A Fuzzy Analytic Hierarchy Process and Cooperative Game Theory Combined Multiple Mobile Robot Navigation Algorithm

Abstract

1. Introduction

2. Problem Description

3. Fuzzy-Based Analytic Hierarchy Process

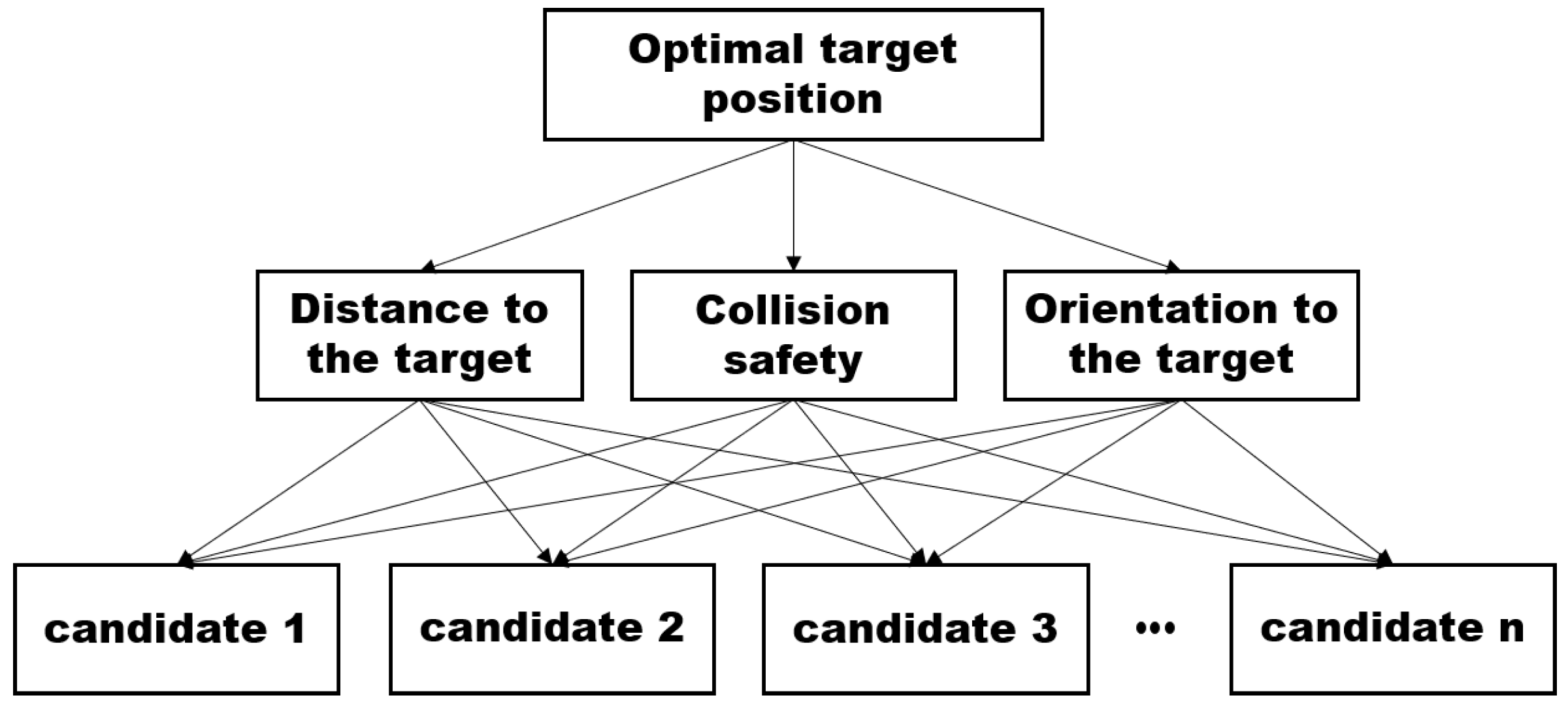

- Step 1: Model the problem as a hierarchy: the decision goal, the alternatives as solution candidates, and the objectives to evaluate the candidates.

- Step 2: Establish priorities among the considered objectives: define the relative importance of the objectives by comparing them in pairs using a nine-point scale.

- Step 3: Synthesize the user’s priorities to yield a set of overall priorities for the hierarchy.

- Step 4: Check the consistency of the decision making.

- Step 5: Evaluate the candidates considering the weighted importance matrix.

- Step 1: Definition of the relative importance among objectives.where represents the n-th objectives. RM is defined based on the notion that the first objective is a times as important as the second objective while b times as important as the third objective. Furthermore, the second objective is c times as important as the third. The general form of the RM is

- Step 2: Consistency check of the relative important matrix.

- Step 3: Fuzzification of the relative importance matrix.

- Step 4: Calculation of fuzzy synthetic extent.

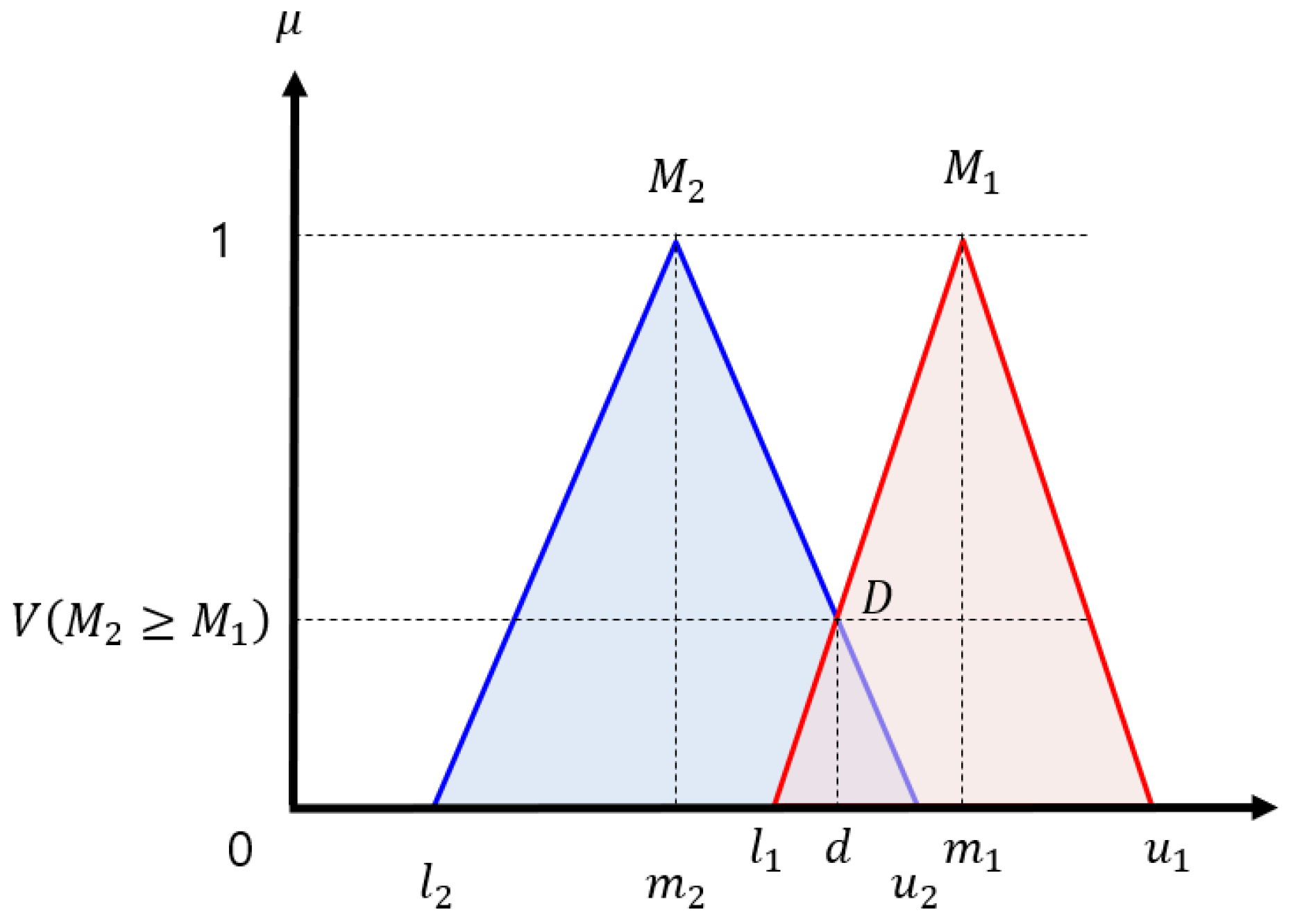

- Step 5: Calculation of weight vectors of FRM.

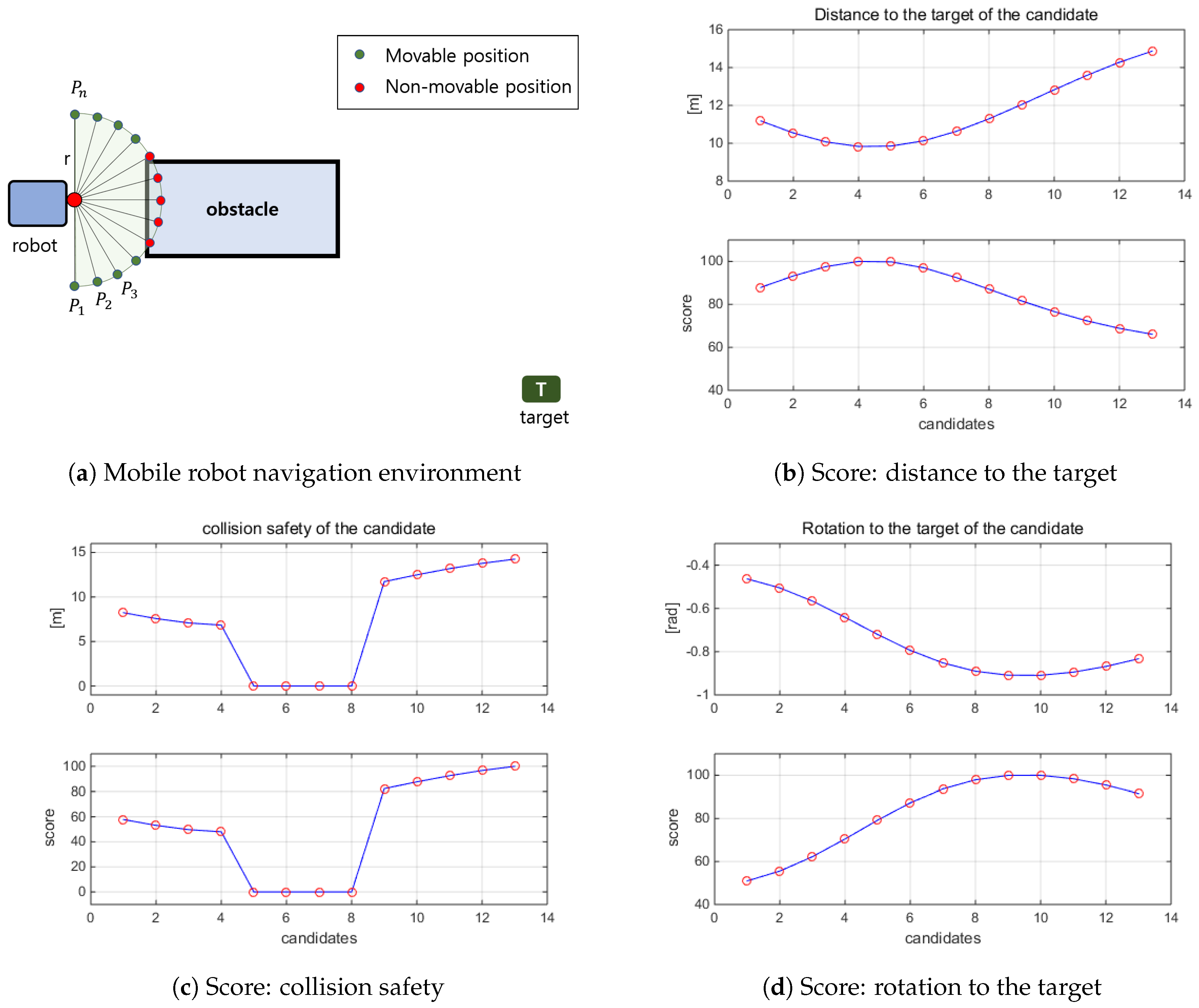

4. Application of FAHP to Multi-Robot Collision-Free Navigation

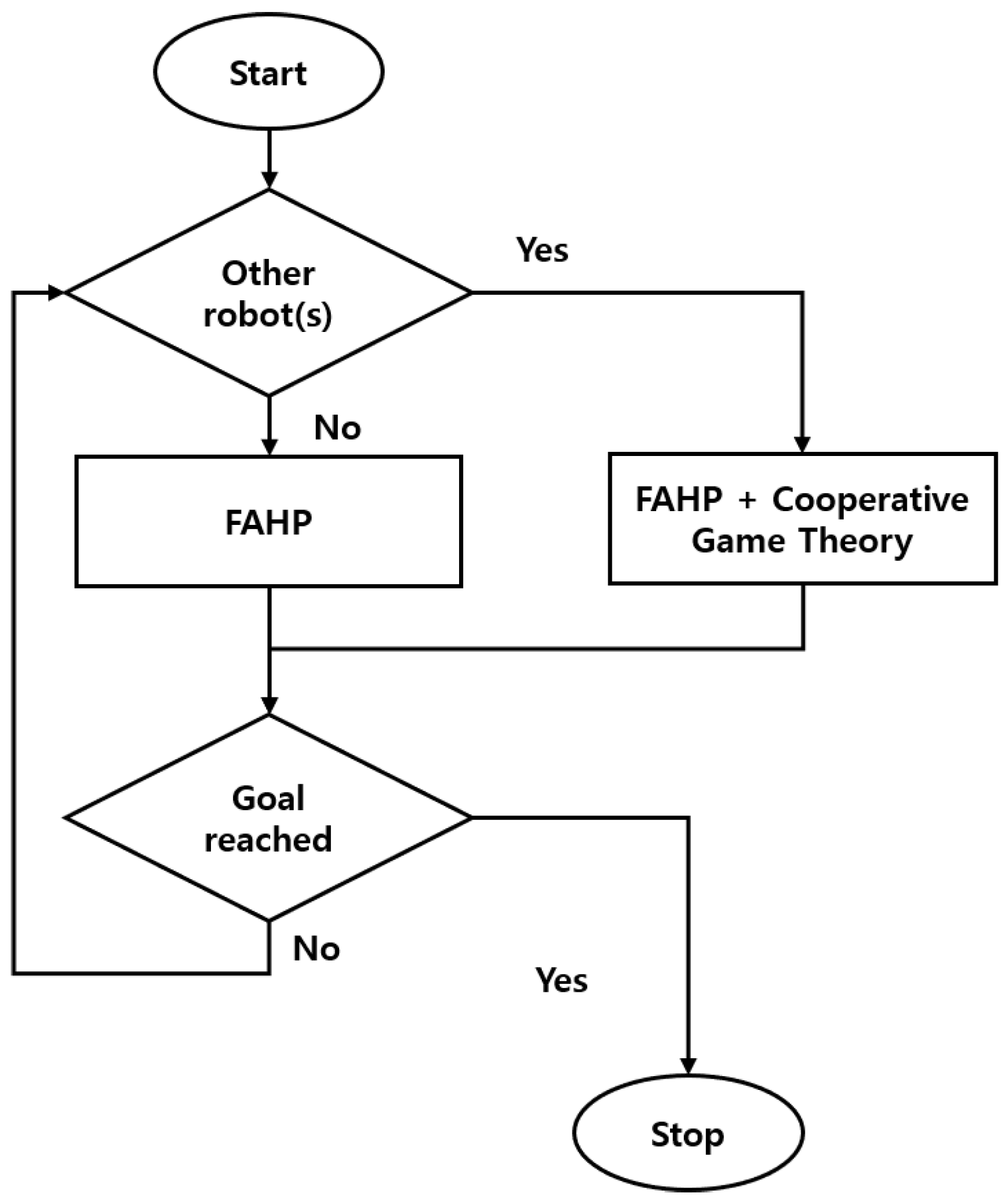

4.1. FAHP Algorithm-Based Mobile Robot Navigation

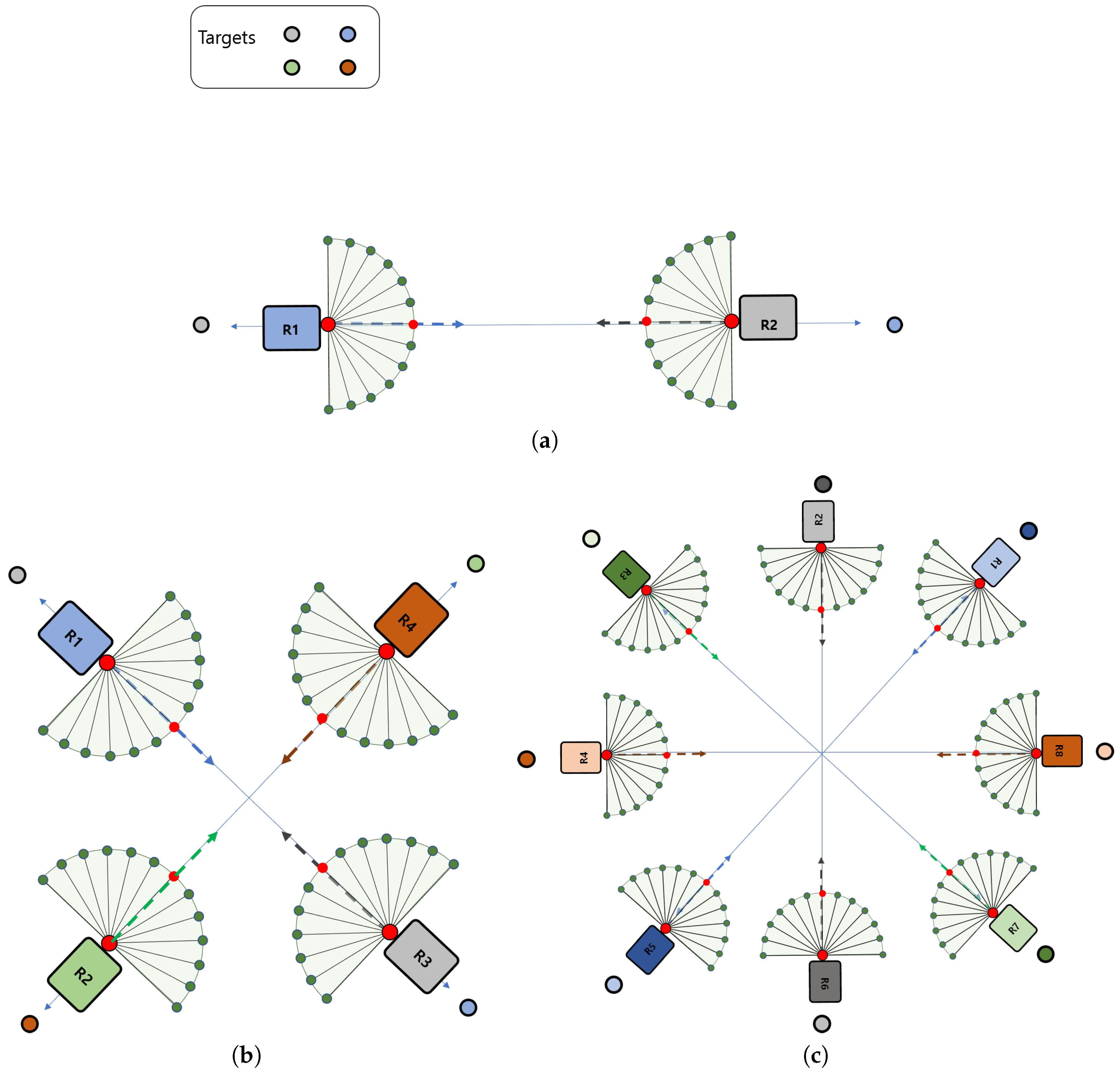

4.2. FAHP and Cooperative Game Theory Combined Algorithm-Based Mobile Robot Navigation

5. Simulation and Results

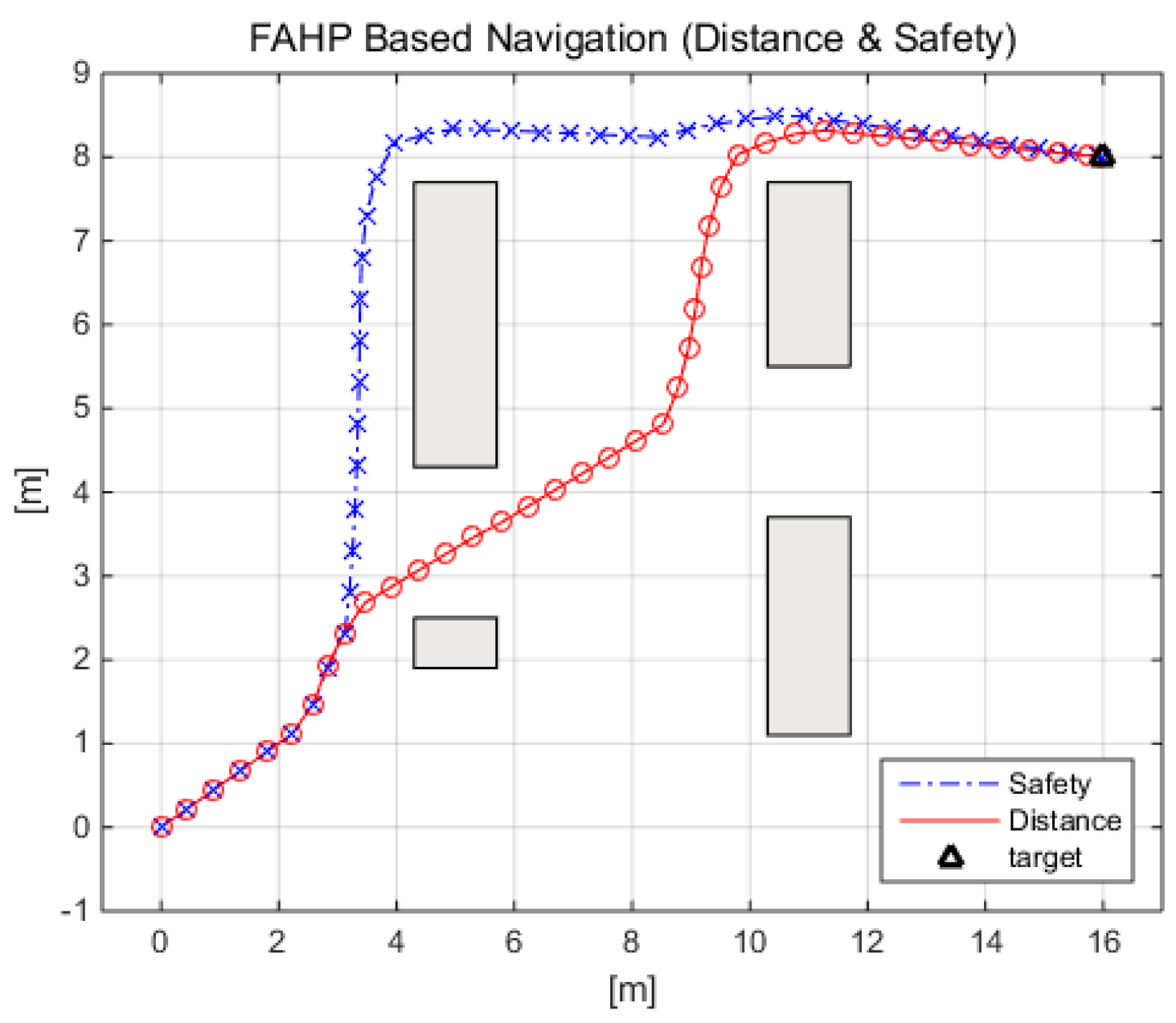

5.1. Simulation I (FAHP-Based Single Mobile Robot Navigation)

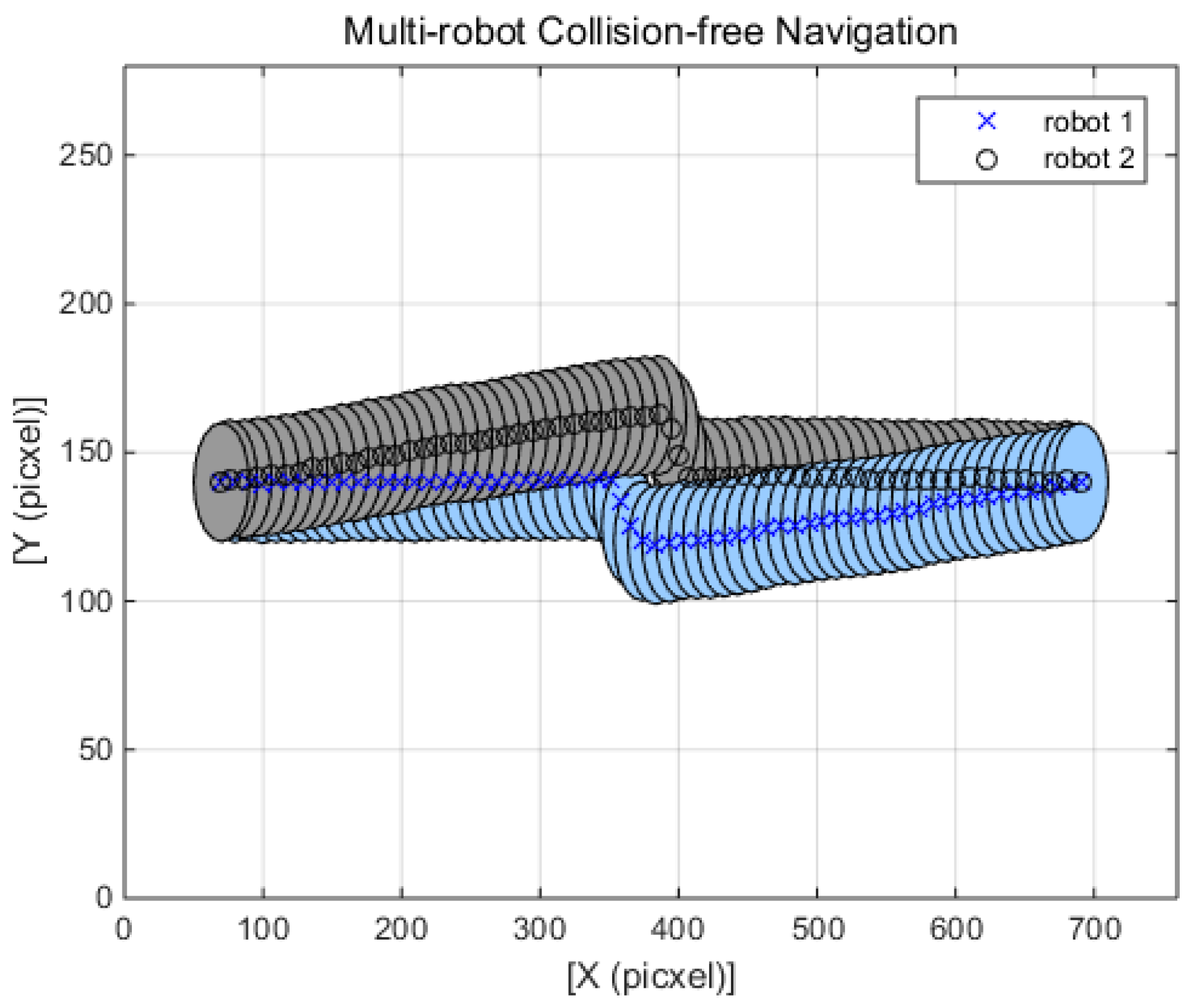

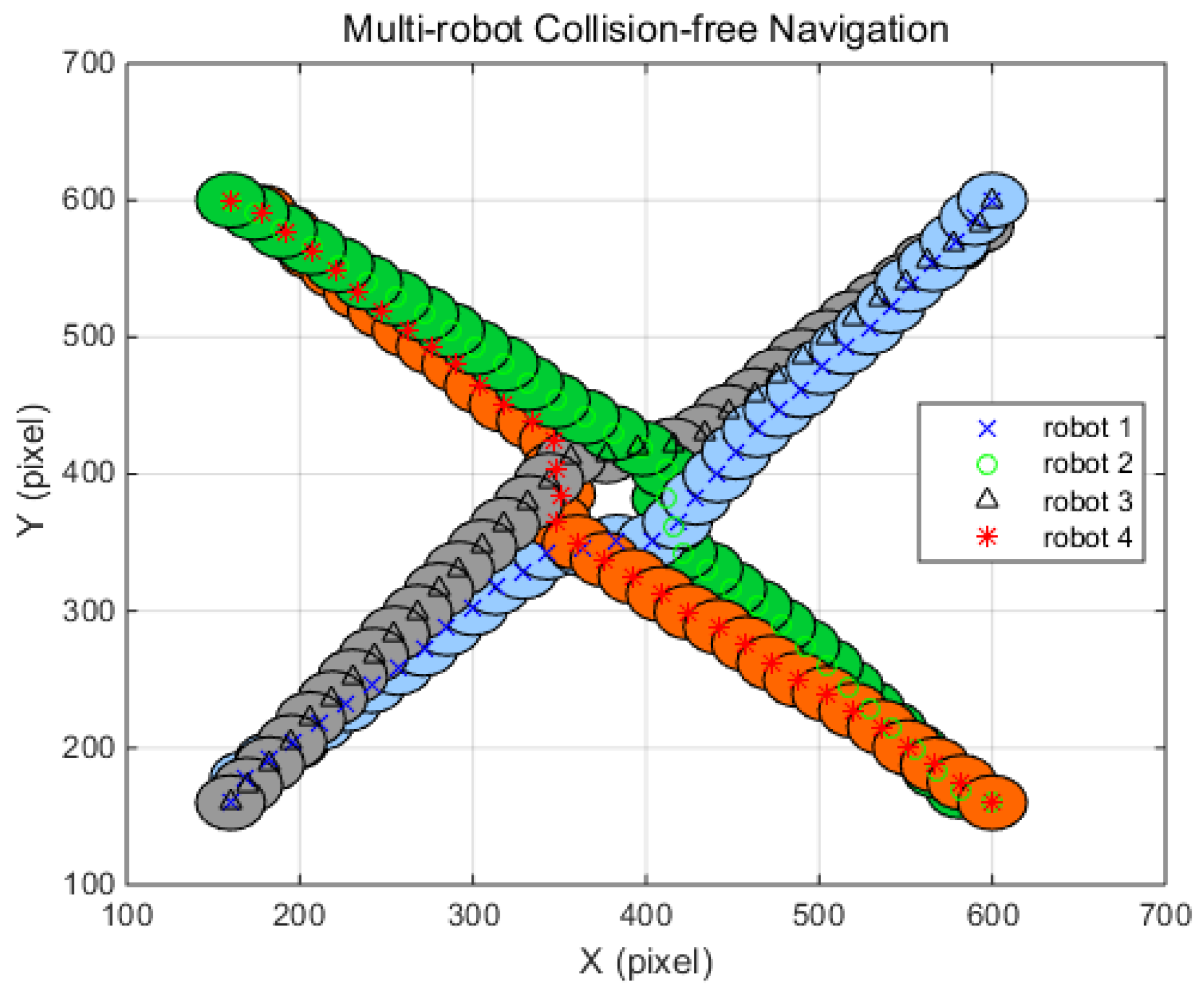

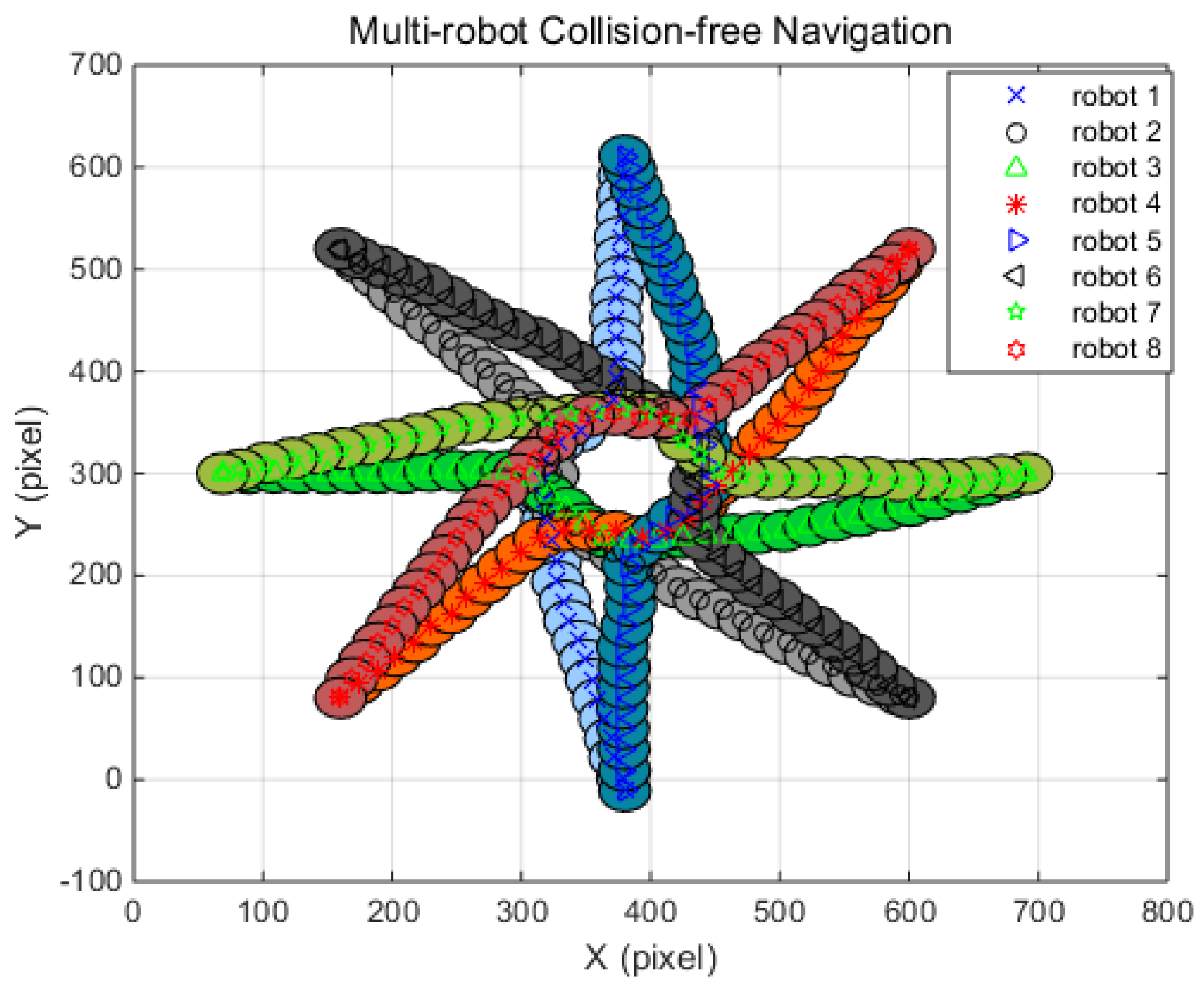

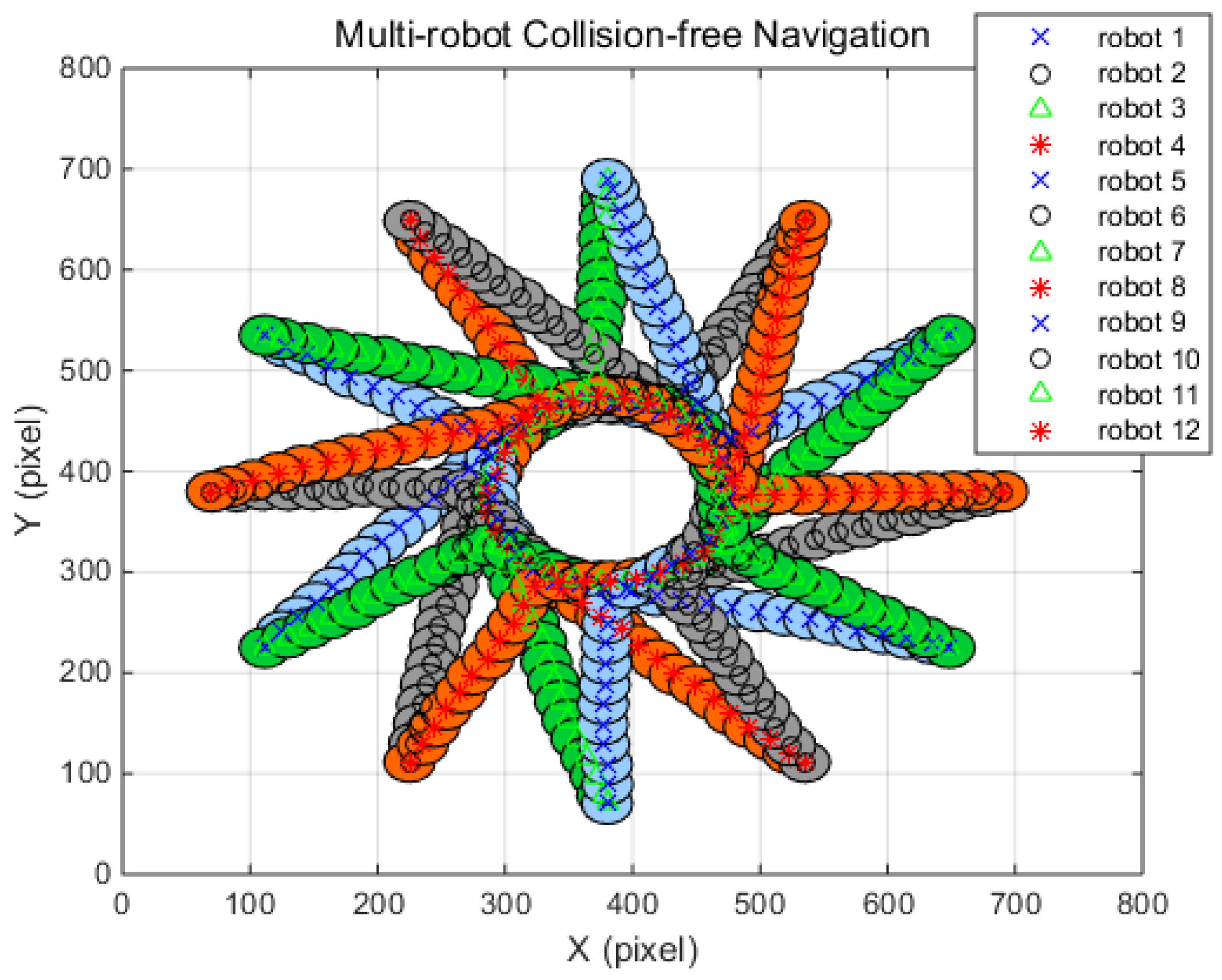

5.2. Simulation II (FAHP-CGT-Based Multi-Robot Navigation under No Obstacle Condition)

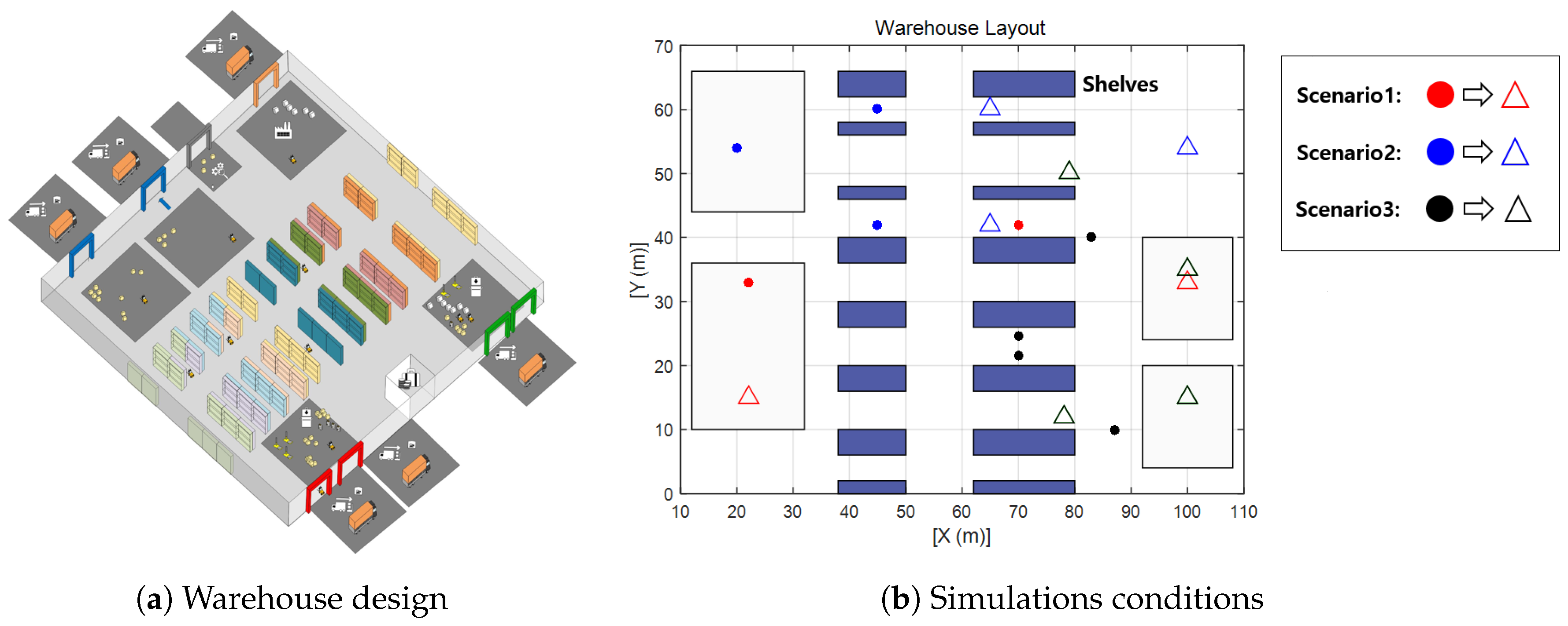

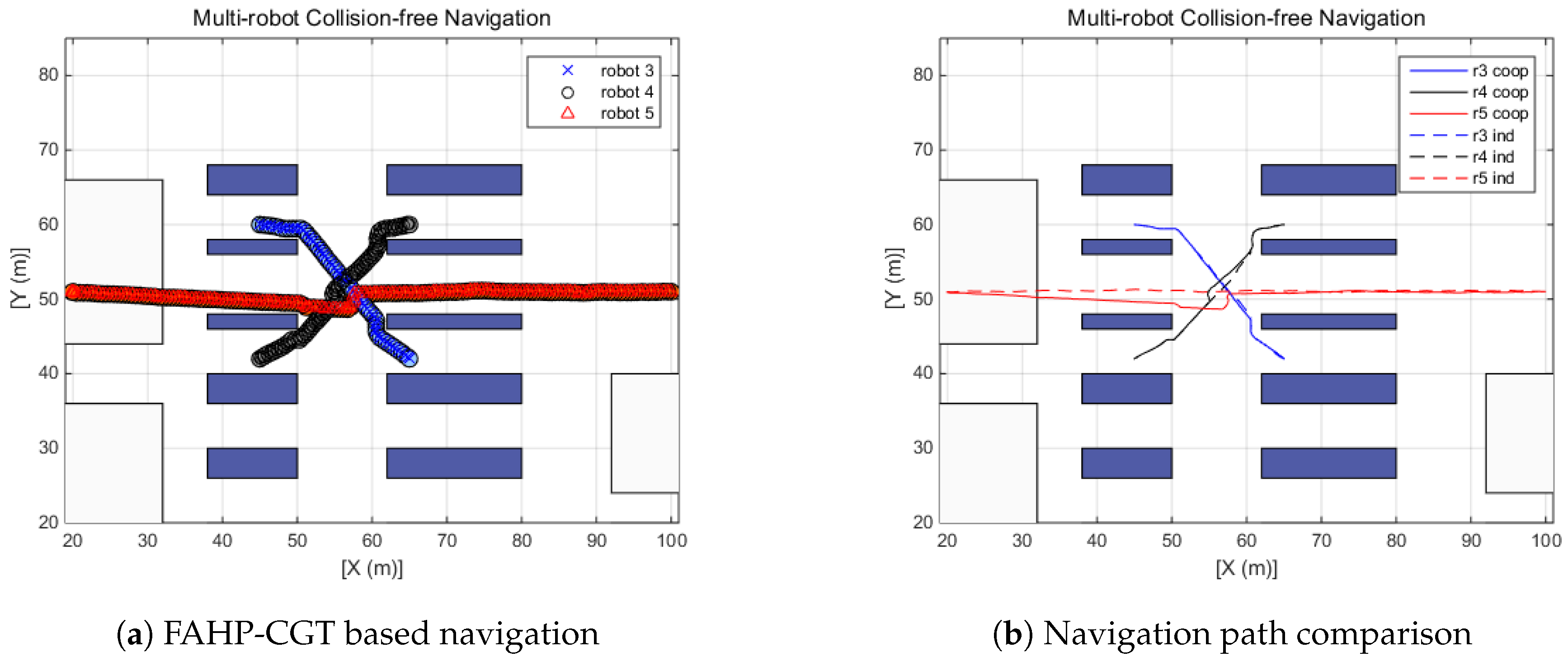

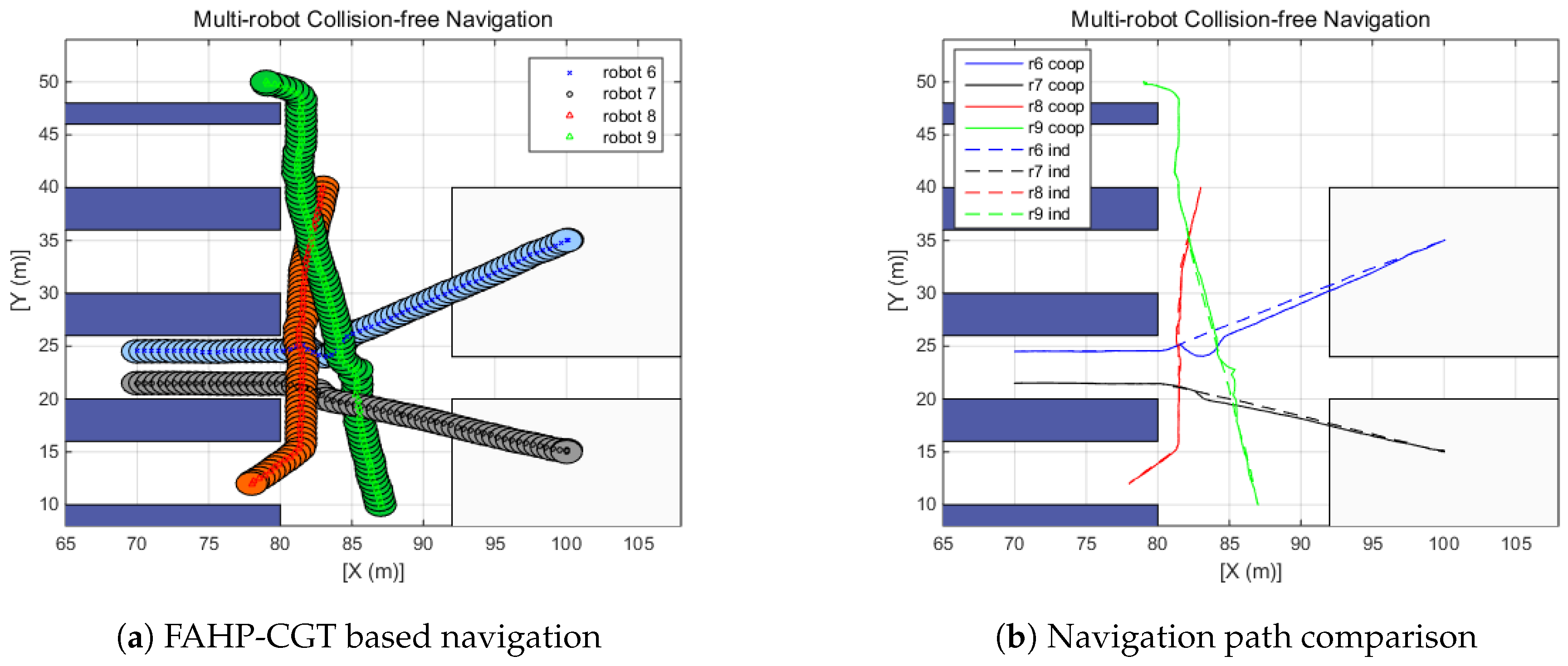

5.3. Simulation III (FAHP-CGT Based Multi-Robot Navigation under a Warehouse Environment)

6. Conclusions

Author Contributions

Conflicts of Interest

References

- Parker, L.E.; Rus, D.; Sukhatme, G.S. Multiple mobile robot systems. In Springer Handbook of Robotics; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1335–1384. [Google Scholar]

- Castillo, O.; Trujillo, L.; Melin, P. Multiple objective genetic algorithms for path-planning optimization in autonomous mobile robots. Soft Comput. 2007, 11, 269–279. [Google Scholar] [CrossRef]

- Masehian, E.; Sedighizadeh, D. A multi-objective PSO-based algorithm for robot path planning. In Proceedings of the 2010 IEEE International Conference on Industrial Technology, Vina del Mar, Chile, 14–17 March 2010; pp. 465–470. [Google Scholar]

- Ahmed, F.; Deb, K. Multi-objective optimal path planning using elitist non-dominated sorting genetic algorithms. Soft Comput. 2013, 17, 1283–1299. [Google Scholar] [CrossRef]

- Ma, Y.; Hu, M.; Yan, X. Multi-objective path planning for unmanned surface vehicle with currents effects. ISA Trans. 2018, 75, 137–156. [Google Scholar] [CrossRef] [PubMed]

- Yunqiang, H.; Wende, K.; Lin, C.; Xiaokun, L. Research on multi-objective path planning of a robot based on artificial potential field method. Int. J. Wirel. Mob. Comput. 2018, 15, 335–341. [Google Scholar] [CrossRef]

- Kouzehgar, M.; Rajesh Elara, M.; Ann Philip, M.; Arunmozhi, M.; Prabakaran, V. Multi-Criteria Decision Making for Efficient Tiling Path Planning in a Tetris-Inspired Self-Reconfigurable Cleaning Robot. Appl. Sci. 2019, 9, 63. [Google Scholar] [CrossRef]

- Zhang, J.H.; Zhang, Y.; Zhou, Y. Path planning of mobile robot based on hybrid multi-objective bare bones particle swarm optimization with differential evolution. IEEE Access 2018, 6, 44542–44555. [Google Scholar] [CrossRef]

- Sathiya, V.; Chinnadurai, M. Evolutionary Algorithms-Based Multi-Objective Optimal Mobile Robot Trajectory Planning. Robotica 2019, 37, 1363–1382. [Google Scholar] [CrossRef]

- Kim, C.; Langari, R. Analytical Hierarchy Process and Brain Limbic System combined strategy for mobile robot navigation. In Proceedings of the 2010 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Montreal, ON, Canada, 6–9 July 2010; pp. 967–972. [Google Scholar]

- Satty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Atthirawong, W.; MacCarthy, B. An application of the analytical hierarchy process to international location decision-making. In Gregory, Mike, Proceedings of The 7th Annual Cambridge International Manufacturing Symposium: Restructuring Global Manufacturing; University of Cambridge: Cambridge, UK, 2002; pp. 1–18. [Google Scholar]

- Locatelli, G.; Mancini, M. A framework for the selection of the right nuclear power plant. Int. J. Prod. Res. 2012, 50, 4753–4766. [Google Scholar] [CrossRef]

- Chen, P.Y.; Wu, J.K.; Pai, N.S.; Lai, Y.C. Design and Implementation of an Autonomous Parking Controller Using a Fuzzy controller and AHP for Car-Like Mobile Robot. Int. J. Comput. Consum. Control 2014, 3, 27–39. [Google Scholar]

- Bagga, P.; Joshi, A.; Hans, R. QoS based Web Service Selection and Multi-Criteria Decision Making Methods. Int. J. Interact. Multimed. Artif. Intell. 2019, 5. [Google Scholar] [CrossRef]

- Taibi, A.; Atmani, B. Combining Fuzzy AHP with GIS and Decision Rules for Industrial Site Selection. Int. J. Interact. Multimed. Artif. Intell. 2017, 4. [Google Scholar] [CrossRef]

- Enríquez, J.M.L.; López, M.Á.; García, V.M.; López, M.; Cañadas, R.; Velasco, S.; León, M. Practica. a virtual reality platform for specialized training oriented to improve the productivity. IJIMAI 2019, 5, 94–101. [Google Scholar]

- Cobos-Guzman, S.; Verdú, E.; Herrera-Viedma, E.; Crespo, R.G. Fuzzy logic expert system for selecting robotic hands using kinematic parameters. J. Ambient Intell. Humaniz. Comput. 2020, 11, 1553–1564. [Google Scholar] [CrossRef]

- Velasquez, M.; Hester, P.T. An analysis of multi-criteria decision making methods. Int. J. Oper. Res. 2013, 10, 56–66. [Google Scholar]

- Kim, C.; Kim, Y.; Yi, H. Fuzzy Analytic Hierarchy Process-Based Mobile Robot Path Planning. Electronics 2020, 9, 290. [Google Scholar] [CrossRef]

- Hennes, D.; Claes, D.; Meeussen, W.; Tuyls, K. Multi-robot collision avoidance with localization uncertainty. In Proceedings of the AAMAS 2012, Valencia, Spain, 4–8 June 2012; pp. 147–154. [Google Scholar]

- Rashid, A.T.; Ali, A.A.; Frasca, M.; Fortuna, L. Multi-robot collision-free navigation based on reciprocal orientation. Robot. Auton. Syst. 2012, 60, 1221–1230. [Google Scholar] [CrossRef]

- Palm, R.; Bouguerra, A.; Abdullah, M. Multi-robot navigation using market-based optimization. In Complex Systems; Springer: Berlin/Heidelberg, Germany, 2016; pp. 337–367. [Google Scholar]

- Jose, K.; Pratihar, D.K. Task allocation and collision-free path planning of centralized multi-robots system for industrial plant inspection using heuristic methods. Robot. Auton. Syst. 2016, 80, 34–42. [Google Scholar] [CrossRef]

- Claes, D.; Tuyls, K. Multi robot collision avoidance in a shared workspace. Auton. Robot. 2018, 42, 1749–1770. [Google Scholar] [CrossRef]

- Fan, T.; Long, P.; Liu, W.; Pan, J. Fully distributed multi-robot collision avoidance via deep reinforcement learning for safe and efficient navigation in complex scenarios. arXiv 2018, arXiv:1808.03841. [Google Scholar]

- Ma, J.; Lu, H.; Xiao, J.; Zeng, Z.; Zheng, Z. Multi-robot Target Encirclement Control with Collision Avoidance via Deep Reinforcement Learning. J. Intell. Robot. Syst. 2019. [Google Scholar] [CrossRef]

- Bae, H.; Kim, G.; Kim, J.; Qian, D.; Lee, S. Multi-Robot Path Planning Method Using Reinforcement Learning. Appl. Sci. 2019, 9, 3057. [Google Scholar] [CrossRef]

- Semsar-Kazerooni, E.; Khorasani, K. A game theory approach to multi-agent team cooperation. In Proceedings of the 2009 American Control Conference, St. Louis, MO, USA, 10–12 June 2009; pp. 4512–4518. [Google Scholar]

- Cui, R.; Guo, J.; Gao, B. Game theory-based negotiation for multiple robots task allocation. Robotica 2013, 31, 923–934. [Google Scholar] [CrossRef]

- Aghajani, A.; Doustmohammadi, A. Formation control of multi-vehicle systems using cooperative game theory. In Proceedings of the 2015 15th International Conference on Control, Automation and Systems (ICCAS), Busan, Korea, 13–16 October 2015; pp. 704–709. [Google Scholar]

- Jang, I.; Shin, H.S.; Tsourdos, A. A game-theoretical approach to heterogeneous multi-robot task assignment problem with minimum workload requirements. In Proceedings of the 2017 Workshop on Research, Education and Development of Unmanned Aerial Systems (RED-UAS), Linkoping, Sweden, 3–5 October 2017; pp. 156–161. [Google Scholar]

- Kabir, G.; Akhtar Hasin, M.A. Multi-criteria inventory classification through integration of fuzzy analytic hierarchy process and artificial neural network. Int. J. Ind. Syst. Eng. 2013, 14, 74–103. [Google Scholar] [CrossRef]

- Chang, D.Y. Applications of the extent analysis method on fuzzy AHP. Eur. J. Oper. Res. 1996, 95, 649–655. [Google Scholar] [CrossRef]

- Anand, M.D.; Selvaraj, T.; Kumanan, S.; Johnny, M.A. Application of multicriteria decision making for selection of robotic system using fuzzy analytic hierarchy process. Int. J. Manag. Decis. Mak. 2008, 9, 75. [Google Scholar] [CrossRef]

- Noorul Haq, A.; Kannan, G. Design of an integrated supplier selection and multi-echelon distribution inventory model in a built-to-order supply chain environment. Int. J. Prod. Res. 2006, 44, 1963–1985. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision Making for Leaders: The Analytic Hierarchy Process for Decisions in a Complex World; RWS Publications: Pittsburgh, PA, USA, 1990. [Google Scholar]

- Chang, D.Y. Extent analysis and synthetic decision. Optim. Tech. Appl. 1992, 1, 352–355. [Google Scholar]

- Sahu, N.K.; Sahu, A.K.; Sahu, A.K. Appraisement and benchmarking of third-party logistic service provider by exploration of risk-based approach. Cogent Bus. Manag. 2015, 2, 1121637. [Google Scholar] [CrossRef]

- Mas-Colell, A.; Whinston, M.D.; Green, J.R. Microeconomic Theory; Oxford University Press: New York, NY, USA, 1995; Volume 1. [Google Scholar]

- Dziong, Z. ATM Network Resource Management; McGraw-Hill: New York, NY, USA, 1997. [Google Scholar]

- Ali, A.A.; Rashid, A.T.; Frasca, M.; Fortuna, L. An algorithm for multi-robot collision-free navigation based on shortest distance. Robot. Auton. Syst. 2016, 75, 119–128. [Google Scholar] [CrossRef]

- Halabudenco, D. Warehouse. Planning. Grouping. Optimize. Available online: https://ipvm.com/forums/video-surveillance/topics/warehouse-planning-grouping-optimize (accessed on 1 May 2020).

| Intensity of Importance | Definition |

|---|---|

| (1, 1, 1 + d) | Equal importance of objectives |

| (3 − d, 3, 3 + d) | Moderate importance of one objective relative to another |

| (5 − d, 5, 5 + d) | Strong importance of one objective relative to another |

| (7 − d, 7, 7 + d) | Very strong importance of one objective relative to another |

| (9 − d, 9, 9) | Extreme importance of one objective relative to another |

| (x − d, x, x + d), x = 2, 4, 6, 8 | Intermediate values between two adjacent judgements |

| Number of Objectives | RC |

|---|---|

| 3 | 0.58 |

| 4 | 0.90 |

| 5 | 1.12 |

| 6 | 1.24 |

| 7 | 1.32 |

| 8 | 1.41 |

| 9 | 1.45 |

| Notation | Definition | Multi-Robot Application |

|---|---|---|

| n | Number of players | Number of robots |

| Strategy space of player i | All the candidates for robot i | |

| Strategy of player i | Selection of robot i among candidates | |

| Strategy profile of n players | Each robot’s solution | |

| Strategy profile of n − 1 players | A set without the selection of robot i | |

| U | Domain of all possible outcomes | A set of possible benefit for robots |

| Payoffs given to players under strategy s | Benefit of robots | |

| Payoff to player i under strategy s | Benefit of robot i |

| Two Robots | Four Robots | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R | R | Average | ROA | SDA | R | R | R | R | Average | ROA | SDA | |

| Initial position | (70, 140) | (690, 140) | (160, 160) | (600, 160) | (600, 600) | (160, 600) | ||||||

| Target position | (690, 140) | (70, 140) | (600, 600) | (160, 600) | (160, 160) | (600, 160) | ||||||

| Travel distance (pixel) | 630.09 | 630.42 | 630.26 | 644.00 | 641.00 | 641.42 | 639.23 | 639.07 | 642.82 | 640.63 | 661.00 | 649.00 |

| Increased distance(%) | 1.6 | 1.7 | 1.7 | 3.9 | 3.4 | 3.5 | 3.1 | 3.1 | 3.7 | 3.3 | 6.6 | 4.7 |

| Eight Robots | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| R | R | R | R | R | R | R | R | Average | ROA | SDA | |

| Initial position | (380, 611) | (160, 520) | (69, 300) | (160, 80) | (380, −11) | (600, 80) | (691, 300) | (600, 520) | |||

| Target position | (380, −11) | (600, 80) | (691, 300) | (600, 520) | (380, 611) | (160, 520) | (69, 300) | (160, 80) | |||

| Travel distance (pixel) | 651.26 | 652.90 | 657.42 | 656.89 | 654.59 | 658.05 | 657.24 | 655.07 | 655.43 | 687.00 | 652.00 |

| Increased distance (%) | 5.0 | 5.3 | 6.0 | 5.9 | 5.6 | 6.1 | 6.0 | 5.7 | 5.7 | 10.8 | 5.2 |

| 12 Robots | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R | R | R | R | R | R | R | R | R | R | R | R | Average | ROA | SDA | |

| Travel distance (pixel) | 674.15 | 679.24 | 679.44 | 681.68 | 678.37 | 676.24 | 675.31 | 680.48 | 679.76 | 678.30 | 679.99 | 675.87 | 678.04 | 713.00 | 675.00 |

| Increased distance (%) | 8.73 | 9.55 | 9.59 | 9.95 | 9.42 | 9.07 | 8.92 | 9.75 | 9.64 | 9.40 | 9.68 | 9.01 | 9.36 | 15.00 | 8.87 |

| R | R | R | R | R | R | R | R | R | |

|---|---|---|---|---|---|---|---|---|---|

| Initial position | (70, 42) | (22, 35) | (45, 60) | (45, 42) | (100, 51) | (70, 24.5) | (70, 21.5) | (83, 40) | (78, 12) |

| Target position | (22, 15) | (100,33) | (65, 42) | (65, 60) | (20, 51) | (100, 35) | (100, 15) | (87, 10) | (79, 50) |

| Scenario 1 | Scenario 2 | Scenario 3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| R | R | R | R | R | R | R | R | R | |

| Original travel distance (m) | 58.03 | 78.00 | 28.79 | 28.66 | 80.04 | 32.62 | 31.05 | 29.53 | 42.06 |

| Cooperative travel distance (m) | 58.95 | 78.54 | 28.94 | 29.18 | 82.16 | 34.28 | 31.35 | 29.63 | 42.71 |

| Increased distance (%) | 1.6 | 0.7 | 0.5 | 1.8 | 2.6 | 5.1 | 1.0 | 0.3 | 1.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, C.; Won, J.-S. A Fuzzy Analytic Hierarchy Process and Cooperative Game Theory Combined Multiple Mobile Robot Navigation Algorithm. Sensors 2020, 20, 2827. https://doi.org/10.3390/s20102827

Kim C, Won J-S. A Fuzzy Analytic Hierarchy Process and Cooperative Game Theory Combined Multiple Mobile Robot Navigation Algorithm. Sensors. 2020; 20(10):2827. https://doi.org/10.3390/s20102827

Chicago/Turabian StyleKim, Changwon, and Jong-Seob Won. 2020. "A Fuzzy Analytic Hierarchy Process and Cooperative Game Theory Combined Multiple Mobile Robot Navigation Algorithm" Sensors 20, no. 10: 2827. https://doi.org/10.3390/s20102827

APA StyleKim, C., & Won, J.-S. (2020). A Fuzzy Analytic Hierarchy Process and Cooperative Game Theory Combined Multiple Mobile Robot Navigation Algorithm. Sensors, 20(10), 2827. https://doi.org/10.3390/s20102827