Deceleration Planning Algorithm Based on Classified Multi-Layer Perceptron Models for Smart Regenerative Braking of EV in Diverse Deceleration Conditions

Abstract

1. Introduction

2. System Overview

2.1. Description of Deceleration Conditions

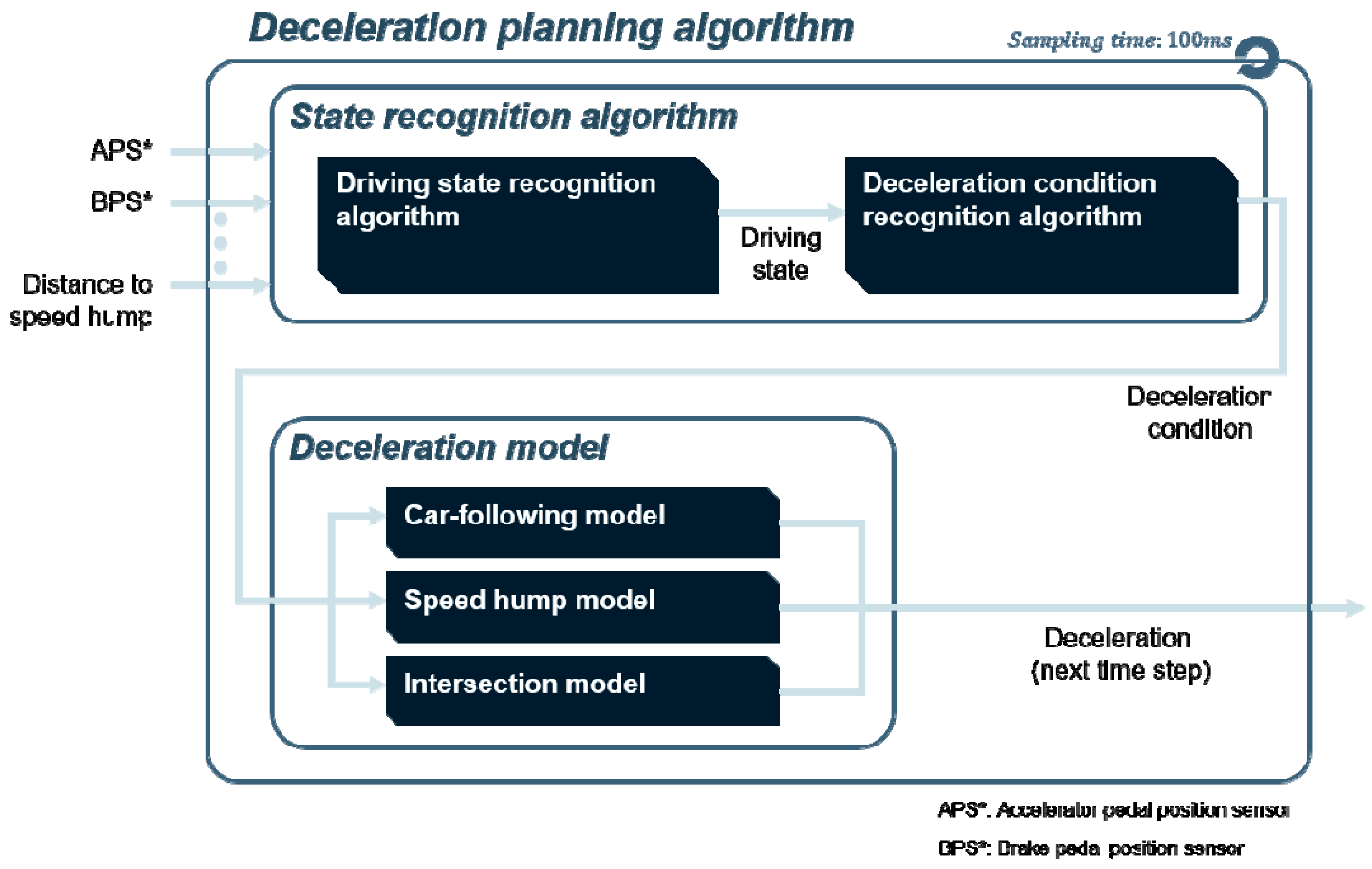

2.2. Algorithm Overview

3. State Recognition Algorithm

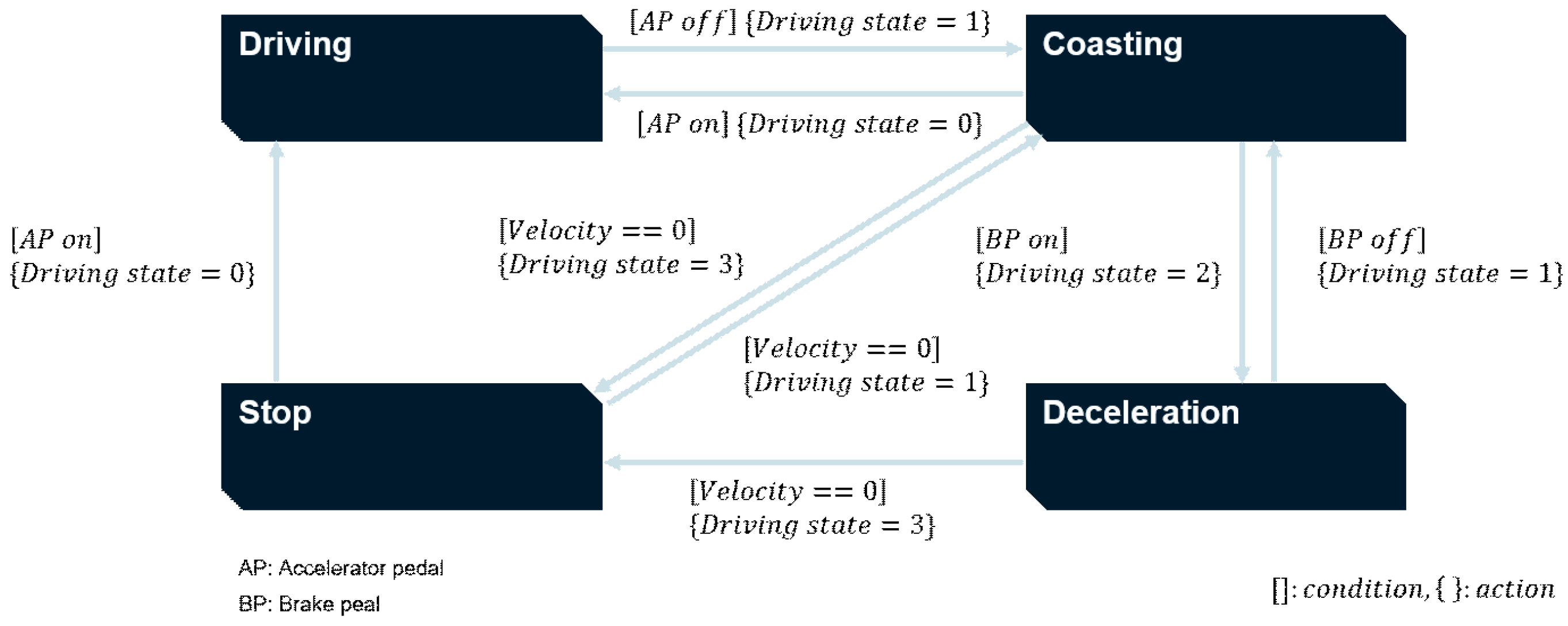

3.1. Driving State Recognition Algorithm

- Driving: driver pushes the accelerator pedal.

- Coasting: driver pushes neither the accelerator nor the brake pedal.

- Deceleration: driver pushes the brake pedal and the velocity is not zero.

- Stop: vehicle speed is zero, which means that the vehicle does not move at all.

3.2. Deceleration Condition Recognition Algorithm

4. Deceleration Model Based on Multi-Layer Perceptron

4.1. Design of the Input Layer

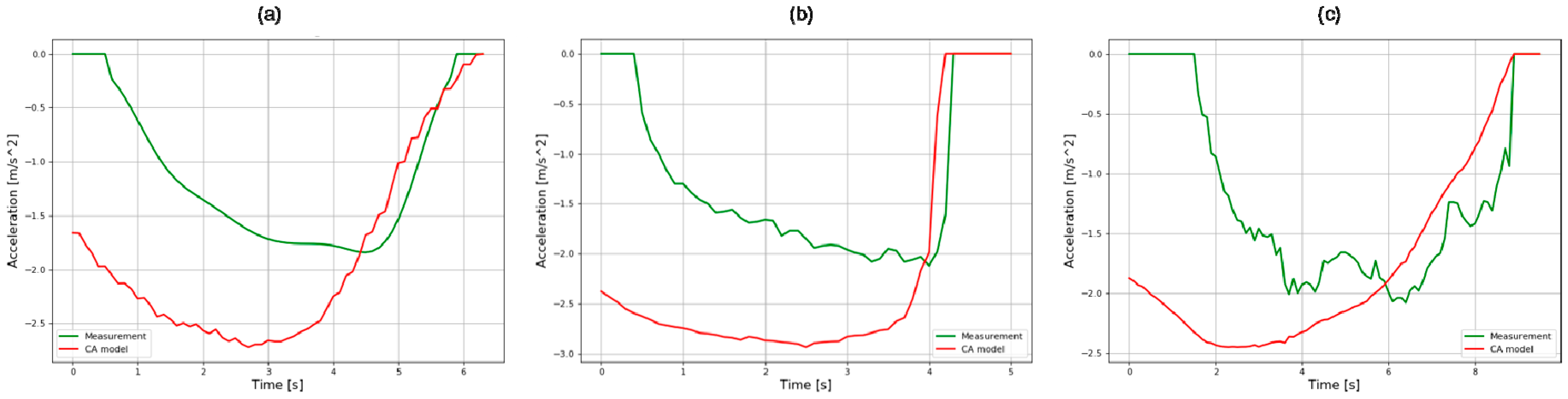

4.1.1. Driver Behavior during Deceleration

4.1.2. Selection of the Input Set

4.1.3. Normalization of Inputs

4.2. Design of the Hidden Layer

5. Experiments

5.1. Experiment Environments

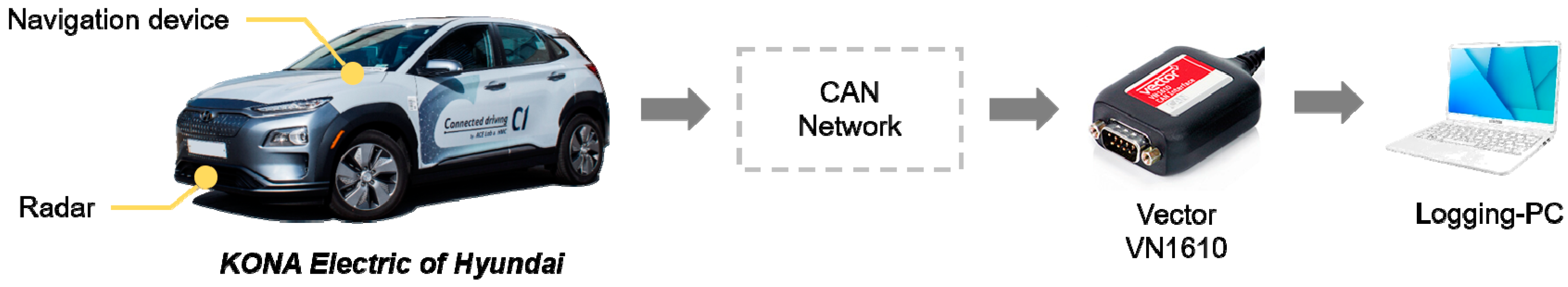

5.1.1. Test Vehicle Configuration

5.1.2. Test Route

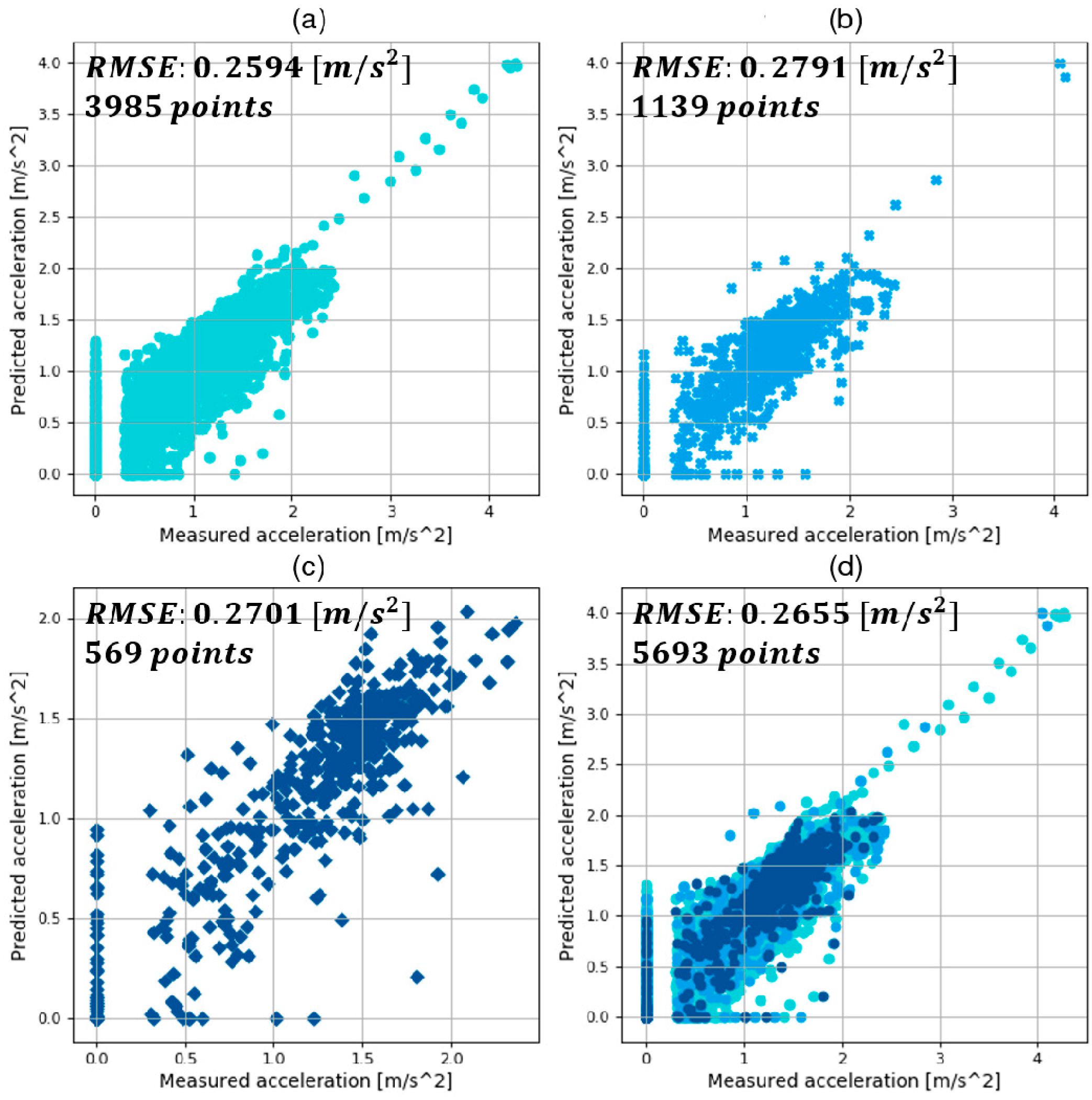

5.2. Training

5.2.1. Input and Target Data

5.2.2. Dataset Splitting

5.2.3. Training and Hyper-Parameter Optimization

6. Validation through Driving Simulation

6.1. Driving Simulation Process

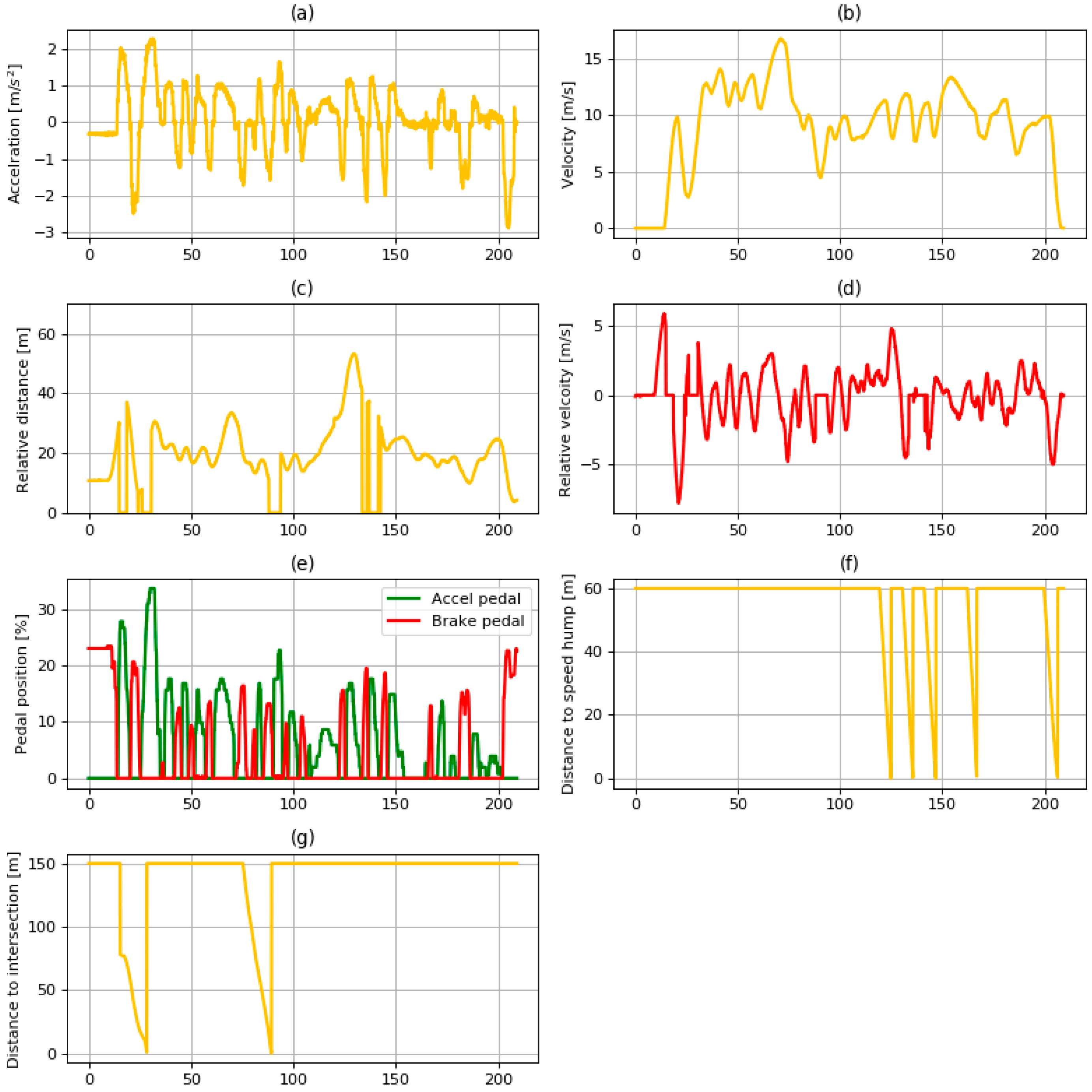

6.2. Data for Driving Simulation

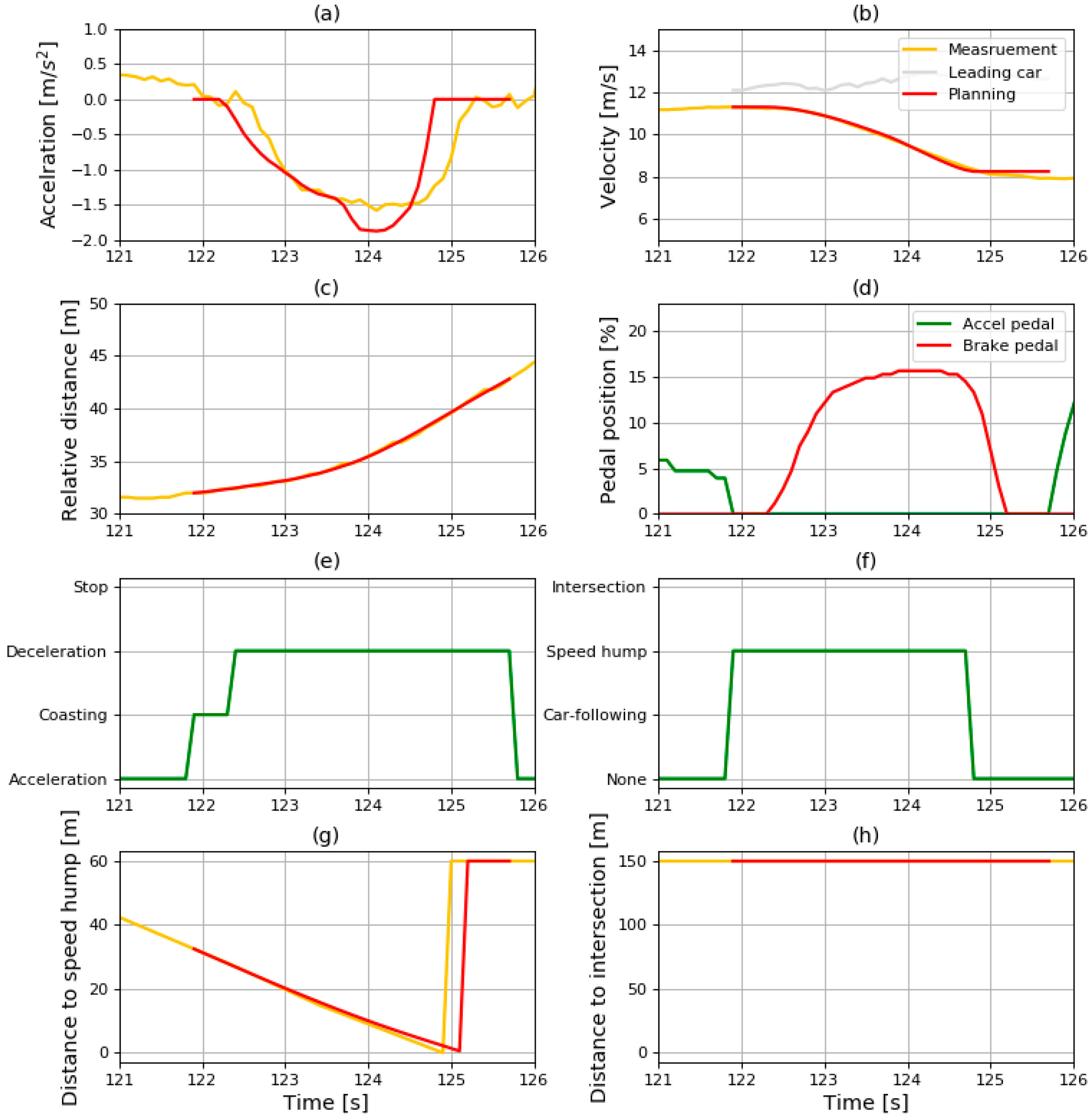

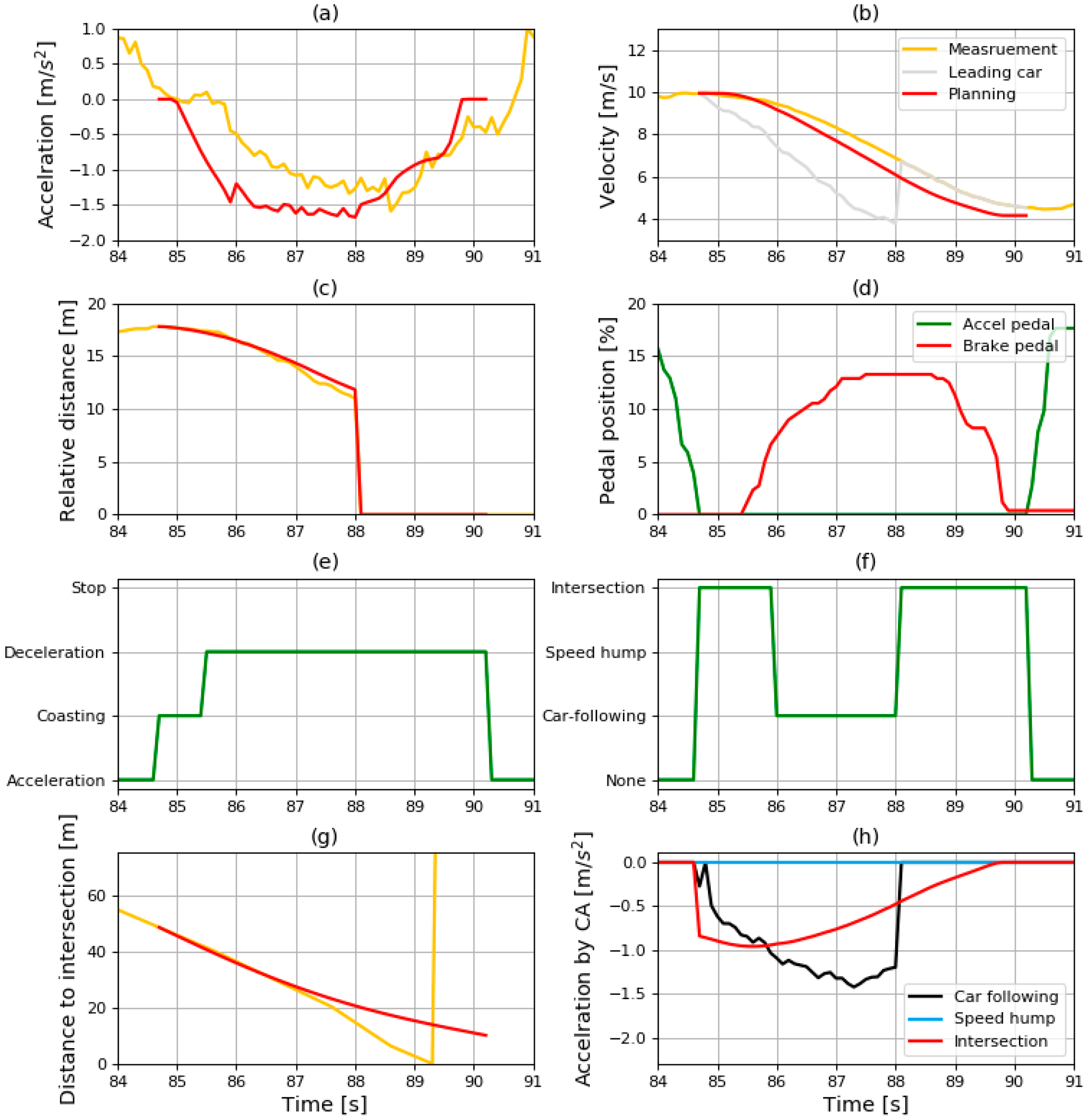

- Relative distance: The data of relative distance were acquired from the radar sensor described in Table 1. Sometimes, the distance value decreased to zero, which means that there were no vehicles in front of the ego vehicle.

- Distance to a speed bump: Distance to a speed bump was calculated using the locations of the ego vehicle and speed bumps acquired from the navigation device. When the distance to the speed bump was more than 60 m or when there were no speed bumps in front of the ego vehicle, the value was 60 m.

- Distance to an intersection: Similar to the distance to a speed bump, the distance to an intersection was calculated using the locations of the ego vehicle and intersection from the navigation device. When the distance to the intersection was more than 150 m or when there was no intersection in front of the ego vehicle, the value remained at 150 m.

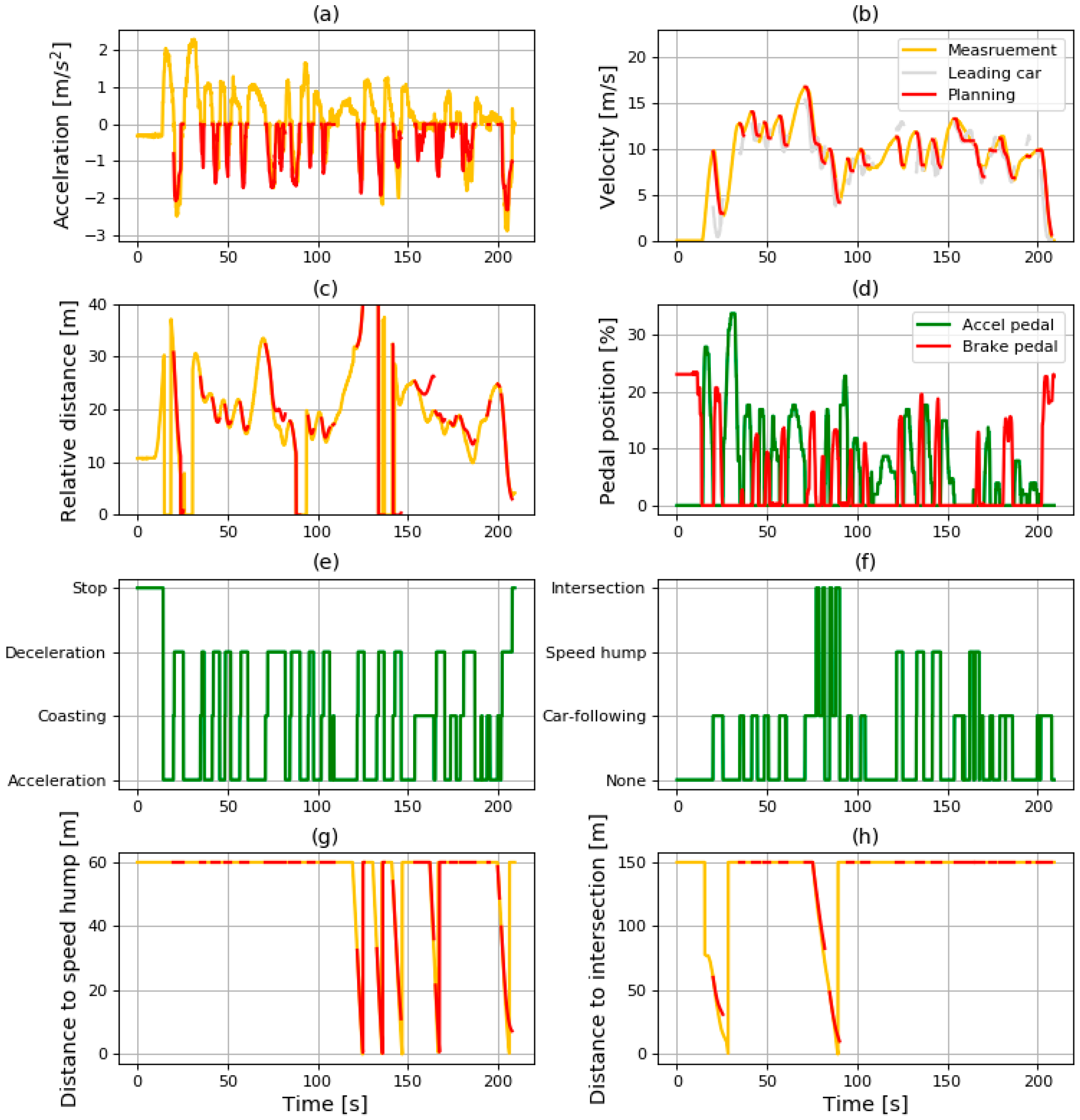

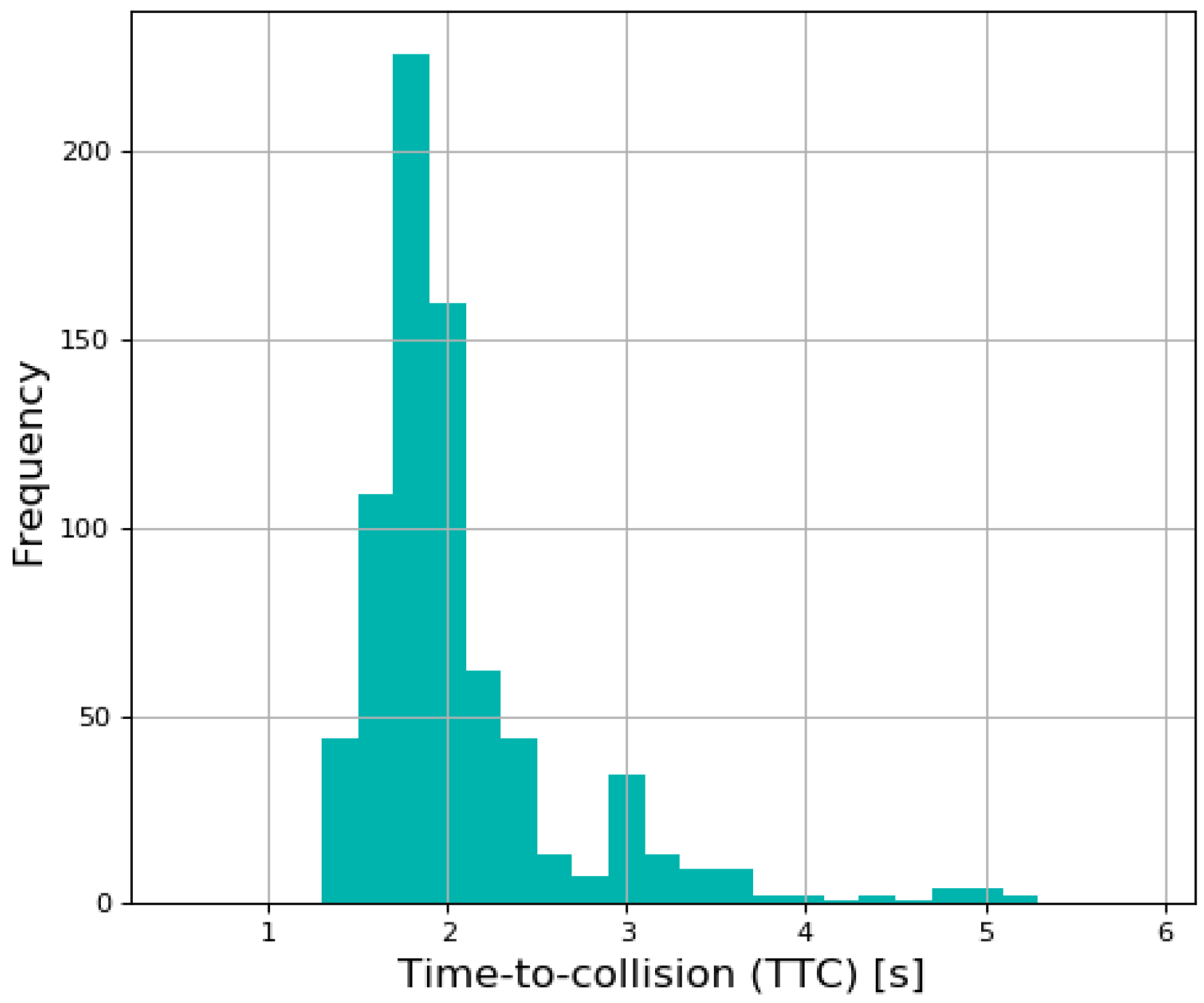

6.3. Results of the Driving Simulation

6.3.1. Overall Description of the Driving Simulation Results

6.3.2. Results in Car-Following Condition

6.3.3. Results from the Speed Bump Condition

6.3.4. Results in Intersection Condition

6.4. Comparison with the Integrated ANN Model

7. Conclusions

- The best model in car-following showed a validation RMSE of and a total RMSE of ;

- The best model in speed bump showed a validation RMSE of and a total RMSE of ;

- The best model in intersection showed a validation RMSE of and a total RMSE of .

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Van Boekel, J.J.P.; Besselink, I.J.M.; Nijmeijer, H. Design and realization of a One-Pedal-Driving algorithm for the TU/e Lupo EL. World Electr. Veh. J. 2015, 7, 226–237. [Google Scholar] [CrossRef]

- Jung, M.; Kessler, F.; Müller, P.; Wahl, S. Vehicle Integration and Driving Characteristics of the BMW Active E. ATZ Wordwide 2012, 114, 52–56. [Google Scholar] [CrossRef]

- Helmbrecht, M.; Olaverri-Monreal, C.; Bengler, K.; Vilimek, R.; Keinath, A. How electric vehicles affect driving behavioral patterns. IEEE Intell. Transp. Syst. Mag. 2014, 6, 22–32. [Google Scholar] [CrossRef]

- Lee, J.; Kim, H. Control Apparatus and Method for Regenerative Braking of Eco-Friendly Vehicle. K.R. Patent 101558772, 21 June 2014. [Google Scholar]

- McCall, J.C.; Trivedi, M.M. Driver Behavior and Situation-aware Brake Assistance for Intelligent Vehicles. Proc. IEEE 2007, 95, 374–387. [Google Scholar] [CrossRef]

- Lin, C.L.; Hung, H.C.; Li, J.C. Active control of regenerative brake for electric vehicles. High. Throughput 2018, 7, 84. [Google Scholar] [CrossRef]

- Qian, G.; Wang, G. Research on the Anti-Disturbance Control Method of Brake-by-Wire Unit for Electric Vehicles. World Electr. Veh. J. 2019, 10, 44. [Google Scholar]

- Hasenjager, M.; Wersing, H. Personalization in advanced driver assistance systems and autonomous vehicles: A review. IEEE Conf. Intell. Transp. Syst. Proc. ITSC 2018, 1–7. [Google Scholar] [CrossRef]

- Moon, S.; Yi, K. Human driving data-based design of a vehicle adaptive cruise control algorithm. Veh. Syst. Dyn. 2008, 46, 661–690. [Google Scholar] [CrossRef]

- Morton, J.; Wheeler, T.A.; Kochenderfer, M.J. Analysis of Recurrent Neural Networks for Probabilistic Modeling of Driver Behavior. IEEE Trans. Intell. Transp. Syst. 2017, 18, 1289–1298. [Google Scholar] [CrossRef]

- Colombaroni, C.; Fusco, G. Artificial neural network models for car following: Experimental analysis and calibration issues. J. Intell. Transp. Syst. Technol. Plan. Oper. 2014, 18, 5–16. [Google Scholar] [CrossRef]

- Zheng, J.; Suzuki, K.; Fujita, M. Car-following behavior with instantaneous driver-vehicle reaction delay: A neural-network-based methodology. Transp. Res. Part. C Emerg. Technol. 2013, 36, 339–351. [Google Scholar] [CrossRef]

- Zhou, M.; Qu, X.; Li, X. A recurrent neural network based microscopic car following model to predict traffic oscillation. Transp. Res. Part. C Emerg. Technol. 2017, 84, 245–264. [Google Scholar] [CrossRef]

- Chong, L.; Abbas, M.M.; Medina, A. Simulation of Driver Behavior with Agent-Based Back-Propagation Neural Network. Transp. Res. Rec. J. Transp. Res. Board 2011, 2249, 44–51. [Google Scholar] [CrossRef]

- Cheng, Z.; Chow, M.-Y.; Jung, D.; Jeon, J. A big data based deep learning approach for vehicle speed prediction. In Proceedings of the IEEE 26th International Symposium on Industrial Electronics (ISIE), Edinburgh, UK, 19–21 June 2017; pp. 389–394. [Google Scholar]

- Khodayari, A.; Ghaffari, A.; Kazemi, R.; Braunstingl, R. A Modified Car-Following Model Based on a Neural Network Model of the Human Driver Effects. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 2012, 42, 1440–1449. [Google Scholar] [CrossRef]

- Jia, H.; Juan, Z.; Ni, A. Develop a car-following model using data collected by five-wheel system. In Proceedings of the 2003 IEEE International Conference on Intelligent Transportation Systems, Shanghai, China, 12–15 October 2003; Volume 1, pp. 346–351. [Google Scholar]

- Chong, L.; Abbas, M.M.; Medina Flintsch, A.; Higgs, B. A rule-based neural network approach to model driver naturalistic behavior in traffic. Transp. Res. Part C Emerg. Technol. 2013, 32, 207–223. [Google Scholar] [CrossRef]

- Lang, D.; Schmied, R.; Del Re, L. Prediction of Preceding Driver Behavior for Fuel Efficient Cooperative Adaptive Cruise Control. SAE Int. J. Engin. 2014, 7, 14–20. [Google Scholar] [CrossRef]

- Li, Y.; Wang, H.; Wang, W.; Liu, S.; Xiang, Y. Reducing the risk of rear-end collisions with infrastructure-to-vehicle (I2V) integration of variable speed limit control and adaptive cruise control system. Traffic Inj. Prev. 2016, 17, 597–603. [Google Scholar] [CrossRef] [PubMed]

- Yeon, K.; Min, K.; Shin, J.; Myoungho, S.; Han, M. Ego-vehicle speed prediction using a long short-term memeory based recurrent neural network. Int. J. Automot. Technol. 2019, 20, 713–722. [Google Scholar] [CrossRef]

- Drezga, I.; Rahman, S. Input variable selection for ann-based short-term load forecasting. IEEE Trans. Power Syst. 1998, 13, 1238–1244. [Google Scholar] [CrossRef]

| Deceleration Factor | Required Velocity | Distance to Object |

|---|---|---|

| Car-following | Preceding vehicle speed | Relative distance |

| Speed bump | Minimum velocity (30 km/h) | Distance to speed bump |

| Intersection | Minimum velocity (15 km/h) | Distance to intersection |

| Hyper-Parameter | Specifications |

|---|---|

| Number of hidden nodes in first hidden layer | 20–40 (5 units) |

| Number of hidden nodes in second hidden layer | 20–40 (5 units) |

| Activation function in each hidden layer | Relu, Sigmoid, Tanh, elu |

| Optimizer | SGD, ADAGRAD, NADAM, RMSprop |

| Dropout | 0.1–0.3 (0.1 units) |

| Iteration of training | 200, 400 |

| Index | Value |

|---|---|

| Maximum range | 150 m |

| FOV (field of view) | ±10° over 60 m |

| ±45° under 60 m | |

| Update rate | 50 ms |

| Hyper-Parameter | Car-Following | Speed Bump | Intersection |

|---|---|---|---|

| Number of hidden nodes in first hidden layer | 25 | 30 | 25 |

| Number of hidden nodes in second hidden layer | 25 | 30 | 30 |

| Activation function in each hidden layer | Relu | Relu | Relu |

| Optimizer | RMSprop | NADAM | NADAM |

| Dropout | 0.1 | 0.1 | 0.1 |

| Iteration of training | 400 | 400 | 400 |

| Deceleration Condition | RMSE (m/s) |

|---|---|

| Car-following | 0.088 |

| Speed bump | 0.015 |

| Intersection | 0.27 |

| Classified Structure | Integrated Structure | |

|---|---|---|

| RMSE of velocity (m/s) | 0.312 | 0.901 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sim, G.; Min, K.; Ahn, S.; Sunwoo, M.; Jo, K. Deceleration Planning Algorithm Based on Classified Multi-Layer Perceptron Models for Smart Regenerative Braking of EV in Diverse Deceleration Conditions. Sensors 2019, 19, 4020. https://doi.org/10.3390/s19184020

Sim G, Min K, Ahn S, Sunwoo M, Jo K. Deceleration Planning Algorithm Based on Classified Multi-Layer Perceptron Models for Smart Regenerative Braking of EV in Diverse Deceleration Conditions. Sensors. 2019; 19(18):4020. https://doi.org/10.3390/s19184020

Chicago/Turabian StyleSim, Gyubin, Kyunghan Min, Seongju Ahn, Myoungho Sunwoo, and Kichun Jo. 2019. "Deceleration Planning Algorithm Based on Classified Multi-Layer Perceptron Models for Smart Regenerative Braking of EV in Diverse Deceleration Conditions" Sensors 19, no. 18: 4020. https://doi.org/10.3390/s19184020

APA StyleSim, G., Min, K., Ahn, S., Sunwoo, M., & Jo, K. (2019). Deceleration Planning Algorithm Based on Classified Multi-Layer Perceptron Models for Smart Regenerative Braking of EV in Diverse Deceleration Conditions. Sensors, 19(18), 4020. https://doi.org/10.3390/s19184020