2.1. Tri-Axis Fluxgate Sensor with an Orthogonal Fluxguide

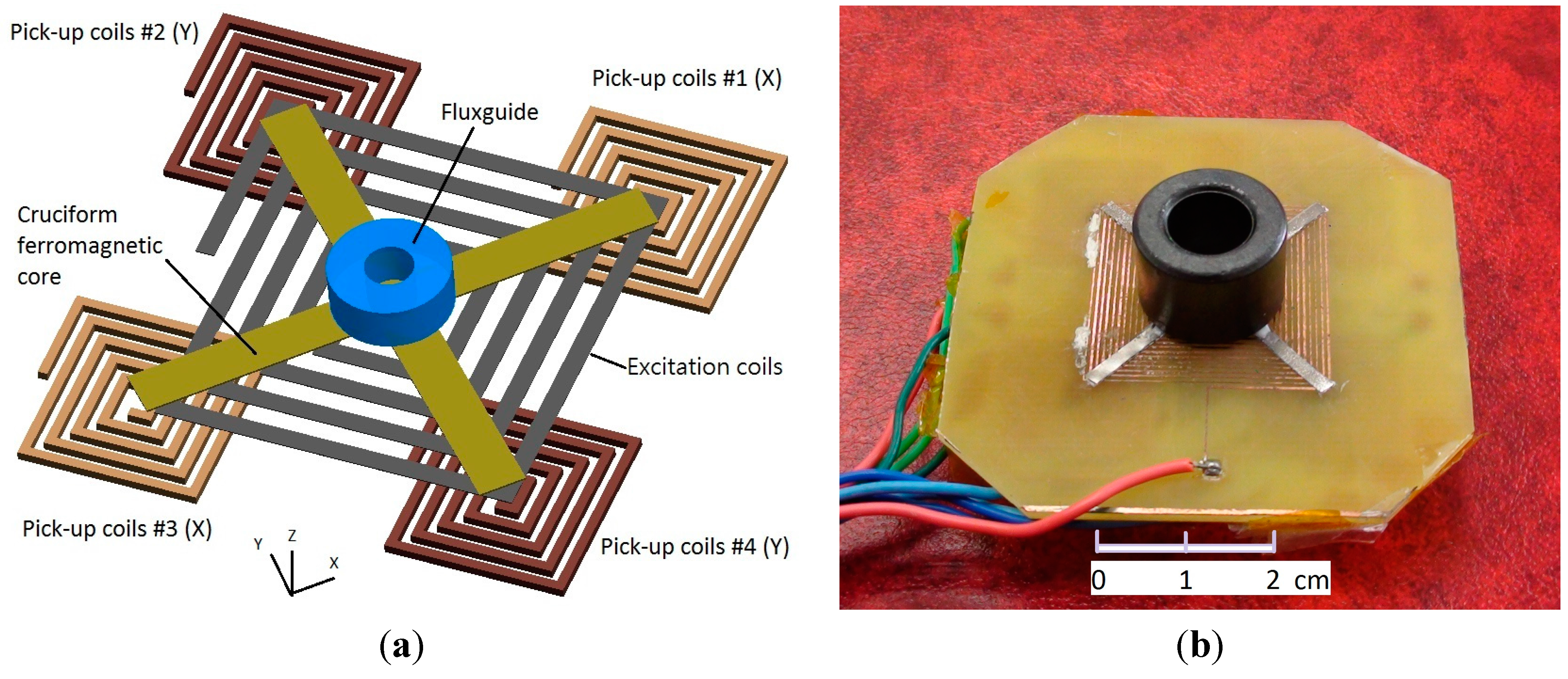

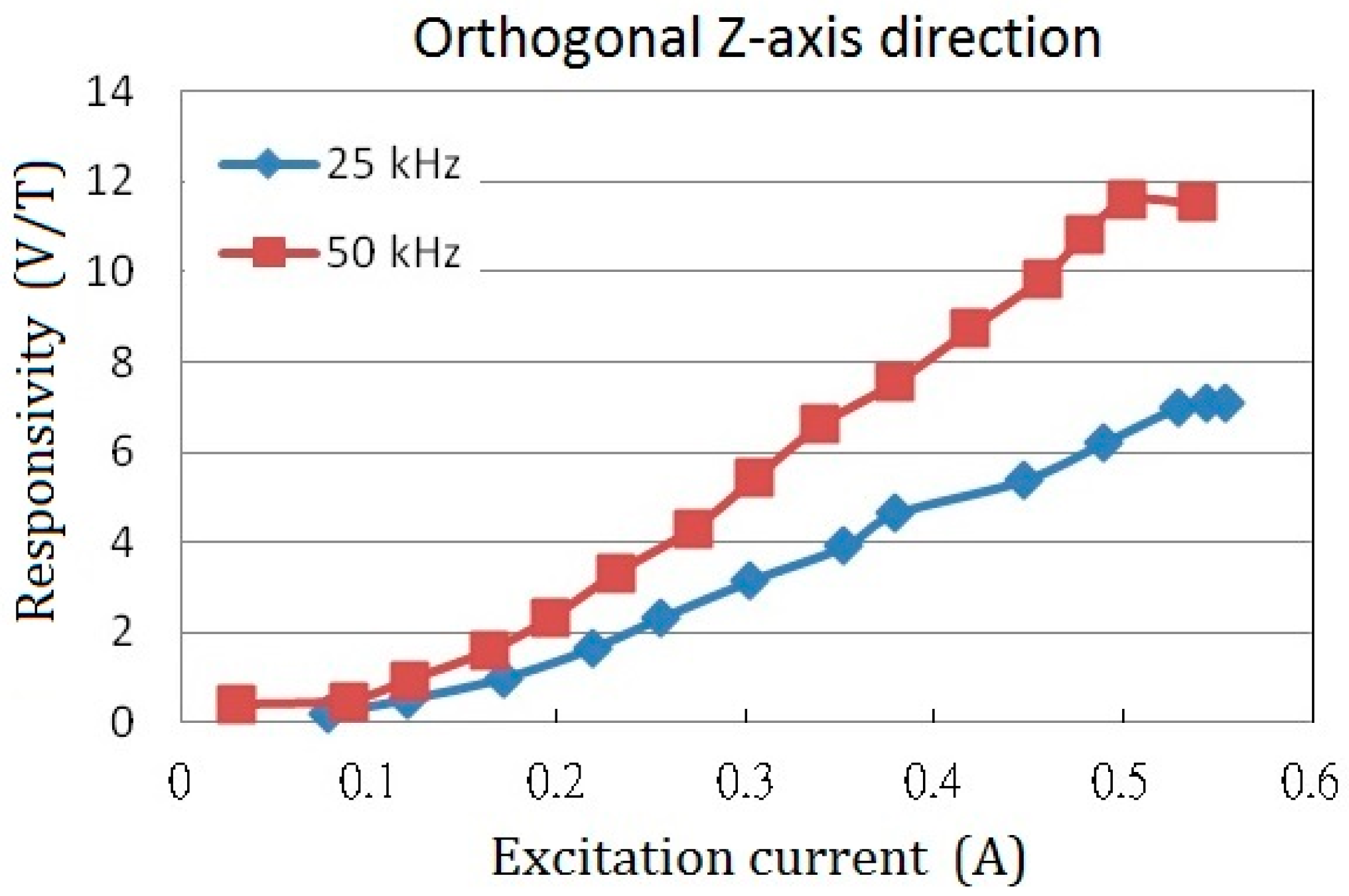

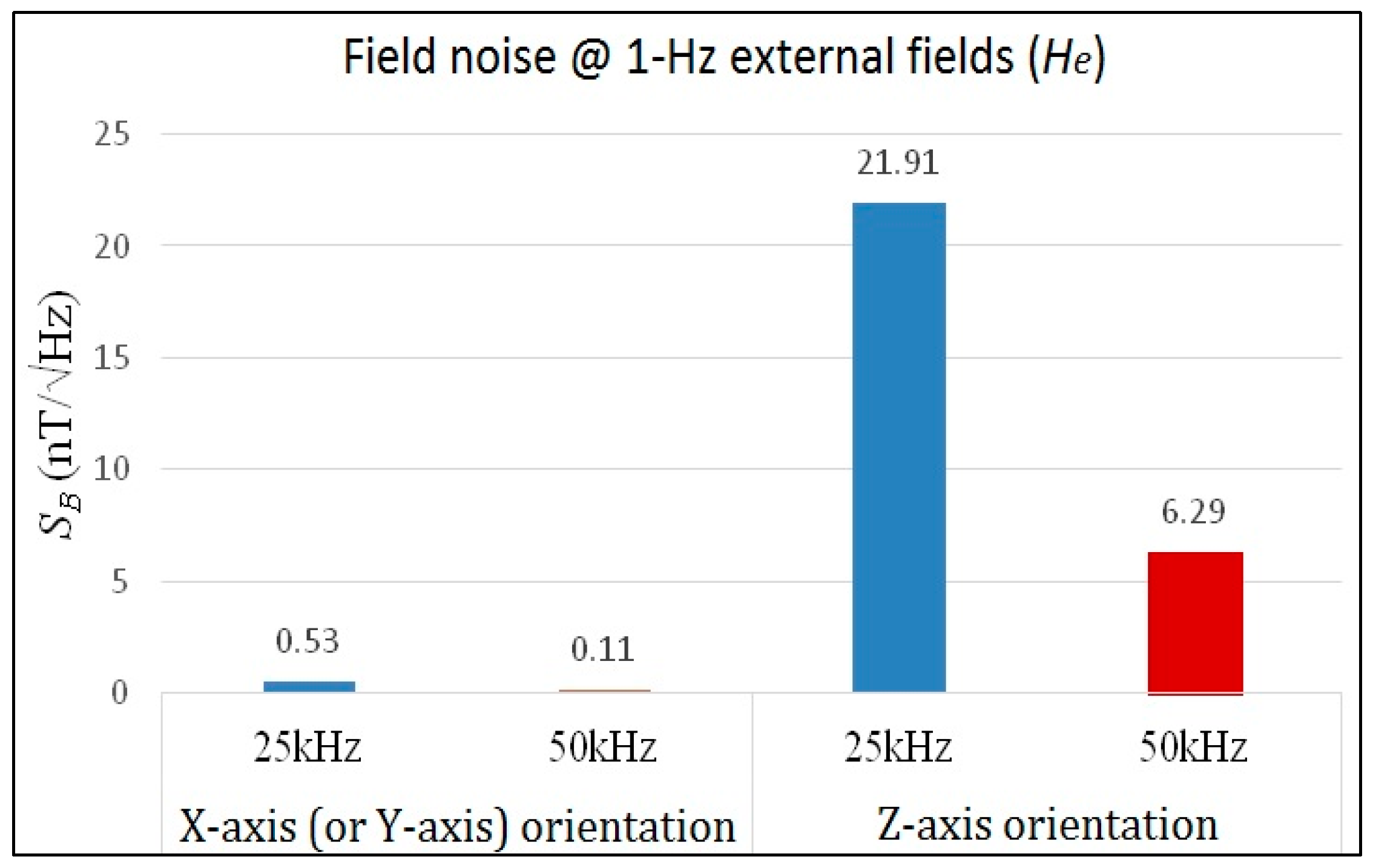

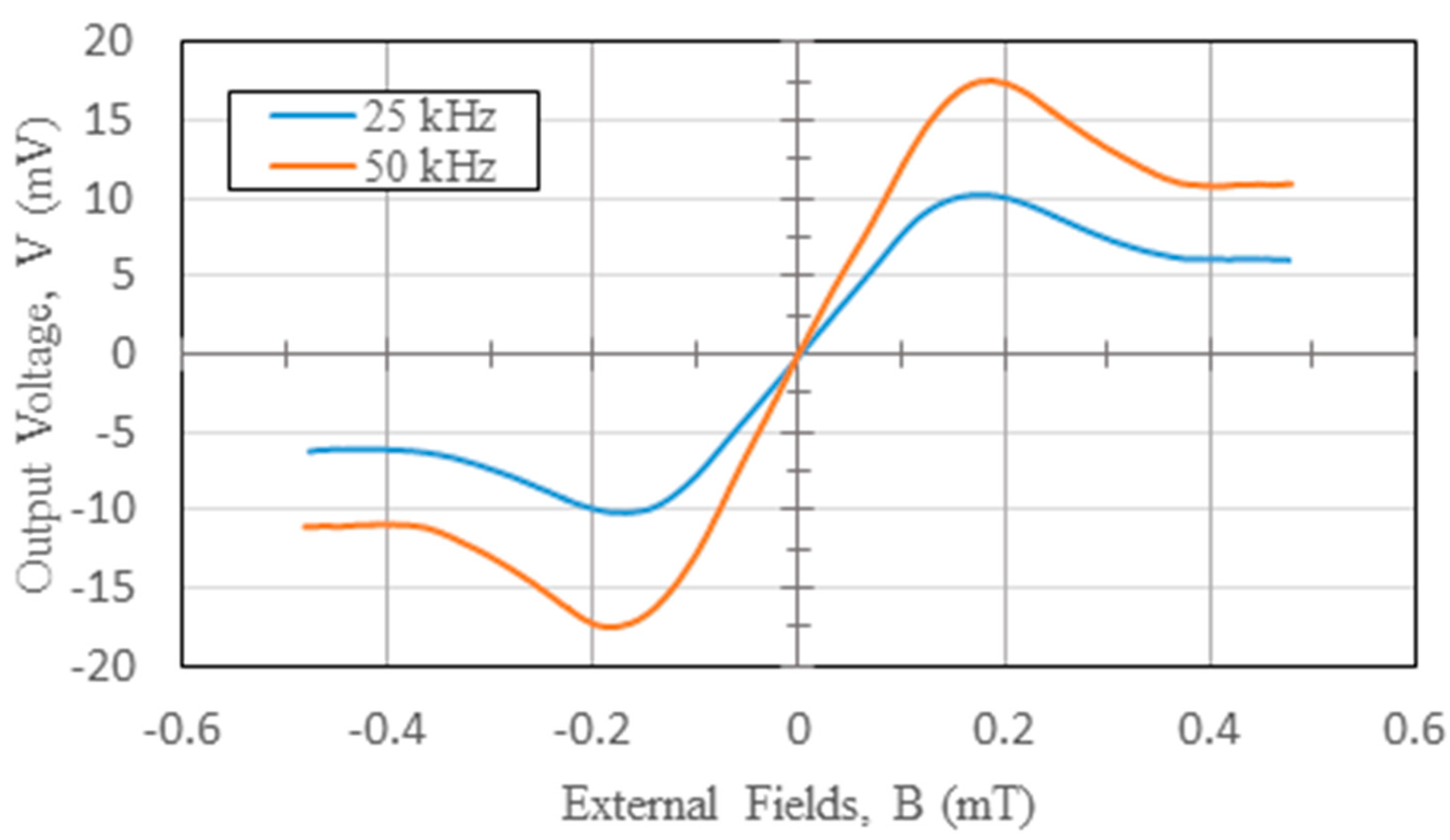

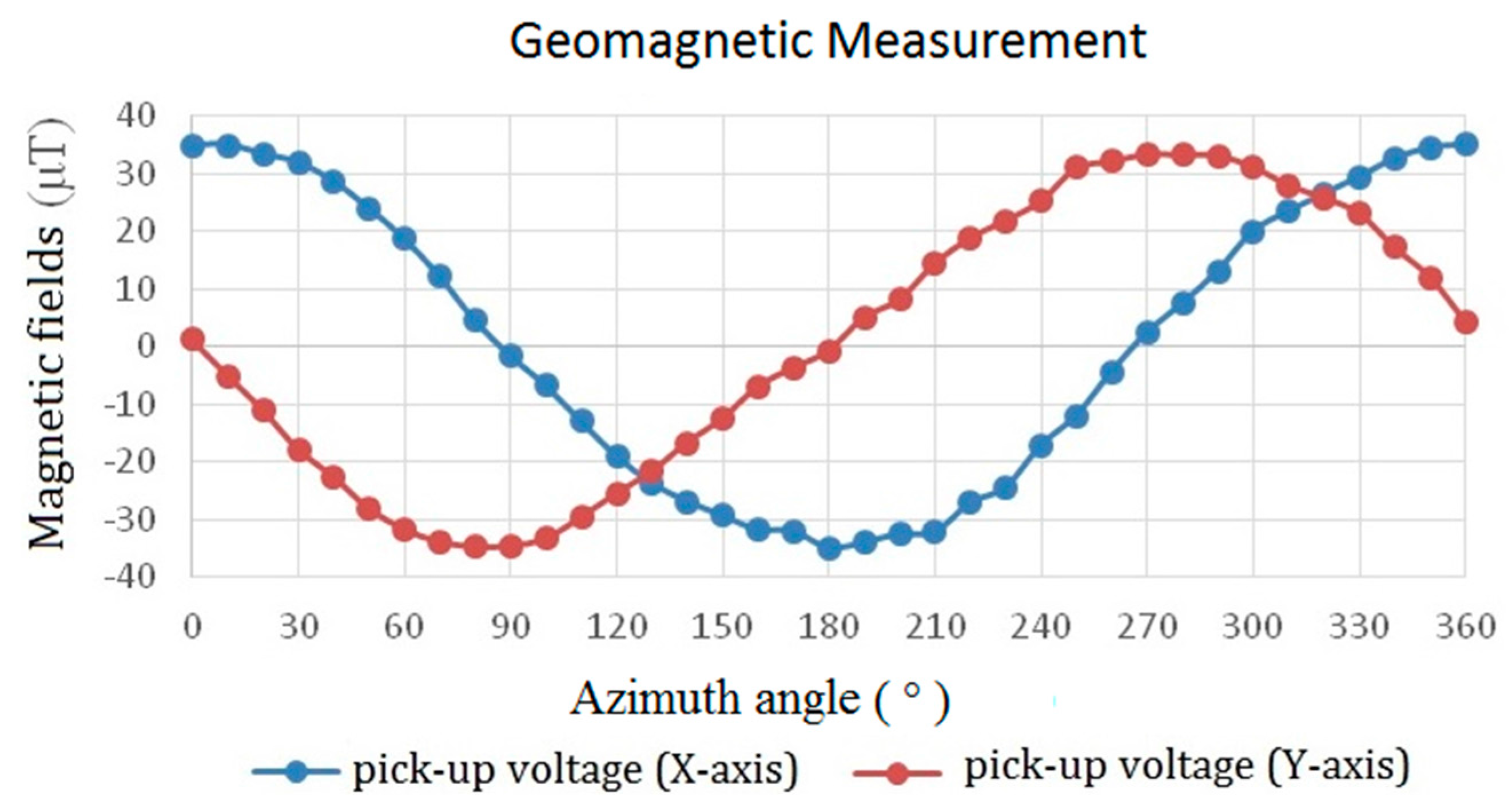

The proposed tri-axis fluxgate sensor is mainly composed of a bi-axis fluxgate with a cruciform ferromagnetic core, a planar excitation coil and four planar pick-up coils. It is noted that the planar fluxgate in fact evolves from the Vacquier-type dual-core fluxgate magnetometer and combines two individual ferromagnetic cores in one, leading to a more compact configuration. The cross-shaped core is placed along the diagonals of the square excitation coils so that the excited magnetic fields are in opposite direction in pairs, and they can cancel each other in the pick-up coils, which are arranged beneath the excitation coils and centered on four endpoints of the cruciform core. Due to the nature of flux convergence (divergence) of the magnetic fields near the endpoints of the magnetic core, this design is able to detect in-plane magnetic field vectors in X- and Y-axis. To expand such a device to measure an additional magnetic field vector in the Z-axis, an orthogonally cylindrical ferromagnetic tube acting as a fluxguide is hence employed to collect or concentrate magnetic fields and then emit or deflect the fields into the planar cruciform core, as depicted in the perspective structure of

Figure 1a. With the addition of a fluxguide, the bi-axial planar fluxgate sensor is able to detect the orthogonal field vectors along the Z-axis. The main advantage of the above design is beneficial from the much simpler process and assembly steps, which are rather dissimilar to those of certain spatial fluxgates fabricated or assembled by more complicated process [

12,

13]. The as-fabricated tri-axis fluxgate magnetometer is shown in

Figure 1b.

Two diagonal pick-up coils are designed in series for each sensing direction such that the total number of turns for an individual axis is 24, and 20 for the excitation coils. The wire width of coils is 0.35 mm with a similar wire gap. The excitation coils are formed by photolithography and dip-etching processes on the front side of the PCB substrate, while four pick-up coils are made simultaneously on the back side. The square thick-film Cu wires of the planar coils configure with a thickness of 35 μm. Metglas™ 2714A ferromagnetic sheet (Metglas, Conway, SC, USA) is adopted as the ferromagnetic core and it is 15 μm thick, 2 mm wide and 40 mm long in each sensing direction, featuring a low magnetic saturation of 10 µT obtained by the second-harmonic analysis experiments. The cylindrical tube of Ni-Zn ferrite fluxguide is measured as 9 mm in inner diameter, 16 mm in outer diameter, and 13 mm in height. The permeability of the ferromagnetic core and ferrite fluxguide are 80,000 and 4π × 10−4 H/m, respectively.

Figure 1.

(a) Conceptual schematic of the planar fluxgate structure with an orthogonal fluxguide; (b) the PCB-based tri-axis fluxgate magnetometer. Note that all pick-up coils are implemented on the back side of the PCB.

Figure 1.

(a) Conceptual schematic of the planar fluxgate structure with an orthogonal fluxguide; (b) the PCB-based tri-axis fluxgate magnetometer. Note that all pick-up coils are implemented on the back side of the PCB.

2.2. Design and Analytic Simulation of the Fluxgate Magnetometer

To investigate the sensing principle of our proposed device, we utilize Maxwell

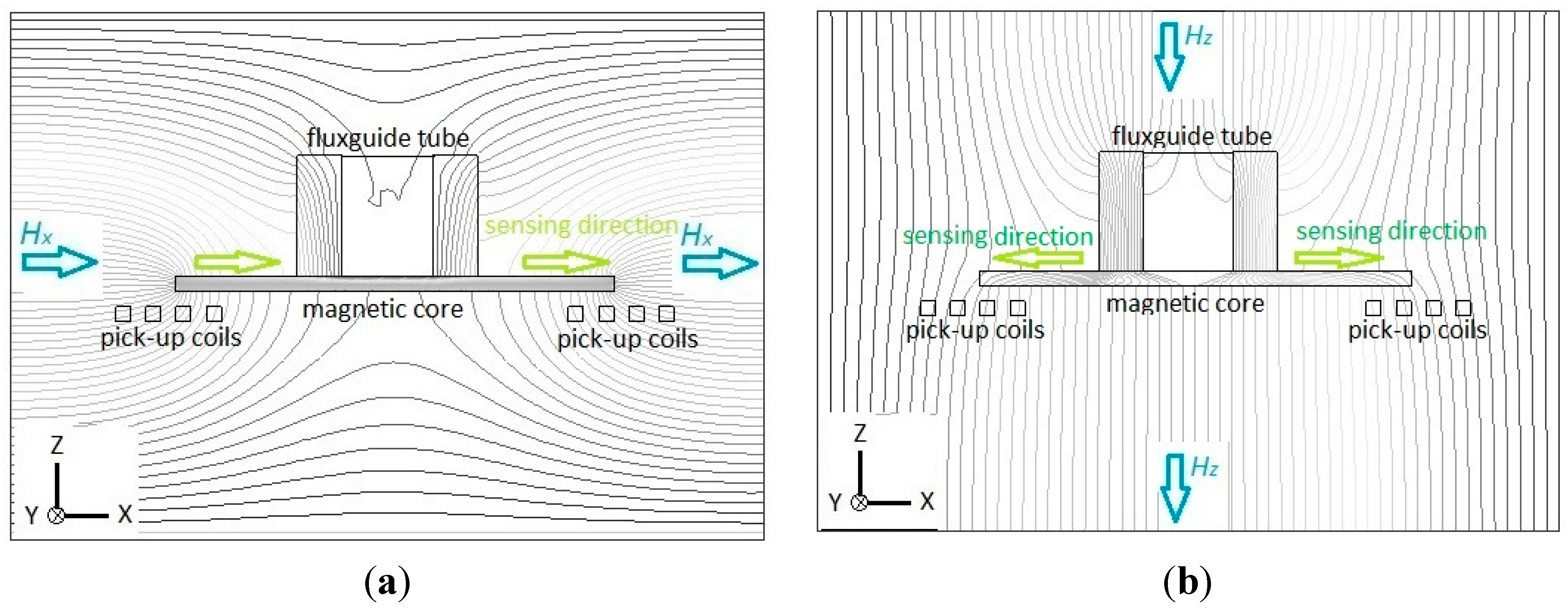

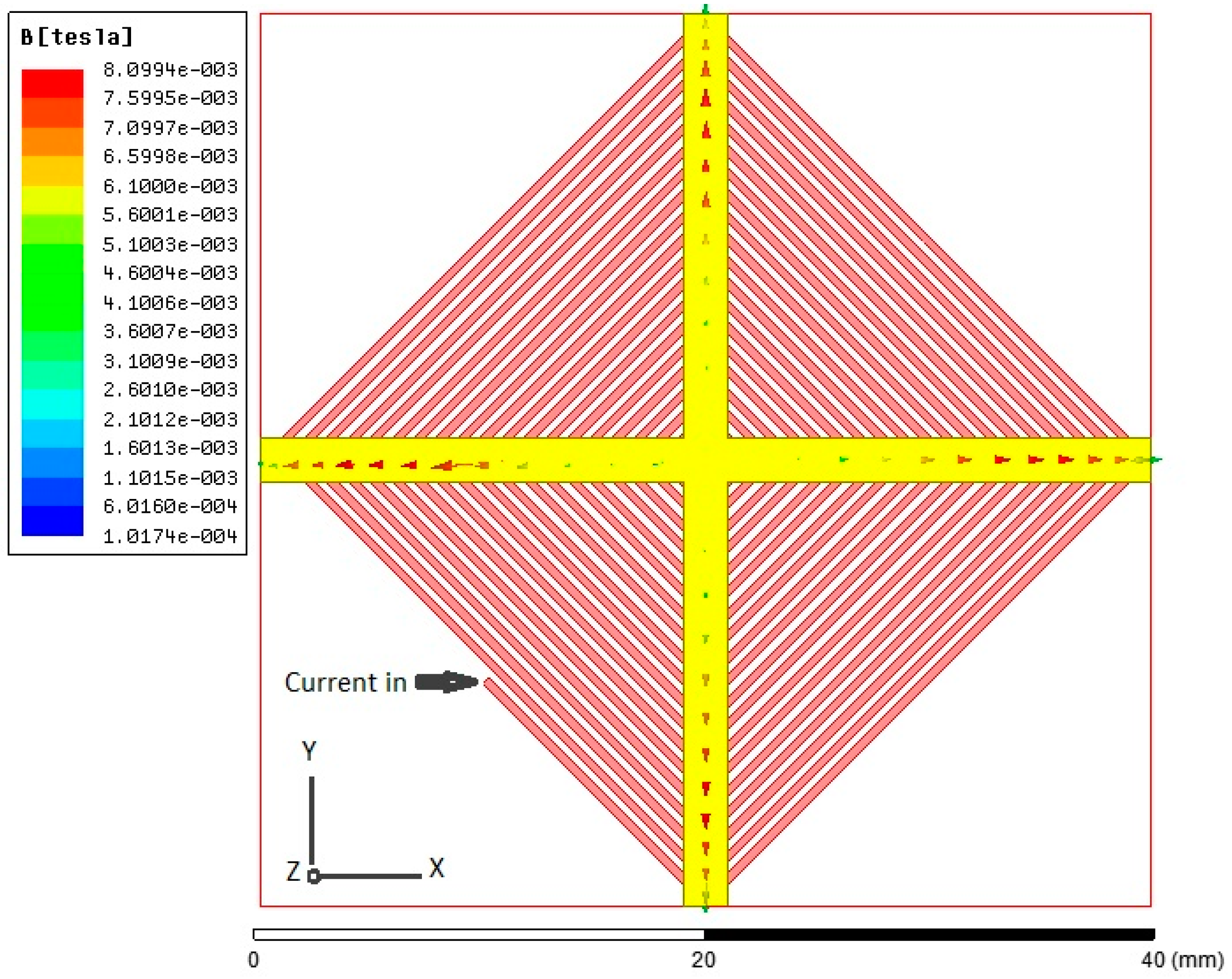

® SV 2-D simulator software (Ansoft Corporation., Pittsburgh, PA, USA, 2002) to model and analyze the visualization of magnetism. First, let us verify the sensing principle of the planar fluxgate only with a cruciform core, and the cross-section along the core is shown in

Figure 2. For the detection of X-axis (or Y-axis) magnetic fields, the magnetic flux lines are assumed to be parallel to the axial direction of the magnetic core, as depicted in

Figure 2a. It can be visibly seen that magnetic flux lines may exhibit convergence or divergence near the ends of the core, and more importantly, a number of flux lines are concentrated or squeezed into the interior of the core until they deviate into air (or vacuum) at the other end. This phenomenon helps generate a variation of the vector field intensity magnitude and flux density around both core ends and this thus can be converted to voltage induced by two pick-up coils beneath them. It is noted that the parallel flux lines near the up and bottom surface of the core may generate the same sensing directions for the corresponding pick-up coils in X-axis due to the fluxguiding (or flux concentration) effect. By implementing a X-Y sensing circuit, one can sum up the induced voltage of two pick-up coils and successfully obtain the vector magnitude of magnetic fields in X-axis (or Y-axis). On the other hand, the Z-axis flux lines, as observed in

Figure 2b, are applied to pass through the magnetic core without any flux concentration effect occurred in it. Therefore the planar fluxgate is considered merely sensitive to the in-plane field vectors.

Figure 2.

Flux line diagrams illustrate the sensing principle of the planar fluxgate only with a cruciform core and the cross-section is along the longitudinal core: (a) in X-axis sensing direction; (b) in Z-axis sensing direction.

Figure 2.

Flux line diagrams illustrate the sensing principle of the planar fluxgate only with a cruciform core and the cross-section is along the longitudinal core: (a) in X-axis sensing direction; (b) in Z-axis sensing direction.

Next, the working principle of the planar fluxgate with a cruciform core and a vertically orthogonal fluxguide is investigated. For the X-axis (or Y-axis) detection, the distribution of magnetic flux lines is considered highly comparable with the planar device, in particular near the ends of the core, when compared with

Figure 2a and

Figure 3a. The simply different part in the flux line diagrams is the interior region of the fluxguide in

Figure 3a, which has a trivial effect on both ends of the core. Through the simulation of flux line distribution, it is confirmed that the tri-axis sensor with a fluxguide does not generate significant interference for X-axis (or Y-axis) detection and surely obtain the vector component of magnetic fields in X-axis (or Y-axis) as the planar one. In contrast to the same sensing directions for X-axis measurement, the sensing directions for pick-up coils are formed in reverse when exposed to Z-axis fields. Therefore, by employing a X-axis (or Y-axis) sensing mode with the same winding direction in the pick-up coils, one may sum up the induced voltage of two pick-up coils and successfully obtain the vector magnitude of magnetic fields in X-axis (or Y-axis) since the induction effect caused by the Z-axis fields is called off each other. On the other hand, for the measurement of the Z-axis field component, let’s assume that the magnetic fields are set to be parallel to the longitudinal orientation of the fluxguide.

Figure 3b clearly reveals that considerable flux lines near the top of the fluxguide are bent and guided into its interior, and transferred in the magnetic core along X- axis (or Y-axis), and diverged into air (or vacuum) in the end. Similarly this phenomenon also generates a vector field intensity and flux density magnitude variation around both core ends and voltage is thus induced by two planar pick-up coils. As a result, it can be seen from

Figure 3 that the sensing directions of two pick-up coils are transverse to the X-Y plane in the same direction when the sensor measures X-axis fields. On the other hand, the sensing directions of in-series pick-up coils are simutaneously outward (or inward) the center of the fluxguide while measuring the fields along Z-axis. By using Z-axis sensing mode with the opposite winding direction in pick-up coils, one may sum up the induced voltage from two or four planar pick-up coils and acquire the vector component of magnetic fields in the Z-axis direction. Likewise, the magnetic induction from the generated X- or Y-axis field vectors is finally called off in the pick-up procedure. In consequence, these can clarify that our proposed planar fluxgate with a fluxguide is sensitive to the orthogonal Z-axis field vectors. Hence, the field components in the X-, Y- and Z-axis are readily available if the orthogonal tri-axis sensing modes are properly applied and switched by the transducing circuit (to be discussed elsewhere). Nevertheless, comparing the magnetic flux density in the cores exhibited in

Figure 3a,b, one can realize that the X-axis field components derived from the Z-axis field vectors are still far less than those from X-axis fields, and it may affect the responsivity of the Z-axis field direction. In addition, the experimental results of orthogonality analysis later exhibited in

Table 1 are able to clarify the significant division of the spatial fields along the Cartesian coordinates.

Figure 3.

Flux line diagrams illustrate the sensing principle of the planar fluxgate with a cruciform core and an orthogonal fluxguide, and the cross-section is along the longitudinal core: (a) in X-axis sensing direction; (b) in Z-axis sensing direction.

Figure 3.

Flux line diagrams illustrate the sensing principle of the planar fluxgate with a cruciform core and an orthogonal fluxguide, and the cross-section is along the longitudinal core: (a) in X-axis sensing direction; (b) in Z-axis sensing direction.

Table 1.

The experimental results of orthogonality analysis.

Table 1.

The experimental results of orthogonality analysis.

| Condition | Under a X-Axis Field (50 G) | Under a Y-Axis Field (50 G) | Under a Z-Axis Field (50 G) | Non-Orthogonality (%) |

|---|

| Measurement | |

|---|

Pick-Up Voltage Vx

(X-axis sensing mode) | 2.21 (V) | 5.6 (mV) | 16.8 (mV) | 0.25

(X-Y plane) | 0.76

(X-Z plane) |

Pick-Up Voltage Vz

(Z-axis sensing mode) | 16.4 (mV) | 16.1 (mV) | 204 (mV) | 8.04

(X-Z plane) | 7.89

(Y-Z plane) |

A cross-cored fluxgate consists of two perpendicular ferromagnetic cores. If the permeability of the core material is assumed high, then the voltage in X-axis (or Y-axis) induced by these pick-up coils can be calculated on the basis of the Faraday’s law in consideration of demagnetization factor

D as follows:

where

N is the number of each pick-up coil turns,

A is the cross-sectional area of the magnetic core,

He is the external dc field, µ

d is the time-dependent permeability and

Bi(

t) is the magnetic flux density in the longitudinal course of the

i-th magnetic core [

26]. Equation (1) argues that the output voltage from all pick-up coils is associated with the number of coil turns

N, external dc fields

He and the derivative of permeability µ

d. Also, the time-dependent permeability µ

d is comparable to the gradient of the

B-H curve of the core material, and in consequence the higher it is, the greater the output voltage is. Besides, demagnetization factor

D is considered dominant in building up the induced voltage. As one knows, demagnetization factor is mainly related to the aspect ratio of core diameter (or width in this study) to core length. Accordingly, a narrow and long magnetic core featuring a smaller aspect ratio can considerably reduce demagnetization effect and thus raise the voltage in Equation (1). Apart from the use of a high-permeability core, it is also essential to optimize the dimensional configurations of the planar coils and the magnetic core for responsivity enhancement and power reduction in consideration of demagnetization effects.

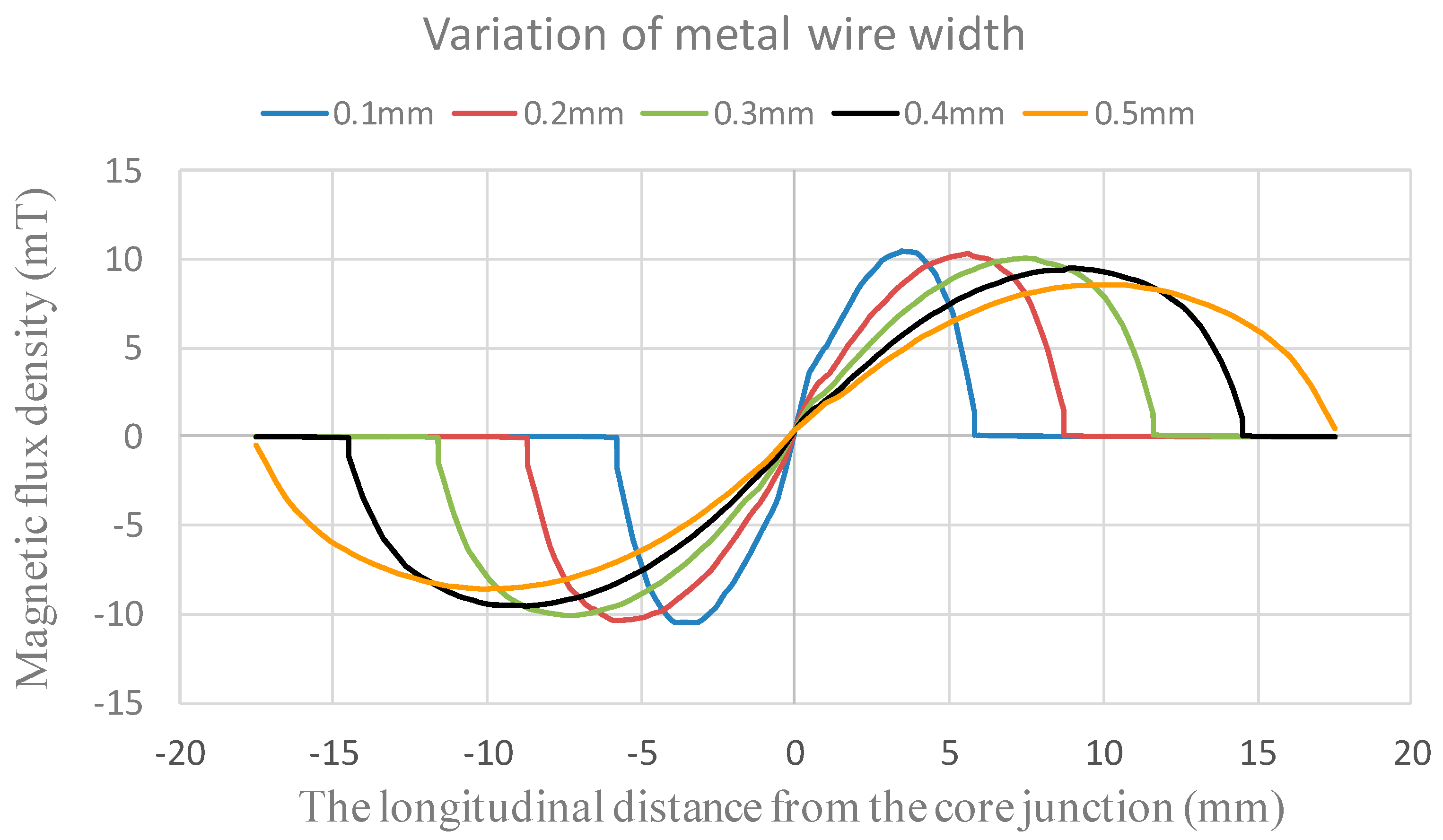

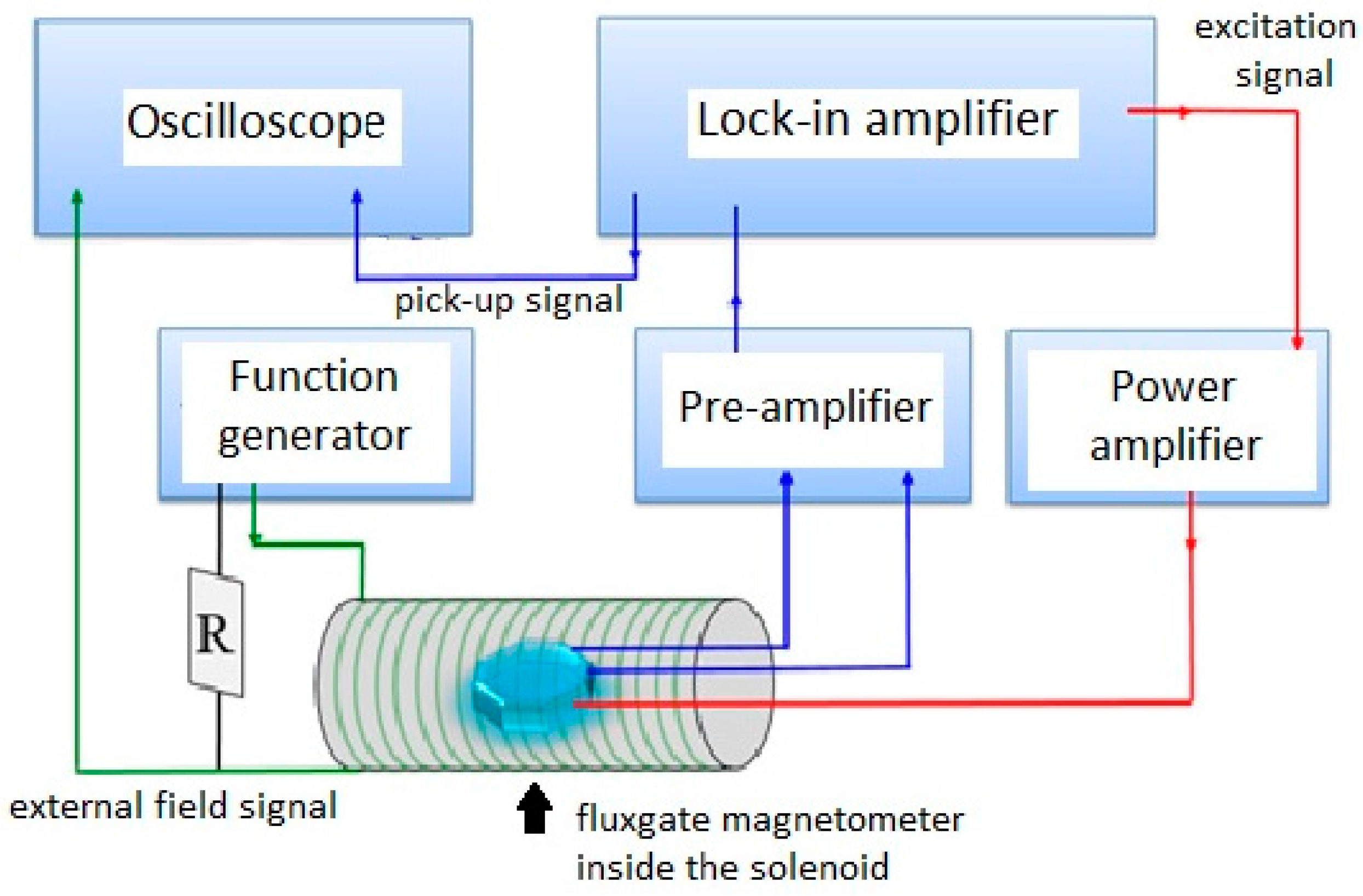

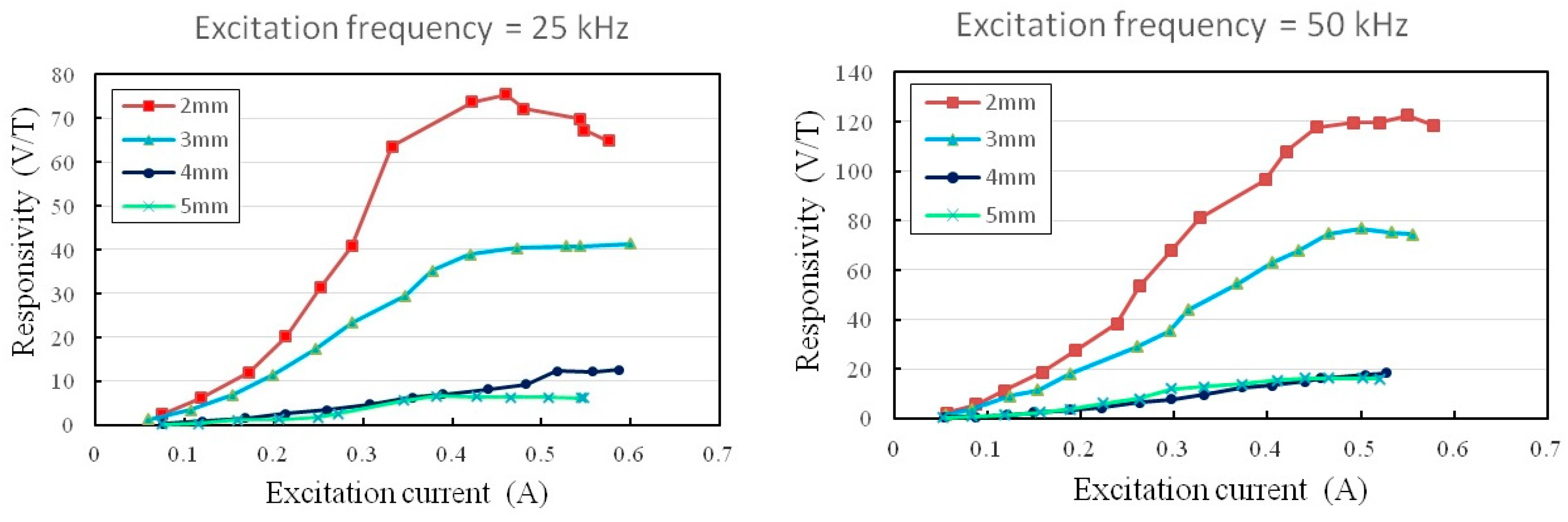

2.3. Simulation and Analysis for Excitation Coils and Core Magnetization

Furthermore, by using an electromagnetic 3-D simulator ANSYS Maxwell

® (ANSYS, Inc., Canonsburg, PA, USA), it is imperative to find the locally optimal dimension in terms of the metal wire width of the excitation coils for the proposed fluxgate. Therefore, we simulate and evaluate the distribution of magnetic flux density (

B) along the axis of the magnetic core while core magnetization and sensor excitation are fulfilled. To investigate design diversity of the copper excitation coils, the following parameters are modulated for simulations: (1) metal wire width = 0.1–0.5 mm with a 0.1 mm interval; (2) metal wire gap = 0.1–0.5 mm with a 0.1 mm interval; and (3) excitation current = 0.1–0.5 A with a 0.1 A interval. Next, some key constants and variables are given: (1) Cu metal resistivity = 17 μΩ-m; (2) core (2714 A) permeability = 80,000 H/m; and (3) core length (single rod) = 40 mm and core width = 2 mm. It can be seen that numerous simulations were carried out by a combination order, and one can acquire the induction trend excited by the excitation coils. For example, assuming a uniform excitation current through the coils, one of the series simulation results provided in

Figure 4 indicates the theoretical magnetic flux density along the core length with respect to various Cu metal wire width from 0.1 mm to 0.5 mm when metal wire gap is 0.1 mm and excitation current is 0.5 A. From the comprehensive simulations, it is reveled that the maximum value of magnetic flux density appears to occur near the middle position of the half-core, and the influence of various metal wire gaps on the magnetic flux density can be trivial. Thus, by considering the overall sensor dimensions and PCB processing feasibility, the miniature fluxgate is fabricated to have an excitation coils with 0.35 mm in wire gap as well as wire width for further device analysis later.

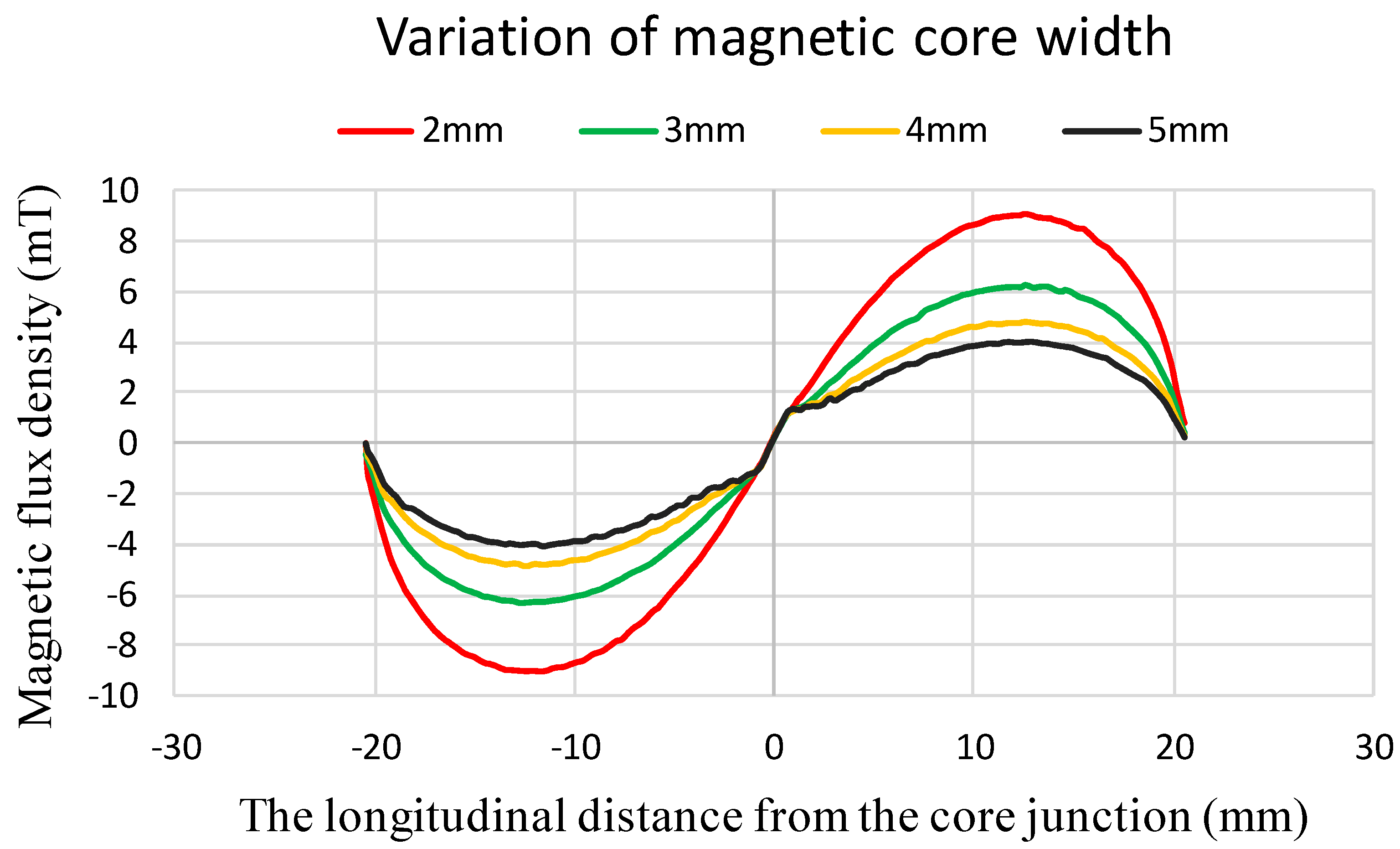

Also, based on the resultant parametric settings, we survey magnetic flux density along the longitudinal distance of the magnetic core

vs. various ferromagnetic core width designs. Therefore, as shown in

Figure 5, its shown that the theoretical magnetic flux density in the interior of core along the longitudinal direction is relatively decreased when the core width is increased from 2 mm to 5 mm. Apparently, the variation of core width is related to the cross-sectional area and demagnetization effect of the core geometry, and by referring to Equation (1), the simulation results also make it evident that the demagnetization factor is probably more dominant in improving the device responsivity.

Figure 4.

The theoretical magnetic flux density along the magnetic core vs. the distance from the core junction with respect to various wire width.

Figure 4.

The theoretical magnetic flux density along the magnetic core vs. the distance from the core junction with respect to various wire width.

Figure 5.

The theoretical magnetic flux density along the longitudinal core vs. the distance from the core junction with respect to various core width.

Figure 5.

The theoretical magnetic flux density along the longitudinal core vs. the distance from the core junction with respect to various core width.

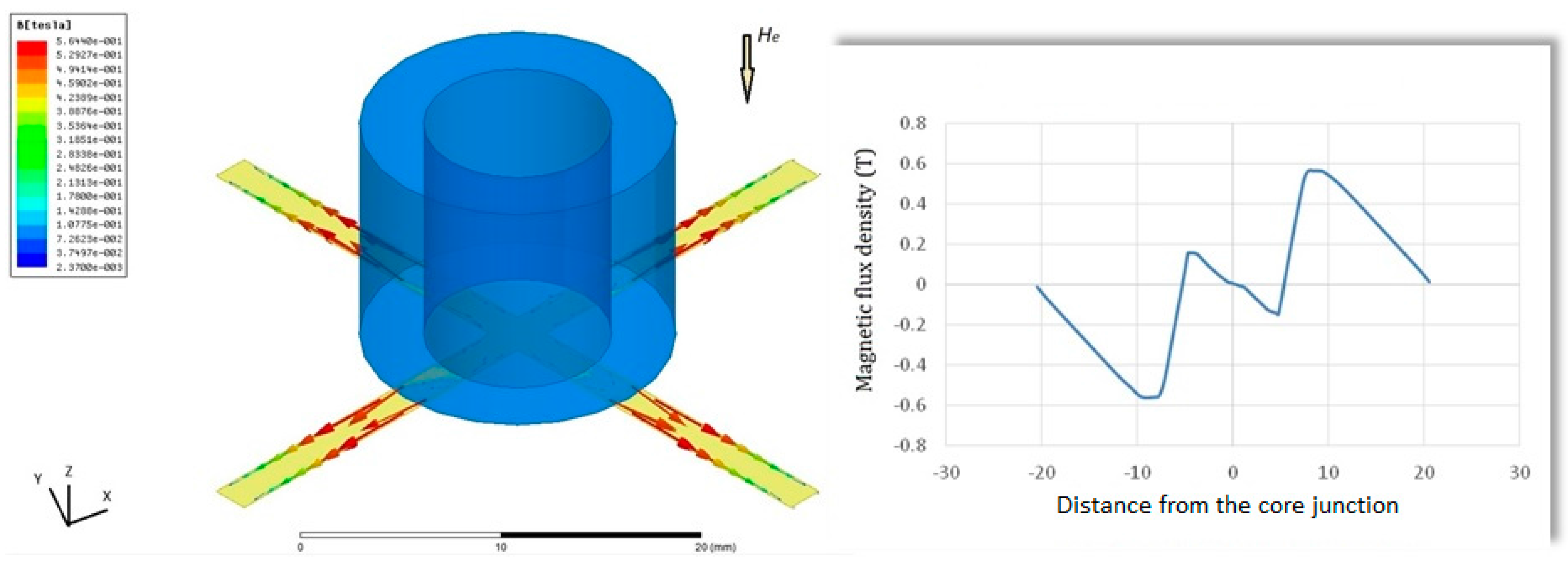

Afterward, a 3-D model example of the planar excitation coils with a 2-mm cruciform ferromagnetic core, as shown in

Figure 6, is accordingly built and analyzed. For electromagnetic excitation and core magnetization, an excitation current of 0.5 A and the

B-H loop data of the core material are employed, and it is found that the excitation coils are easily able to achieve the magnetic saturation of the core employed (>10 µT). Again the location of maximum flux density is approximately close to the middle position of the half-core in X- or Y-sensing orientation, which is feasible for in-plane detection. In addition, to measure the orthogonal Z-axis fields, another ultimate design including the planar excitation coils with a cruciform core and a ferrite fluxguide tube, as given in

Figure 7, is then analyzed under a 40 A/m magnetic field along Z-axis. One can observe that a linear distribution of magnetic flux density in the core rises from the inner diameter (

i.e., ±4.5 mm) to the outer diameter (

i.e., ±8 mm) and reaches the maximum value of 0.56 T, yet, beyond that point, the magnetic flux density is linearly decreased to zero with the increased longitudinal distance till the end of the core. The orthogonal flux vectors guided into the in-plane core, even though not all of them, can be easily measured by switching to the Z-axis sensing mode. According to the simulated result, it is also promising to elevate the variation of magnetic flux density,

i.e., the responsivity, within the sensing area of a pick-up coils simply by placing a larger cylindrical fluxguide tube close to the end of the core. From the manufacturing point of view, the proposed simple structure is particularly considered superior to those complicated 3-D devices using traditionally monolithic or assembly methods employed before.

Figure 6.

A 3-D model of a planar excitation coils and its simulated result with a 2-mm cruciform ferromagnetic core under the excitation current of 5 A.

Figure 6.

A 3-D model of a planar excitation coils and its simulated result with a 2-mm cruciform ferromagnetic core under the excitation current of 5 A.

Figure 7.

A 3-D modeling and simulation result of a tri-axis planar device with a 2-mm cruciform ferromagnetic core and a fluxguide (left); The variation of magnetic flux density along the core is also available and the magnetic fields in Z-axis is 40 A/m (right).

Figure 7.

A 3-D modeling and simulation result of a tri-axis planar device with a 2-mm cruciform ferromagnetic core and a fluxguide (left); The variation of magnetic flux density along the core is also available and the magnetic fields in Z-axis is 40 A/m (right).