Concrete Condition Assessment Using Impact-Echo Method and Extreme Learning Machines

Abstract

:1. Introduction

2. Related Work

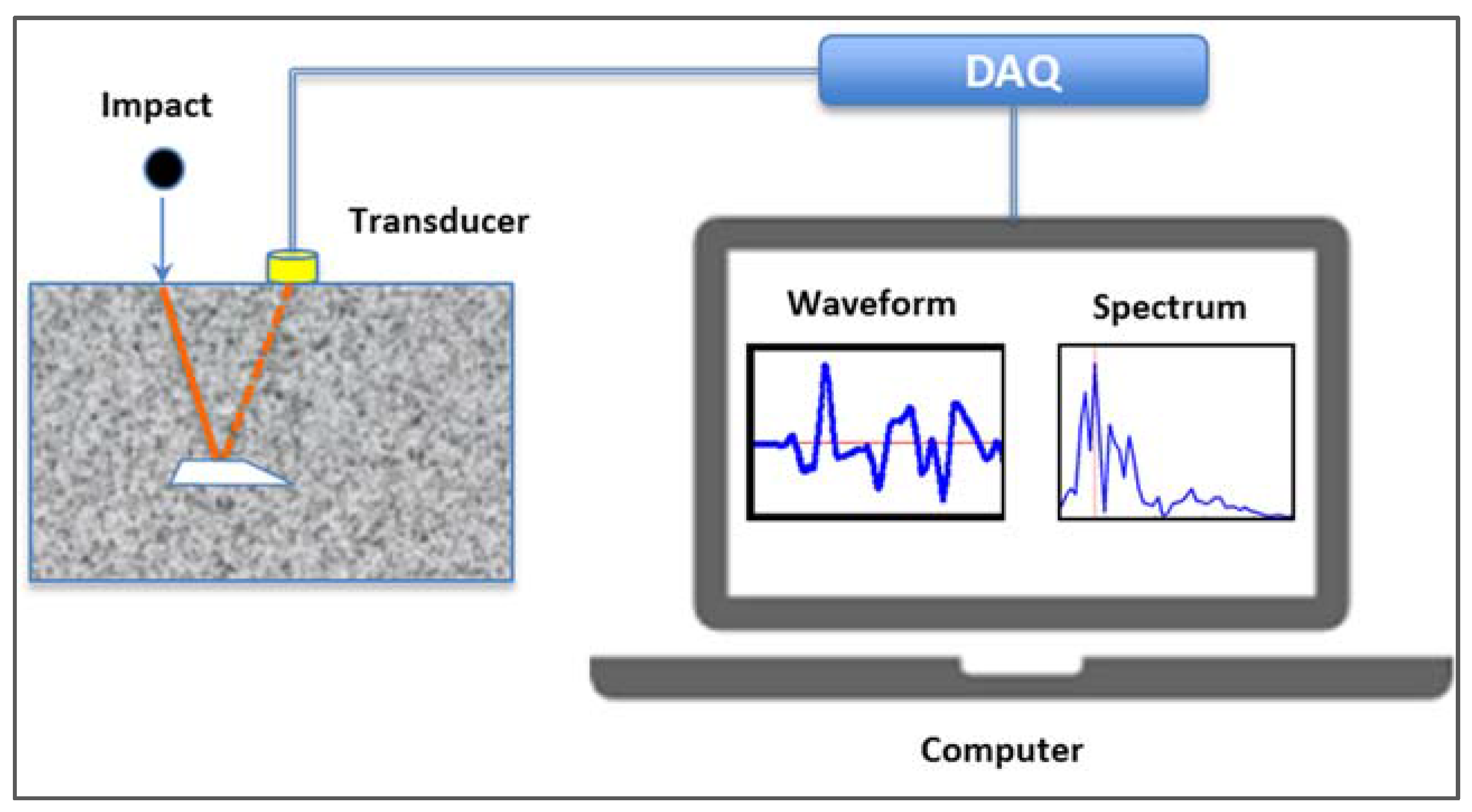

3. The Proposed Methodology

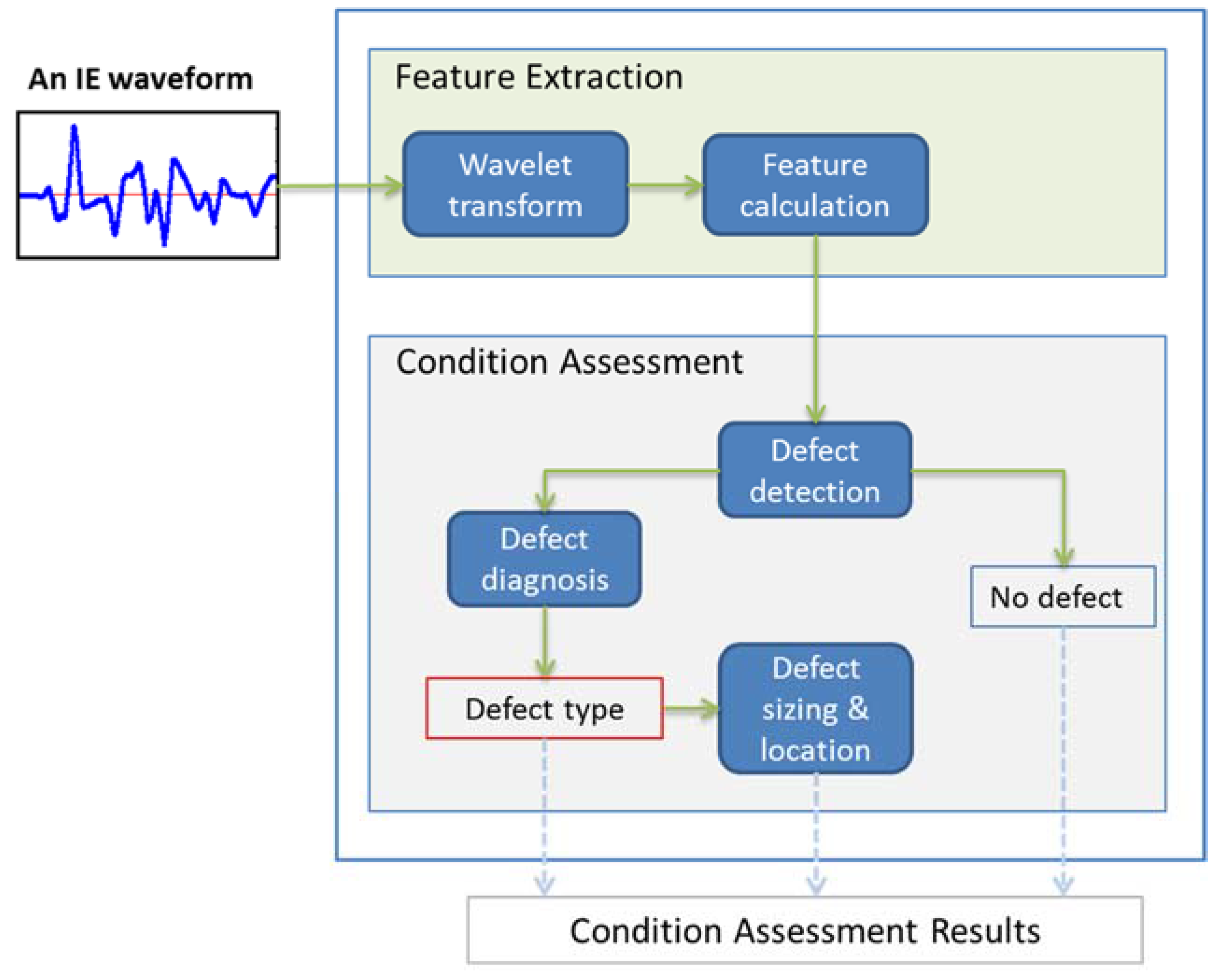

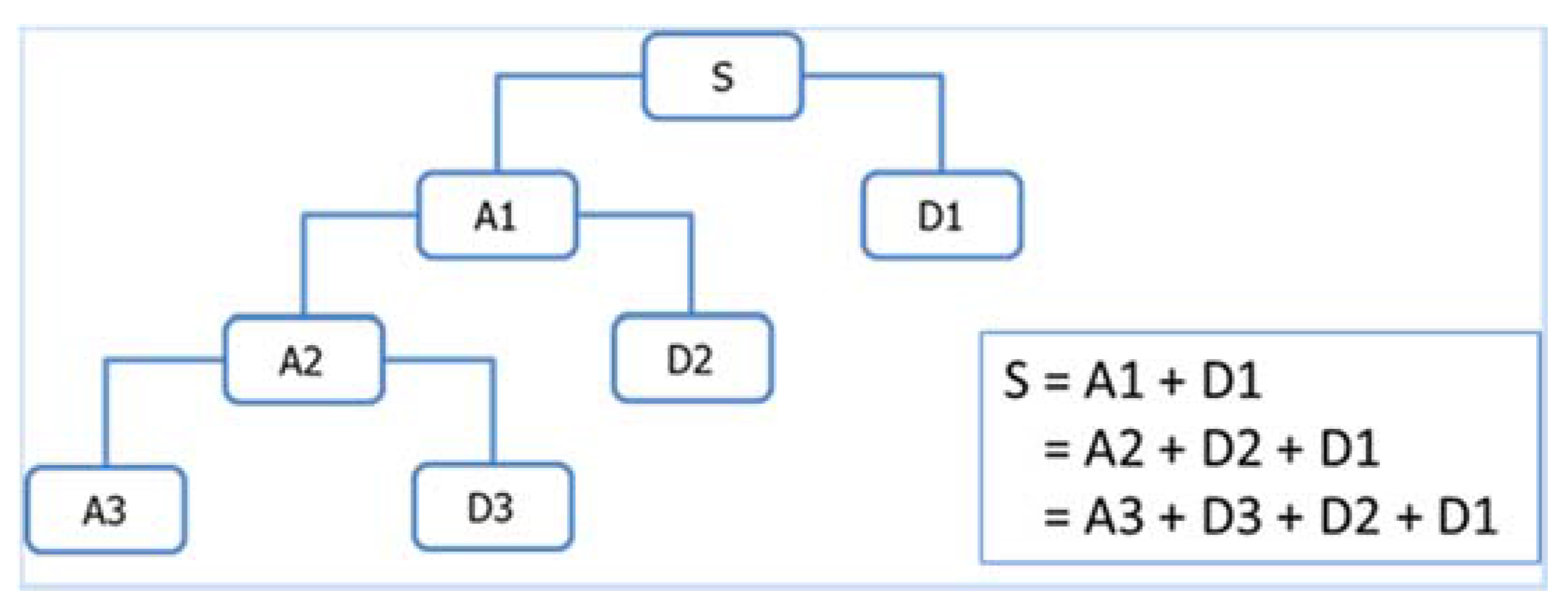

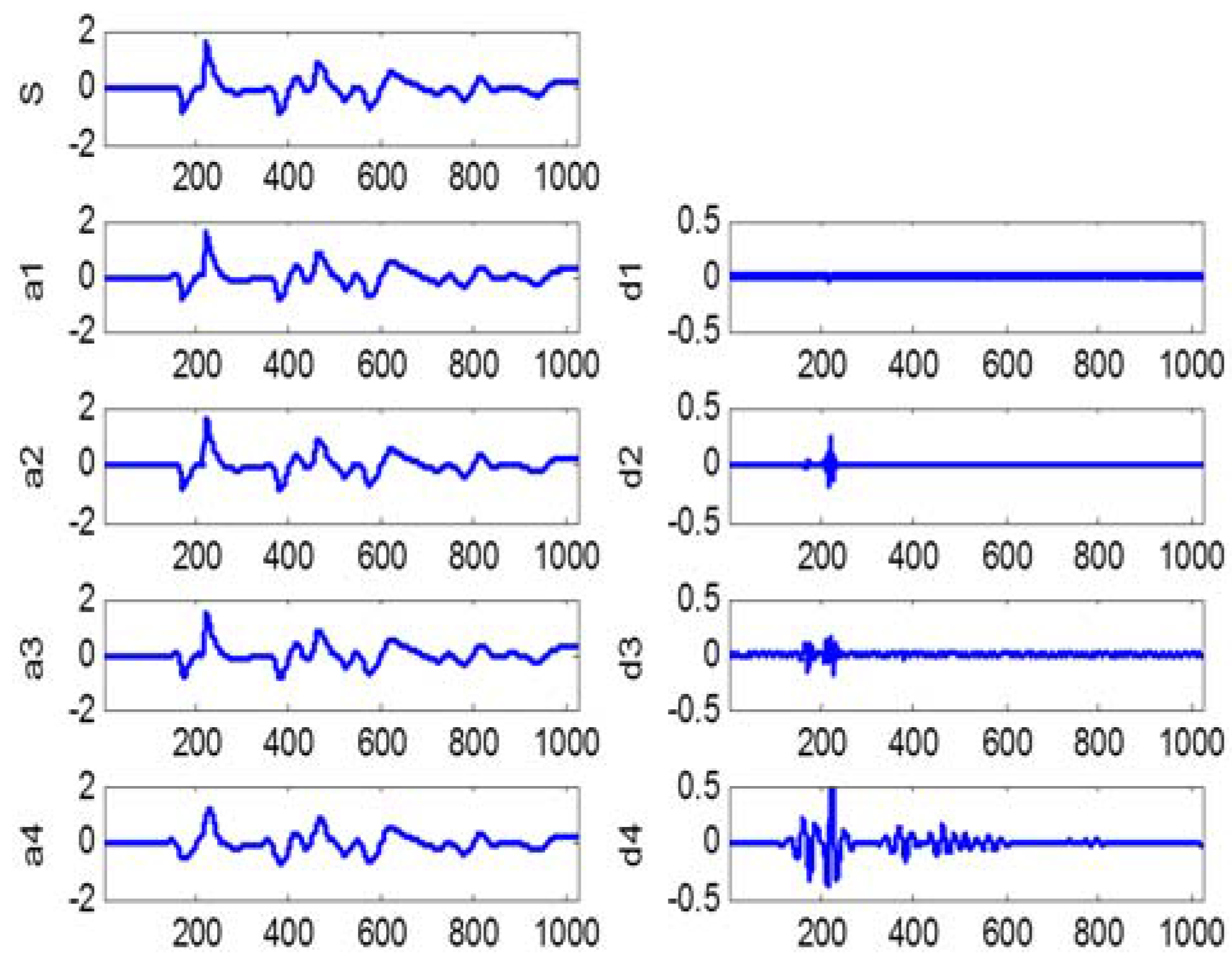

3.1. Feature Extraction

3.2. Full Condition Assessment

4. Experimental Details

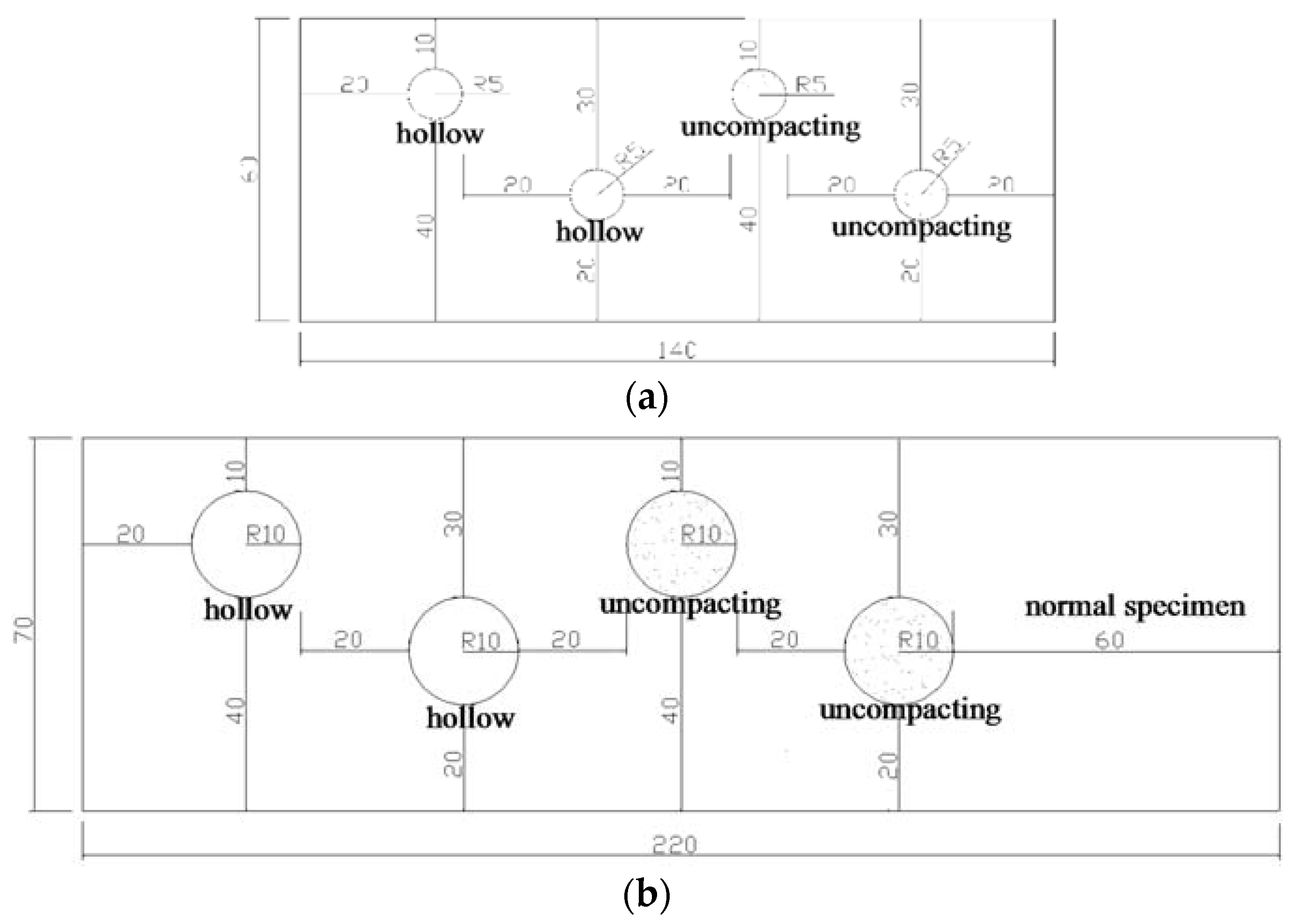

4.1. Concrete Specimens for Testing

4.2. Testing Hardware

4.3. Test Parameter Setting

5. Evaluation Results and Discussion

5.1. Evaluation Data Samples

5.2. Model Performance Measures and Performance Evaluation Method

5.3. Results

5.3.1. Defect Detection

5.3.2. Defect Diagnosis

5.3.3. Defect Sizing

5.3.4. Defect Location

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| ELM | Extreme learning machine |

| IE | Impact-echo |

| NDT/NDE | Non-destructive test/evaluation |

References

- Hertlein, B.H. Stress wave testing of concrete: A 25-year review and a peek into the future. Construct. Build. Mater. 2013, 38, 7240–7245. [Google Scholar] [CrossRef]

- Wiggenhauser, H. Advanced NDT Methods for the Assessment of Concrete Structures, Concrete Repair, Rehabilitation and Retrofitting II; Alexander, M.G., Beushausen, H.-D., Dehn, F., Moyo, P., Eds.; Taylor and Francis Group: London, UK, 2009. [Google Scholar]

- McCann, D.M.; Forde, M.C. Review of NDT methods in the assessment of concrete and masonry structures. NDT E Int. 2001, 34, 71–84. [Google Scholar] [CrossRef]

- Hoła, J.; Bień, J.; Sadowski, L.; Schabowicz, K. Non-Destructive and Semi-Destructive Diagnostics of Concrete Structures in Assessment of Their Durability. Bull. Pol. Acad. Sci. Tech. Sci. 2015, 63, 87–96. [Google Scholar] [CrossRef]

- Azari, H.; Nazarian, S.; Yuan, D. Assessing sensitivity of impact echo and ultrasonic surface waves methods for nondestructive evaluation of concrete structures. Construct. Build. Mater. 2014, 71, 384–391. [Google Scholar] [CrossRef]

- Sansalone, M.J.; Streett, W.B. Impact-Echo: Nondestructive Evaluation of Concrete and Masonry; Bullbrier Press: Ithaca, NY, USA, 1997. [Google Scholar]

- Sansalone, M.J. Impact-Echo: The complete story. ACI Struct. J. 1997, 94, 777–786. [Google Scholar]

- Valenzuela, M.L.; Sansalone, M.J.; Streett, W.B.; Krumhansl, C.L. Use of sound for the interpretation of impact-echo signals. In Proceedings of the 4th International Conference on Auditory Display (ICAD1997), Palo Alto, CA, USA, 2–5 November 1997.

- Carino, N.J.; Sansalone, M.J.; Hsu, N.N. A point sourcepoint receiver, pulse-echo technique for flaw detection in concrete. ACI J. 1986, 83, 199–208. [Google Scholar]

- Sansalone, M.; Carino, N.J. Impact-Echo: A Method for Flaw Detection in Concrete Using Transient Stress Waves; National Bureau of Standard: Gaithersburg, MD, USA, 1986. [Google Scholar]

- Hsiao, C.; Cheng, C.C.; Liou, T.; Juang, Y. Detecting flaws in concrete blocks using the impact-echo method. NDT E Int. 2008, 41, 98–107. [Google Scholar] [CrossRef]

- Lin, C.C.; Liu, P.L.; Yeh, P.L. Application of empirical mode decomposition in the impact-echo test. NDT E Int. 2009, 42, 589–588. [Google Scholar] [CrossRef]

- Zhang, Y.; Xie, Z.H. Ensemble empirical mode decomposition of impact-echo data for testing concrete structures. NDT E Int. 2012, 51, 74–84. [Google Scholar] [CrossRef]

- Huang, G.B.; Zhu, Q.Y.; Siew, C.K. Extreme learning machine: Theory and applications. Neurocomputing 2006, 70, 489–501. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Agrawal, A. Robotic Inspection of Bridges Using Impact-echo Technology; UTRC-RITA Project Final Report; The City College of New York: New York, NY, USA.

- Krüger, M.; Grosse, C.U. Impact-Echo-Techniques for Crack Depth Measurement. Sustain. Bridges 2007, 29. [Google Scholar]

- Chaudhary, M.T.A. Effectiveness of Impact Echo Testing in Detecting Flaws in Prestressed Concrete Slabs. Construct. Build. Mater. 2013, 47, 753–759. [Google Scholar] [CrossRef]

- Liang, M.T.; Su, P.J. Detection of the corrosion damage of rebar in concrete using impact-echo method. Cement Concr. Res. 2001, 31, 1427–1436. [Google Scholar] [CrossRef]

- Song, K.-I.; Cho, G.-C. Bonding state evaluation of tunnel shotcrete applied onto hard rocks using the impact-echo method. NDT E Int. 2009, 42, 487–500. [Google Scholar] [CrossRef]

- Abraham, O.; Leonard, C.; Cote, P.; Piwakowski, B. Time-frequency Analysis of Impact-Echo Signals: Numerical Modeling and Experimental Validation. ACI Mater. J. 2000, 97, 645–665. [Google Scholar]

- Bouden, T.; Djerfi, F.; Dib, S.; Nibouche, M. Hilbert Huang Transform for enhancing the impact-echo method of nondestructive testing. J. Autom. Syst. Eng. 2012, 6, 172–184. [Google Scholar]

- Daubechies, I. Ten Lectures on Wavelets; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 1992. [Google Scholar]

- Samuel, P.D.; Pines, D.J. Classifying helicopter gearbox faults using a normalized energy metric. Smart Mater. Struct. 2001, 10, 145–153. [Google Scholar] [CrossRef]

- Lotfollahi, Y.M.A.; Hesari, M.A. Using Wavelet Analysis in Crack Detection at the Arch Concrete Dam Under Frequency Analysis with FEM. Res. India Publ. J. Wavelet Theory Appl. 2008, 2, 61–81. [Google Scholar]

- Noh, H.Y.; Nair, K.; Lignos, D.G.; Kiremidjian, A. Application of Wavelet Coefficient Energies of Stationary and Non-Stationary Response Signals for Structural Damage Diagnosis. In Proceedings of the 7th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 9–11 September 2009.

- Luk, B.L.; Jiang, Z.D.; Liu, L.K.P.; Tong, F. Impact Acoustic Non-Destructive Evaluation in Noisy Environment Based on Wavelet Packet. In Proceedings of the International Multi Conference of Engineers and Computer Scientists 2008 Vol II, IMECS 2008, Hong Kong, China, 19–21 March 2008.

- Yeh, P.L.; Liu, P.L. Application of the Wavelet Transform and the Enhanced Fourier Spectrum in the Impact Echo Test. NDT E Int. 2008, 41, 382–394. [Google Scholar] [CrossRef]

- Luk, B.L.; Liu, K.P.; Jiang, Z.D.; Tong, F. Robotic impact-acoustics system for tile-wall bonding integrity inspection. Mechatronics 2009, 19, 1251–1260. [Google Scholar] [CrossRef]

- Ying, Y.; Garrett, J., Jr.; Oppenheim, I.; Soibelman, L.; Harley, J.; Shi, J.; Jin, Y. Toward Data-Driven Structural Health Monitoring: Application of Machine Learning and Signal Processing to Damage Detection. J. Comput. Civ. Eng. 2013, 27, 667–680. [Google Scholar] [CrossRef]

- Farrar, C.R.; Worden, K. Structural Health Monitoring: A Machine Learning Perspective; John Wiley and Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Srivastava, A.N.; Han, J. Machine Learning and Knowledge Discovery for Engineering Systems Health Management; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Pratt, D.; Sansalone, M.J. The use of a neural network for automating impact-echo signal analysis. ACI Mater. J. 1992, 89, 777–786. [Google Scholar]

- Sadowski, L. Non-destructive identification of pull-off adhesion between concrete layers. Autom. Construct. 2015, 57, 146–155. [Google Scholar] [CrossRef]

- Sadowskia, L.; Nikoo, M.; Nikoo, M. Principal component analysis combined with a self organization feature map to determine the pull-off adhesion between concrete layers. Construct. Build. Mater. 2015, 78, 386–396. [Google Scholar] [CrossRef]

- Li, B.; Cao, J.; Xiao, J.Z.; Zhang, X.; Wang, H.F. Robotic Impact-echo Non-Destructive Evaluation based on FFT and SVM. In Proceedings of the 11th World Congress on Intelligent Control and Automation, Shenyang, China, 29 June–4 July 2014; pp. 2854–2859.

- Igual, J.; Salazar, A.; Safont, G.; Vergara, L. Semi-supervised Bayesian classification of materials with impact-echo signals. Sensors 2015, 15, 1528–11550. [Google Scholar] [CrossRef] [PubMed]

- He, B.; Xu, D.; Nian, R.; van Heeswijk, M.; Yu, Q.; Miche, Y.; Lendasse, A. Fast face recognition via sparse coding and extreme learning machine. Cogn. Comput. 2014, 6, 264–277. [Google Scholar] [CrossRef]

- Bazi, Y.; Alajlan, N.; Melgani, F.; AlHichri, H.; Malek, S.; Yager, R.R. Differential evolution extreme learning machine for the classification of hyperspectral images. IEEE Geosci. Remote Sens. Lett. 2014, 11, 1066–1070. [Google Scholar] [CrossRef]

- Kaya, Y.; Uyar, M. A hybrid decision support system based on rough set and extreme learning machine for diagnosis of hepatitis disease. Appl. Soft Comput. 2013, 13, 3429–3438. [Google Scholar] [CrossRef]

- Yang, X.; Mao, K. Reduced ELMs for causal relation extraction from unstructured text. IEEE Intell. Syst. 2013, 28, 48–52. [Google Scholar]

- Yan, W.Z.; Yu, L.J. On Accurate and Reliable Anomaly Detection for Gas Turbine Combustors: A Deep Learning Approach. In Proceedings of the Annual Conference of the Prognostics and Health Management Society 2015, San Diego, CA, USA, 18–24 October 2015.

- Yang, X.; Pang, S.; Shen, W.; Lin, X.; Jiang, K.; Wang, Y. Aero Engine Fault Diagnosis Using an Optimized Extreme Learning Machine. Int. J. Aerosp. Eng. 2016, 2016. [Google Scholar] [CrossRef]

- Wong, P.K.; Yang, Z.X.; Vong, C.M.; Zhong, J.H. Real-time fault diagnosis for gas turbine generator systems using extreme learning machine. Neurocomputing 2014, 128, 249–257. [Google Scholar] [CrossRef]

- Huang, G.B.; Zhou, H.M.; Ding, X.J.; Zhang, R. Extreme learning machine for regression and multiclass classification. IEEE Trans. Syst. Man Cybern. Part B Cybern. 2012, 42, 513–529. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.B. An Insight into Extreme Learning Machines: Random Neurons, Random Features and Kernels. Cognitive Computation 2014, 6, 376–390. [Google Scholar] [CrossRef]

- Impect-Echo. Available online: www.impect-echo.co (accessed on 21 March 2016).

- Yu, C.H. Resampling methods: Concepts, applications, and justification. Available online: http://pareonline.net/getvn.asp?v=8&n=19 (accessed on 21 March 2016).

- Powers, D.M.W. Evaluation: From precision, recall and F-measure to ROC, informedness, markedness and correlation. J. Mach. Learn. Technol. 2011, 2, 37–63. [Google Scholar]

| Domain | Feature Name | No. |

|---|---|---|

| wavelet coefficients | energy | 1 |

| reconstructed waveform | energy | 2 |

| spectrum of reconstructed waveform | total power | 3 |

| mean power | 4 | |

| peak frequency | 5 | |

| mean frequency | 6 | |

| 1st spectral moment | 7 | |

| 2nd spectral moment | 8 | |

| 3rd spectral moment | 9 | |

| 4th spectral moment | 10 |

| Cement | Medium Sand | Crushed Stone Aggregate | Coal Ash | Admixture | Water |

|---|---|---|---|---|---|

| 360 | 708 | 1107 | 55 | 4.56 | 170 |

| Block Thickness | # of Sampling Points |

|---|---|

| 40 cm | 26 |

| 50 cm | 26 |

| 60 cm | 26 |

| 70 cm | 26 |

| Defect Type-> | Type 1 Defect | Type 2 Defect | Type 3 Defect | ||||

|---|---|---|---|---|---|---|---|

| Defect Size -> | 10 cm | 20 cm | 10 cm | 20 cm | 10 cm | 20 cm | |

| Defect location | 10 cm | 52 | 26 | 26 | 26 | 26 | 26 |

| 20 cm | 52 | 26 | 26 | 26 | 26 | 26 | |

| 30 cm | 52 | 26 | 26 | 26 | 26 | 26 | |

| 40 cm | 52 | 52 | 26 | 26 | 26 | 26 | |

| PREDICTED | |||

|---|---|---|---|

| TRUE | Normal | 99.13% | 0.87% |

| Fault | 0.00% | 100.00% | |

| PREDICTED | |||

|---|---|---|---|

| TRUE | Normal | 97.70% | 2.30% |

| Fault | 27.80% | 72.20% | |

| Predicted | ||||

|---|---|---|---|---|

| Type 1 | Type 2 | Type 3 | ||

| True | Type 1 | 98.31% | 1.41% | 0.28% |

| Type 2 | 2.12% | 97.71% | 0.17% | |

| Type 3 | 0.16% | 0.64% | 99.20% | |

| Predicted Defect Sizes | |||

|---|---|---|---|

| 10 cm | 20 cm | ||

| True defect sizes | 10 cm | 99.02% | 0.98% |

| 20 cm | 0.52% | 99.48% | |

| Predicted Defect Sizes | |||

|---|---|---|---|

| 10 cm | 20 cm | ||

| True defect sizes | 10 cm | 100.0% | 0.0% |

| 20 cm | 0.0% | 100.0% | |

| Predicted Defect Sizes | |||

|---|---|---|---|

| 10 cm | 20 cm | ||

| True defect sizes | 10 cm | 100.0% | 0.0% |

| 20 cm | 0.0% | 100.0% | |

| Predicted Defect Location | |||||

|---|---|---|---|---|---|

| True defect location | 10 cm | 87.25 | 5.88 | 1.96 | 4.90 |

| 20 cm | 4.29 | 88.10 | 2.86 | 4.76 | |

| 30 cm | 0.00 | 0.52 | 88.54 | 10.94 | |

| 40 cm | 7.41 | 0.93 | 10.19 | 81.48 | |

| Predicted Defect Location | |||||

|---|---|---|---|---|---|

| True defect location | 10 cm | 98.67 | 0.00 | 0.00 | 1.33 |

| 20 cm | 0.00 | 100.00 | 0.00 | 0.00 | |

| 30 cm | 0.00 | 0.00 | 98.00 | 2.00 | |

| 40 cm | 0.64 | 0.00 | 0.96 | 98.40 | |

| Predicted Defect Location | |||||

|---|---|---|---|---|---|

| True defect location | 10 cm | 97.92 | 1.39 | 0.00 | 0.69 |

| 20 cm | 0.64 | 98.08 | 0.00 | 1.28 | |

| 30 cm | 0.00 | 0.00 | 99.36 | 0.64 | |

| 40 cm | 0.64 | 2.56 | 0.64 | 96.15 | |

| Predicted Defect Location | |||||

|---|---|---|---|---|---|

| True defect location | 10 cm | 100.00 | 0.00 | 0.00 | 0.00 |

| 20 cm | 0.00 | 100.00 | 0.00 | 0.00 | |

| 30 cm | 0.00 | 0.00 | 100.00 | 0.00 | |

| 40 cm | 0.00 | 0.00 | 0.00 | 100.00 | |

| Predicted Defect Location | |||||

|---|---|---|---|---|---|

| True defect location | 10 cm | 96.79 | 1.92 | 1.28 | 0.00 |

| 20 cm | 1.28 | 98.72 | 0.00 | 0.00 | |

| 30 cm | 0.00 | 0.00 | 96.15 | 3.85 | |

| 40 cm | 0.00 | 0.00 | 5.13 | 94.87 | |

| Predicted Defect Location | |||||

|---|---|---|---|---|---|

| True defect location | 10 cm | 97.44 | 0.00 | 2.56 | 0.00 |

| 20 cm | 1.28 | 98.72 | 0.00 | 0.00 | |

| 30 cm | 0.00 | 0.00 | 98.72 | 1.28 | |

| 40 cm | 0.00 | 0.00 | 0.00 | 100.00 | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.-K.; Yan, W.; Cui, D.-M. Concrete Condition Assessment Using Impact-Echo Method and Extreme Learning Machines. Sensors 2016, 16, 447. https://doi.org/10.3390/s16040447

Zhang J-K, Yan W, Cui D-M. Concrete Condition Assessment Using Impact-Echo Method and Extreme Learning Machines. Sensors. 2016; 16(4):447. https://doi.org/10.3390/s16040447

Chicago/Turabian StyleZhang, Jing-Kui, Weizhong Yan, and De-Mi Cui. 2016. "Concrete Condition Assessment Using Impact-Echo Method and Extreme Learning Machines" Sensors 16, no. 4: 447. https://doi.org/10.3390/s16040447

APA StyleZhang, J.-K., Yan, W., & Cui, D.-M. (2016). Concrete Condition Assessment Using Impact-Echo Method and Extreme Learning Machines. Sensors, 16(4), 447. https://doi.org/10.3390/s16040447