OFBG-Based Smart Double-Skin Tubular Confined-Concrete Column with Basalt FRP-Steel Composite

Abstract

1. Introduction

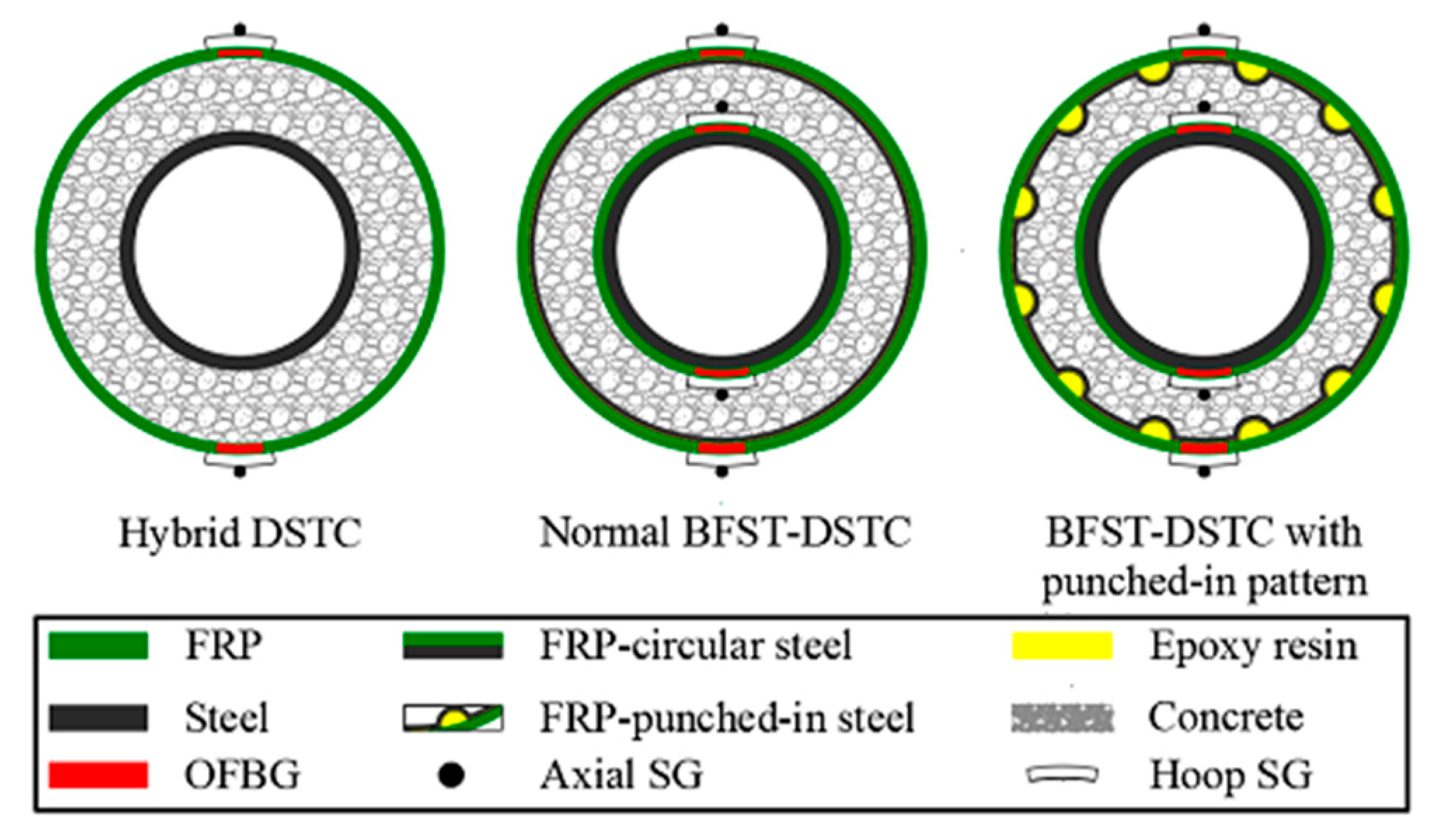

2. Design, Manufacturing, and Sensing Principle of the Smart BFST-DSTC

2.1. Design of the Smart BFST-DSTC

2.2. Fabrication of the Scaled Smart BFST-DSTC

2.3. Sensing Principle of the OFBG

3. Lab Tests on the Smart Columns

3.1. Test Specimens

3.2. Materials

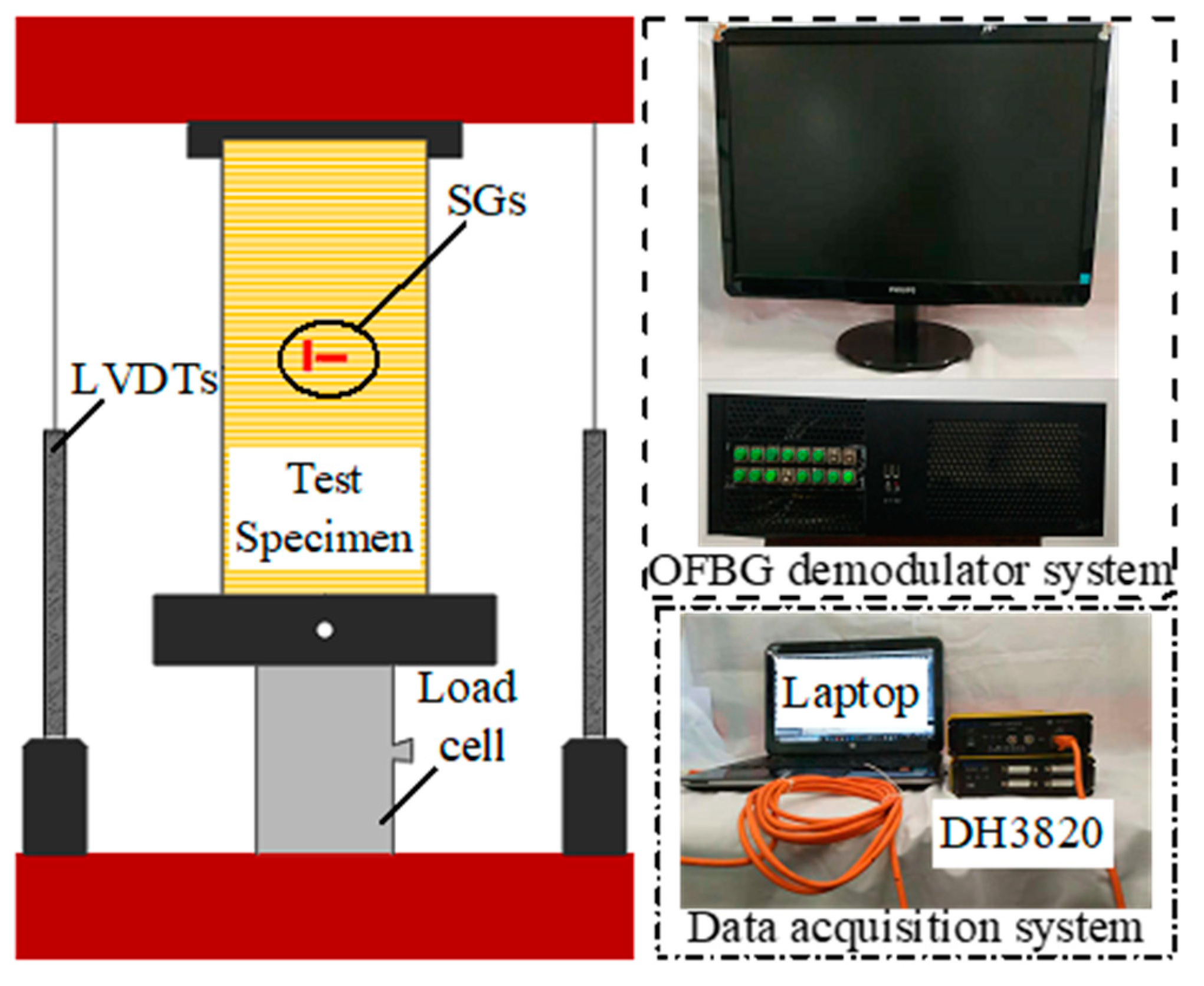

3.3. Test Set-Up and Loading Procedure

4. Results and Discussions

4.1. Mechanical Performance and Behavior of the Proposed BFST-DSTC

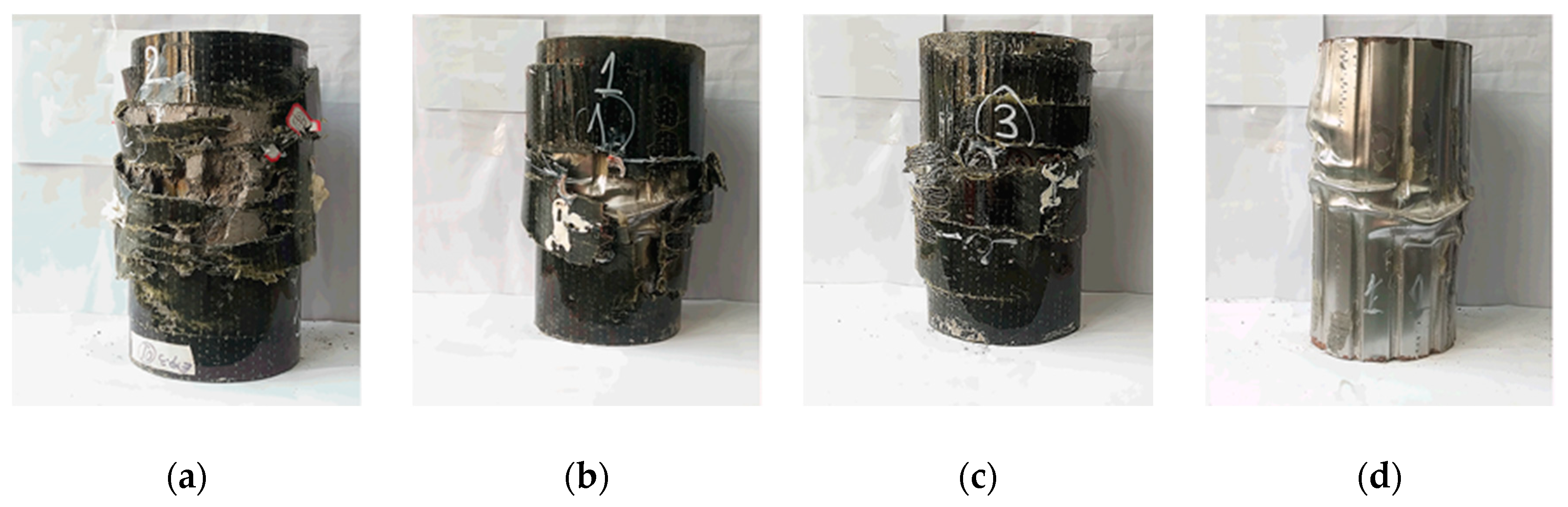

4.1.1. Failure and Damage Mechanisms

4.1.2. Load-Carrying Capacity and Confinement Ratio

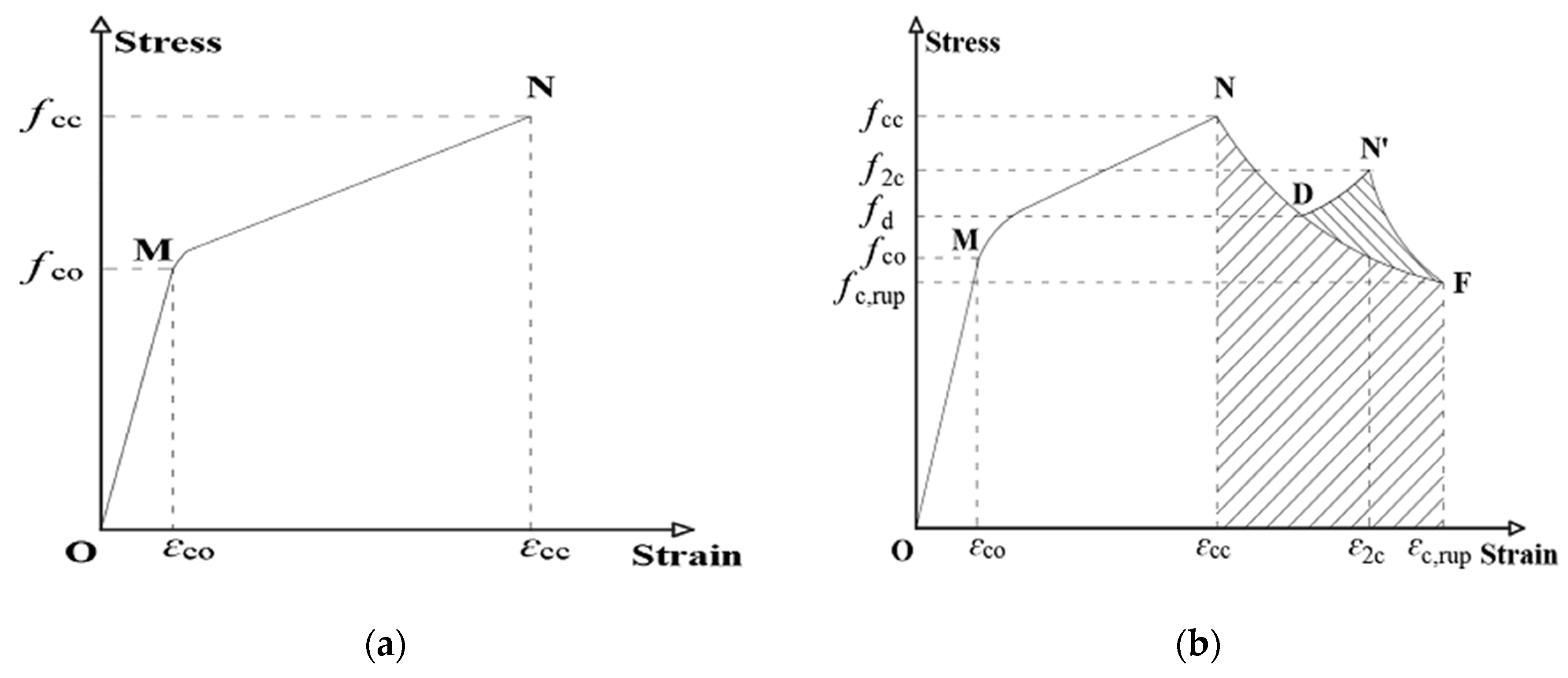

4.1.3. Axial Stress–Strain Behavior

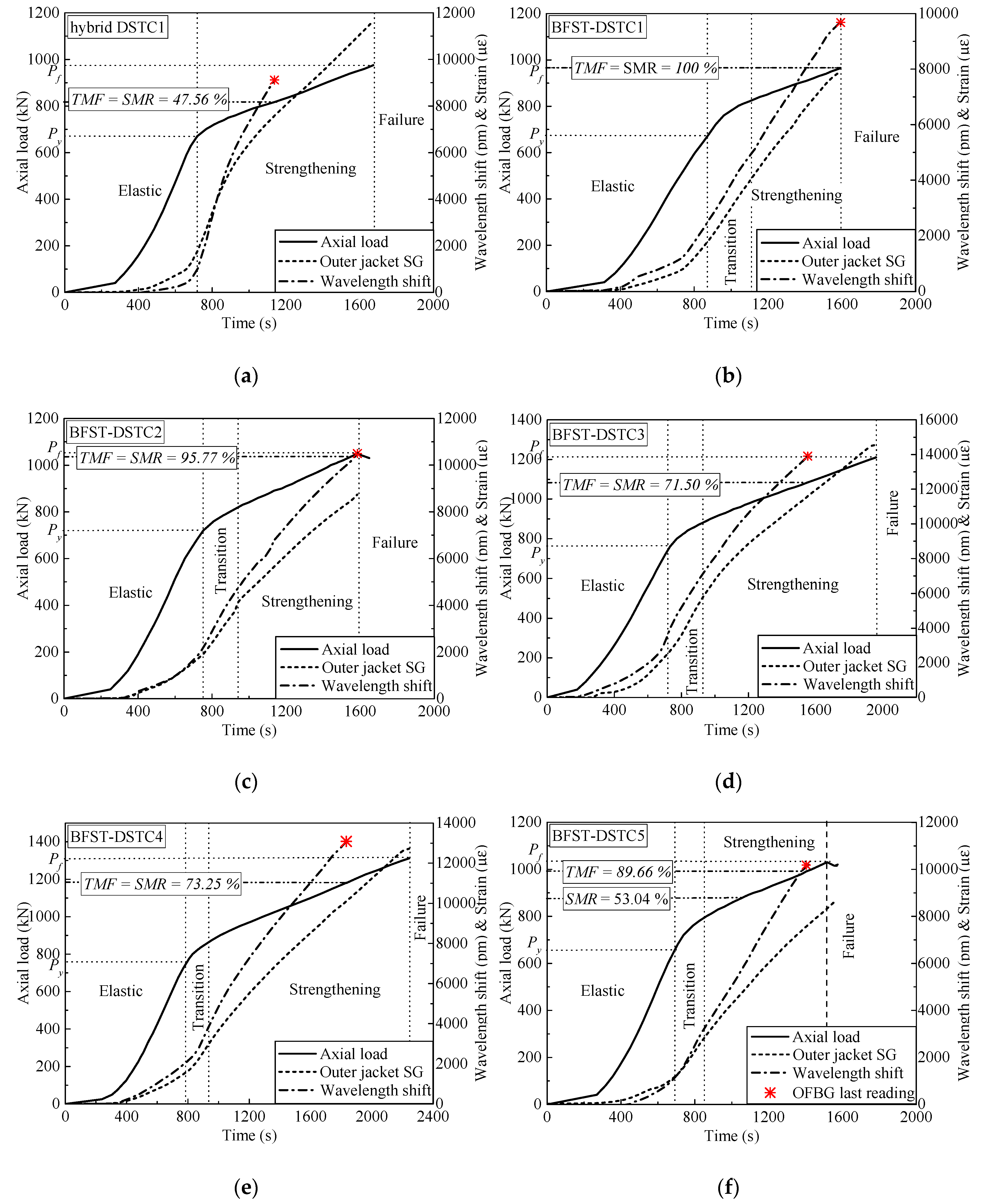

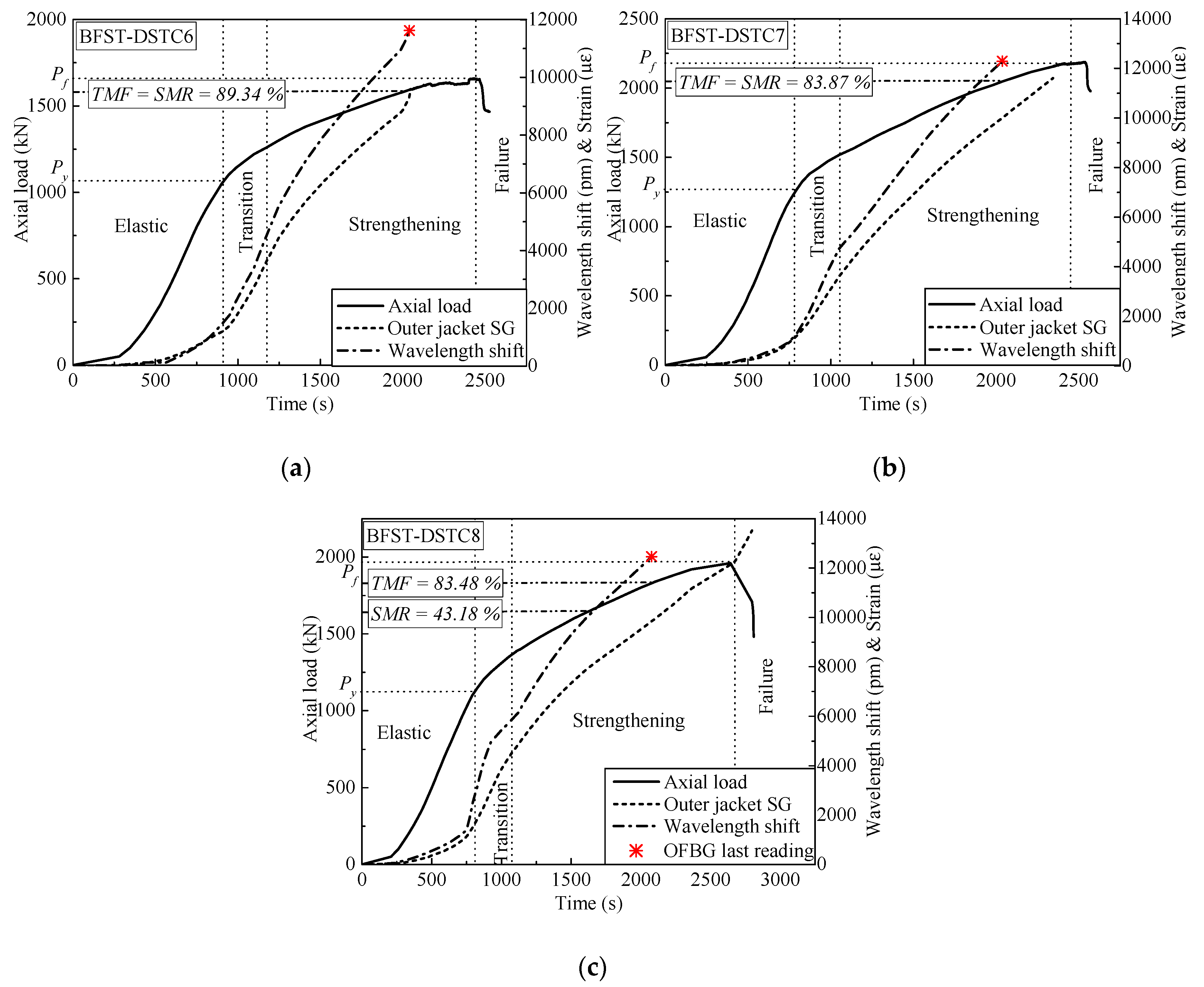

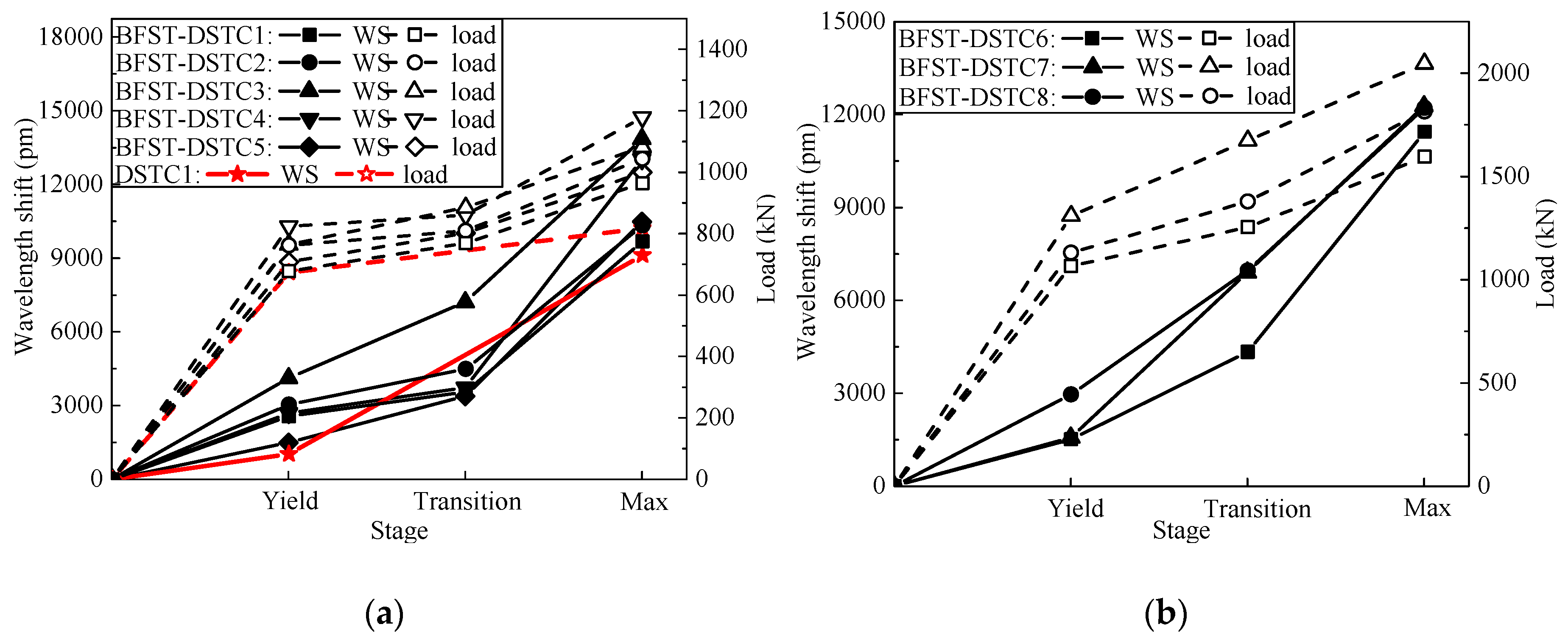

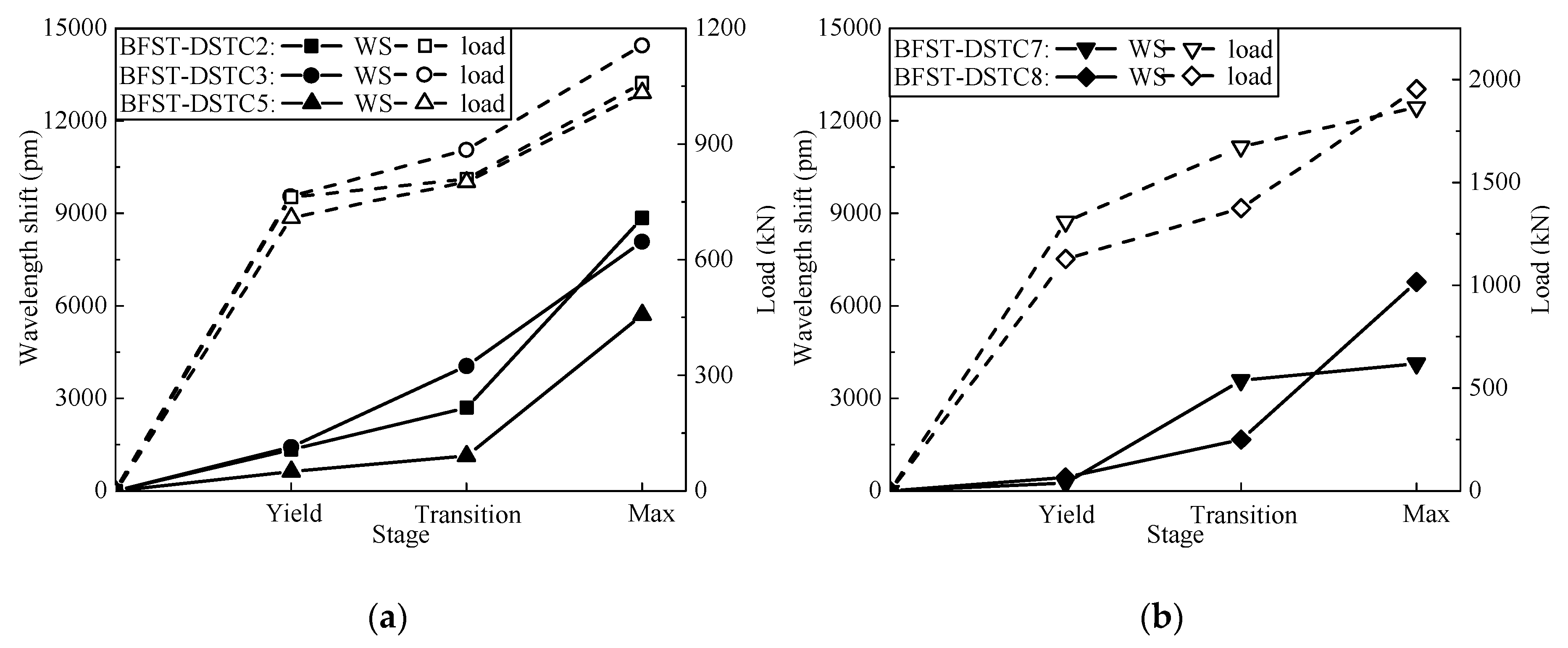

4.2. Self-Sensing Performance Analysis Based on WS from the Outer Tube

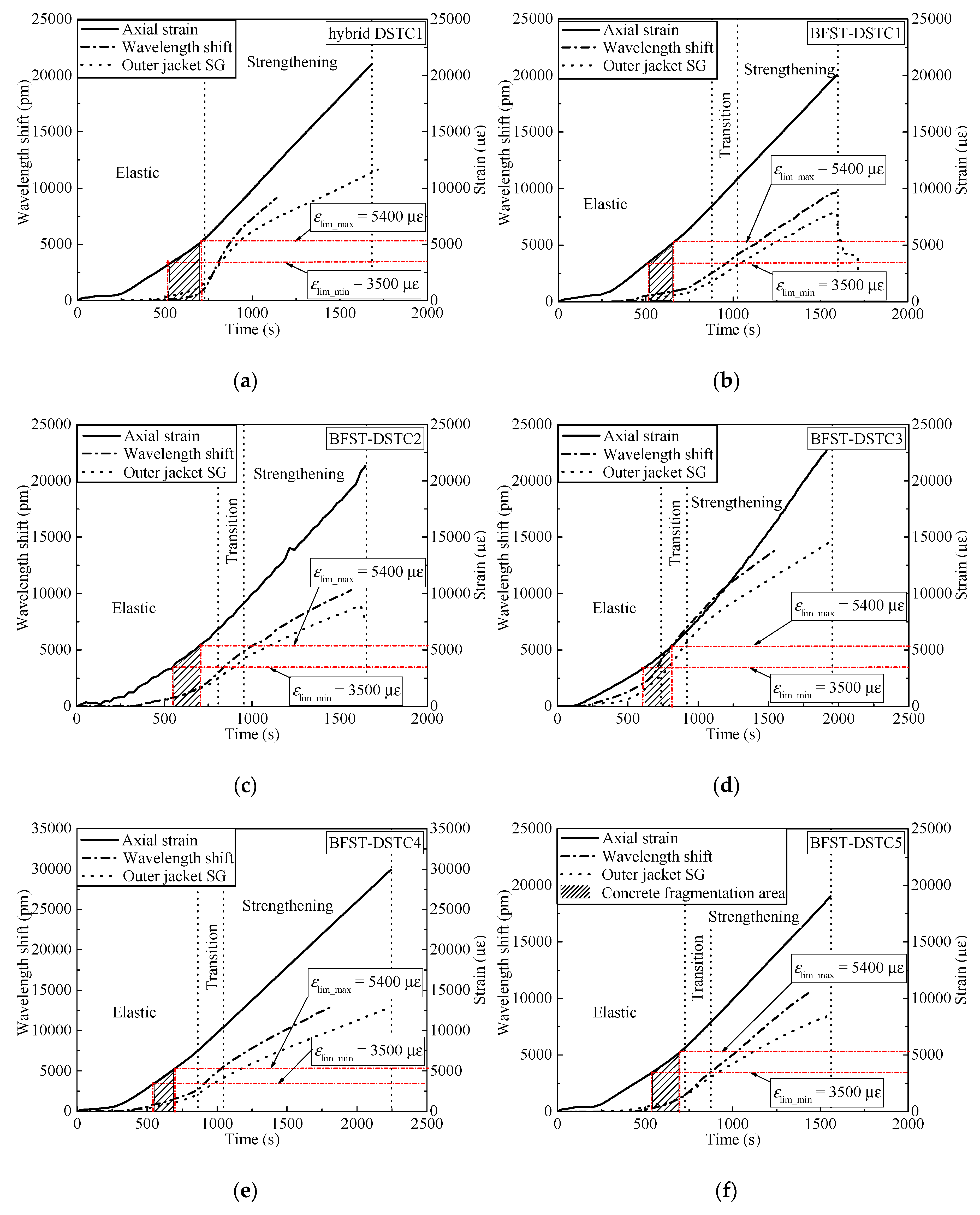

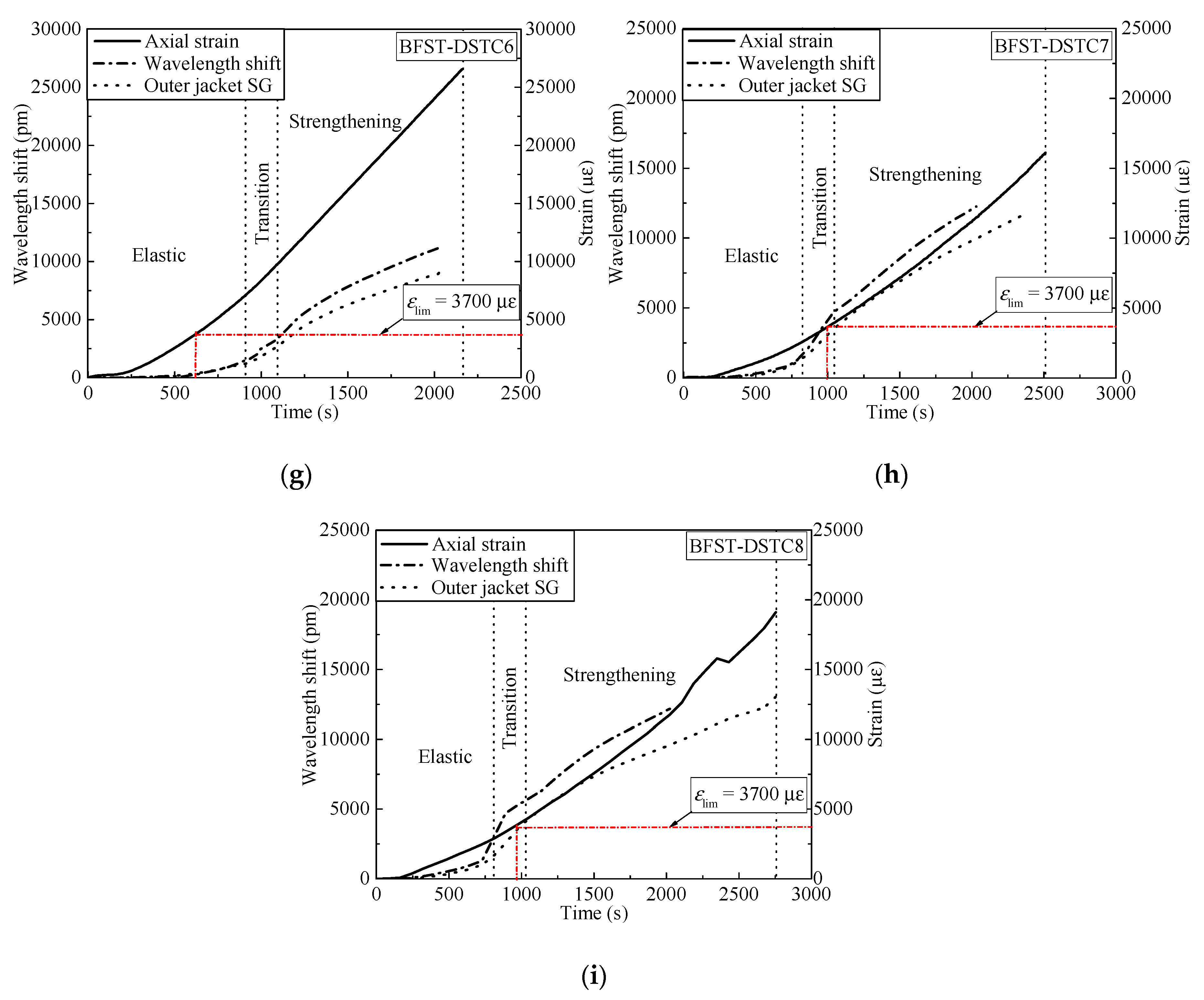

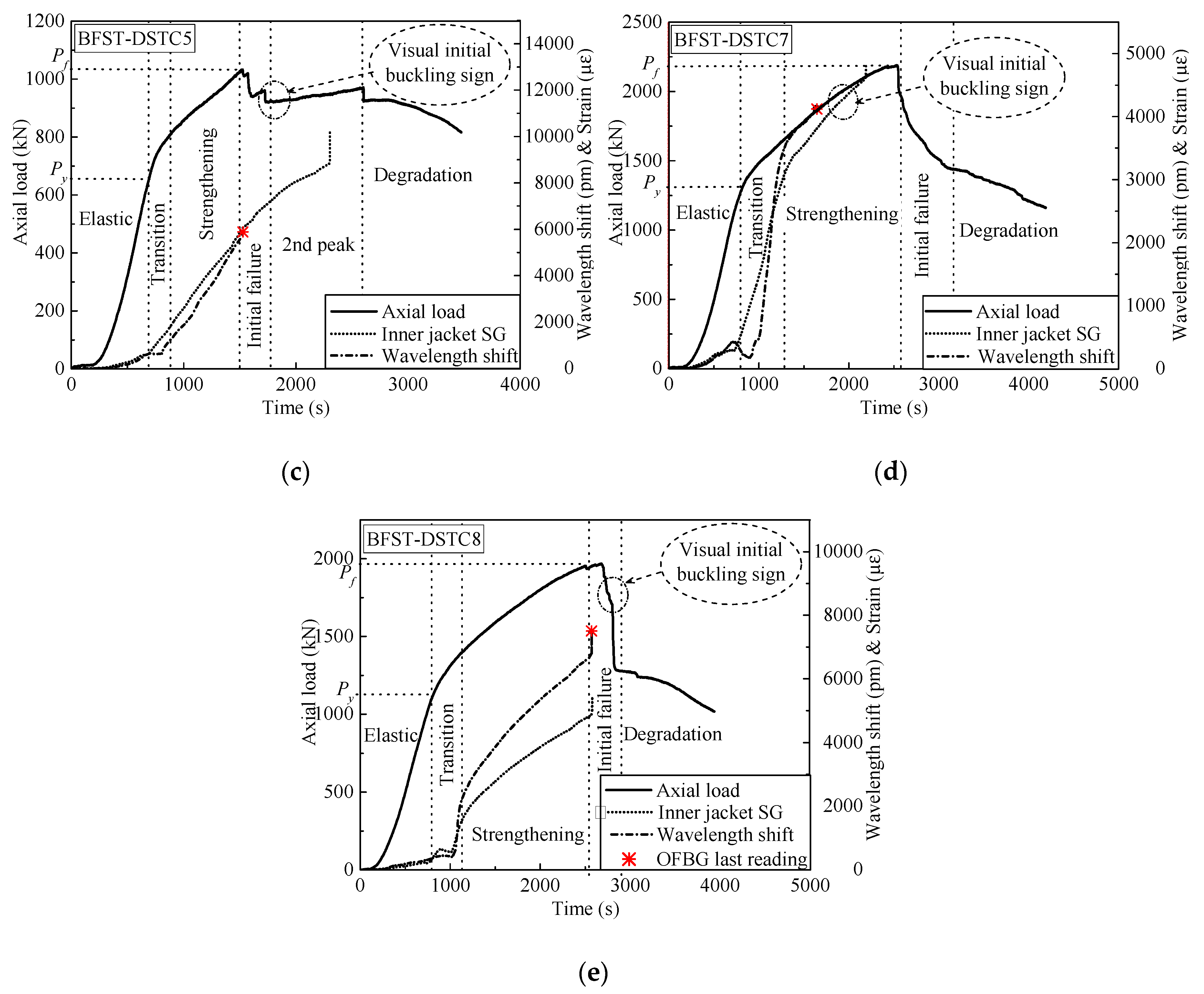

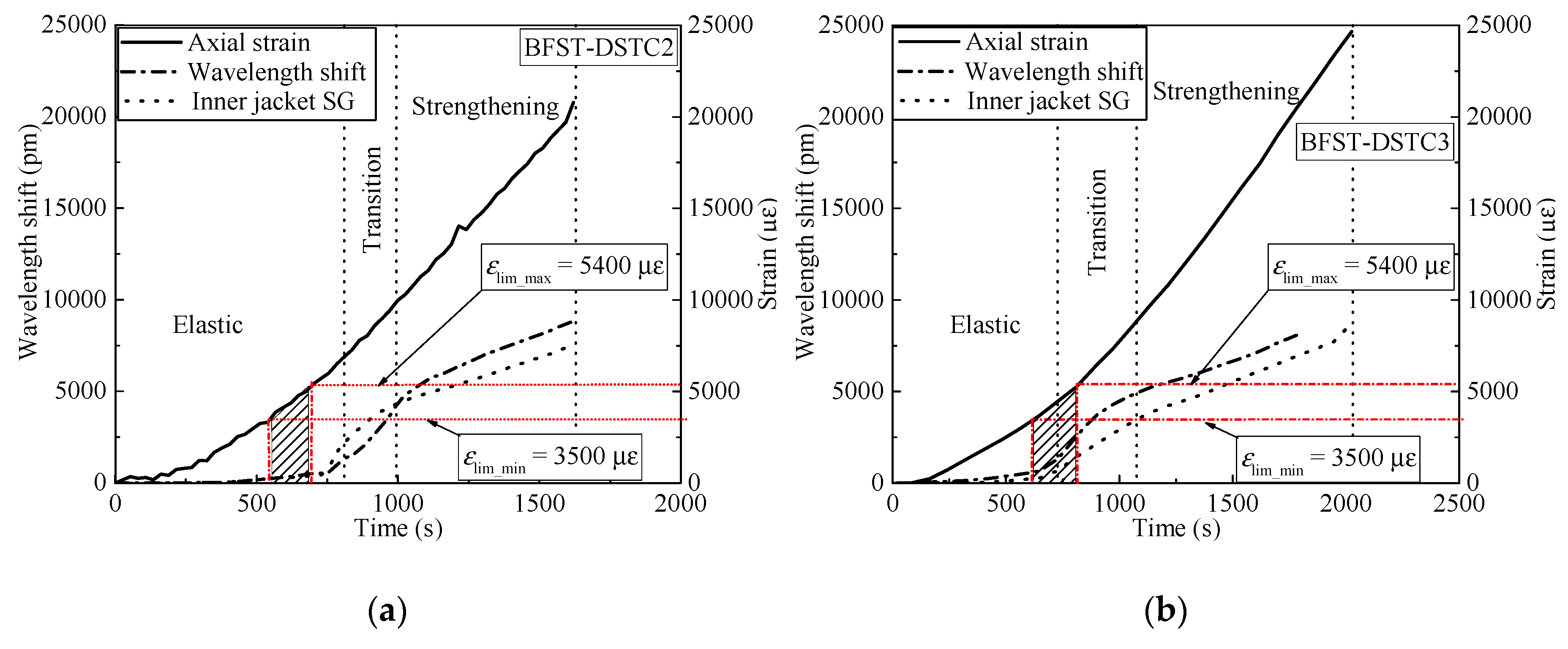

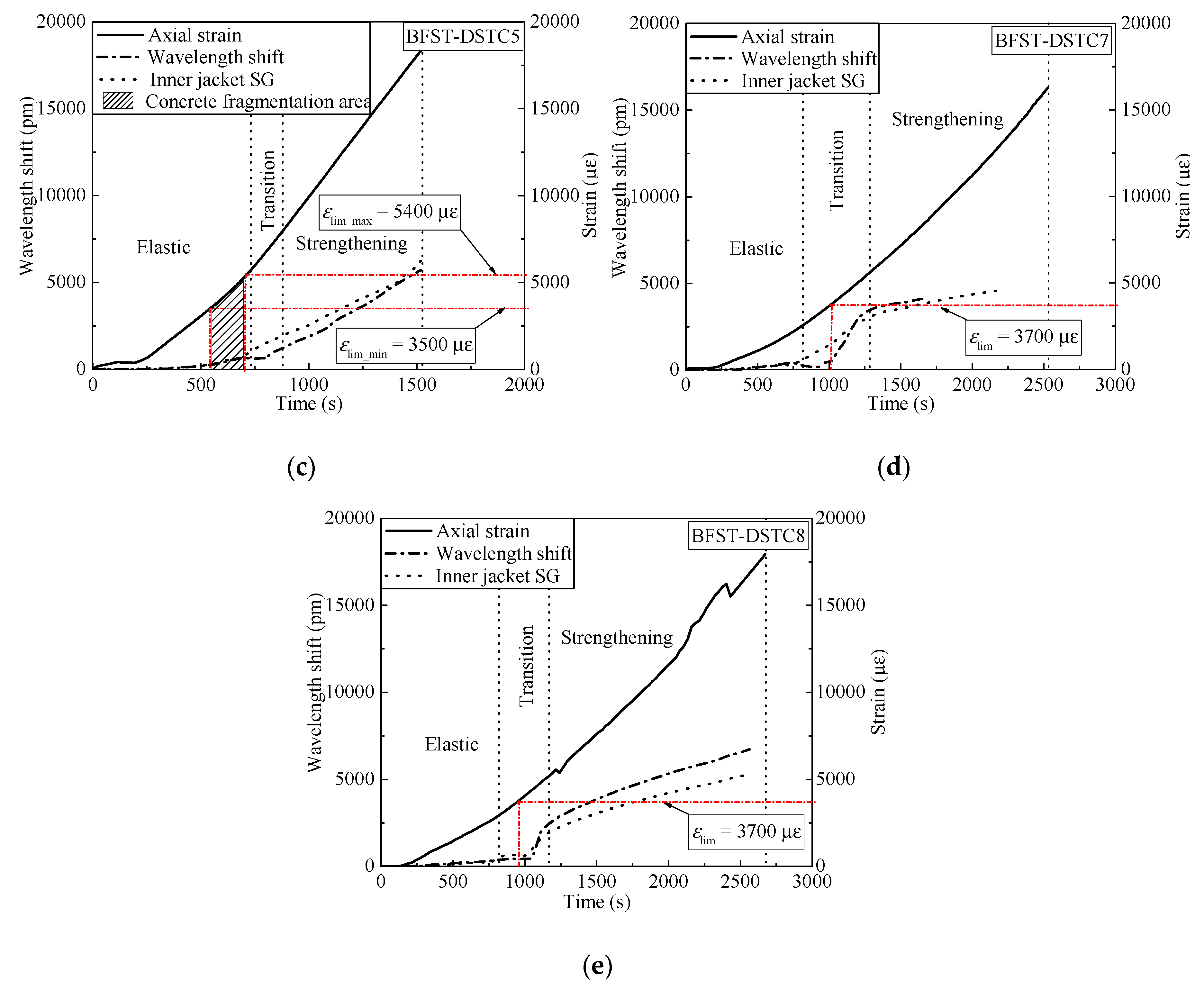

4.3. Self-Sensing Performance Analysis Based on WS from the Inner Tube

5. Conclusions

- With the built-in concept, an innovative FRP-based confined concrete system with self-sensing ability is easy to develop and cost-effective. The proposed smart BFST-DSTC shows potential mechanical benefits to overtake the hybrid DSTC as a modern form of structural columns. The additional inner FRP layer and outer steel skin with punched-in patterns improve the loading capacity, the confinement ratio, and the confinement efficiency compared with the hybrid DSTC.

- The OFBGs embedded in the outer tube satisfied the self-monitoring requirements of the strain condition in the proposed smart BFST-DSTC and hybrid DSTC within their service limit. Specimens with punched-in outer steel had a SMR and TMF beyond 70% of the strengthening load. These outcomes are wide enough to detect minor and major deformations of the BFST-DSTC.

- The embedded OFBGs monitor the hoop strain of the inner and outer FRP jackets and provide early failure warning for the inner tube. The WS from the inner FRP jacket can help for further damage evaluation of the BFST-DSTC in the post-peak stage.

- The load and WS curves from the inner and outer tubes showed good linear relation at each piecewise segment. The WS of the built-in OFBGs in both tubes can monitor the axial load history of the FRP-confined concrete.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ASTM | American standard test method |

| BFRP | Basalt fiber reinforced polymer |

| BFST | Basalt FRP-steel tube |

| CFFT | Concrete-filled FRP tube |

| CFST | Concrete-filled steel tube |

| DSTC | Double-skin tubular column |

| ɛcc | Compressive strain of confined concrete |

| ɛco | Compressive strain of unconfined concrete |

| ɛlim | Average strain limit value of concrete in specimens with HSC |

| f2c | Compressive strength at the 2nd ascending segment at the post-peak |

| fcc | Compressive strength of confined concrete |

| fco | Compressive strength of unconfined concrete |

| fd | Compressive strength of confined concrete after the rupture of the FRP |

| FRP | Fiber-reinforced polymer |

| GFRP | Glass fiber reinforced polymer |

| HSC | High strength concrete |

| LVDTs | Linear variable displacement transducers |

| NSC | Normal strength concrete |

| OFBGs | Optical fiber Bragg grating sensor |

| OFS | Optical fiber sensors |

| Pf | Ultimate load/Maximum load capacity of the column |

| Py | Yield load/load at the yield point |

| SG | Electric strain gauge |

| SMR | Strain measurement range of the built-in OFBGs with error between OFBGs and SG ±2.5% |

| TMF | Total measurement from OFBGs |

| UV | Ultraviolet |

| WS | Wavelength shift |

| εlim_max | Maximum strain limit value of concrete in specimens with NSC |

| εlim_min | Minimum strain limit value of concrete in specimens with NSC |

References

- Ozbakkaloglu, T. Concrete-filled FRP tubes: Manufacture and testing of new forms designed for improved performance. J. Compos. Constr. 2012, 17, 280–291. [Google Scholar] [CrossRef]

- Cao, Q.; Tao, J.; Wu, Z.; Ma, Z.J. Behavior of FRP-Steel Confined Concrete Tubular Columns Made of Expansive Self-Consolidating Concrete under Axial Compression. J. Compos. Constr. 2017, 21, 04017037. [Google Scholar] [CrossRef]

- Teng, J.G.; Yu, T.; Wong, Y.L.; Dong, S.L. Hybrid FRP–concrete–steel tubular columns: Concept and behavior. Constr. Build. Mater. 2007, 21, 846–854. [Google Scholar] [CrossRef]

- Idris, Y.; Ozbakkaloglu, T. Flexural behavior of FRP-HSC-steel composite beams. Thin Walled Struct. 2014, 80, 207–216. [Google Scholar] [CrossRef]

- Louk Fanggi, B.A.; Ozbakkaloglu, T. Compressive behavior of aramid FRP–HSC–steel double-skin tubular columns. Constr. Build. Mater. 2013, 48, 554–565. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Fanggi, B.L. Axial Compressive Behavior of FRP-Concrete-Steel Double-Skin Tubular Columns Made of Normal- and High-Strength Concrete. J. Compos. Constr. 2014, 18, 04013027. [Google Scholar] [CrossRef]

- Wong, Y.L.; Yu, T.; Teng, J.G.; Dong, S.L. Behavior of FRP-confined concrete in annular section columns. Compos. Part B-Eng. 2008, 39, 451–466. [Google Scholar] [CrossRef]

- Yu, T.; Teng, J. Behavior of hybrid FRP-Concrete-Steel double-skin tubular columns with a square outer tube and a circular inner tube subjected to axial compression. J. Compos. Constr. 2012, 17, 271–279. [Google Scholar] [CrossRef]

- Pham, T.M.; Hadi, M.N.S.; Tran, T.M. Maximum usable strain of FRP-confined concrete. Constr. Build. Mater. 2015, 83, 119–127. [Google Scholar] [CrossRef]

- Yu, T.; Zhang, S.; Huang, L.; Chan, C. Compressive behavior of hybrid double-skin tubular columns with a large rupture strain FRP tube. Compos. Struct. 2017, 171, 10–18. [Google Scholar] [CrossRef]

- Li, D.S.; Chen, Z.; Feng, Q.M.; Wang, Y.L. Damage analysis of CFRP-confined circular concrete-filled steel tubular columns by acoustic emission techniques. Smart Mater. Struct. 2015, 24, 11. [Google Scholar] [CrossRef]

- Xu, B.; Li, B.; Song, G.B. Active Debonding Detection for Large Rectangular CFSTs Based on Wavelet Packet Energy Spectrum with Piezoceramics. J. Struct. Eng. 2013, 139, 1435–1443. [Google Scholar] [CrossRef]

- Luo, M.; Li, W.; Hei, C.; Song, G. Concrete Infill Monitoring in Concrete-Filled FRP Tubes Using a PZT-Based Ultrasonic Time-of-Flight Method. Sensors 2016, 16, 2083. [Google Scholar] [CrossRef] [PubMed]

- Marcus, M.A.; Chan, P.K.C.; Wang, A.; Lau, A.K.; Jin, W.; Zhou, L. Utilization of fiber optic Bragg grating sensors in concrete columns confined with glass-fiber-reinforced plastic (GFRP) laminate under uniaxial compression test. In Proceedings of the SPIE of Conference, Boston, MA, USA, 11 January 1999. [Google Scholar]

- Xin, Y.; Hui, L. Self-sensing concrete-filled FRP tubes using FBG strain sensors. In Proceedings of the SPIE—International Society for Optics and Photonics Conference, Harbin, China, 1 July 2007. [Google Scholar]

- Ou, J.P.; Zhou, Z. Optic Fiber Bragg-Grating-Based Sensing Technologies and Their Applications in Structural Health Monitoring—Art. no. 659503. In Fundamental Problems of Optoelectronics and Microelectronics III, Pts 1 and 2; Kulchin, Y.N., Ou, J., Vitrik, O.B., Zhou, Z., Eds.; Spie-Int Soc Optical Engineering: Bellingham, WA, USA, 2007; p. 59503. [Google Scholar]

- Coricciati, A.; Ingrosso, I.; Sergi, A.P.; Largo, A. Application of Smart FRP Devices for the Structural Health Monitoring of Heritage Buildings—A Case Study: The Monastery of Sant’Angelo d’Ocre. Key Eng. Mater. 2017, 747, 448–455. [Google Scholar] [CrossRef]

- Christof, H.; Müller, L.; Küppers, S.; Hofmann, P.; Giebel, E.; Frick, S.; Gabler, M.; Gresser, G.T. Integration Methods of Sensors in FRP Components. In Materials Science Forum; Trans Tech Publications: Zürich, Switzerland, 2015. [Google Scholar]

- Zhou, Z.; Sasy Chan, Y.W.; Ou, J.P. Optical fiber sensor-based smart structures. J. Phys. Conf. Ser. 2018, 1065, 252003. [Google Scholar] [CrossRef]

- Tang, Y.S.; Wu, Z.S. Distributed Long-Gauge Optical Fiber Sensors Based Self-Sensing FRP Bar for Concrete Structure. Sensors 2016, 16, 286. [Google Scholar] [CrossRef]

- Zhou, Z.; Sasy Chan, Y.W.; Ou, J.P. Advances in FRP-Based Smart Components and Structures. In Structural Health Monitoring of Composite Structures Using Fiber Optic Methods, 1st ed.; Rajan, G., Prusty, G.B., Eds.; CRC Press: Boca Raton, FL, USA, 2016; pp. 371–413. [Google Scholar]

- Li, D.; Zhou, Z.; Ou, J. Development and sensing properties study of FRP-FBG smart stay cable for bridge health monitoring applications. Measurement 2011, 44, 722–729. [Google Scholar] [CrossRef]

- Huang, M.; Zhou, Z.; Huang, Y.; Ou, J. A distributed self-sensing FRP anchor rod with built-in optical fiber sensor. Measurement 2013, 46, 1363–1370. [Google Scholar] [CrossRef]

- Zhou, Z.; He, J.; Chen, G.; Ou, J. A Smart Steel Strand for the Evaluation of Prestress Loss Distribution in Post-tensioned Concrete Structures. J. Intell. Mater. Syst. Struct. 2009, 20, 1901–1912. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, Z.; Shao, L. Fiber-Reinforced Polymer-Packaged Optical Fiber Bragg Grating Strain Sensors for Infrastructures under Harsh Environment. J. Sens. 2016, 2016, 1–18. [Google Scholar] [CrossRef]

- Tang, Y.S.; Wu, Z.S.; Yang, C.Q.; Wu, G.; Shen, S. A new type of smart basalt fiber-reinforced polymer bars as both reinforcements and sensors for civil engineering application. Smart Mater. Struct. 2010, 19, 14. [Google Scholar] [CrossRef]

- Deng, J.; Zheng, Y.; Wang, Y.; Liu, T.; Li, H. Study on Axial Compressive Capacity of FRP-Confined Concrete-Filled Steel Tubes and Its Comparisons with Other Composite Structural Systems. Int. J. Polym. Sci. 2017, 2017, 1–7. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Li, N.; Li, S. Behavior of FRP-Confined Concrete-Filled Steel Tube Columns. Polymers 2014, 6, 1333–1349. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, G.; Li, G. Performance of circular concrete-filled fiber-reinforced polymer-steel composite tube columns under axial compression. J. Reinf. Plast. Compos. 2014, 33, 1911–1928. [Google Scholar] [CrossRef]

- Yu, T.; Hu, Y.M.; Teng, J.G. Cyclic lateral response of FRP-confined circular concrete-filled steel tubular columns. J. Constr. Steel Res. 2016, 124, 12–22. [Google Scholar] [CrossRef]

- Ghaemdoust, M.R.; Narmashiri, K.; Yousefi, O. Structural behaviors of deficient steel SHS short columns strengthened using CFRP. Constr. Build. Mater. 2016, 126, 1002–1011. [Google Scholar] [CrossRef]

- Batikha, M.; Chen, J.F.; Rotter, J.M.; Teng, J.G. Strengthening metallic cylindrical shells against elephant’s foot buckling with FRP. Thin Walled Struct. 2009, 47, 1078–1091. [Google Scholar] [CrossRef]

- Huang, L.; Yin, P.; Yan, L.; Kasal, B. Behavior of hybrid GFRP–perforated-steel tube-encased concrete column under uniaxial compression. Compos. Struct. 2016, 142, 313–324. [Google Scholar] [CrossRef]

- China Planning Press. Technical Code for Infrastructure Application of FRP Composite; China Planning Press: Beijing, China, 2010. [Google Scholar]

- BS18. British Standard Method for Tensile Test of Metals; British Standard Institution: London, UK, 1987. [Google Scholar]

- ASTM. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; American Standard Test Method: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ACI. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2003. [Google Scholar]

| Specimen no. | Inner Tube | Outer Tube | Concrete Strength [MPa] | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| tis3 (mm) | dis4 (mm) | ni5 | Type | tos6 (mm) | Steel Layer Type | dos7 (mm) | no8 | Type | ||

| Hybrid DSTC1 | 4.0 | 100 | 0 | NS 1 | 0 | N/A | N/A | 3 | NS 1 | 20.02 |

| BFST-DSTC1 | 4.0 | 100 | 2 | Smart 2 | 0.7 | Punched-in | 150 | 2 | Smart | 20.02 |

| BFST-DSTC2 | 4.0 | 100 | 2 | Smart | 0.7 | Punched-in | 150 | 3 | Smart | 20.02 |

| BFST-DSTC3 | 4.0 | 100 | 3 | Smart | 0.7 | Punched-in | 150 | 3 | Smart | 20.02 |

| BFST-DSTC4 | 4.0 | 100 | 3 | Smart 2 | 1.2 | Punched-in | 150 | 3 | Smart | 20.02 |

| BFST-DSTC5 | 4.0 | 100 | 2 | Smart | 0.7 | Normal | 150 | 3 | Smart | 20.02 |

| Hybrid DSTC2 | 4.0 | 100 | 0 | NS 1 | 0 | N/A | N/A | 3 | NS 1 | 60.55 |

| BFST-DSTC6 | 4.0 | 100 | 2 | Smart 2 | 0.7 | Punched-in | 150 | 6 | Smart | 60.55 |

| BFST-DSTC7 | 4.0 | 100 | 3 | Smart | 0.7 | Punched-in | 150 | 9 | Smart | 60.55 |

| BFST-DSTC8 | 4.0 | 100 | 2 | Smart | 0.7 | Normal | 150 | 9 | Smart | 60.55 |

| Steel Thickness [mm] | Yield Strength [MPa] | Tensile Modulus [GPa] | Ultimate Stress [MPa] |

|---|---|---|---|

| 4.0 | 270.64 | 191.0 | 335 |

| 6.0 | 260.15 | 189.0 | 410 |

| 0.7 | 196.19 | 189.5 | 313.12 |

| 1.2 | 195 | 189.5 | 313.12 |

| Specimen no. | Py [kN] | Pf [kN] | fcc/fco | Enhanced Ratio | ɛcc/ɛco |

|---|---|---|---|---|---|

| Hybrid DSTC1 | 673.4 | 975.6 | 1.31 | 1 | 10.45 |

| BFST-DSTC1 | 679.3 | 964.4 | 1.23 | 0.94 | 10.03 |

| BFST-DSTC2 | 761.7 | 1061.7 | 1.42 | 1.08 | 10.42 |

| BFST-DSTC3 | 764.3 | 1211.7 | 1.83 | 1.42 | 17.16 |

| BFST-DSTC4 | 823.7 | 1312.3 | 1.43 | 1.09 | 14.96 |

| BFST-DSTC5 | 708.5 | 1033.1 | 1.36 | 1.04 | 9.18 |

| Hybrid DSTC2 | 1022.1 | 1505.4 | 1.59 | 1 | 9.60 |

| BFST-DSTC6 | 1062.7 | 1657.1 | 1.45 | 0.91 | 11.89 |

| BFST-DSTC7 | 1309.4 | 2189.6 | 2.30 | 1.45 | 18.33 |

| BFST-DSTC8 | 1127.9 | 1968.8 | 1.87 | 1.18 | 16.02 |

| Specimen | SMR (%) | Error (%) | TMF (%) |

|---|---|---|---|

| Hybrid DSTC1 | 47.56 | +1.11 | 47.56 |

| BFST-DSTC1 | 100.00 | +1.57 | 100.00 |

| BFST-DSTC2 | 96.01 | −0.31 | 96.01 |

| BFST-DSTC3 | 71.50 | −0.94 | 71.50 |

| BFST-DSTC4 | 73.25 | −1.75 | 73.25 |

| BFST-DSTC5 | 53.04 | +2.37 | 89.66 |

| BFST-DSTC6 | 89.34 | +0.12 | 89.34 |

| BFST-DSTC7 | 83.87 | +1.37 | 83.87 |

| BFST-DSTC8 | 43.18 | +1.98 | 83.48 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sasy Chan, Y.W.; Zhou, Z.; Liu, W.; Ou, J. OFBG-Based Smart Double-Skin Tubular Confined-Concrete Column with Basalt FRP-Steel Composite. Sensors 2019, 19, 3572. https://doi.org/10.3390/s19163572

Sasy Chan YW, Zhou Z, Liu W, Ou J. OFBG-Based Smart Double-Skin Tubular Confined-Concrete Column with Basalt FRP-Steel Composite. Sensors. 2019; 19(16):3572. https://doi.org/10.3390/s19163572

Chicago/Turabian StyleSasy Chan, Yung William, Zhi Zhou, Wanqiu Liu, and Jinping Ou. 2019. "OFBG-Based Smart Double-Skin Tubular Confined-Concrete Column with Basalt FRP-Steel Composite" Sensors 19, no. 16: 3572. https://doi.org/10.3390/s19163572

APA StyleSasy Chan, Y. W., Zhou, Z., Liu, W., & Ou, J. (2019). OFBG-Based Smart Double-Skin Tubular Confined-Concrete Column with Basalt FRP-Steel Composite. Sensors, 19(16), 3572. https://doi.org/10.3390/s19163572