Multiparametric Monitoring in Equatorian Tomato Greenhouses (I): Wireless Sensor Network Benchmarking

Abstract

1. Introduction

2. Related Work

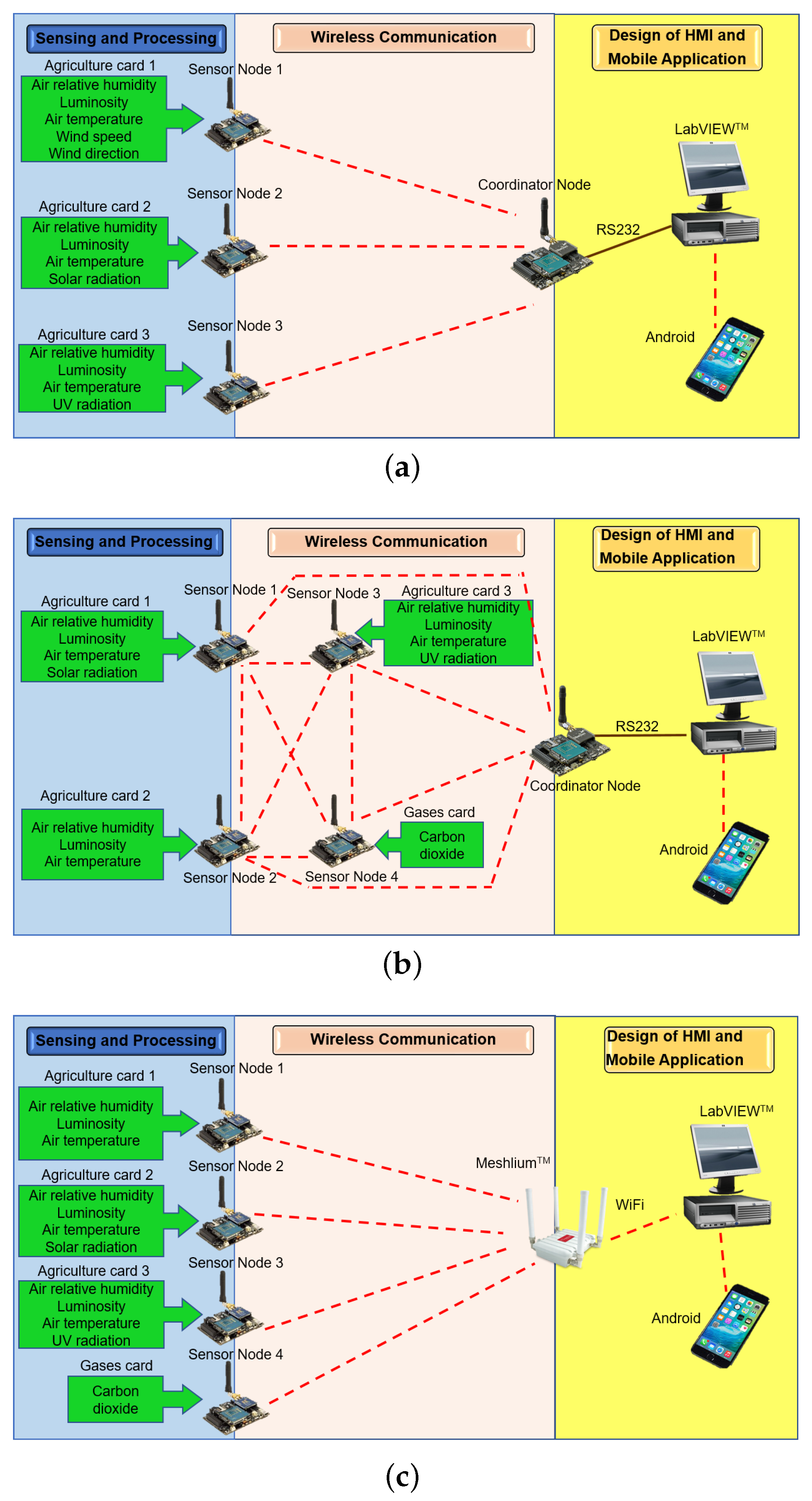

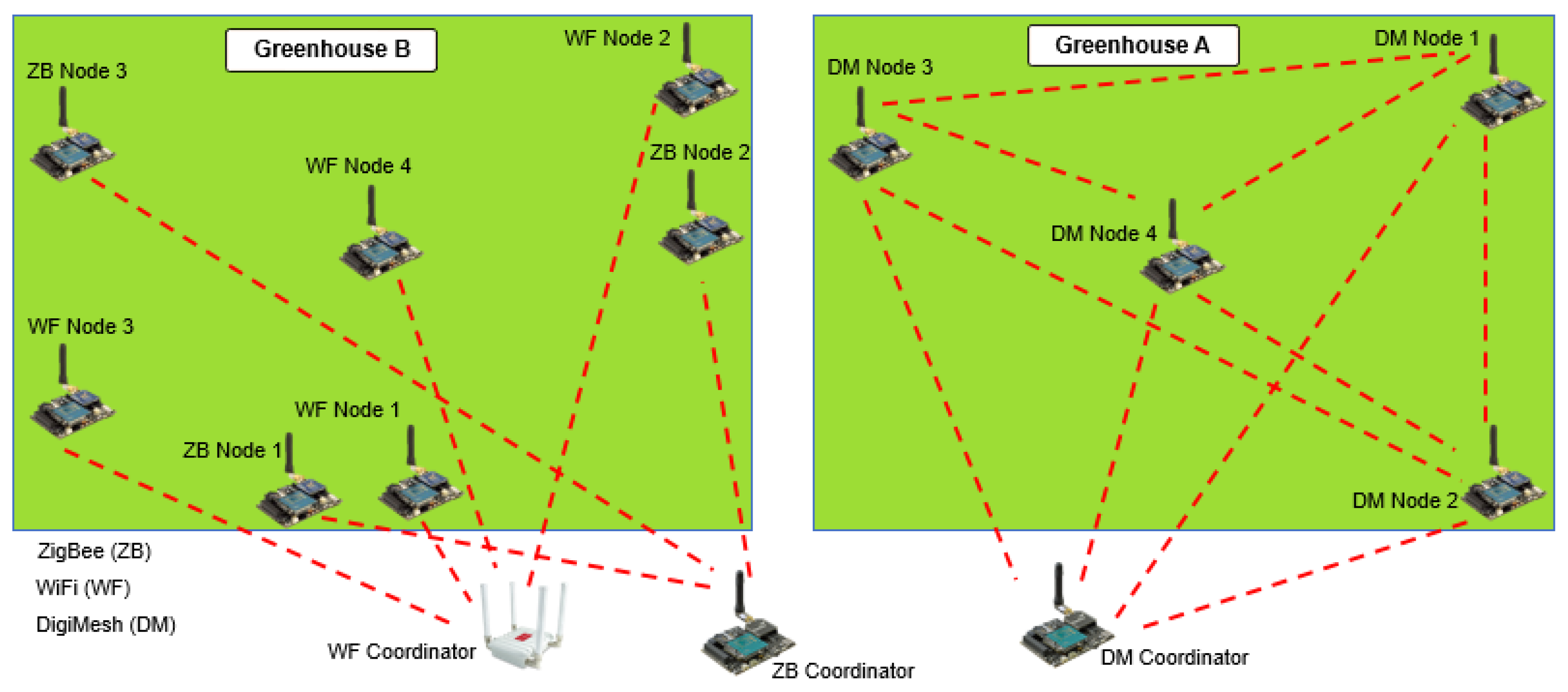

3. Proposed System for Tomato Greenhouse Monitoring with WSNs

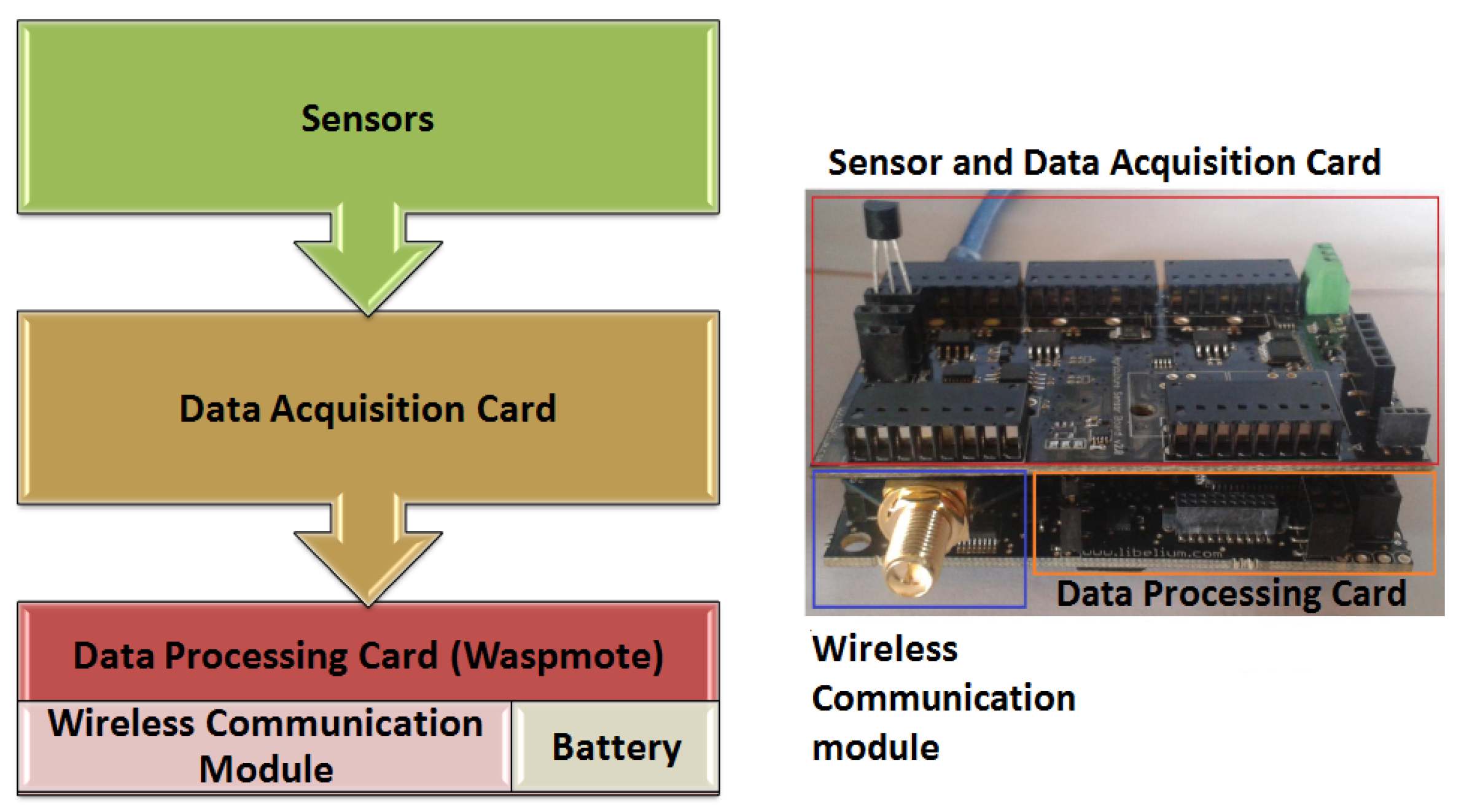

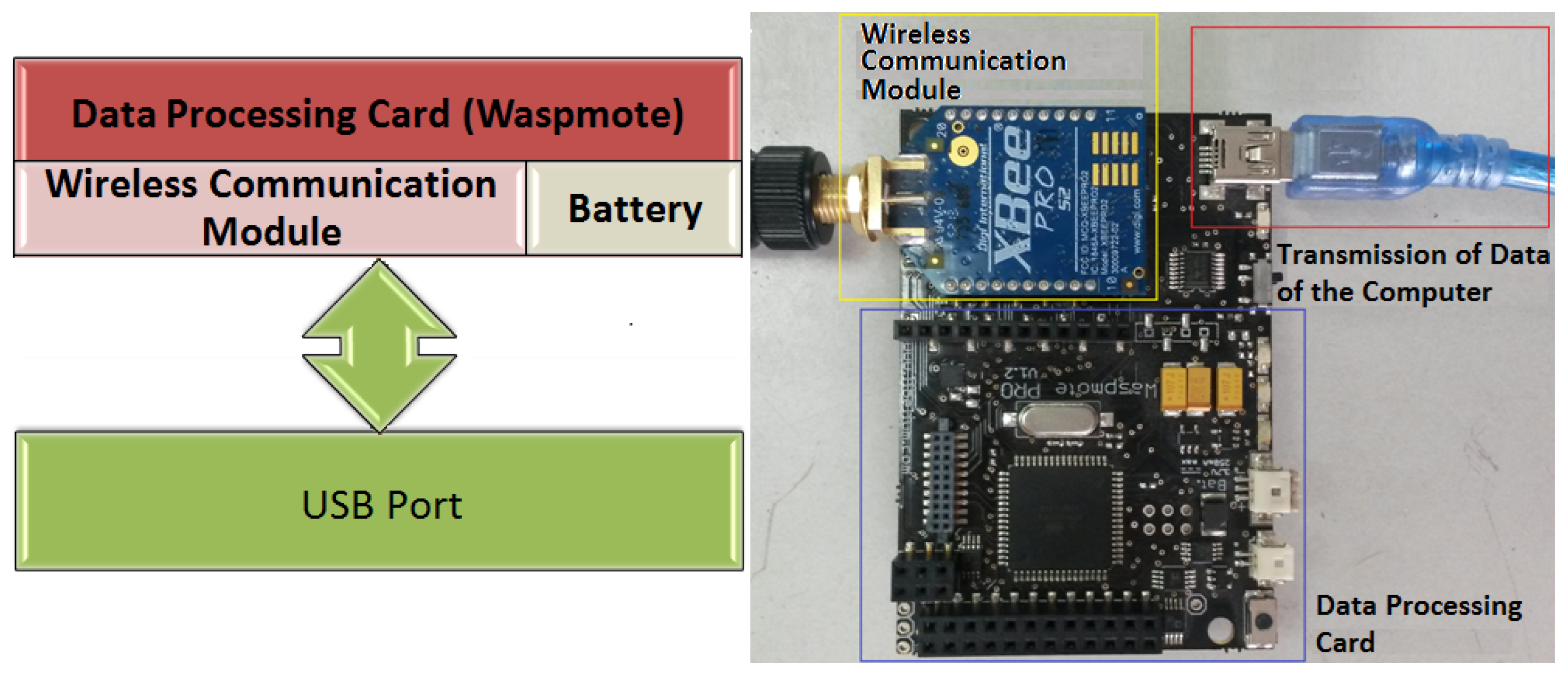

3.1. Data Acquisition and Processing

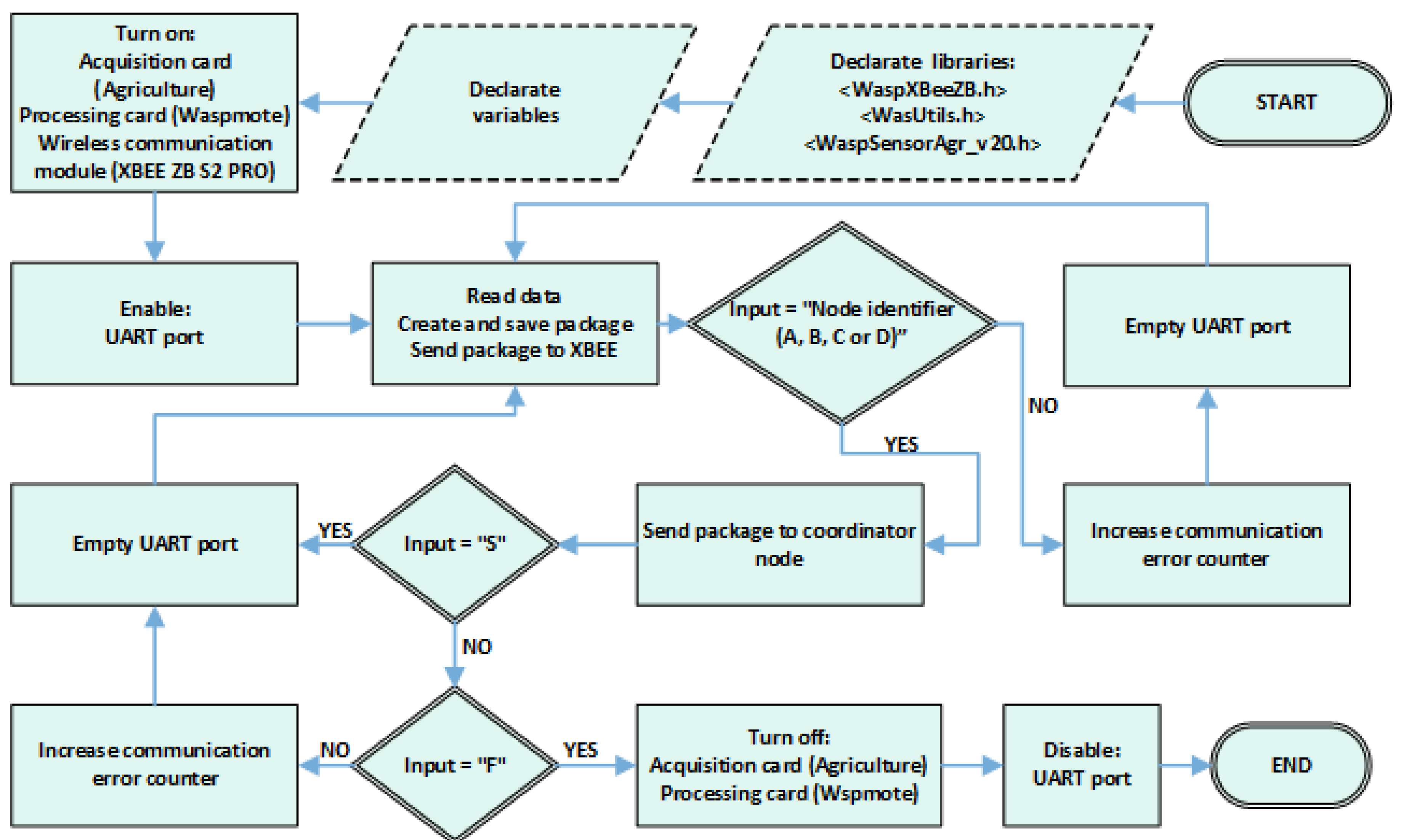

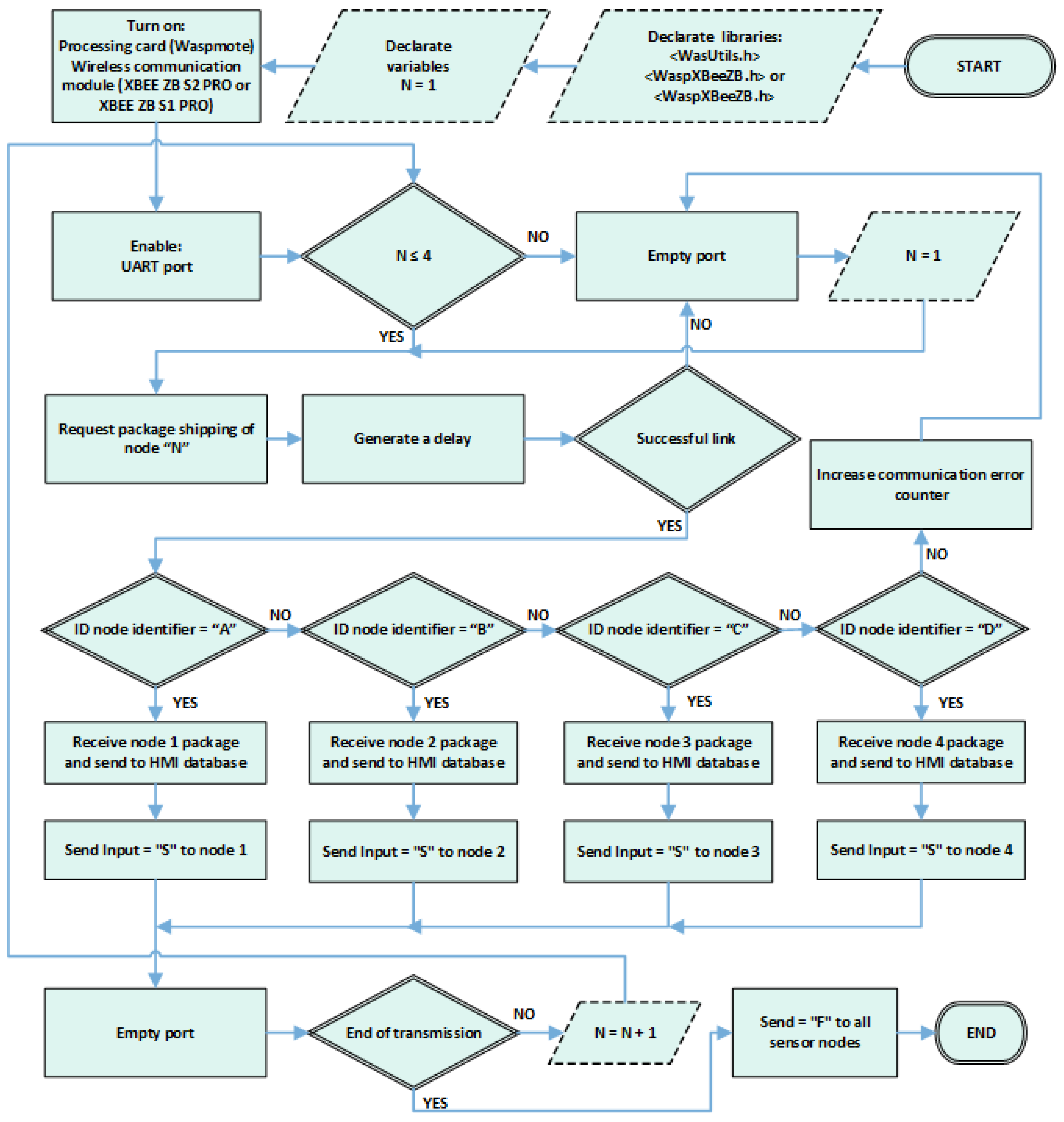

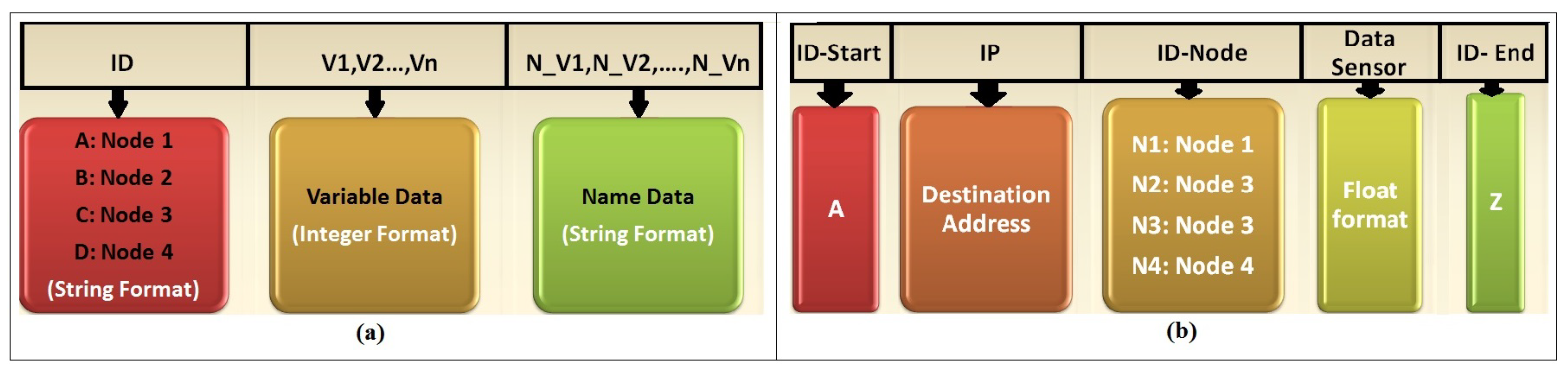

3.2. Transmission and Reception of Packages for ZigBee and DigiMesh Networks

3.3. Transmission and Reception of Packages for WiFi Network

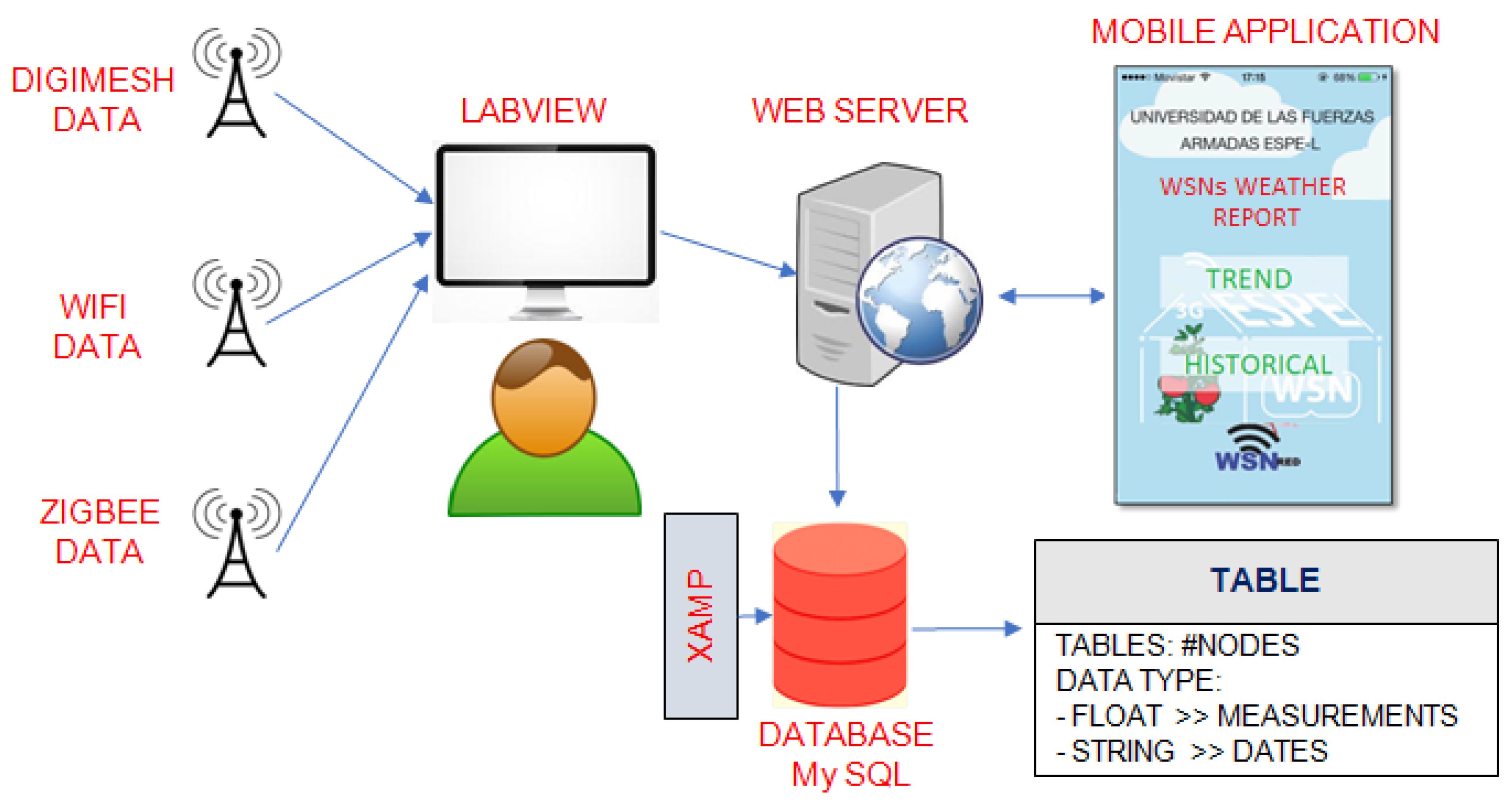

3.4. HMI Design

3.5. Mobile Application Development

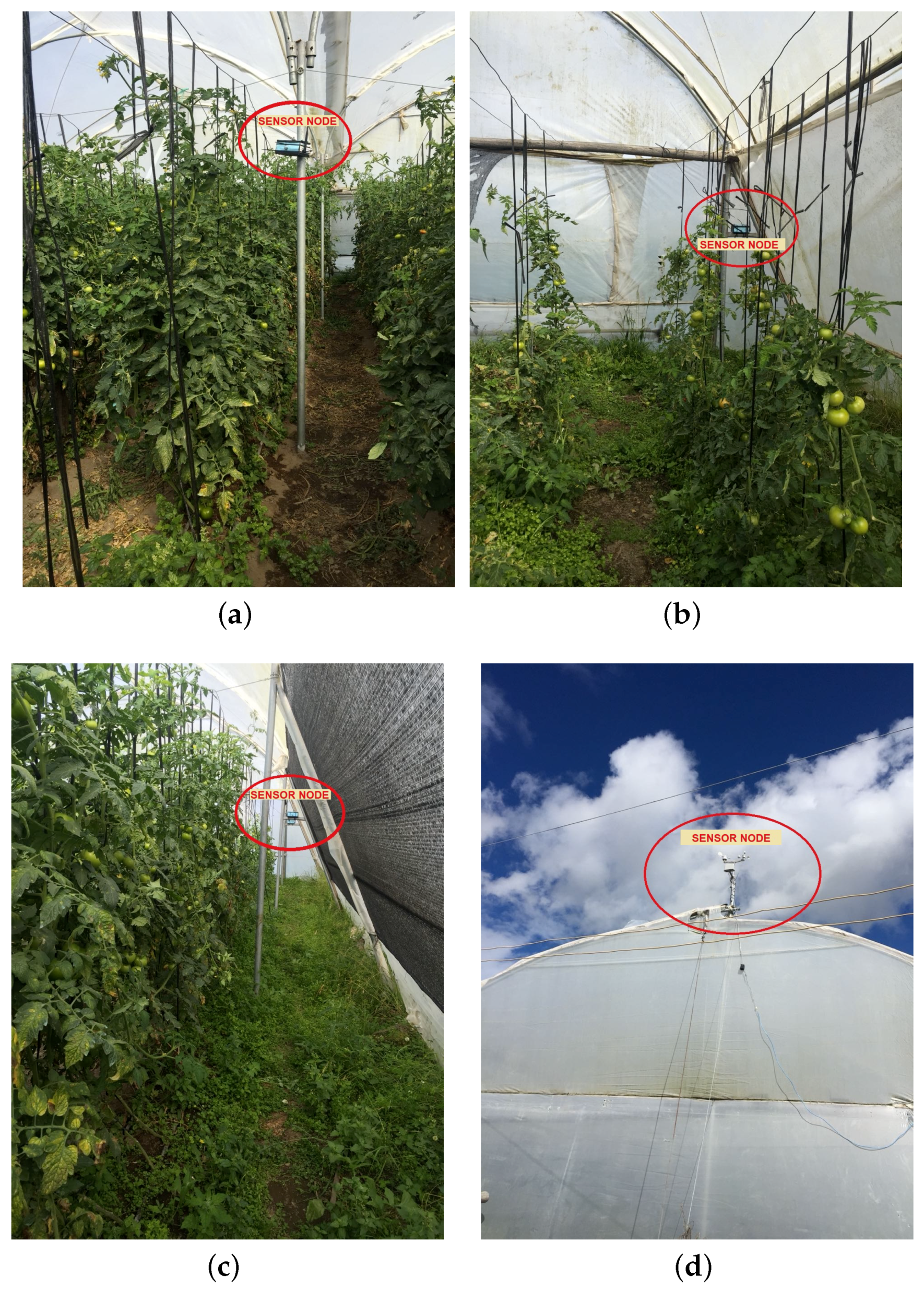

3.6. Startup

4. Results

4.1. Node Configuration Complexity in the Case of Network Scalability

4.2. Data Transmission Speed

5. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- INEC (Instituto Nacional de Estadística y Censos). Encuesta de Superficie y Producción Agropecuaria Continua: Quito, Ecuador, 2015. Available online: http://www.ecuadorencifras.gob.ec//documentos/web-inec/Estadisticas_agropecuarias/espac/espac_2014-2015/2015/Presentacion%20de%20resultados%20ESPAC_2015.pdf (accessed on 22 March 2017).

- Lee, H.; Kim, M.S.; Jeong, D.; Delwiche, S.R.; Chao, K.; Cho, B.K. Detection of cracks on tomatoes using a hyperspectral near-infrared reflectance imaging system. Sensors 2014, 14, 18837–18850. [Google Scholar] [CrossRef] [PubMed]

- Shrestha, S.; Deleuran, L.C.; Olesen, M.H.; Gislum, R. Use of multispectral imaging in varietal identification of tomato. Sensors 2015, 15, 4496–4512. [Google Scholar] [CrossRef] [PubMed]

- Atherton, J.; Rudich, J. The Tomato Crop: A Scientific Basis for Improvement; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Suárez Barón, J.C.; Suarez Baron, M.J. Monitoreo de variables ambientales en invernaderos usando tecnología ZIGBEE. In Proceedings of the XLIII Jornadas Argentinas de Informática e Investigación Operativa (43JAIIO)-VI Congreso Argentino de AgroInformática (CAI), Buenos Aires, Argentina, 1–5 September 2014; pp. 165–175. [Google Scholar]

- Hemraj, S. Power estimation and automation of green house using wireless sensor network. In Proceedings of the 5th International Conference on Confluence the Next Generation Information Technology Summit (Confluence), Noida, India, 25–26 September 2014; pp. 436–441. [Google Scholar]

- Roldán, J.J.; Joossen, G.; Sanz, D.; del Cerro, J.; Barrientos, A. Mini-UAV based sensory system for measuring environmental variables in greenhouses. Sensors 2015, 15, 3334–3350. [Google Scholar] [CrossRef] [PubMed]

- Srbinovska, M.; Gavrovski, C.; Dimcev, V.; Krkoleva, A.; Borozan, V. Environmental parameters monitoring in precision agriculture using wireless sensor networks. J. Clean. Prod. 2015, 88, 297–307. [Google Scholar] [CrossRef]

- Hwang, J.; Yoe, H. Study on the context-aware middleware for ubiquitous greenhouses using wireless sensor networks. Sensors 2011, 11, 4539–4561. [Google Scholar] [CrossRef] [PubMed]

- Duarte-Galvan, C.; Romero-Troncoso, R.d.J.; Torres-Pacheco, I.; Guevara-Gonzalez, R.G.; Fernandez- Jaramillo, A.A.; Contreras-Medina, L.M.; Carrillo-Serrano, R.V.; Millan-Almaraz, J.R. FPGA-Based Smart Sensor for Drought Stress Detection in Tomato Plants Using Novel Physiological Variables and Discrete Wavelet Transform. Sensors 2014, 14, 18650–18669. [Google Scholar] [CrossRef] [PubMed]

- Kalaivani, T.; Allirani, A.; Priya, P. A survey on ZigBee based wireless sensor networks in agriculture. In Proceedings of the 3rd International Conference on Trendz in Information Sciences and Computing (TISC), Chennai, India, 8–9 December 2011; pp. 85–89. [Google Scholar]

- Chang, C.L.; Huang, Y.M.; Hong, G.F. Using a Novel Wireless-Networked Decentralized Control Scheme under Unpredictable Environmental Conditions. Sensors 2015, 15, 28690–28716. [Google Scholar] [CrossRef] [PubMed]

- Ibayashi, H.; Kaneda, Y.; Imahara, J.; Oishi, N.; Kuroda, M.; Mineno, H. A Reliable Wireless Control System for Tomato Hydroponics. Sensors 2016, 16, 644. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Xu, L.; Tan, C.; Goodman, E.D.; Fu, D.; Xin, L. Digitization and visualization of greenhouse tomato plants in indoor environments. Sensors 2015, 15, 4019–4051. [Google Scholar] [CrossRef] [PubMed]

- Roldán, J.J.; Garcia-Aunon, P.; Garzón, M.; de León, J.; del Cerro, J.; Barrientos, A. Heterogeneous multi-robot system for mapping environmental variables of greenhouses. Sensors 2016, 16, 1018. [Google Scholar] [CrossRef] [PubMed]

- Xiaoyan, Z.; Xiangyang, Z.; Chen, D.; Zhaohui, C.; Shangming, S.; Zhaohui, Z. The design and implementation of the greenhouse monitoring system based on GSM and RF technologies. In Proceedings of the International Conference on Computational Problem-solving (ICCP), Jiuzhai, China, 26–28 October 2013; pp. 32–35. [Google Scholar]

- Asolkar, P.S.; Bhadade, U.S. An Effective Method of Controlling the Greenhouse and Crop Monitoring Using GSM. In Proceedings of the International Conference on Computing Communication Control and Automation (ICCUBEA), Pune, India, 26–27 February 2015; pp. 214–219. [Google Scholar]

- Huang, H.; Bian, H.; Zhu, S.; Jin, J. A Greenhouse Remote Monitoring System Based on GSM. In Proceedings of the International Conference on Information Management, Innovation Management and Industrial Engineering (ICIII), Shenzhen, China, 26–27 November 2011; pp. 357–360. [Google Scholar]

- Li, X.H.; Cheng, X.; Yan, K.; Gong, P. A Monitoring System for Vegetable Greenhouses based on a Wireless Sensor Network. Sensors 2010, 10, 8963–8980. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.B.; Xiu, D.B.; Shi, Y.P.; Wang, X.; Wang, M.M.; Wang, R.X. Design of Wireless Sensor System for Agricultural Micro Environment Based on WiFi. Appl. Mech. Mater. 2013, 303–306, 215–222. [Google Scholar] [CrossRef]

- Mendez, G.R.; Yunus, M.A.M.; Mukhopadhyay, S.C. A WiFi based smart wireless sensor network for monitoring an agricultural environment. In Proceedings of the of International Conference on Instrumentation and Measurement Technology (I2MTC), Graz, Austria, 13–16 May 2012; pp. 2640–2645. [Google Scholar]

- Wang, Y.; Di, W. Application of Wi-Fi Wireless Communication Technology In The Remote Monitoring of the Greenhouse. In Proceedings of the 1st International Conference on Information Sciences, Machinery, Materials and Energy (ICISMME), Chongqing, China, 11–13 April 2015. [Google Scholar]

- Deng, X.; Zheng, L.; Li, M. Development of a field wireless sensors network based on ZigBee technology. In Proceedings of the World Automation Congress (WAC), Kobe, Japan, 19–23 September 2010; pp. 463–467. [Google Scholar]

- Wang, W.; He, G.; Wan, J. Research on ZigBee wireless communication technology. In Proceedings of the International Conference on Electrical and Control Engineering (ICECE), Yichang, China, 16–18 September 2011; pp. 1245–1249. [Google Scholar]

- Baviskar, J.; Mulla, A.; Baviskar, A.; Ashtekar, S.; Chintawar, A. Real Time Monitoring and Control System for Green House Based on 802.15.4 Wireless Sensor Network. In Proceedings of the 4th International Conference on Communication Systems and Network Technologies (CSNT), Bhopal, India, 7–9 April 2014; pp. 98–103. [Google Scholar]

- Farahani, S. ZigBee Wireless Networks and Transceivers, 1st ed.; Newnes: Oxford, UK, 2008. [Google Scholar]

- Erazo, M.; Rivas, D.; Pérez, M.; Galarza, O.; Bautista, V.; Huerta, M.; Rojo-Álvarez, J.L. Design and implementation of a wireless sensor network for rose greenhouses monitoring. In Proceedings of the 6th International Conference on Automation, Robotics and Applications (ICARA), Queenstown, New Zealand, 17–19 February 2015; pp. 256–261. [Google Scholar]

- Pawlowski, A.; Guzman, J.L.; Rodríguez, F.; Berenguel, M.; Sánchez, J.; Dormido, S. Simulation of Greenhouse Climate Monitoring and Control with Wireless Sensor Network and Event-Based Control. Sensors 2009, 9, 232–252. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Xiaoguang, H.; Ke, C.; Ketai, H. The applications of WiFi-based Wireless Sensor Network in Internet of Things and Smart Grid. In Proceedings of the 6th IEEE Conference on Industrial Electronics and Applications (ICIEA), Beijing, China, 21–23 June 2011; pp. 789–793. [Google Scholar]

- Ruiz-Garcia, L.; Lunadei, L.; Barreiro, P.; Robla, I. A Review of Wireless Sensor Technologies and Applications in Agriculture and Food Industry: State of the Art and Current Trends. Sensors 2009, 9, 4728–4750. [Google Scholar] [CrossRef] [PubMed]

- Jimenez, A.; Jimenez, S.; Lozada, P.; Jimenez, C. Wireless Sensors Network in the Efficient Management of Greenhouse Crops. In Proceedings of the 9th International Conference on Information Technology: New Generations (ITNG), Las Vegas, NV, USA, 16–18 April 2012; pp. 680–685. [Google Scholar]

- Montoya, F.G.; Gomez, J.; Cama, A.; Zapata-Sierra, A.; Martinez, F.; De La Cruz, J.L.; Manzano-Agugliaro, F. A monitoring system for intensive agriculture based on mesh networks and the Android system. Comput. Electron. Agric. 2013, 99, 14–20. [Google Scholar] [CrossRef]

- Erazo-Rodas, M.; Sandoval-Moreno, M.; Muñoz-Romero, S.; Rivas, D.; Huerta, M.; Rojo-Álvarez, J.L. Multiparametric Monitoring in Equatorian Tomato Greenhouse (II): Energy Consumption Dynamics. Sensors 2018, 18, 2556. [Google Scholar]

- Erazo-Rodas, M.; Sandoval-Moreno, M.; Muñoz-Romero, S.; Rivas, D.; Huerta, M.; Rojo-Álvarez, J.L. Multiparametric Monitoring in Equatorian Tomato Greenhouse (III): Environment Measurement Dynamics. Sensors 2018, 18, 2557. [Google Scholar]

- Zhuang, W.; Zhi, J.; Hong, L.G. Temperature and Humidity Measure-Control System Based on CAN and Digital Sensors. In Proceedings of the International Forum on Information Technology and Applications (IFITA), Chengdu, China, 15–17 May 2009; pp. 548–550. [Google Scholar]

- Li, X.; Liu, Q.; Yang, R.; Zhang, H.; Zhang, J.; Cai, E. The Design and Implementation of the Leaf Area Index Sensor. Sensors 2015, 15, 6250–6269. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Li, X.; Yang, R. Greenhouse Environment Control and Monitoring System in the Hilly Area of Chongqing. In Proceedings of the International Conference on Intelligent Computation Technology and Automation (ICICTA), Shenzhen, China, 28–29 March 2011; pp. 93–96. [Google Scholar]

- Yulong, J.; Jiaqiang, Y. Design an Intelligent Environment Control System for GreenHouse Based on RS485 Bus. In Proceedings of the 2nd International Conference on Digital Manufacturing and Automation (ICDMA), Zhangjiajie, China, 5–7 August 2011; pp. 361–364. [Google Scholar]

- Hwang, J.; Shin, C.; Yoe, H. A wireless sensor network-based ubiquitous paprika growth management system. Sensors 2010, 10, 11566–11589. [Google Scholar] [CrossRef] [PubMed]

- Ramírez, M.; Guadalupe, L.; Fuentes-Marilles, O.; García-Jiménez, F. Heladas; Sistema Nacional de Protección Civil: México, Mexico, 2012. (In Spanich) [Google Scholar]

- Mancuso, M.; Bustaffa, F. A wireless sensors network for monitoring environmental variables in a tomato greenhouse. In Proceedings of the International Workshop on Factory Communication Systems, Torino, Italy, 28–30 June 2006; pp. 107–110. [Google Scholar]

- Huang, Y. Design and Realization of Wireless Sensor Network for Vegetable Greenhouse Information Acquisition. In Proceedings of the 6th International Conference on Wireless Communications Networking and Mobile Computing (WiCOM), Chengdu, China, 23–25 September 2010; pp. 1–4. [Google Scholar]

- Ahonen, T.; Virrankoski, R.; Elmusrati, M. Greenhouse Monitoring with Wireless Sensor Network. In Proceedings of the International Conference on Mechtronic and Embedded Systems and Applications (MESA), Beijing, China, 12–15 October 2008; pp. 403–408. [Google Scholar]

- Saad, S.; Munirah Kamarudin, L.; Kamarudin, K.; Nooriman, W.; Mamduh, S.; Zakaria, A.; Md Shakaff, A.; Jaafar, M. A real-time greenhouse monitoring system for mango with Wireless Sensor Network (WSN). In Proceedings of the 2nd International Conference on Electronic Design (ICED), Penang, Malaysia, 19–21 August 2014; pp. 521–526. [Google Scholar]

- Khedo, K.K.; Hosseny, M.R.; Toonah, M.Z. PotatoSense: A wireless sensor network system for precision agriculture. In Proceedings of the IST-Africa Conference, Le Meridien Ile Maurice, Mauritius, 7–9 May 2014; pp. 1–11. [Google Scholar]

- Sun, D.; Jiang, S.; Wang, W.; Tang, J. WSN Design and Implementation in a Tea Plantation for Drought Monitoring. In Proceedings of the International Conference on Cyber-Enabled Distributed Computing and Knowledge Discovery (CyberC), Huangshan, China, 10–12 October2010; pp. 156–159. [Google Scholar]

- Ceballos, M.; Gorricho, J.L.; Palma, O.; Huerta, M.; Rivas, D.; Erazo, M. Fuzzy System of Irrigation to Applied to the Growth of Habanero Pepper (Capsicum chinese Jacq.) under Protected Conditions in Yucatan—México. Int. J. Distrib. Sens. Netw. 2015, 11, 6. [Google Scholar] [CrossRef]

- Aquino-Santos, R.; González-Potes, A.; Edwards-Block, A.; Virgen-Ortiz, R.A. Developing a new wireless sensor network platform and its application in precision agriculture. Sensors 2011, 11, 1192–1211. [Google Scholar] [CrossRef] [PubMed]

- Salazar, R.; Rojano, A.; Lopez, I.; Schmidt, U. A Model for the Combine Description of the Temperature and Relative Humidity Regime in the Greenhouse. In Proceedings of the 9th Mexican International Conference on Artificial Intelligence (MICAI), Pachuca, Mexico, 8–13 November 2010; pp. 113–117. [Google Scholar]

- Nuez, F. El Cultivo del Tomate; Mundi-Prensa: Madrid, Spain, 1995. [Google Scholar]

- Rodriguez, R.; Rodriguez, T. Cultivo Moderno del Tomate, 2nd ed.; Mundi-Prensa: Madrid, Spain, 2001. [Google Scholar]

- Boulard, T.; Fatnassi, H.; Roy, J.; Lagier, J.; Fargues, J.; Smits, N.; Rougier, M.; Jeannequin, B. Effect of greenhouse ventilation on humidity of inside air and in leaf boundary-layer. Agric. For. Meteorol. 2004, 125, 225–239. [Google Scholar] [CrossRef]

- Alexander, P.J.; Radhakrishnan, N. Remote lab implementation on an embedded web server. In Proceedings of the International Conference on Circuit Power and Computing Technologies (ICCPCT), Nagercoil, India, 19–20 March 2015; pp. 1–5. [Google Scholar]

- Grønli, T.M.; Hansen, J.; Ghinea, G.; Younas, M. Mobile application platform heterogeneity: Android vs. In Windows Phone vs. iOS vs. Firefox OS. In Proceedings of the 28th International Conference on Advanced Information Networking and Applications (AINA), Victoria, BC, Canada, 13–16 May 2014; pp. 635–641. [Google Scholar]

- Tiernan, P. Enhancing the learning experience of undergraduate technology students with LabVIEW™ software. Comput. Educ. 2010, 55, 1579–1588. [Google Scholar] [CrossRef]

- Kofler, M. The Definitive Guide to MySQL 5; Apress: New York, NY, USA, 2006. [Google Scholar]

- Martín, A.R.; Martín, M.J.R. Aplicaciones Web, 2nd ed.; Ediciones Paraninfo, SA: Madrid, Spain, 2014. [Google Scholar]

- Olsson, M. Using PHP. In PHP 7 Quick Scripting Reference, 2nd ed.; Springer: Berlin, Germay, 2016; pp. 1–4. [Google Scholar]

- CENTA (Centro Nacional de Tecnología Agropecuaria y Forestal). Guía Técnica Cultivo de Tomate: Arce, El Salvador. Available online: http://www.centa.gob.sv/docs/guias/hortalizas/Guia%20Tomate.pdf (accessed on 10 July 2018).

| Geographical Location, Case Study, and Cultivation Area | Monitored Variables | Communication Technology | Network Topology | Store and Visualization Data | Objective |

|---|---|---|---|---|---|

| Iwata-Center Japan Tomato greenhouse (not specified area) [13] | Air temperature Luminosity Air relative humidity | Wireless ZigBee 2.4 GHz and 400 MHz | Star (3 sensor nodes) | Not specified | Comparative study of quality wireless communication in 400 MHZ and 2.4 GHz bands |

| Cotopaxi-Ecuador Rose greenhouse (50 m) [27] | Air temperature Air relative humidity CO Soil moisture Luminosity | Wireless ZigBee 2.4 GHz | Star (3 sensor nodes) | LabVIEW | Hardware and software development Data analysis of variables |

| Southern Italy Tomato greenhouse (100 m) [41] | Air temperature Air relative humidity | Wireless ZigBee 2.4 GHz | Mesh (6 sensor nodes) | LabVIEW | Hardware and software development Data analysis of variables |

| Chongqing-Center China Vegetables greenhouse (424.4 m) [37] | Air temperature Luminosity Air relative humidity CO | Wired Modbus | Bus (1 master—1 slave) | C&S System | Hardware and software development Data analysis of variables |

| Hubei-North China Vegetables greenhouse (100 m) [42] | Air temperature Luminosity Air relative humidity | Wireless ZigBee 2.4 GHz | Star (20 sensor nodes) | Mobile app | Hardware and software development Data analysis of variables |

| Narpio-Western Finland Vegetables greenhouse (1440 m) [43] | Air temperature Luminosity Air relative humidity CO Solar irradiance | Wireless ZigBee 2.4 GHz | Star (4 sensor nodes) | Not specified | Hardware and software development Data analysis of variables |

| Perlis-Nortwets Malasia Mango garden (520 m) [44] | Air temperature Air relative humidity CO | Wireless ZigBee 2.4 GHz | Star (3 sensor nodes) | LabVIEW | Hardware and software development Data analysis of variables |

| Mauritius-Africa Potato field (5000 m) [45] | Air temperature Air relative humidity Luminosity Soil pH Soil moisture | Wireless WiFi | Tree (6 sensor nodes) | Java | Hardware and software development Data analysis of variables |

| Yingde-North China Tea plantation (not specified area) [46] | Air temperature Soil water content Air relative humidity | Wired / Wireless Ethernet and GPRS | Mesh (20 sensor nodes) | Not specified | Hardware and software development Data analysis of variables |

| Yucatán-Southeast Mexico Habanero pepper garden (482.4 m) [47] | Air temperature Air relative humidity Soil moisture | Wireless ZigBee 2.4 GHz | Star (6 sensor nodes) | Arduino | Fuzzy logic control of the irrigation system |

| Colima-Mexico Not specified (Not specified area ) [48] | Air temperature Air relative humidity Soil moisture | Wireless LORA-CBF | Star (5 sensor nodes) | Not specified | Evaluate a new WSN applied in agriculture |

| Variable | Normal Ranges | Level | Effect |

|---|---|---|---|

| Air temperature | Day (20–25 C) Night (15–18 C) | Higher | It affects fruiting (fall flowers, limitation on the mincemeat) (>30 C), and bad fertilization of fruit and therefore evil fruit filling |

| Less | Short blade syndrome and fertilization problems (<10 C) | ||

| Air relative humidity | 50 y 60 % | Higher | Fruit cracking, difficulty fertilization, reduces the absorption of nutrients, and poor fruit set |

| Less | Securing the pollen to the stigma of the flower, water stress, stomatal closure, and reductions photosynthesis | ||

| Soil moisture | 50% | High | Accelerated growth in plants, slows ripening of fruits, and increases the relative humidity |

| Low | Fruit cracking, and water stress | ||

| Solar radiation | 0.85 MJ/m | Excess | Burnt fruit and plants |

| Decrease | Lost productivity | ||

| Luminosity | 8–16 h | Higher | Higher crop biomass, and increased density of plants |

| Less | Fall Flower, insufficient pollination, and fruit size smaller | ||

| CO | 500–2000 ppm | High | Best plant development, and increased productivity |

| Low | Photorespiration |

| Variable | Sensor | Model | Range of measuring | Output signal | Power consumption |

|---|---|---|---|---|---|

| Carbon dioxide | Solid electrolyte | TGS4161 | 350–10,000 ppm | Linear | 5 mA |

| Wind direction | Wind vane | WS-3000 | 16 positions | Discrete | <300 A |

| Air relative humidity | Capacitor polymer | 808H5V5 | 0–100% RH | Linear | 0.38 mA |

| Luminosity | Photoresist | LDR | 0–130,000 lux | Exponential | 0 A |

| Solar radiation | Apogee quantum | SQ-110 | 410–655 nm | Pulses | 0 A |

| UV radiation | Photodiode | SU-100 | 250–400 nm | Sinusoidal | 0 A |

| Air temperature | Thermistor | MCP9700A | −40 C to +125 C | Linear | 6 A |

| Wind speed | Anemometer | WS-3000 | 0–240 Km/h | Digital | <400 mA |

| Module | Node | MAC | Destination | PAN ID | Channel | Baud Rate |

|---|---|---|---|---|---|---|

| XBee ZB Pro S2 | Node 1 | 0013A20040B5B798 | DL: 13A200 DH: FFFF | 4321 | 18 | 9600 19,200 57,600 |

| Node 2 | 0013A20040B5B7C2 | |||||

| Node 3 | 0013A20040B5B794 | |||||

| Coordinator | 0013A20040B5B339 | |||||

| DigiMesh Xbee Zb Pro S1 | Node 1 | 0013A20040BDA364 | 1234 | C | ||

| Node 2 | 0013A20040BDA365 | |||||

| Node 3 | 0013A20040BBB3D7 | |||||

| Node 4 | 0013A20040BDA364 | |||||

| Coordinator | 0013A20040BBB3FA |

| Feature | Greenhouse A | Greenhouse B |

|---|---|---|

| Type | Sawtooth | Curve |

| Dimensions | Height: 5 m, length 80 m, width 50 m. | Height 5 m, length 70 m, width 50 m. |

| Phenological state [59] | Flowering | Harvest |

| Crop | Bulky | Less bulky |

| Network | Sensor Node | Transmission Rate (Bits) | (Bits) | Approximate (Seconds) | (bps) |

|---|---|---|---|---|---|

| DigiMesh | Node 1 | 318 | 974 | 3 (All active nodes) 10 (1 Faulty node) 20 (2 Faulty nodes) | 324.667 (All active nodes) 97.4 (Faulty node) 48.7 (2 Faulty nodes) |

| Node 2 | 278 | ||||

| Node 3 | 318 | ||||

| Node 4 | 60 | ||||

| ZigBee | Node 1 | 334 | 970 | 3 (All cases) | 323.333 (All cases) |

| Node 2 | 318 | ||||

| Node 3 | 318 | ||||

| WiFi | Node 1 | 318 | 696 | 8 (All cases) | 87 (All cases) |

| Node 2 | 318 | ||||

| Node 3 | 318 | ||||

| Node 4 | 60 |

| Height (m) | (Bits) | ||

|---|---|---|---|

| DigiMesh | ZigBee | WiFi | |

| 0 | 974 | 625 | 984 |

| 0.5 | 974 | 625 | 984 |

| 1 | 974 | 625 | 984 |

| 1.5 | 974 | 970 | 1044 |

| 1.8 | 974 | 970 | 1044 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Erazo-Rodas, M.; Sandoval-Moreno, M.; Muñoz-Romero, S.; Huerta, M.; Rivas-Lalaleo, D.; Naranjo, C.; Rojo-Álvarez, J.L. Multiparametric Monitoring in Equatorian Tomato Greenhouses (I): Wireless Sensor Network Benchmarking. Sensors 2018, 18, 2555. https://doi.org/10.3390/s18082555

Erazo-Rodas M, Sandoval-Moreno M, Muñoz-Romero S, Huerta M, Rivas-Lalaleo D, Naranjo C, Rojo-Álvarez JL. Multiparametric Monitoring in Equatorian Tomato Greenhouses (I): Wireless Sensor Network Benchmarking. Sensors. 2018; 18(8):2555. https://doi.org/10.3390/s18082555

Chicago/Turabian StyleErazo-Rodas, Mayra, Mary Sandoval-Moreno, Sergio Muñoz-Romero, Mónica Huerta, David Rivas-Lalaleo, César Naranjo, and José Luis Rojo-Álvarez. 2018. "Multiparametric Monitoring in Equatorian Tomato Greenhouses (I): Wireless Sensor Network Benchmarking" Sensors 18, no. 8: 2555. https://doi.org/10.3390/s18082555

APA StyleErazo-Rodas, M., Sandoval-Moreno, M., Muñoz-Romero, S., Huerta, M., Rivas-Lalaleo, D., Naranjo, C., & Rojo-Álvarez, J. L. (2018). Multiparametric Monitoring in Equatorian Tomato Greenhouses (I): Wireless Sensor Network Benchmarking. Sensors, 18(8), 2555. https://doi.org/10.3390/s18082555