Vibration and Noise in Magnetic Resonance Imaging of the Vocal Tract: Differences between Whole-Body and Open-Air Devices

Abstract

:1. Introduction

2. Subject and Methods

2.1. Differences in Construction of the Gradient System in the Open-Air and the Whole-Body MRI Equipment

2.2. Sensors for Measurement in a Weak Magnetic Field Environment

2.3. Features for Description of Vibration and Noise Signal Properties

3. Experiments and Results

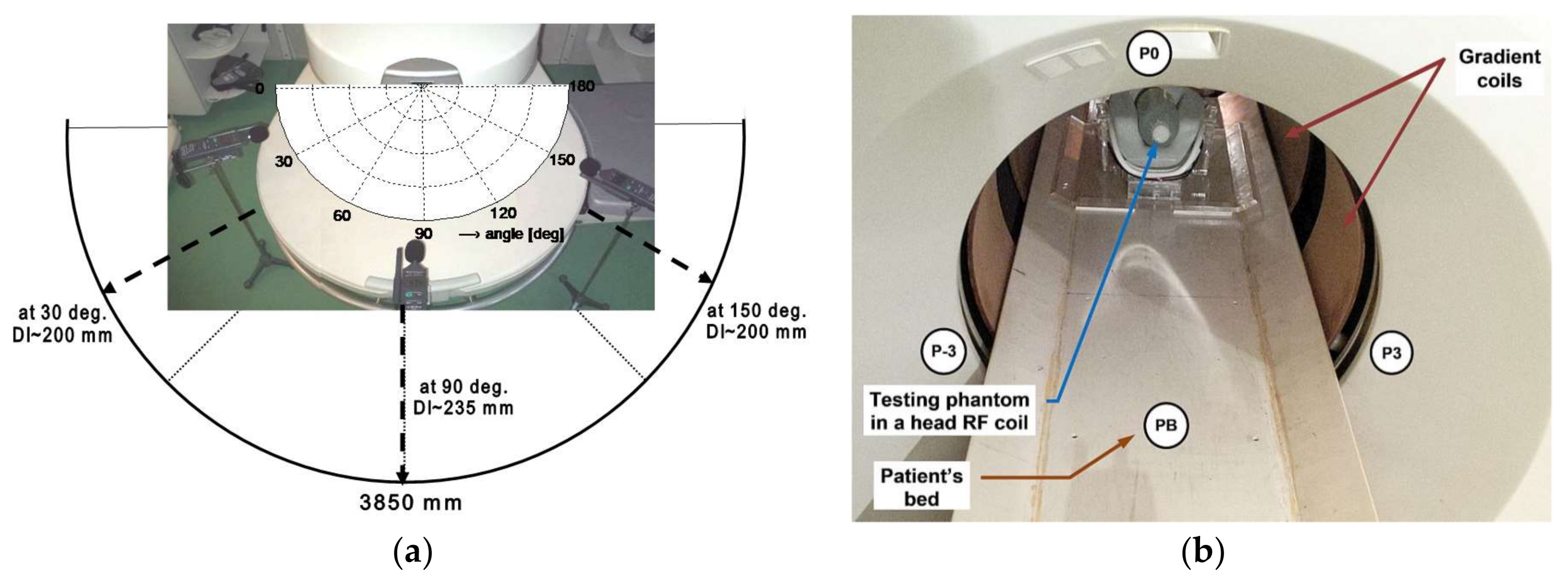

3.1. Mapping of Vibration and Noise Conditions in the Scanning Area of the Open-Air MRI Device

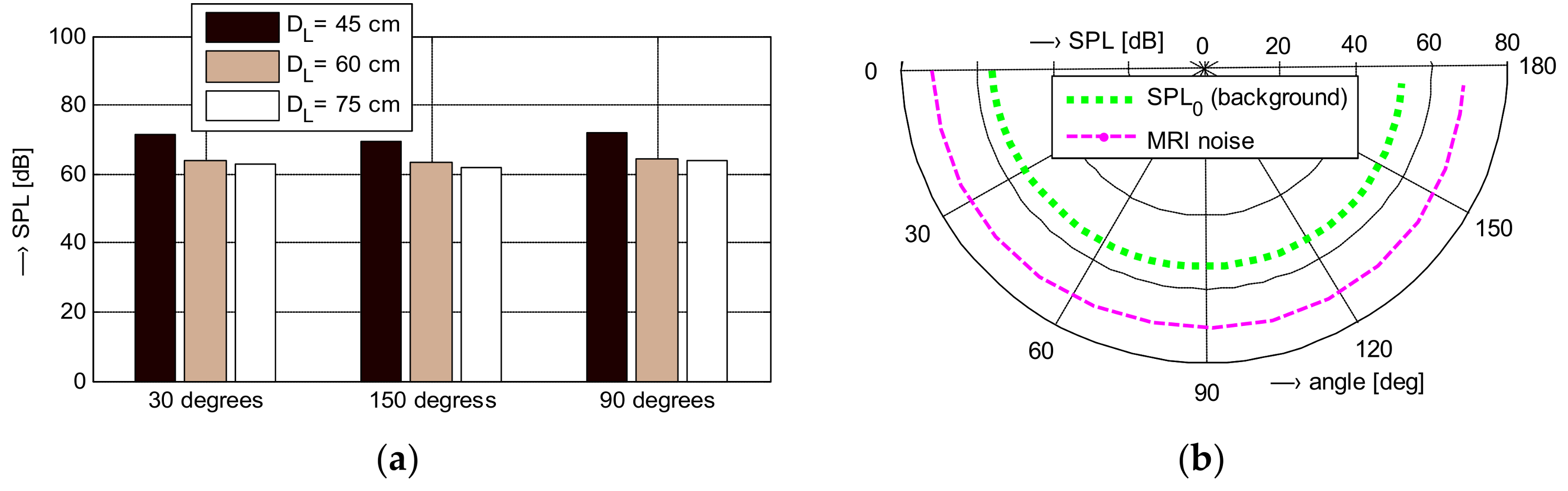

- Measurement of the acoustic noise SPL in the MRI neighborhood in directions of 30°, 90°, and 150°—see the overview photo together with the principal angle diagram of the MRI scanning area in Figure 2a. Discrete MRI noise SPL values measured at distances of 45, 60, and 75 cm from the central point of the scanning area are shown in Figure 3a. The detailed measurement of the directional pattern of the acoustic noise SPL distribution was practically executed in the range of <0°~165°> in 15° steps (excluding the last one because of a patient bed at the position of 180°), at the distance of DL = 60 cm from the MRI device central point—see the resulting diagram in Figure 3b. In both cases, the measurement was realized with the help of the sound level meter of the multi-function environment meter Lafayette DT 8820.

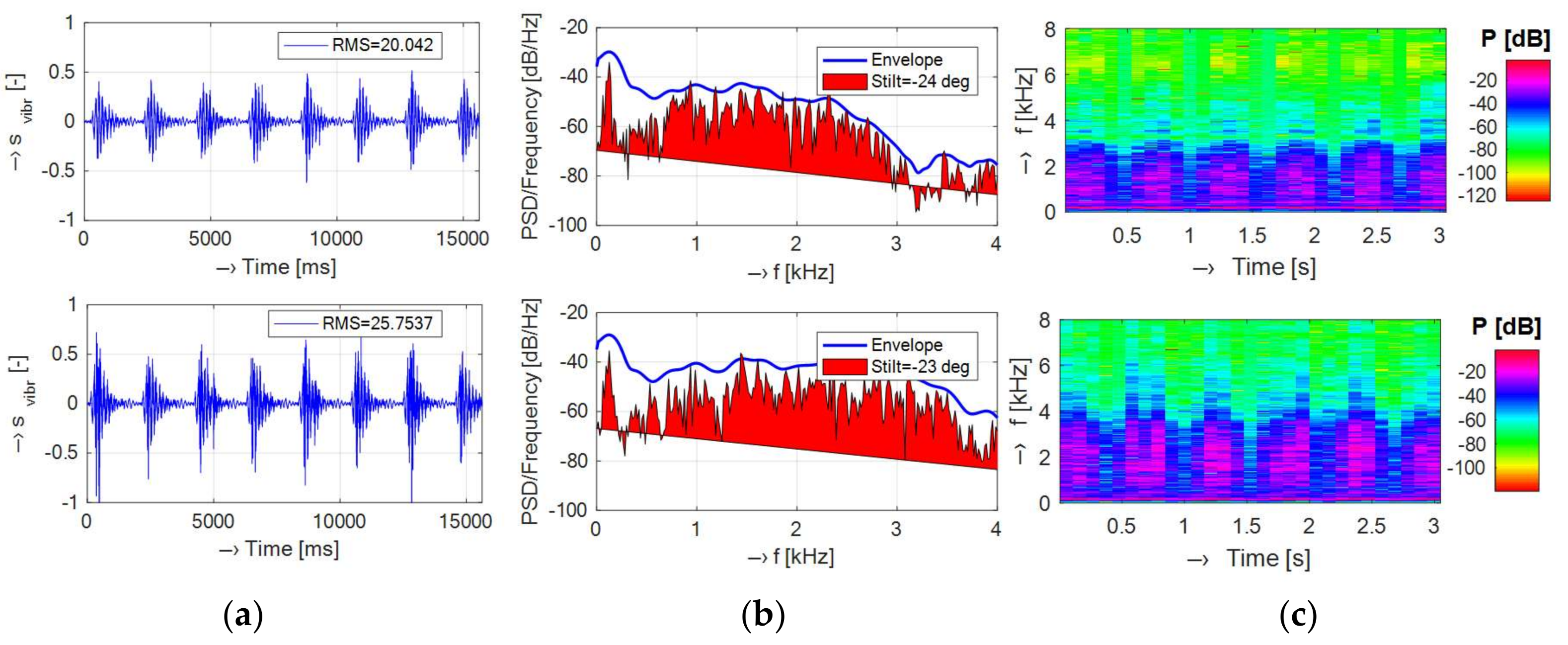

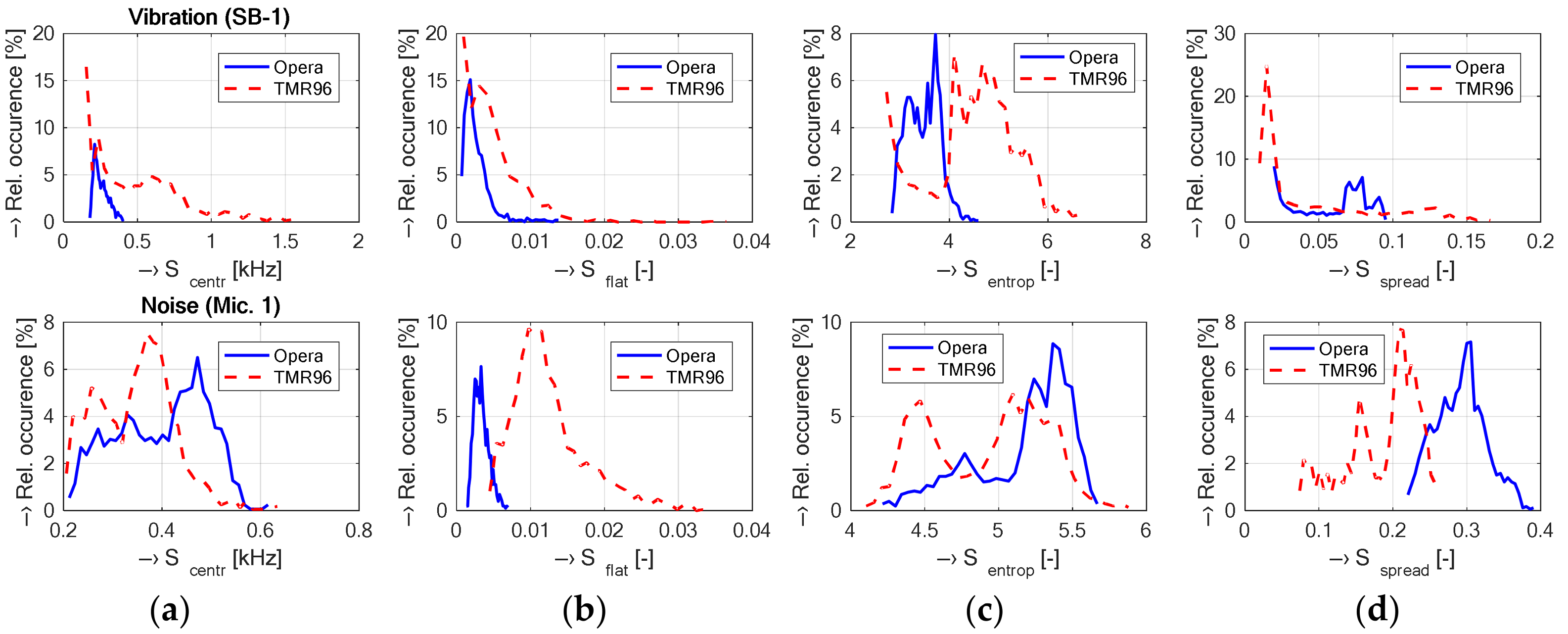

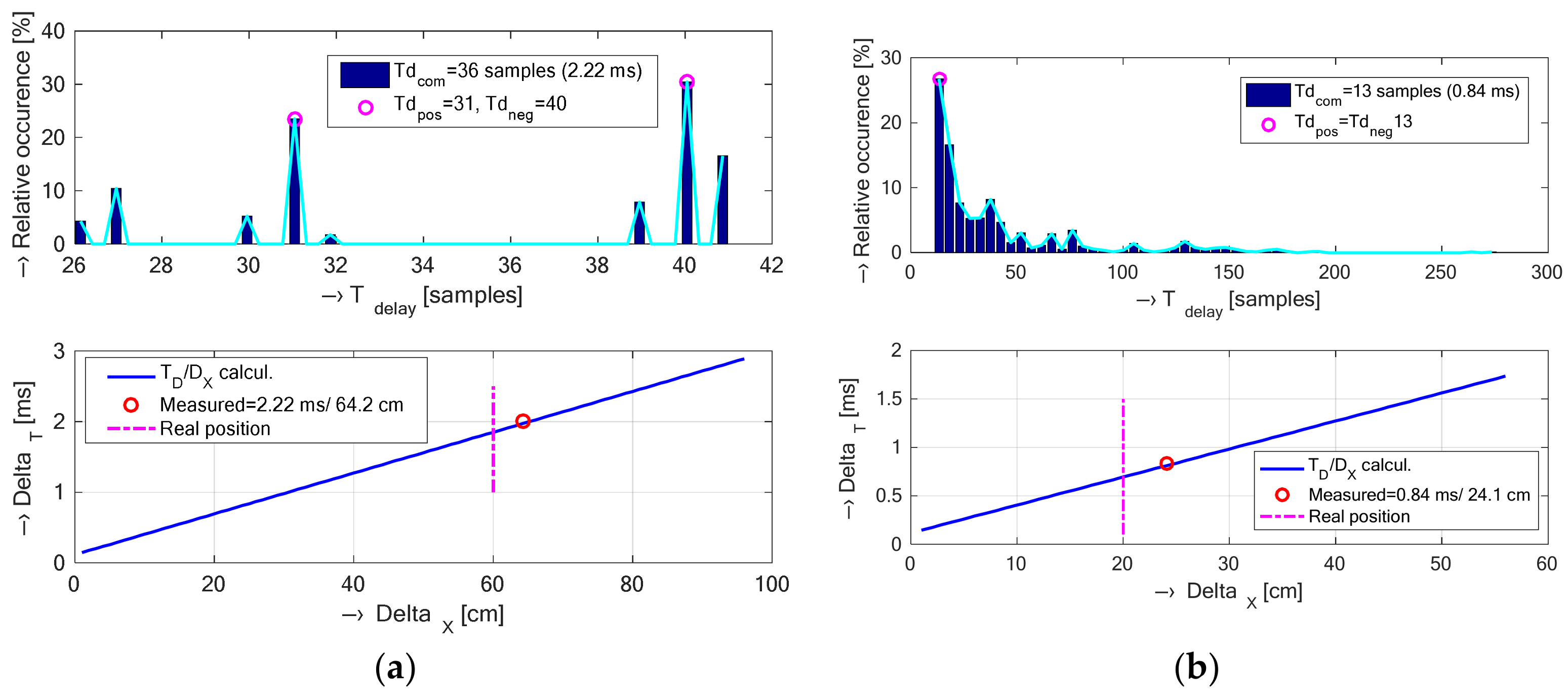

- Parallel real-time recording of the signals from the electrical excitation, the vibration sensor, the microphone and/or the sound level meter. Comparison of both MRI devices in the form of histograms and occurrence density plots of basic and supplementary spectral properties together with the calculated time delays between the electrical excitation of the gradient coils and the subsequently generated noise can be found in Section 3.3.

3.2. Analysis of Vibration and Noise Conditions of the Whole-Body MRI Equipment

- Measurement of the acoustic noise SPL in MRI neighborhood in the direction of 0° at three heights (2, 25, and 55 cm) above the patient’s bed level. Then, the SPL meter was located in ±120° (points P3 and P-3) at the height of 85 cm above the floor—see the arrangement photo in Figure 2b. The SPL meter was always placed at the distance of DL = 60 cm from the front plastic panel to minimize interaction with the magnetic field. The measurement itself was carried out during the SE scan sequence with TE = 18 ms, TR = 400 ms under three noise conditions (obtained discrete noise SPL values are presented in Table 1).

- SPL00—the background noise when all devices are stopped,

- SPL01—the ventilators inside the copper cage are running,

- SPLX—the scanning MR sequence is being executed with ventilation fans running.

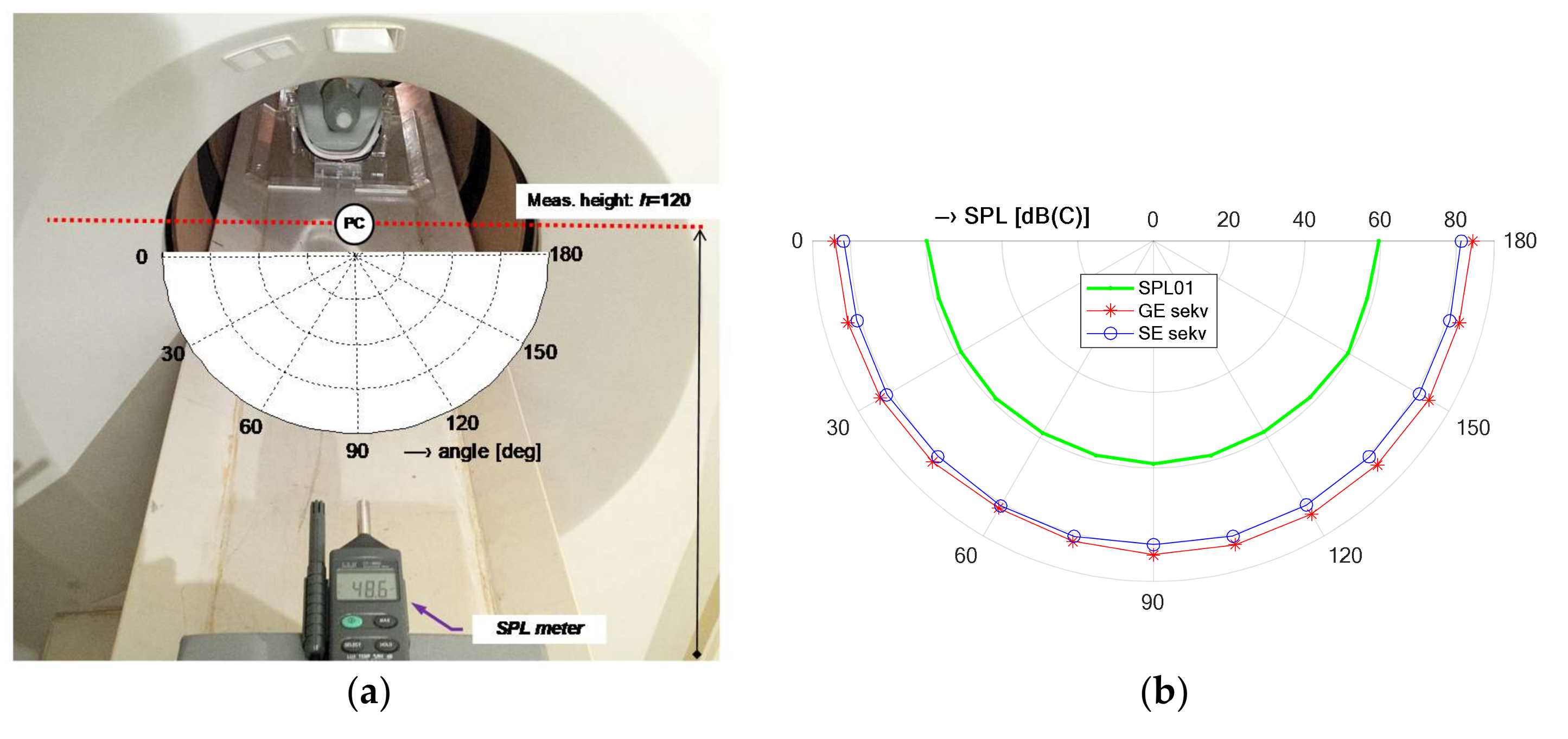

- The detailed measurement of the directional pattern of the acoustic noise SPL distribution in the MRI tube vicinity in the range of 0°~180° with 15° steps, at the distance of DL = 45 cm from the MRI center (point PC) of the scanning area, in the high h = 120 cm above the floor level (25 cm above the patient’s bed)—see the arrangement photo in Figure 4a and the resulting diagram for GE/SE sequence (TE = 18 ms, TR = 400 ms) together with SPL01 curve in Figure 4b. In both cases, the measurement was realized with the help of the sound level meter of the multi-function environment meter Lafayette DT 8820.

- Real-time recoding of the voltage signal from a piezoelectric transducer of the SB-1 sensor during execution of a chosen scan MR sequence (SE/GE type with different TE and TR parameter settings) and parallel recording of the electrical excitation signal (impulses from the MRI device gradient coil system) and/or the signals from the vibration sensor/pick-up microphone for time delay calculation and spectral properties comparison.

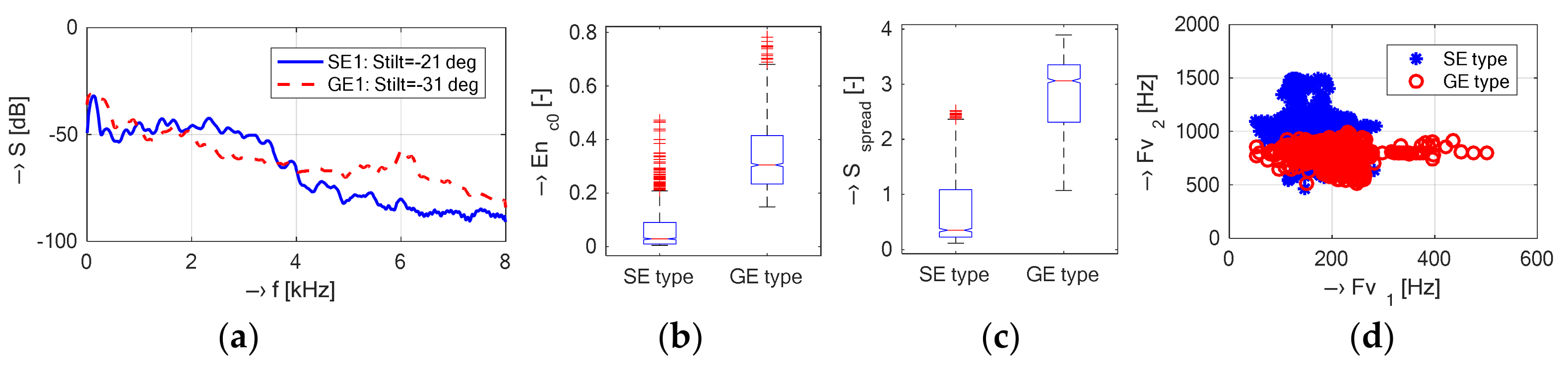

- Mapping of vibration in different parts of the MRI device—the sensor mounted directly on the surface of the front plastic cover at the points P0, P3, P-3, and on the surface of the patient’s bed (PB). The numerical results of the basic spectral features can be seen in Table 2 and the box-plot statistics of the supplementary spectral properties in Figure 5.

- Determination of differences between two mostly used MR scan sequences of SE and GE types; the pick-up sensor at the P3 point—see the visualization of differences of the selected signal features in Figure 6.

3.3. Comparison of Spectral Properties of Vibration and Noise Signals Recorded in Open and Closed MRI Devices

4. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wellard, R.M.; Ravasio, J.P.; Guesne, S.; Bell, C.; Oloyede, A.; Tevelen, G.; Pope, J.M.; Momot, K.I. Simultaneous magnetic resonance imaging and consolidation measurement of articular cartilage. Sensors 2014, 14, 7940–7958. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- He, Z.; He, W.; Wu, J.; Xu, Z. The novel design of a single-sided MRI probe for assessing burn depth. Sensors 2017, 17, 526. [Google Scholar] [CrossRef] [PubMed]

- Panych, L.P.; Madore, B. The physics of MRI safety. J. Magn. Reson. Imaging 2018, 47, 28–43. [Google Scholar] [CrossRef] [PubMed]

- Mainka, A.; Platzek, I.; Mattheus, W.; Fleischer, M.; Müller, A.S. Three-dimensional vocal tract morphology based on multiple magnetic resonance images is highly reproducible during sustained phonation. J. Voice 2017, 31, 504.e11–504.e20. [Google Scholar] [CrossRef] [PubMed]

- Kuortti, J.; Malinen, J.; Ojalammi, A. Post-processing speech recordings during MRI. Biomed. Signal Process. Control 2018, 39, 11–22. [Google Scholar] [CrossRef]

- Freitas, A.C.; Ruthven, M.; Boubertakh, R.; Miquel, M.E. Real-time speech MRI: Commercial Cartesian and non-Cartesian sequences at 3T and feasibility of offline TGV reconstruction to visualise velopharyngeal motion. Phys. Med. 2018, 46, 96–103. [Google Scholar] [CrossRef] [PubMed]

- Sun, G.; Li, M.; Rudd, B.W.; Lim, T.C.; Osterhage, J.; Fugate, E.M.; Lee, J.H. Adaptive speech enhancement using directional microphone in a 4-T MRI scanner. Magn. Reson. Mater. Phys. Biol. Med. 2015, 28, 473–484. [Google Scholar] [CrossRef] [PubMed]

- Vahanesa, C.; Reddy, C.K.; Panahi, I.M. Improving quality and intelligibility of speech using single microphone for the broadband fMRI noise at low SNR. In Proceedings of the IEEE International Conference of the Engineering in Medicine and Biology Society (EMBC), Orlando, FL, USA, 16–20 August 2016; pp. 3674–3678, ISBN 9781457702198. [Google Scholar]

- Han, L.; Shen, Z.; Fu, C.; Liu, C. Design and implementation of sound searching robots in wireless sensor networks. Sensors 2016, 16, 1550. [Google Scholar] [CrossRef] [PubMed]

- Ding, H.; Soon, I.Y.; Yeo, C.K. Over-attenuated components regeneration for speech enhancement. IEEE Trans. Audio Speech Lang. Process. 2010, 18, 2004–2014. [Google Scholar] [CrossRef]

- Přibil, J.; Přibilová, A.; Frollo, I. Analysis of acoustic noise and its suppression in speech recorded during scanning in the open-air MRI. In Advances in Noise Analysis, Mitigation and Control; Ahmed, N., Ed.; InTech: Rijeka, Croatia, 2016; pp. 205–228. ISBN 978-953-51-2674-4. [Google Scholar]

- Přibil, J.; Přibilová, A.; Frollo, I. Mapping and spectral analysis of acoustic vibration in the scanning area of the weak field magnetic resonance imager. J. Vib. Acoust. Trans. ASME 2014, 136, 051005. [Google Scholar] [CrossRef]

- Tayong, R.; Dupont, T.; Leclaire, P. Experimental investigation of holes interaction effect on the sound absorption coefficient of micro-perforated panels under high and medium sound levels. Appl. Acoust. 2011, 72, 777–784. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, X.; Yu, Y. Enhancing low-frequency sound absorption of micro-perforated panel absorbers by combining parallel mechanical impedance. Appl. Acoust. 2018, 130, 300–304. [Google Scholar] [CrossRef]

- Gai, X.L.; Xing, T.; Li, X.H.; Zhang, B.; Wang, F.; Cai, Z.N.; Han, Y. Sound absorption of microperforated panel with L shape division cavity. Appl. Acoust. 2017, 122, 41–50. [Google Scholar] [CrossRef]

- Moelker, A.; Wielopolski, P.A.; Pattynama, M.T. Relationship between magnetic field strength and magnetic-resonance-related acoustic noise levels. Magn. Reson. Mater. Phys. Biol. Med. 2003, 16, 52–55. [Google Scholar] [CrossRef] [PubMed]

- Přibil, J.; Přibilová, A.; Frollo, I. Influence of the human body mass in the open-air MRI on acoustic noise spectrum. Acta IMEKO 2016, 5, 81–86. [Google Scholar] [CrossRef]

- Liang, Z.P.; Lauterbur, P.C. Principles of Magnetic Resonance Imaging: A Signal Processing Perspective; Wiley-IEEE Press: New York, NY, USA, 1999; ISBN 978-0-780-34723-6. [Google Scholar]

- Winkler, S.A.; Alejski, A.; Wade, T.; McKenzie, C.A.; Rutt, B.K. On the accurate analysis of vibroacoustics in head insert gradient coils. Magn. Reson. Med. 2017, 78, 1635–1645. [Google Scholar] [CrossRef] [PubMed]

- Fraden, J. Handbook of Modern Sensors. Physics, Designs, and Applications, 4th ed.; Springer: New York, NY, USA, 2010; ISBN 978-1-4419-6466-3. [Google Scholar]

- E-Scan Opera. Image Quality and Sequences Manual. 830023522 Rev; A, Esaote S.p.A.: Genoa, Italy, 2008. [Google Scholar]

- TNMR Reference Manual, Hardware Reference Manual, DSPect User Guide. Available online: http://www.tecmag.com/support_contact/pulse_sequences/ (accessed on 10 October 2010).

- Andris, P.; Dermek, T.; Frollo, I. Simplified matching and tuning experimental receive coils for low-field NMR measurements. Measurement 2015, 64, 29–33. [Google Scholar] [CrossRef]

- Andris, P.; Frollo, I. Asymmetric spin echo sequence and requirements on static magnetic field of NMR scanner. Measurement 2013, 46, 1530–1534. [Google Scholar] [CrossRef]

- Cho, Z.H.; Park, S.H.; Kim, J.H.; Chung, S.C.; Chung, S.T.; Chung, J.Y.; Moon, C.W.; Yi, J.H.; Sin, C.H.; Wong, E.K. Analysis of acoustic noise in MRI. Magn. Reson. Imaging 1997, 15, 815–822. [Google Scholar] [CrossRef]

- Prince, D.L.; De Wilde, J.P.; Papadaki, A.M.; Curran, J.S.; Kitney, R.I. Investigation of acoustic noise on 15 MRI scanners from 0.2 T to 3 T. J. Magn. Reson. Imaging 2001, 13, 288–293. [Google Scholar] [CrossRef]

| Noise Condition/Measuring Position | at 0° | at 120° | at 120° | |||

|---|---|---|---|---|---|---|

| h0 1 = 55 cm | h0 1 = 25 cm | h0 1 = 2 cm | h1 2 = 85 cm | h1 2 = 85 cm | ||

| SPL00 silent | 47.9 | 47.7 | 47.5 | 47.4 | 47.5 | |

| SPL01 + ventilators | 54.1 | 56.8 | 56.9 | 61.8 | 59.6 | |

| SPLX scan sequence | 77 | 79.1 | 80.1 | 79.5 | 78.7 | |

| Sensor Position/Feature | SignalRMS (-) | Enc0 (-) | Stilt (°) | FV1 (Hz) | FV2 (Hz) |

|---|---|---|---|---|---|

| 0° (TR = 400) | 4.3 | 0.47 | −22 | 429 | 1380 |

| 120° (TR = 400/500) | 2.7/2.4 | 0.38/0.31 | −1/−14 | 352/260 | 1105/1048 |

| −120° (TR = 400) | 2.5 | 0.27 | −13 | 368 | 930 |

| Patient’s bed (TR = 400) | 7.9 | 0.95 | 3 | 398 | 1662 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Přibil, J.; Přibilová, A.; Frollo, I. Vibration and Noise in Magnetic Resonance Imaging of the Vocal Tract: Differences between Whole-Body and Open-Air Devices. Sensors 2018, 18, 1112. https://doi.org/10.3390/s18041112

Přibil J, Přibilová A, Frollo I. Vibration and Noise in Magnetic Resonance Imaging of the Vocal Tract: Differences between Whole-Body and Open-Air Devices. Sensors. 2018; 18(4):1112. https://doi.org/10.3390/s18041112

Chicago/Turabian StylePřibil, Jiří, Anna Přibilová, and Ivan Frollo. 2018. "Vibration and Noise in Magnetic Resonance Imaging of the Vocal Tract: Differences between Whole-Body and Open-Air Devices" Sensors 18, no. 4: 1112. https://doi.org/10.3390/s18041112

APA StylePřibil, J., Přibilová, A., & Frollo, I. (2018). Vibration and Noise in Magnetic Resonance Imaging of the Vocal Tract: Differences between Whole-Body and Open-Air Devices. Sensors, 18(4), 1112. https://doi.org/10.3390/s18041112