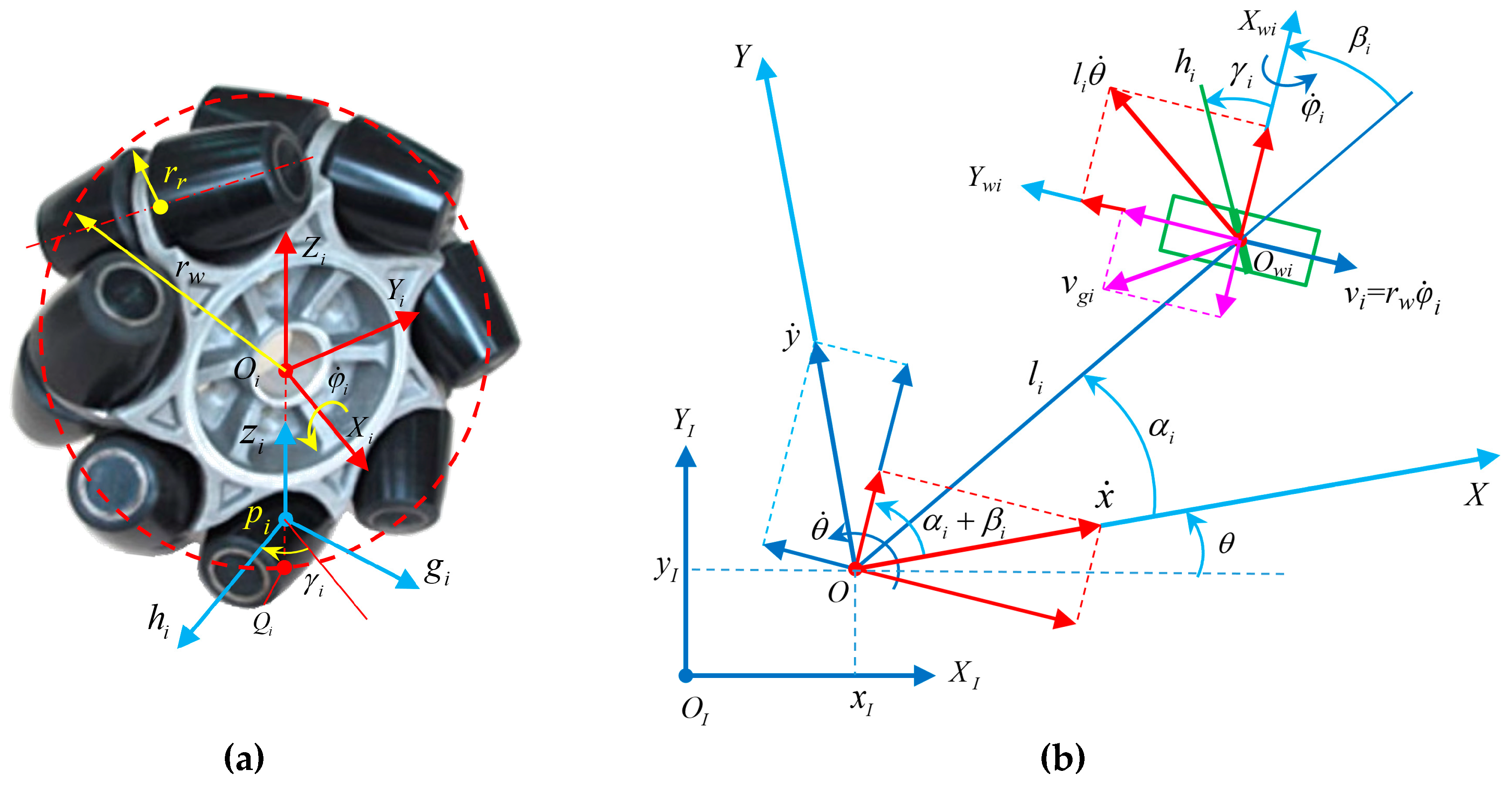

Figure 1.

Kinematic constraint diagram of a robotic Mecanum wheel: (a) structural principle; (b) kinematic constraint.

Figure 1.

Kinematic constraint diagram of a robotic Mecanum wheel: (a) structural principle; (b) kinematic constraint.

Figure 2.

Four-Mecanum-wheeled mobile robot.

Figure 2.

Four-Mecanum-wheeled mobile robot.

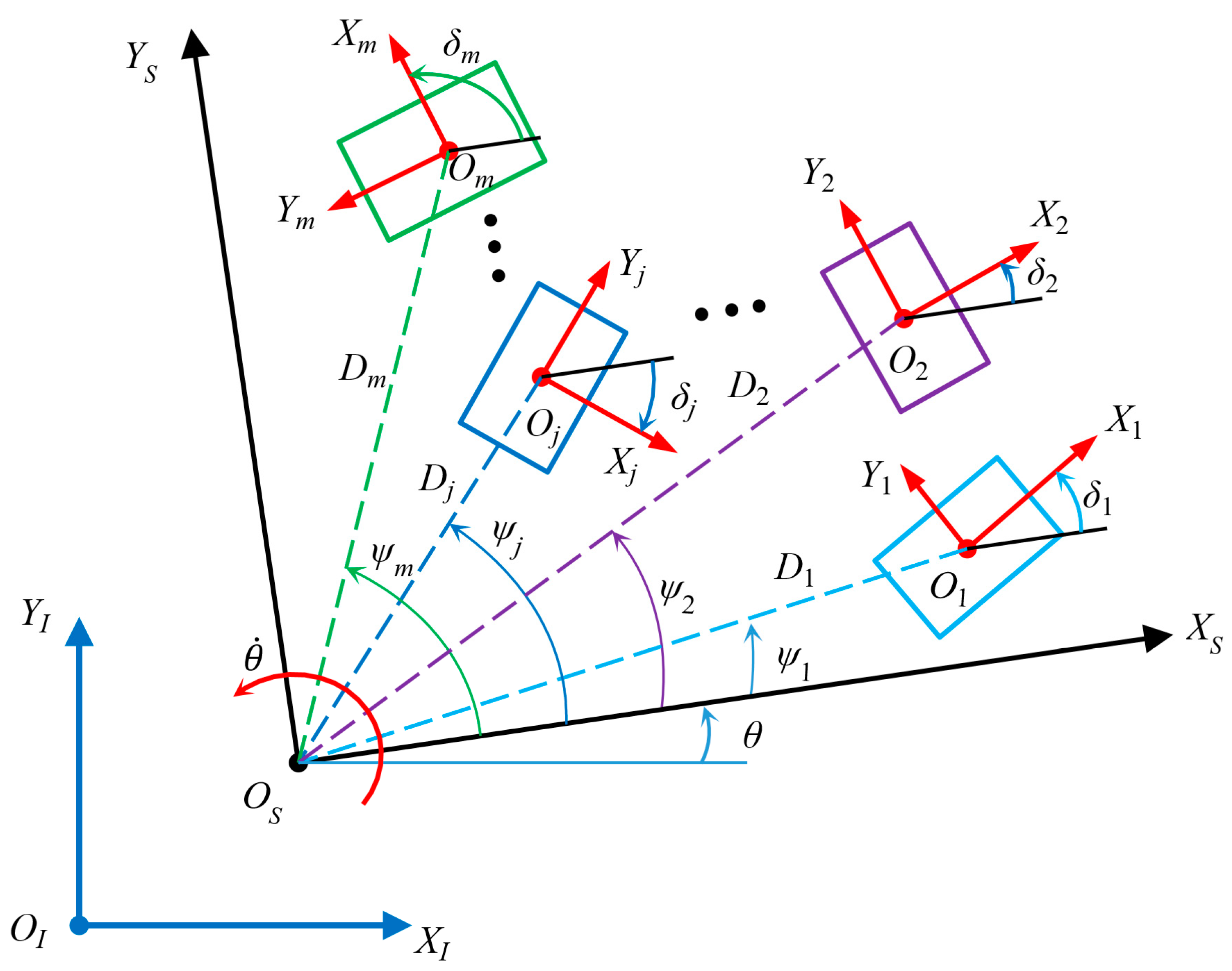

Figure 3.

Multiple-robot mobile system.

Figure 3.

Multiple-robot mobile system.

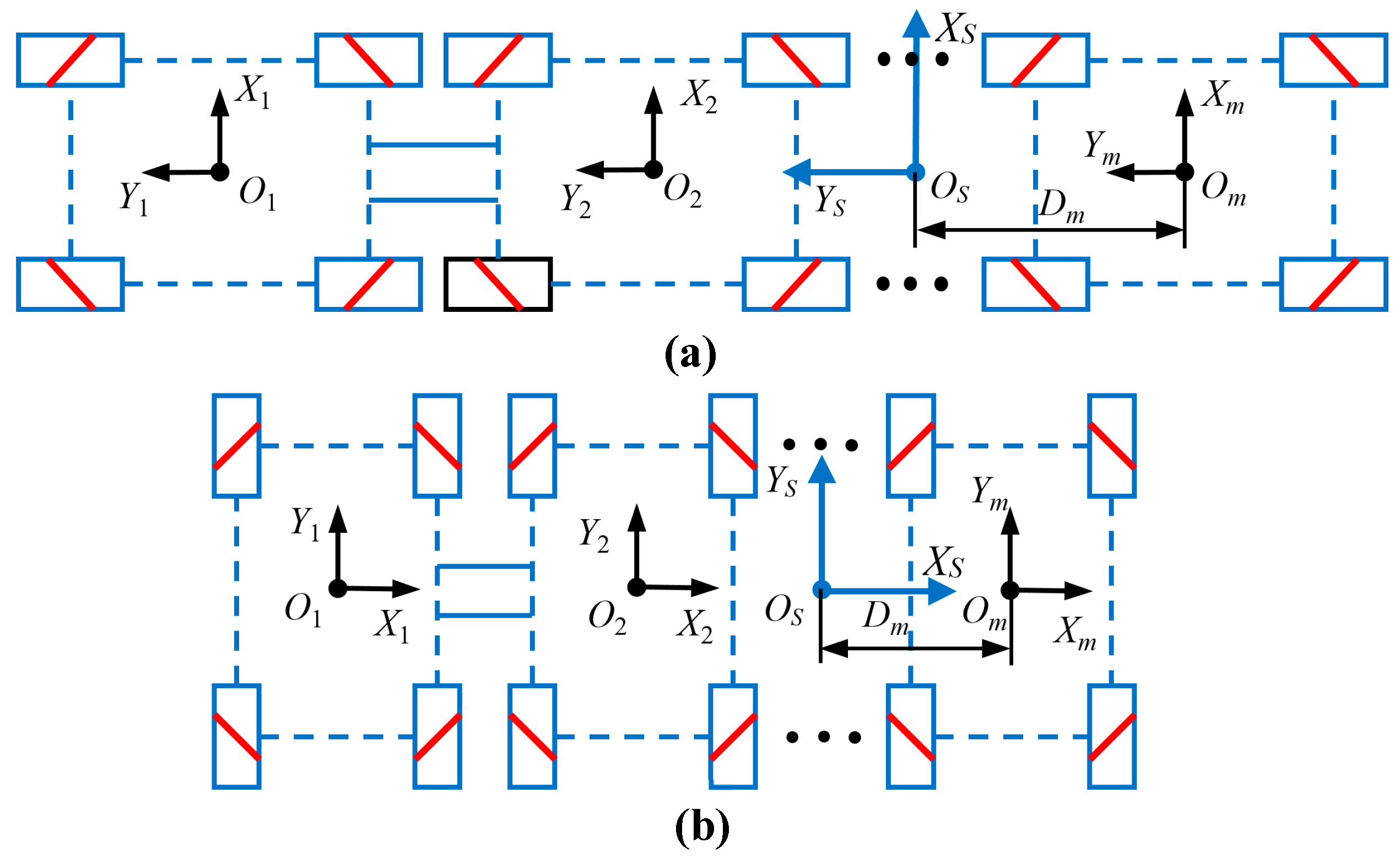

Figure 4.

Combination configurations of multiple four-Mecanum-wheeled mobile platform with symmetrical structure: (a) tandem connected configuration; (b) side-by-side connected configuration.

Figure 4.

Combination configurations of multiple four-Mecanum-wheeled mobile platform with symmetrical structure: (a) tandem connected configuration; (b) side-by-side connected configuration.

Figure 5.

Simulation model of four-Mecanum-wheeled robot platform: (a) 3D model; (b) 8 revolute joints between rollers and hub in single Mecanum wheel subsystem.

Figure 5.

Simulation model of four-Mecanum-wheeled robot platform: (a) 3D model; (b) 8 revolute joints between rollers and hub in single Mecanum wheel subsystem.

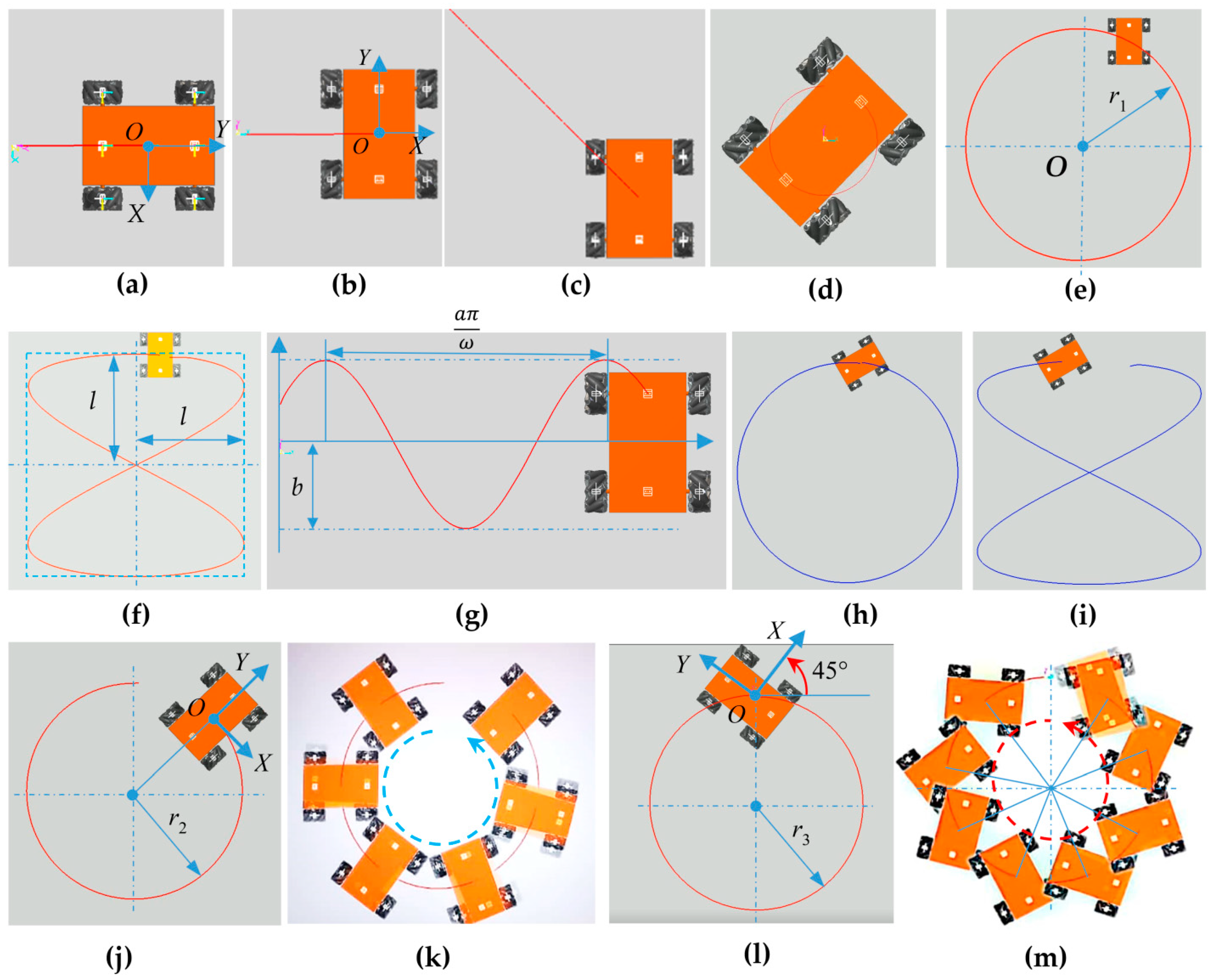

Figure 6.

Motion simulation of robot: (a) longitudinal motion; (b) lateral motion; (c) oblique motion at 45°; (d) turning on the spot; (e) circular motion, where radius r1 of the circle is 2500 mm; (f) translation motion around 8-figure curve; (g) translational motion along a simple harmonic motion curve; (h) circular translation motion of robot in oblique state; (i) translation motion of robot around 8-figure curve in oblique state; (j,k) centripetal circular motion, where radius r2 of the circle is 1350 mm; (l,m) centripetal motion of 45° angle, where radius r3 of the circle is 1350 mm.

Figure 6.

Motion simulation of robot: (a) longitudinal motion; (b) lateral motion; (c) oblique motion at 45°; (d) turning on the spot; (e) circular motion, where radius r1 of the circle is 2500 mm; (f) translation motion around 8-figure curve; (g) translational motion along a simple harmonic motion curve; (h) circular translation motion of robot in oblique state; (i) translation motion of robot around 8-figure curve in oblique state; (j,k) centripetal circular motion, where radius r2 of the circle is 1350 mm; (l,m) centripetal motion of 45° angle, where radius r3 of the circle is 1350 mm.

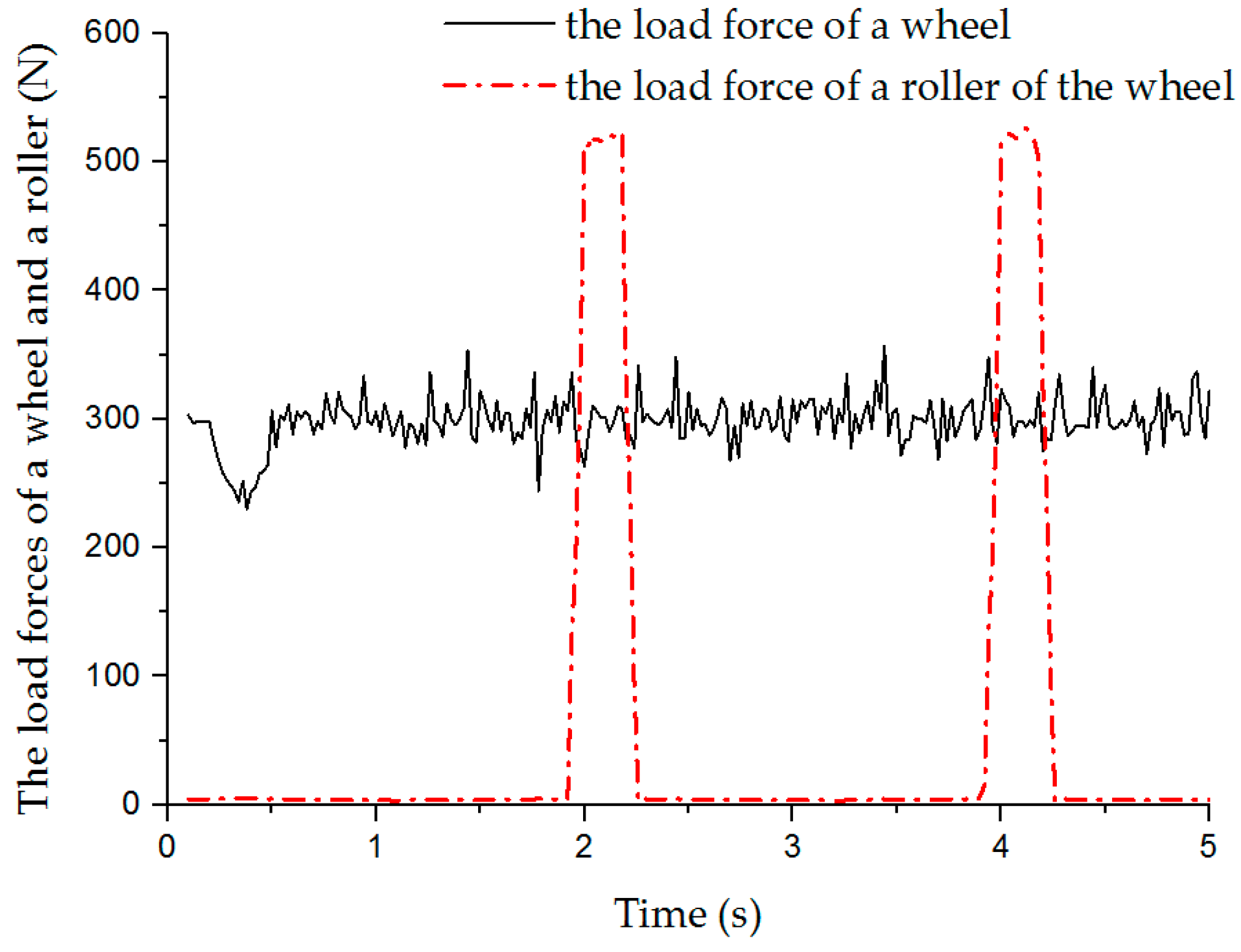

Figure 7.

Wheel load and roller load in longitudinal motion simulation.

Figure 7.

Wheel load and roller load in longitudinal motion simulation.

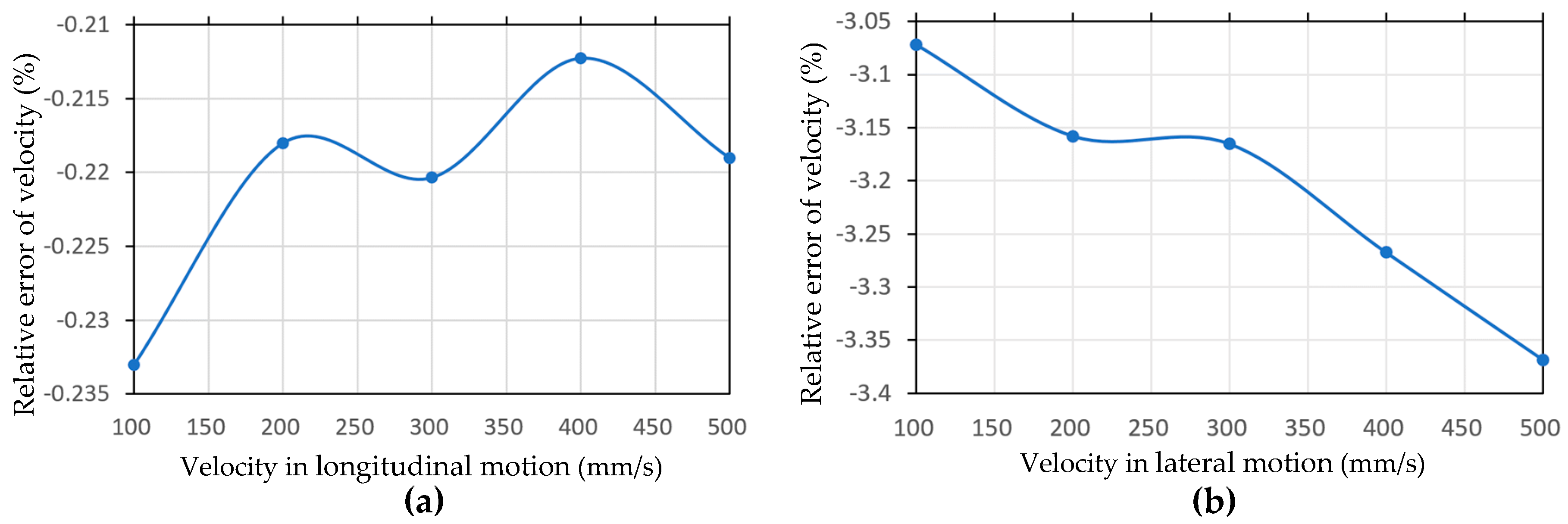

Figure 8.

Relative error of velocity in (a) longitudinal and (b) lateral translation motion simulation.

Figure 8.

Relative error of velocity in (a) longitudinal and (b) lateral translation motion simulation.

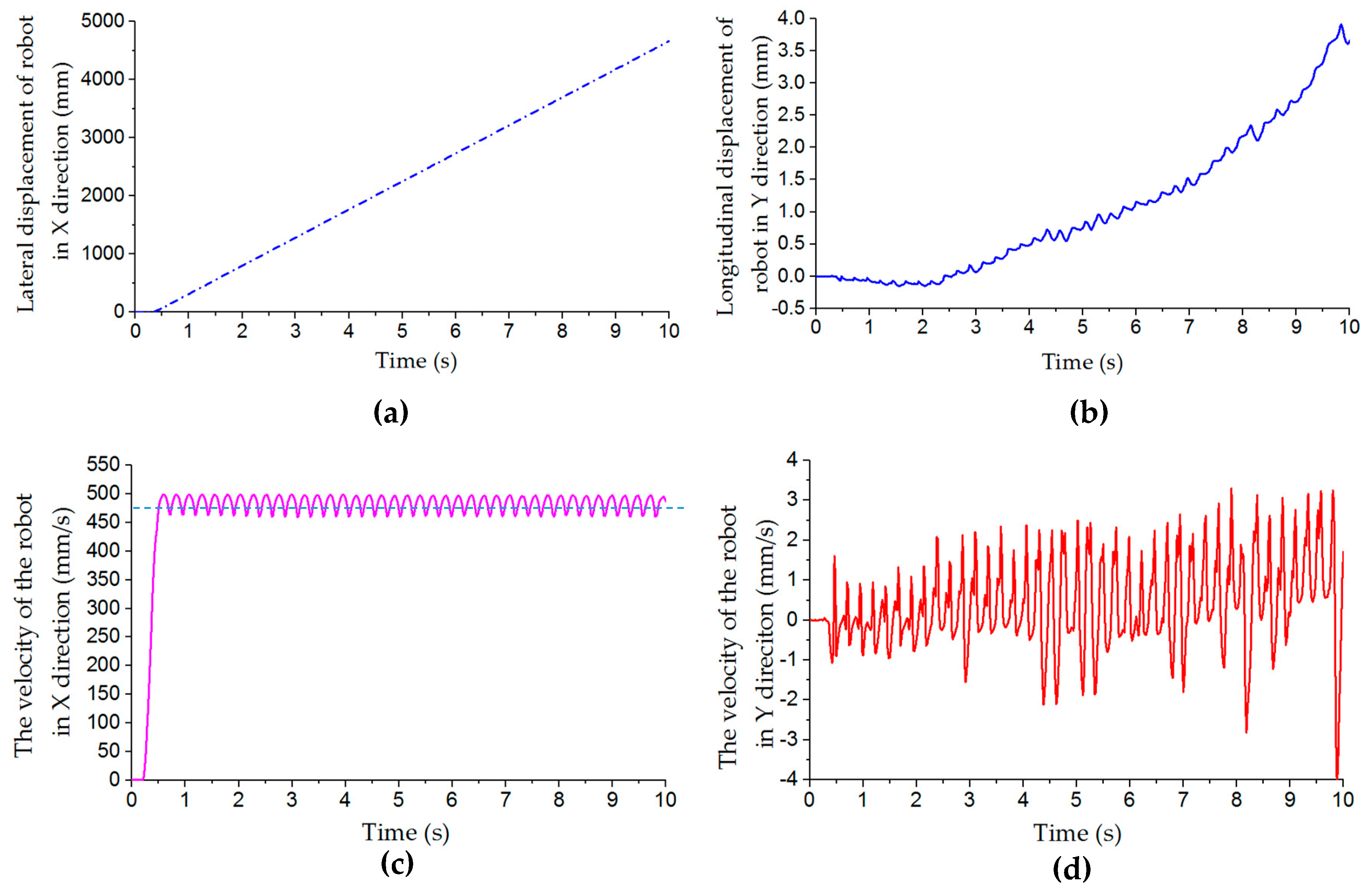

Figure 9.

Displacement and velocity curves of robot in x- and y-directions during lateral motion simulation: (a) lateral displacement curve in x-direction; (b) longitudinal displacement curve in y-direction; (c) velocity curve in x-direction; (d) velocity curve in y-direction.

Figure 9.

Displacement and velocity curves of robot in x- and y-directions during lateral motion simulation: (a) lateral displacement curve in x-direction; (b) longitudinal displacement curve in y-direction; (c) velocity curve in x-direction; (d) velocity curve in y-direction.

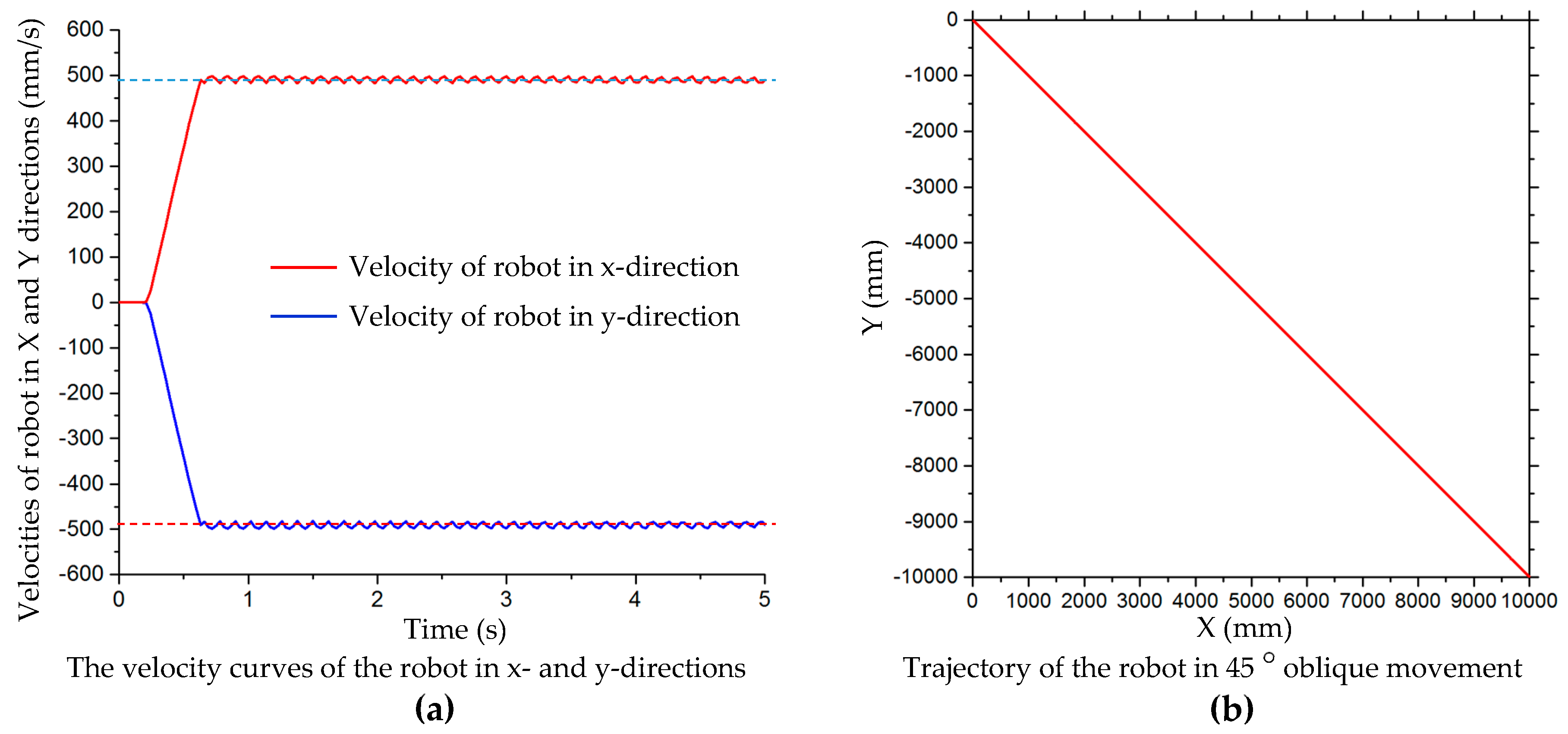

Figure 10.

(a) Velocity curves in x- and y-directions, and (b) trajectory of robot platform in simulation of oblique motion at 45°.

Figure 10.

(a) Velocity curves in x- and y-directions, and (b) trajectory of robot platform in simulation of oblique motion at 45°.

Figure 11.

(a) Trajectory and (b) displacement of robot center in x- and y-axis directions in simulation of turning on the spot in five cycles.

Figure 11.

(a) Trajectory and (b) displacement of robot center in x- and y-axis directions in simulation of turning on the spot in five cycles.

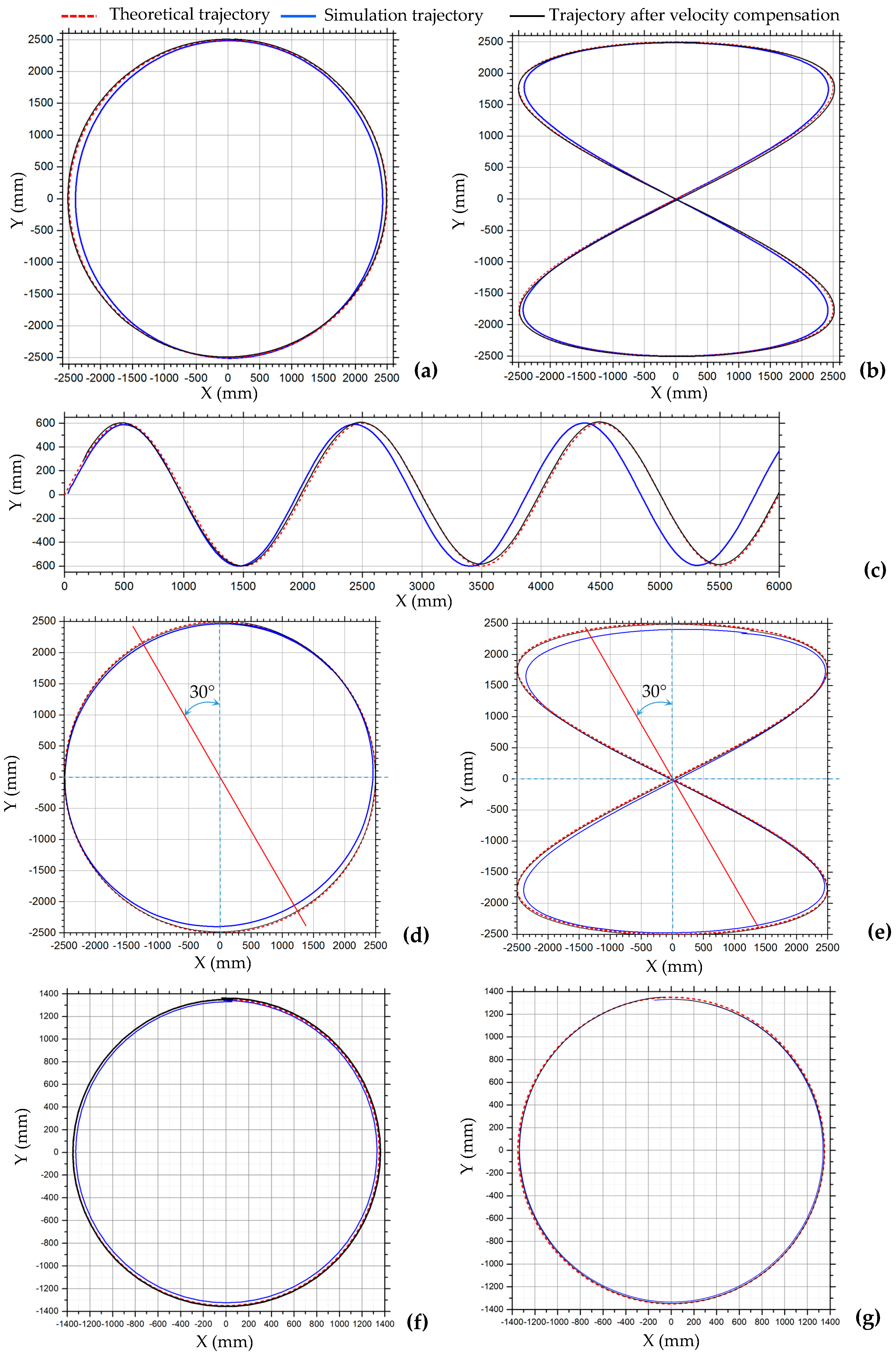

Figure 12.

Trajectories of robot in motion simulation shown in

Figure 6: (

a) circular trajectory in

Figure 6e; (

b) 8-shaped trajectory in

Figure 6f; (

c) simple harmonic motion trajectory in

Figure 6g; (

d) circular trajectory in

Figure 6h; (

e) 8-shaped trajectory in

Figure 6i; (

f) centripetal circular motion in

Figure 6j; (

g) centripetal motion of 45° angle in

Figure 6l.

Figure 12.

Trajectories of robot in motion simulation shown in

Figure 6: (

a) circular trajectory in

Figure 6e; (

b) 8-shaped trajectory in

Figure 6f; (

c) simple harmonic motion trajectory in

Figure 6g; (

d) circular trajectory in

Figure 6h; (

e) 8-shaped trajectory in

Figure 6i; (

f) centripetal circular motion in

Figure 6j; (

g) centripetal motion of 45° angle in

Figure 6l.

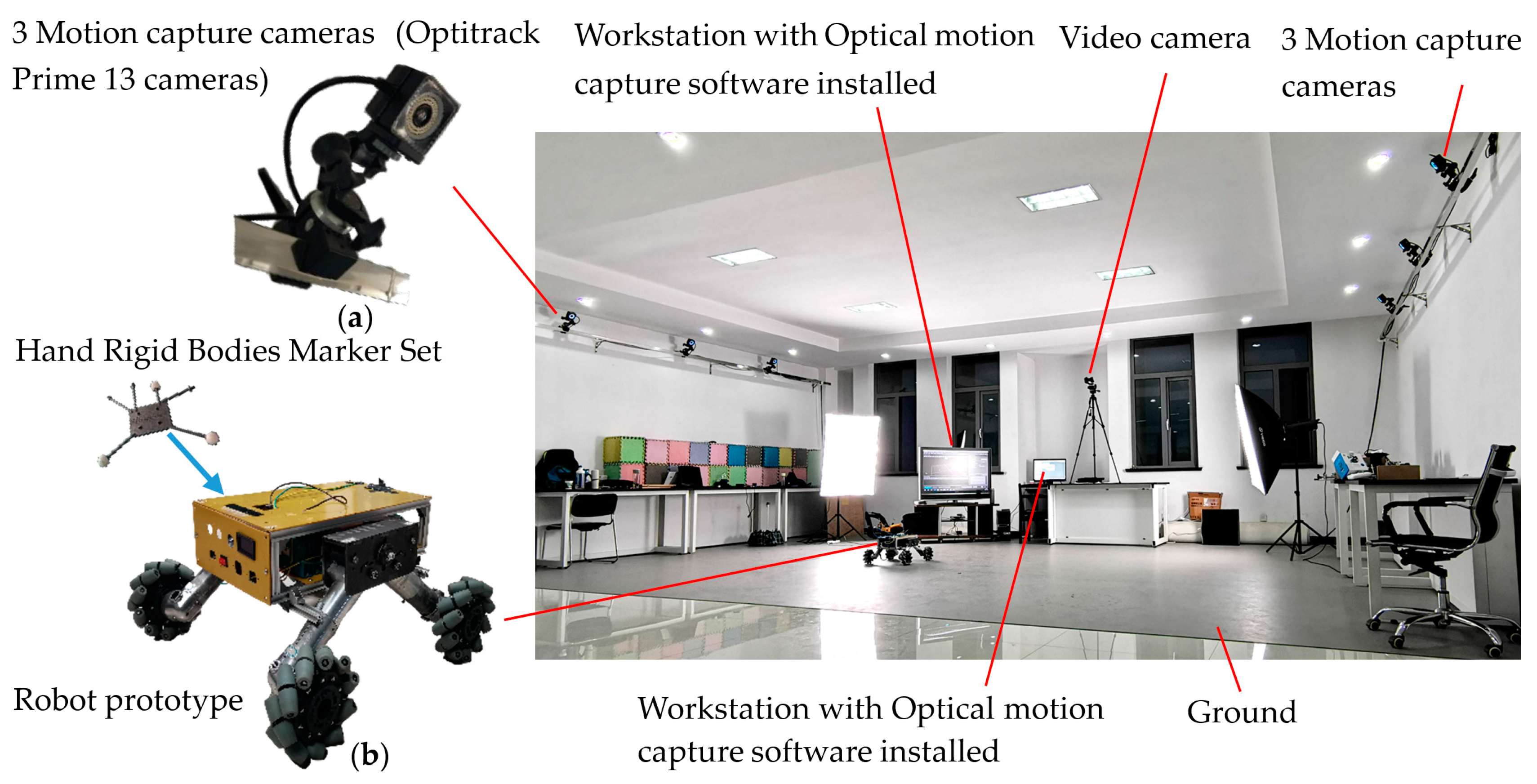

Figure 13.

Test system of the Mecanum-wheeled robot using the Optitrack optical motion capture system: (a) the Optitrack Prime 13 cameras; (b) four-Mecanum-wheeled robot prototype.

Figure 13.

Test system of the Mecanum-wheeled robot using the Optitrack optical motion capture system: (a) the Optitrack Prime 13 cameras; (b) four-Mecanum-wheeled robot prototype.

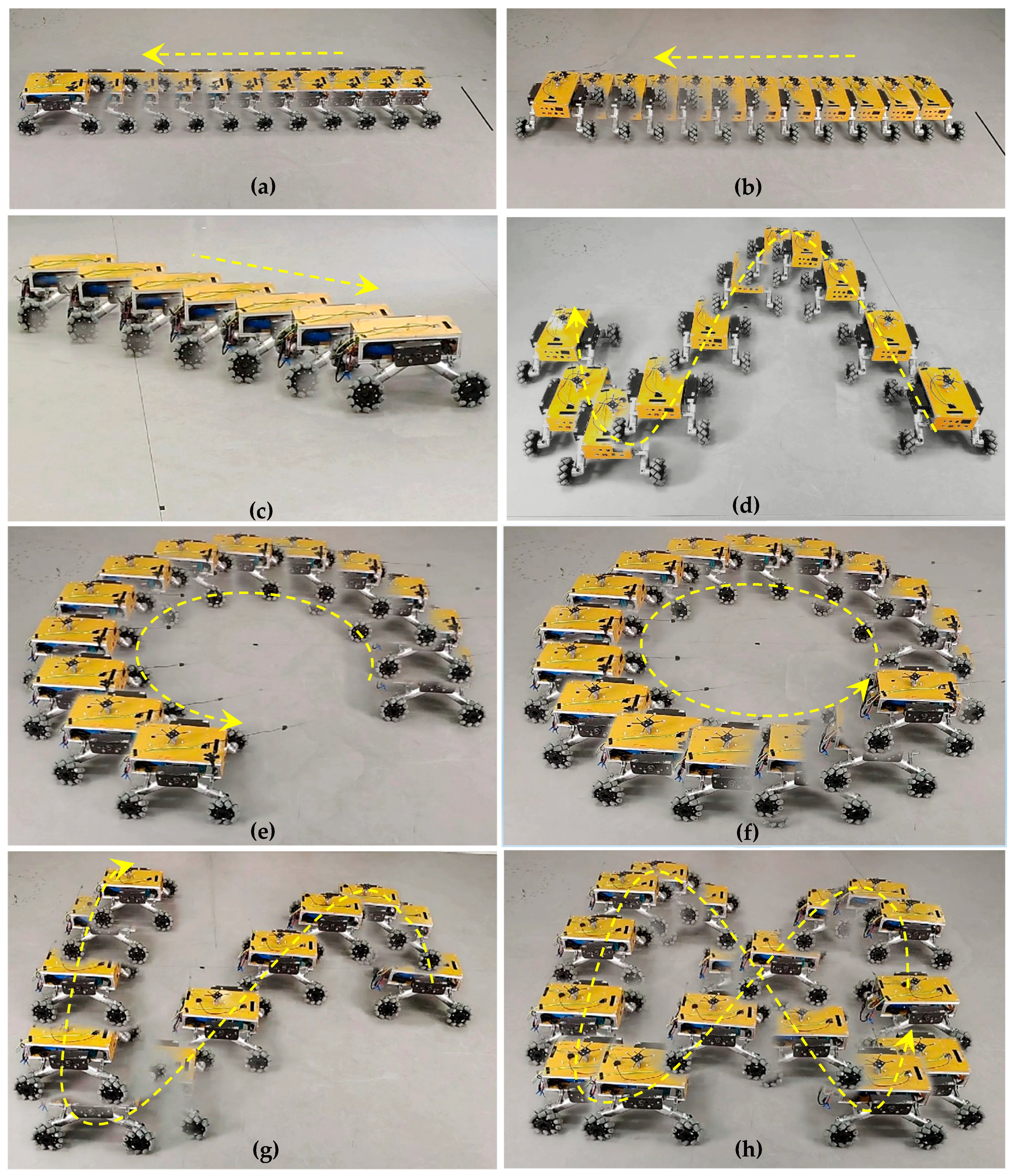

Figure 14.

Motion shots of robot in motion test: (a) longitudinal translation; (b) lateral translation; (c) oblique 45° translation; (d) translation along a simple harmonic curve; (e,f) translation along a circle; (g,h) translation along an 8-shaped curve.

Figure 14.

Motion shots of robot in motion test: (a) longitudinal translation; (b) lateral translation; (c) oblique 45° translation; (d) translation along a simple harmonic curve; (e,f) translation along a circle; (g,h) translation along an 8-shaped curve.

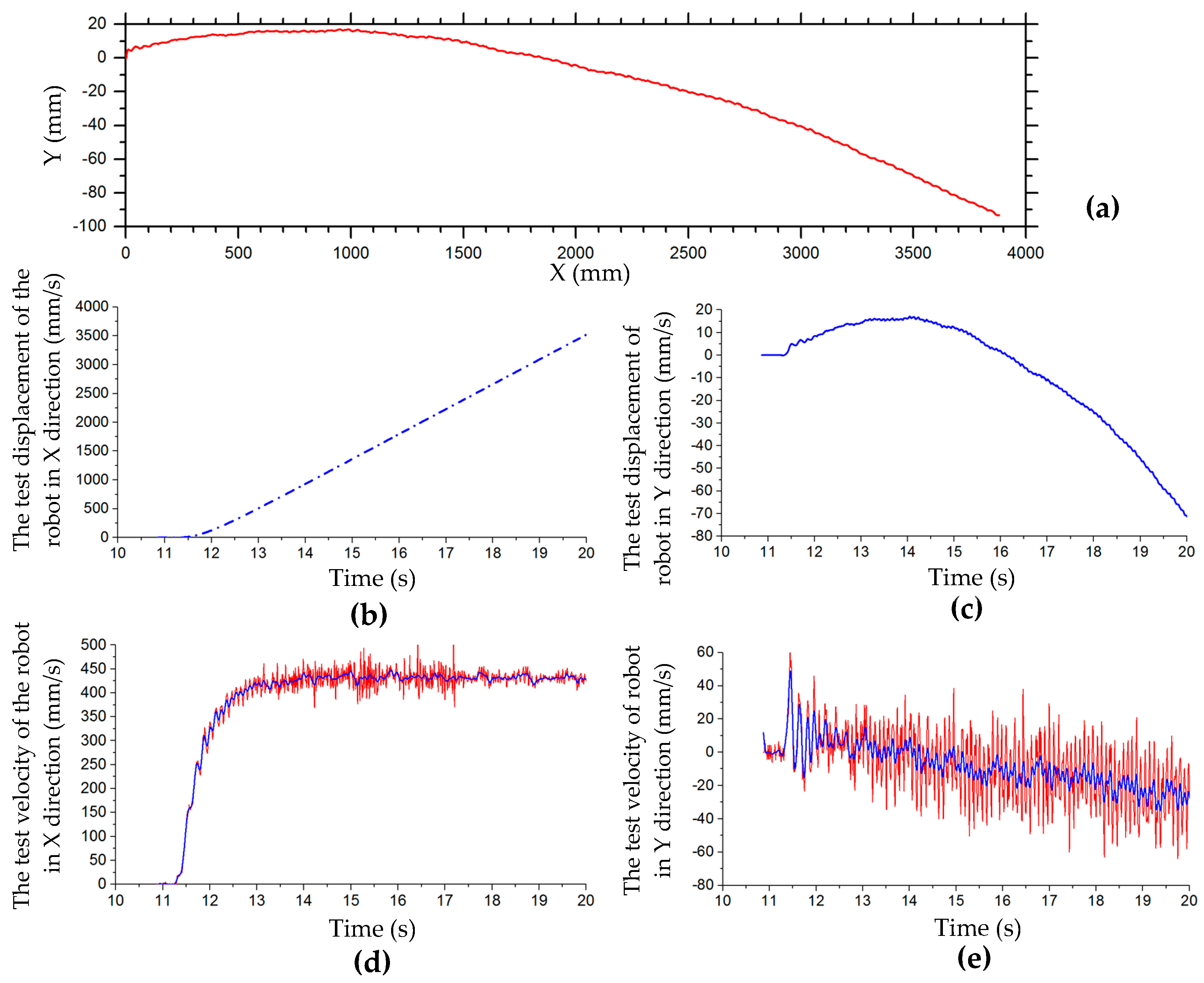

Figure 15.

Trajectory, displacement, and velocity curves of robot in lateral translation motion test at a set velocity of 500 mm/s: (a) trajectory in lateral translation test; (b) lateral displacement curve in x-direction; (c) longitudinal displacement curve in y-direction; (d) test velocity curve in x-direction; (e) test velocity curve in y-direction.

Figure 15.

Trajectory, displacement, and velocity curves of robot in lateral translation motion test at a set velocity of 500 mm/s: (a) trajectory in lateral translation test; (b) lateral displacement curve in x-direction; (c) longitudinal displacement curve in y-direction; (d) test velocity curve in x-direction; (e) test velocity curve in y-direction.

Figure 16.

Oblique 45° translation motion test: (a) trajectories of robot in oblique 45° translation; (b) test displacement curves of the robot in x- and y-directions; (c) test velocity curves of the robot in x- and y-directions.

Figure 16.

Oblique 45° translation motion test: (a) trajectories of robot in oblique 45° translation; (b) test displacement curves of the robot in x- and y-directions; (c) test velocity curves of the robot in x- and y-directions.

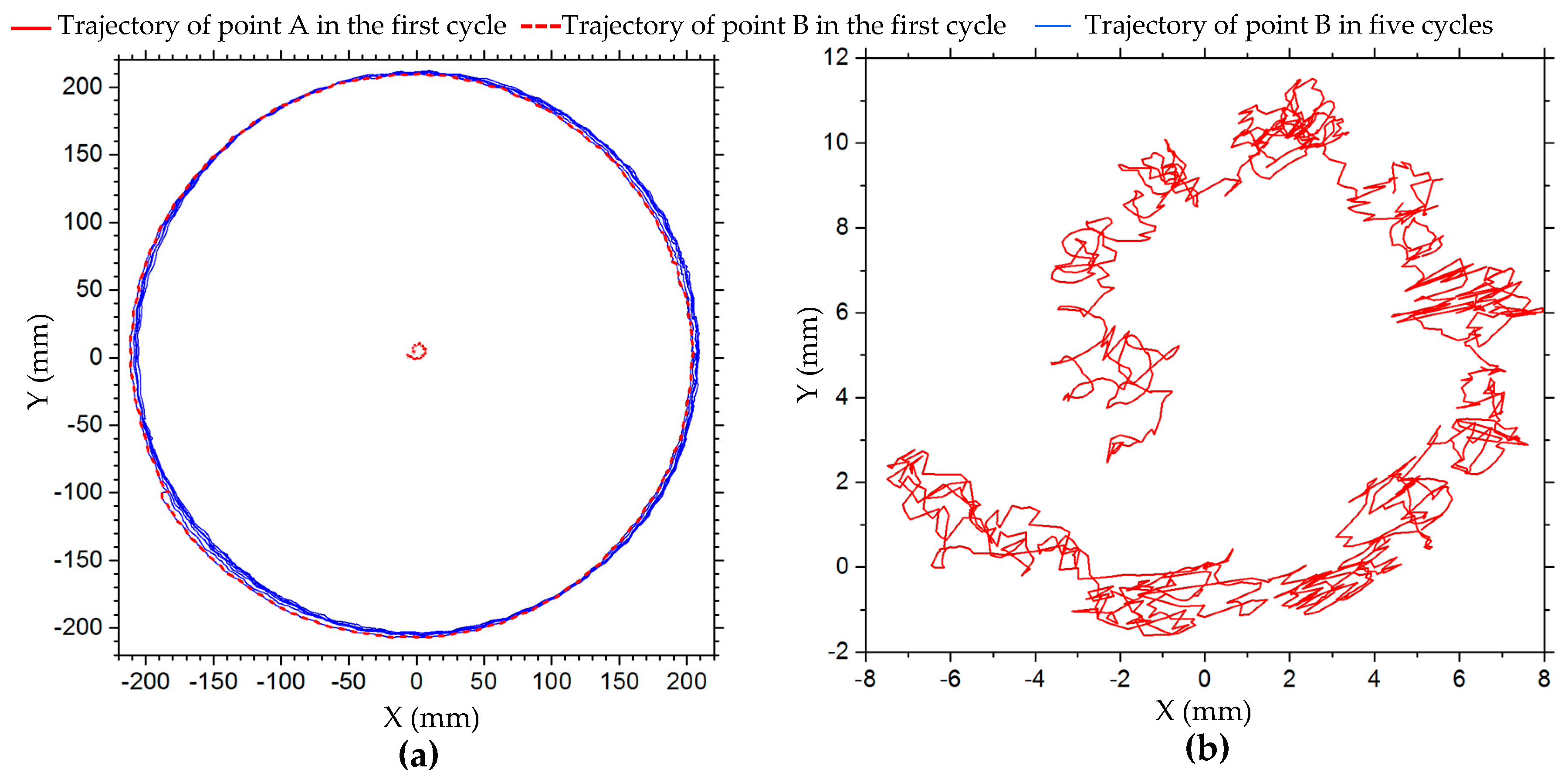

Figure 17.

Trajectories of points A and B of the robot in turning on spot; point A is very close to the center, point B is about 200 mm from the center: (a) trajectories of point A and B in the first cycle, and the trajectory of point B in five cycles; (b) enlarged view of trajectory of point A in the first cycle in (a).

Figure 17.

Trajectories of points A and B of the robot in turning on spot; point A is very close to the center, point B is about 200 mm from the center: (a) trajectories of point A and B in the first cycle, and the trajectory of point B in five cycles; (b) enlarged view of trajectory of point A in the first cycle in (a).

Figure 18.

Trajectories, displacements, and velocities, respectively, of the robot in translation motion along (a–c) a circle, (d–f) an 8-shaped curve, and (g–i) a simple harmonic curve. DX or DY, displacement in x- or y-direction; DXC or DYC, displacement in x- or y-direction with velocity compensation; VX or VY, velocity in x- or y-direction; VXC or VYC, velocity in x- or y-direction with velocity compensation.

Figure 18.

Trajectories, displacements, and velocities, respectively, of the robot in translation motion along (a–c) a circle, (d–f) an 8-shaped curve, and (g–i) a simple harmonic curve. DX or DY, displacement in x- or y-direction; DXC or DYC, displacement in x- or y-direction with velocity compensation; VX or VY, velocity in x- or y-direction; VXC or VYC, velocity in x- or y-direction with velocity compensation.

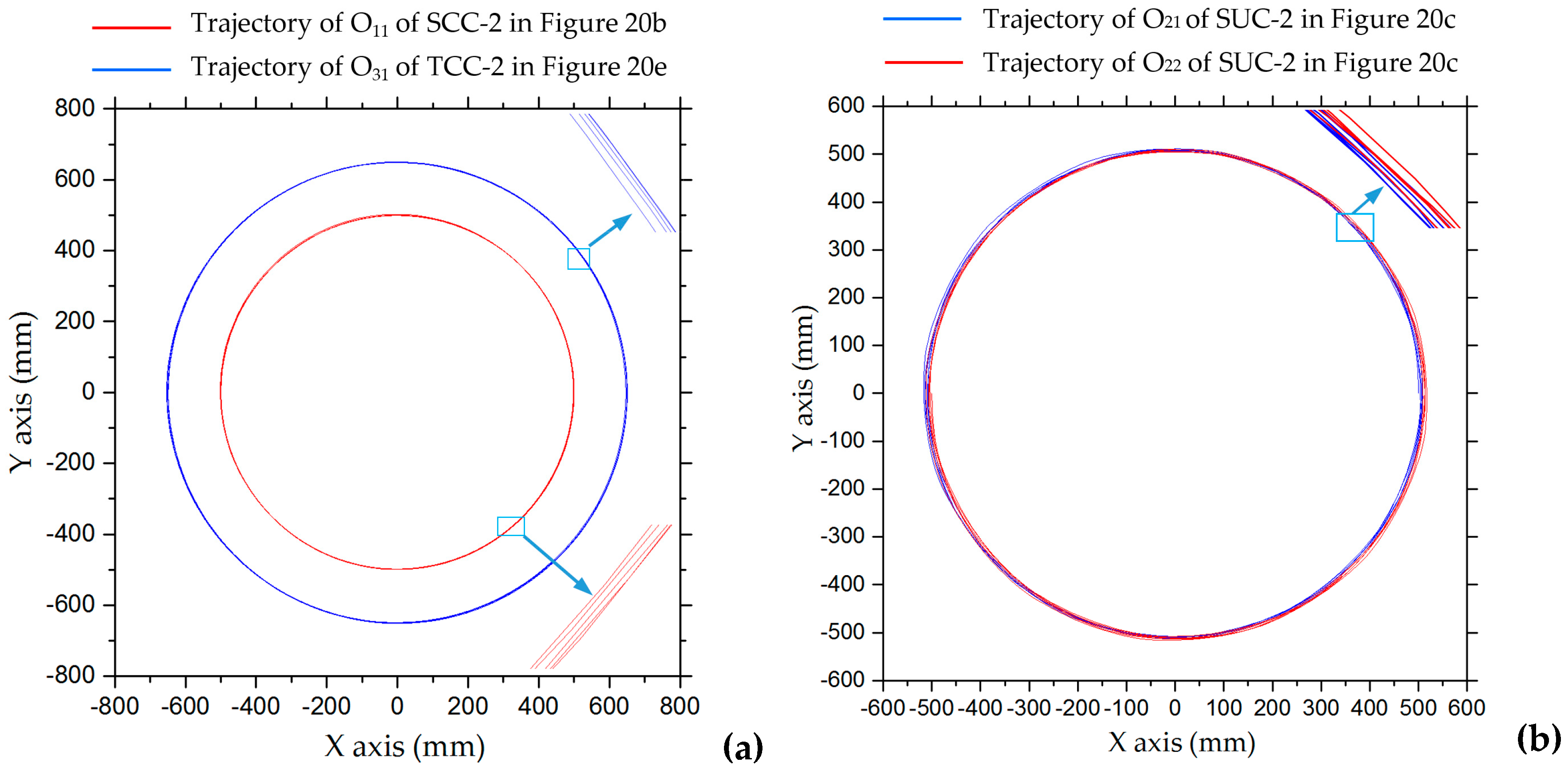

Figure 19.

Configurations of multiple four-Mecanum-wheeled robots: (a) side-by-side connected configuration of two robots (SCC-2); (b) side-by-side unconnected configuration of two robots (SUC-2); (c) tandem connected configuration of two robots (TCC-2); (d) tandem unconnected configuration of two robots (TUC-2); (e) tandem connected configuration of three robots (TCC-3); (f) arbitrary unconnected configuration of two robots (AUC-2); if the two robots are connected, it is an arbitrary connected configuration (ACC-2).

Figure 19.

Configurations of multiple four-Mecanum-wheeled robots: (a) side-by-side connected configuration of two robots (SCC-2); (b) side-by-side unconnected configuration of two robots (SUC-2); (c) tandem connected configuration of two robots (TCC-2); (d) tandem unconnected configuration of two robots (TUC-2); (e) tandem connected configuration of three robots (TCC-3); (f) arbitrary unconnected configuration of two robots (AUC-2); if the two robots are connected, it is an arbitrary connected configuration (ACC-2).

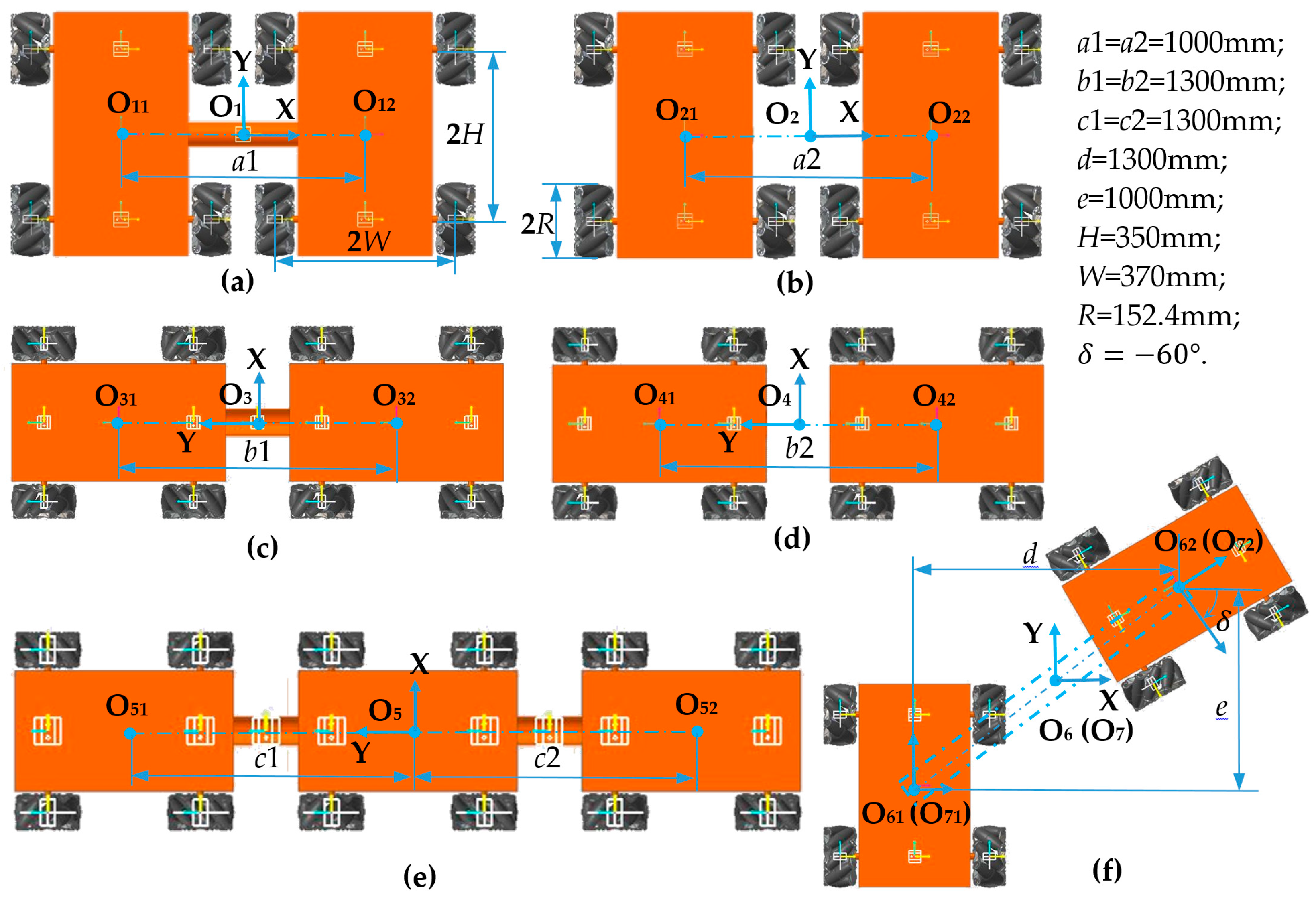

Figure 20.

Simulation of turning on the spot of multiple four-Mecanum-wheeled Robots: (a,b) SCC-2; (c,d) SUC-2; (e,f) TCC-2; (g) TUC-2; (h) TCC-3.

Figure 20.

Simulation of turning on the spot of multiple four-Mecanum-wheeled Robots: (a,b) SCC-2; (c,d) SUC-2; (e,f) TCC-2; (g) TUC-2; (h) TCC-3.

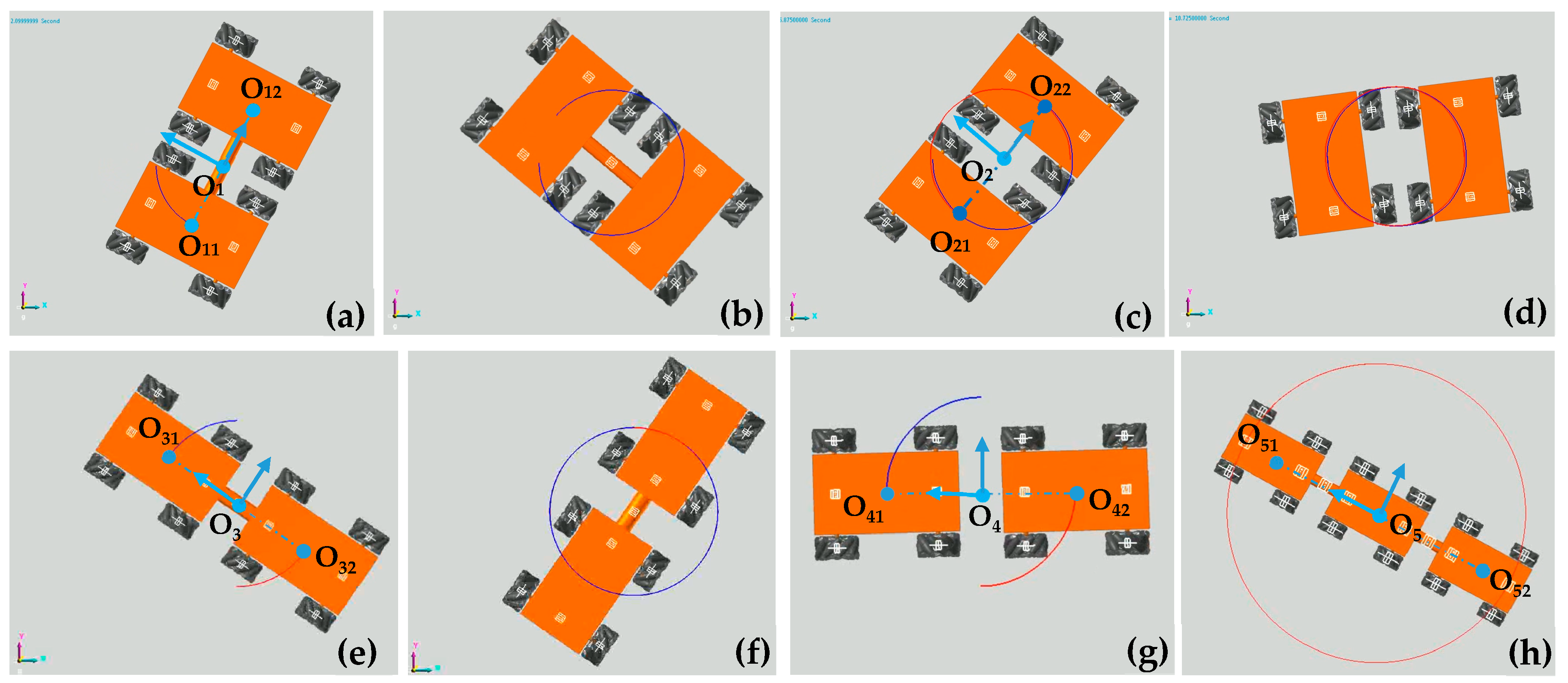

Figure 21.

Trajectories of points on the robots in simulation of turning on the spot after five cycles: (

a) O

11 of SCC-2 in

Figure 20b and O

31 of TCC-2 in

Figure 20e; (

b) O

21 and O

22 of SUC-2 in

Figure 20c.

Figure 21.

Trajectories of points on the robots in simulation of turning on the spot after five cycles: (

a) O

11 of SCC-2 in

Figure 20b and O

31 of TCC-2 in

Figure 20e; (

b) O

21 and O

22 of SUC-2 in

Figure 20c.

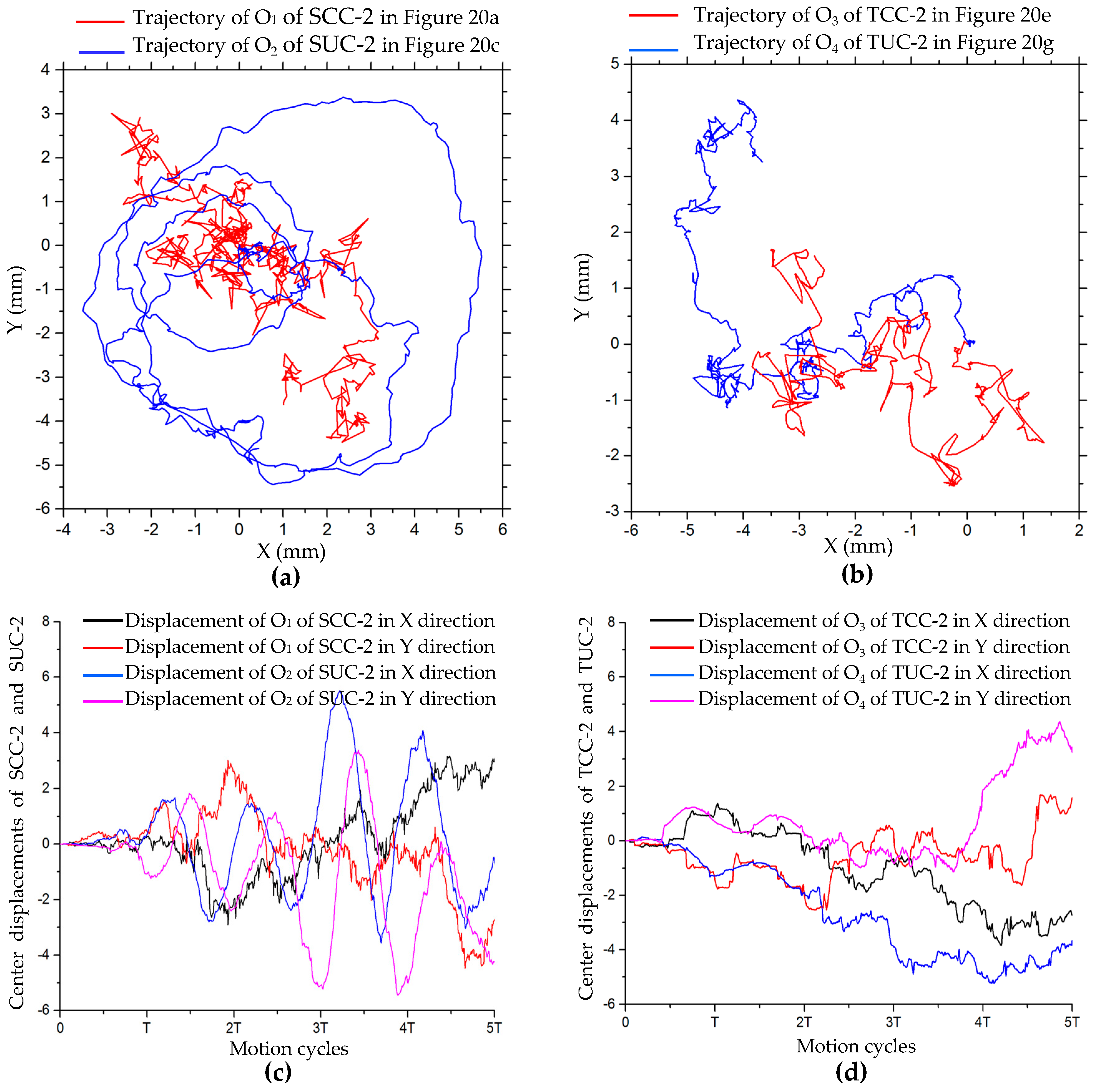

Figure 22.

Trajectories of robot centers and center offset curves for in situ rotating motion: (a) centers O1 of SCC-2 and O2 of SUC-2; (b) centers O3 of TCC-2 and O4 of TUC-2; (c) displacement curves of SCC-2 and SUC-2 in x and y directions; (d) displacement curves of TCC-2 and TUC-2 in x- and y-directions.

Figure 22.

Trajectories of robot centers and center offset curves for in situ rotating motion: (a) centers O1 of SCC-2 and O2 of SUC-2; (b) centers O3 of TCC-2 and O4 of TUC-2; (c) displacement curves of SCC-2 and SUC-2 in x and y directions; (d) displacement curves of TCC-2 and TUC-2 in x- and y-directions.

Figure 23.

Translation simulation process along a circle: (a,b) SUC-2; (c,d) TUC-2; (e) ACC-2; (f,g) AUC-2; (h) the state of AUC-2 after multiple rotation cycles.

Figure 23.

Translation simulation process along a circle: (a,b) SUC-2; (c,d) TUC-2; (e) ACC-2; (f,g) AUC-2; (h) the state of AUC-2 after multiple rotation cycles.

Figure 24.

Trajectories of centers and variation curves of center distance between two robots in translation simulation along a circle: (a) trajectories of centers of SUC-2 and TUC-2; (b) variation curves of center distance between two robots of SUC-2 and TUC-2; (c) simulation trajectory of center O6 of AUC-2; (d) variation curve of center distance between two robots of AUC-2.

Figure 24.

Trajectories of centers and variation curves of center distance between two robots in translation simulation along a circle: (a) trajectories of centers of SUC-2 and TUC-2; (b) variation curves of center distance between two robots of SUC-2 and TUC-2; (c) simulation trajectory of center O6 of AUC-2; (d) variation curve of center distance between two robots of AUC-2.

Figure 25.

Translation motion simulation process of the seven configurations in

Figure 19 along an 8-shaped curve: (

a,

b) SCC-2; (

c,

d) SUC-2; (

e,

f) TCC-2; (

g,

h) TUC-2; (

i,

j) TCC-3; (

k) AUC-2; (

l) ACC-2.

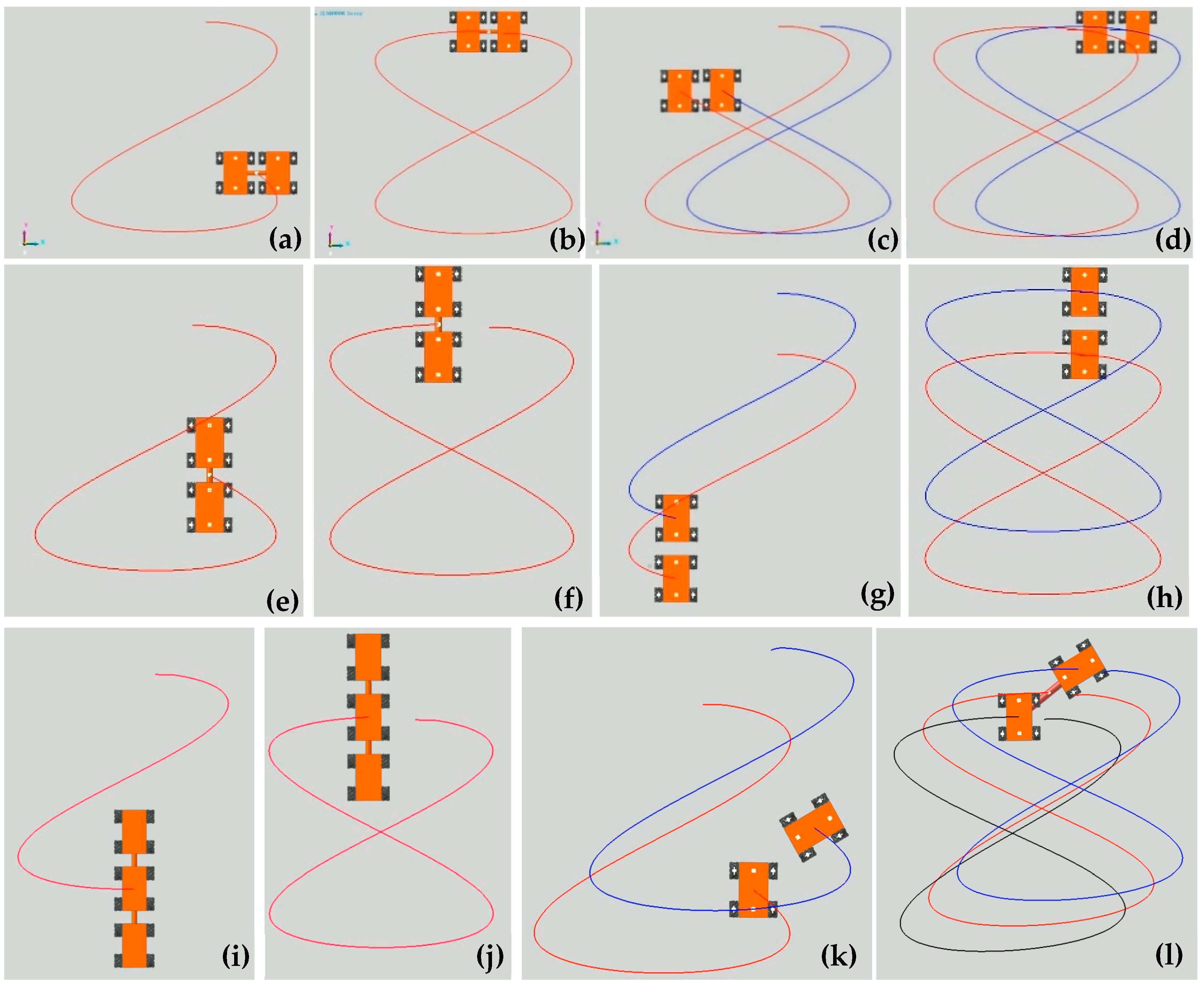

Figure 25.

Translation motion simulation process of the seven configurations in

Figure 19 along an 8-shaped curve: (

a,

b) SCC-2; (

c,

d) SUC-2; (

e,

f) TCC-2; (

g,

h) TUC-2; (

i,

j) TCC-3; (

k) AUC-2; (

l) ACC-2.

Figure 26.

State of four configurations in translation motion along an 8-shaped curve after several cycles: (a) single four-Mecanum-wheeled robot; (b) SCC-2; (c) SUC-2; (d) TCC-2; (e) TUC-2; (f) TCC-3.

Figure 26.

State of four configurations in translation motion along an 8-shaped curve after several cycles: (a) single four-Mecanum-wheeled robot; (b) SCC-2; (c) SUC-2; (d) TCC-2; (e) TUC-2; (f) TCC-3.

Figure 27.

Trajectories of the centers of the robots in translation simulation along an 8-shaped curve: (a) centers O1 of SCC-2 and O2 of SUC-2; (b) centers O3 of TCC-2 and O4 of TUC-2; (c) multiple cycles trajectory of O6 on AUC-2; (d) simulation trajectories of a single robot, TCC-2, SCC-2 and TCC-3.

Figure 27.

Trajectories of the centers of the robots in translation simulation along an 8-shaped curve: (a) centers O1 of SCC-2 and O2 of SUC-2; (b) centers O3 of TCC-2 and O4 of TUC-2; (c) multiple cycles trajectory of O6 on AUC-2; (d) simulation trajectories of a single robot, TCC-2, SCC-2 and TCC-3.

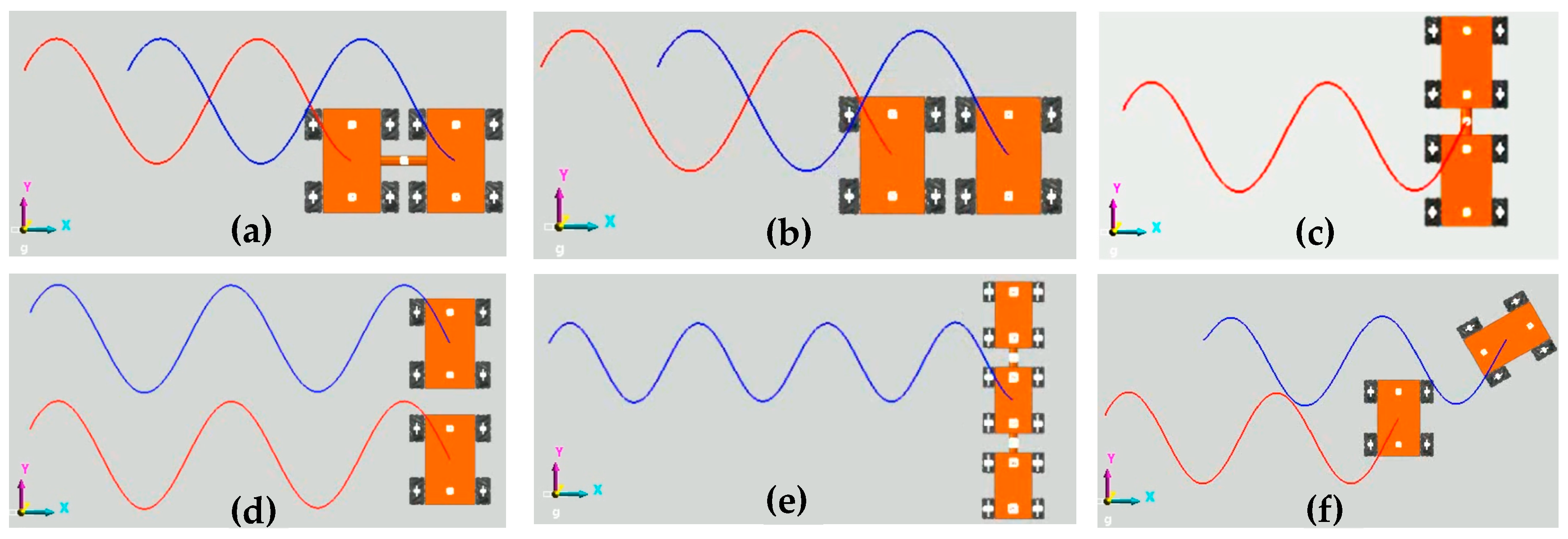

Figure 28.

Translation motion simulation process of configurations along a simple harmonic motion curve: (a) SCC-2; (b) SUC-2; (c) TCC-2; (d) TUC-2; (e) TCC-3; (f) AUC-2.

Figure 28.

Translation motion simulation process of configurations along a simple harmonic motion curve: (a) SCC-2; (b) SUC-2; (c) TCC-2; (d) TUC-2; (e) TCC-3; (f) AUC-2.

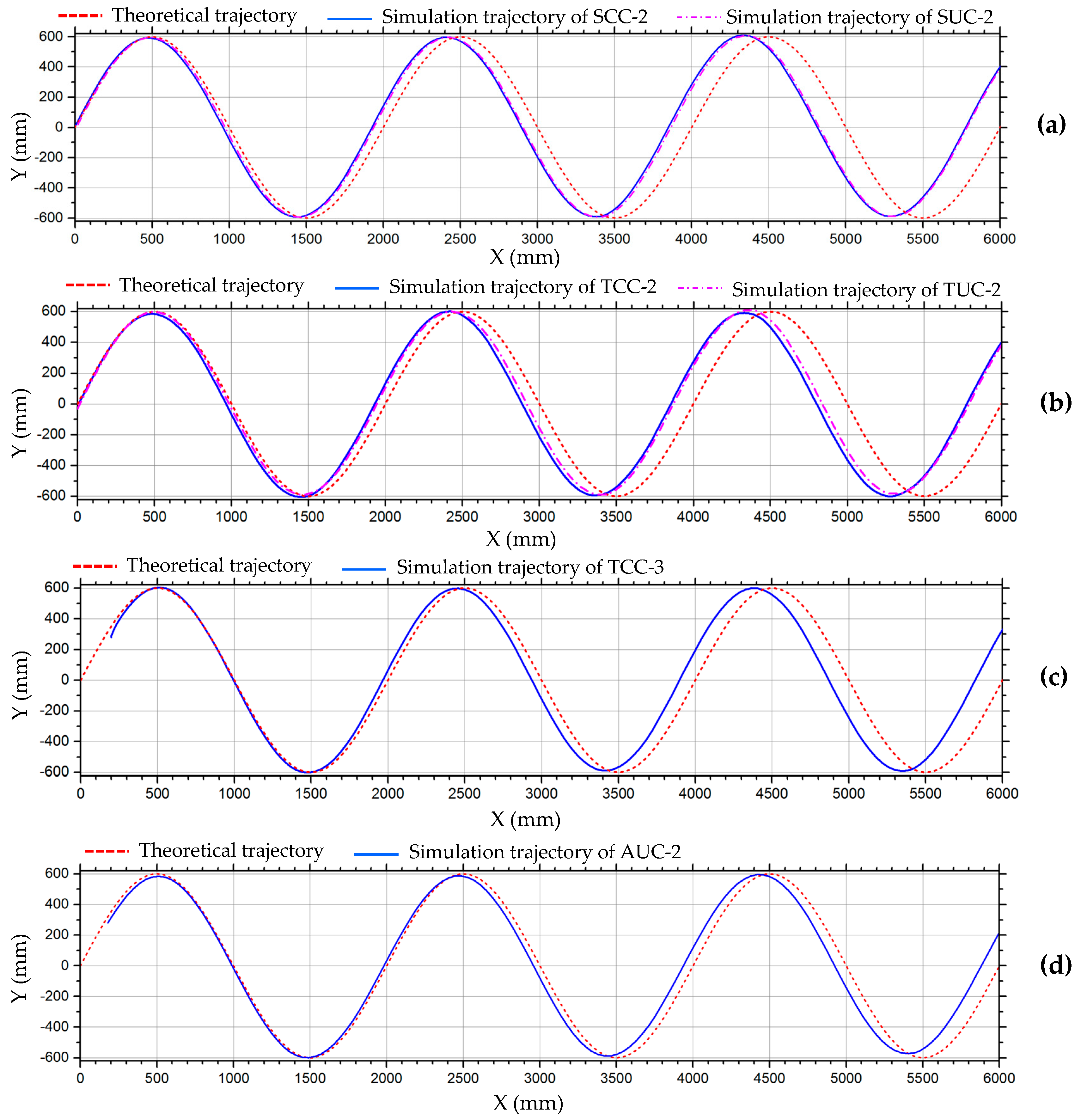

Figure 29.

Simulation trajectories of the six configurations in

Figure 19 along a simple harmonic motion curve: (

a) O

1 of SCC-2 and O

2 of SUC-2; (

b) O

3 of TCC-2 and O

4 of TUC-2; (

c) O

5 of TCC-3; (

d) O

6 of AUC-2.

Figure 29.

Simulation trajectories of the six configurations in

Figure 19 along a simple harmonic motion curve: (

a) O

1 of SCC-2 and O

2 of SUC-2; (

b) O

3 of TCC-2 and O

4 of TUC-2; (

c) O

5 of TCC-3; (

d) O

6 of AUC-2.

Figure 30.

Trajectories of O5 of TCC-3 and O7 of ACC-2 in motion simulation: (a) circular trajectories of TCC-3; (b) 8-shaped trajectories of TCC-3; (c) simple harmonic motion trajectories of TCC-3; (d) circular trajectories of ACC-2; (e) 8-shaped trajectories of ACC-2.

Figure 30.

Trajectories of O5 of TCC-3 and O7 of ACC-2 in motion simulation: (a) circular trajectories of TCC-3; (b) 8-shaped trajectories of TCC-3; (c) simple harmonic motion trajectories of TCC-3; (d) circular trajectories of ACC-2; (e) 8-shaped trajectories of ACC-2.

Table 1.

Material property parameters of ground and roller.

Table 1.

Material property parameters of ground and roller.

| Material | Elastic Modulus E (MPa) | Poisson’s Ratio υ |

|---|

| Concrete | 30,000 | 0.20 |

| Polyurethane | 90 | 0.45 |

Table 2.

Trajectory equations of robot moving in circular, figure-8-shaped, and harmonic curves.

Table 2.

Trajectory equations of robot moving in circular, figure-8-shaped, and harmonic curves.

| Names of Curve | Trajectory Equations in Figure 6 |

|---|

| Circular curve | , where , , , |

| Figure-8-shaped curve | , where , |

| Harmonic curve | , where , , |

Table 3.

Velocity errors and compensation coefficients in longitudinal and lateral motion simulation.

Table 3.

Velocity errors and compensation coefficients in longitudinal and lateral motion simulation.

| Motion Mode | Set Velocity Value (mm/s) | Average Simulation Velocity (mm/s) | Relative Error (%) | Compensation Coefficient | Average Compensation Coefficient |

|---|

| Longitudinal translation motion | 100 | 99.767 | −0.233 | 1.00234 | 1.002 |

| 200 | 199.564 | −0.218 | 1.00218 |

| 300 | 299.339 | −0.220 | 1.00221 |

| 400 | 399.151 | −0.212 | 1.00212 |

| 500 | 498.905 | −0.219 | 1.00219 |

| Lateral translation motion | 100 | 96.928 | −3.072 | 1.03169 | 1.033 |

| 200 | 193.684 | −3.158 | 1.03261 |

| 300 | 290.504 | −3.165 | 1.03269 |

| 400 | 386.930 | −3.268 | 1.03378 |

| 500 | 483.158 | −3.368 | 1.03486 |

Table 4.

Velocity error of simulation results.

Table 4.

Velocity error of simulation results.

| Oblique 45° Motion | Set Velocity Value (mm/s) | Average Simulation Velocity in Steady State (mm/s) | Relative Error (%) |

|---|

| X- axis direction | 200 | 196.566 | −1.717 |

| Y- axis direction | 200 | 196.65 | −1.675 |

| X- axis direction | 500 | 490.061 | −1.988 |

| Y- axis direction | 500 | 490.164 | −1.967 |

Table 5.

Relative error of angular velocity in simulation of turning on the spot.

Table 5.

Relative error of angular velocity in simulation of turning on the spot.

| Set Angular Velocity Value (rad/s) | Average Angular Velocity (rad/s) | Relative Error (%) | Compensation Coefficient |

|---|

| (=0.262) | 0.257 | −1.753 | 1.0195 |

| (=0.524) | 0.514 | −1.920 | 1.0195 |

| (=0.785) | 0.768 | −2.182 | 1.0221 |

Table 6.

Relative errors of displacement in motion simulation along circular and 8-shaped curves.

Table 6.

Relative errors of displacement in motion simulation along circular and 8-shaped curves.

| Motion Mode | Maximum Displacement (mm) | Minimum Displacement (mm) | Relative Error (%) |

|---|

| Circular motion in Figure 12a | X-axis | 2430.51 | −2395.56 | −3.48 |

| Y-axis | 2494.11 | −2498.98 | −0.14 |

| 8-shaped curve motion in Figure 12b | X-axis | 2423.55 | −2430.37 | −2.92 |

| Y-axis | 2494.90 | −2490.90 | −0.28 |

Table 7.

Velocity errors and compensation coefficients in motion tests.

Table 7.

Velocity errors and compensation coefficients in motion tests.

| Motion Mode | Set Velocity Value (mm/s) | Average Test Velocity in Steady State (mm/s) | Relative Error (%) | Compensation Coefficient |

|---|

| Longitudinal translation motion | 100 | 97.822 | −2.178 | 1.022 |

| 200 | 196.287 | −1.857 | 1.019 |

| 300 | 293.731 | −2.090 | 1.021 |

| 400 | 390.558 | −2.361 | 1.024 |

| 500 | 486.907 | −2.619 | 1.027 |

| Lateral translation motion | 100 | 87.621 | −12.379 | 1.141 |

| 200 | 174.193 | −12.904 | 1.148 |

| 300 | 260.675 | −13.108 | 1.151 |

| 400 | 345.426 | −13.644 | 1.158 |

| 500 | 432.065 | −13.587 | 1.157 |

Table 8.

Relative error of angular velocity in motion test of turning on the spot.

Table 8.

Relative error of angular velocity in motion test of turning on the spot.

| Set Angular Velocity Value (rad/s) | Average Angular Velocity (rad/s) | Relative Error (%) |

|---|

| (=0.524) | 0.511 | −2.550 |

| (=1.047) | 1.020 | −2.467 |

Table 9.

Relative errors of displacement in motion test of complex trajectories.

Table 9.

Relative errors of displacement in motion test of complex trajectories.

| Motion Mode | Dmax (mm) | Dmin (mm) | DCmax (mm) | DCmin (mm) | RED (%) | REDC (%) |

|---|

| Circular motion in Figure 18a | X-axis | 834.757 | −860.636 | 978.495 | −981.766 | −15.23% | −1.99% |

| Y-axis | 978.196 | −964.902 | 982.437 | −987.510 | −2.85% | −1.50% |

| 8-shaped curve motion in Figure 18d | X-axis | 807.439 | −914.31 | 952.785 | −1008.12 | −13.91% | −1.95% |

| Y-axis | 995.717 | −980.872 | 1013.374 | −985.743 | −1.17% | −0.04% |

| A simple harmonic curve in Figure 18g | Y-axis | 950.934 | −974.760 | 990.842 | −1005.300 | −3.715% | −0.191% |