Polymer Optical Fiber Tip Mass Production Etch Mechanism to Achieve CPC Shape for Improved Biosensor Performance

Abstract

:1. Introduction

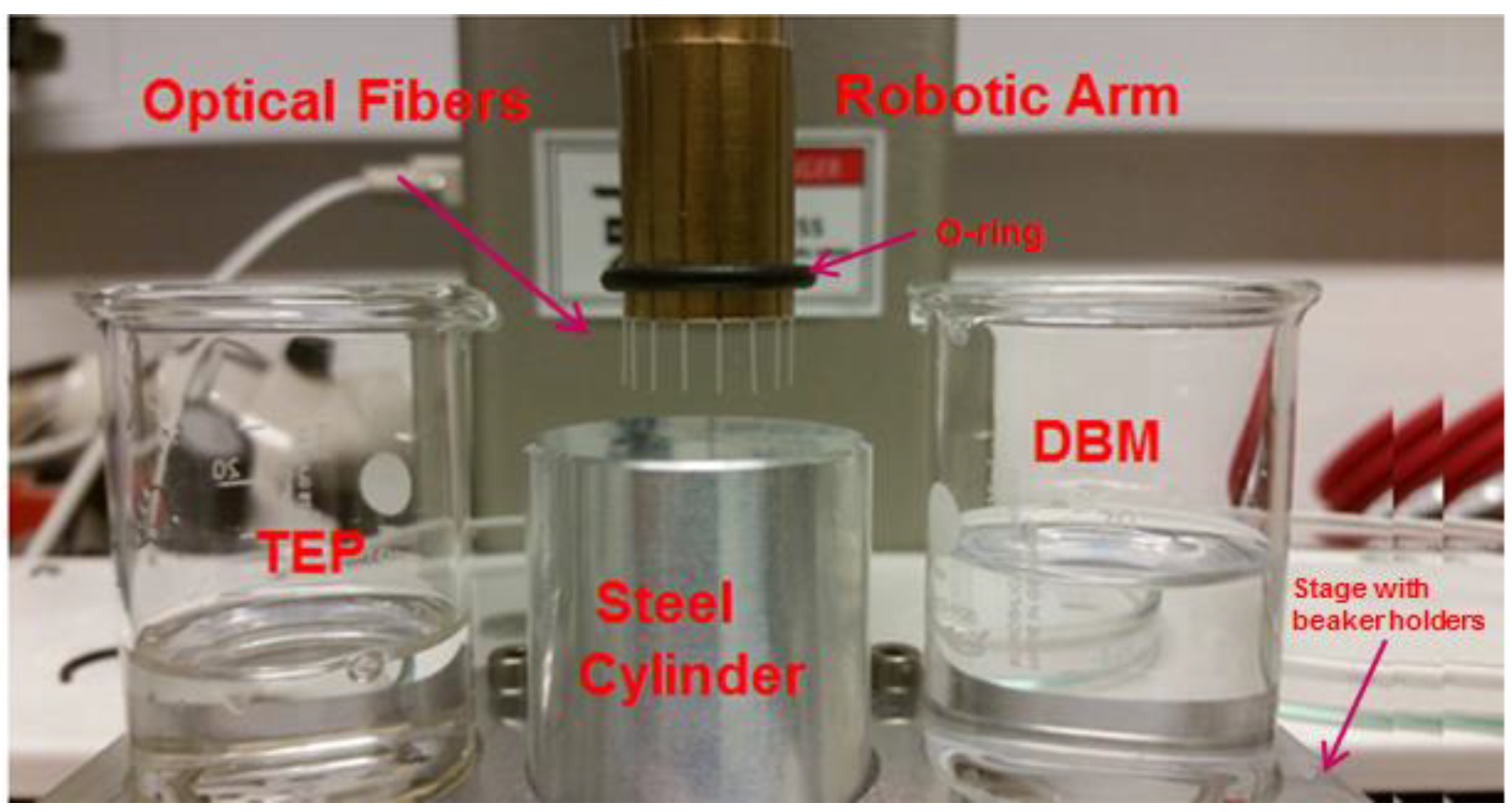

2. Materials and Methods

3. Results and Discussion

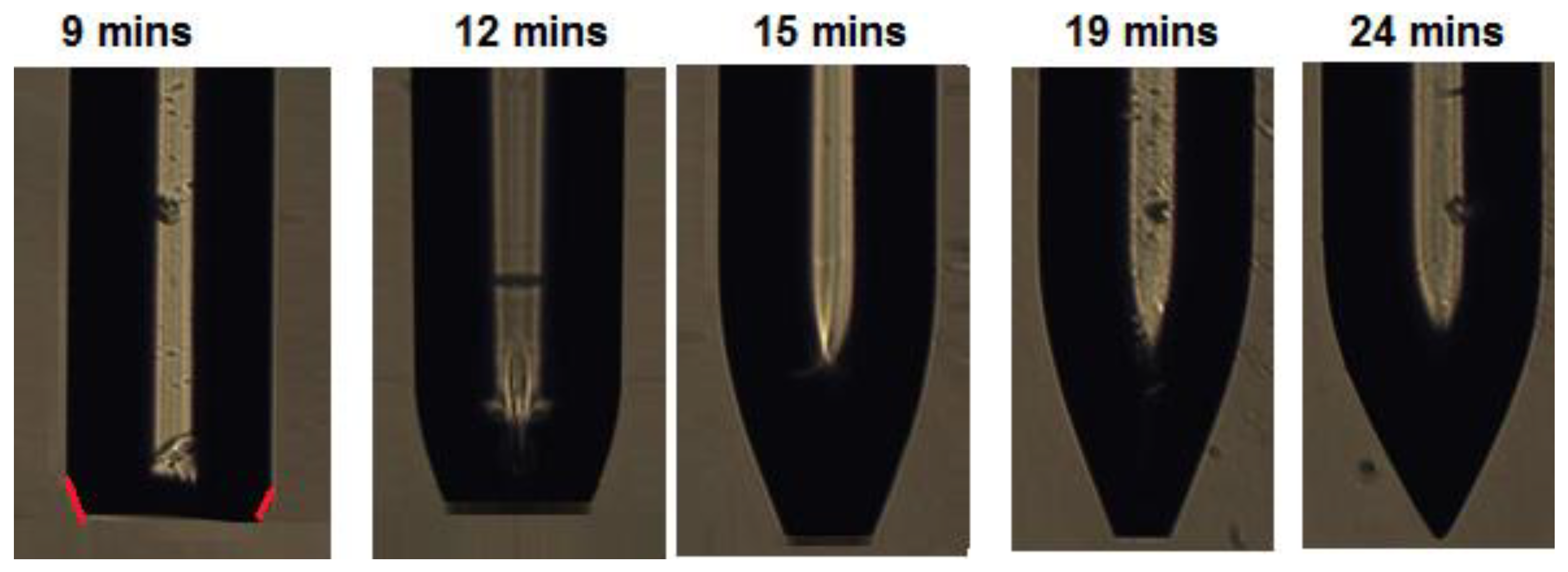

3.1. Etch Mechanism

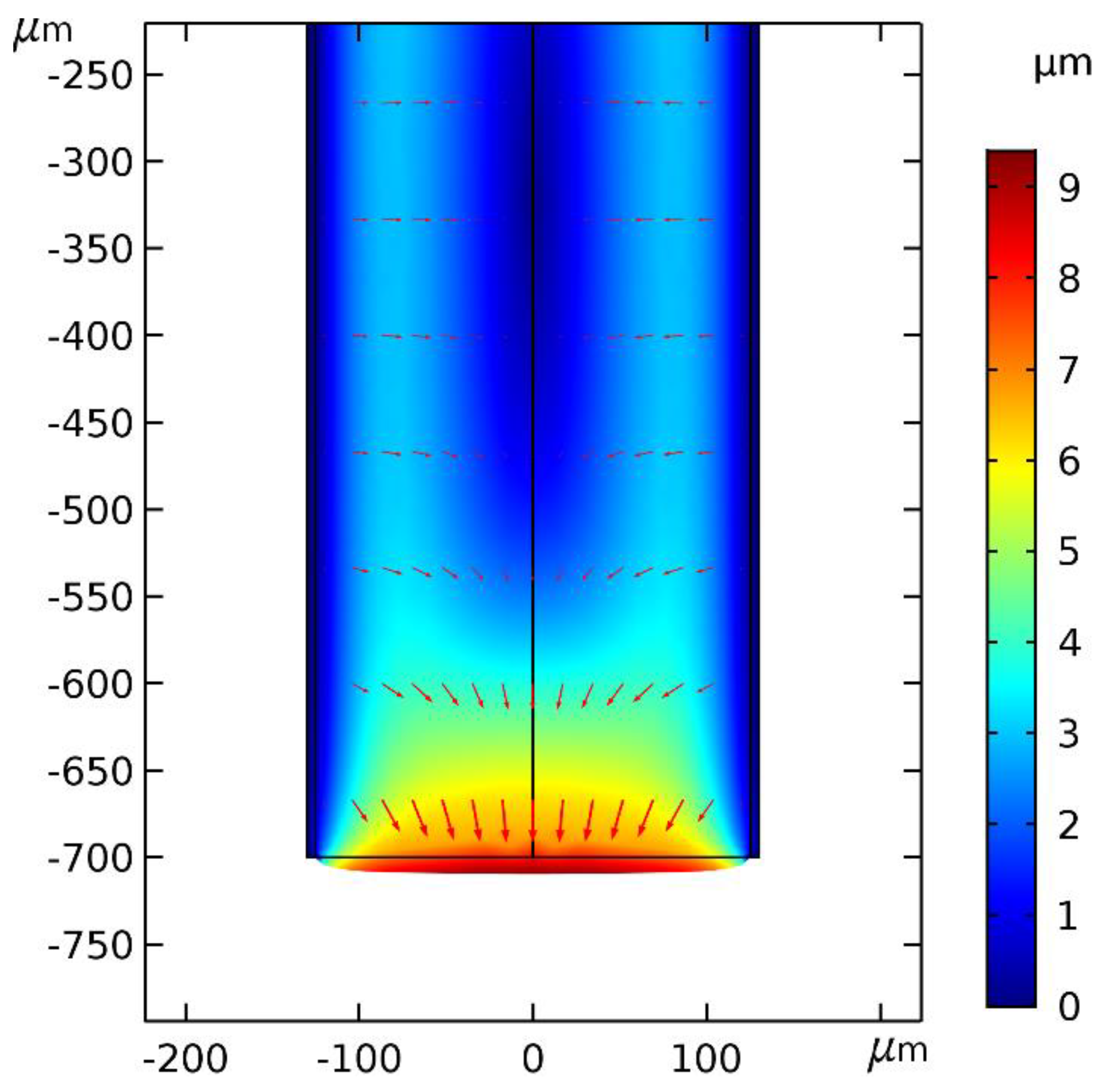

- The concentration profile of anisotropically in-diffused solvent at the fiber tip region. From the fiber drawing polymer molecules are oriented along the fiber axis [36] leading to crystallinity. Diffusion cannot be expected to be isotropic in an anisotropic polymer material [37,38,39]. Thus, it could be that DBM diffusion from the fiber tip along the fiber axis-oriented molecules is much slower than perpendicular to the molecular chain direction. This provides a good explanation for both the almost constant fiber length and the sharp edge maintained at the fiber tip at all etch times.

- The cladding acts as a membrane limiting the DBM transport to the PMMA fiber core. If it is assumed that the DBM partition coefficient at the two PVDF interfaces is 1, the DBM flux F though the membrane is , where D is the DBM diffusivity in PVDF, L is the PVDF thickness, S is the solubility of DBM in PVDF, and P is the DBM permeability of PVDF [38]. This limitation of the DBM access to the core will, to some extent, slow down etch from the side of the fiber.

- The cladding acts as semi-permeable membrane: It is permeable towards DBM but impermeable for the much larger released PMMA polymer chains. This is unlike glass fiber etch inside HF permeable polymer tubes [26] where some transport of the small etch product molecules silicon dioxide (SiO2) and hexafluorosilicic acid (H2SiF6) out through the tube is possible. Thus, in our case, the cladding restricted the polymer swelling and escape of dissolved polymer into the solvent. Furthermore, the polymer-solvent mixture will have a lower density than the surrounding pure DBM (density: 2.5 g/cm3) and thus, due to buoyancy, dissolved material will tend to stay at the fiber tip and in the region between cladding and un-dissolved PMMA core. This is also unlike glass fiber etch inside HF permeable polymer tubes where the product mixture will have higher density than the surrounding HF (density: 1.15 g/cm3). Transport of core polymer out of the PVDF tubing during etch is explained by the osmotic pressure exerted by the polymer solute winning over the buoyancy pressure. The contribution to the osmotic pressure is largest far away from the tip where the concentration of polymer solute in DBM is highest. High polymer concentration at the same time decreases etch speed. At the fiber tip, DBM has direct access to the core, which leads to lower osmotic pressure contribution and higher etch rate.

- Anisotropic etching only due to molecular orientation and length. The crystallinity itself leads to higher etch speed from the vertical side compared to etching from the tip, where the oriented molecule chains are locked deeper into the polymer matrix. At a certain distance from the tip, the etch speed is determined by the angle between the tangent to the etched surface and the fiber axis/molecular orientation, see Figure 3. The higher the angle, the deeper the solvent has to diffuse to free a long molecule. Due to this, the iso-concentration profile corresponding to etch far from the tip might be deviated from close to the tip and lead to the parabolic shape. Note here, that at the fiber tip, there seems to be a critical angle beyond which etching almost stops. This behavior might have similarities to anisotropic etching along crystal planes observed in wet potassium hydroxide (KOH) etching of single crystalline silicon wafers where for instance etching in the <100> direction is 400 times faster than in the <111> direction [42,43]. This results in a sharp edge at the tip, no matter the etch time, which would not have been seen for an isotropic material. For an isotropic polymer etch, edges are rounded off according to the rounded off diffusion profile.

- Anisotropic residual stresses. In the fiber, even after annealing, there will be some residual stresses along the fiber, which are zero at the free plane-cut tip surface. Stresses lower activation energies for diffusion and etch and hence this enhances effects one and five.

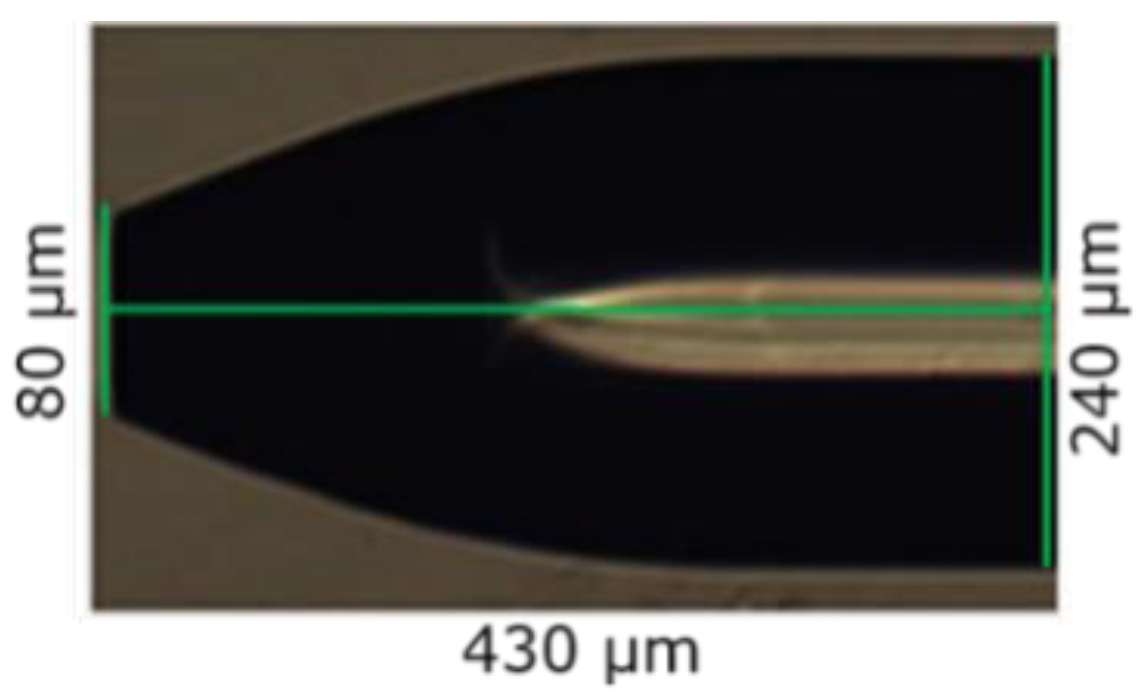

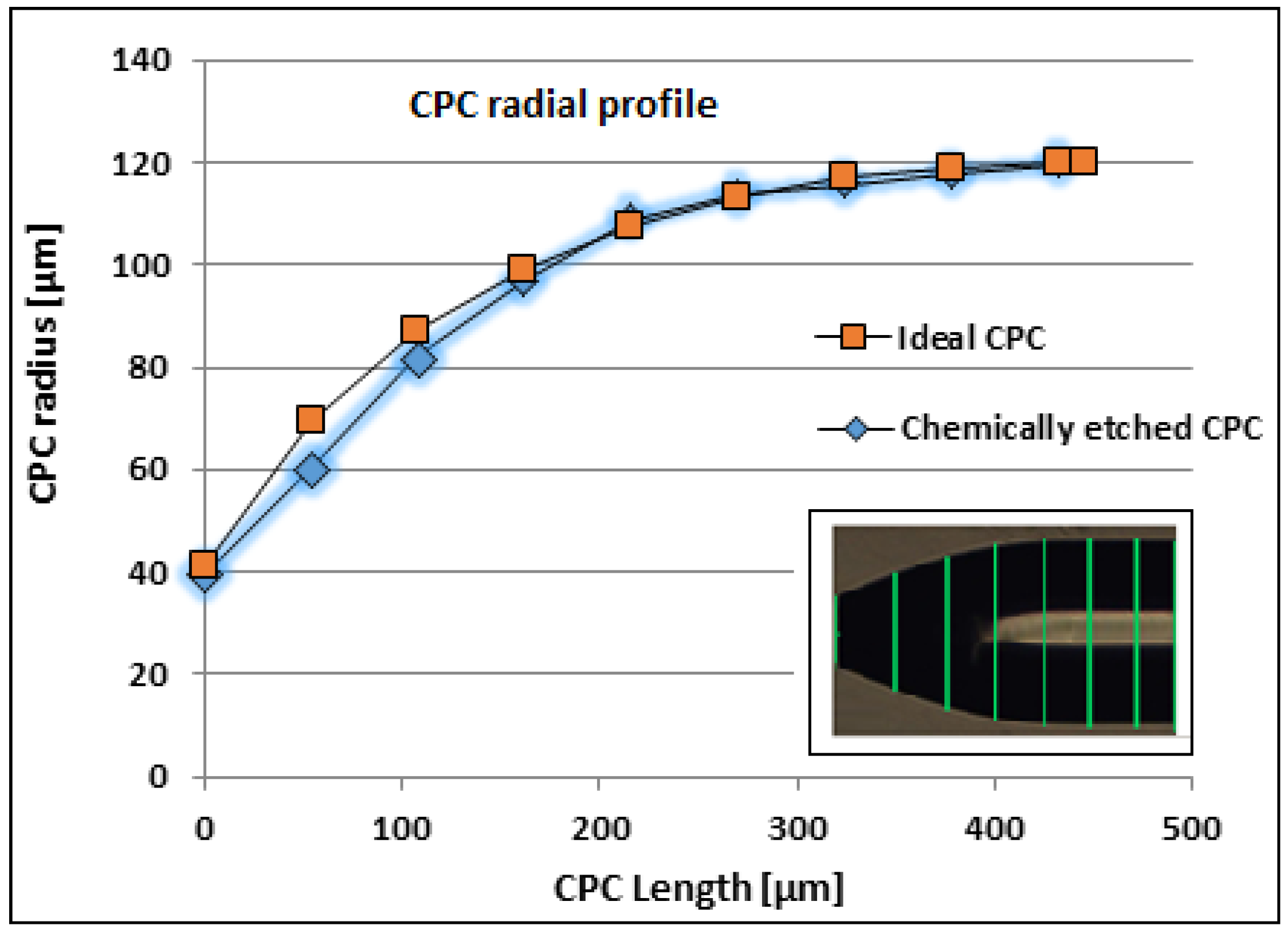

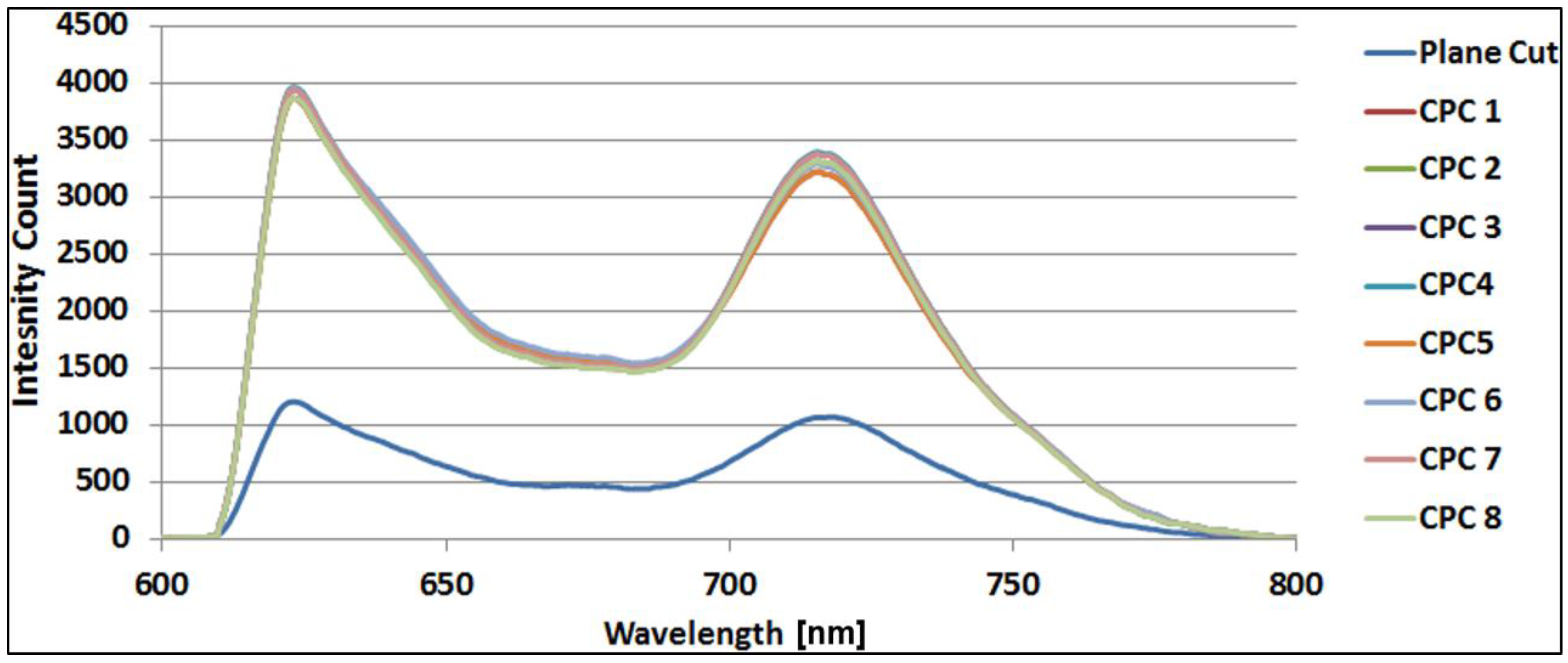

3.2. Characterization

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zubia, J.; Arrue, J. Plastic optical fibers: An introduction to their technological processes and applications. Opt. Fiber Technol. 2001, 7, 101–140. [Google Scholar] [CrossRef]

- Marques, C.A.F.; Webb, D.J.; Andre, P. Polymer optical fiber sensors in human life safety. Opt. Fiber Technol. 2017, 36, 144–154. [Google Scholar] [CrossRef] [Green Version]

- Emiliyanov, G.; Jensen, J.B.; Bang, O.; Hoiby, P.E.; Pedersen, L.H.; Kjaer, E.M.; Lindvold, L. Localized biosensing with Topas microstructured polymer optical fiber. Opt. Lett. 2007, 32, 460–462. [Google Scholar] [CrossRef] [PubMed]

- Hassan, H.U.; Janting, J.; Aasmul, S.; Bang, O. Polymer Optical Fiber Compound Parabolic Concentrator Fiber Tip-Based Glucose Sensor: In Vitro Testing. IEEE Sens. J. 2016, 16, 84838488. [Google Scholar] [CrossRef]

- Jensen, J.B.; Hoiby, P.E.; Emiliyanov, G.; Bang, O.; Pedersen, L.H.; Bjarklev, A. Selective detection of antibodies in microstructured polymer optical fibers. Opt. Express 2005, 13, 5883–5889. [Google Scholar] [CrossRef]

- Cennamo, N.; Massarotti, D.; Conte, L.; Zeni, L. Low cost sensors based on SPR in a plastic optical fiber for biosensor implementation. Sensors 2011, 11, 11752–11760. [Google Scholar] [CrossRef] [PubMed]

- Emiliyanov, G.; Høiby, P.E.; Pedersen, L.H.; Bang, O. Selective serial multi-antibody biosensing with TOPAS microstructured polymer optical fibers. Sensors 2013, 13, 3242–3251. [Google Scholar] [CrossRef]

- Markos, C.; Yuan, W.; Vlachos, K.; Town, G.E.; Bang, O. Label-free biosensing with high sensitivity in dual-core microstructured polymer optical fibers. Opt. Express 2011, 19, 7790–7798. [Google Scholar] [CrossRef]

- Schyrr, B.; Pasche, S.; Scolan, E.; Ischer, R.; Ferrario, D.; Porchet, J.A.; Voirin, G. Development of a polymer optical fiber pH sensor for on-body monitoring application. Sens. Actuators B 2014, 194, 238–248. [Google Scholar] [CrossRef]

- Zhang, H.; Kulkarni, A.; Kim, H.; Woo, D.; Kim, Y.-J.; Hong, B.H.; Choi, J.-B.; Kim, T. Detection of Acetone Vapor Using Graphene on Polymer Optical Fiber. J. Nanosci. Nanotechnol. 2011, 11, 5939–5943. [Google Scholar] [CrossRef]

- Woyessa, G.; Fasano, A.; Markos, C.; Rasmussen, H.; Bang, O. Low loss polycarbonate polymer optical fiber for high temperature FBG humidity sensing. IEEE Photonics Technol. Lett. 2017, 29, 575–578. [Google Scholar] [CrossRef]

- Marques, C.A.F.; Peng, G.-D.; Webb, D.J. Highly sensitive liquid level monitoring system utilizing polymer fiber Bragg gratings. Opt. Express 2015, 23, 6058–6072. [Google Scholar] [CrossRef] [PubMed]

- Müller, A.J.; Knuth, M.; Nikolaus, K.S.; Krivánek, R.; Küster, F.; Hasslacher, C. First clinical evaluation of a new percutaneous optical fiber glucose sensor for continuous glucose monitoring in diabetes. J. Diabetes Sci. Technol. 2013, 7, 13–23. [Google Scholar] [CrossRef]

- Pickup, J.C.; Khan, F.; Zhi, Z.L.; Coulter, J.; Birch, D.J.S. Fluorescence intensity- and lifetime-based glucose sensing using glucose/galactose-binding protein. J. Diabetes Sci. Technol. 2013, 7, 62–71. [Google Scholar] [CrossRef] [PubMed]

- Ballerstadt, R.; Evans, C.; Gowda, A.; McNichols, R. Fiber-coupled fluorescence affinity sensor for 3-day in vivo glucose sensing. J. Diabetes Sci. Technol. 2007, 1, 384–393. [Google Scholar] [CrossRef]

- Hassan, H.U.; Nielsen, K.; Aasmul, S.; Bang, O. Polymer optical fiber compound parabolic concentrator tip for enhanced coupling efficiency for fluorescence based glucose sensors. Biomed. Opt. Express 2015, 6, 5008–5020. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Woehler, A.; Wlodarczyk, J.; Neher, E. Signal/noise analysis of FRET-based sensors. Biophys. J. 2010, 99, 2344–2354. [Google Scholar] [CrossRef]

- Hassan, H.U.; Lacraz, A.; Kalli, K.; Bang, O. Femtosecond laser micromachining of compound parabolic concentrator fiber tipped glucose sensors. J. Biomed. Opt. 2017, 22, 037003. [Google Scholar] [CrossRef] [Green Version]

- Winston, R.; Welford, W. The Optics of Non-Imaging Concentrators. Light and Solar Energy; Academic Press: New York, NY, USA, 1978. [Google Scholar]

- Rabl, A. Optical and thermal properties of compound parabolic concentrators. Sol. Energy 1976, 18, 497–511. [Google Scholar] [CrossRef]

- Chen, L.C.; Low, A.L.Y.; Chien, S.F. Compound parabolic tapered fiber for fiber coupling with a highly divergent source. Appl. Opt. 2004, 43, 5923–5925. [Google Scholar] [CrossRef]

- Mononobe, S.; Ohtsu, M. Fabrication of a pencil-shaped fiber probe for near-field optics by selective chemical etching. J. Light. Technol. 1996, 14, 2231–2235. [Google Scholar] [CrossRef]

- Pangaribuan, T.; Yamada, K.; Jiang, S.; Ohsawa, H.; Ohtsu, M. Reproducible Fabrication Technique of Nanomeric Tip Diameter Fiber Probe for Photon Scanning Tunneling Microscope. Jpn. J. Appl. Phys. 1992, 31, L1302–L1304. [Google Scholar] [CrossRef]

- Muramatsu, H.; Homma, K.; Chiba, N.; Yamamoto, N.; Egawa, A. Dynamic etching method for fabricating a variety of tip shapes in the optical fibre probe of a scanning near-field optical microscope. J. Microsc. 1999, 194, 383–387. [Google Scholar] [CrossRef] [PubMed]

- Puygranier, B.A.F.; Dawson, P. Chemical etching of optical fibre tips—Experiment and model. Ultramicroscopy 2000, 85, 235–248. [Google Scholar] [CrossRef]

- Stöckle, R.; Fokas, C.; Deckert, V.; Zenobi, R.; Sick, B.; Hecht, B.; Wild, U.P. High-quality near-field optical probes by tube-etching. Appl. Phys. Lett. 1999, 75, 160–162. [Google Scholar] [CrossRef]

- Zhu, W.; Shi, T.; Tang, Z.; Gong, B.; Liao, G.; Tully, J. Dynamic selective etching: A facile route to parabolic optical fiber nano-probe. Opt. Express 2013, 21, 6919–6927. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.M.; Jou, D.C.; Chen, M.H.; Wu, S.H.; Cheng, W.H. An optimum approach for fabrication of tapered hemispherical-end fiber for laser module packaging. J. Electron. Mater. 2001, 30, 271–274. [Google Scholar] [CrossRef]

- Merchant, D.F.; Scully, P.J.; Schmitt, N.F. Chemical tapering of polymer optical fibre. Sens. Actuators A 1999, 76, 365–371. [Google Scholar] [CrossRef]

- Supian, L.S.; Syuhaimiah-rahman, M. Polymer Optical Fiber Coupler Fabrication using Chemical Etching and Lapping Technique. In Proceedings of the 2013 IEEE 4th International Conference on Photonics (ICP), Melaka, Malaysia, 28–30 October 2013; pp. 184–186. [Google Scholar]

- Hu, X.; Pun, C.-F.J.; Tam, H.-Y.; Mégret, P.; Caucheteur, C. Highly reflective Bragg gratings in slightly etched step-index polymer optical fiber. Opt. Express 2014, 22, 18807–18817. [Google Scholar] [CrossRef]

- Rajan, G.; Liu, B.; Luo, Y.; Ambikairajah, E.; Peng, G.D. High sensitivity force and pressure measurements using etched singlemode polymer fiber bragg gratings. IEEE Sens. J. 2013, 13, 1794–1800. [Google Scholar] [CrossRef]

- Dang, T.T.; Egesborg, H.; Janting, J.; Shah, R.; Aaskov, D.; Hall, J.F.; Aasmul, S. Biostable Glucose Permeable Polymer. U.S. Patent 9,848,805B2, 26 December 2017. [Google Scholar]

- Bottino, A.; Capannelli, G.; Munari, S.; Turturro, A. Solubility parameters of poly (vinylidene fluoride). J. Polym. Sci. Part B Polym. Phys. 1988, 26, 785–794. [Google Scholar] [CrossRef]

- Hansen, C.M. Hansen Solubility Parameters. A User’s Handbook, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2007; ISBN 9780849372483. [Google Scholar]

- Stajanca, P.; Cetinkaya, O.; Schukar, M.; Mergo, P.; Webb, D.J.; Krebber, K. Molecular alignment relaxation in polymer optical fibers for sensing applications. Opt. Fiber Technol. 2016, 28, 11–17. [Google Scholar] [CrossRef] [Green Version]

- Hartley, G.S. Diffusion and swelling of high polymers. Part III. Anisotropic swelling in oriented polymer film. Trans. Faraday Soc. 1949, 45, 820–832. [Google Scholar] [CrossRef]

- Janting, J. Microsystem Reliability: Polymer Adhesive and Coating Materials for Packaging; LAP Lambert Academic Publishing: Riga, Latvia, 2009; ISBN 978-3-8383-3426-4. [Google Scholar]

- Crank, J. The Mathematics of Diffusion; Oxford University Press: Oxford, UK, 1975. [Google Scholar]

- Miller-Chou, B.A.; Koenig, J.L. A review of polymer dissolution. Prog. Polym. Sci. 2003, 28, 1223–1270. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.; Lahoti, S.P.; Sitlani, M.P.; Kallolimath, S.C.; Putta, R. Investigation of Inter-Layer Dielectric (ILD) failure by hygroscopic swelling. In Proceedings of the 2005 Electronic Components and Technology Conference, Lake Buena Vista, FL, USA, 31 May–3 June 2005; Volume 2, pp. 1254–1260. [Google Scholar]

- Petersen, K.E. Silicon as a Mechanical Material. Proc. IEEE 1982, 70, 420–457. [Google Scholar] [CrossRef]

- Elwenspoek, M. On the Mechanism of Anisotropic Etching of Silicon. J. Electrochem. Soc. 1993, 140, 2075–2080. [Google Scholar] [CrossRef]

| Core Material | Cladding Material | Fiber Diameter | Core Diameter | Cladding Thickness |

|---|---|---|---|---|

| PMMA* | Fluorine polymer | 250 µm | 240 µm | 5 µm |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassan, H.U.; Bang, O.; Janting, J. Polymer Optical Fiber Tip Mass Production Etch Mechanism to Achieve CPC Shape for Improved Biosensor Performance. Sensors 2019, 19, 285. https://doi.org/10.3390/s19020285

Hassan HU, Bang O, Janting J. Polymer Optical Fiber Tip Mass Production Etch Mechanism to Achieve CPC Shape for Improved Biosensor Performance. Sensors. 2019; 19(2):285. https://doi.org/10.3390/s19020285

Chicago/Turabian StyleHassan, Hafeez Ul, Ole Bang, and Jakob Janting. 2019. "Polymer Optical Fiber Tip Mass Production Etch Mechanism to Achieve CPC Shape for Improved Biosensor Performance" Sensors 19, no. 2: 285. https://doi.org/10.3390/s19020285

APA StyleHassan, H. U., Bang, O., & Janting, J. (2019). Polymer Optical Fiber Tip Mass Production Etch Mechanism to Achieve CPC Shape for Improved Biosensor Performance. Sensors, 19(2), 285. https://doi.org/10.3390/s19020285