The Analysis of FBG Central Wavelength Variation with Crack Propagation Based on a Self-Adaptive Multi-Peak Detection Algorithm

Abstract

1. Introduction

2. Central Wavelength Detection Algorithm

2.1. De-Noising Pre-treatment of the FBG Reflectivity Spectrum

2.2. Flow of the Multi-Peak Central Wavelength Detection Algorithm

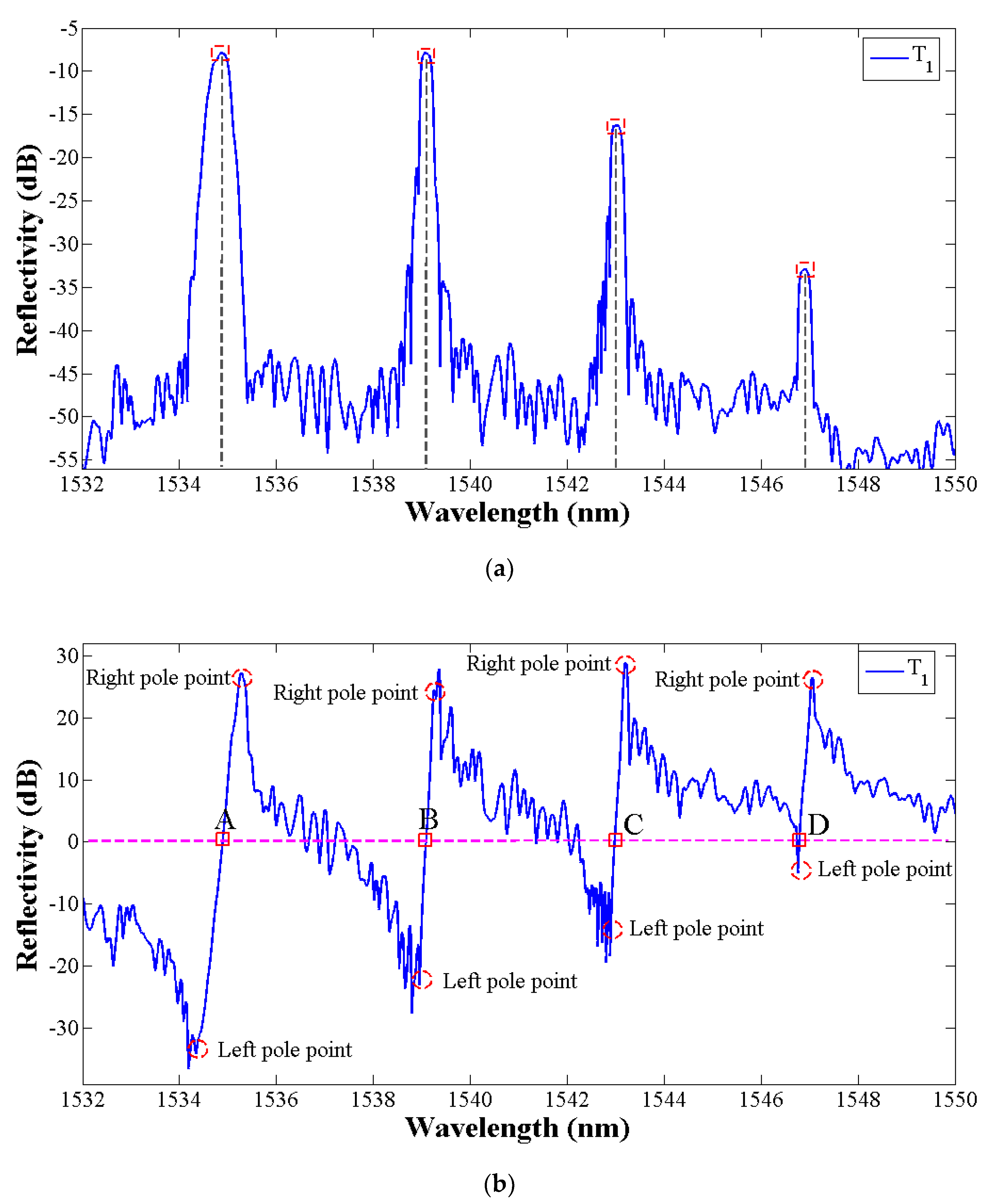

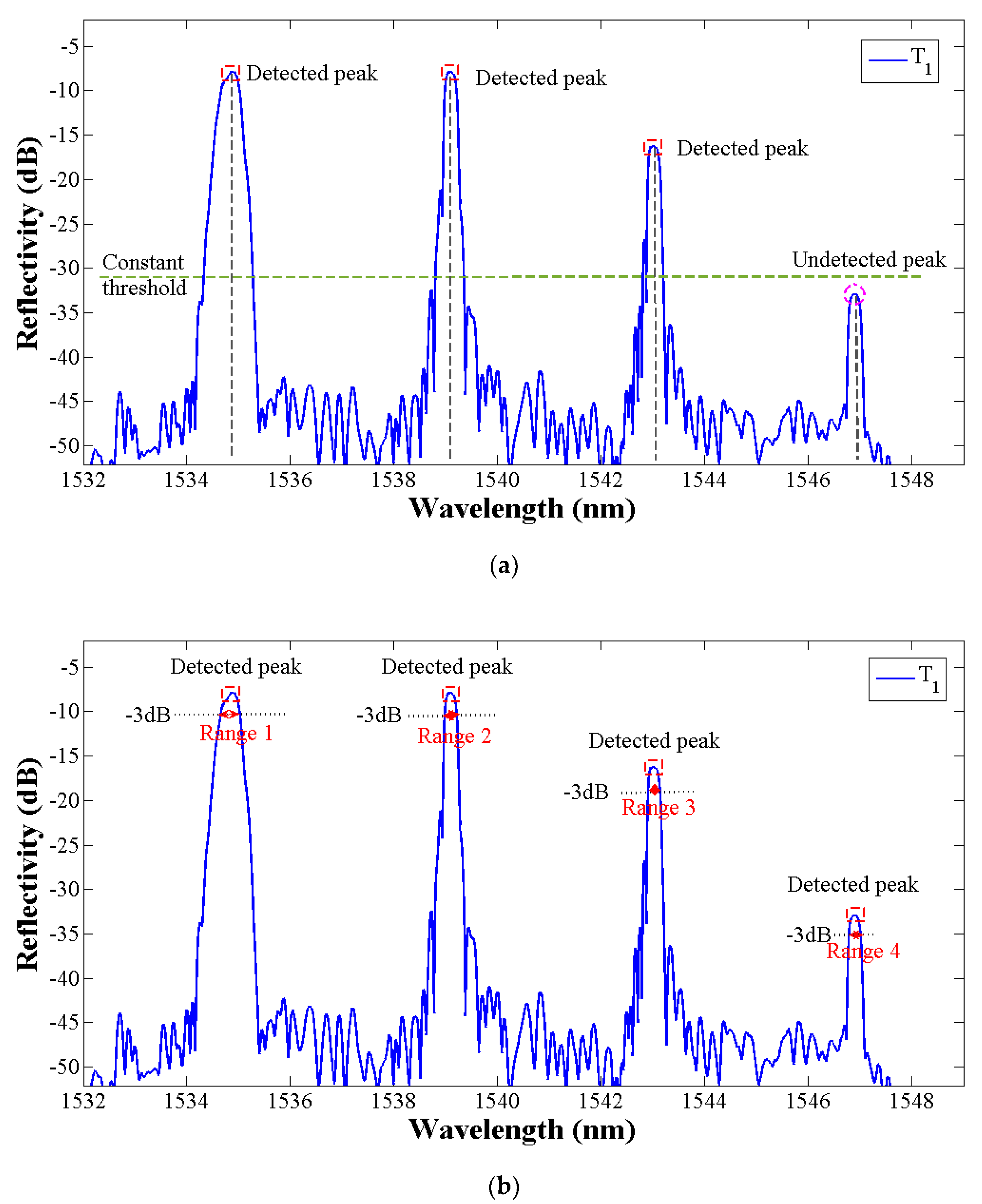

2.2.1. Pre-position of the Peak and the Peak Region Segmentation

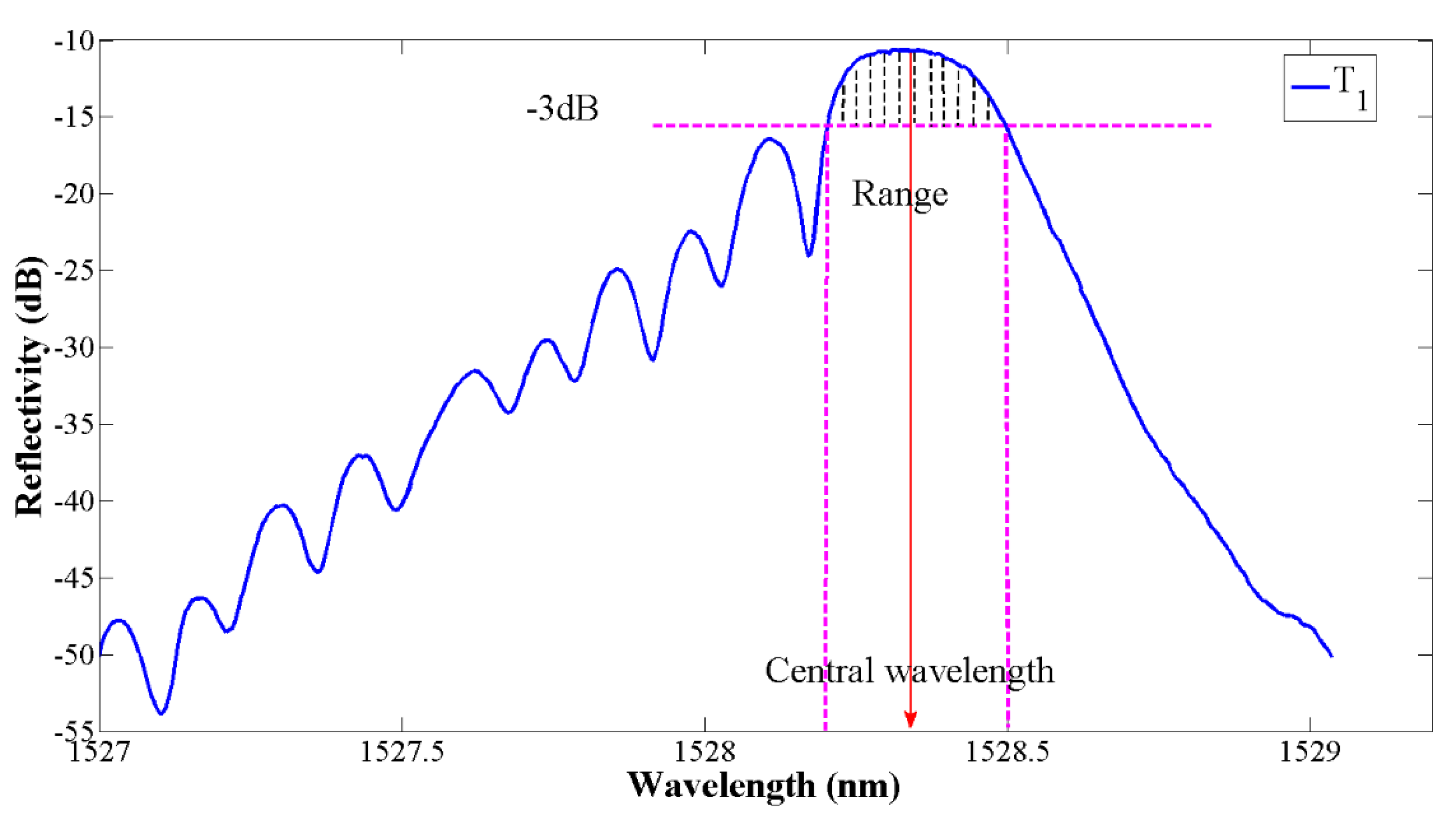

2.2.2. Central Wavelength Seeking

3. Damage Monitoring Experiment Design

3.1. Specimens: Material and Geometry

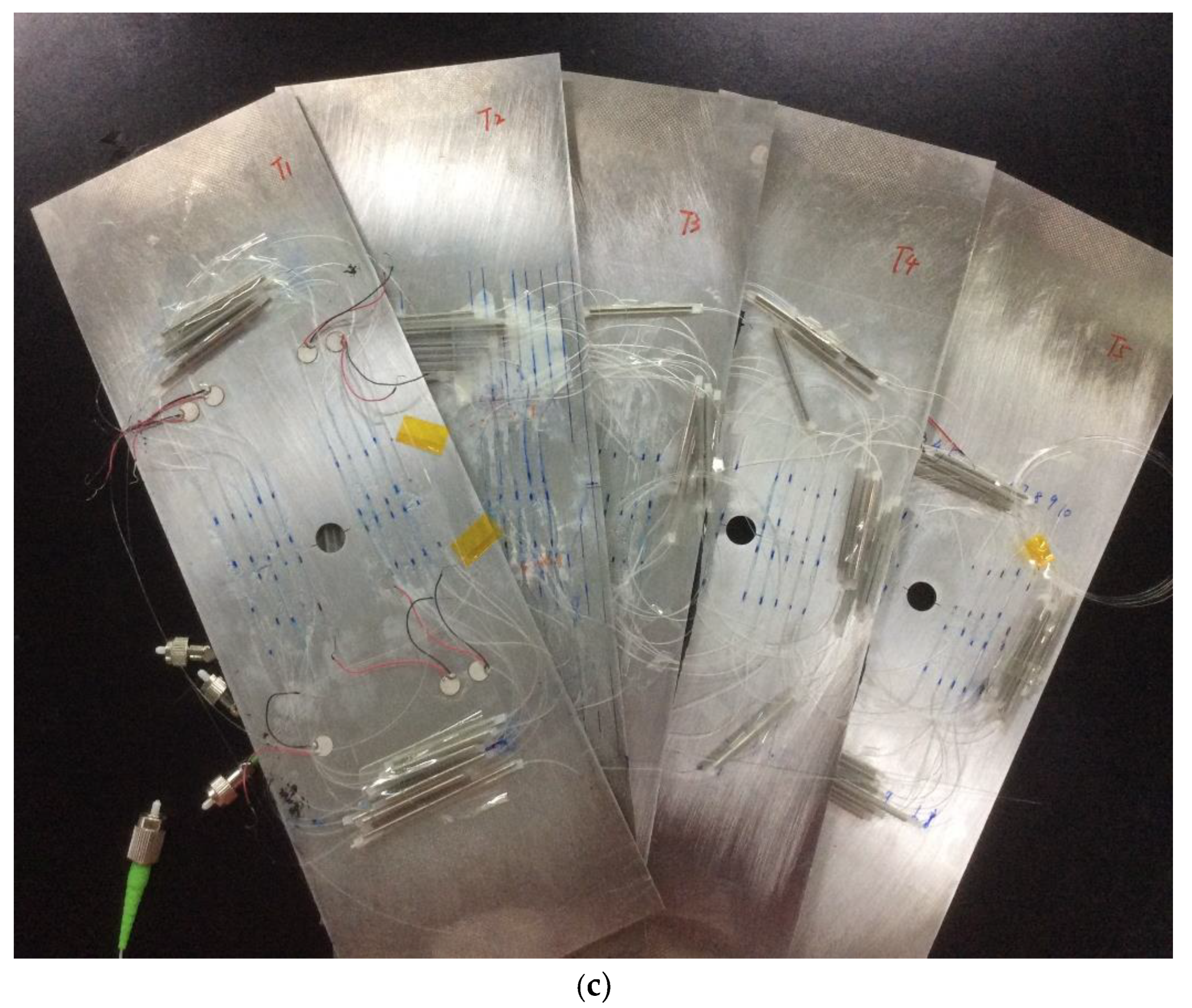

3.2. FBG Sensors Network Design

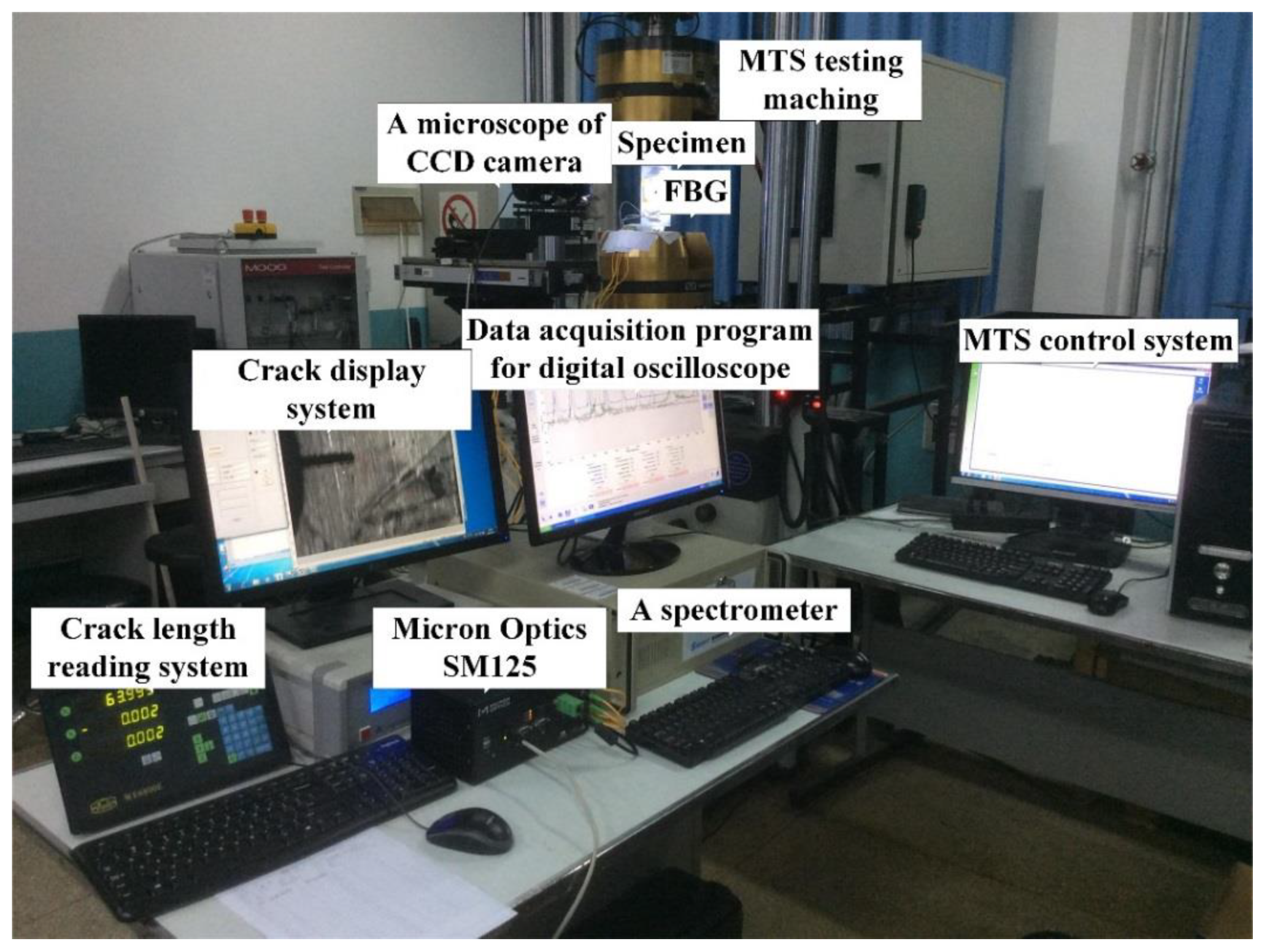

3.3. Experimental Setup

4. Results and Discussion

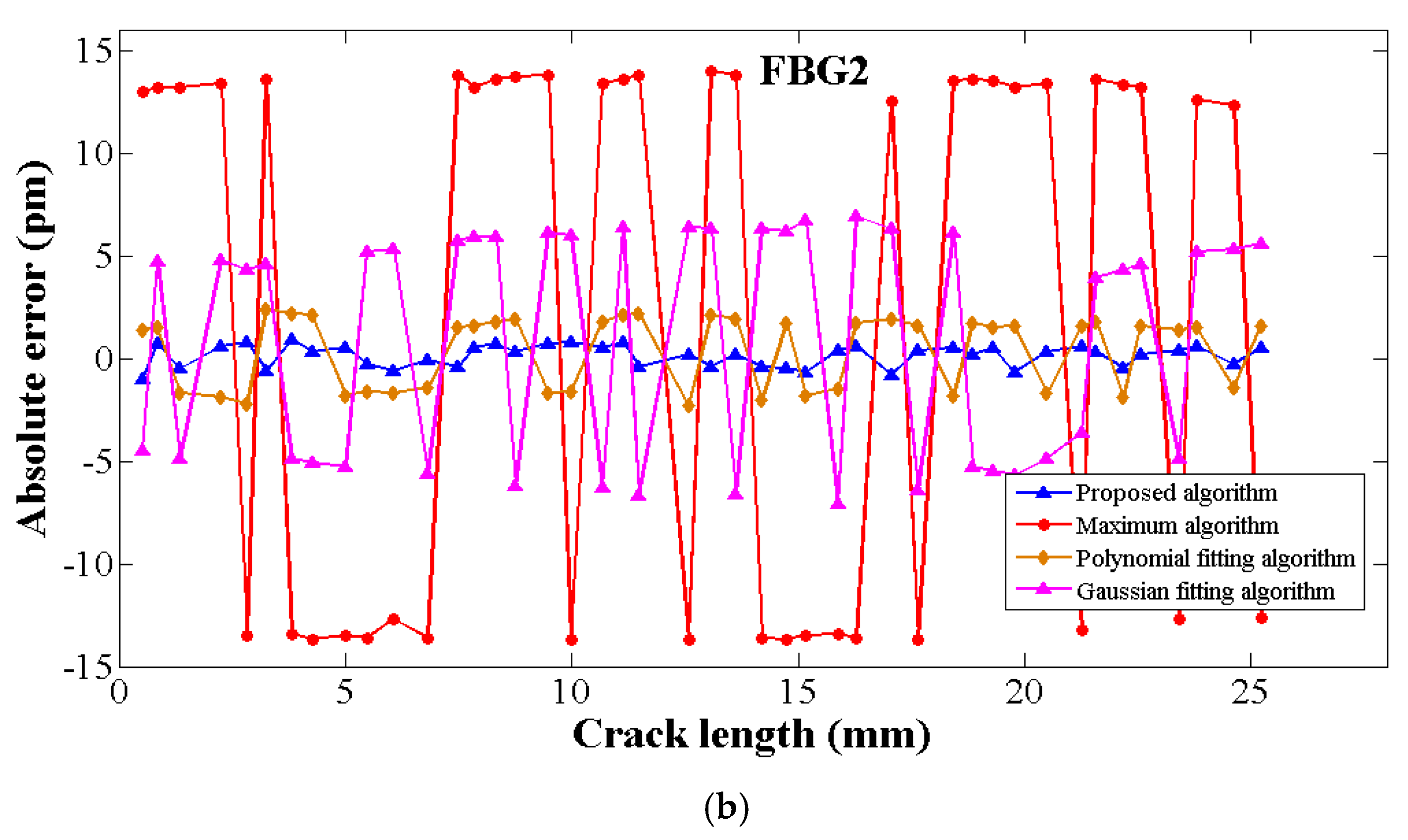

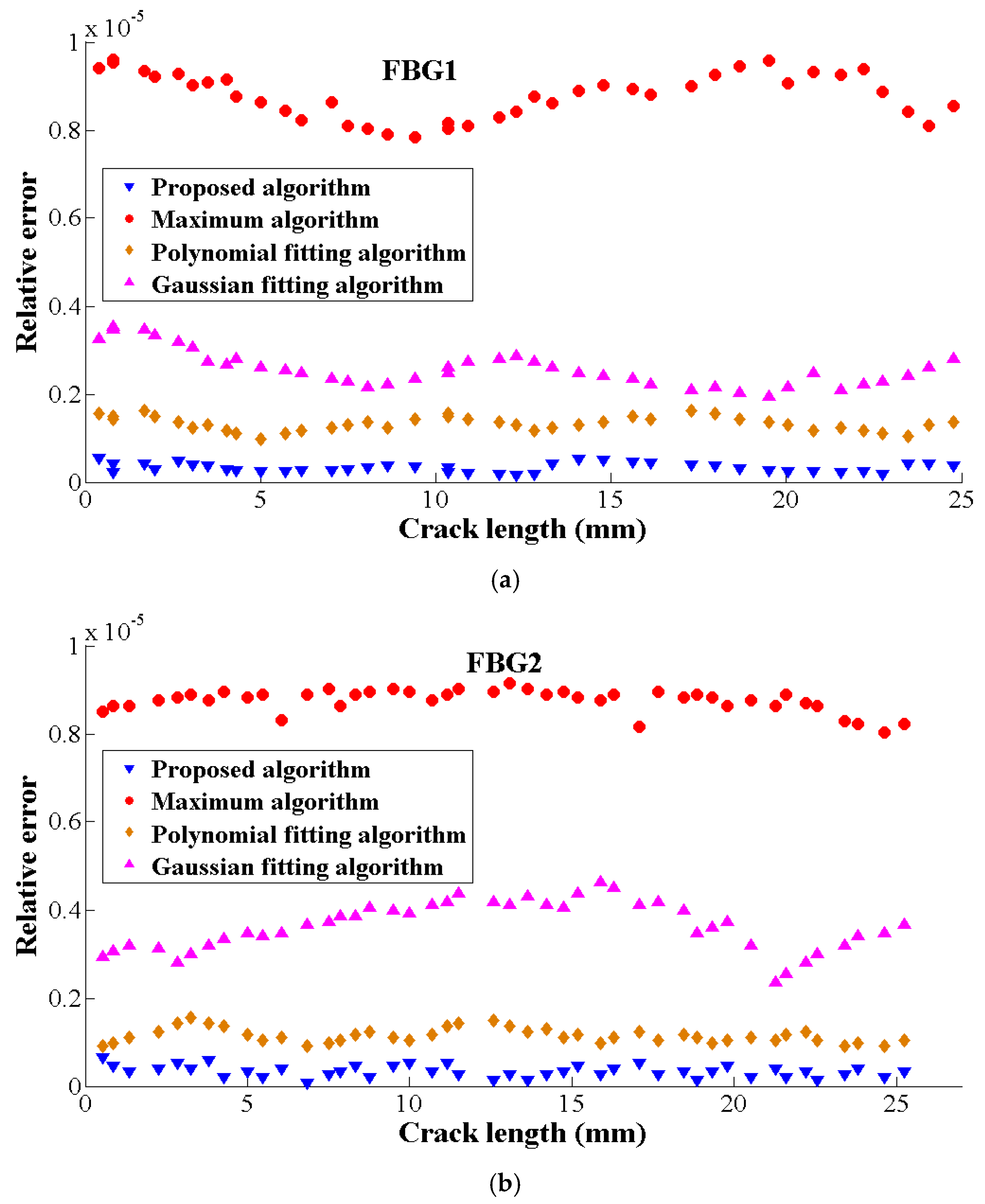

4.1. Evaluate the Effectivity of the Central Wavelength Algorithm

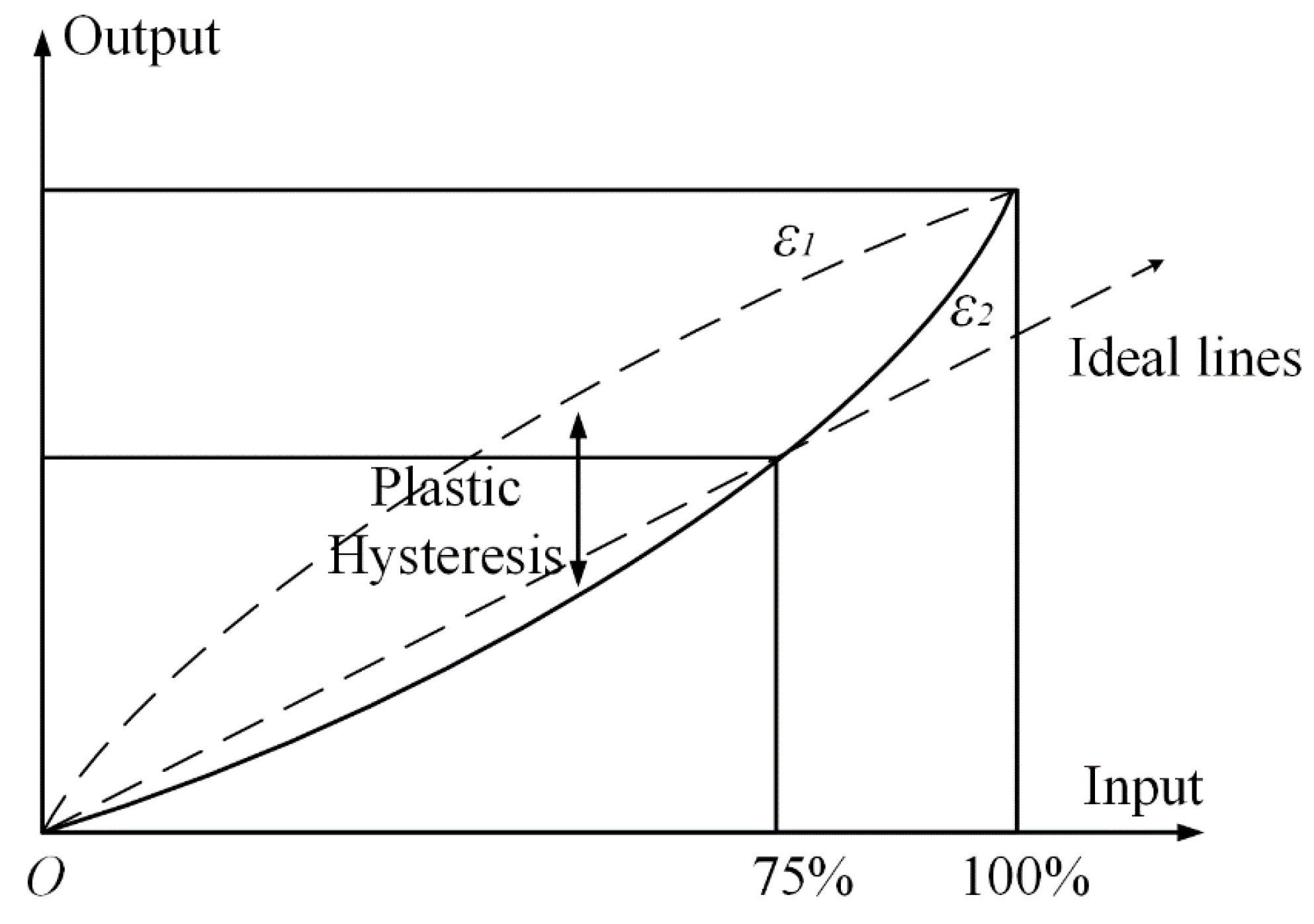

4.2. Analysis the Central Wavelength Shifts with Crack Propagation

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Balageas, D. Introduction to Structural Health Monitoring. In Structural Health Monitoring; ISTE: Washington, DC, USA, 2010. [Google Scholar]

- Grattan, K.T.V.; Sun, T. Fiber optic sensor technology: An overview. Sens. Actuators A Phys. 2000, 82, 40–61. [Google Scholar] [CrossRef]

- Zhou, J.; Cai, Z.; Zhao, P.; Tang, B. Efficient Sensor Placement Optimization for Shape Deformation Sensing of Antenna Structures with Fiber Bragg Grating Strain Sensors. Sensors 2018, 18, 2481. [Google Scholar] [CrossRef] [PubMed]

- Xiao, F.; Chen, G.; Hulsey, J. Monitoring Bridge Dynamic Responses Using Fiber Bragg Grating Tiltmeters. Sensors 2017, 17, 2390. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhang, J. Model Study of the Influence of Ambient Temperature and Installation Types on Surface Temperature Measurement by Using a Fiber Bragg Grating Sensor. Sensors 2016, 16, 975. [Google Scholar] [CrossRef] [PubMed]

- Okabe, Y.; Tsuji, R.; Takeda, N. Application of chirped fiber Bragg grating sensors for identification of crack locations in composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 59–65. [Google Scholar] [CrossRef]

- Bouiadjra, B.B.; Elmeguenni, M.; Benguediab, M.; Belhouari, M.; Nait-Abdelaziz, M. Numerical estimation of the effects of microcavities on the plastic zone size ahead of the crack tip in aluminum alloy 2024 T3. Mater. Des. 2009, 30, 752–757. [Google Scholar] [CrossRef]

- Jin, B.; Zhang, W.; Zhang, M.; Ren, F.; Dai, W.; Wang, Y. Investigation on Characteristic Variation of the FBG Spectrum with Crack Propagation in Aluminum Plate Structures. Materials 2017, 10, 588. [Google Scholar] [CrossRef] [PubMed]

- Holmes, C.; Carpenter, L.G.; Gates, J.C.; Smith, P.G.R. Miniaturization of Bragg-multiplexed membrane transducers. J. Micromech. Microeng. 2012, 22, 025017–25023. [Google Scholar] [CrossRef]

- Ren, F.; Zhang, W.; Li, Y.; Lan, Y.; Xie, Y.; Dai, W. The Temperature Compensation of FBG Sensor for Monitoring the Stress on Hole-edge. IEEE Photon. J. 2018, 10, 1–9. [Google Scholar] [CrossRef]

- Jesus, C.; Jorge, P.A.S.; Baptista, J.M.; Frazão, O. Cladding modes FBG curvature sensor based on a core misaligned splice. Proc. SPIE 2011, 7753, 77538U. [Google Scholar]

- Tosi, D. Review and Analysis of Peak Tracking Techniques for Fiber Bragg Grating Sensors. Sensors 2017, 17, 2368. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.J.; Bai, J.; Wu, Z.T.; Zhao, X.; Zhang, J. Optimization and Comparison of the Peak-detection Algorithms for the Reflection Spectrum of Fiber Bragg Grating. Acta Photonica Sin. 2015, 5, 323–334. [Google Scholar]

- Liu, F.; Tong, X.; Zhang, C.; Deng, C.; Xiong, Q.; Zheng, Z.; Wang, P. Multi-peak detection algorithm based on the Hilbert transform for optical FBG sensing. Opt. Fiber Technol. 2018, 45, 47–52. [Google Scholar] [CrossRef]

- Lee, H.W.; Park, H.J.; Lee, J.H.; Song, M. Accuracy improvement in peak positioning of spectrally distorted fiber Bragg grating sensors by Gaussian curve fitting. Appl. Opt. 2007, 46, 2205–2208. [Google Scholar] [CrossRef] [PubMed]

- Park, H.J.; Song, M. Linear FBG Temperature Sensor Interrogation with Fabry-Perot ITU Multi-wavelength Reference. Sensors 2008, 8, 6769–6776. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Wang, K.; Liu, H.L.; Chen, L.J.; Yang, X. Processing FBG sensing signals with three-point peak-detection algorithm. Opt. Precis. Eng. 2013, 21, 2751–2756. [Google Scholar] [CrossRef]

- Theodosiou, A.; Komodromos, M.; Kalli, K. Accurate and fast demodulation algorithm for multi-peak FBG reflection spectra using a combination of cross correlation and Hilbert transformation. J. Lightwave Technol. 2017, 35, 3956–3962. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, K.; Liu, H.L. Self-Adaptive Multi-Peak Detection Algorithm for FBG Sensing Signal. IEEE Sens. J. 2016, 16, 2658–2665. [Google Scholar] [CrossRef]

- Hue, C.; Le Cadre, J.P.; Perez, P. Sequential Monte Carlo methods for multiple target tracking and data fusion. IEEE Trans. Signal Process. 2002, 50, 309–325. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, D.; Zeng, J.; Asundi, A. Genetic algorithm-support vector regression for high reliability SHM system based on FBG sensor network. Opt. Lasers Eng. 2011, 50, 148–153. [Google Scholar] [CrossRef]

- Liang, J.J.; Suganthan, P.N.; Chan, C.C.; Huang, V.L. Wavelength detection in FBG sensor network using tree search DMS-PSO. IEEE Photonics Technol. Lett. 2006, 18, 1305–1307. [Google Scholar] [CrossRef]

- Liang, J.J.; Chan, C.C. Improving the performance of a FBG sensor network using a novel dynamic multi-swarm particle swarm optimizer. Proc. SPIE 2005, 1, 373–378. [Google Scholar]

- Mahmoud, S.; Lease, K. The effect of specimen thickness on the experimental characterization of critical crack-tip-opening angle in 2024-T351 aluminum alloy. Eng. Fract. Mech. 2003, 70, 443–456. [Google Scholar] [CrossRef]

- Peters, K.; Pattis, P.; Botsis, J.; Giaccari, P. Experimental verification of response of embedded optical fiber Bragg grating sensors in non-homogeneous strain fields. Opt. Lasers Eng. 2000, 33, 107–119. [Google Scholar] [CrossRef]

- Huang, H.M.; Yuan, S.F. Study on the spectral response of fiber Bragg grating sensor under non-uniform strain distribution in structural health monitoring. Optoelectron. Lett. 2011, 7, 109–112. [Google Scholar] [CrossRef]

- Pereira, G.F.; Mikkelsen, L.P.; Mcgugan, M. Crack Detection in Fibre Reinforced Plastic Structures Using Embedded Fibre Bragg Grating Sensors: Theory, Model Development and Experimental Validation. PLoS ONE 2015, 10, e0141495. [Google Scholar] [CrossRef] [PubMed]

- Pereira, G.; Mikkelsen, L.P.; Mcgugan, M. Fibre Bragg Grating Sensor Signal Post-processing Algorithm: Crack Growth Monitoring in Fibre Reinforced Plastic Structures. Photoptics 2015, 181, 63–80. [Google Scholar]

- Su, Y.; Zhu, Y.; Zhang, B.; Zhou, H.; Li, J.; Wang, F. Spectral characterization of polarization dependent loss in fiber Bragg grating under local pressure and the analysis of secondary peak. Opt. Fiber Technol. 2015, 24, 77–83. [Google Scholar] [CrossRef]

- McKenzie, I.; Jones, R.; Marshall, I.H.; Galea, S. Optical fibre sensors for health monitoring of bonded repair systems. Compos. Struct. 2000, 50, 405–416. [Google Scholar] [CrossRef]

- Yashiro, S.; Takeda, N.; Okabe, T.; Sekine, H. A new approach to predicting multiple damage states in composite laminates with embedded FBG sensors. Compos. Sci. Technol. 2005, 65, 659–667. [Google Scholar] [CrossRef]

- Sans, D.; Stutz, S.; Renart, J.; Mayugo, J.A.; Botsis, J. Crack tip identification with long FBG sensors in mixed-mode delamination. Compos. Struct. 2012, 94, 2879–2887. [Google Scholar] [CrossRef]

- Takeda, S.; Okabe, Y.; Takeda, N. Delamination detection in CFRP laminates with embedded small-diameter fiber Bragg grating sensors. Compos. Part A 2002, 33, 1–980. [Google Scholar] [CrossRef]

- Dong, X.Y.; Guan, B.O.; Yuan, S.Z.; Dong, X.Y.; Tam, H.Y. Strain gradient chirp of uniform fiber Bragg grating without shift of central Bragg wavelength. Opt. Commun. 2002, 202, 91–95. [Google Scholar] [CrossRef]

- Chong, L.; Liu, X.; Li, S. Study on strain properties for fiber Bragg grating sensor. Photon. Optoelectron. Meet. 2008. [Google Scholar] [CrossRef]

- Dragomiretskiy, K.; Zosso, D. Variational Mode Decomposition. IEEE Trans. Signal Process. 2014, 62, 531–544. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, M. Denoising of the Fiber Bragg Grating Deformation Spectrum Signal Using Variational Mode Decomposition Combined with Wavelet Thresholding. Appl. Sci. 2019, 9, 180. [Google Scholar] [CrossRef]

- Soto, M.A.; Ramírez, J.A.; Thévenaz, L. Optimizing Image Denoising for Long-Range Brillouin Distributed Fiber Sensing. J. Lightwave Technol. 2018, 36, 1168–1177. [Google Scholar] [CrossRef]

- Jiao, S.; Shi, W. Self-adaptive partial discharge denoising based on variational mode decomposition and wavelet packet transform. Chin. Autom. Congr. 2017, 7301–7306. [Google Scholar] [CrossRef]

- Li, M.; Yao, J. All-fiber temporal photonic fractional Hilbert transformer based on a directly designed fiber Bragg grating. Opt. Lett. 2010, 35, 223. [Google Scholar] [CrossRef] [PubMed]

- Cai, L.J.; Li, Z.Y.; Tang, Z.H.; Meng, W.; Liu, Q. A Novel Peak-Seek Algorithm Used in FBG Sensor Demodulation System for Vibration Monitoring. Appl. Mech. Mater. 2012, 160, 135–139. [Google Scholar] [CrossRef]

- T.C. O’Haver. 2017. Available online: https://terpconnect.umd.edu/~toh/spectrum/Integration.html (accessed on 1 March 2019).

- Chen, Y.; Yang, X.; Liu, H.L.; Yang, K.; Zhang, Y.L. Processing FBG Sensing Signals with Exponent Modified Gaussian Curve Fitting Peak Detection Method. Spectrosc. Spectr. Anal. 2016, 36, 1526–1531. [Google Scholar]

- Hutchinson, J.W. Plastic stress and strain fields at a crack tip. J. Mech. Phys. Solids 1968, 16, 337–342. [Google Scholar] [CrossRef]

- Chen, B.L.; Shin, C.S. Fiber Bragg Gratings Array for Structural Health Monitoring. Adv. Mater. Res. 2008. [Google Scholar] [CrossRef]

- Tanaka, N.; Okabe, Y.; Takeda, N. Temperature-compensated strain measurement using fiber Bragg grating sensors embedded in composite laminates. Smart Mater. Struct. 2003, 12, 940. [Google Scholar] [CrossRef]

- James, S.W.; Dockney, M.L.; Tatam, R.P. Simultaneous independent temperature and strain measurement using in-fibre Bragg grating sensors. Electron. Lett. 1996, 32, 1133–1134. [Google Scholar] [CrossRef]

- Patrick, H.J.; Williams, G.M.; Kersey, A.D.; Pedrazzani, J.; Vengsarkar, A. Hybrid fiber Bragg grating/long period fiber grating sensor for strain/temperature discrimination. IEEE Photon. Technol. Lett. 1996, 8, 1223–1225. [Google Scholar] [CrossRef]

- Farahi, F.; Webb, D.J.; Jones, J.D.C.; Jackson, D.A. Simultaneous measurement of temperature and strain: Cross-sensitivity considerations. J. Lightwave Technol. 1990, 8, 138–142. [Google Scholar] [CrossRef]

- Fernandez-Valdivielso, C.; Matıas, I.R.; Arregui, F.J. Simultaneous measurement of strain and temperature using a fiber Bragg grating and a thermochromic material. Sens. Actuators A Phys. 2002, 101, 107–116. [Google Scholar] [CrossRef]

- Flanagan, T.B.; Clewley, J.D. Hysteresis in metal hydrides. J. Less Common Met. 1982, 83, 127–141. [Google Scholar] [CrossRef]

- Chang, C.S.; Pimbley, W.T.; Conway, H.D. An analysis of metal fatigue based on hysteresis energy. Exp. Mech. 1968, 8, 133–137. [Google Scholar] [CrossRef]

- Balasubramaniam, R. Hysteresis in metal–hydrogen systems. J. Alloys Compd. 1997, 253, 203–206. [Google Scholar] [CrossRef]

- Mayergoyz, I.D. Mathematical Models of Hysteresis; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Krasnosel’skii, M.A.; Pokrovskii, A.V. Systems with Hysteresis; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Davino, D.; Visone, C.; Ambrosino, C.; Campopiano, S.; Cusano, A.; Cutolo, A. Compensation of hysteresis in magnetic field sensors employing Fiber Bragg Grating and magneto-elastic materials. Sens. Actuators A Phys. 2008, 147, 127–136. [Google Scholar] [CrossRef]

- Fusiek, G.; Niewczas, P.; Dziuda, L.; McDonald, J.R. Hysteresis compensation for a piezoelectric fiber optic voltage sensor. Opt. Eng. 2005, 44, 114402. [Google Scholar] [CrossRef]

- Wan, K.T.; Leung, C.K.Y.; Olson, N.G. Investigation of the strain transfer for surface-attached optical fiber strain sensors. Smart Mater. Struct. 2008, 17, 035037. [Google Scholar] [CrossRef]

- Yu, Y.; Luo, L.; Li, B.; Guo, L.; Yan, J.; Soga, K. Double peak-induced distance error in short-time-Fourier-transform-Brillouin optical time domain reflectometers event detection and the recovery method. Appl. Opt. 2015, 54, E196–E202. [Google Scholar] [CrossRef] [PubMed]

- Bassett, G., Jr.; Koenker, R. Asymptotic Theory of Least Absolute Error Regression. Publ. Am. Stat. Assoc. 1978, 73, 618–622. [Google Scholar] [CrossRef]

- Copeland, K.T.; Checkoway, H.; McMichael, A.J.; Holbrook, R.H. Bias due to misclassification in the estimation of relative risk. Am. J. Epidemiol. 1977, 105, 488–495. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Zhang, M.; Wang, X.; Zhao, Y.; Jin, B.; Dai, W. The Analysis of FBG Central Wavelength Variation with Crack Propagation Based on a Self-Adaptive Multi-Peak Detection Algorithm. Sensors 2019, 19, 1056. https://doi.org/10.3390/s19051056

Zhang W, Zhang M, Wang X, Zhao Y, Jin B, Dai W. The Analysis of FBG Central Wavelength Variation with Crack Propagation Based on a Self-Adaptive Multi-Peak Detection Algorithm. Sensors. 2019; 19(5):1056. https://doi.org/10.3390/s19051056

Chicago/Turabian StyleZhang, Weifang, Meng Zhang, Xiangyu Wang, Yan Zhao, Bo Jin, and Wei Dai. 2019. "The Analysis of FBG Central Wavelength Variation with Crack Propagation Based on a Self-Adaptive Multi-Peak Detection Algorithm" Sensors 19, no. 5: 1056. https://doi.org/10.3390/s19051056

APA StyleZhang, W., Zhang, M., Wang, X., Zhao, Y., Jin, B., & Dai, W. (2019). The Analysis of FBG Central Wavelength Variation with Crack Propagation Based on a Self-Adaptive Multi-Peak Detection Algorithm. Sensors, 19(5), 1056. https://doi.org/10.3390/s19051056