Design and Analysis of a Combined Strain–Vibration–Temperature Sensor with Two Fiber Bragg Gratings and a Trapezoidal Beam

Abstract

:1. Introduction

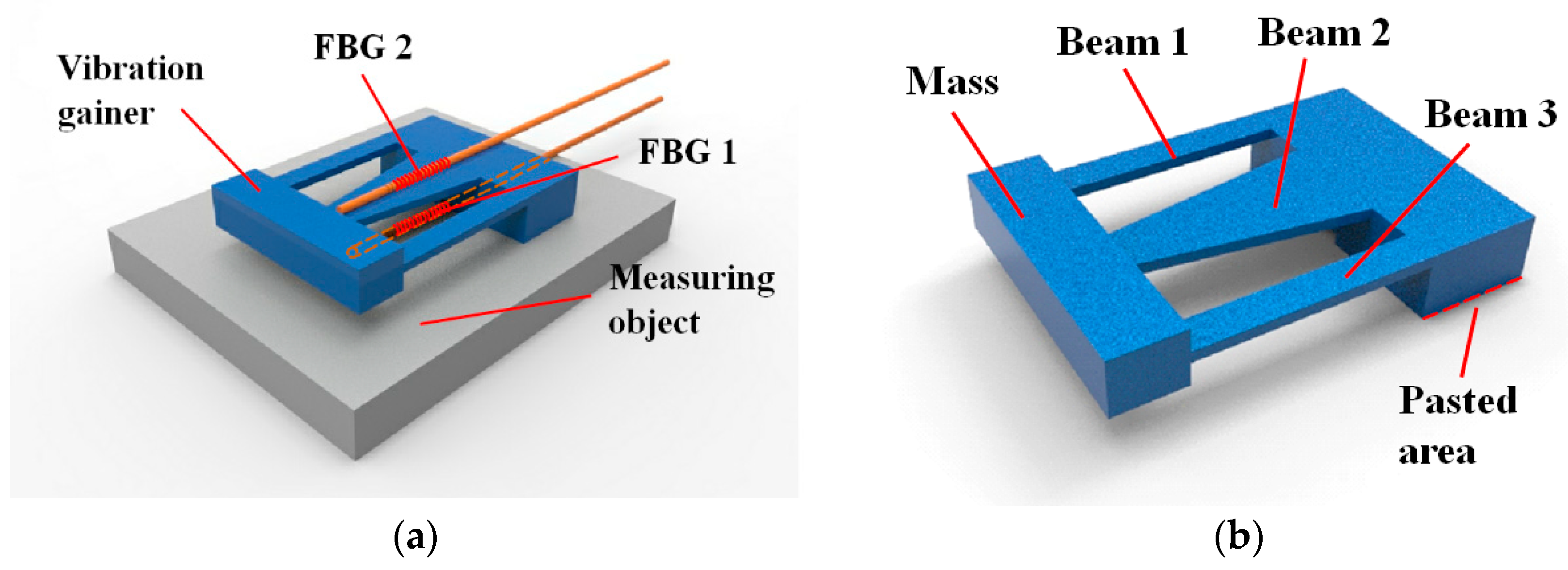

2. Sensor Design

2.1. Sensor Structure

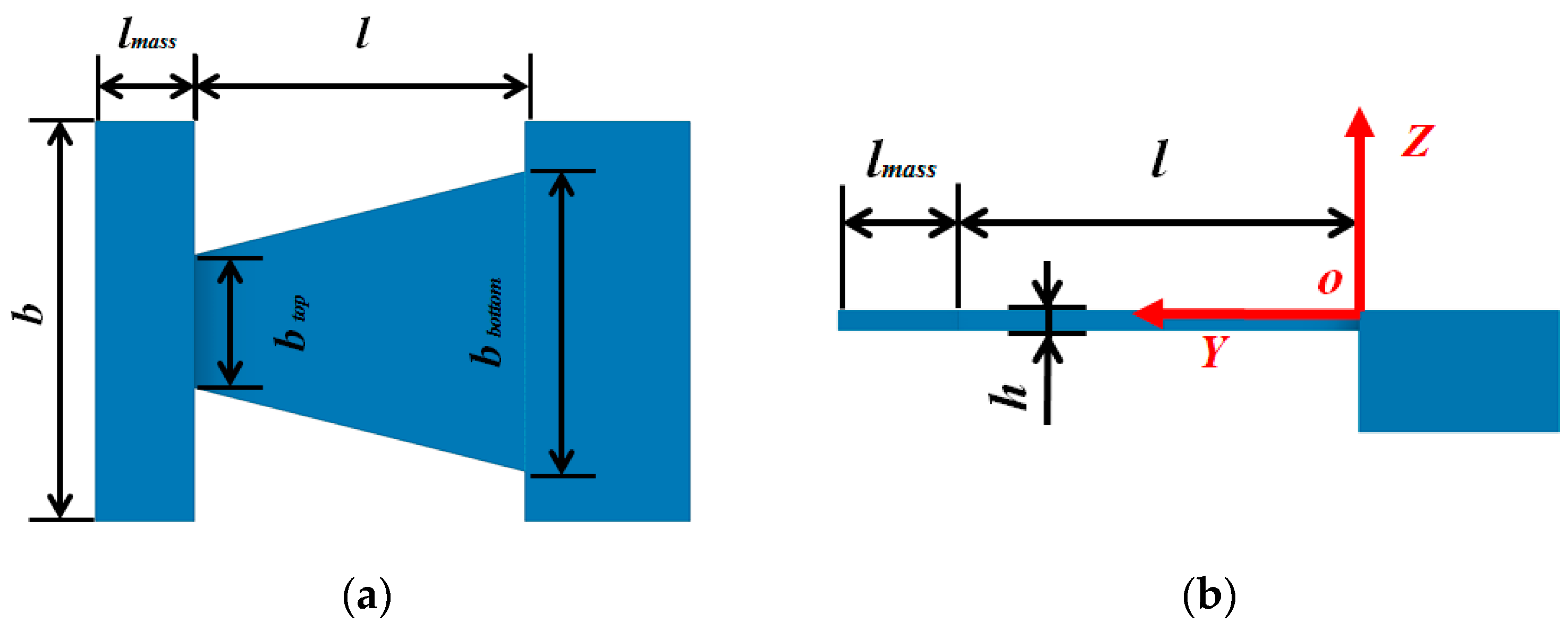

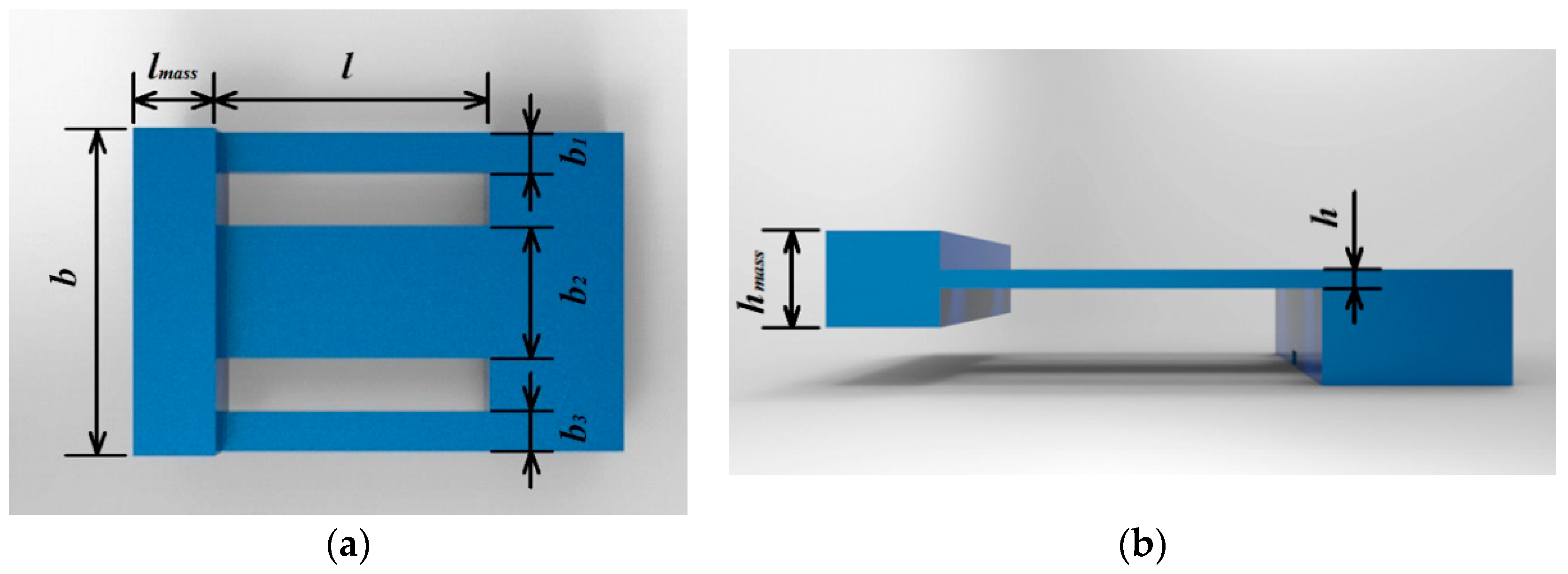

2.2. Theoretical Analysis of Surface Strain of the Beam

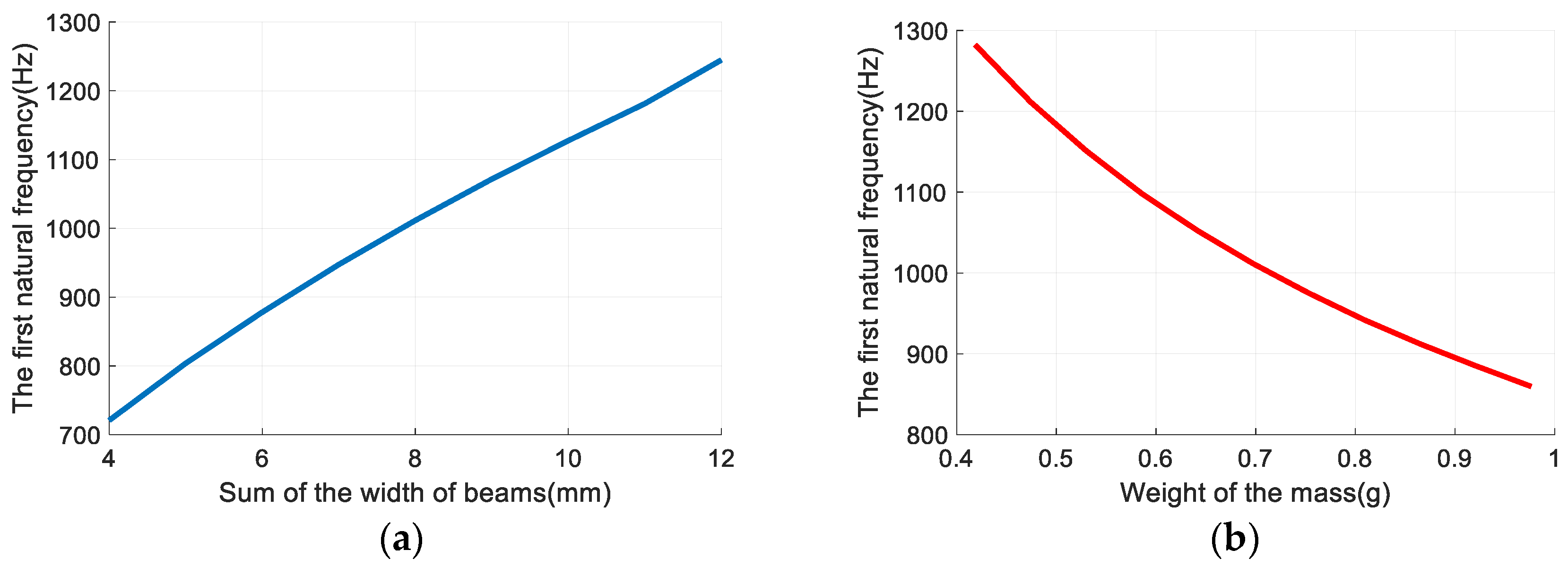

2.3. Geometry Parameters Optimization

3. Experiments and Analysis

3.1. Individual Measurement

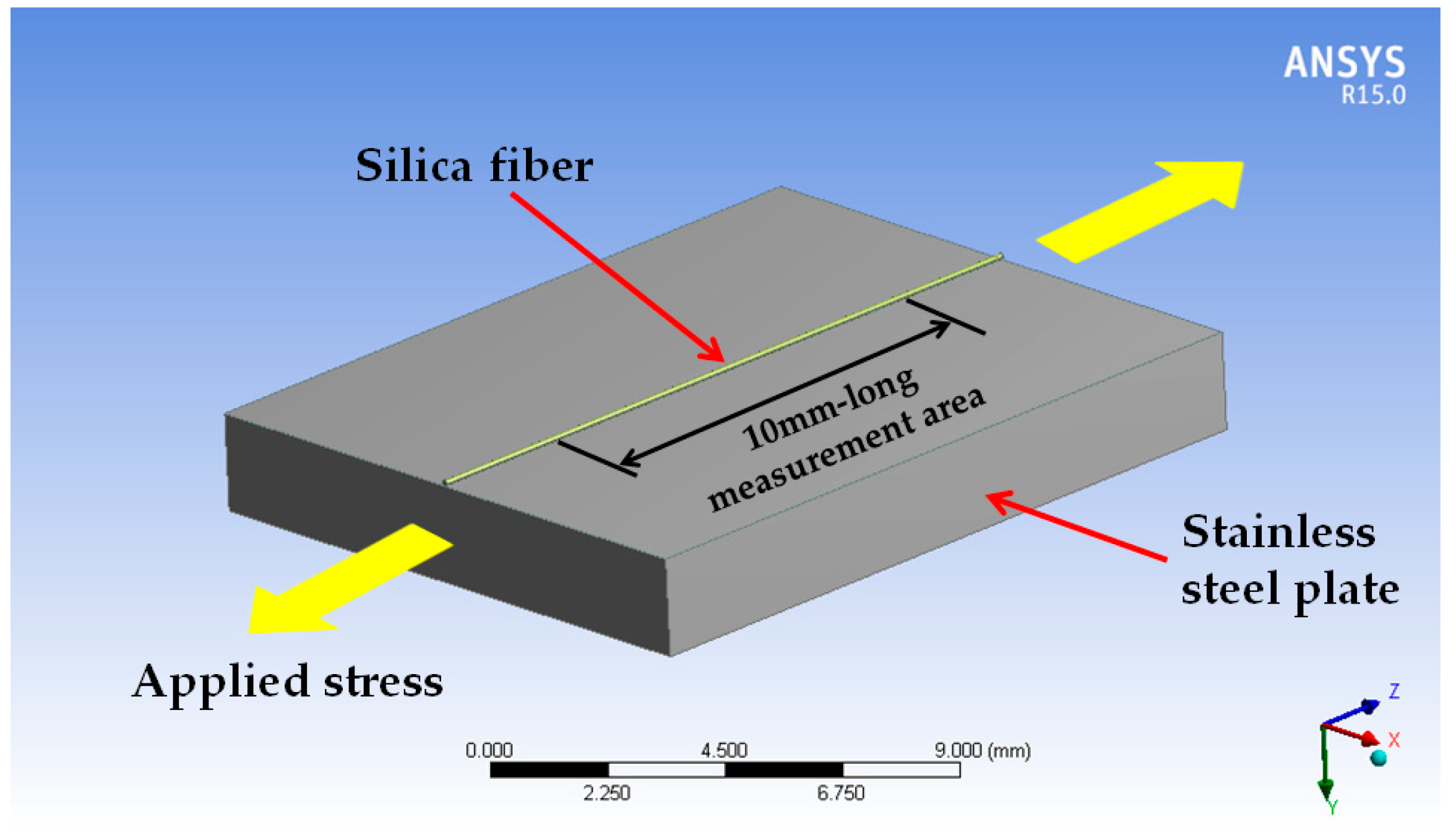

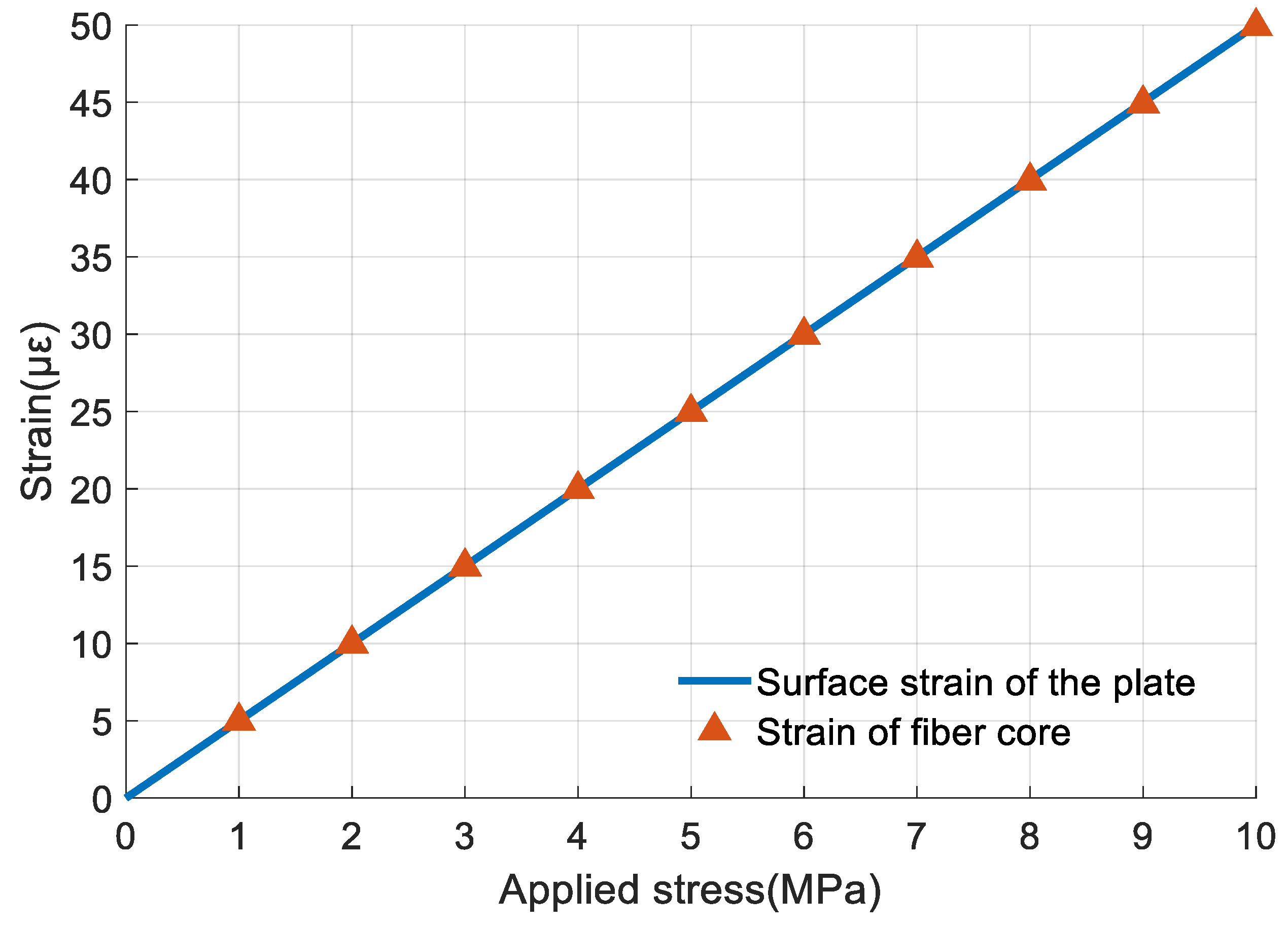

3.1.1. Strain Measurement

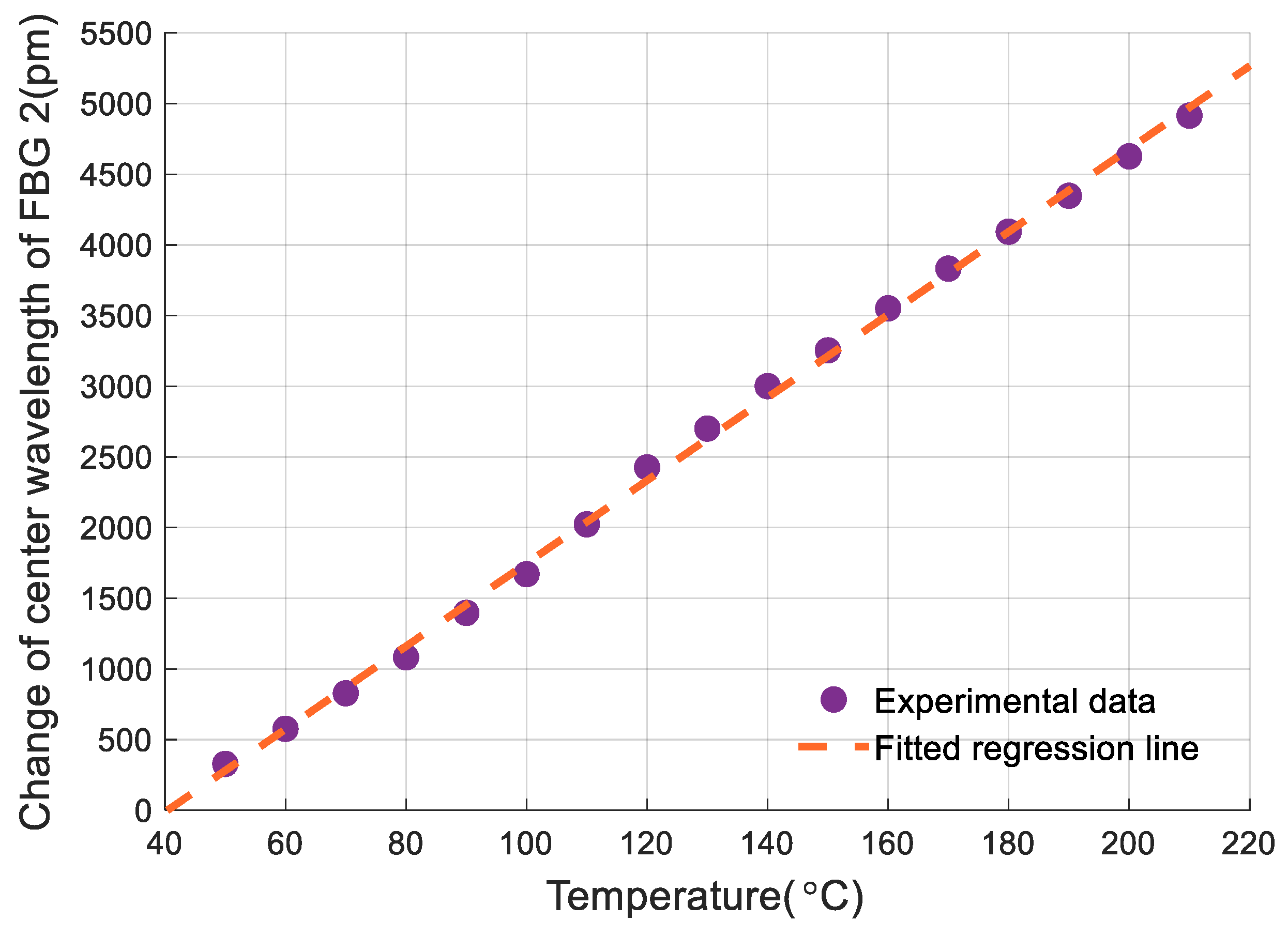

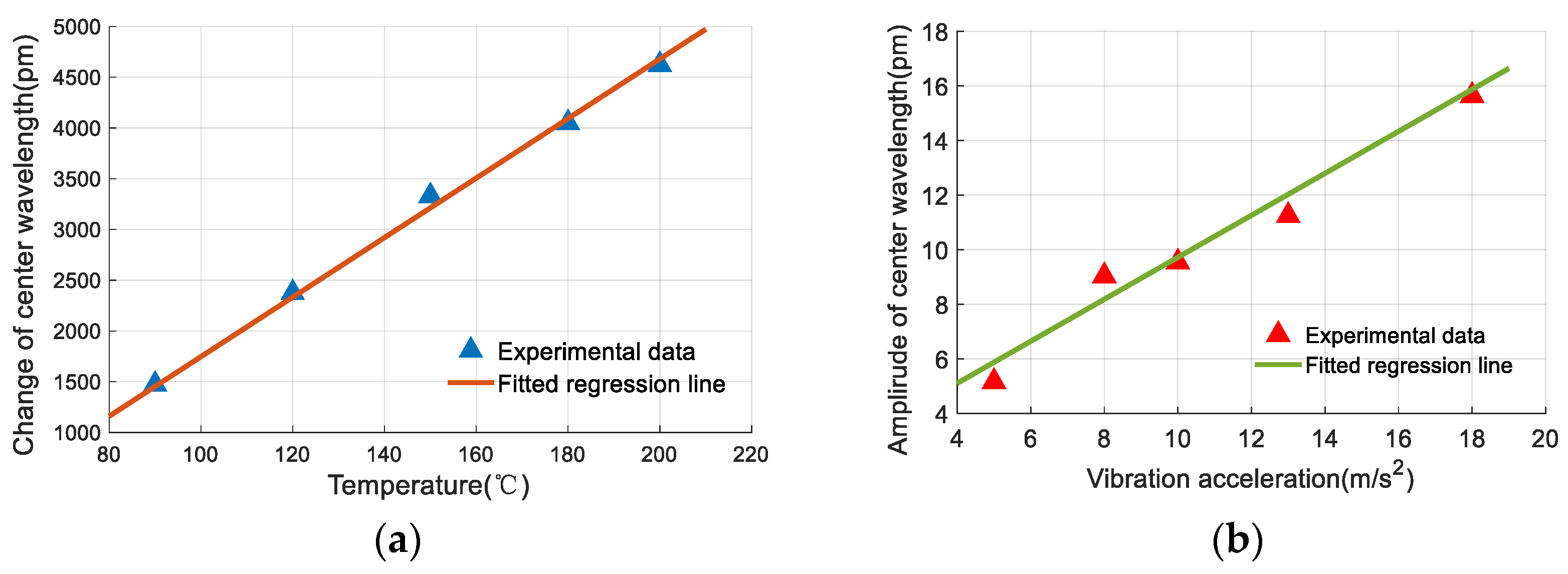

3.1.2. Temperature Measurement

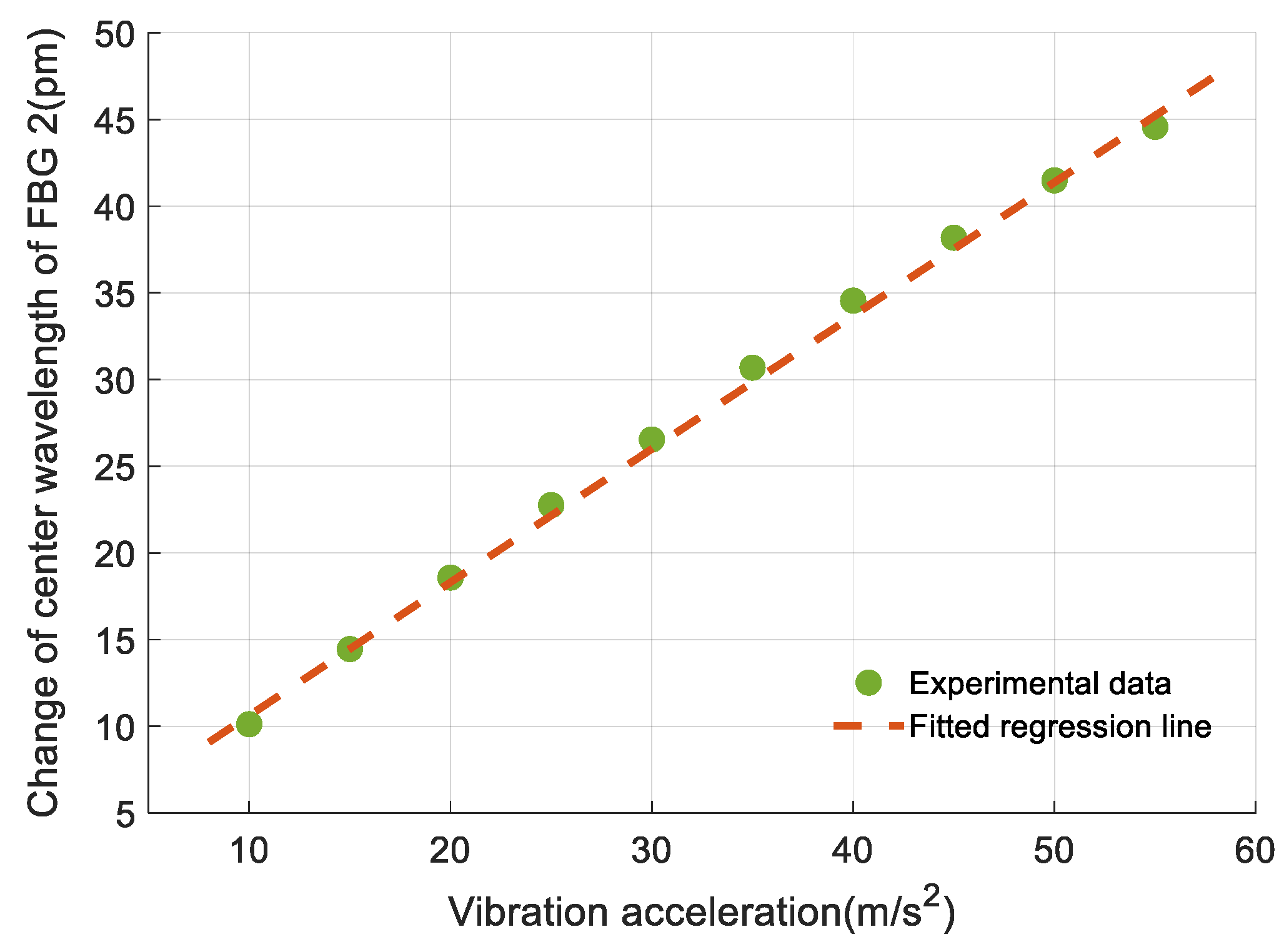

3.1.3. Vibration Measurement

3.2. Simultaneous Measurement

3.2.1. Separated of Temperature and Vibration

3.2.2. Modified of Strain Measurement

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Oliveira, R.D.; Ramos, C.A.; Marques, A.T. Health monitoring of composite structures by embedded FBG and interferometric Fabry–Pérot sensors. Comput. Struct. 2008, 86, 340–346. [Google Scholar] [CrossRef]

- Torres, B.; Paya-Zaforteza, I.; Calderón, P.A.; Adam, J.M. Analysis of the strain transfer in a new FBG sensor for Structural Health Monitoring. Eng. Struct. 2011, 33, 539–548. [Google Scholar] [CrossRef] [Green Version]

- Hameed, Z.; Hong, Y.; Cho, Y.; Ahn, S.; Song, C. Condition monitoring and fault detection of wind turbines and related algorithms: A review. Renew. Sustain. Energy Rev. 2009, 13, 1–39. [Google Scholar] [CrossRef]

- Zhou, J.; Gu, Y.; Fei, P.; Mai, W.; Gao, Y.; Yang, R.; Bao, G.; Wang, Z.L. Flexible Piezotronic Strain Sensor. Nano Lett. 2008, 8, 3035–3040. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly stretchable and sensitive strain sensor based on silver nanowire-elastomer nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef] [PubMed]

- Scott, S.; Scuderi, M.; Peroulis, D. A 600 °C wireless multimorph-based capacitive MEMS temperature sensor for component health monitoring. In Proceedings of the IEEE Micro Electro Mechanical Systems, Paris, France, 29 January–2 February 2012; pp. 496–499. [Google Scholar]

- Basten, T.G.H.; Schiphorst, F.B.A. Structural health monitoring with a wireless vibration sensor network. In Proceedings of the International Conference on Noise and Vibration Engineering (ISMA2012)/International Conference on Uncertainty in Structural Dynamics (Usd2012), Leuven, Belgium, 17–19 September 2012; pp. 3273–3283. [Google Scholar]

- Al Handawi, K.; Vahdati, N.; Rostron, P.; Lawand, L.; Shiryayev, O. Strain based FBG sensor for real-time corrosion rate monitoring in pre-stressed structures. Sens. Actuators B Chem. 2016, 236, 276–285. [Google Scholar] [CrossRef]

- Wei, P.; Dai, Z.; Zheng, L.; Li, M. Fault diagnosis of the rolling bearing with optical fiber Bragg grating vibration sensor. Proc. SPIE 2016, 155, 101552I. [Google Scholar] [CrossRef]

- Naeem, K.; Kim, B.H.; Kim, B.; Chung, Y. High-Sensitivity Temperature Sensor Based on a Selectively-Polymer-Filled Two-Core Photonic Crystal Fiber In-Line Interferometer. IEEE Sens. J. 2015, 15, 3998–4003. [Google Scholar] [CrossRef]

- Guo, H.; Xiao, G.; Mrad, N.; Yao, J. Fiber Optic Sensors for Structural Health Monitoring of Air Platforms. Sensors 2011, 11, 3687–3705. [Google Scholar] [CrossRef]

- Degrieck, J.; Waele, W.D.; Verleysen, P. Monitoring of fibre reinforced composites with embedded optical fibre Bragg sensors, with application to filament wound pressure vessels. NDT E Int. 2001, 34, 289–296. [Google Scholar] [CrossRef]

- Luyckx, G.; Voet, E.; Lammens, N.; Degrieck, J. Strain Measurements of Composite Laminates with Embedded Fibre Bragg Gratings: Criticism and Opportunities for Research. Sensors 2011, 11, 384–408. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Qian, L.; Fan, D.; Liang, W.; Ou, Y.; Tian, T. Doppler Effect-Based Optical Fiber Vibration Sensor Using Frequency-Shifted Interferometry Demodulation. J. Lightw. Technol. 2017, 35, 3483–3488. [Google Scholar] [CrossRef]

- Mckenzie, I. Fiber optic sensing in space structures: The experience of the European Space Agency. Proc. SPIE 2005, 5855, 262–269. [Google Scholar] [CrossRef]

- Xu, M.G.; Dong, L.; Reekie, L.; Tucknott, J.A.; Cruz, J.L. Temperature-independent strain sensor using a chirped Bragg grating in a tapered optical fibre. Electron. Lett. 1995, 31, 823–825. [Google Scholar] [CrossRef]

- Khan, M.M.; Panwar, N.; Dhawan, R. Modified cantilever beam shaped FBG based accelerometer with self temperature compensation. Sens. Actuators A Phys. 2014, 205, 79–85. [Google Scholar] [CrossRef]

- Mikel, B.; Helan, R.; Buchta, Z.; Holik, M.; Jelinek, M.; Cip, O. Optical fiber sensors for measurement strain and vibration. Proc. SPIE Int. Soc. Opt. Eng. 2015, 9450, 94500G. [Google Scholar] [CrossRef]

- Mizutani, Y.; Groves, R.M. Multi-Functional Measurement Using a Single FBG Sensor. Exp. Mech. 2011, 51, 1489–1498. [Google Scholar] [CrossRef] [Green Version]

- Salo, J.; Korhonen, I. Calculated estimate of FBG sensor’s suitability for beam vibration and strain measuring. Measurement 2014, 47, 178–183. [Google Scholar] [CrossRef]

- Jiang, S.-C.; Wang, J.; Sui, Q.-M.; Ye, Q.-L.; Wang, L.-J. Study of Three-Component FBG Vibration Sensor for Simultaneous Measurement of Vibration, Temperature, and Verticality. J. Sens. 2015, 2015, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Othonos, A.; Kalli, K.; Pureur, D.; Mugnier, A. Fibre Bragg Gratings. In Wavelength Filters in Fibre Optics; Springer: New York, NY, USA, 2006; Volume 123, pp. 189–269. [Google Scholar]

- Zhang, G.; Gao, S.; Liu, H.; Niu, S. A low frequency piezoelectric energy harvester with trapezoidal cantilever beam: Theory and experiment. Microsyst. Technol. 2017, 23, 3457–3466. [Google Scholar] [CrossRef]

- Thomson, W.T. Theory of Vibration with Applications, 2nd ed.; Prentice-Hall, Inc.: Englewood Cliffs, NJ, USA, 1981; pp. 218–232. [Google Scholar]

- Yao, K.; Lin, Q.; Jiang, Z.; Zhao, N.; Tian, B.; Shi, P.; Peng, G.D. Modeling and Analysis of a Combined Stress-Vibration Fiber Bragg Grating Sensor. Sensors 2018, 18, 743. [Google Scholar] [CrossRef] [PubMed]

- Kisała, P. Generation of a zone chirp in uniform bragg grating as a way of obtaining double functionality of a sensor. Metrol. Meas. Syst. 2012, 19, 727–738. [Google Scholar] [CrossRef]

| Geometry Parameters | Value | Geometry Properties | Value | Material Properties | Value |

|---|---|---|---|---|---|

| l (m) | 10 × 10−3 | b2upper (m) | 2 × 10−3 | E (GPa) | 193 |

| h (m) | 0.5 × 10−3 | b3 (m) | 1.5 × 10−3 | G (GPa) | 73.7 |

| bsum (m) | 8 × 10−3 | lmass (m) | 3 × 10−3 | ρ (kg∙m−3) | 7750 |

| b1 (m) | 1.5 × 10−3 | hmass (m) | 2.5 × 10−3 | υ | 0.31 |

| b2 (m) | 5 × 10−3 | bmass (m) | 12 × 10−3 |

| Serial Number | Temperature (°C) | Vibration Acceleration (m/s2) | Strain (με) |

|---|---|---|---|

| 1 | 90 | 5 | 35.7 |

| 2 | 120 | 10 | 53.5 |

| 3 | 150 | 13 | 82.6 |

| 4 | 180 | 8 | 99.4 |

| 5 | 200 | 18 | 121.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, K.; Lin, Q.; Jiang, Z.; Zhao, N.; Peng, G.-D.; Tian, B.; Jia, W.; Yang, P. Design and Analysis of a Combined Strain–Vibration–Temperature Sensor with Two Fiber Bragg Gratings and a Trapezoidal Beam. Sensors 2019, 19, 3571. https://doi.org/10.3390/s19163571

Yao K, Lin Q, Jiang Z, Zhao N, Peng G-D, Tian B, Jia W, Yang P. Design and Analysis of a Combined Strain–Vibration–Temperature Sensor with Two Fiber Bragg Gratings and a Trapezoidal Beam. Sensors. 2019; 19(16):3571. https://doi.org/10.3390/s19163571

Chicago/Turabian StyleYao, Kun, Qijing Lin, Zhuangde Jiang, Na Zhao, Gang-Ding Peng, Bian Tian, Wenyun Jia, and Ping Yang. 2019. "Design and Analysis of a Combined Strain–Vibration–Temperature Sensor with Two Fiber Bragg Gratings and a Trapezoidal Beam" Sensors 19, no. 16: 3571. https://doi.org/10.3390/s19163571

APA StyleYao, K., Lin, Q., Jiang, Z., Zhao, N., Peng, G.-D., Tian, B., Jia, W., & Yang, P. (2019). Design and Analysis of a Combined Strain–Vibration–Temperature Sensor with Two Fiber Bragg Gratings and a Trapezoidal Beam. Sensors, 19(16), 3571. https://doi.org/10.3390/s19163571