Smart RFID Sensors Embedded in Building Structures for Early Damage Detection and Long-Term Monitoring

Abstract

1. Introduction

2. Passive Radio Frequency Identification (RFID)-Based Sensors for Embedment into Concrete

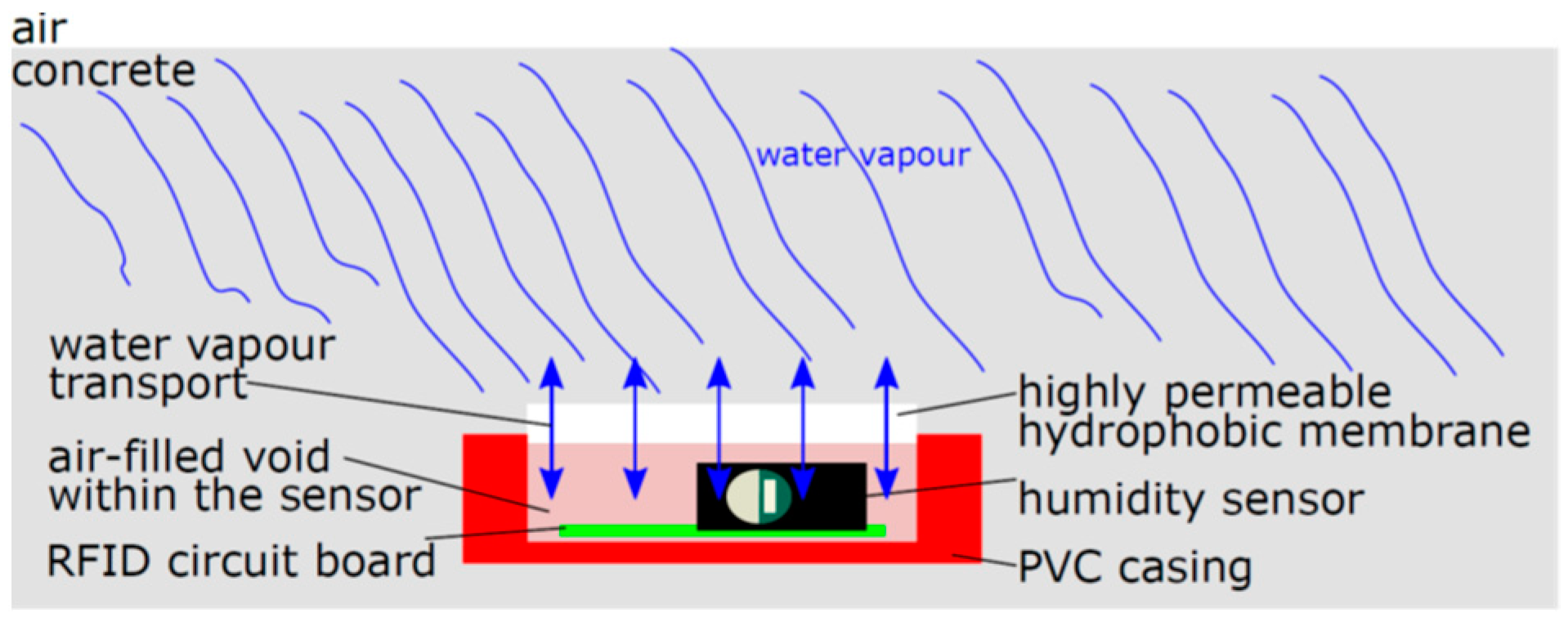

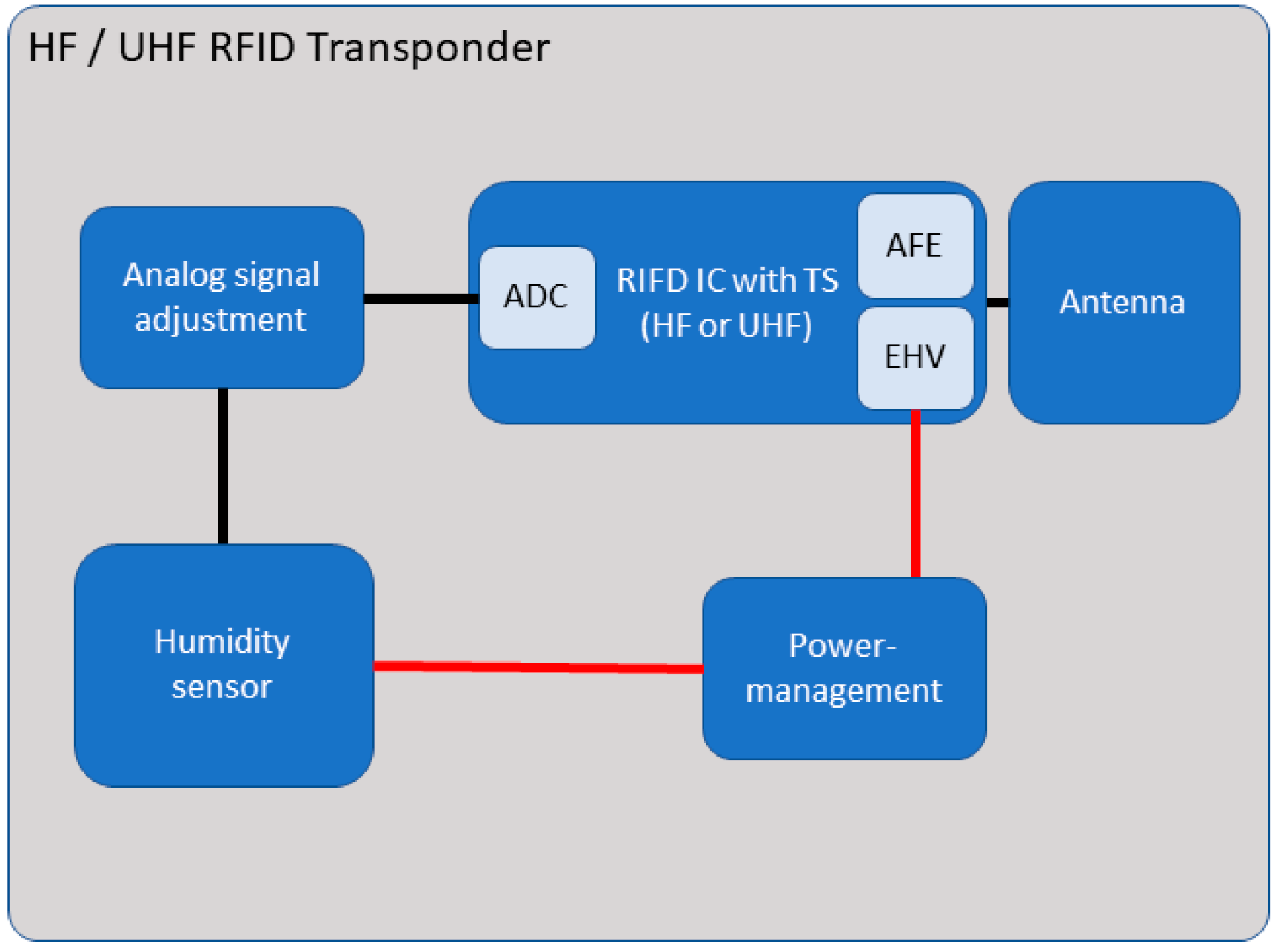

2.1. Measurement Principle of Passive RFID-Based Sensors for Civil Engineering

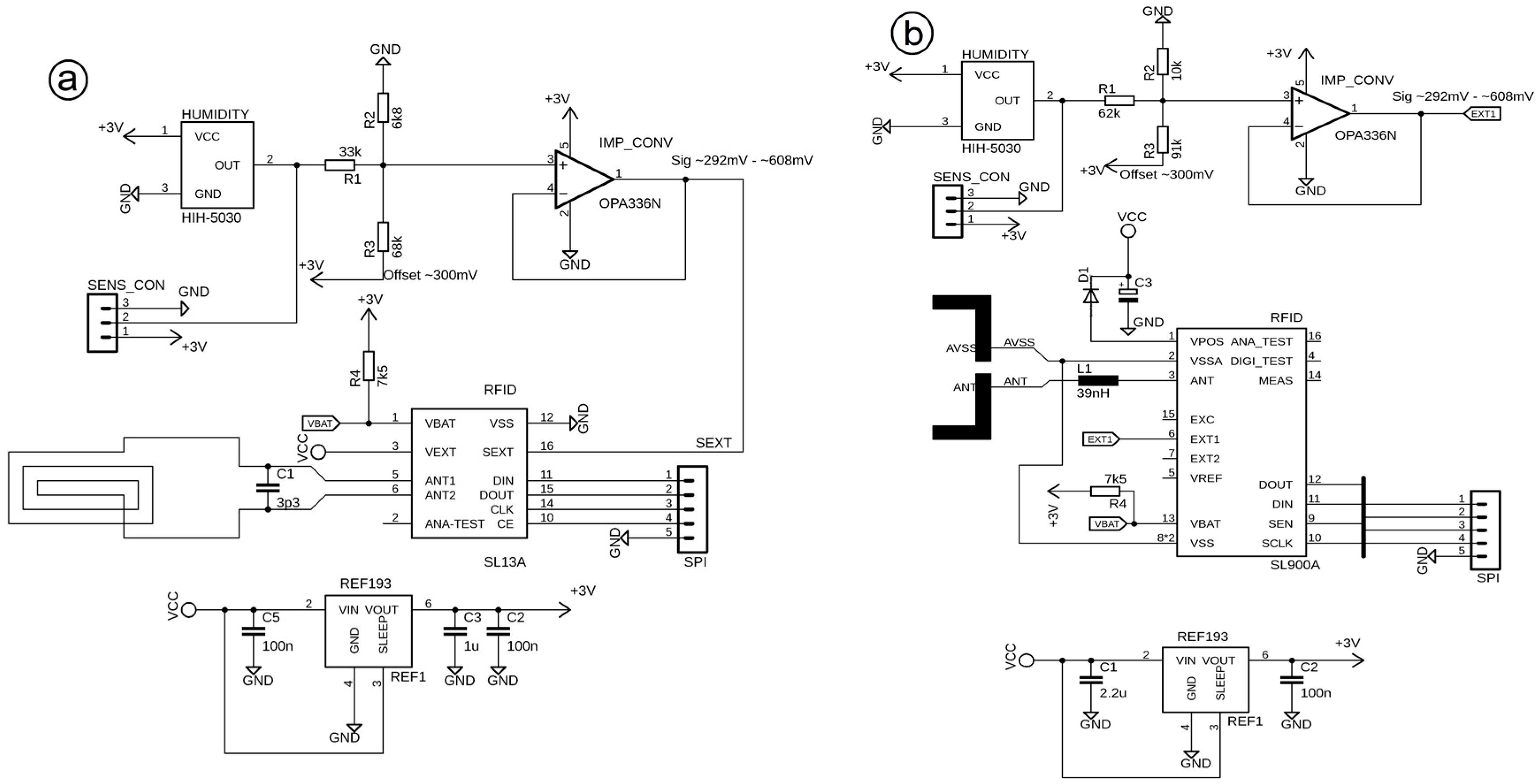

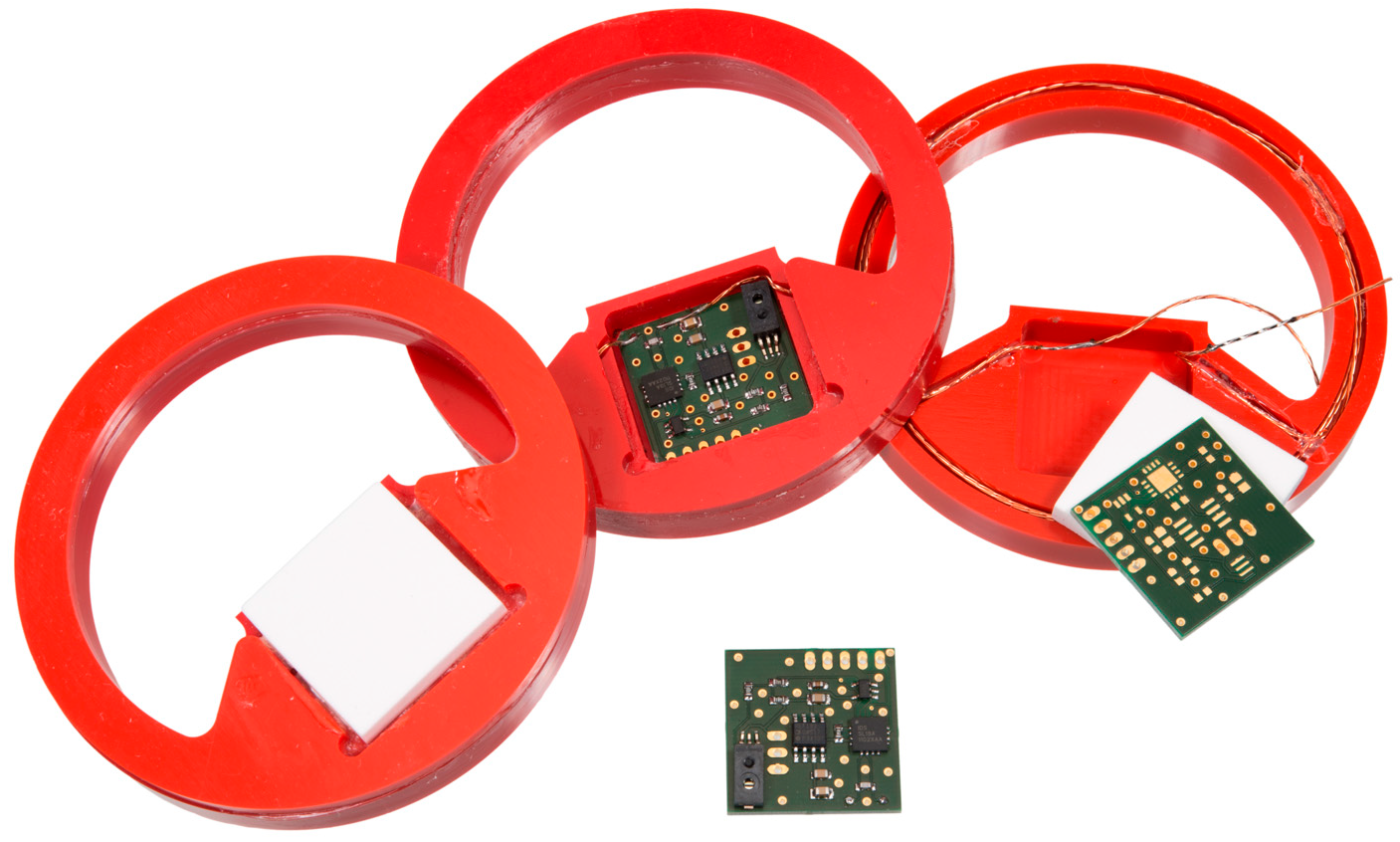

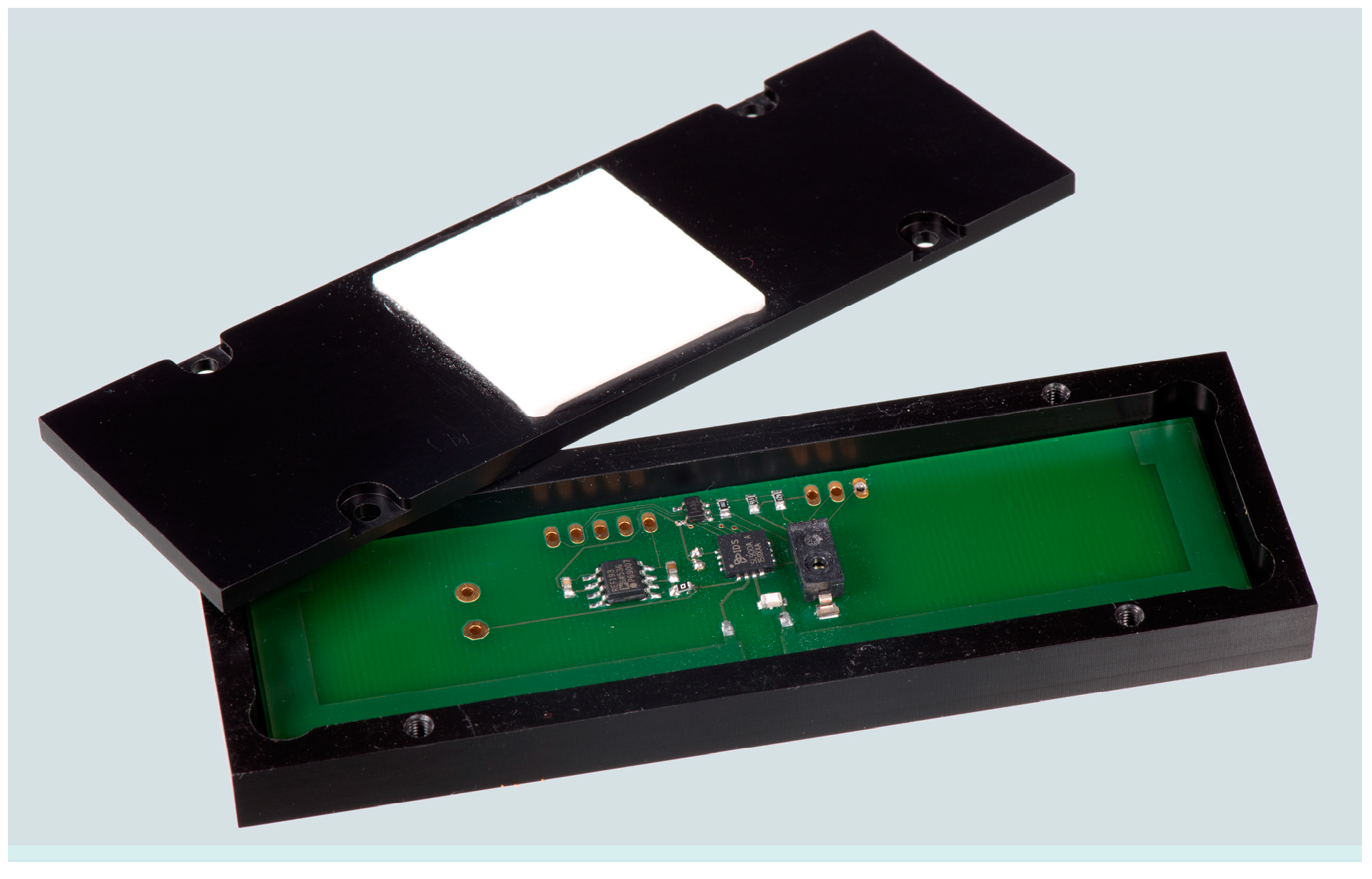

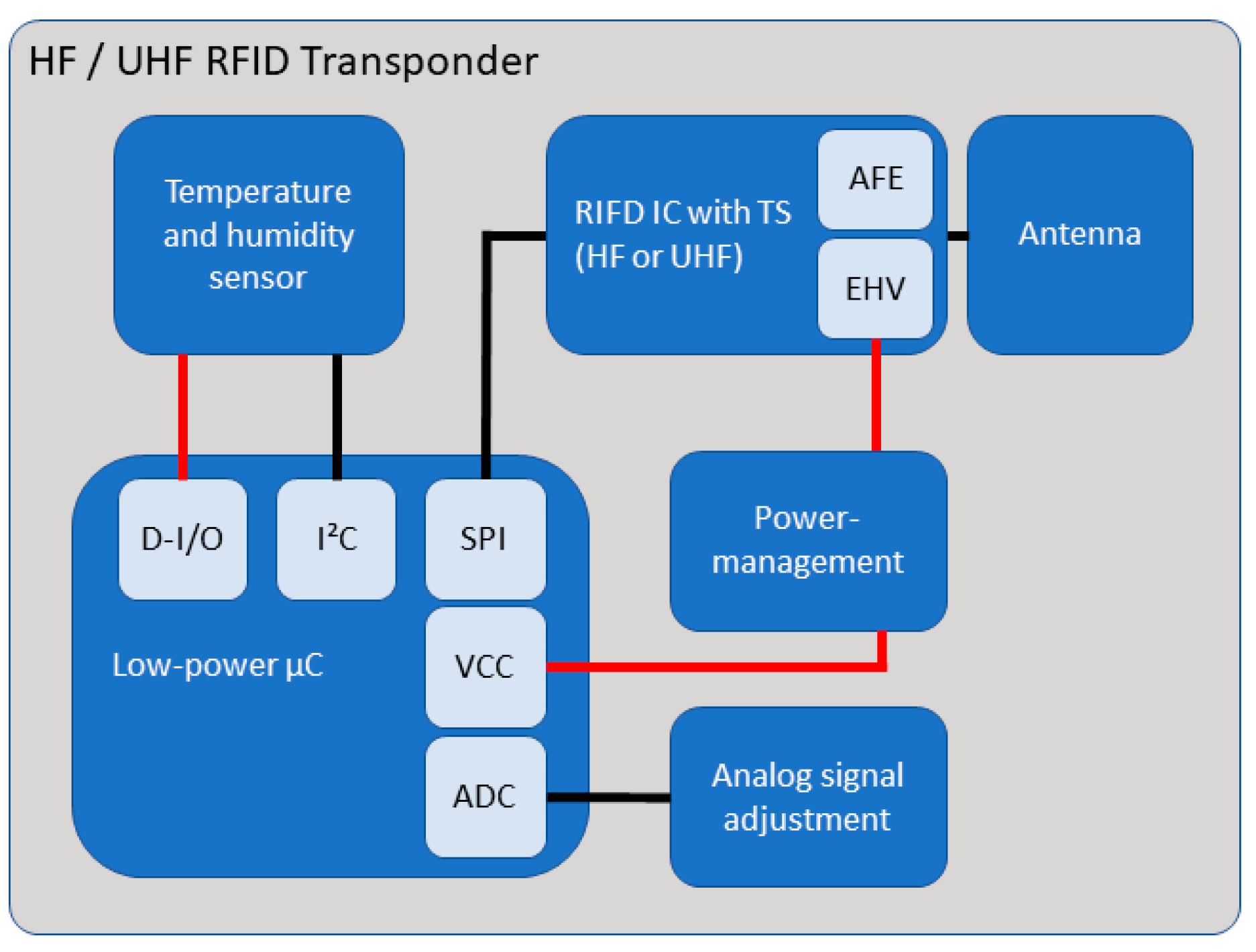

2.2. Layout and Design of the RFID Circuit

3. Experimental Setup

3.1. Humidity Sensors

3.2. Determination of the Signal Strength

3.3. Determination of the Specimen Weight and Storage

3.4. Test of the Casing Materials in Sodium Hydroxide (SH) Solution

4. Results and Interpretation

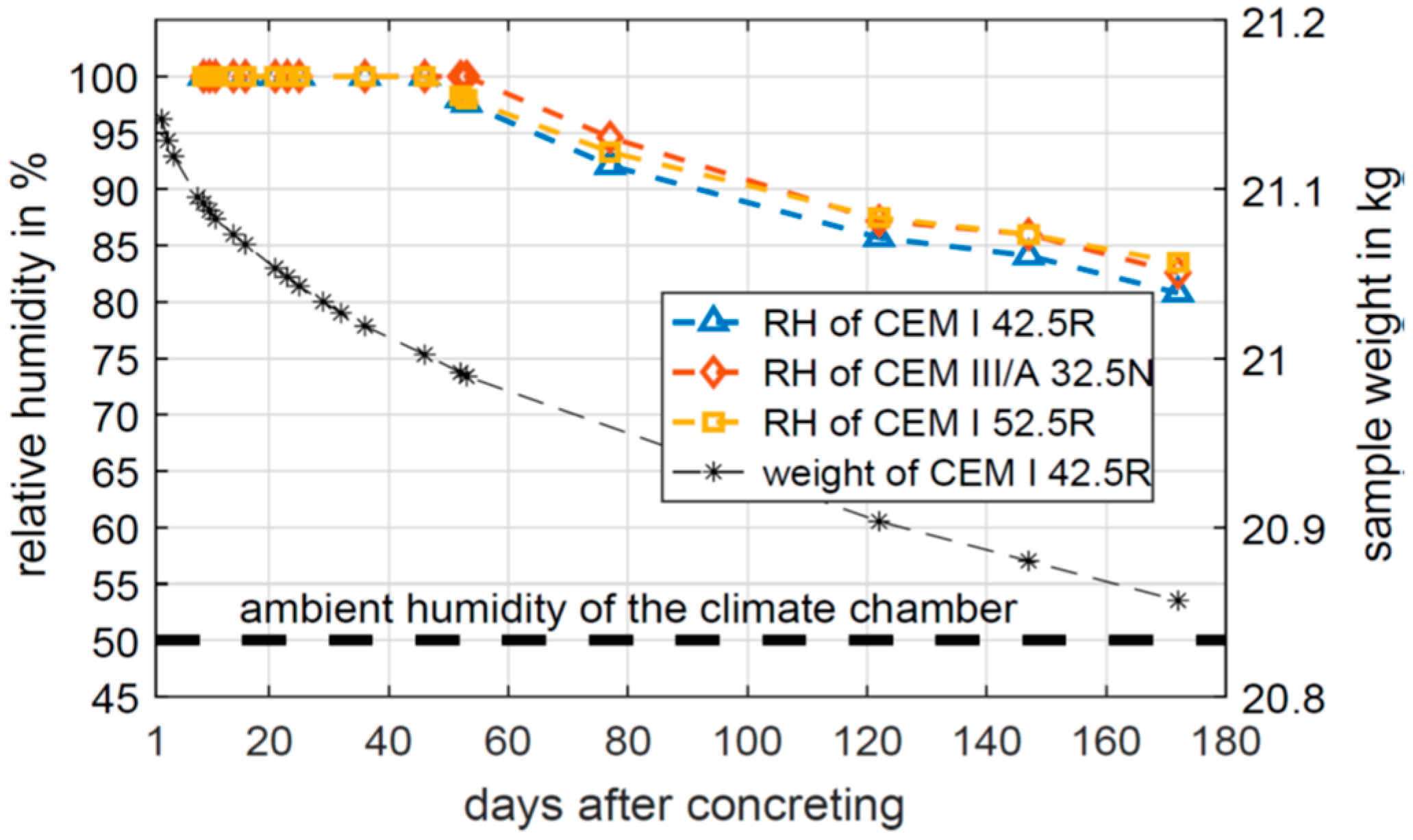

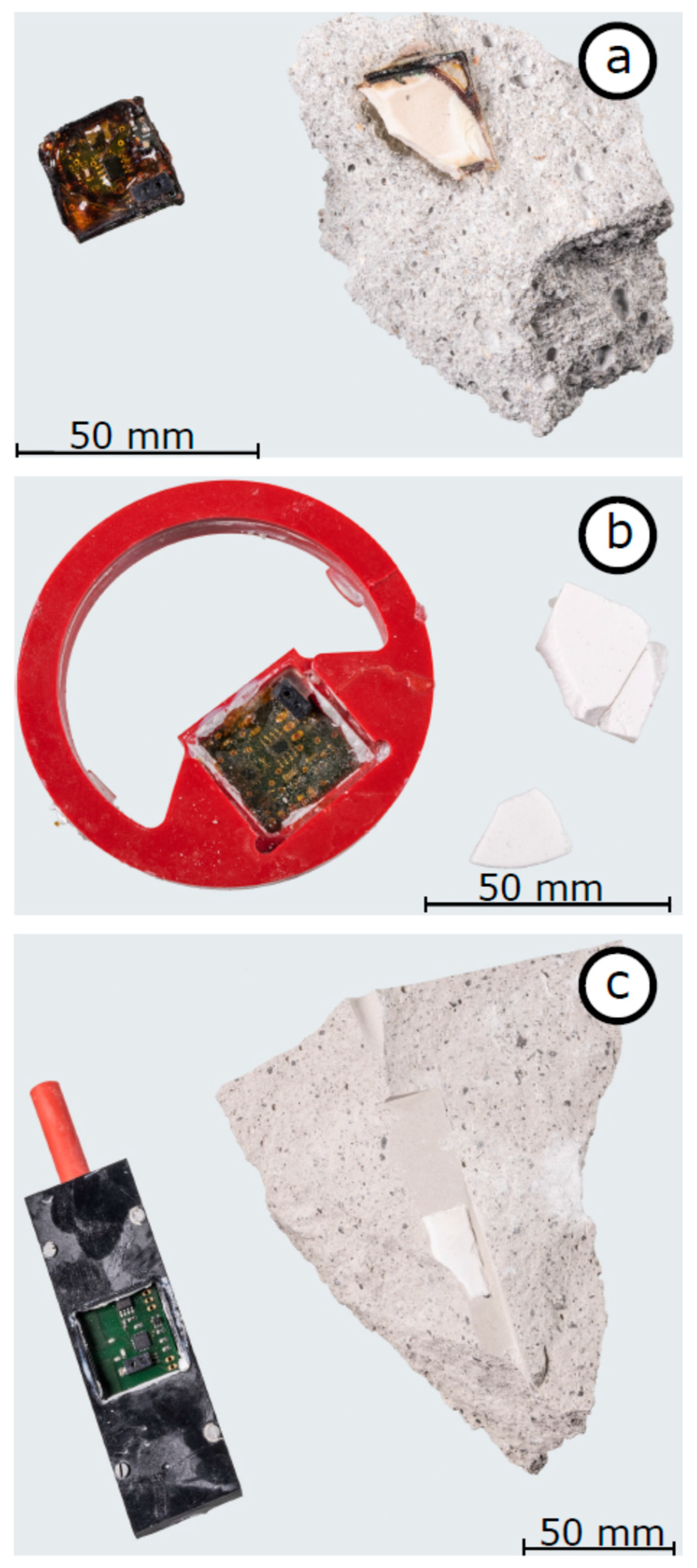

4.1. Preliminary Case Study of RFID-Based Sensors Embedded in Concrete

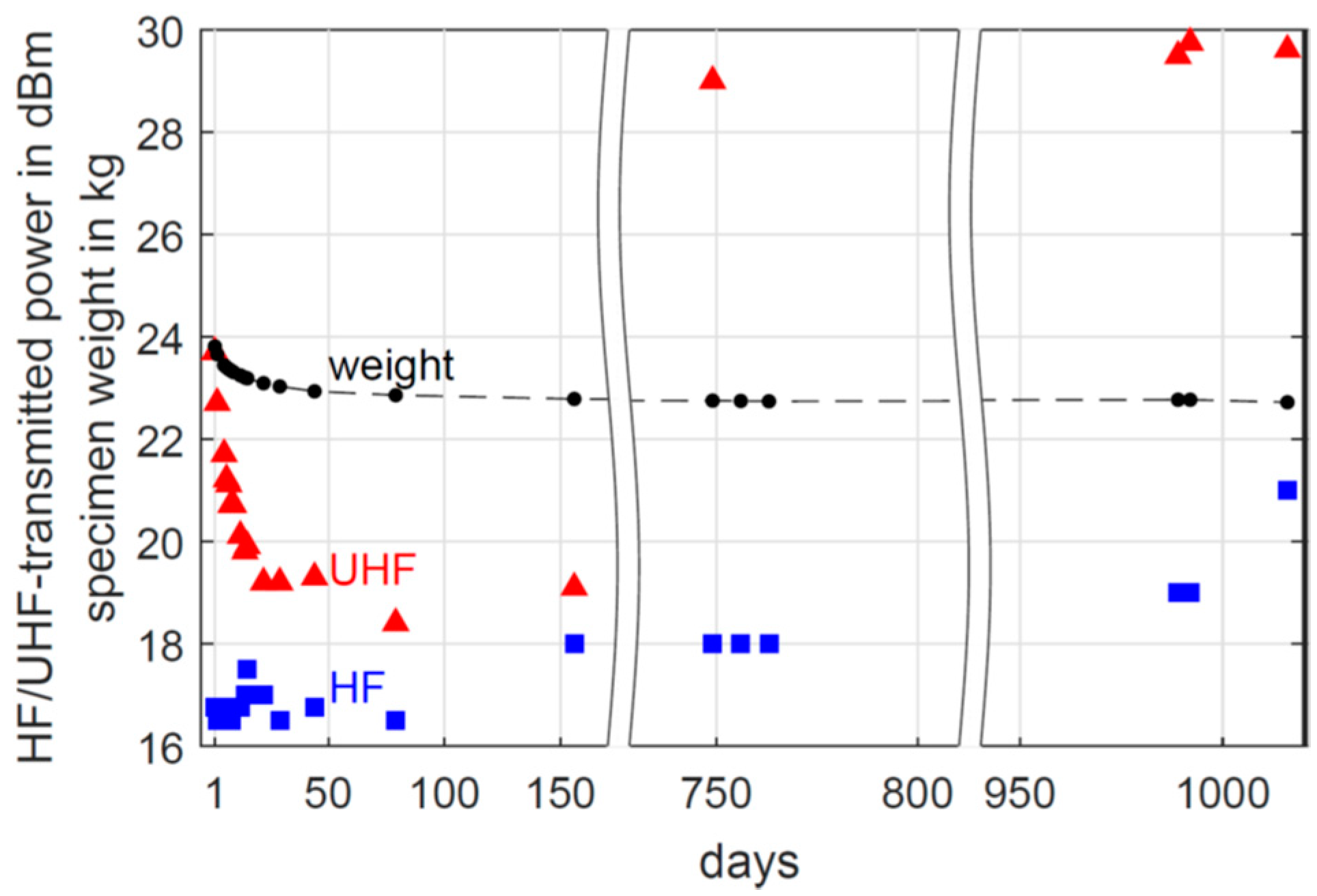

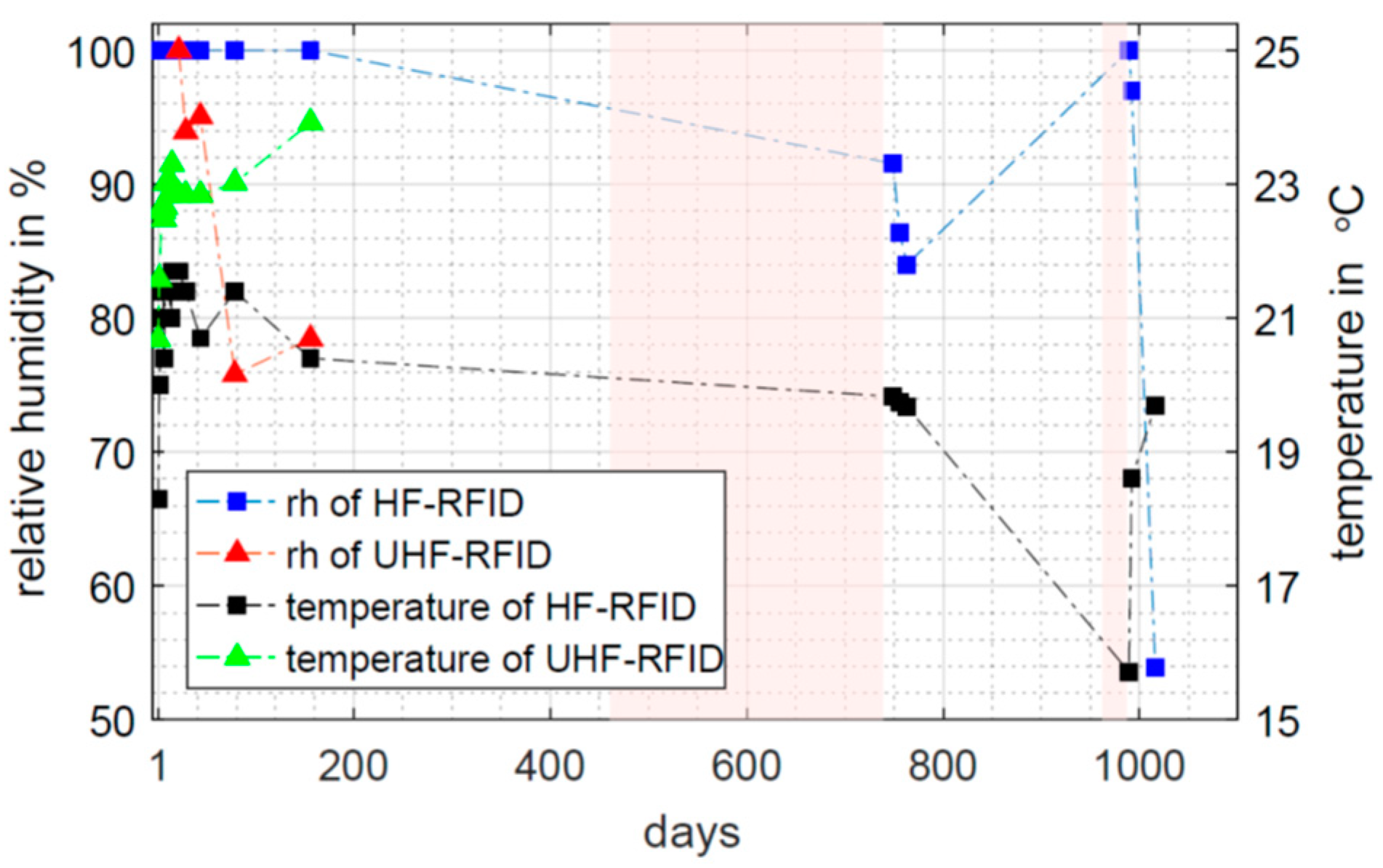

4.2. Long-Term Measurement from RFID-Based Sensors Embedded in Building Materials

4.3. Long-Term Stability of Sensor Components and Materials in Alkaline Cementitious Environment

4.4. Accelerated Aging Test of the Casing and Filter Membrane Materials

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kunert, U.; Link, H. Verkehrsinfrastruktur: Substanzerhaltung erfordert deutlich höhere Investitionen. DIW-Wochenber. 2013, 80, 32–38. [Google Scholar]

- Dauberschmidt, C. Chloridbelasteter Beton–immer ein Entsorgungsfall? Regionaltagung des Deutschen Beton- und Bautechnikvereins; Germany, 2010; pp. 1–23. Available online: http://dauberschmidt.com/Dauberschmidt_Chloride%20im%20Beton.pdf (accessed on 12 December 2019).

- Schubert, M. Verkehrsverflechtungsprognose 2030. Forschungsbericht Bundesministerium für Verkehr und digitale Infrastruktur. 2014, pp. 1–14. Available online: https://www.bmvi.de/SharedDocs/DE/Anlage/G/verkehrsverflechtungsprognose-2030-zusammenfassung-los-3.pdf?__blob=publicationFile (accessed on 12 December 2019).

- Koch, G.H.; Brongers, M.P.; Thompson, N.G.; Virmani, Y.P.; Payer, J.H. Corrosion Cost and Preventive Strategies in the United States; Technical Report Federal Highway Administration; Federal Highway Administration: Washington, DC, USA, March 2002. [Google Scholar]

- Deutscher Bundestag. Bauwerksprüfung nach DIN 1076 Bedeutung, Organisation, Kosten; Technical Report; Bundesministerium für Verkehr, Bau und Stadtentwicklung: Berlin, Germany, 2013; pp. 1–42. [Google Scholar]

- Dauberschmidt, C.; Vestner, S. Grundlagen des kathodischen Korrosionsschutzes von Stahl in Beton. In Symposium Kathodischer Korrosionsschutz von Stahlbetonbauwerken; Germany, 2009; Volume 18, pp. 1–19. [Google Scholar]

- Leon-Salas, W.D.; Halmen, C. A RFID sensor for corrosion monitoring in concrete. IEEE Sens. J. 2015, 16, 32–42. [Google Scholar] [CrossRef]

- Shi, X. Monitoring of reinforced concrete corrosion. In Eco-Efficient Repair and Rehabilitation of Concrete Infrastructures; Elsevier: Amsterdam, The Netherlands, 2018; pp. 69–95. [Google Scholar] [CrossRef]

- Nürnberger, U. Korrosion und Korrosionsschutz im Bauwesen; Bauverlag: Wiesbaden/Berlin, Germany, 1995; Volume 1. [Google Scholar]

- Ong, J.B.; You, Z.; Mills-Beale, J.; Tan, E.L.; Pereles, B.D.; Ong, K.G. A wireless, passive embedded sensor for real-time monitoring of water content in civil engineering materials. IEEE Sens. J. 2008, 8, 2053–2058. [Google Scholar] [CrossRef]

- Feng, Y.; Xie, L.; Chen, Q.; Zheng, L.-R. Low-cost printed chipless RFID humidity sensor tag for intelligent packaging. IEEE Sens. J. 2014, 15, 3201–3208. [Google Scholar] [CrossRef]

- Zhou, S.; Deng, F.; Yu, L.; Li, B.; Wu, X.; Yin, B. A novel passive wireless sensor for concrete humidity monitoring. Sensors 2016, 16, 1535. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.; Heiß, M.; Fu, Q.; Gay, N.A. A prototype RFID humidity sensor for built environment monitoring. In Proceedings of the International Workshop on Education Technology and Training & 2008 International Workshop on Geoscience and Remote Sensing, Shanghai, China, 21–22 December 2008; Volume 2, pp. 496–499. [Google Scholar] [CrossRef]

- Fernandez-Salmeron, J.; Rivadeneyra, A.; Rodríguez, M.A.C.; Capitan-Vallvey, L.F.; Palma, A.J. HF RFID tag as humidity sensor: Two different approaches. IEEE Sens. J. 2015, 15, 5726–5733. [Google Scholar] [CrossRef]

- Chang, C.-Y.; Hung, S.-S. Implementing RFIC and sensor technology to measure temperature and humidity inside concrete structures. Constr. Build. Mater. 2012, 26, 628–637. [Google Scholar] [CrossRef]

- Murthy, S.G.N. Batteryless wireless RFID based embedded sensors for long term monitoring of reinforced concrete structures. In Proceedings of the International Symposium NDT-CE, Berlin, Germany, 15–17 September 2015; pp. 15–17. [Google Scholar]

- Meng, Z.; Li, Z. RFID tag as a sensor—A review on the innovative designs and applications. Meas. Sci. Rev. 2016, 16, 305–315. [Google Scholar] [CrossRef]

- Cui, L.; Zhang, Z.; Gao, N.; Meng, Z.; Li, Z. Radio frequency identification and sensing techniques and their applications—A review of the state-of-the-art. Sensors 2019, 19, 4012. [Google Scholar] [CrossRef] [PubMed]

- Bartholmai, M.; Johann, S.; Kammermeier, M.; Müller, M.; Strangfeld, C. Transmission characteristics of RFID sensor systems embedded in concrete. In Proceedings of the IEEE Sensors, Orlando, FL, USA, 30 October–3 November 2016; pp. 1–3. [Google Scholar] [CrossRef]

- Zhang, J.; Tian, G.Y.; Marindra, A.M.; Sunny, A.I.; Zhao, A.B. A review of passive RFID tag antenna-based sensors and systems for structural health monitoring applications. Sensors 2017, 17, 265. [Google Scholar] [CrossRef] [PubMed]

- Brunner, B.; Strässler, D.; Küng, R. RFID-Sensoren im Beton. Elektron.-Internet Things 2016, 5, 58–61. [Google Scholar]

- Lesthaeghe, T.; Frishman, S.; Holland, S.D. RFID Tags for Detecting Concrete Degradation in Bridge Decks. In Technical Report Institute for Transportation; Iowa State University: Ames, IA, USA, 2013; pp. 1–26. [Google Scholar]

- Strangfeld, C.; Johann, S.; Müller, M.; Bartholmai, M. Embedded passive RFID-based sensors for moisture monitoring in concrete. IEEE Sens. 2017, 1–3. [Google Scholar] [CrossRef]

- Strangfeld, C.; Kruschwitz, S. Monitoring of the absolute water content in porous materials based on embedded humidity sensors. Constr. Build. Mater. 2018, 177, 511–521. [Google Scholar] [CrossRef]

- Bundesnetzagentur. RFID, das kontaktlose Informationssystem; Technical Report; Bundesministerium für Wirtschaft und Energie: Berlin, Germany, 2019. [Google Scholar]

- Bartholmai, M.; Johann, S.; Kammermeier, M.; Müller, M.; Strangfeld, C. RFID sensor systems embedded in concrete–systematical investigation of the transmission characteristics. In Proceedings of the 8th European Workshop on Structural Health Monitoring, Bilbao, Spain, 5–8 July 2016; pp. 1–5. [Google Scholar]

- Johann, S.; Strangfeld, C.; Müller, M.; Mieller, B.; Bartholmai, M. RFID sensor systems embedded in concrete-requirements for long-term operation. In Proceedings of the 33rd Danubia Adria Symposium, Portoroz, Solvenia, 4 December 2016; pp. 1–6. [Google Scholar]

- Tiebe, C. Prüfbericht 18019710: Prüfung von fünf Feuchtesensoren; Test Report; Bundesanstalt für Materialforschung und –prüfung: Berlin, Germany, 2017. [Google Scholar]

- Strangfeld, C.; Johann, S.; Müller, M.; Bartholmai, M. Moisture measurements by means of RFID sensor systems in screed and concrete. In Proceedings of the 8th European Workshop on Structural Health Monitoring, Bilbao, Spain, 5–8 July 2016; pp. 1–10. [Google Scholar]

- Bartholmai, M.; Johann, S.; Strangfeld, C. Embedded wireless sensor systems for long-term SHM and corrosion detection in concrete components. In Proceedings of the 8th International Conference on Structural Health Monitoring of Intelligent Infrastructure, Brisbane, Australia, 19 December 2017; pp. 1–7. [Google Scholar]

| Section | Title | Purpose | Considered Quantities |

|---|---|---|---|

| 4.1 | Preliminary case study | Initial prove of the measurement concept | Relative humidity |

| 4.2 | Long-term measurements | Verification of the sensor long-term stability | Transmitted power Relative humidity Temperature |

| 4.3 | Examination of embedded components and materials | Investigation of the components exposed to concrete | Visual inspection |

| 4.4 | Accelerated aging tests of the used materials | Laboratory tests in sodium hydroxide (SH) solution for detailed material characterisation | Weight of material samples |

| Concrete Type | Abbreviation in the Text | Compressive Strength (Nmm−2) | Water to Cement Ratio | Hydration Type |

|---|---|---|---|---|

| CEM I 42.5R | C1 | 42.5 | 0.5 | rapid |

| CEM III/A 32.5N | C2 | 32.5 | 0.5 | normal |

| CEM I 52.5R | C3 | 52.5 | 0.4 | rapid |

| Material | Mass Variation after 2 Days in % | Mass Variation after 5 Days in % | Mass Variation after 7 Days in % | Mass Variation after 12 Days in % |

|---|---|---|---|---|

| Epoxy resin | −0.02 | −0.09 | −0.12 | −0.07 |

| PVC | 0 | 0 | 0 | +0.02 |

| Quartz glass filter | +0.88 | −0.05 | −1.54 | −2.22 |

| PTFE 1 µm | 0 | −0.02 | −0.06 | −0.08 |

| PTFE 10 µm PTFE 50 µm | 0 0 | 0 0 | 0 0 | −0.01 0 |

| PTFE 100 µm | 0 | +0.01 | +0.01 | +0.01 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Strangfeld, C.; Johann, S.; Bartholmai, M. Smart RFID Sensors Embedded in Building Structures for Early Damage Detection and Long-Term Monitoring. Sensors 2019, 19, 5514. https://doi.org/10.3390/s19245514

Strangfeld C, Johann S, Bartholmai M. Smart RFID Sensors Embedded in Building Structures for Early Damage Detection and Long-Term Monitoring. Sensors. 2019; 19(24):5514. https://doi.org/10.3390/s19245514

Chicago/Turabian StyleStrangfeld, Christoph, Sergej Johann, and Matthias Bartholmai. 2019. "Smart RFID Sensors Embedded in Building Structures for Early Damage Detection and Long-Term Monitoring" Sensors 19, no. 24: 5514. https://doi.org/10.3390/s19245514

APA StyleStrangfeld, C., Johann, S., & Bartholmai, M. (2019). Smart RFID Sensors Embedded in Building Structures for Early Damage Detection and Long-Term Monitoring. Sensors, 19(24), 5514. https://doi.org/10.3390/s19245514