Formation of High-Purity Indium Oxide Nanoparticles and Their Application to Sensitive Detection of Ammonia

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Method

3. Results and Discussion

3.1. Solution Compositions

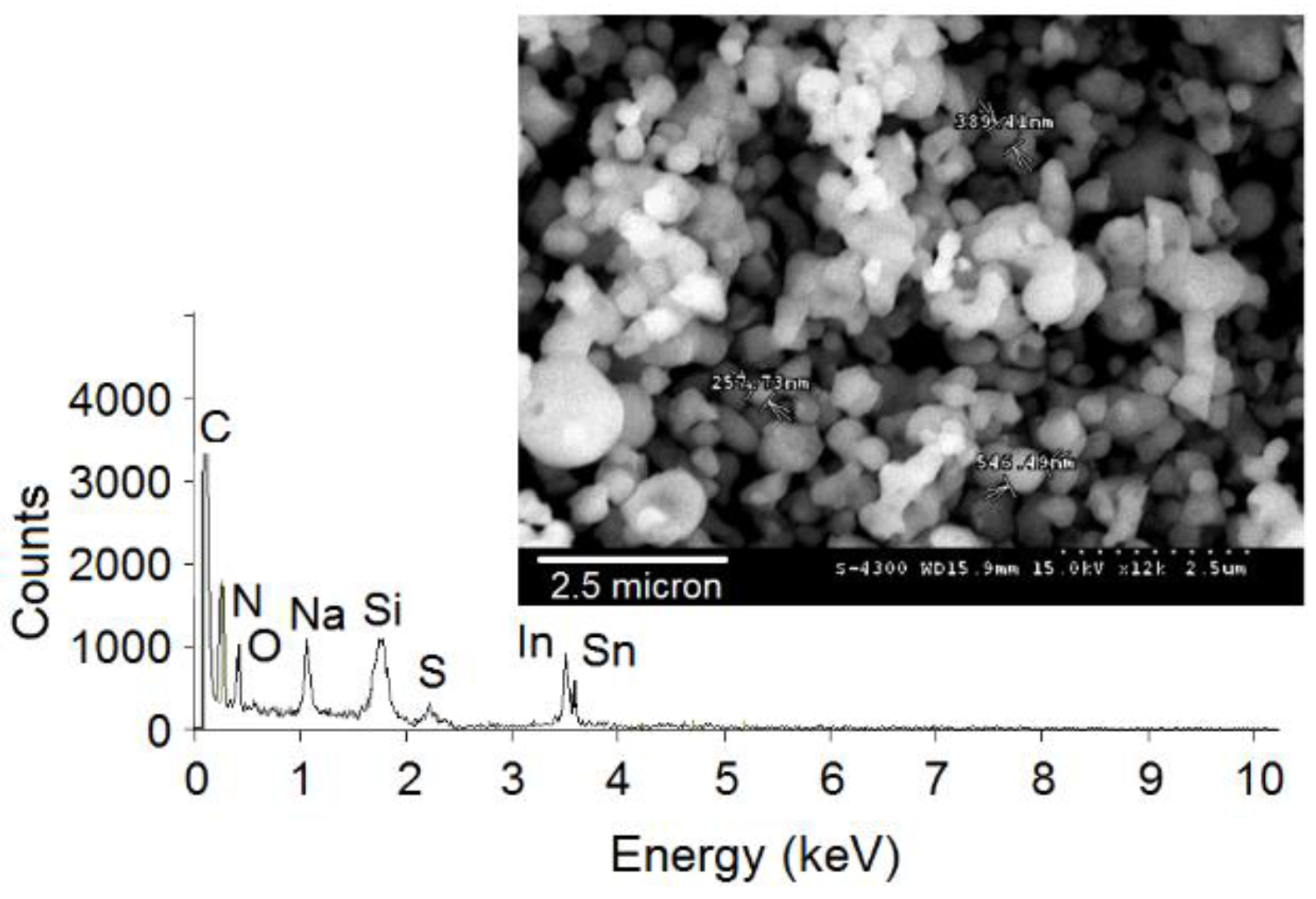

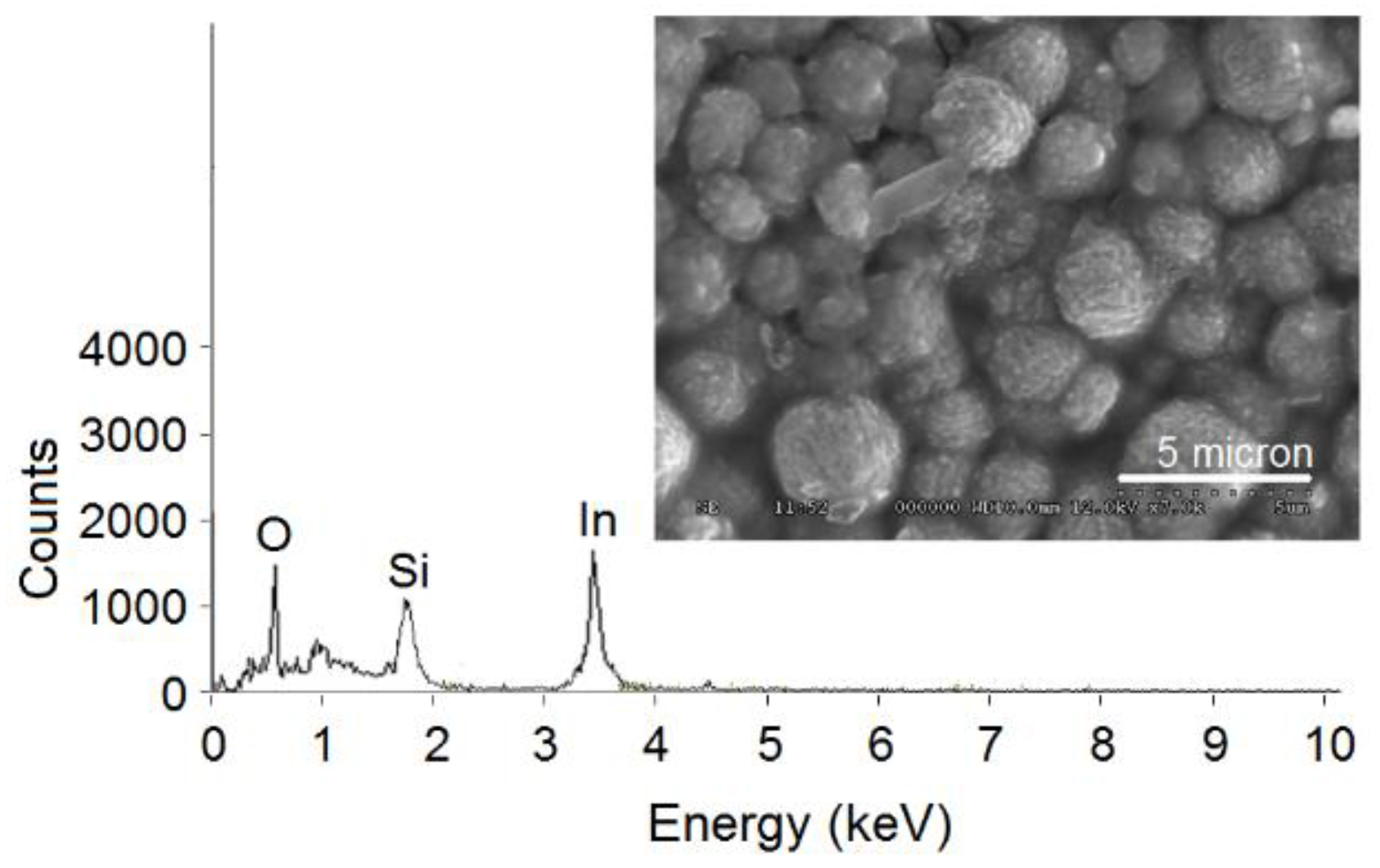

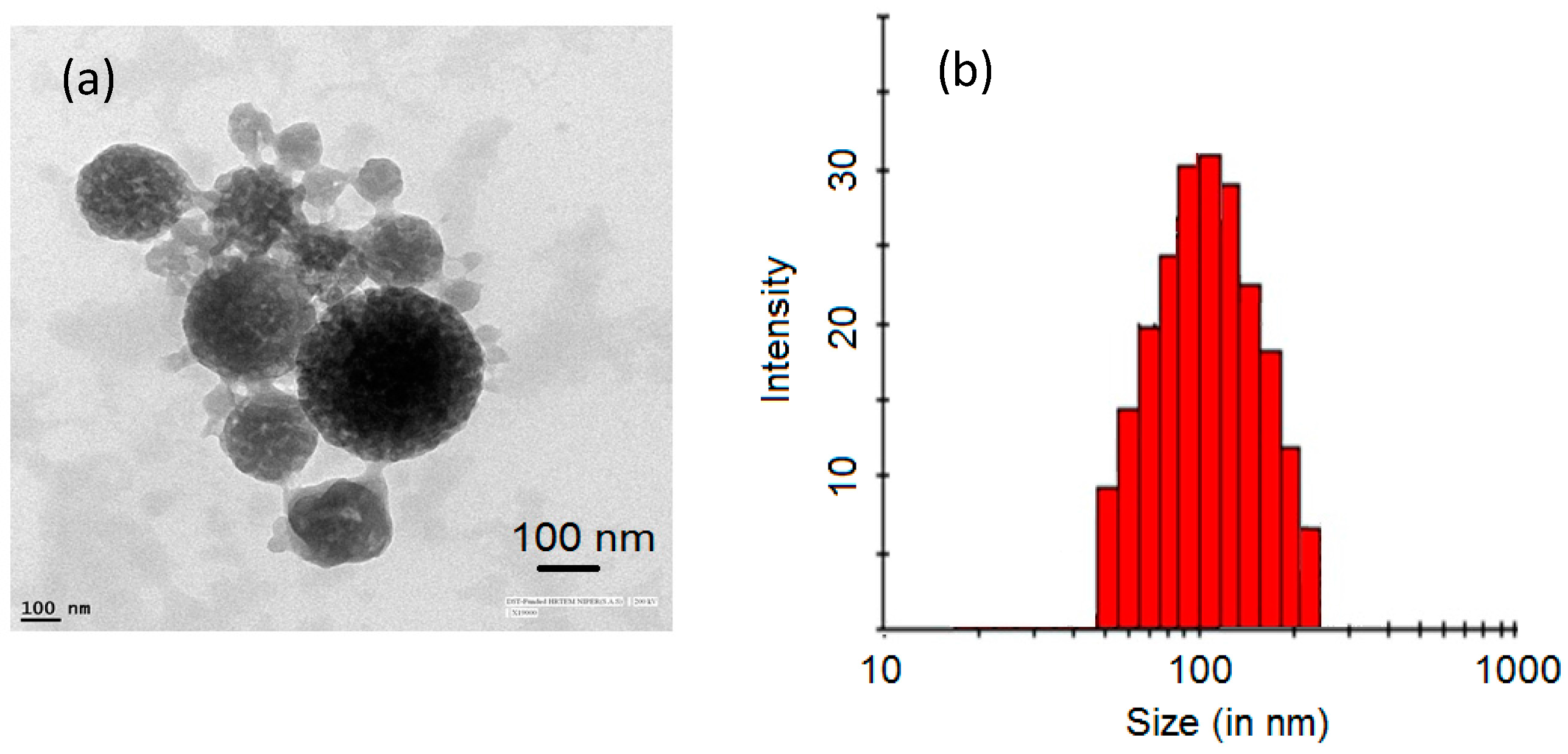

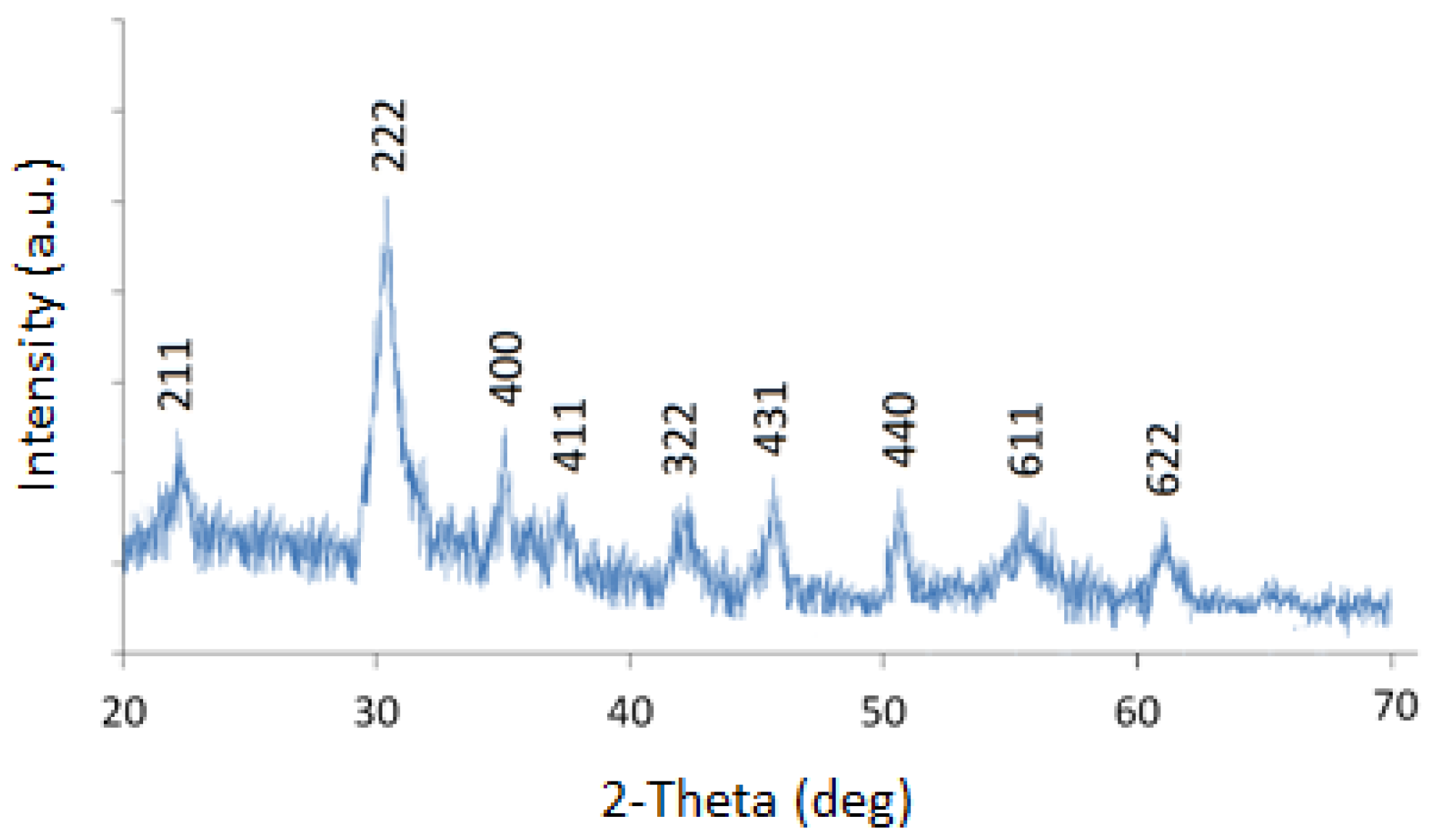

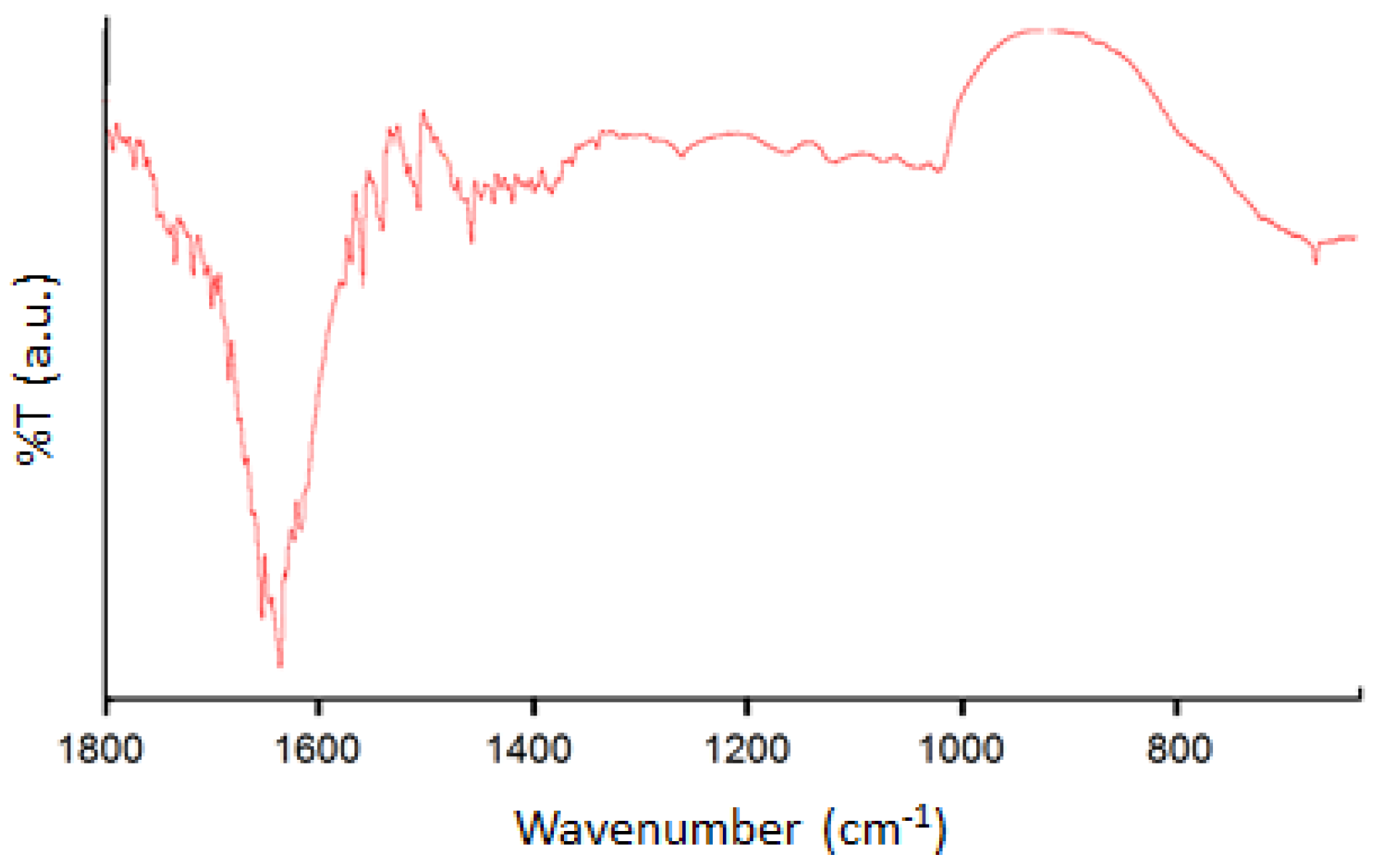

3.2. Characterization of In2O3 Nanoparticles

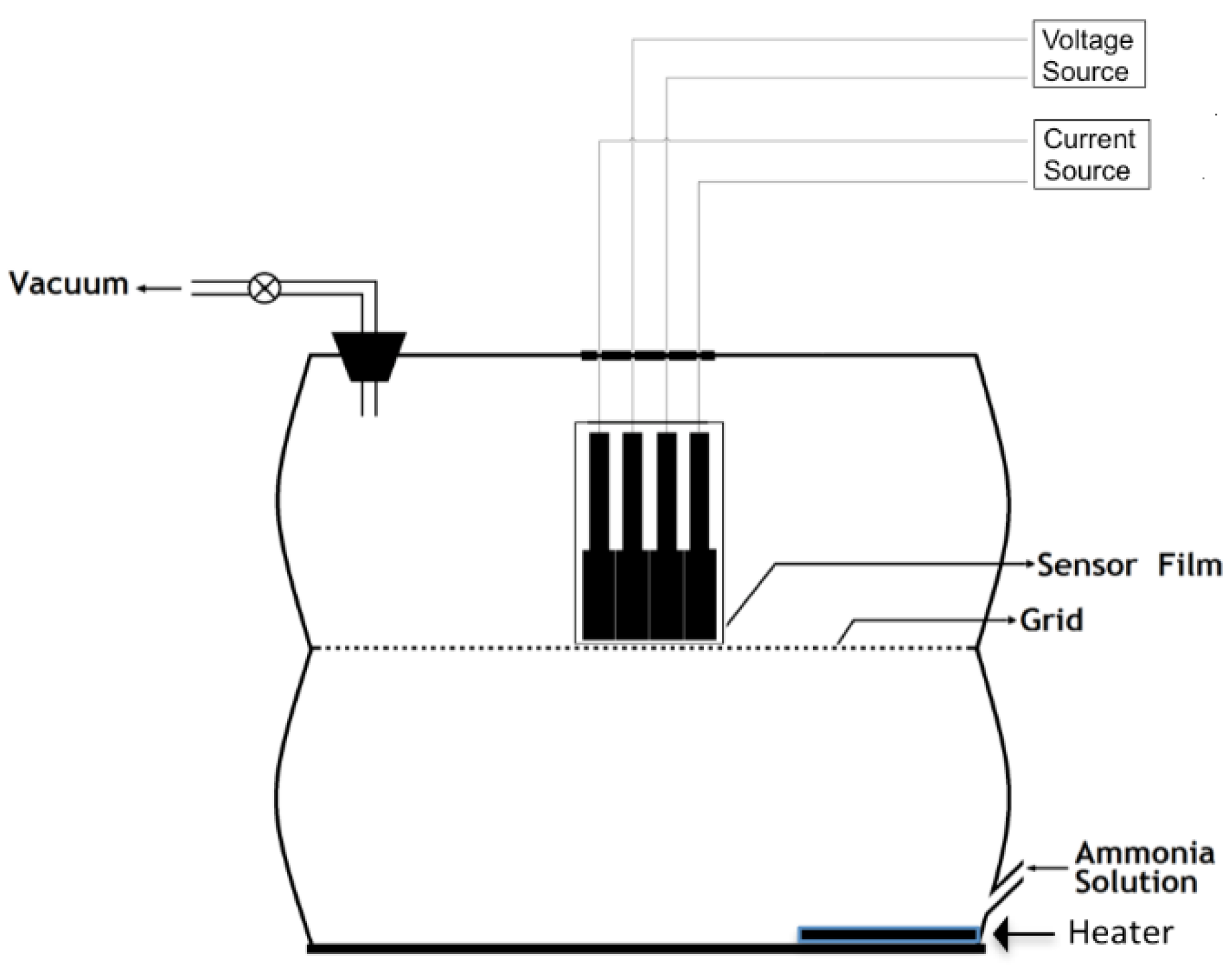

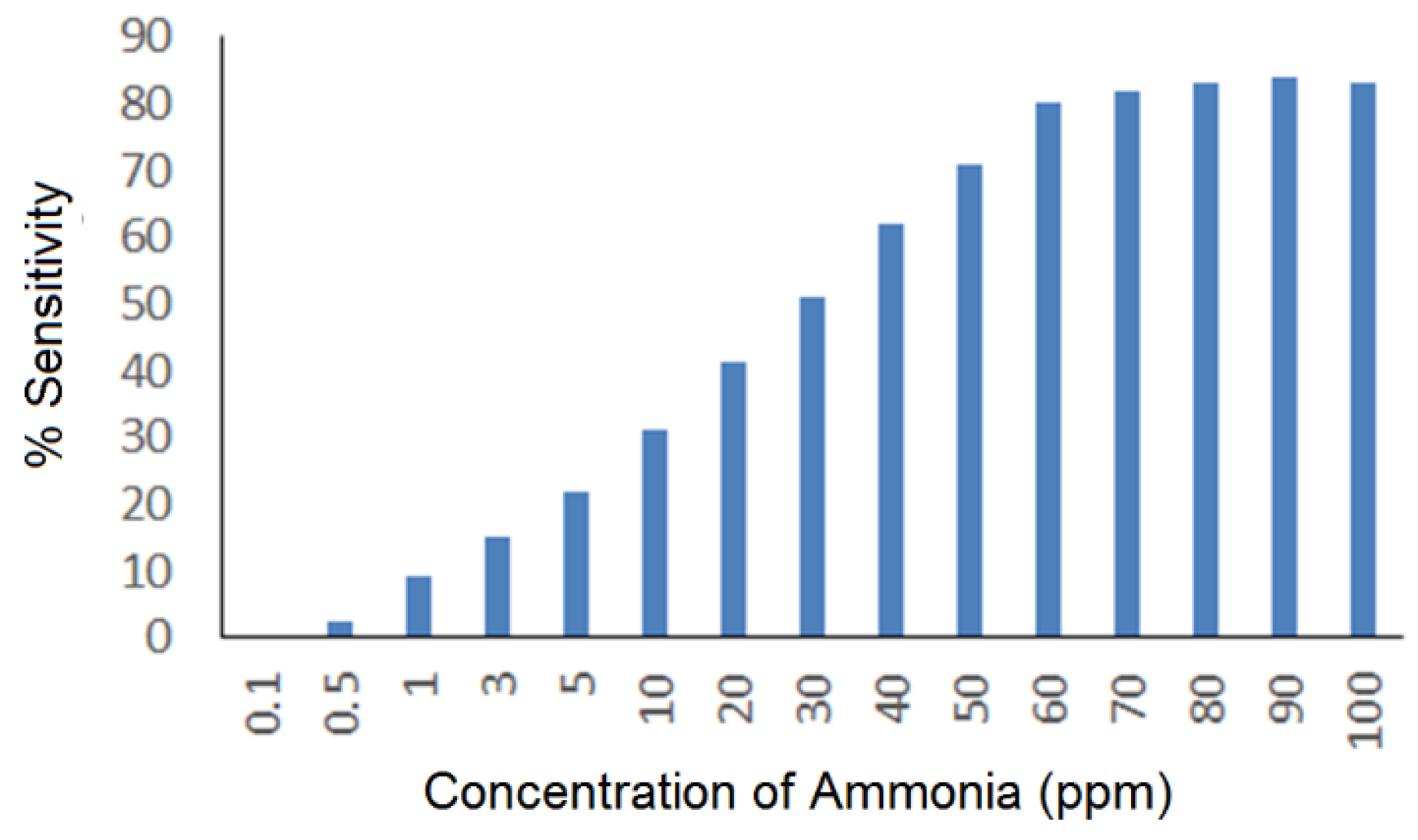

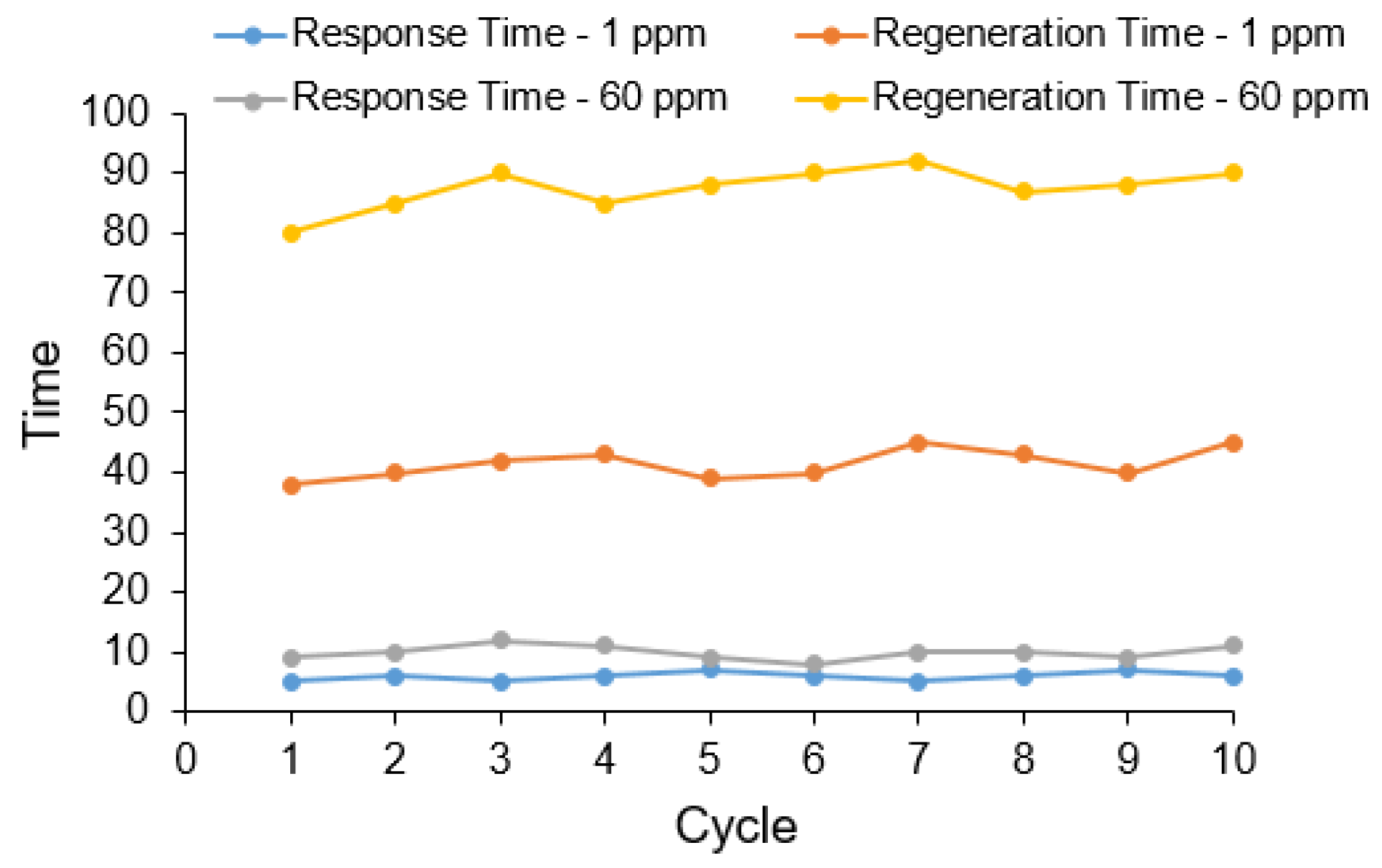

3.3. Use of In2O3 Nanoparticles for Ammonia Sensing

| Concentration of NH3 | Parameters Observed for Material Calcined at 500 °C | Parameters Observed for Material Calcined at 700 °C | ||||

|---|---|---|---|---|---|---|

| Sensitivity | Response Time | Recovery Time | Sensitivity | Response Time | Recovery Time | |

| 5 ppm | 22 ± 2% | 10 ± 4 | 50 ± 10 | 25 ± 2% | 8 ± 4 | 40 ± 6 |

| 60 ppm | 78 ± 3% | 10 ± 4 | 100 ± 10 | 85 ± 4% | 10 ± 4 | 85 ± 10 |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- George, P.P.; Gedanken, A. Synthesis, Characterization, and Photoluminescence Properties of In2O3 Nanocrystals Encapsulated by Carbon Vesicles and Neat In2O3 Nanocrystals Generated by the RAPET Technique. Eur. J. Inorg. Chem. 2008, 2008, 919–924. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, Z.; Li, C.; Tang, T.; Liu, X.; Han, S.; Lei, B.; Zhou, C. Detection of NO2 down to ppb Levels Using Individual and Multiple In2O3 Nanowire Devices. Nano Lett. 2004, 4, 1919–1924. [Google Scholar] [CrossRef]

- Cui, J.; Wang, A.; Edleman, N.L.; Ni, J.; Lee, P.; Armstrong, N.R.; Marks, T.J. Indium Tin Oxide Alternatives—High Work Function Transparent Conducting Oxides as Anodes for Organic Light-Emitting Diodes. Adv. Mater. 2001, 13, 1476–1480. [Google Scholar] [CrossRef]

- Zhao, P.; Huang, T.; Huang, K. Fabrication of Indium Sulfide Hollow Spheres and Their Conversion to Indium Oxide Hollow Spheres Consisting of Multipore Nanoflakes. J. Phys. Chem. C 2007, 111, 12890–12897. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, D.; Han, S.; Li, C.; Tang, T.; Jin, W.; Liu, X.; Lei, B.; Zhou, C. Laser Ablation Synthesis and Electron Transport Studies of Tin Oxide Nanowires. Adv. Mater. 2003, 15, 1754–1757. [Google Scholar] [CrossRef]

- Shinde, D.V.; Ahn, D.Y.; Jadhav, V.V.; Lee, D.Y.; Shrestha, N.K.; Lee, J.K.; Lee, H.W.; Maneb, R.S.; Han, S.-H. A coordination chemistry approach for shape controlled synthesis of indium oxide nanostructures and their photoelectrochemical properties. J. Mater. Chem. A 2014, 2, 5490–5498. [Google Scholar] [CrossRef]

- Zheng, M.; Zhang, L.; Zhang, X.; Zhang, J.; Li, G. Fabrication and optical absorption of ordered indium oxide nanowire arrays embedded in anodic alumina membranes. Chem. Phys. Lett. 2001, 334, 298–302. [Google Scholar] [CrossRef]

- Dai, Z.R.; Pan, Z.W.; Wang, Z.L. Novel Nanostructures of Functional Oxides Synthesized by Thermal Evaporation. Adv. Funct. Mater. 2003, 13, 9–24. [Google Scholar] [CrossRef]

- Li, B.; Xie, Y.; Jing, M.; Rong, G.; Tang, Y.; Zhang, G. In2O3 Hollow Microspheres: Synthesis from Designed In(OH)3 Precursors and Applications in Gas Sensors and Photocatalysis. Langmuir 2006, 22, 9380–9385. [Google Scholar] [CrossRef] [PubMed]

- Tseng, W.J.; Tseng, T.-T.; Wu, H.-M.; Her, Y.-C.; Yang, T.-J. Facile Synthesis of Monodispersed In2O3 Hollow Spheres and Application in Photocatalysis and Gas Sensing. J. Am. Ceram. Soc. 2013, 96, 719–725. [Google Scholar] [CrossRef]

- Kim, S.-J.; Hwang, I.-S.; Choi, J.-K.; Kang, Y.C.; Lee, J.-H. Enhanced C2H5OH sensing characteristics of nano-porous In2O3 hollow spheres prepared by sucrose-mediated hydrothermal reaction. Sens. Actuators B Chem. 2011, 155, 512–518. [Google Scholar] [CrossRef]

- Hyodo, T.; Inoue, H.; Motomura, H.; Matsuo, K.; Hashishin, T.; Tamaki, J.; Shimizu, Y.; Egashira, M. NO2 sensing properties of macroporous In2O3-based powders fabricated by utilizing ultrasonic spray pyrolysis employing polymethylmethacrylate microspheres as a template. Sens. Actuators B Chem. 2010, 151, 265–273. [Google Scholar] [CrossRef]

- Zhao, H.; Dong, H.; Zhang, L.; Wang, X.; Yang, H. Controlled synthesis and photocatalytic properties of porous hollow In2O3 microcubes with different sizes. Mater. Chem. Phys. 2011, 130, 921–931. [Google Scholar] [CrossRef]

- Jiang, H.; Zhao, L.; Gai, L.; Ma, L.; Maa, Y.; Lib, M. Hierarchical rh-In2O3 crystals derived from InOOH counterparts and their sensitivity to ammonia gas. Cryst. Eng. Comm. 2013, 15, 7003–7009. [Google Scholar] [CrossRef]

- Bal, A.K.; Singh, A.; Bedi, R.K. Characterization and room temperature sensing of ammonia and ethanol by thermally oxidized indium films. Phys. B 2010, 405, 3124–3128. [Google Scholar]

- Guo, P.; Pan, H. Selectivity of Ti-doped In2O3 ceramics as an ammonia sensor. Sens. Actuators B 2006, 114, 762–767. [Google Scholar] [CrossRef]

- Shen, X.; Li, L.; Wu, Z.; Lü, H.; Lü, J. Ultrasonic-Assisted Acid Leaching of Indium from Blast Furnace Sludge. Metall. Mater Trans. B 2013, 44, 1324–1328. [Google Scholar] [CrossRef]

- Hasegawa, H.; Rahman, I.M.M.; Umehara, Y.; Sawai, H.; Maki, T.; Furusho, Y.; Mizutani, S. Selective recovery of indium from the etching waste solution of the flat-panel display fabrication process. Microchem. J. 2013, 110, 133–139. [Google Scholar] [CrossRef]

- Hsieh, S.-J.; Chen, C.-C.; Say, W.C. Process for recovery of indium from ITO scraps and metallurgic microstructures. Mater. Sci. Eng. B 2009, 158, 82–87. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Z.; Li, Q.; Liu, Z.; Zeng, L. Recovery of indium from used indium-tin oxide (ITO) targets. Hydrometallurgy 2011, 105, 207–212. [Google Scholar] [CrossRef]

- Virolainen, S.; Ibana, D.; Paatero, E. Recovery of indium from indium tin oxide by solvent extraction. Hydrometallurgy 2011, 107, 56–61. [Google Scholar] [CrossRef]

- Gupta, B.; Deep, A.; Malik, P. Liquid–liquid extraction and recovery of indium using Cyanex 923. Anal. Chim. Acta 2004, 513, 463–471. [Google Scholar] [CrossRef]

- Liu, G. Synthesis, characterization of In2O3 nanocrystals and their photoluminescence property. Inter. J. Electrochem. Sci. 2011, 6, 2162–2170. [Google Scholar]

- Yuan, Z.; Zhang, J.; Liu, G. Synthesis of In2O3 nanocrystals via hydro/solvothermal route and their photoluminescence properties. Inter. J. Electrochem. Sci. 2013, 8, 1794–1801. [Google Scholar]

- Souza, E.C.C.; Rey, J.F.Q.; Muccillo, E.N.S. Synthesis and characterization of spherical and narrow size distribution indium oxide nanoparticles. Appl. Sur. Sci. 2009, 255, 3779–3783. [Google Scholar] [CrossRef]

- Nizhnik, O.; Higuchi, K.; Maenaka, K. Self-calibrated humidity sensor in CMOS without post-processing. Sensors 2012, 12, 226–232. [Google Scholar] [CrossRef] [PubMed]

- Konvalina, G.; Haick, H. Effect of humidity on nanoparticle-based chemiresistors: a comparison between synthetic and real-world samples. Appl. Mater. Interfaces 2012, 4, 317–325. [Google Scholar] [CrossRef] [PubMed]

- Shehada, N.; Brönstrup, G.; Funka, K.; Christiansen, S.; Leja, M.; Haick, H. Ultrasensitive silicon nanowire for real-world gas sensing: noninvasive diagnosis of cancer from breath volatolome. Nano Lett. 2015, 15, 1288–1295. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Cancilla, J.C.; Torrecilla, J.S.; Haick, H. Artificial sensing intelligence with silicon nanowires for ultraselective detection in the gas phase. Nano Lett. 2014, 14, 933–938. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhardwaj, S.K.; Bhardwaj, N.; Kukkar, M.; Sharma, A.L.; Kim, K.-H.; Deep, A. Formation of High-Purity Indium Oxide Nanoparticles and Their Application to Sensitive Detection of Ammonia. Sensors 2015, 15, 31930-31938. https://doi.org/10.3390/s151229895

Bhardwaj SK, Bhardwaj N, Kukkar M, Sharma AL, Kim K-H, Deep A. Formation of High-Purity Indium Oxide Nanoparticles and Their Application to Sensitive Detection of Ammonia. Sensors. 2015; 15(12):31930-31938. https://doi.org/10.3390/s151229895

Chicago/Turabian StyleBhardwaj, Sanjeev K., Neha Bhardwaj, Manil Kukkar, Amit L. Sharma, Ki-Hyun Kim, and Akash Deep. 2015. "Formation of High-Purity Indium Oxide Nanoparticles and Their Application to Sensitive Detection of Ammonia" Sensors 15, no. 12: 31930-31938. https://doi.org/10.3390/s151229895