Dual-Level Capacitive Micromachined Uncooled Thermal Detector

Abstract

1. Introduction

2. Design and Simulations

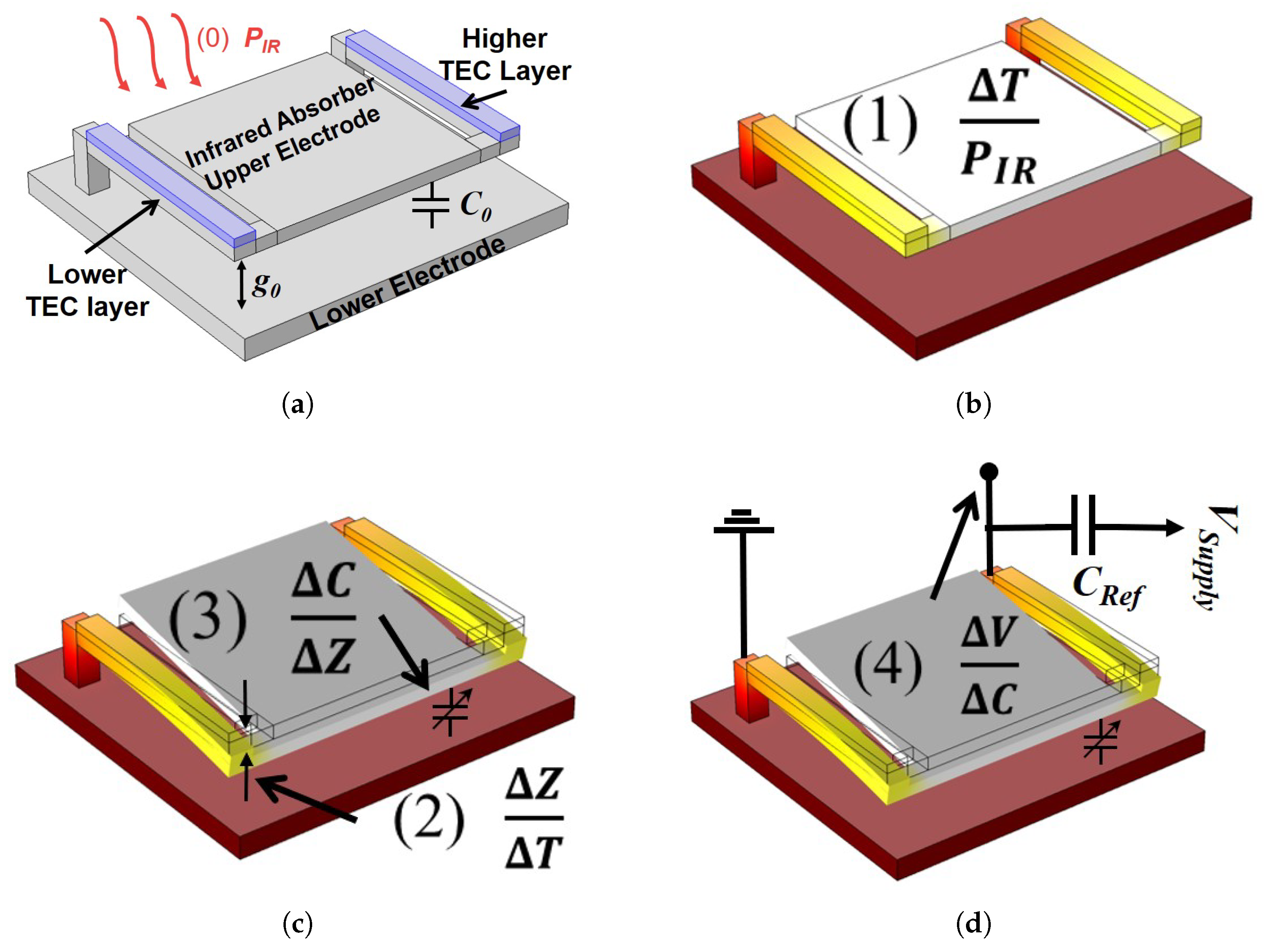

2.1. Working Principle

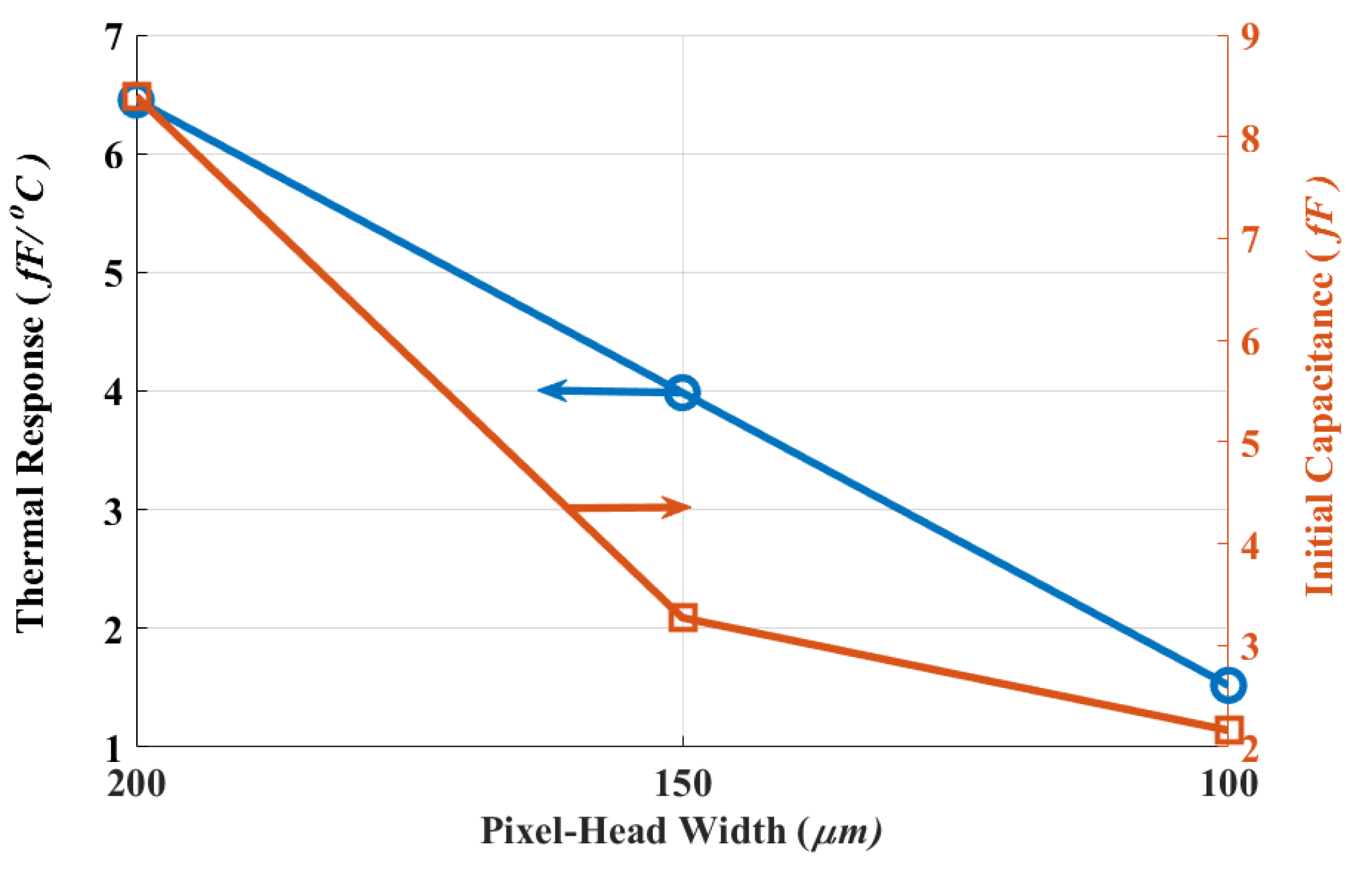

2.2. Typical Trade-Off: Sensitivity vs. Area

3. Proposed Design and Finite Element Analysis

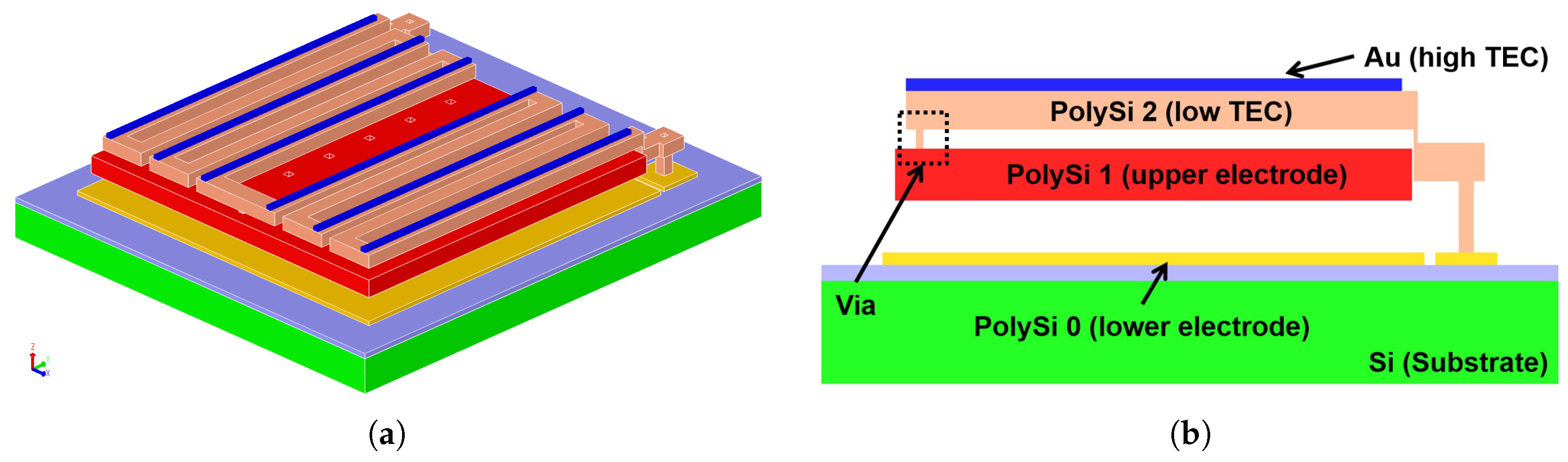

3.1. Dual-Level Architecture

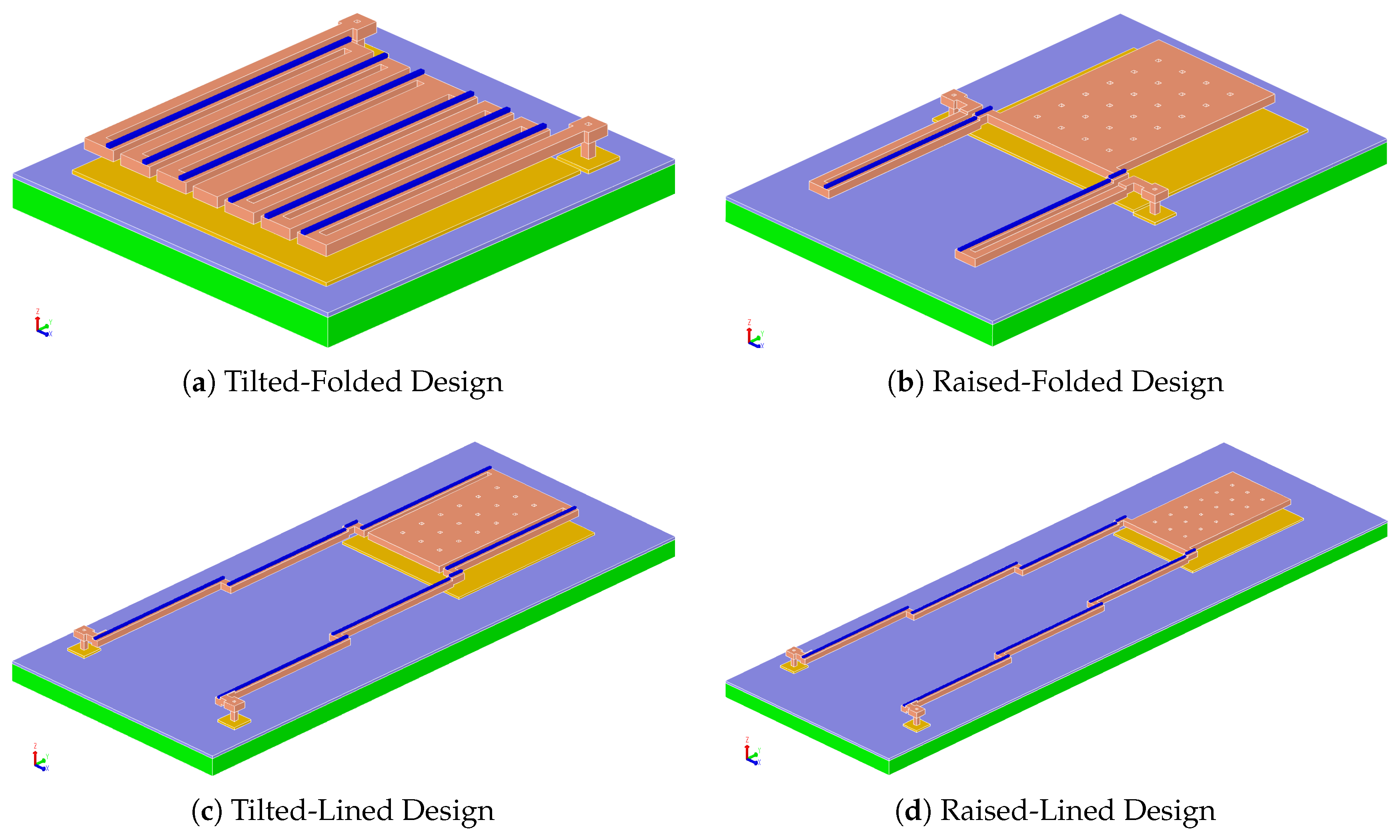

3.2. Reference Designs

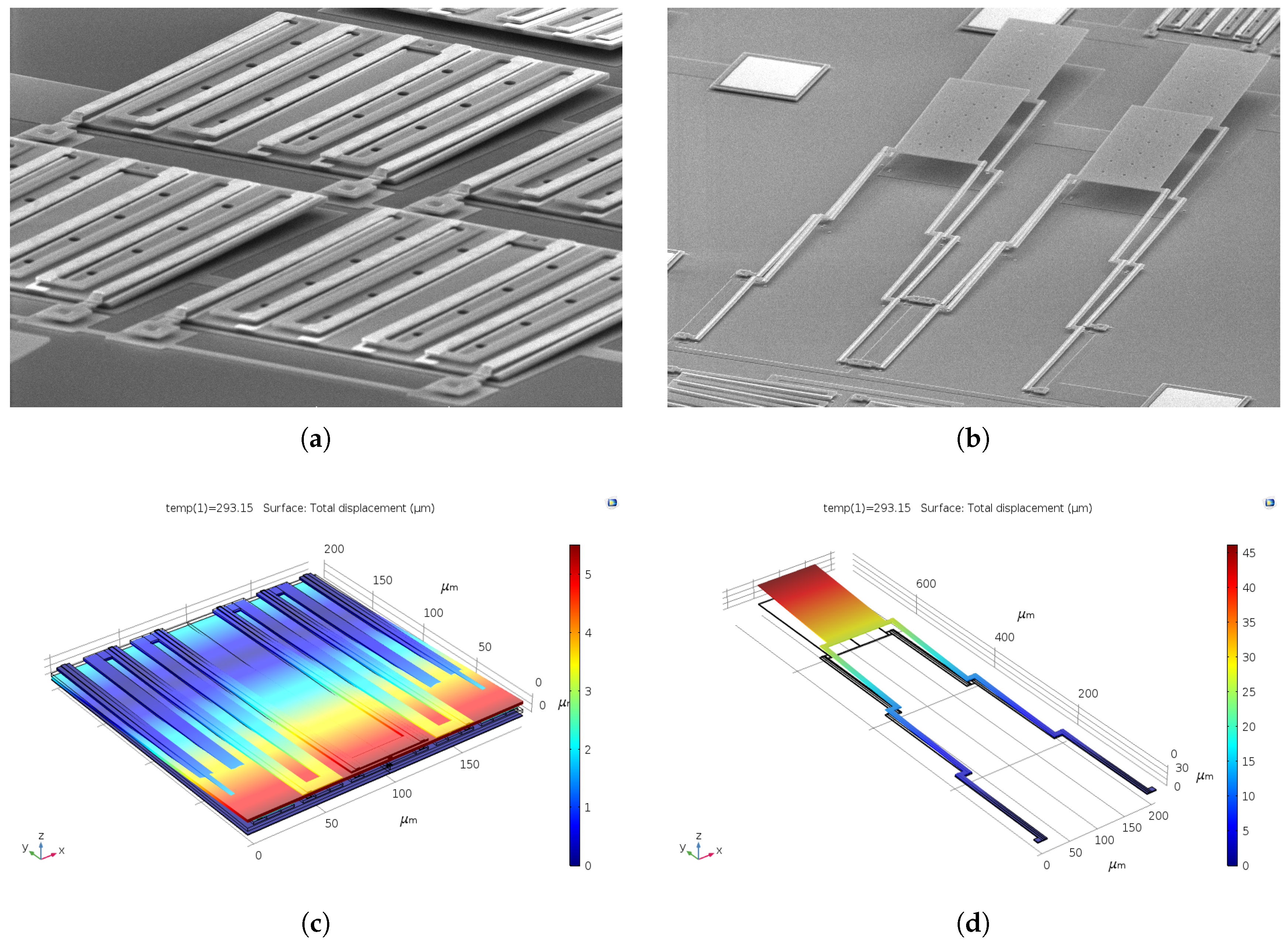

3.3. Residual Stress Considerations

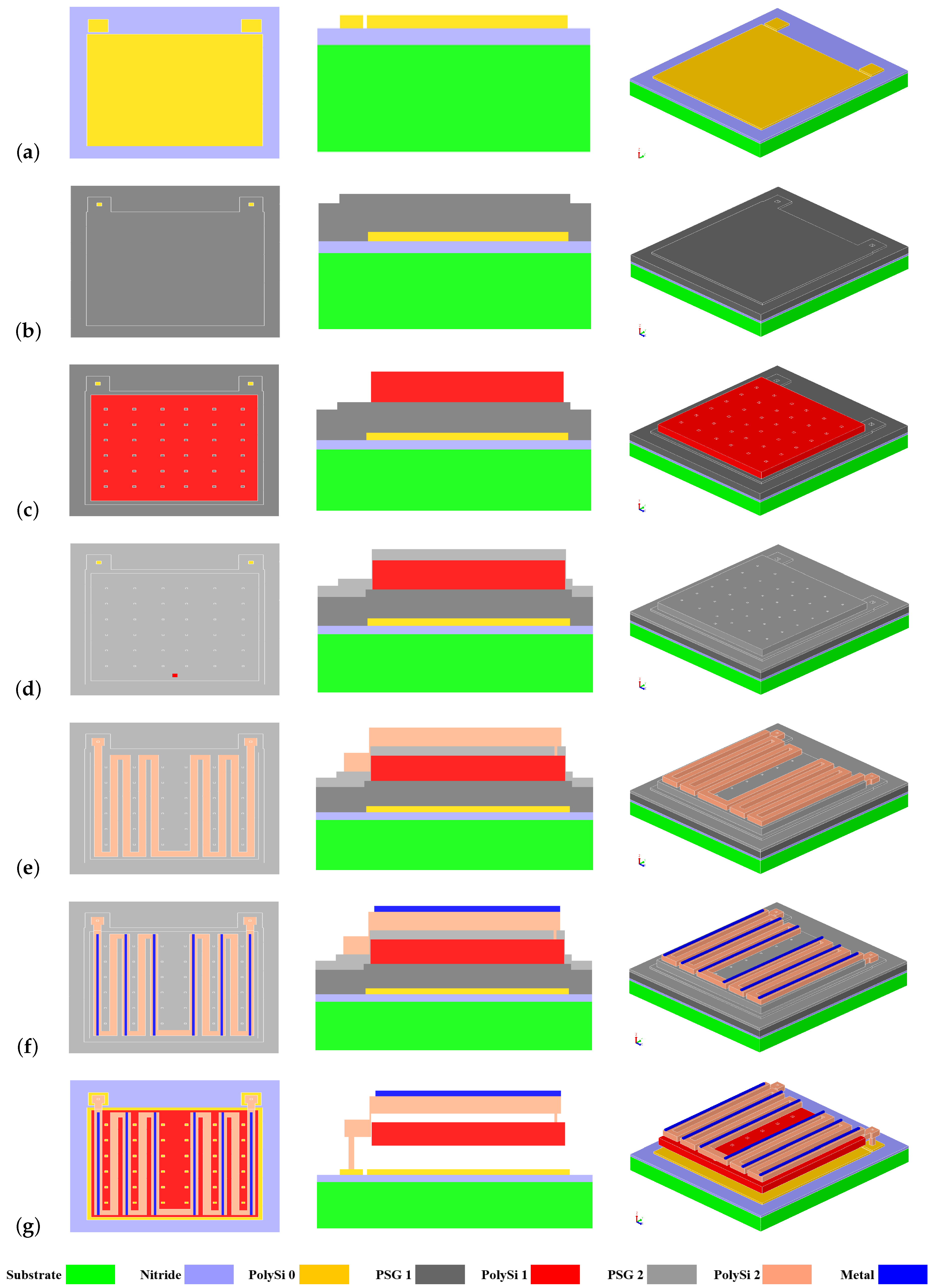

4. Fabrication

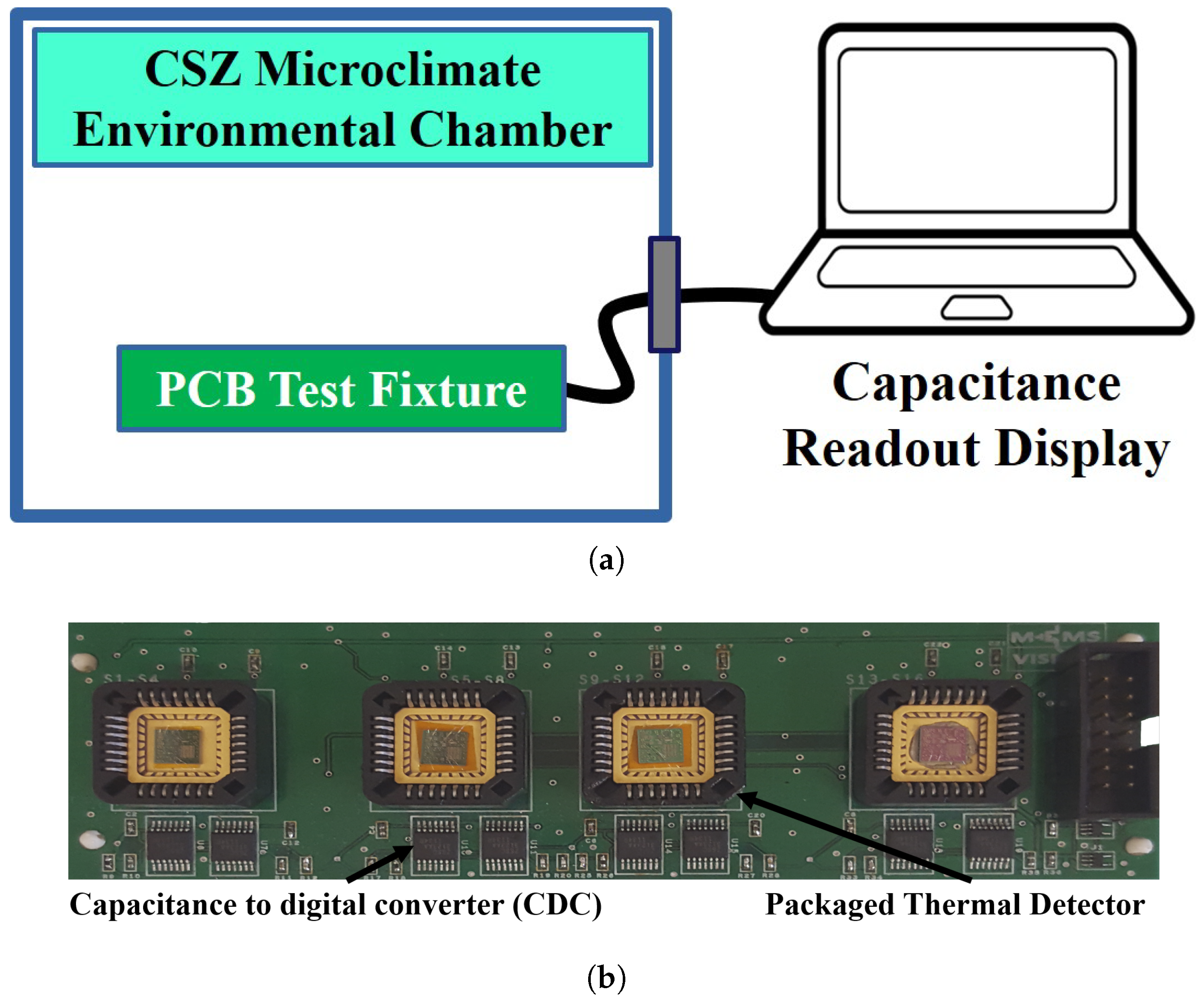

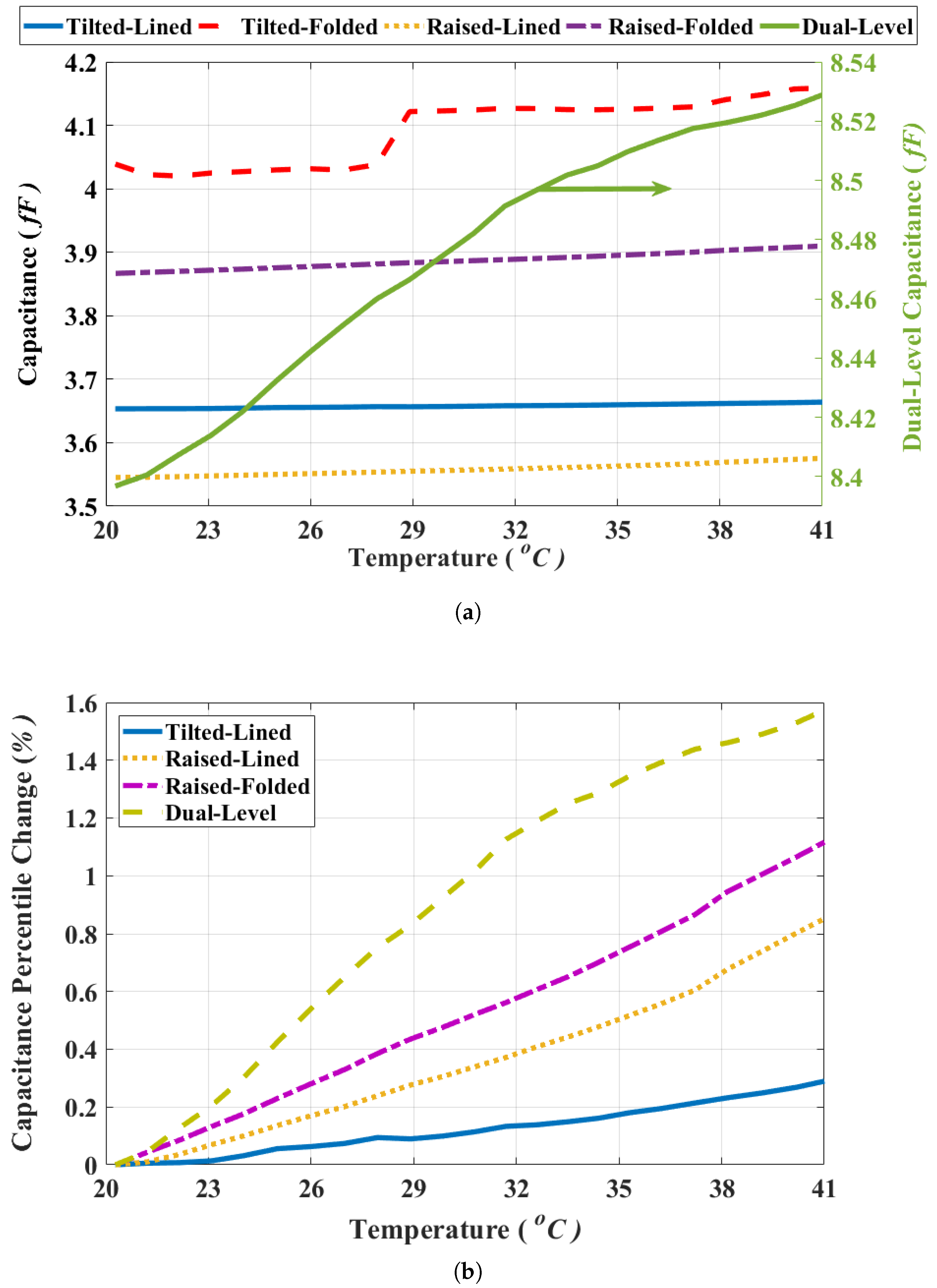

5. Characterization and Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rogalski, A. History of infrared detectors. Opto-Electron. Rev. 2012, 20, 279–308. [Google Scholar] [CrossRef]

- Frank, N.; Vieider, C.; Jakobsen, H. MEMS-based uncooled infrared bolometer arrays: A review. Proc. SPIE 2008, 6836, 68360D. [Google Scholar] [CrossRef]

- Hanson, C.M.; Beratan, H.R.; Owen, R.A.; Mac Corbin, S.M. Uncooled thermal imaging at Texas Instruments. Proc. SPIE 1992, 1735, 17–26. [Google Scholar] [CrossRef]

- Mounier, E. Microbolometers: A market perspective. Proc. SPIE 2012, 8252, 825210. [Google Scholar] [CrossRef]

- Lei, S. Uncooled infrared focal plane array imaging in China. Proc. SPIE 2015, 9451, 945119. [Google Scholar] [CrossRef]

- Datskos, P.; Oden, P.; Thundat, T.; Wachter, E.; Warmack, R.; Hunter, S. Remote infrared radiation detection using piezoresistive microcantilevers. Appl. Phys. Lett. 1996, 69, 2986–2988. [Google Scholar] [CrossRef]

- Zhao, Y.; Mao, M.; Horowitz, R.; Majumdar, A.; Varesi, J.; Norton, P.; Kitching, J. Optomechanical uncooled infrared imaging system: Design, microfabrication, and performance. J. Microelectromech. Syst. 2002, 11, 136–146. [Google Scholar] [CrossRef]

- Dong, F.; Zhang, Q.; Chen, D.; Pan, L.; Guo, Z.; Wang, W.; Duan, Z.; Wu, X. An uncooled optically readable infrared imaging detector. Sens. Actuators A Phys. 2007, 133, 236–242. [Google Scholar] [CrossRef]

- Adiyan, U.; Civitçi, F.; Ferhanoğlu, O.; Torun, H.; Urey, H. A 35-μm Pitch IR thermo-mechanical MEMS sensor with AC-coupled optical readout. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 87–92. [Google Scholar] [CrossRef]

- Ivanova, K.; Ivanov, T.; Rangelow, I. Micromachined Arch-type cantilever as high sensitivity uncooled infrared detector. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2005, 23, 3153–3157. [Google Scholar] [CrossRef]

- Park, W.T. Piezoresistivity. In Encyclopedia of Nanotechnology; Springer: Berlin, Germany, 2012; pp. 2111–2117. [Google Scholar]

- Steffanson, M.; Rangelow, I. Microthermomechanical infrared sensors. Opto-Electron. Rev. 2014, 22, 1–15. [Google Scholar] [CrossRef]

- Hunter, S.R.; Amantea, R.A.; Goodman, L.A.; Kharas, D.B.; Gershtein, S.; Matey, J.R.; Perna, S.N.; Yu, Y.; Maley, N.; White, L.K. High-sensitivity uncooled microcantilever infrared imaging arrays. Proc. SPIE 2003, 5074, 469–480. [Google Scholar]

- Aziz, A.A.; Tawfik, H.; Sharaf, A.; Elshurfa, A.; Serry, M.; Sedky, S. A new vertical suspension inertial grade gyroscope. In Proceedings of the 2013 Transducers & Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII), Barcelona, Spain, 16–20 June 2013; pp. 956–959. [Google Scholar]

- Zhang, Q.; Cicek, P.V.; Allidina, K.; Nabki, F.; El-Gamal, M.N. Surface-micromachined CMUT using low-temperature deposited silicon carbide membranes for above-IC integration. J. Microelectromech. Syst. 2014, 23, 482–493. [Google Scholar] [CrossRef]

- Elsayed, M.Y.; Cicek, P.V.; Nabki, F.; El-Gamal, M.N. Surface micromachined combined magnetometer/accelerometer for above-IC integration. J. Microelectromech. Syst. 2015, 24, 1029–1037. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, Q.; Dong, F.; Chen, D.; Xiong, Z.; Miao, Z.; Li, C.; Jiao, B.; Wu, X. Performance analysis of microcantilever arrays for optical readout uncooled infrared imaging. Sens. Actuators A Phys. 2007, 137, 13–19. [Google Scholar] [CrossRef]

- Tawfik, H.; El-Gamal, M.N.; Nabki, F. Shock rejection & ambient temperature compensation mechanism for uncooled micocantilever thermal detector. In Proceedings of the 2013 IEEE 20th International Conference on Electronics, Circuits, and Systems (ICECS), Abu Dhabi, United Arab, 8–11 December 2013; pp. 827–830. [Google Scholar]

- Corbeil, J.; Lavrik, N.; Rajic, S.; Datskos, P. “Self-leveling” uncooled microcantilever thermal detector. Appl. Phys. Lett. 2002, 81, 1306–1308. [Google Scholar] [CrossRef]

- Oden, P.I.; Datskos, P.; Warmack, R.; Wachter, E.; Thundat, T. Optical and Infrared Detection Using Microcantilevers; Oak Ridge National Lab.: Oak Ridge, TN, USA, 1996; Technical Report. [Google Scholar]

- Awad, E.; Al-Khalli, N.; Abdel-Rahman, M.; Alduraibi, M.; Debbar, N. Comparison of V2O5 microbolometer optical performance using NiCr and Ti thin-films. IEEE Photon. Technol. Lett. 2015, 27, 462–465. [Google Scholar] [CrossRef]

- Mao, M.; Perazzo, T.; Kwon, O.; Majumdar, A.; Varesi, J.; Norton, P. Direct-view uncooled micro-optomechanical infrared camera. In Proceedings of the Twelfth IEEE International Conference on Micro Electro Mechanical Systems, Orlando, FL, USA, 21 January 1999; pp. 100–105. [Google Scholar]

- Chen, C.N.; Huang, W.C. A CMOS-MEMS Thermopile With Low Thermal Conductance and a Near-Perfect Emissivity in the 8–14-μm Wavelength Range. IEEE Electron Device Lett. 2011, 32, 96–98. [Google Scholar] [CrossRef]

- Lai, J.; Perazzo, T.; Shi, Z.; Majumdar, A. Optimization and performance of high-resolution micro-optomechanical thermal sensors. Sens. Actuators A Phys. 1997, 58, 113–119. [Google Scholar] [CrossRef]

- Kwon, I.W.; Kim, J.E.; Hwang, C.H.; Kim, T.S.; Lee, Y.S.; Lee, H.C. A high fill-factor uncooled infrared detector with thermo-mechanical bimaterial structure. Def. Secur. Symp. Int. Soc. Opt. Photonics 2007, 6542. [Google Scholar] [CrossRef]

- Johnstone, R.W.; Parameswaran, M. Curl and effective height of micromachined bi-layer cantilevers under differing residual stresses. In Proceedings of the Canadian Conference on Electrical and Computer Engineering, Ottawa, ON, Canada, 7–10 May 2006; pp. 1617–1620. [Google Scholar]

- Hunter, S.R.; Maurer, G.S.; Simelgor, G.; Radhakrishnan, S.; Gray, J.; Bachir, K.; Pennell, T.; Bauer, M.; Jagadish, U. Development and optimization of microcantilever based IR imaging arrays. Proc. SPIE 2008, 6940, 694013. [Google Scholar]

- Cowen, A.; Hardy, B.; Mahadevan, R.; Wilcenski, S. PolyMUMPs Design Handbook; MEMSCAP Inc.: Skoppum, Norway, 2011. [Google Scholar]

- Miao, Z.; Zhang, Q.; Chen, D.; Guo, Z.; Dong, F.; Xiong, Z.; Wu, X.; Li, C.; Jiao, B. Uncooled IR imaging using optomechanical detectors. Ultramicroscopy 2007, 107, 610–616. [Google Scholar] [CrossRef] [PubMed]

| Tilted-Lined | Tilted-Folded | Raised-Lined | Raised-Folded | Dual-Level (Proposed) | |

|---|---|---|---|---|---|

| Head Dimensions (m) | |||||

| Microcantilever Dimensions (m) | |||||

| Deflection Rate (nm/C) | 339 | 117 | 339 | 39 | 119 |

| Tip Deflection Due to Stress (m) |

| Tilted-Lined | Tilted-Folded | Raised-Lined | Raised-Folded | Dual-Level | |

|---|---|---|---|---|---|

| Fill-Factor (%) | 55 | 10 | 55 | 70 | 100 |

| Initial Capacitance (pF) | 3.65 | 4.04 | 3.55 | 3.87 | 8.34 |

| Rate (fF/C) | 0.5 | * | 1.4 | 2.1 | 6.5 |

| TCC (ppm) | 135 | * | 403 | 535 | 768 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tawfik, H.H.; Allidina, K.; Nabki, F.; El-Gamal, M.N. Dual-Level Capacitive Micromachined Uncooled Thermal Detector. Sensors 2019, 19, 5434. https://doi.org/10.3390/s19245434

Tawfik HH, Allidina K, Nabki F, El-Gamal MN. Dual-Level Capacitive Micromachined Uncooled Thermal Detector. Sensors. 2019; 19(24):5434. https://doi.org/10.3390/s19245434

Chicago/Turabian StyleTawfik, Hani H., Karim Allidina, Frederic Nabki, and Mourad N. El-Gamal. 2019. "Dual-Level Capacitive Micromachined Uncooled Thermal Detector" Sensors 19, no. 24: 5434. https://doi.org/10.3390/s19245434

APA StyleTawfik, H. H., Allidina, K., Nabki, F., & El-Gamal, M. N. (2019). Dual-Level Capacitive Micromachined Uncooled Thermal Detector. Sensors, 19(24), 5434. https://doi.org/10.3390/s19245434