qubit is merely a linear combination of the two basic states and , expressed by the Equation (5):where and ∈ such that the satisfy the Equation (6):in which and are, respectively, the probabilities of finding the qubit in and after a measurement in the basis.

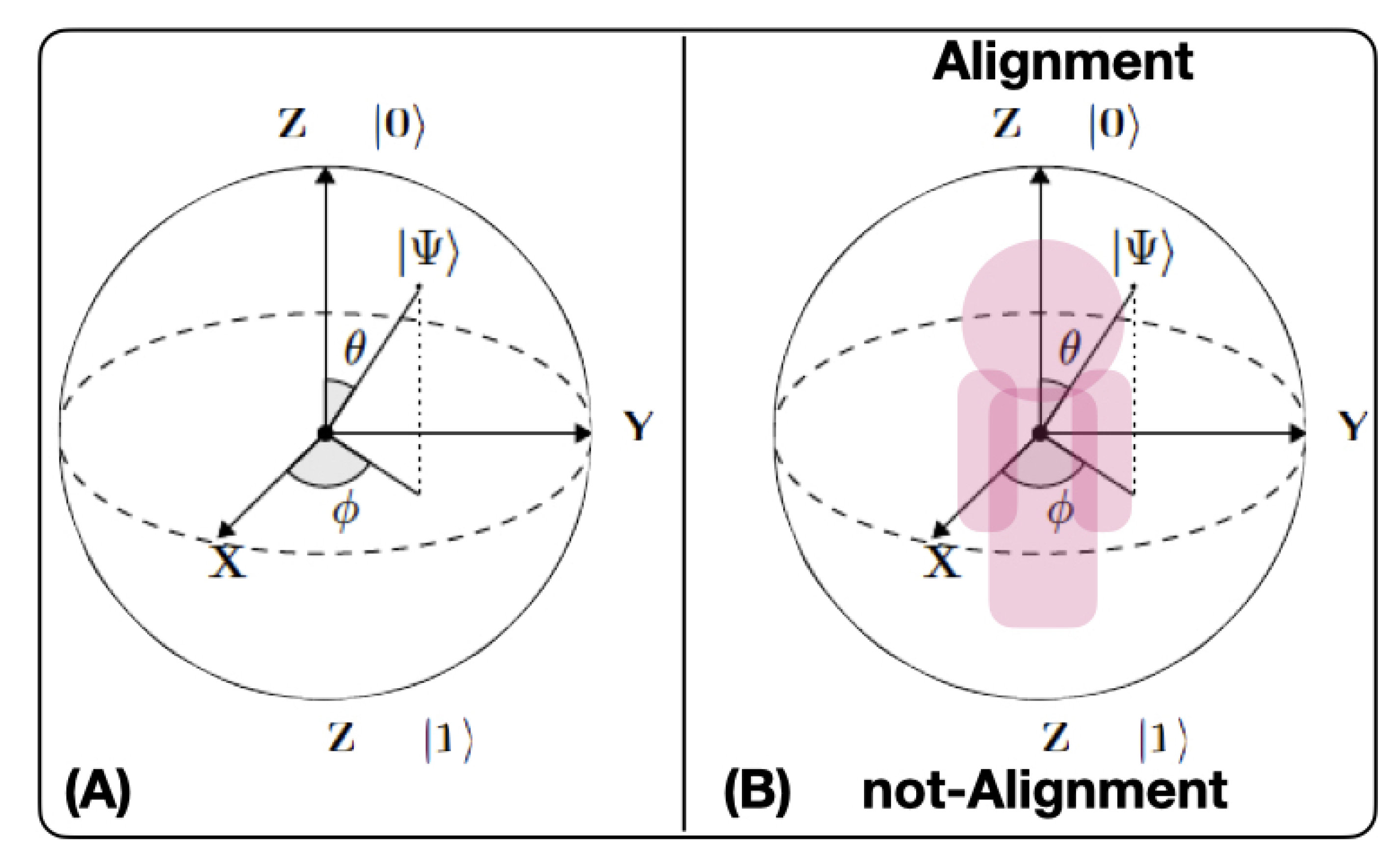

- Bloch’s sphereBloch’s sphere, as shown in Figure 2A, is commonly used to geometrically represent a qubit [52]. This is a useful and common geometric image of the quantum evolution of a single- or two-level system. On the Bloch sphere, of unitary radius, the Z-axis is the computational axis and its positive direction coincides with the state , and the negative with the state . A qubit can be represented as a point on the Bloch sphere with the help of two parameters (, ), as expressed by Equation (7):When several qubits are utilized, their aggregated state can be determined utilizing the tensorial product of the individual qubits. If the multiple qubit state can be expressed as a linear combination of the and states, then the aggregated state can be represented, as in Equation (8):where and . However, if the aggregate state cannot be expressed as the product of the individual states, in other words, if no qubit states and can be found, such that , this state is called entangled state, which is stronger than any other classical correlation [53].The reduced purity of a qubit in an state , as given by Equation (9), is a coefficient that indicates the level of a qubit entanglement in the state [54]. A value of indicates that the qubit is not entangled with the other qubits, and a value of indicates that the qubit is maximally entangled with the other qubits in the state.

- Quantum circuitA quantum circuit is a computational sequence that consists of performing a series of coherent quantum operations on qubits. By organizing the qubits into an orderly sequence of quantum gates, measurements, and resets, all of which can be conditioned and use data from the classical calculation in real-time, quantum computing can be simulated. These sequences typically follow a standardized pattern:

- Initialization and reset. First, we begin our quantum calculation with a specified quantum state for each qubit. This is achieved using the initialization operations, typically on the Z-computation axis, and reset. The resets can be done using a single-qubit gate combination that tracks whether we have succeeded in creating the desired state through measurements. Qubit initialization in a desired state can then continue to apply single-qubit gates.

- Quantum gates. Second, we implement a sequence of quantum gates that manipulate the qubits, as needed by the targeted algorithm following certain quantum circuit design principles.

- Measurement. Third, we measure the qubits. Classical computers translate the measurements of each qubits as classical results (0 and 1) and then store them in either one of the two classical bits. Measurement is understood to be projected into the Z-computational basis unless otherwise stated.

- Quantum gateA quantum gate consists of several mathematical operations applied to the qubits that change the amplitude of their probabilities and, thus, perform the intended computations [54]. The quantum computing basic elements are described in detail:

- –

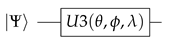

- The gate is a single qubit gate that has three parameters , and which represent a sequence of rotations around the Bloch sphere’s axes such that around the Z axis, around the X axis, around the Z axis, around the X axis, and a around the Z axis. It can be used to obtain any single qubit gate. Equation (10) provides its mathematical representation,and Equation (11) its quantum circuit equivalent:

- –

- The or conditional NOT gate is a two qubit computation gate with one qubit acting as control and the other as target. The gate performs a selective negation of the target qubit. If the control qubit is in superposition, then creates entanglement. Equation (12) provides its mathematical representation,and Equation (13) its quantum circuit equivalent:

- –

- The or Toffoli gate is a three qubit computation gate with two qubits and acting as controls and one qubit acting as target. The gate applies an X to the target qubit only when both controls and qubits are in state . Equation (14) provides its mathematical represetnation:and Equation (15) its quantum circuit equivalent [54]:

- –

- The Z-measurement of a quantum state—a self-adjoint operator on the Hilbert space—results in the measured object being in an eigenstate of the Z operator or computational basis, with the corresponding eigenvalue being the value measured. The measurement, also called observation, of a quantum state, is a stochastic non-reversible operation and, therefore, cannot be considered as a quantum gate, as it allocates a unique value to the variable observed. In mathematical terms, the probability p of a measurement result m occurring when the state is measured is given by Equation (16):where represents a set of operators acting on the state space, such that and the state of the system after the measurement is given by Equation (17):Equation (18) shows its quantum circuit equivalent as a symbolic box:

3. Quantum Strategic Organizational Design

3.1. QSOD Qubit

3.2. QSOD Design Principles

- Calculation of conditional probabilitiesThe conditional probabilities that will give rise to the quantum circuit are derived from a preliminary analysis of the KPIs that are associated with each node of the complex network in question. This analysis, as indicated above, is based on the method based on genetic algorithms presented in [2]. Specifically, for each node, there are typically three related KPIs. The selected chromosome has subsequently 12 real numbers between 0 and 1, and we have used real value crossover and mutation with probabilities of 60% and 7%, respectively. The population was built over 8000 individuals and it ran over 1000 generations. Once the trajectories associated with each node have been calculated, by applying the Bayes theorem, it is trivial to calculate the relative probability of alignment or non-alignment at each node concerning those to which it is connected.

- Initialization and resetThe initialization and reset of the qubits is typically standardized to the state on the computational Z-axis.

- Rotation angle computationThe conditional probabilities translate into qubit rotation angles depending on its decision network dependencies:

- –

- For a root node with no parents, the possible states are two and . A trivial application of Equation (7), states that a qubit intialized to state and rotated by a gate , being , transforms it into . Therefore, taking Equation (5) into account and the definition of the Bloch sphere’s angles, the rotation angle that is required to calculate the probabilities of being in state and can be expressed by Equation (19):

- –

- Controlled rotationsControlled rotations are not elementary quantum gates and they need to be deconstructed into elementary operations. As described by Nielsen and Chuang [54], being m the maximum number of parent nodes a child has, the controlled rotation expressing the conditional probabilities needs of the addition of “dummy” qubits in order to decompose the controlled rotation into gates and one . This is exemplified in Equation (21) for qubits, “dummy” qubits and a total of gates.Additionally, as a direct application of Equation (13), this equation converts into Equation (23):or in its quantum circuit equivalent that is shown in Equation (24):This method works, because, if the control qubit is in state , all we have is followed by a and the effect is trivial. If the control qubit is in state , the net effect is a controlled rotation on the qubit.

- Measurement of the QSOD qubits to obtain the probabilities of alignment states.The measurements are mainly used in the end to extract computational results from the quantum states. This will allow for us to explore the quantum states of the qubits and make an interpretation that allows for improving the management system that is related to the industrial process.

4. Case Study. Qsod Circuit

- Section 4.1. Scope establishment.

- Section 4.2. Specification of population and sampling.

- Section 4.3. QSOD circuit design.

- Section 4.4. Analysis of results.

4.1. Scope Establishment

4.2. Specification of Population and Sampling

4.3. QSOD Circuit Design

- Calculation of conditional probabilities.For each node, there are typically three related KPIs. The selected chromosome has subsequently 12 real numbers between 0 and 1, and we have used real value crossover and mutation with probabilities of 60% and 7%, respectively. The population was built over 8000 individuals and it ran over 1000 generations. Once the trajectories associated with each node have been calculated, it is trivial to calculate the relative probability of alignment or non-alignment at each node concerning those to which it is connected. This process is executed for each node in parallel without the loss of performance.

- Initialization and reset.In Step 0, each one of the nodes is assigned to a qubit, , , , , and a “dummy” node is created. The qubits are initialized and reset to state. This allows for a controlled comparison of the probabilities through qubit rotations.

- Rotation angle computation.

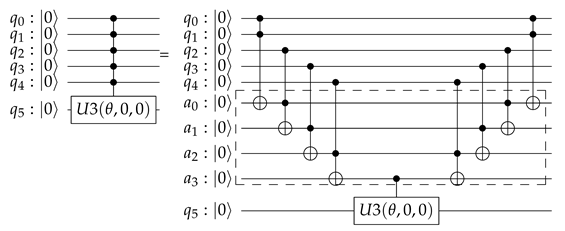

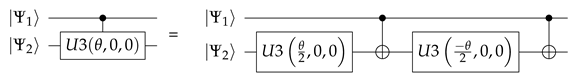

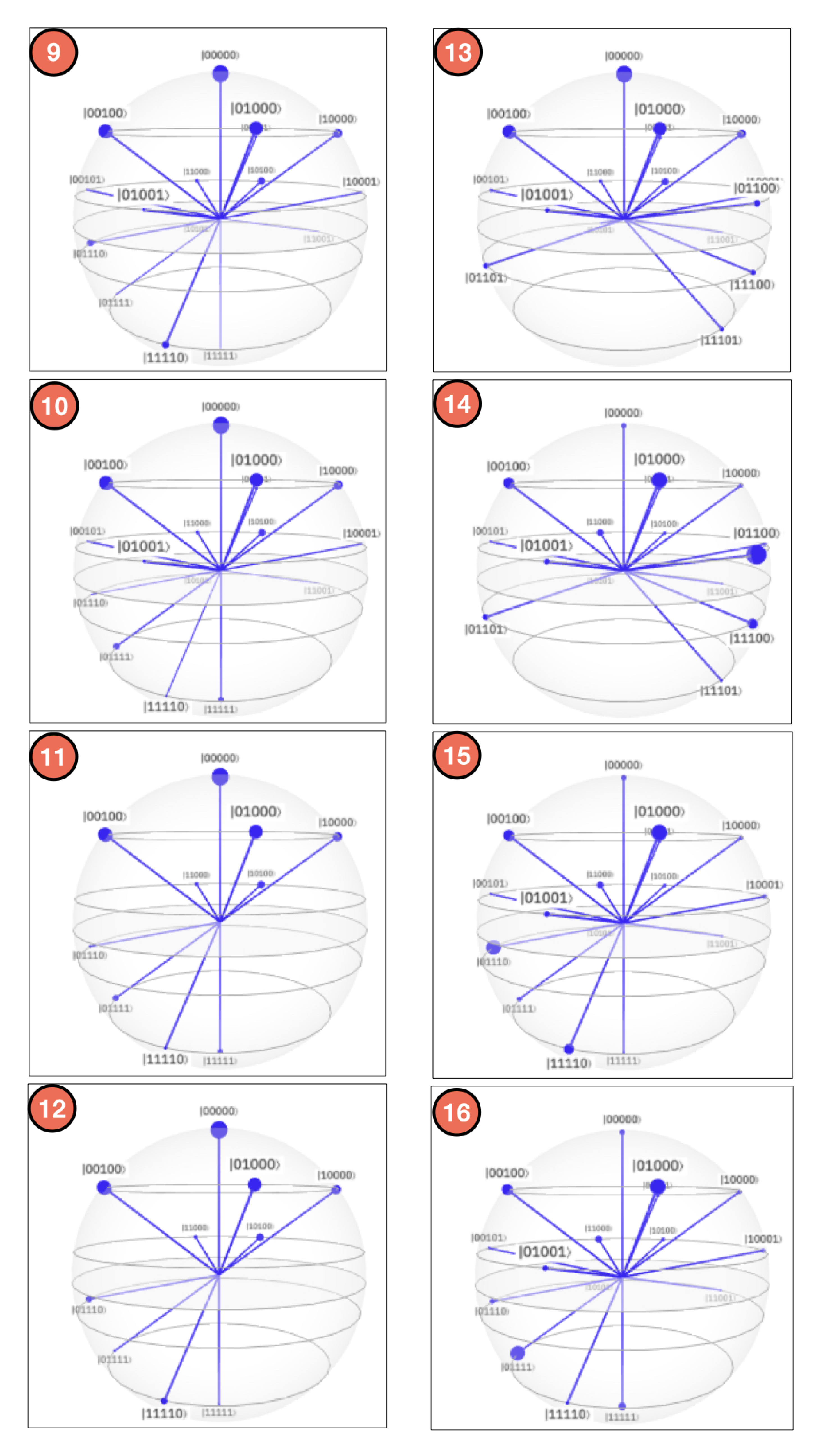

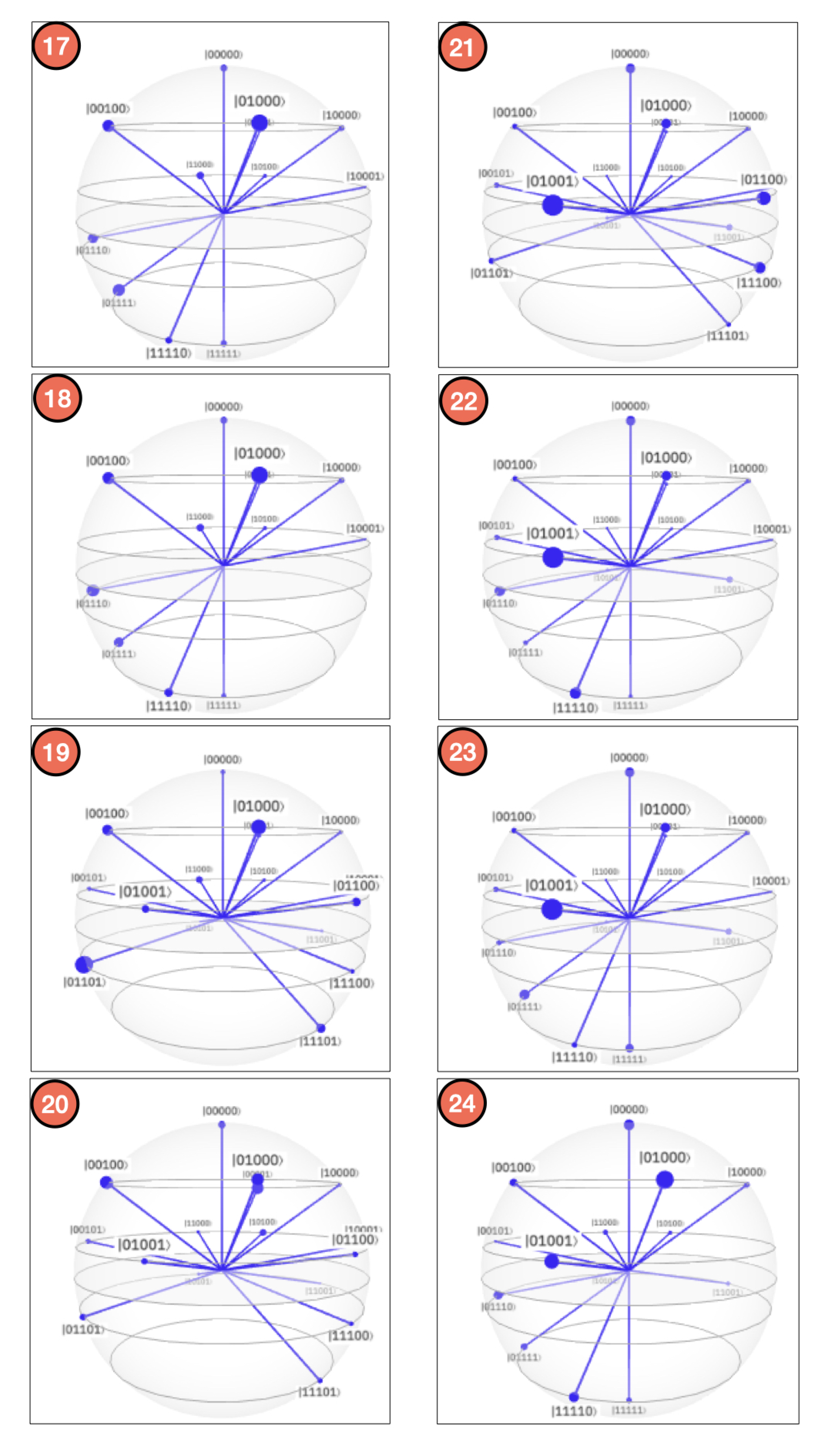

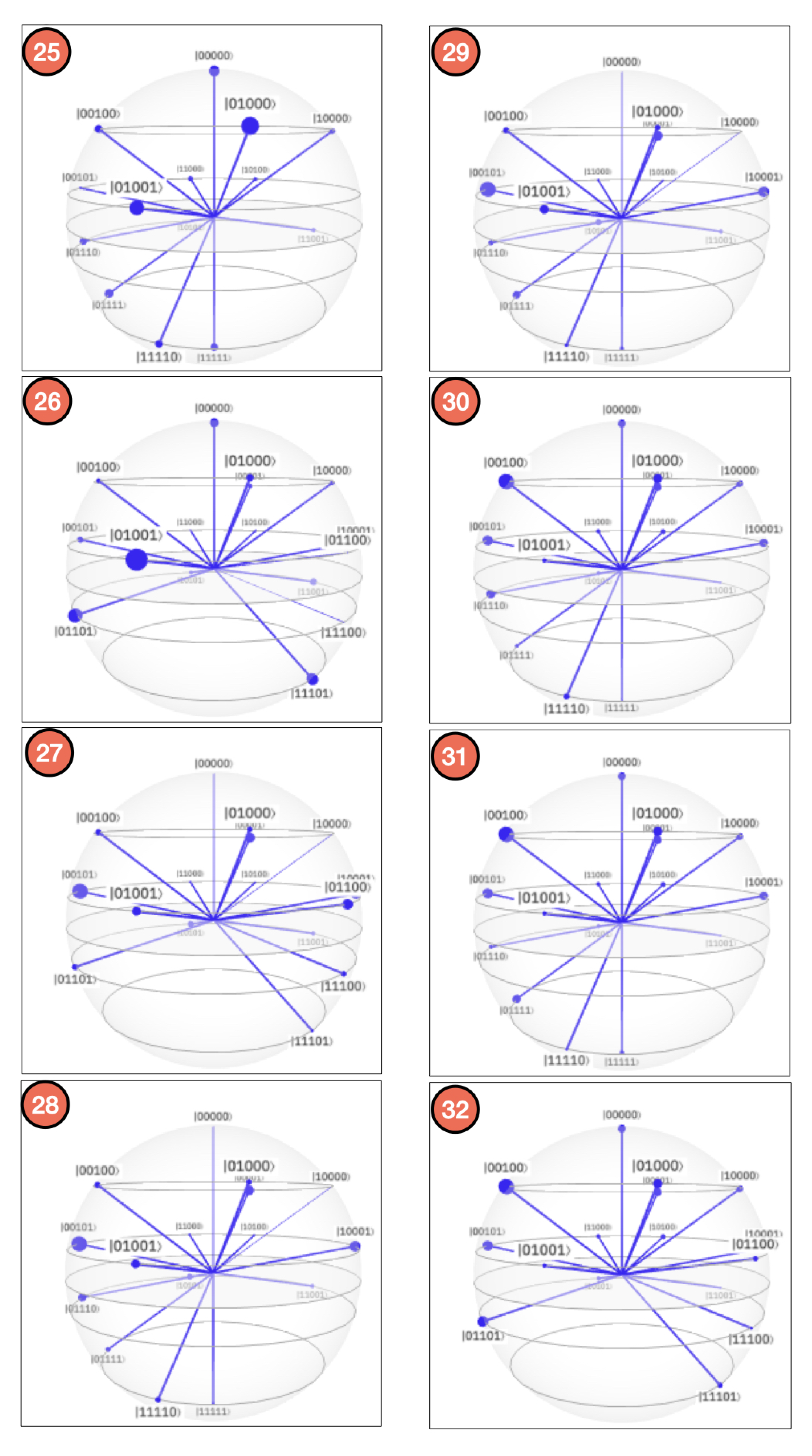

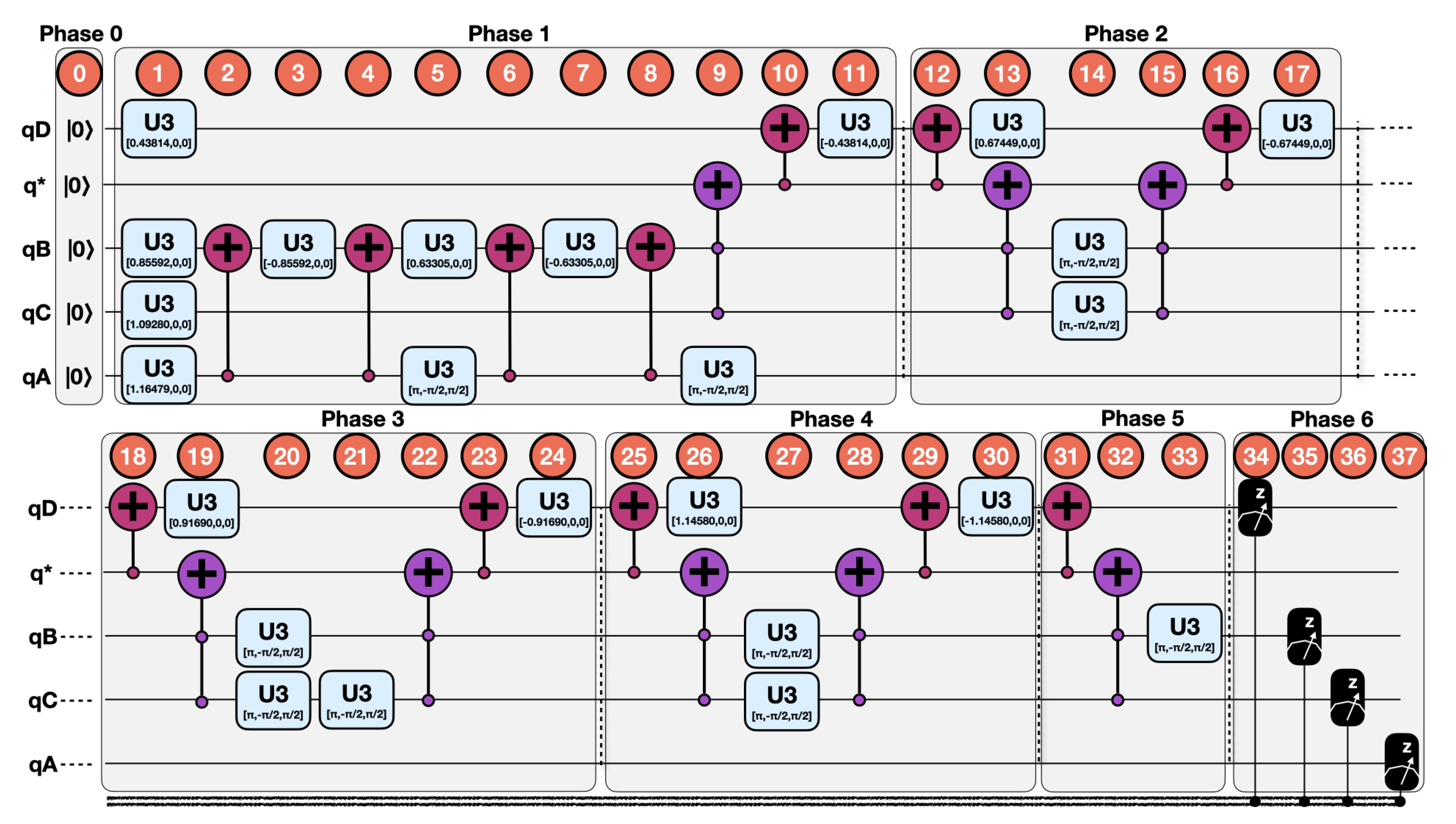

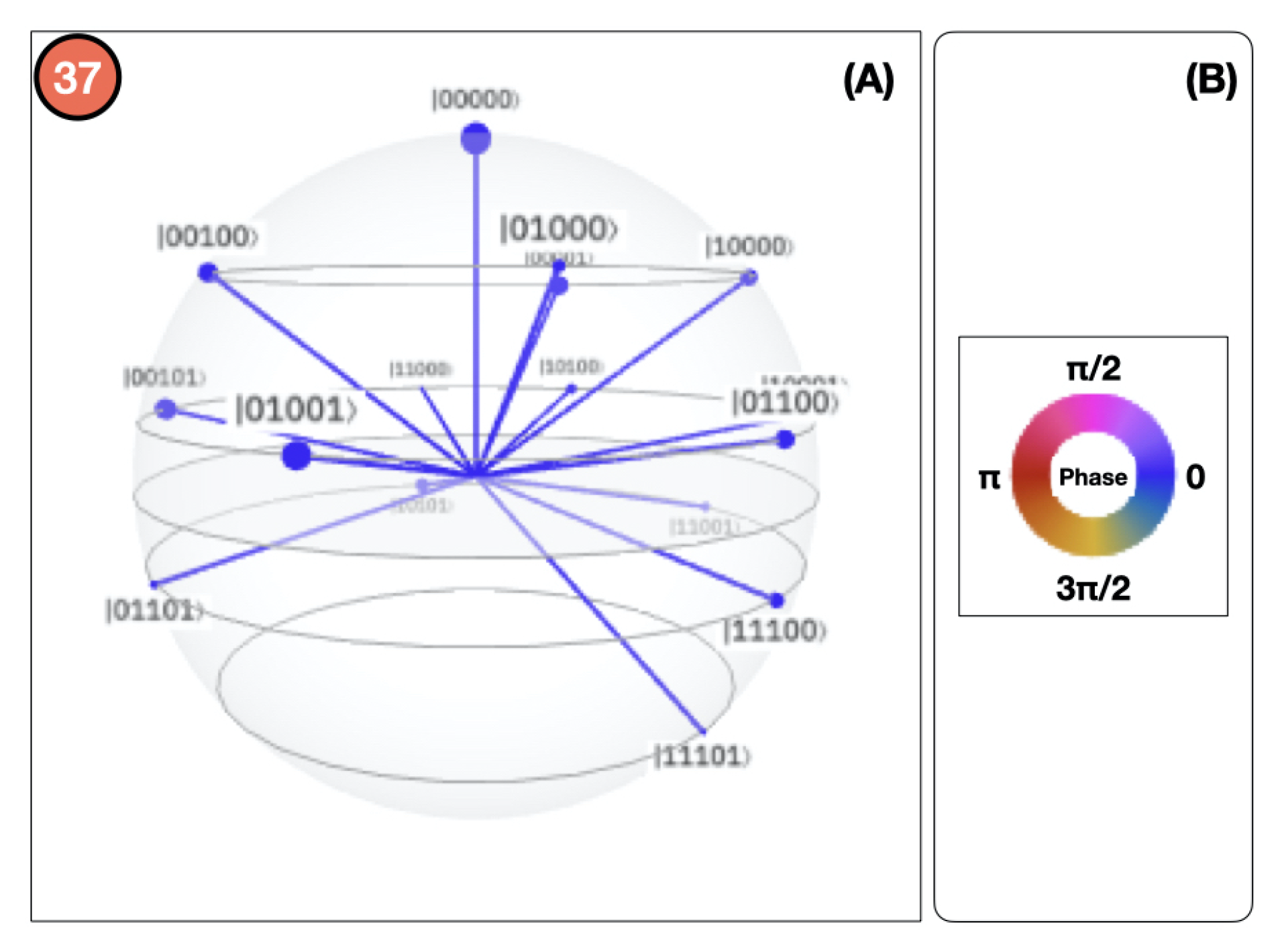

- Controlled rotations.By systematically applying Equation (21) to each qubit, we obtain the QSOD circuit that is shown in Figure 4.Figure 5A visualizes the quantum state of each step of the final state. The Bloch sphere provides a global view of a multi-qubit quantum state in the computational basis. Node size is proportional to state probabilities, and color reflects the phase of each basis state as shown in Figure 5B. The constant color blue that reflects the phase of each basis state does not change throughout the circuit. For the interested reader, in Appendix A, the Bloch sphere states of each step in the circuit are displayed in Figure A1, Figure A2, Figure A3 and Figure A4.The 37 steps that make up the QSOD have been divided into six distinct phases in order to improve the clarity of the explanation. We will now comment on the logic behind each of them:

- –

- Phase 0. Step 0.Phase 0 performs the initialization and reset, as previously explained in Section 4.3.

- –

- Phase 1. Step 1–Step 11.This phase is subdivided in three conceptual parts:First. This phase starts in Step 1 by rotating and by and radians respectively as calculated in Equation (25). This is because both and are root qubits and Equation (19) applies.Second, two controlled rotations on qubit in Steps 1–3 are performed, as calculated in Equation (26). As described in Equation (24), since qubit has a parent qubit, we need to perform two controlled rotations properly aligned by CNOT gates. Depending on the state of qubit : in Step 1 and in Step 3, in the case that is in state , and in Step 5 and in the case that is in state . In this case, a is performed, so as to generate proper alignment.Third, on qubit , we need to perform a total of four controlled rotations throughout the circuit. This is because each of its parent qubits and can have two states, and we need to represent the rotations corresponding to the states , , , and . A controlled rotation is performed on qubit conditioned by the state of its parent qubits and , as calculated in Equation (26). This is done with a controlled rotation in Step 1 and a controlled rotation in Step 11, properly aligned through CNOT and ccX gates, as described in Equation (21) in Steps 9–10 and Steps 31–33.

- –

- Phase 2. Step 12–Step 17.In phase 2, we perform the second controlled rotation on qubit as related to the states of qubit and . A controlled rotation is performed on qubit conditioned by the state of its parent qubits and , as calculated in Equation (26). This is done with a controlled rotation in Step 13 and a controlled rotation in Step 17, properly aligned through CNOT and ccX gates, as described in Equation (21) in Steps 12 and Steps 14–16.

- –

- Phase 3. Step 18–Step 24.In phase 3, we perform the second controlled rotation on qubit as related to the states of qubit and . A controlled rotation is performed on qubit conditioned by the state of its parent qubits and , as calculated in Equation (26). This is done with a controlled rotation in Step 19 and a controlled rotation in Step 24, properly aligned through CNOT and ccX gates, as described in Equation (21) in Steps 18 and Steps 20–23.

- –

- Phase 4. Step 25–Step 30.In phase 4, we perform the second controlled rotation on qubit as related to the states of qubit and . A controlled rotation is performed on qubit conditioned by the state of its parent qubits and , as calculated in Equation (26). This is done with a controlled rotation in Step 26 and a controlled rotation in Step 30, properly aligned through CNOT and ccX gates, as described in Equation (21) in Steps 25 and Steps 27–29.

- –

- Phase 5. Step 31–Step 33.As mentioned earlier, in phase 5 the controlled rotation of qubit as related to the states of qubit and started in Phase 1, qubits 1 and 9–11, is completed.

- –

- Phase 5. Step 34–Step 37.Finally, in phase 6 each one of the qubits is measured, as expressed by Equation (17).

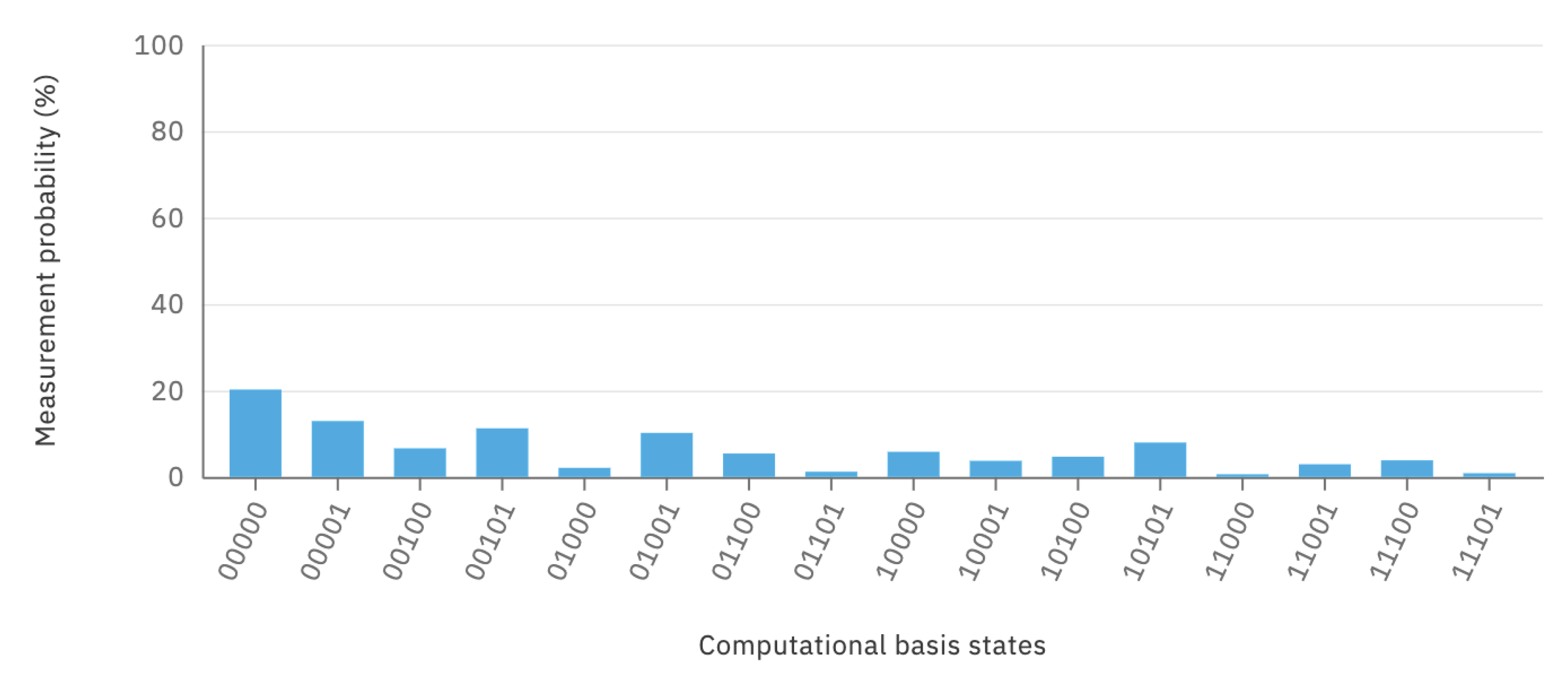

4.4. Analysis of Results

5. Conclusions, Further Research and Limitations

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| QSOD | Quantum Strategic Organizational Design |

| KPI | Key Performance Indicator |

| DLT | Distributed Ledger Technology |

Appendix A

References

- Grant, R.M. Organization Structure and Management Systems: The Fundamentals of Strategy Implementation. In Contemporary Strategy Analysis, 7th ed.; John Wiley & Sons: West Sussex, UK, 2010; pp. 174–206. [Google Scholar]

- Villalba-Diez, J.; Ordieres-Mere, J.; Chudzick, H.; Lopez-Rojo, P. NEMAWASHI: Attaining Value Stream alignment within Complex Organizational Networks; Procedia CIRP; Elsevier: Cranfield, UK, 2015; Volume 37, pp. 134–139. [Google Scholar] [CrossRef] [Green Version]

- Tennant, C.; Roberts, P. Hoshin Kanri: Implementing the Catchball Process. Long Range Plan. 2001, 34, 287–308. [Google Scholar] [CrossRef]

- Cattani, G.; Ferriani, S.; Negro, G.; Perretti, F. The Structure of Consensus: Network Ties, Legitimation, and Exit Rates of U.S. Feature Film Producer Organizations. Adm. Sci. Q. 2008, 53, 145–182. [Google Scholar] [CrossRef] [Green Version]

- Cross, R.L.; Singer, J.; Colella, S.; Thomas, R.J.; Silverstone, Y. (Eds.) The Organizational Network Fieldbook: Best Practices, Techniques and Exercises to Drive Organizational Innovation and Performance, 1st ed.; Jossey-Bass: San Francisco, CA, USA, 2010. [Google Scholar]

- Burton, R.M.; Øbel, B.; Håkonsson, D.D. Organizational Design: A Step-by-Step Approach, 3rd ed.; Cambridge University Press: Cambridge, UK, 2015. [Google Scholar]

- Barabási, A.-L. Network Science; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar]

- Villalba-Diez, J.; Molina, M.; Ordieres-Mere, J.; Sun, S.; Schmidt, D.; Wellbrock, W. Geometric Deep Lean Learning: Deep Learning in Industry 4.0 Cyber–Physical Complex Networks. Sensors 2020, 20, 763. [Google Scholar] [CrossRef] [Green Version]

- Villalba-Diez, J.; Ordieres-Mere, J. Improving manufacturing operational performance by standardizing process management. Trans. Eng. Manag. 2015, 62, 351–360. [Google Scholar] [CrossRef]

- Villalba-Diez, J. The HOSHIN KANRI FOREST. Lean Strategic Organizational Design, 1st ed.; CRC Press, Taylor and Francis Group LLC: Boca Raton, FL, USA, 2017. [Google Scholar]

- Villalba-Diez, J. The Lean Brain Theory. Complex Networked Lean Strategic Organizational Design; CRC Press, Taylor and Francis Group LLC: Boca Raton, FL, USA, 2017. [Google Scholar]

- Powell, T.C. Organizational alignment as competitive advantage. Strateg. Manag. J. 1992, 13, 119–134. [Google Scholar] [CrossRef]

- Sender, S.W. Systematic agreement: A theory of organizational alignment. Hum. Resour. Dev. Q. 1997, 8, 23–40. [Google Scholar] [CrossRef]

- Ravi, K.; Joshi, P.M.; Porth, J.S. Organizational alignment and performance: Past, present and future. Manag. Decis. 2007, 45, 503–517. [Google Scholar]

- Bryan, A.; Arnold, M.; Lisa, E.; Barratt, A.M. Organizational alignment and supply chain governance structure: Introduction and construct validation. Int. J. Logist. Manag. 2009, 20, 169–186. [Google Scholar]

- Quirós, I. Organizational alignment: A model to explain the relationships between organizational relevant variables. Int. J. Organ. Anal. 2009, 17, 285–305. [Google Scholar] [CrossRef]

- Münch, J.; Fagerholm, F.; Kettunen, P.; Pagels, M.; Partanen, J. The Effects of GQM+Strategies on Organizational Alignment. arXiv 2013, arXiv:1311.6221. [Google Scholar]

- Sousa, H.P.; do Prado Leite, J.C.S. Modeling Organizational Alignment. In Conceptual Modeling; Yu, E., Dobbie, G., Jarke, M., Purao, S., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 407–414. [Google Scholar]

- Carrillo, F.J.; Edvardsson, B.; Reynoso, J.; Maravillo, E. Alignment of resources, actors and contexts for value creation: Bringing knowledge management into service-dominant logic. Int. J. Qual. Serv. Sci. 2019, 11, 424–438. [Google Scholar] [CrossRef]

- Yung-Chang, H.; Ming-Ho, W. How organizational structure and strategic alignment influence new product success. Manag. Decis. 2020, 58, 182–200. [Google Scholar] [CrossRef]

- Piattini, M.; Peterssen, G.; Pérez-Castillo, R. Quantum Computing: A New Software Engineering Golden Age. SIGSOFT Softw. Eng. Notes 2020, 45, 12–14. [Google Scholar] [CrossRef]

- Gyongyosi, L.; Imre, S. A Survey on quantum computing technology. Comput. Sci. Rev. 2019, 31, 51–71. [Google Scholar] [CrossRef]

- Shor, P.W. Algorithms for quantum computation: Discrete logarithms and factoring. In Proceedings of the 35th Annual Symposium on Foundations of Computer Science, Santa Fe, NM, USA, 20–22 November 1994; pp. 124–134. [Google Scholar] [CrossRef]

- Grover, L.K. A fast quantum mechanical algorithm for database search. In Proceedings of the STOC ’96, Philadelphia, PA, USA, 22–24 May 1996. [Google Scholar]

- Nielsen, T.D.; Jensen, F.V. Bayesian Networks and Decision Graphs, 2nd ed.; Springer: New York, NY, USA, 2009. [Google Scholar]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar] [CrossRef] [Green Version]

- Huh, J.H.; Seo, K. An Indoor Location-Based Control System Using Bluetooth Beacons for IoT Systems. Sensors 2017, 17, 2917. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, H.G.; Huh, J.H. A Cost-Effective Redundant Digital Excitation Control System and Test Bed Experiment for Safe Power Supply for Process Industry 4.0. Processes 2018, 6, 85. [Google Scholar] [CrossRef] [Green Version]

- Park, S.; Huh, J.H. Effect of Cooperation on Manufacturing IT Project Development and Test Bed for Successful Industry 4.0 Project: Safety Management for Security. Processes 2018, 6, 88. [Google Scholar] [CrossRef] [Green Version]

- Powell, D.; Romero, D.; Gaiardelli, P.; Cimini, C.; Cavalieri, S. Towards Digital Lean Cyber-Physical Production Systems: Industry 4.0 Technologies as Enablers of Leaner Production. In Advances in Production Management Systems. Smart Manufacturing for Industry 4.0; Moon, I., Lee, G.M., Park, J., Kiritsis, D., von Cieminski, G., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 353–362. [Google Scholar]

- Sun, S.; Zheng, X.; Villalba-Diez, J.; Ordieres-Mere, J. Indoor Air-Quality Data-Monitoring System: Long-Term Monitoring Benefits. Sensors 2019, 19, 4157. [Google Scholar] [CrossRef] [Green Version]

- Ordieres-Mere, J.; Villalba-Diez, J.; Zheng, X. Challenges and Opportunities for Publishing IIoT Data in Manufacturing as a Service Business. Procedia Manuf. 2019, 39, 185–193. [Google Scholar] [CrossRef]

- Mosterman, P.J.; Zander, J. Industry 4.0 as a Cyber-Physical System study. Softw. Syst. Model. 2016, 15, 17–29. [Google Scholar] [CrossRef]

- Jiang, P.; Ding, K.; Leng, J. Towards a cyber-physical-social-connected and service-oriented manufacturing paradigm: Social Manufacturing. Manuf. Lett. 2016, 7, 15–21. [Google Scholar] [CrossRef]

- Sun, S.; Zheng, X.; Villalba-Díez, J.; Ordieres-Meré, J. Data Handling in Industry 4.0: Interoperability Based on Distributed Ledger Technology. Sensors 2020, 20, 3046. [Google Scholar] [CrossRef] [PubMed]

- Shah, R.; Ward, P. Lean Manufacturing: Context, practice bundles and performance. J. Oper. Manag. 2003, 21, 129–149. [Google Scholar] [CrossRef]

- Villalba-Diez, J.; Ordieres-Meré, J.; Nuber, G. The HOSHIN KANRI TREE. Cross-Plant Lean Shopfloor Management. Procedia CIRP 2015, 32, 150–155. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; Wang, Q.; Zhao, Z. SLAE–CPS: Smart Lean Automation Engine Enabled by Cyber-Physical Systems Technologies. Sensors 2017, 17, 1500. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Villalba-Diez, J.; Ordieres-Mere, J. Strategic Lean Organizational Design: Towards Lean World-Small World Configurations through Discrete Dynamic Organizational Motifs. Math. Probl. Eng. 2016, 2016, 1–10. [Google Scholar] [CrossRef]

- Villalba-Diez, J.; Ordieres-Mere, J.; Rubio-Valdehita, S. Lean Learning Patterns. (CPD)nA vs. KATA. Procedia CIRP 2016, 54, 147–151. [Google Scholar] [CrossRef] [Green Version]

- Jimenez, P.; Villalba-Diez, J.; Ordieres-Meré, J. HOSHIN KANRI Visualization with Neo4j. Empowering Leaders to Operationalize Lean Structural Networks. In PROCEDIA CIRP; Elsevier: Athens, Greece, 2016; Volume 55, pp. 284–289. [Google Scholar] [CrossRef] [Green Version]

- Villalba-Diez, J.; DeSanctis, I.; Ordieres-Meré, J.; Ciarapica, F. Lean Structural Network Resilience. In Complex Networks & Its Applications VI: Proceedings of Complex Networks 2017 (The Sixth International Conference on Complex Networks and Their Applications); Cherifi, C., Cherifi, H., Karsai, M., Musolesi, M., Eds.; Studies in Computational Intelligence; Springer International Publishing: Lyon, France, 2017; pp. 609–619. [Google Scholar]

- Romero, D.; Gaiardelli, P.; Powell, D.; Wuest, T.; Thürer, M. Digital Lean Cyber-Physical Production Systems: The Emergence of Digital Lean Manufacturing and the Significance of Digital Waste. In Advances in Production Management Systems. Production Management for Data-Driven, Intelligent, Collaborative, and Sustainable Manufacturing; Moon, I., Lee, G.M., Park, J., Kiritsis, D., von Cieminski, G., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 11–20. [Google Scholar]

- Villalba-Diez, J.; Schmidt, D.; Gevers, R.; Ordieres-Meré, J.; Buchwitz, M.; Wellbrock, W. Deep learning for industrial computer vision quality control in the printing industry 4.0. Sensors 2019, 19, 3987. [Google Scholar] [CrossRef] [Green Version]

- Villalba-Diez, J.; Zheng, X.; Schmidt, D.; Molina, M. Characterization of Industry 4.0 Lean Management Problem-Solving Behavioral Patterns Using EEG Sensors and Deep Learning. Sensors 2019, 19, 2841. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schmidt, D.; Villalba Diez, J.; Ordieres-Meré, J.; Gevers, R.; Schwiep, J.; Molina, M. Industry 4.0 Lean Shopfloor Management Characterization Using EEG Sensors and Deep Learning. Sensors 2020, 20, 2860. [Google Scholar] [CrossRef]

- Villalba-Diez, J.; Ordieres-Mere, J.; Molina, M.; Rossner, M.; Lay, M. Lean dendrochronology: Complexity reduction by representation of kpi dynamics looking at strategic organizational design. Manag. Prod. Eng. Rev. 2018, 9, 3–9. [Google Scholar] [CrossRef]

- Jabeur, N.; Sahli, N.; Zeadally, S. Enabling Cyber Physical Systems with Wireless Sensor Networking Technologies, Multiagent System Paradigm, and Natural Ecosystems. Mob. Inf. Syst. 2015, 2015, 15. [Google Scholar] [CrossRef] [Green Version]

- Linnea, C. Stable Coexistence of Three Species in Competition. Ph.D. Thesis, LinköPing Universitet, Linköping, Sweden, 2009. [Google Scholar]

- Bossomaier, T.; Barnett, L.; Harré, M.; Lizier, J.T. Statistical Preliminaries. In An Introduction to Transfer Entropy: Information Flow in Complex Systems; Springer International Publishing: Cham, Switzerland, 2016; pp. 11–32. [Google Scholar]

- Jaeger, G. (Ed.) Quantum Information: An Overview; Springer: New York, NY, USA, 2007; pp. 81–89. [Google Scholar]

- Mosseri, R.; Dandoloff, R. Geometry of entangled states, Bloch spheres and Hopf fibrations. J. Phys. A Math. Gen. 2001, 34, 10243–10252. [Google Scholar] [CrossRef] [Green Version]

- Doherty, A.C.; Parrilo, P.A.; Spedalieri, F.M. Distinguishing separable and entangled states. Phys. Rev. Lett. 2002, 88, 187904. [Google Scholar] [CrossRef] [Green Version]

- Nielsen, M.A.; Chuang, I. Quantum Computation and Quantum Information; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Barenco, A.; Bennett, C.H.; Cleve, R.; DiVincenzo, D.P.; Margolus, N.; Shor, P.; Sleator, T.; Smolin, J.A.; Weinfurter, H. Elementary gates for quantum computation. Phys. Rev. A 1995, 52, 3457–3467. [Google Scholar] [CrossRef] [Green Version]

- Eisenhardt, K. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- van Rossum, G. Python Tutorial, Technical Report CS-R9526; Centrum voor Wiskunde en Informatica (CWI): Amsterdam, The Netherlands, 1995. [Google Scholar]

- Wille, R.; Meter, R.V.; Naveh, Y. IBM’s Qiskit Tool Chain: Working with and Developing for Real Quantum Computers. In Proceedings of the 2019 Design, Automation Test in Europe Conference Exhibition (DATE), Grenoble, France, 9–13 May 2019; pp. 1234–1240. [Google Scholar] [CrossRef]

| Qubits | Probability of Alignment | Reduced Purity |

|---|---|---|

| 49.135% | 0.9178 | |

| 58.335% | 0.9026 | |

| 73.000% | 0.9178 | |

| 69.745% | 0.9794 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villalba-Diez, J.; Zheng, X. Quantum Strategic Organizational Design: Alignment in Industry 4.0 Complex-Networked Cyber-Physical Lean Management Systems. Sensors 2020, 20, 5856. https://doi.org/10.3390/s20205856

Villalba-Diez J, Zheng X. Quantum Strategic Organizational Design: Alignment in Industry 4.0 Complex-Networked Cyber-Physical Lean Management Systems. Sensors. 2020; 20(20):5856. https://doi.org/10.3390/s20205856

Chicago/Turabian StyleVillalba-Diez, Javier, and Xiaochen Zheng. 2020. "Quantum Strategic Organizational Design: Alignment in Industry 4.0 Complex-Networked Cyber-Physical Lean Management Systems" Sensors 20, no. 20: 5856. https://doi.org/10.3390/s20205856

APA StyleVillalba-Diez, J., & Zheng, X. (2020). Quantum Strategic Organizational Design: Alignment in Industry 4.0 Complex-Networked Cyber-Physical Lean Management Systems. Sensors, 20(20), 5856. https://doi.org/10.3390/s20205856