Effects of AlN Coating Layer on High Temperature Characteristics of Langasite SAW Sensors

Abstract

:1. Introduction

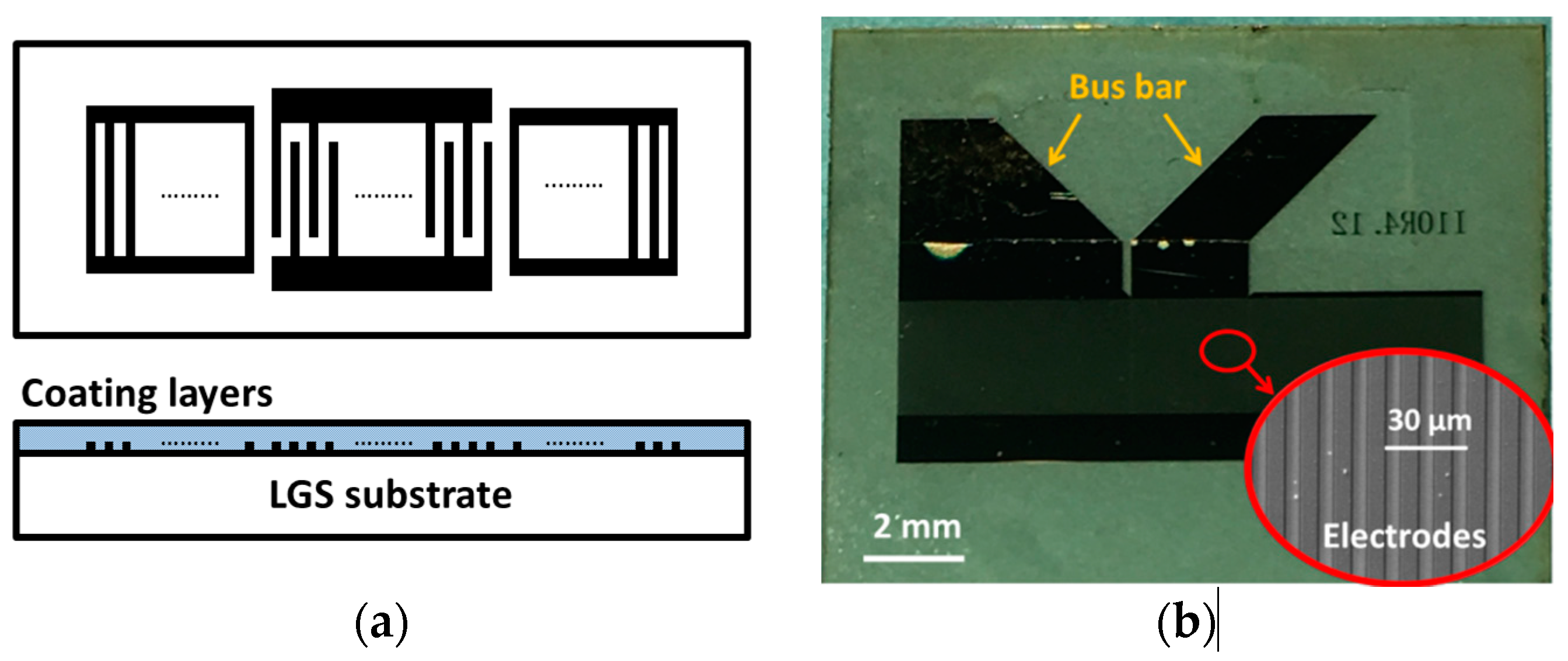

2. Experimental Setup

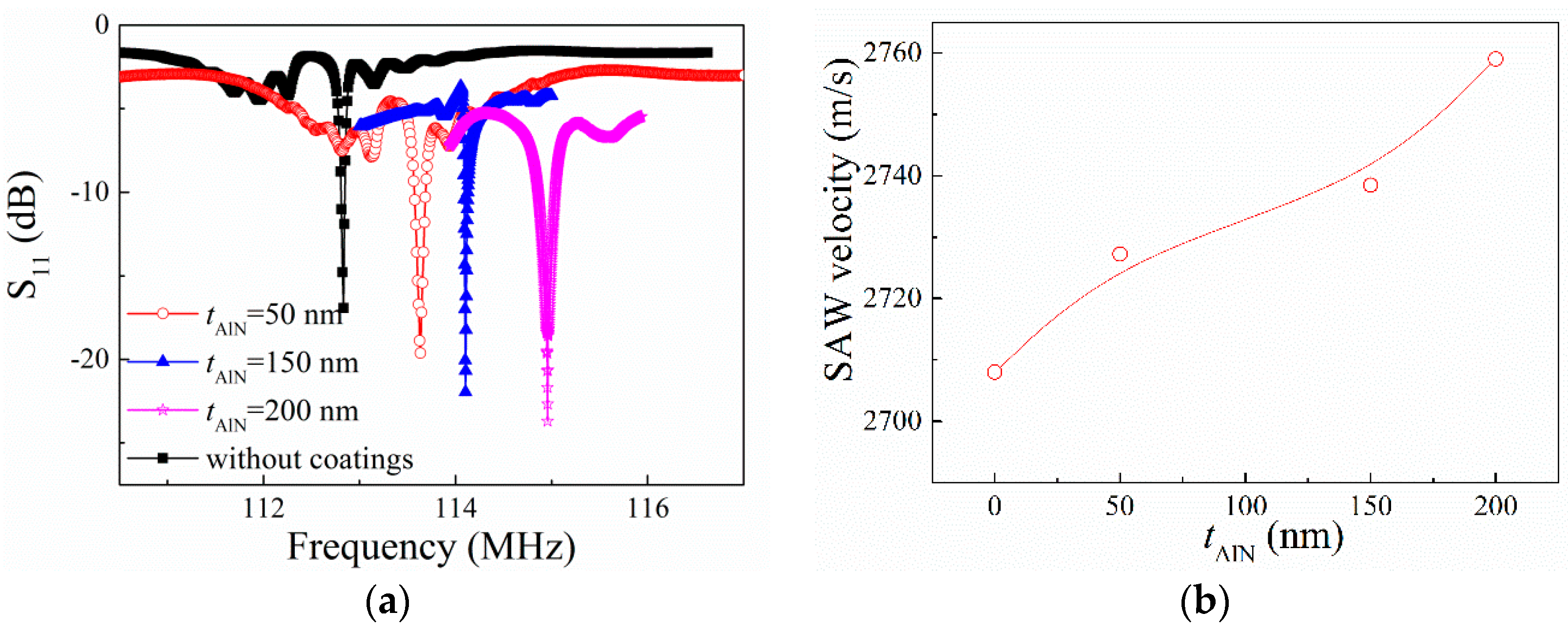

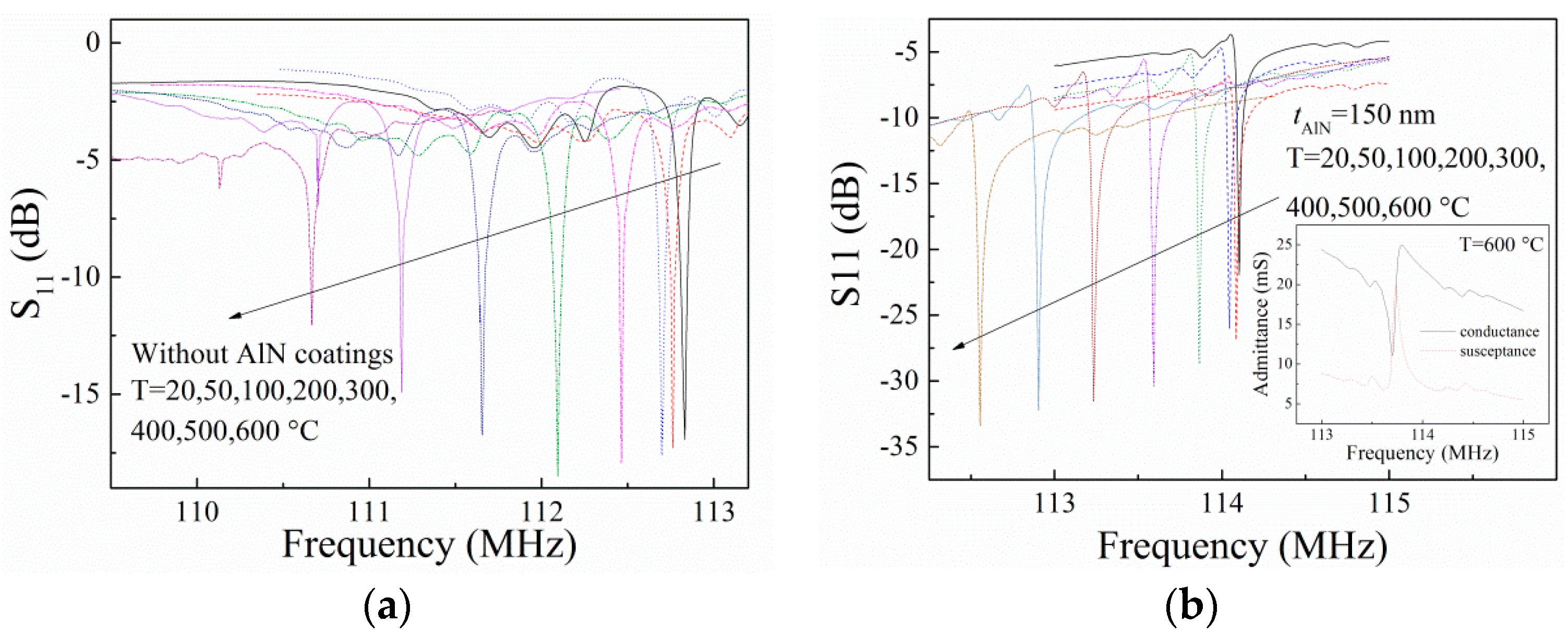

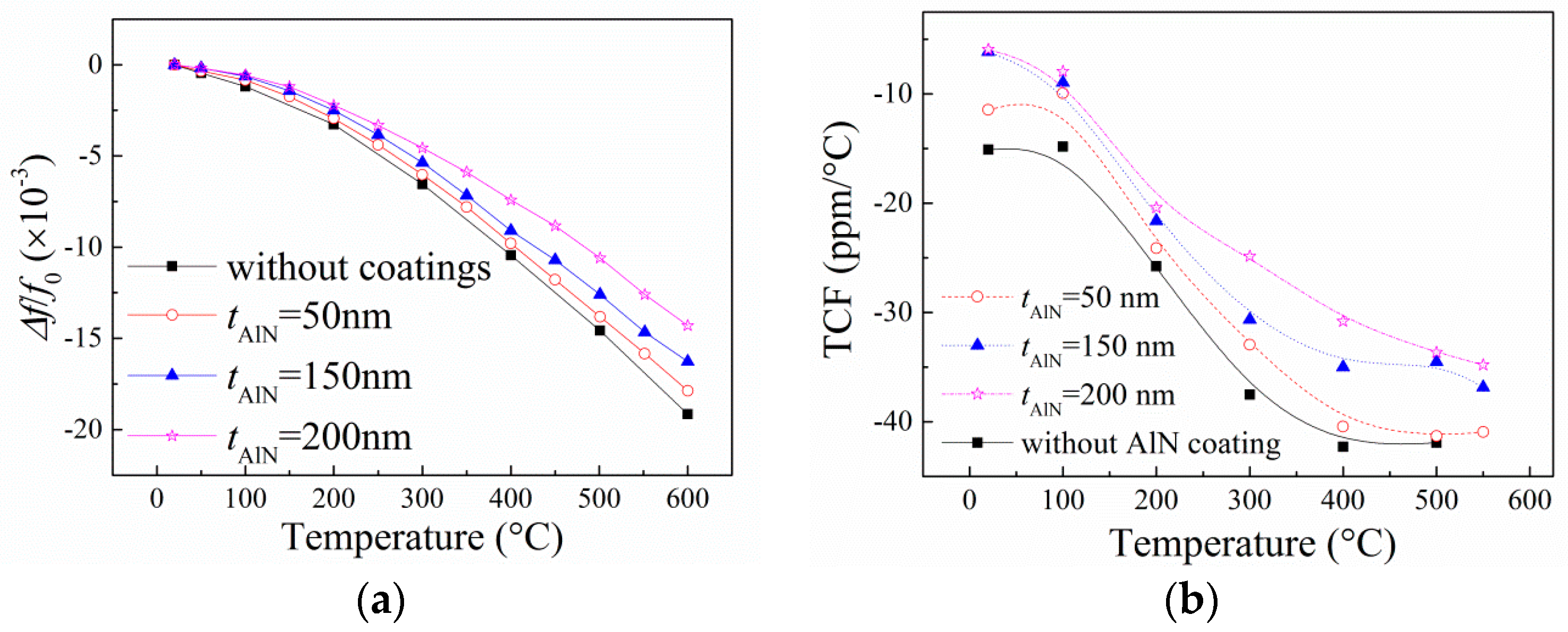

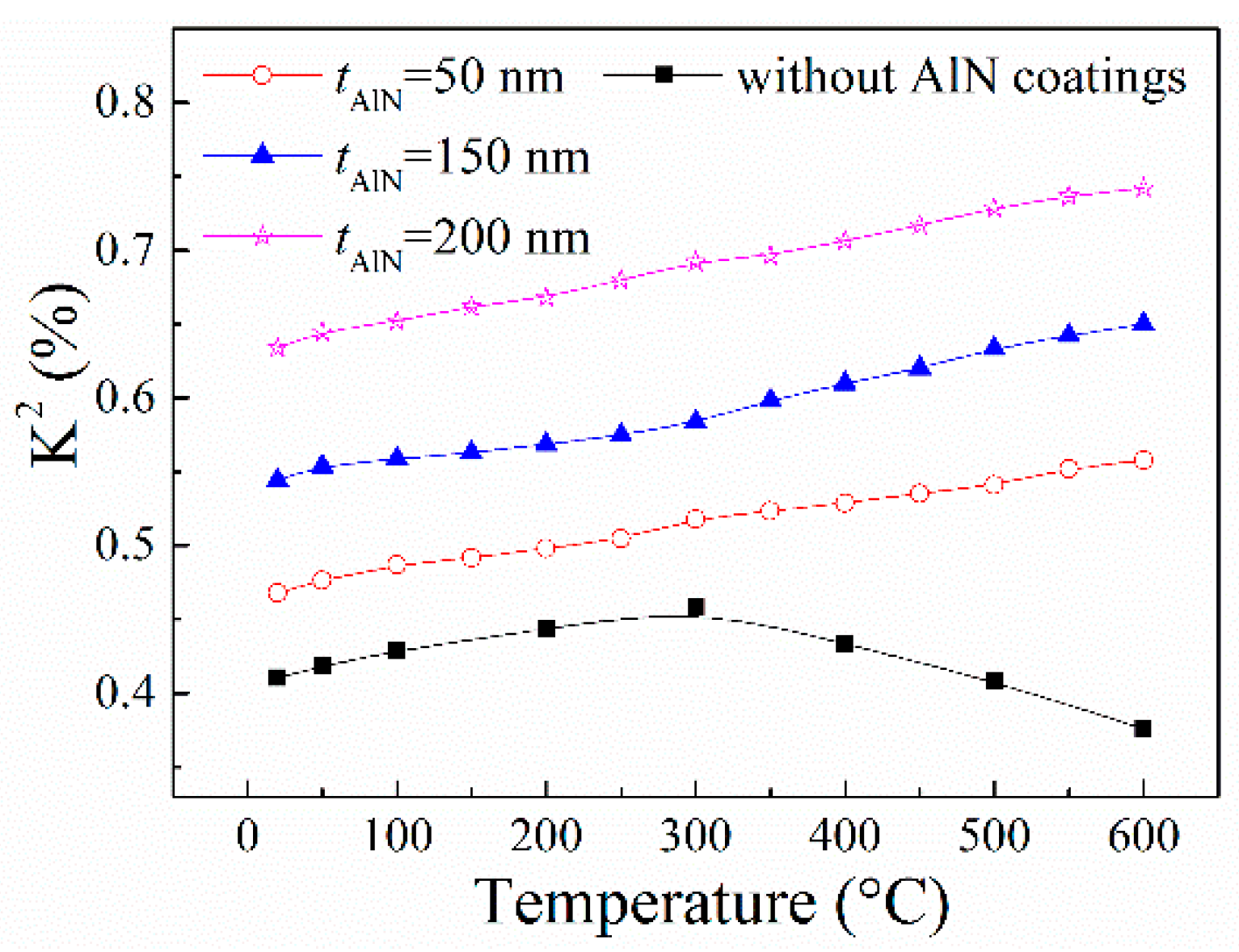

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shrena, I.; Eisele, D.; Mayer, E.; Reindl, L.M.; Bardong, J.; Schmitt, M. SAW-properties of langasite at high temperatures: Measurement and analysis. In Proceedings of the 2009 3rd International Conference on Signals, Circuits and Systems, Medenine, Tunisia, 6–8 November 2009; pp. 1–4.

- Zheng, P.; Greve, D.W.; Oppenheim, I.J.; Chin, T.L.; Malone, V. Langasite surface acoustic wave sensors: Fabrication and testing. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 295–303. [Google Scholar] [CrossRef] [PubMed]

- Thiele, J.A.; Da Cunha, M.P. High temperature LGS SAW gas sensor. Sens. Actuators B Chem. 2006, 2, 816–822. [Google Scholar] [CrossRef]

- Greve, D.W.; Chin, T.L.; Zheng, P.; Ohodnicki, P.; Baltrus, J.; Oppenheim, I.J. Surface acoustic wave devices for harsh environment wireless sensing. Sensors 2013, 13, 6910–6935. [Google Scholar] [CrossRef] [PubMed]

- Shu, L.; Peng, B.; Yang, Z.; Wang, R.; Deng, S.; Liu, X. High-Temperature SAW Wireless Strain Sensor with Langasite. Sensors 2015, 15, 28531–28542. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Kim, K.; Zhang, S.; Johnson, J.; Salazar, G. High-temperature piezoelectric sensing. Sensors 2013, 14, 144–169. [Google Scholar] [CrossRef] [PubMed]

- Frankel, D.J.; Bernhardt, G.P.; Sturtevant, B.T.; Moonlight, T.; da Cunha, M.P.; Lad, R.J. Stable electrodes and ultrathin passivation coatings for high temperature sensors in harsh environments. In Proceedings of the 2008 IEEE Sensors Conference, Lecce, Italy, 26–29 October 2008; pp. 82–85.

- Da Cunha, M.P.; Lad, R.J.; Moonlight, T.; Bernhardt, G.; Frankel, D.J. High temperature stability of langasite surface acoustic wave devices. In Proceedings of the IEEE International Ultrasonics Symposium, Beijing, China, 2–5 November 2008; pp. 205–208.

- Freudenberg, J.; Von Schickfus, M.; Hunklinger, S. A SAW immunosensor for operation in liquid using a SiO2 protective layer. Sens. Actuators B Chem. 2001, 76, 147–151. [Google Scholar] [CrossRef]

- Iriarte, G.F.; Rodríguez, J.G.; Calle, F. Synthesis of c-axis oriented AlN thin films on different substrates: A review. Mater. Res. Bull. 2010, 45, 1039–1045. [Google Scholar] [CrossRef]

- Lee, J.O.; Park, C.; Kim, J.J.; Kim, J.; Park, J.W.; Yoo, K.H. Formation of low-resistance ohmic contacts between carbon nanotube and metal electrodes by a rapid thermal annealing method. J. Phys. D Appl. Phys. 2000, 33. [Google Scholar] [CrossRef]

- Bu, G.; Ciplys, D.; Shur, M.; Schowalter, L.J.; Schujman, S.; Gaska, R. Surface acoustic wave velocity in single-crystal AIN substrates. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2006, 53, 251–254. [Google Scholar] [CrossRef] [PubMed]

- Anisimkin, V.I.S.; Voronova, N.V. Acoustic Properties of the Film/Plate Layered Structure. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2011, 58, 578–584. [Google Scholar] [CrossRef] [PubMed]

- Bardong, J.; Aubert, T.; Naumenko, N.; Bruckner, G.; Salzmann, S.; Reindl, L.M. Experimental and Theoretical Investigations of Some Useful Langasite Cuts for High-Temperature SAW Applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 4, 814–823. [Google Scholar] [CrossRef] [PubMed]

- Aubert, T.; Elmazria, O.; Assouar, B.; Blampain, E.; Hamdan, A.; Genève, D.; Weber, S. Investigations on AlN/Sapphire Piezoelectric Bilayer Structure for High-Temperature SAW Applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 5, 999–1005. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.M.; Yen, T.T.; Lai, Y.J.; Felmetsger, V.V.; Hopcroft, M.A.; Kuypers, J.H.; Pisano, A.P. Experimental Study of Temperature-Compensated Aluminum Nitride Lamb Wave Resonators. In Proceedings of the IEEE International Frequency Control Symposium, 2009 Joint with the 22nd European Frequency and Time forum, Besancon, France, 20–24 April 2009; pp. 5–9.

- Belknap, E. Mechanical Characterization of SAW-based Sensors for Wireless High Temperature Strain Measurements. Master’s Thesis, Ohio State University, Columbus, OH, USA, July 2011. [Google Scholar]

- Zhou, C.; Yang, Y.; Cai, H.; Ren, T.L.; Chan, M.; Yang, C.Y. Temperature-compensated high-frequency surface acoustic wave device. IEEE Electron Device Lett. 2013, 12, 1572–1574. [Google Scholar] [CrossRef]

- Da Cunha, M.P.; Moonlight, T.; Lad, R.; Frankel, D.; Bernhard, G. High temperature sensing technology for applications up to 1000 °C. In Proceedings of the 2008 IEEE Sensors, Lecce, Italy, 26–29 October 2008; pp. 752–755.

- Ying, Y.; Da-Zhong, Z. A Y type SAW mass sensor with metal array reflectors. Sens. Actuators B Chem. 2005, 2, 244–248. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shu, L.; Peng, B.; Cui, Y.; Gong, D.; Yang, Z.; Liu, X.; Zhang, W. Effects of AlN Coating Layer on High Temperature Characteristics of Langasite SAW Sensors. Sensors 2016, 16, 1436. https://doi.org/10.3390/s16091436

Shu L, Peng B, Cui Y, Gong D, Yang Z, Liu X, Zhang W. Effects of AlN Coating Layer on High Temperature Characteristics of Langasite SAW Sensors. Sensors. 2016; 16(9):1436. https://doi.org/10.3390/s16091436

Chicago/Turabian StyleShu, Lin, Bin Peng, Yilin Cui, Dongdong Gong, Zhengbing Yang, Xingzhao Liu, and Wanli Zhang. 2016. "Effects of AlN Coating Layer on High Temperature Characteristics of Langasite SAW Sensors" Sensors 16, no. 9: 1436. https://doi.org/10.3390/s16091436

APA StyleShu, L., Peng, B., Cui, Y., Gong, D., Yang, Z., Liu, X., & Zhang, W. (2016). Effects of AlN Coating Layer on High Temperature Characteristics of Langasite SAW Sensors. Sensors, 16(9), 1436. https://doi.org/10.3390/s16091436