The Non-Destructive Test of Steel Corrosion in Reinforced Concrete Bridges Using a Micro-Magnetic Sensor

Abstract

:1. Introduction

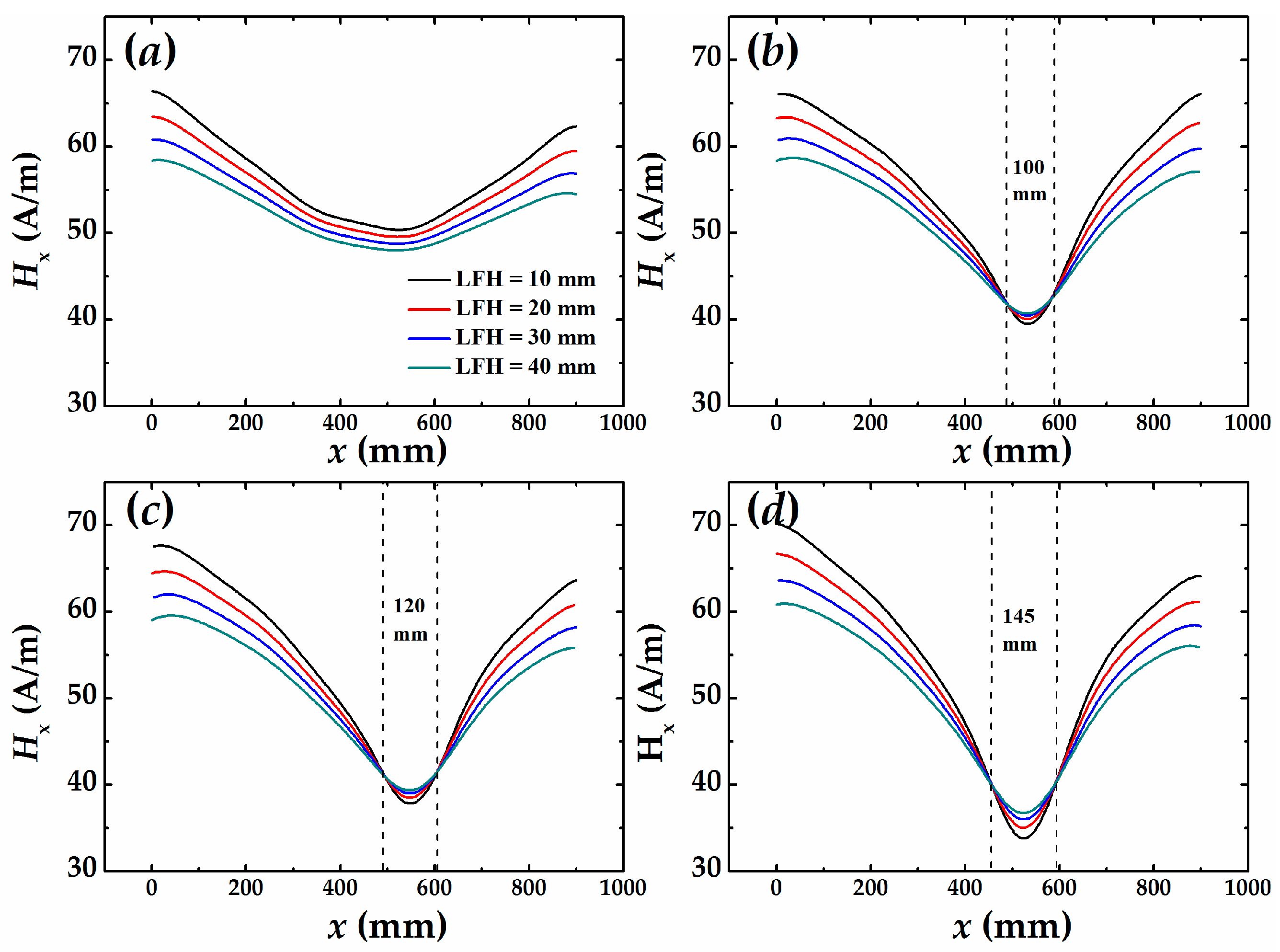

2. Experimental Setup and Theoretical Model Based on Micro-Magnetic Sensor

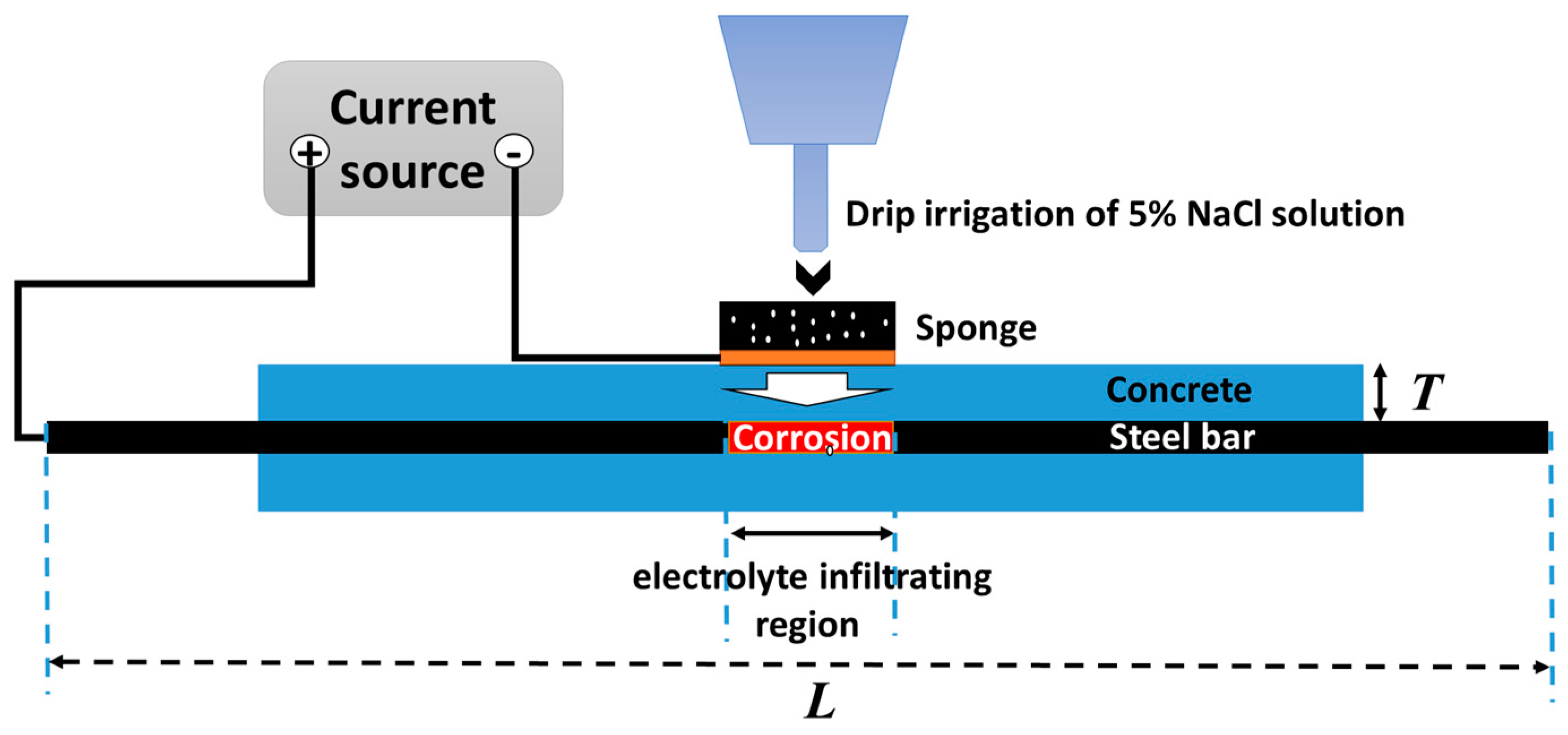

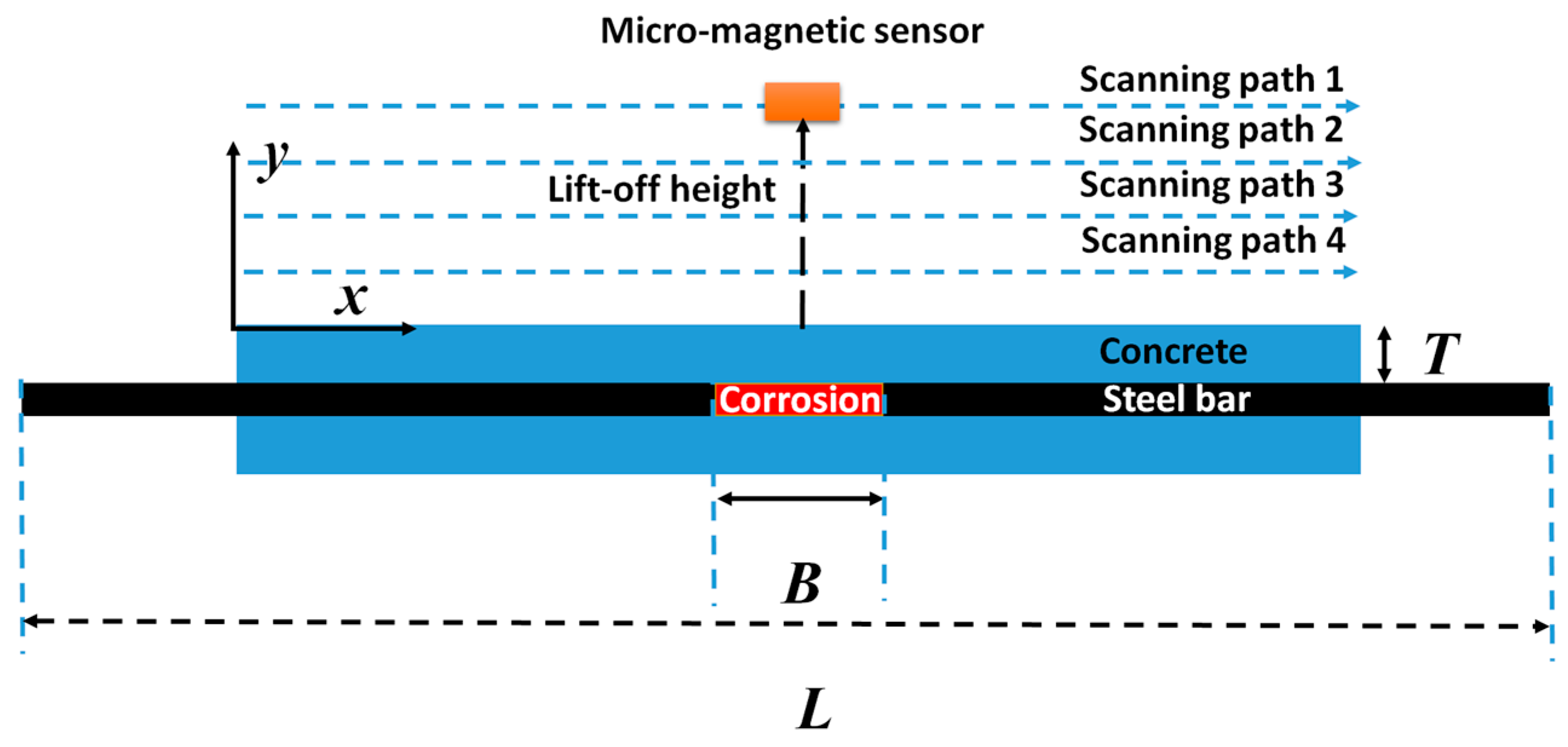

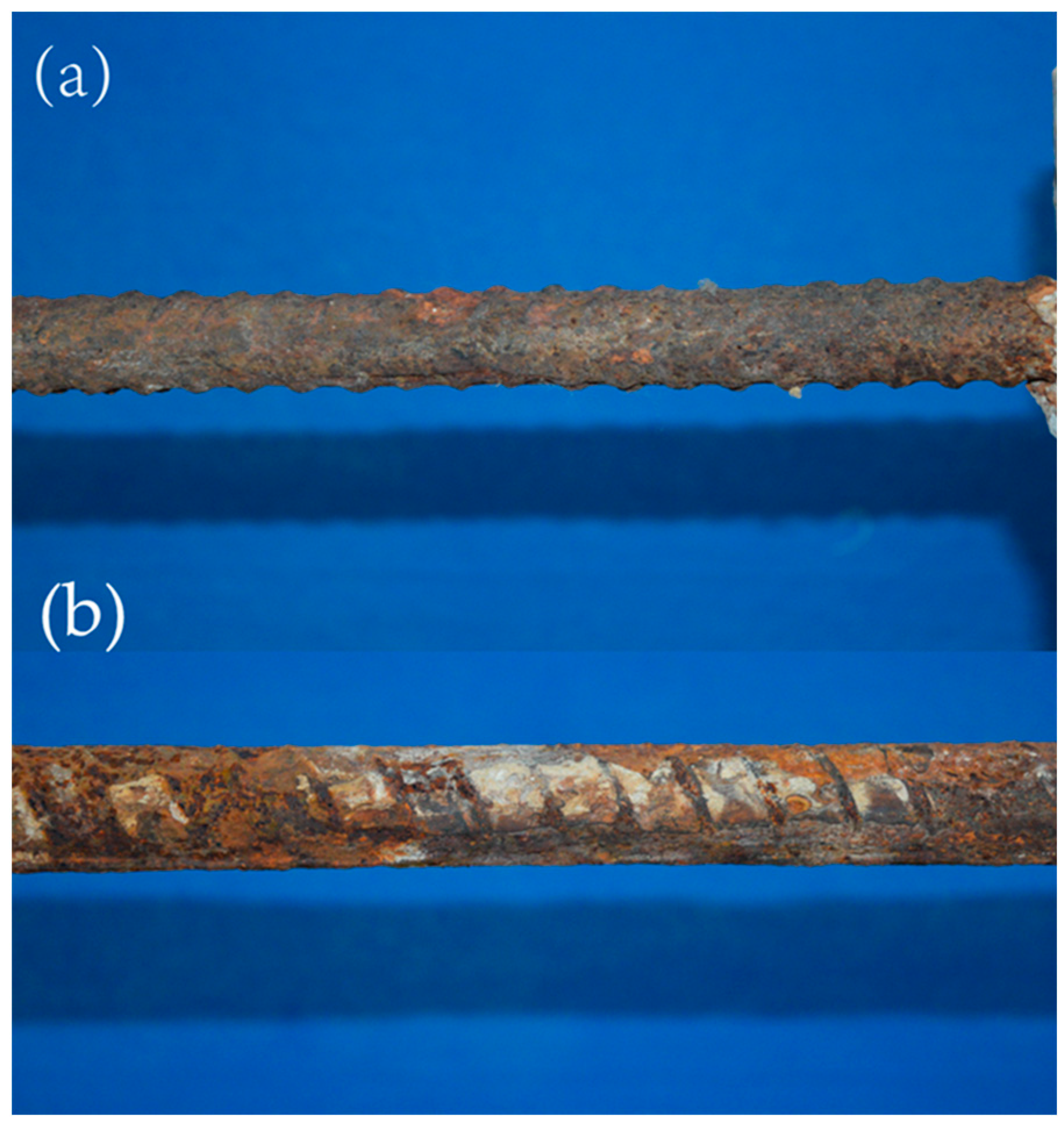

2.1. Experiment Details Based on Micro-Magnetic Sensors

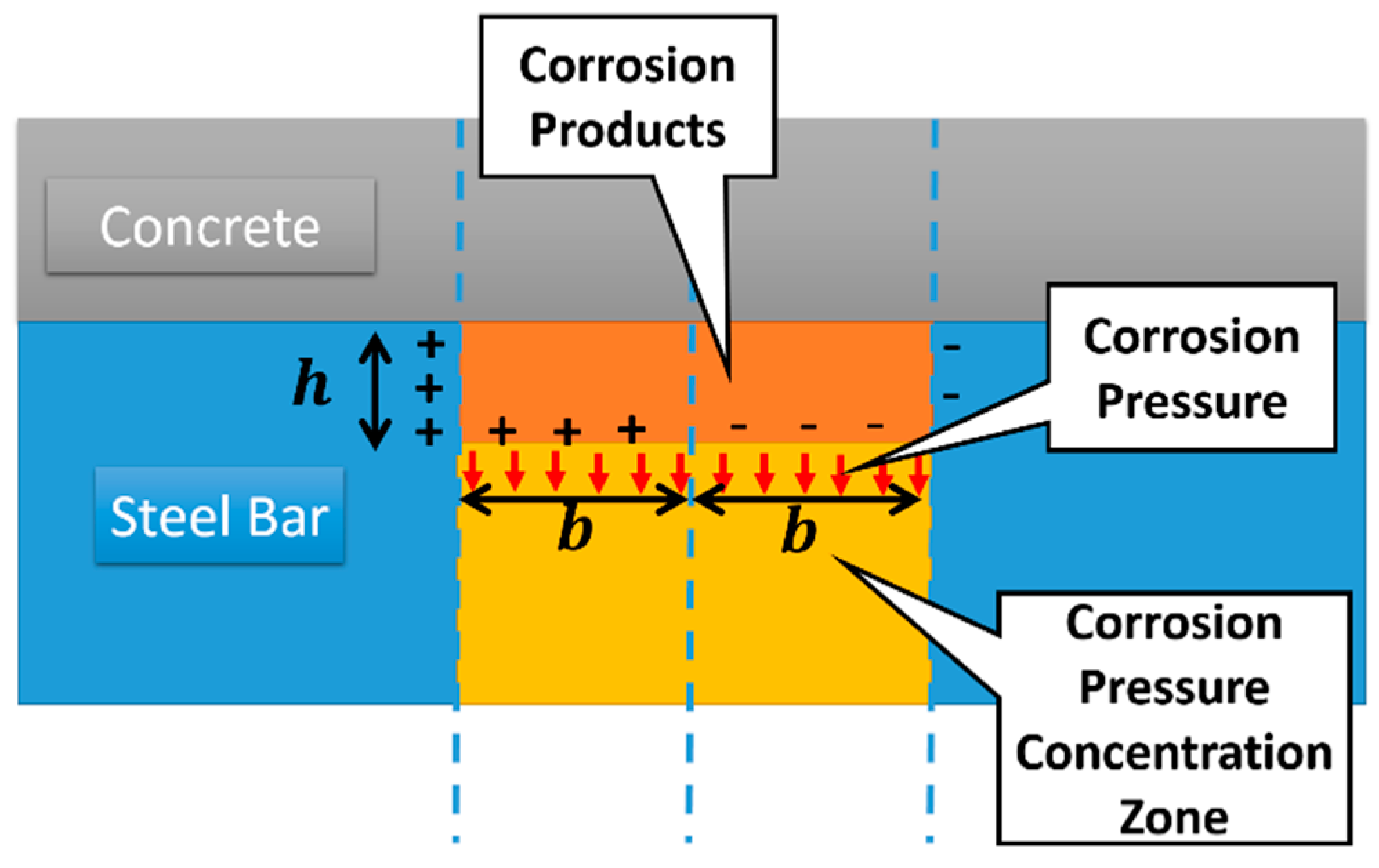

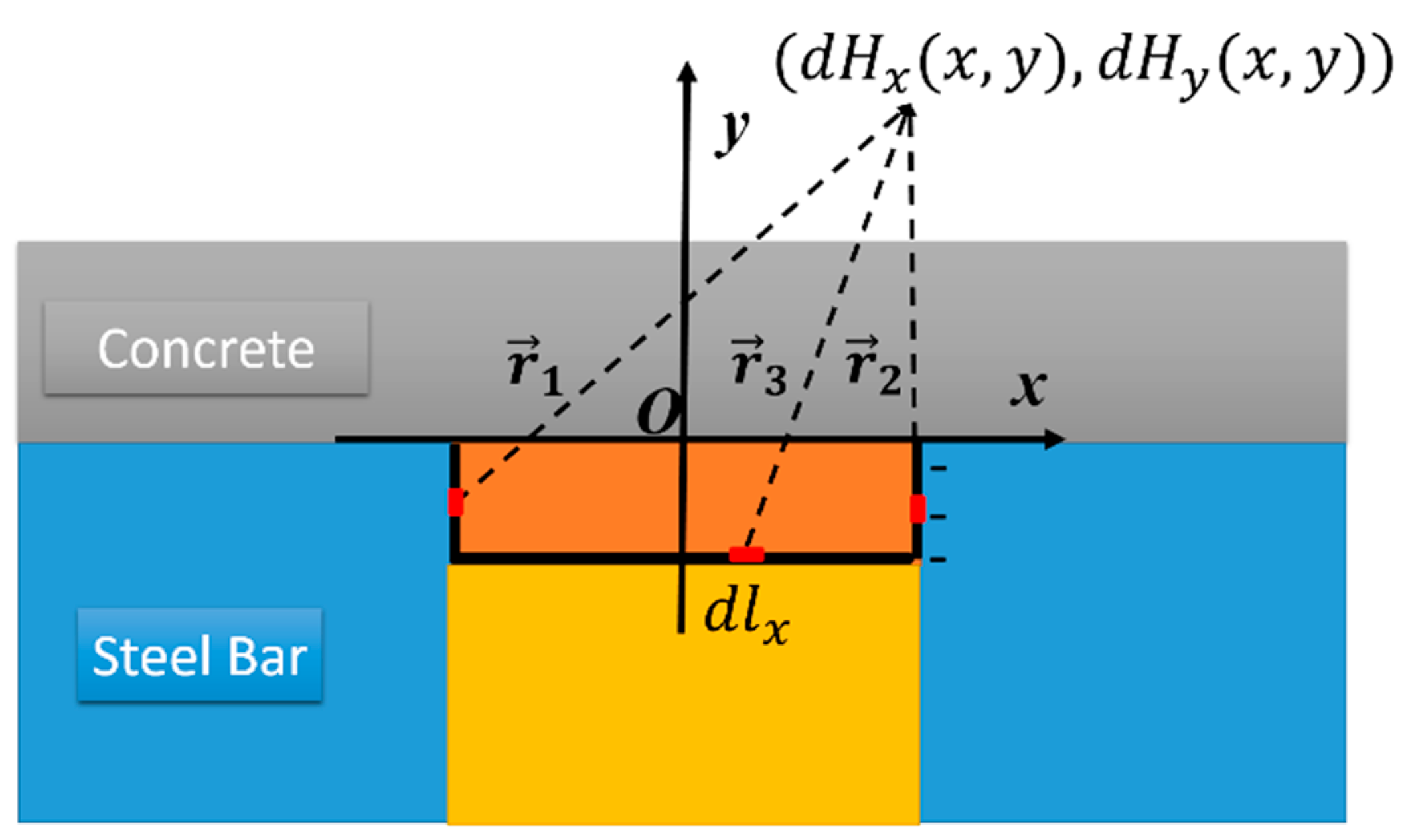

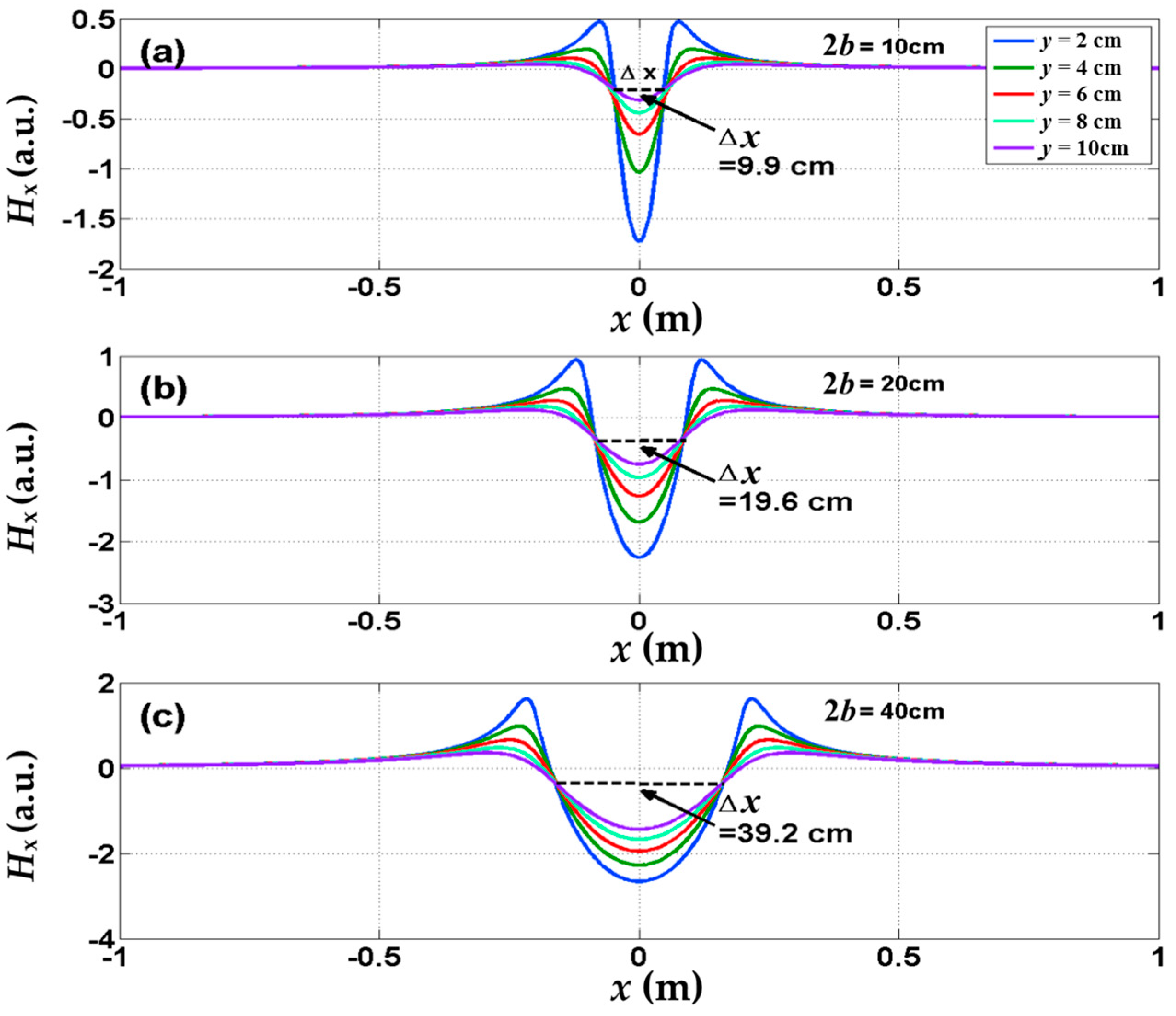

2.2. Theoretical Model for Measured Data

3. Results and Discussion for Steel Corrosion Based on Micro-Magnetic Sensor

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lorenz, W.J.; Mansfeld, F. Determination of Corrosion Rates by Electrochemical DC and AC Methods. Corros. Sci. 1981, 21, 647–672. [Google Scholar] [CrossRef]

- Yeih, W.; Huang, R. Detection of the Corrosion Damage in Reinforced Concrete Members by Ultrasonic Testing. Cem. Concr. Res. 1998, 28, 1071–1083. [Google Scholar] [CrossRef]

- Tian, G.Y.; Rangarajan, S.; Sophian, A. Stress Measurement using Novel Eddy Current Probe. In Proceedings of the BINDT Annual Conference, Torquay, UK, 14–16 September 2004.

- Kobayashi, K.; Banthia, N. Corrosion Detection in Reinforced Concrete using Induction Heating and Infrared Thermography. J. Civil Struct. Health Monitor. 2011, 1, 25–35. [Google Scholar] [CrossRef]

- Suzuki, S.; Suzuki, S.; Matsubara, E.; Waseda, Y. In-situ X-ray Diffraction of Corrosion Products Formed on Iron Surfaces. Mater. Trans. 2005, 46, 637–662. [Google Scholar]

- Sakamoto, H.; Okada, M.; Homma, M. Theoretical Analysis of Barkhausen Noise in Carbon Steels. IEEE Trans. Magn. 1987, 23, 2236–2238. [Google Scholar] [CrossRef]

- Piotrowski, L.; Augustyniak, B.; Chmielewski, M.; Kowalewski, Z. Possibility of Application of Magnetoacoustic Emission for the Assessment of Plastic Deformation Level in Ferrous Materials. IEEE Trans. Magn. 2011, 47, 2087–2092. [Google Scholar] [CrossRef]

- Langman, R.A.; Mutton, P.J. Estimation of Residual Stresses in Railway Wheels by means of Stress-induced Magnetic Anisotropy. NDT E Inter. 1993, 26, 195–205. [Google Scholar] [CrossRef]

- Fitzgerald, C.S. Inspection for Rail Defects by Magnetic Induction. In Proceedings of the SPIE 2458 Nondestructive Evaluation of Aging Railroads, Oakland, CA, USA, 6 June 1995.

- Hall, D.R. Electromagnetic Inspection of Wire Ropes and strand-supported structures. Insight 2003, 45, 471–475. [Google Scholar] [CrossRef]

- Bergamini, A.; Christen, R. A Simple Approach to the Localization of Flaws in Large Diameter Steel Cables. In Proceedings of the SPIE 5047 Smart Nondestructive Evaluation and Health Monitoring of Structural and Biological Systems II, San Diego, CA, USA, 2 March 2003.

- Krieger, J.; Krause, H.J.; Gampe, U.; Sawade, G. Magnetic Field Measurements on Bridges and Development of a Mobile SQUID-System. In Proceedings of the SPIE 3587 Nondestructive Evaluation of Bridges and Highways III, Newport Beach, CA, USA, 3 March 1999.

- Xiong, E.G.; Wang, S.L.; Zhang, J.F.; Li, B. Magnetic Flux Leakage Testing Mechanism and Its Application. In Proceedings of the International Symposium on Innovation & Sustainability of Structures in Civil Engineering, Guangzhou, China, 29–30 November 2009.

- Wang, Z.D.; Gu, Y.; Wang, Y.S. A Review of Three Magnetic NDT Technologies. J. Magn. Magn. Mater. 2012, 324, 382–388. [Google Scholar] [CrossRef]

- Dubov, A.A. A Study of Metal Properties Using the Method of Magnetic Memory. Met. Sci. Heat Treat. 1997, 39, 401–405. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, C.; Li, R.; Cai, M.; Jia, G. Theory and Application of Magnetic Flux Leakage Pipeline Detection. Sensors 2015, 15, 31036–31055. [Google Scholar] [CrossRef] [PubMed]

- Han, W.H.; Shen, X.H.; Xu, J.; Wang, P.; Tian, G.Y.; Wu, Z.Y. Fast Estimation of Defect Profiles from the Magnetic Flux Leakage Signal Based on a Multi-Power Affine Projection Algorithm. Sensors 2014, 14, 16454–16466. [Google Scholar] [CrossRef] [PubMed]

- Yao, K.; Deng, B.; Wang, Z.D. Numerical Studies to Signal Characteristics with the Metal Magnetic Memory-effect in Plastically Deformed Samples. NDT E Inter. 2012, 47, 7–17. [Google Scholar] [CrossRef]

- Morón, C.; Cabrera, C.; Morón, A.; García, A.; González, M. Magnetic Sensors Based on Amorphous Ferromagnetic Materials: A Review. Sensors 2015, 15, 28340–28366. [Google Scholar] [CrossRef] [PubMed]

- Förster, F. Nondestructive Inspection by the Method of Magnetic Leakage Fields: Theoretical and Experimental Foundations of the Detection of Surface Cracks of Finite and Infinite Depth. Sov. J. Nondestr. Test 1982, 8, 841–859. [Google Scholar]

- Zatsepin, N.N.; Shcherbinin, V.E. Calculation of the Magnetostatic Field of Surface Defects I. Field to Pography of Defect Models. Sov. J. Nondestr. Test 1966, 5, 385–393. [Google Scholar]

- Shur, M.L.; Zagidulin, R.V.; Shcherbinin, V.E. Theoretical Problems of the Field Formation from a Surface Defect. Defektoskopiya 1988, 3, 14–25. (In Russian) [Google Scholar]

- Zagidulin, R.V. Calculation of the Remnant Magnetic Field of a Discontinuity Defect in a Ferromagnetic Sample. II. Remnant Magnetic Field of a Defect in the Air. Defektoskopiya 1998, 10, 33–39. (In Russian) [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Liao, L.; Zhao, R.; Zhou, J.; Yang, M.; Xia, R. The Non-Destructive Test of Steel Corrosion in Reinforced Concrete Bridges Using a Micro-Magnetic Sensor. Sensors 2016, 16, 1439. https://doi.org/10.3390/s16091439

Zhang H, Liao L, Zhao R, Zhou J, Yang M, Xia R. The Non-Destructive Test of Steel Corrosion in Reinforced Concrete Bridges Using a Micro-Magnetic Sensor. Sensors. 2016; 16(9):1439. https://doi.org/10.3390/s16091439

Chicago/Turabian StyleZhang, Hong, Leng Liao, Ruiqiang Zhao, Jianting Zhou, Mao Yang, and Runchuan Xia. 2016. "The Non-Destructive Test of Steel Corrosion in Reinforced Concrete Bridges Using a Micro-Magnetic Sensor" Sensors 16, no. 9: 1439. https://doi.org/10.3390/s16091439

APA StyleZhang, H., Liao, L., Zhao, R., Zhou, J., Yang, M., & Xia, R. (2016). The Non-Destructive Test of Steel Corrosion in Reinforced Concrete Bridges Using a Micro-Magnetic Sensor. Sensors, 16(9), 1439. https://doi.org/10.3390/s16091439