1. Introduction

Structural health monitoring (SHM) is expected to play a major role in the development of large wind turbines with higher efficiency and lower cost-of-energy [

1]. Li

et al. [

2] gave a comprehensive review on the damage detection methods for wind turbine blades. Taylor

et al. [

3] presented an ongoing work to implement real-time SHM systems for operational research-scale wind turbine blades with piezoelectric active sensors. Park [

4] designed a real-time monitoring system with FBG sensors for a 2 MW wind turbine (type U88). Those wind turbines are usually subjected to severe operational loads, therefore they requires stringent safety measures and more frequent maintenance, but it is quite difficult and costly to perform inspection and maintenance work on these large wind turbines, mainly because of their height and limitations associated with the remoteness of the installation locations, such as offshore wind farms. Clearly, obtaining precise and real time information using SHM systems can be invaluable for improving safety, for lowering the frequency of sudden breakdowns and, more importantly, for moving away from a costly schedule-based maintenance toward a cost-effective and condition-based maintenance; all factors lead to the significant reduction in the operational cost of wind turbines [

5].

A precondition for the wind turbine SHM is the understanding of loads, which is important to manufacturers and wind-farm owners. For the manufacturer, a better understanding of the loads enables improved designs. For the wind-farm operator, understanding loads caused by the damage enables the better detection of potentially damaging situations, and it provides an early alert to “blade throw” events, which could have catastrophic consequences for anything in the surrounding area.

The Fiber Bragg grating (FBG) shows an advantage over the conventional strain sensor in understanding loads of the wind turbine blade. Typically wind turbines are designed for a 20-year operational life, and during that time the sensor will undergo approximately 60 million cycles. A conventional strain sensor will typically fail after less than 60,000 cycles, but the FBG shows no degradation in the performance after 100 million cycles. Therefore, once embedded within the wind turbine blade during the manufacturing process, the FBG is there for the life of the wind turbines, with no need for servicing or recalibration [

6].

The development of the wind turbine SHM using FBG strain sensors has received wide attention recently due to the increasing interest in renewable energy. Kim

et al. [

7] employed the operational modal analysis to construct a displacement-strain transformation matrix for a real-time shape estimation technique, and the developed technique is applied to a wind turbine blade, in which the FBG sensors are embedded. Arsenault

et al. [

8] calculated the power spectra density based on the strain response of the wind turbine blade, a lumped mass was attached near the tip of the blade to simulate the damage, and the comparison between the lumped mass-added blade power spectra and that of the intact blade was made in order to detect damage. Nichols

et al. [

9] detected the presence of damage-induced nonlinearities in composite structures using only the structural vibration response, and the damage was assumed to change the coupling between different locations on the structure from linear to nonlinear; two informational metrics, the time-delayed mutual information and time-delayed transfer entropy, were obtained from the obtained time-series data, so the presence of the impact damage was detected in a thick composite sandwich plate. Lau

et al. [

10] employed the FBG as a structural health monitoring device for fiber reinforced plastic materials by either embedding into, or bonding onto, the structures, and the accuracy of the strain with the FBG sensor is highly dependent on the bonding characteristics among the bare optical fiber, protective coating, adhesive layer and host material. Okabe

et al. [

11] developed small-diameter FBG sensors for embedding the laminated composite plate without deterioration of the mechanical properties. Tsuda [

12] constructed two types of FBG ultrasonic sensing for the damage detection in carbon-fiber reinforced plastics. Therefore, it can be concluded that the key procedure of the SHM is to extract the damage-sensitive feature from the measured parameter and track those features with the presence of damage, with the primary goal of the SHM to combine advances in both sensing and data analysis in order to produce an automated system capable of detecting damage without requiring visual inspecting [

9].

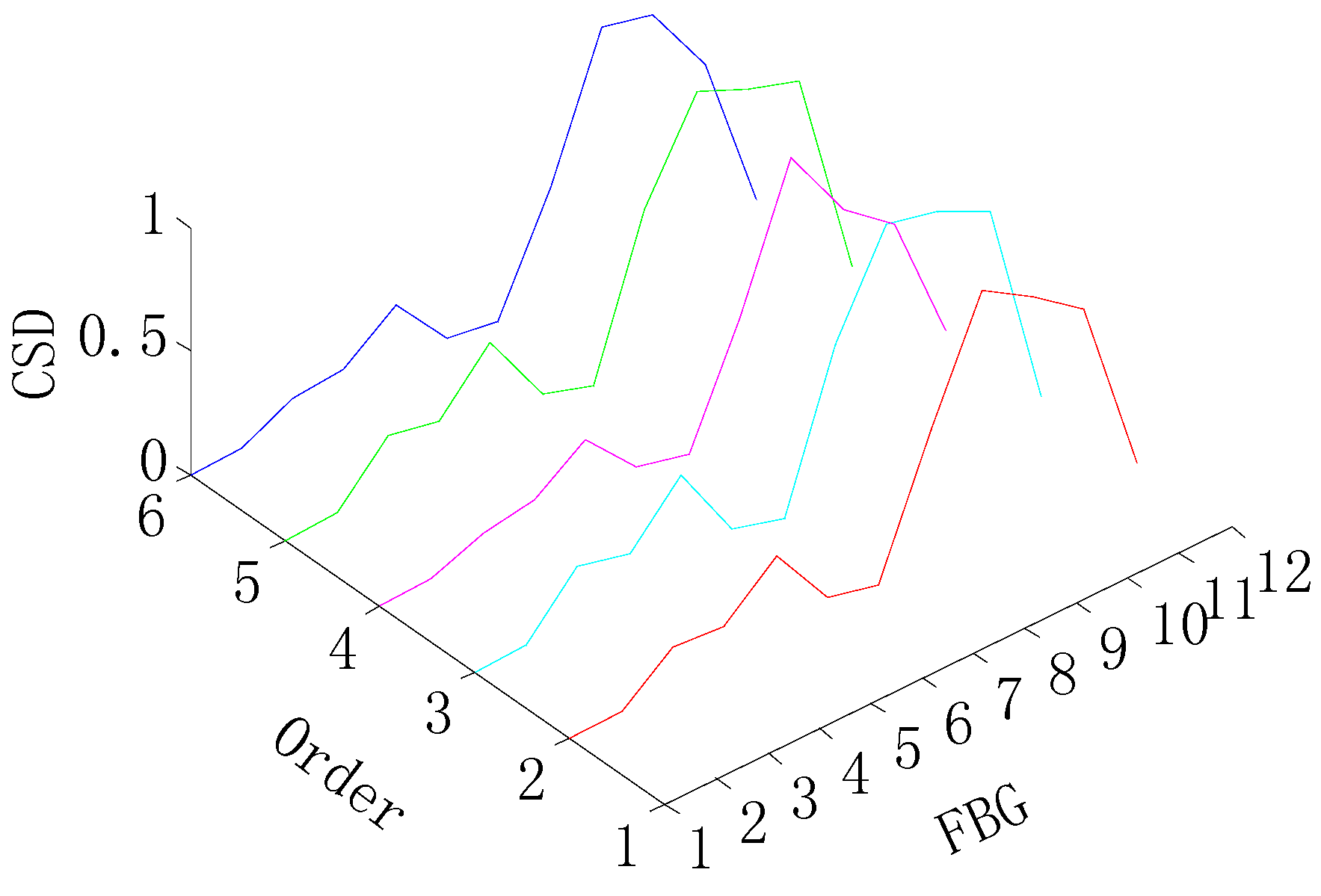

The presence of damage is always accompanied with the local variation on strain parameters in the vicinity, but those in the intact region remain unchanged, so the damage sensitive feature must be able to measure and display this dissimilarity of the strain parameter due to damage. As a nonparametric test statistic method, the Chi-square distribution (CSD) can provide a probabilistic procedure for testing the hypothesis that two probabilistic distributions have been generated from the same underlying distribution, and then the structural dissimilarity is measured based on the empirical estimates. Rubner

et al. [

13] employed the CSD to complete the texture dissimilarity measure. Mathiassen and Skavhaung [

14] employed it to measure the texture dissimilarity in composites, and then Puzicha [

15] utilized it to evaluate the dissimilarity for the color and texture. In this study, the CSD is adopted to be as an effective damage-sensitive feature and individual information source for the damage detection.

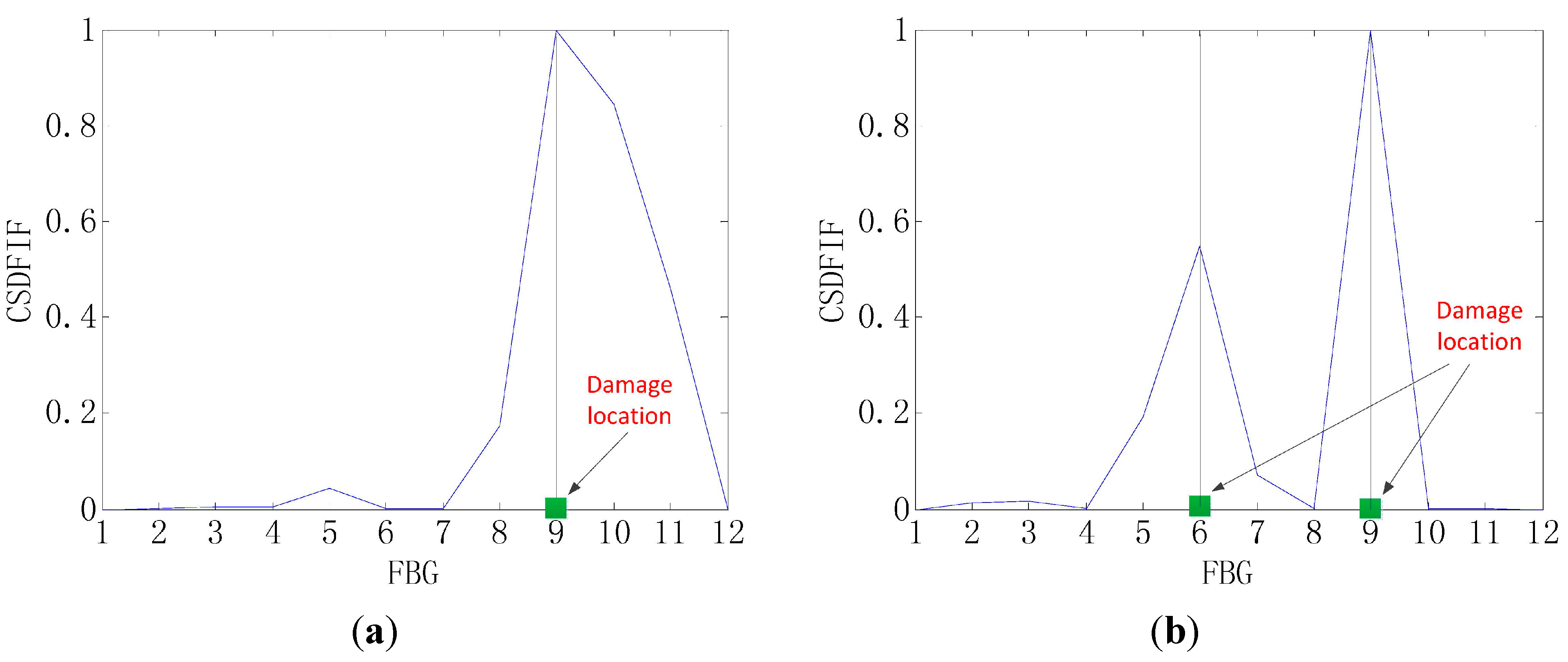

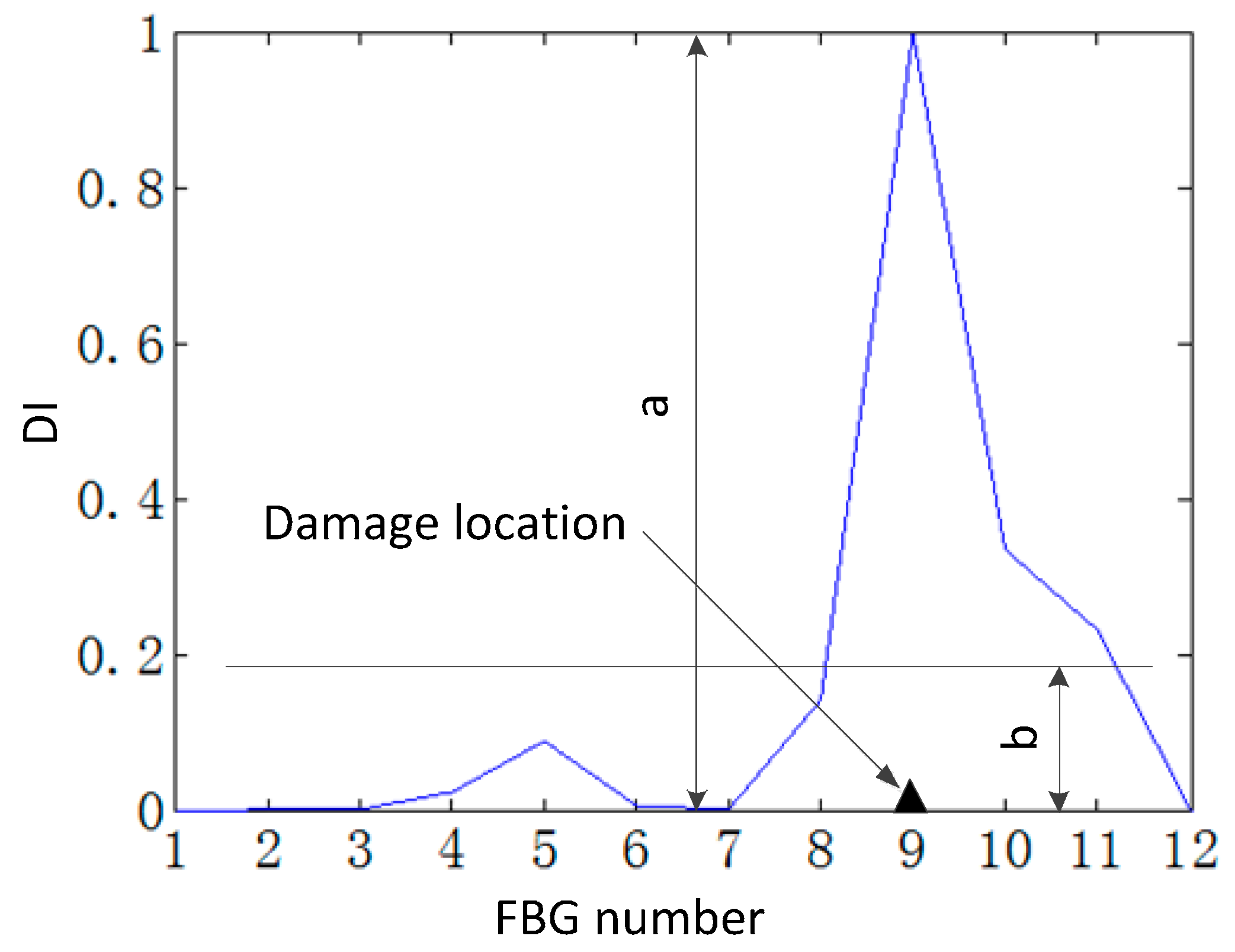

To fuse and optimize explicit information of the individual information source CSD on the damage location, an information fusion method addressed as a feature information fusion (FIF) method is developed, and it can combine data from multiple information sources and related information from associated databases, in order to achieve improved accuracies and more specific inferences than could be achieved by the use of a single source alone. Each source makes its local decision based on its observation, and the local decision of each source is sent to the fusion center, where the global decision based on the local decisions is obtained.

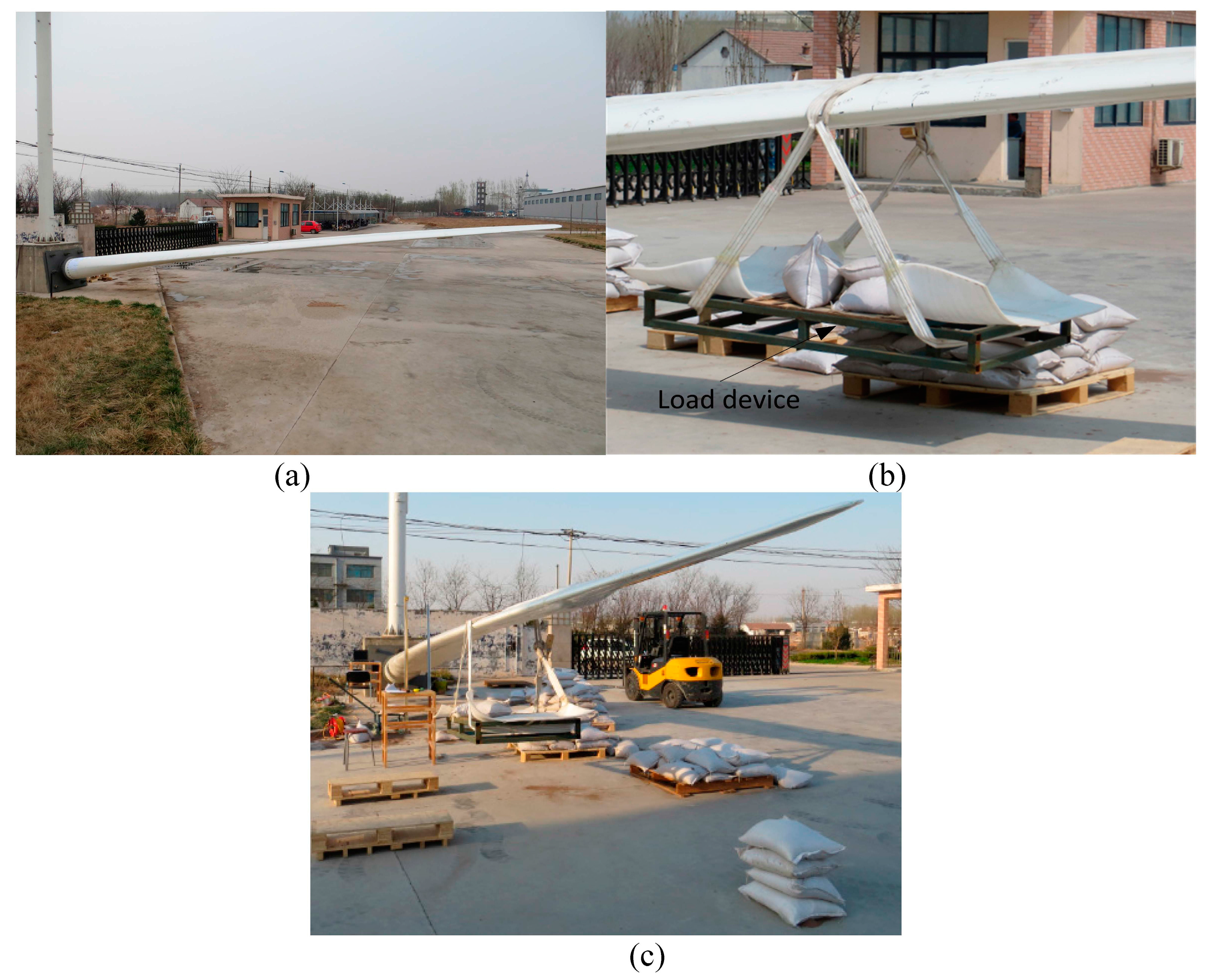

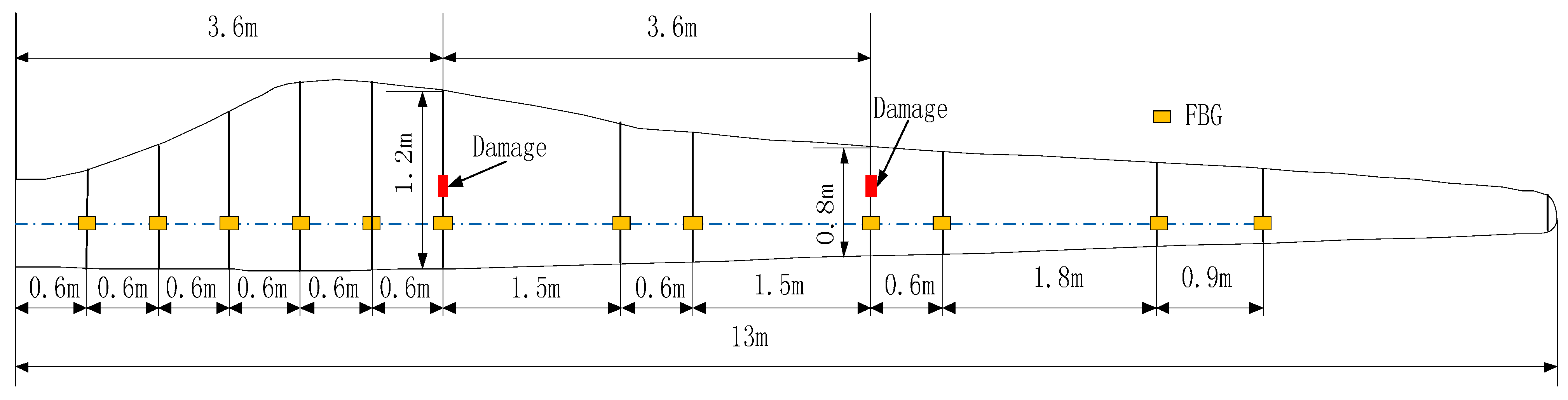

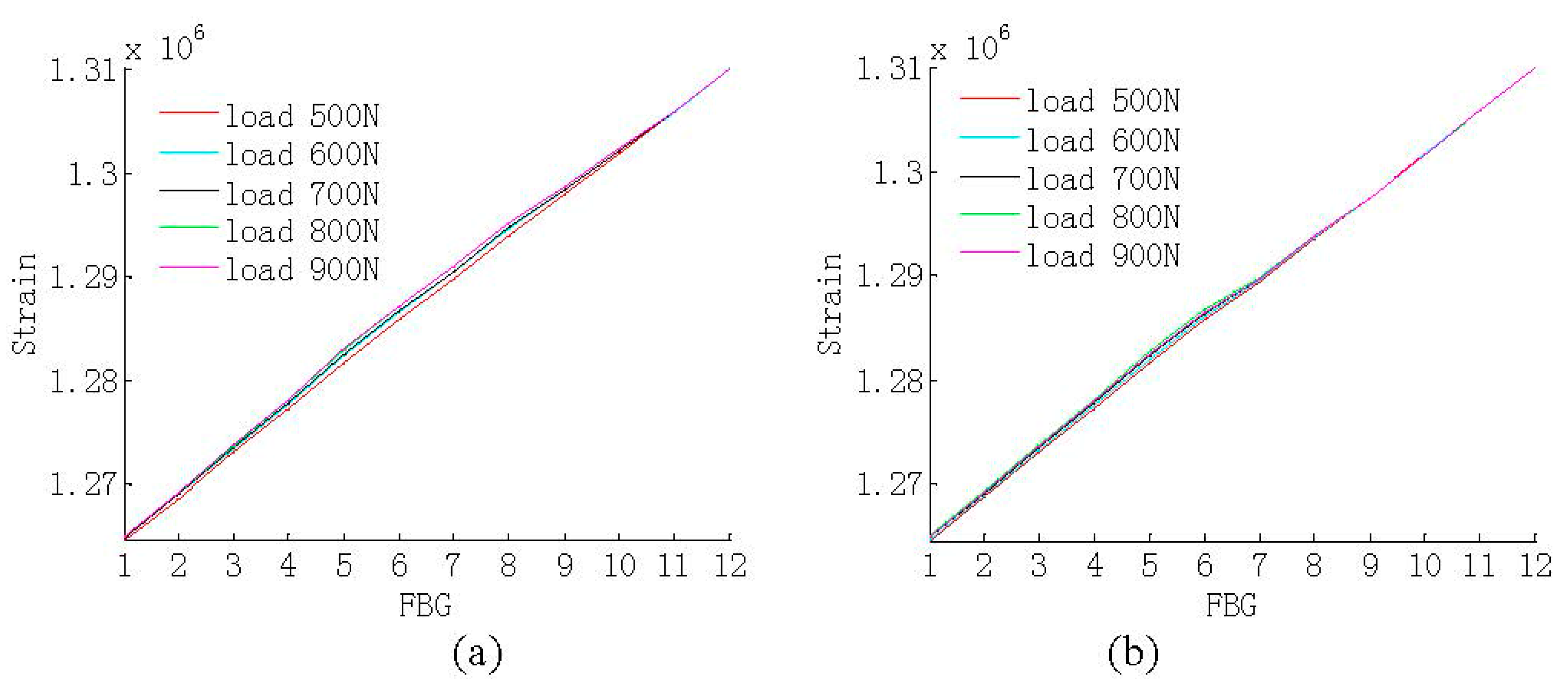

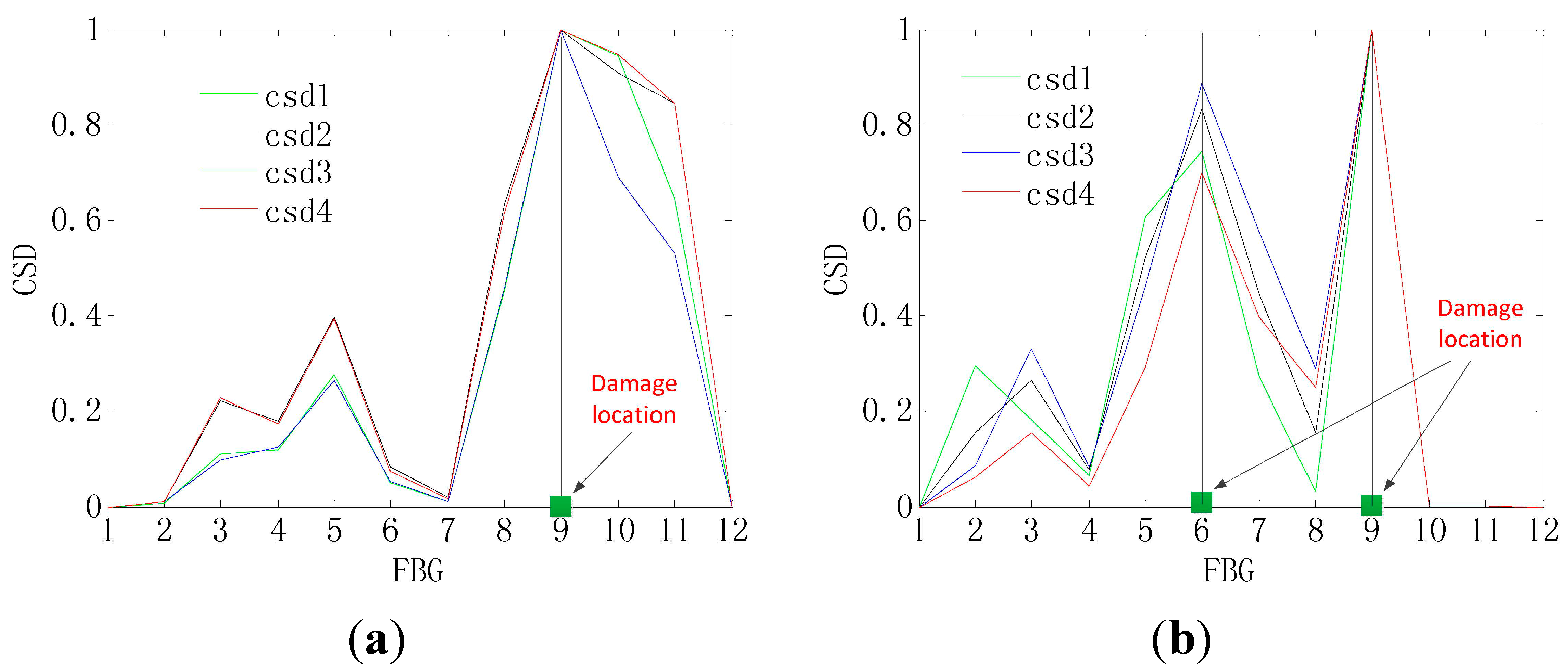

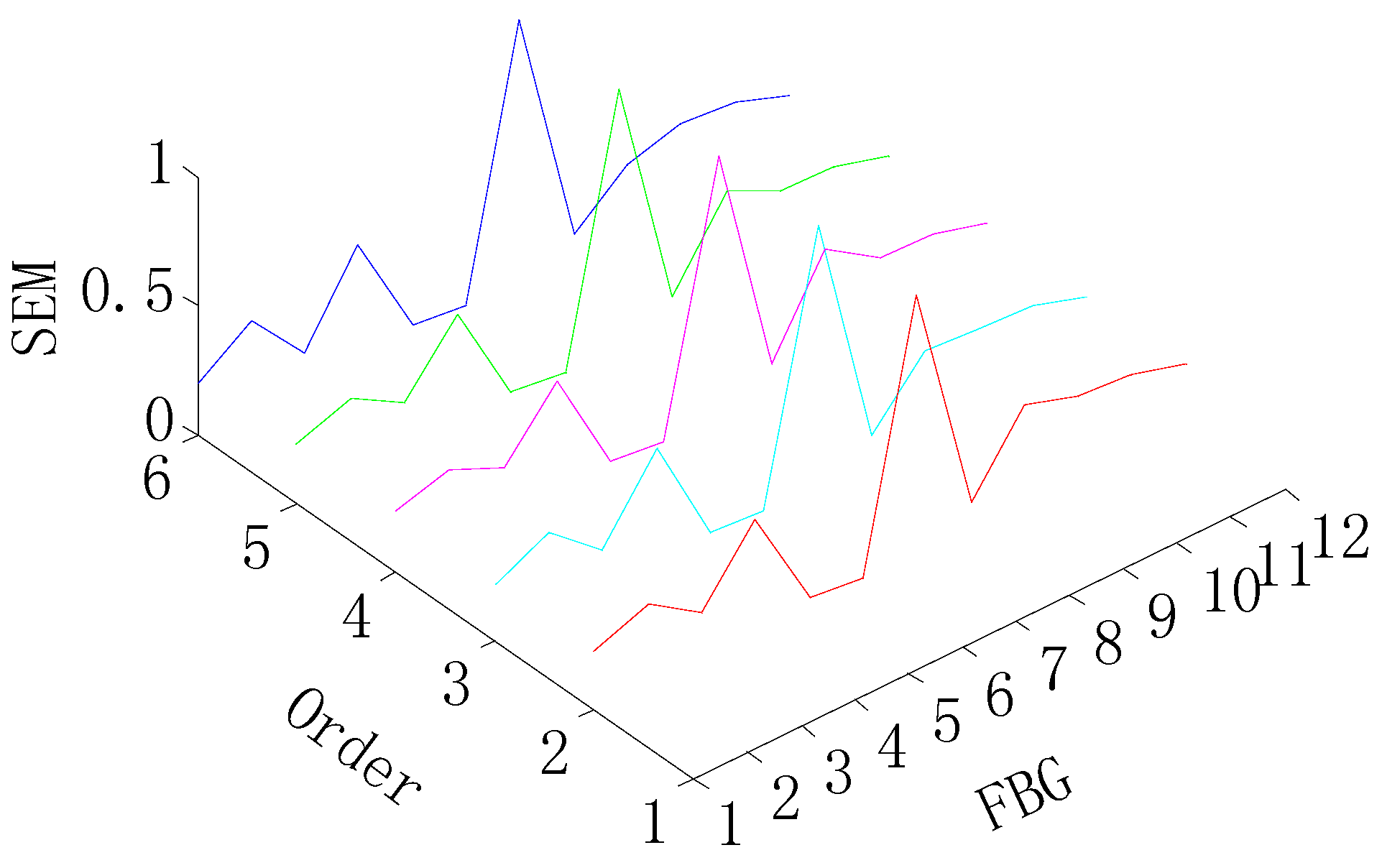

In this paper, a damage detection method in the wind turbine blade based on the FBG is presented. Firstly, the strain response under varying levels of static load is measured using a distributed sensor network, consisting of twelve FBG sensors adhered to the windward side of the wind turbine blade, which is consistent with the situation in service. The presence of damage increases the dissimilarity among strain responses under different levels of static loads, so the dissimilarity is measured by the damage-sensitive feature CSD, which is adopted as the individual information source, and then the local decision on the damage detection is made. Secondly, the feature information fusion (FIF) method is proposed to fuse and optimize information in the above individual information source in order to obtain the global and optimal decision for the damage detection, so the damage is detected accurately on the basis of the global decision. Furthermore, the mean damage detection error (MDDE) is used to describe the damage detection error quantitatively, and the strain energy method (SEM) is employed to show the advantage of the proposed method. Finally, the proposed method does not require the full strain history to detect the current damage, unlike the FBG peak wavelength measurement, and results show that it can deliver encouraging results of the damage detection in the wind turbine blade.

2. Damage Detection Method

In this section, a damage detection method based on the CSD and FIF is developed. The first procedure is to adopt the CSD as the damage-sensitive feature and individual information source, and the next is to employ the FIF to obtain a global and optimal decision for the damage detection.

2.1. The Chi-Square Distribution

The Chi-square distribution is a widely used tool in the statistics and pattern recognition to measure the texture dissimilarity, and it is defined as follows:

where

and

represent probability density functions respectively, L represents the element number,

j denotes the feature dimension, and

N is the number of the feature dimension.

On the right side of Equation (1), the numerator represents the difference between two probability density function, and the denominator represents the sum of them, so it can be concluded that the CSD indicates the difference between two probability density functions and it can be used to measure the dissimilarity among them. The presence of damage is always accompanied with the variation on local strain parameters, and corresponding ones in the intact region remain unchanged, so the CSD can be used to indicate the difference among strain responses with the presence of damage and be regarded as an effective damage-sensitive feature.

When the CSD is used to be an damage-sensitive feature of the wind turbine blade, the strain responses under the static load are measured using the distributed strain sensor system, and then the normalization of the strain response is conducted; therefore, the strain response can be regarded as two probability distribution functions, suppose that

and

are the normalized strain responses under the load

and

respectively, the corresponding CSD can be given as follows:

where

represents the length of the wind turbine blade, and

denotes the CSD based on the strain response under the load

l and

m.Suppose that the wind turbine blade is divided into

elements, the CSD of the

ith element is defined as follows:

where

represents the coordinate of the

ith element,

and

denote the normalized strain response of the

ith element under the load

l and

m respectively, and the

represents the CSD of the

ith element under the load

l and

m.

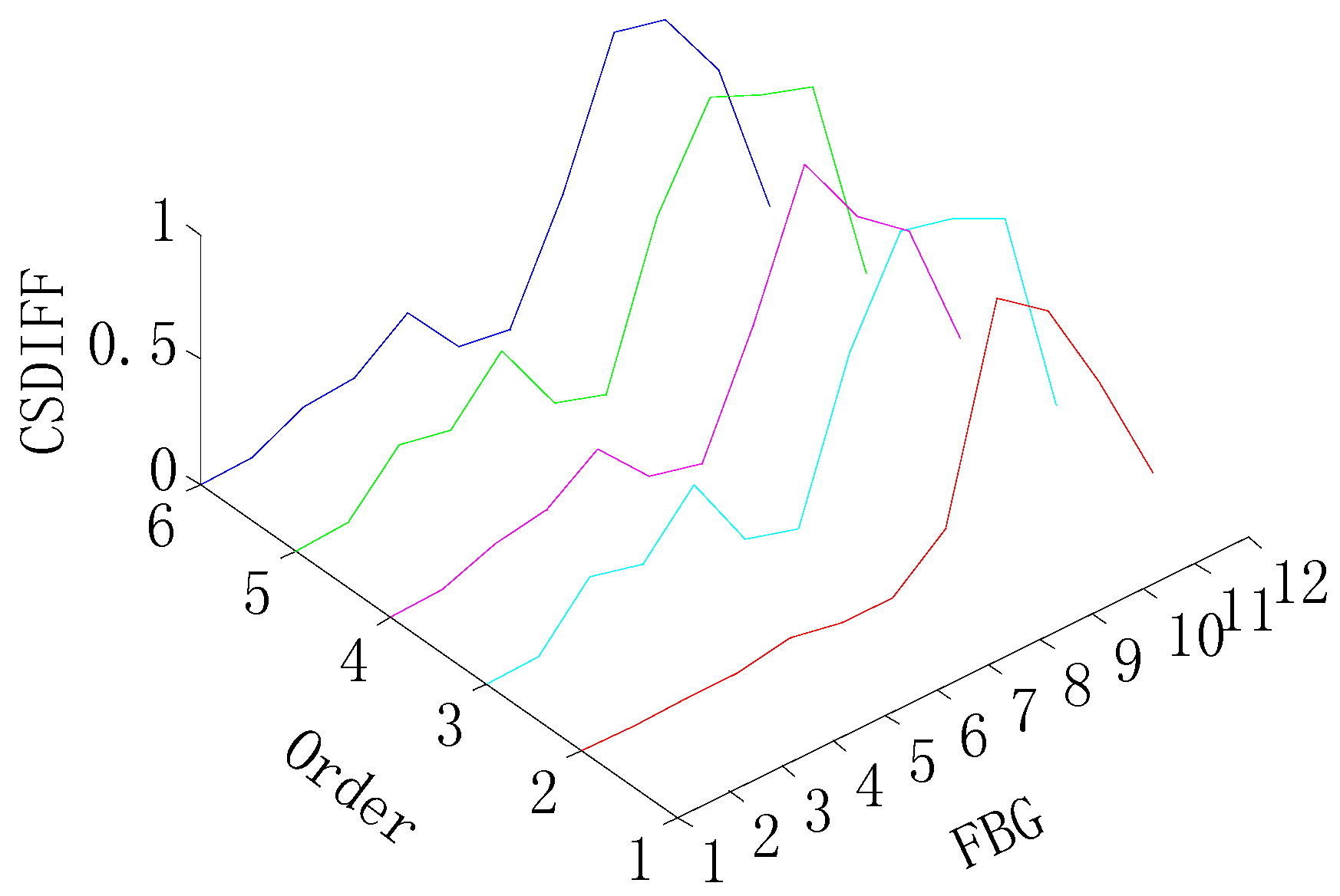

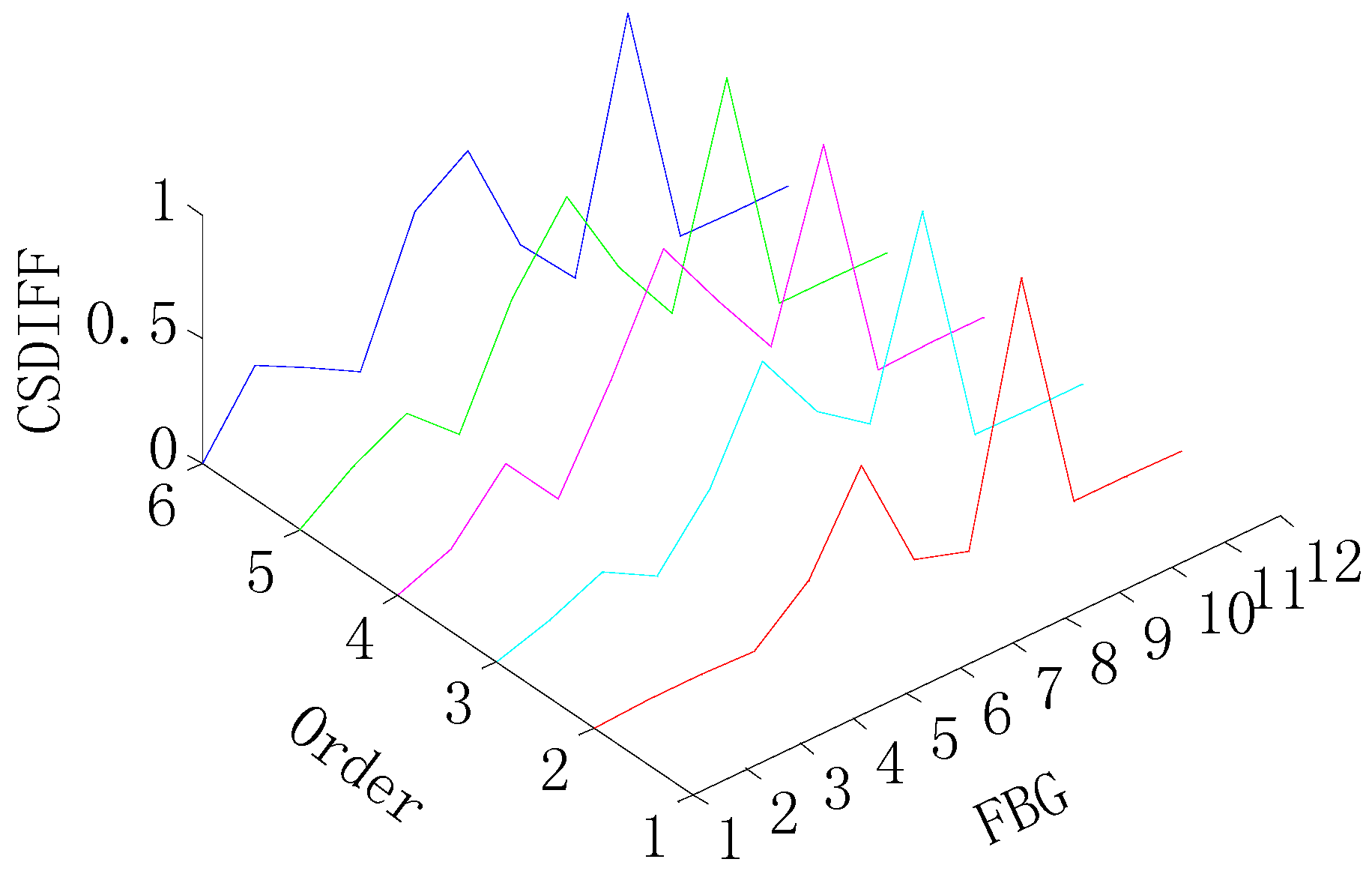

For the damage detection in the wind turbine blade, the CSD under different static loads are regarded as individual local decisions, so how to obtain a global and optimal decision based on them should be taken into account. Then, the feature information fusion method (FIF) is adopted in order to retain the advantage and abandon the shortcoming of the individual information sources at the same time, which is introduced in the next section.

2.2. The Feature Information Fusion (FIF)

In the FIF, judgments and decisions are made on the basis of the past information, and they are modified regularly when additional information become available. This is particularly important when a subjective decision has to be made, initially, with the lack of information, and then refined subsequently with later incoming information.

Suppose that there are two information sources

and

, and NE objects need to be identified, which can be expressed as

, so the probability of each object is denoted as

respectively, let the kernel function and index function of the information source be

and

, respectively, so the probability of each object can be calculated as follows:

then the conditional probability of each object has been obtained; that is,

is already known, so the conditional probability

of the object

can be given as follows:

When the decision of each information source is considered as independent, the above equation can also be written as:

It is crucial to select the information on the damage location as the feature information, and the maximal probability of each object is considered as the feature information in the FIF, so Equation (6) can be written as:

If there is

independent information sources need to decided, the above procedure of selecting the feature information should be done twice. Let the maximum of the vector

be the feature information denoted as

, and then the maximum of the above is assumed to be zero, so the vector becomes

To obtain the next feature information, the maximum of the above-modified vector is denoted as

is obtained; therefore, the corresponding information fusion can be given as follows:

In the process of obtaining the global and optimal decision, the triangle kernel is adopted as the kernel function of the information source, the CSD under the smallest static load is regarded as the index function in the information fusion, and corresponding ones under other loads are adopted as individual information sources. To retain the advantage and abandon the shortcoming of the CSD at the same time, the most important information of the above individual information sources is selected as the feature information, so the global and optimal decision is made for the damage detection.

Generally speaking, the main advantage of the proposed method is that the proposed FIF can fuse the information of the individual information for the damage detection. Secondly it doesn’t need the information of the intact wind turbine blade, so it is a non-baseline damage detection method, Finally, only the strain response in the windward side of the wind turbine blade is used, which is more consistent with the situation in service.