Fabrication of Activated Carbon Decorated with ZnO Nanorod-Based Electrodes for Desalination of Brackish Water Using Capacitive Deionization Technology

Abstract

1. Introduction

2. Results and Discussions

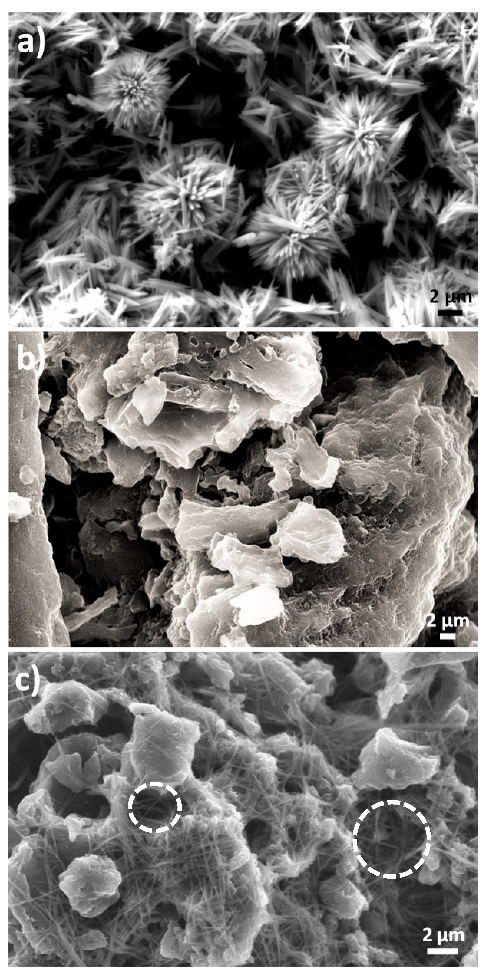

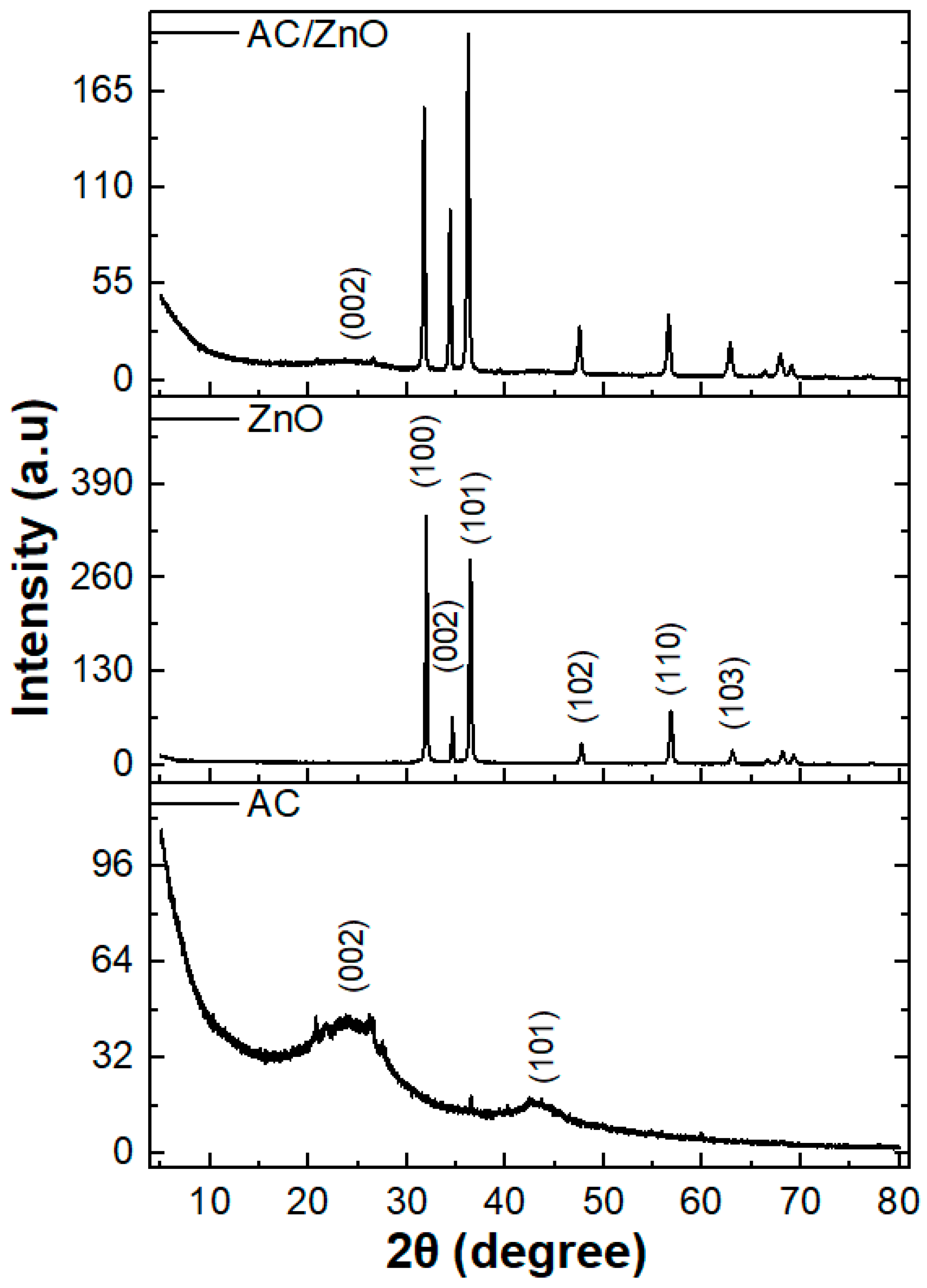

2.1. SEM and DRX Characterization

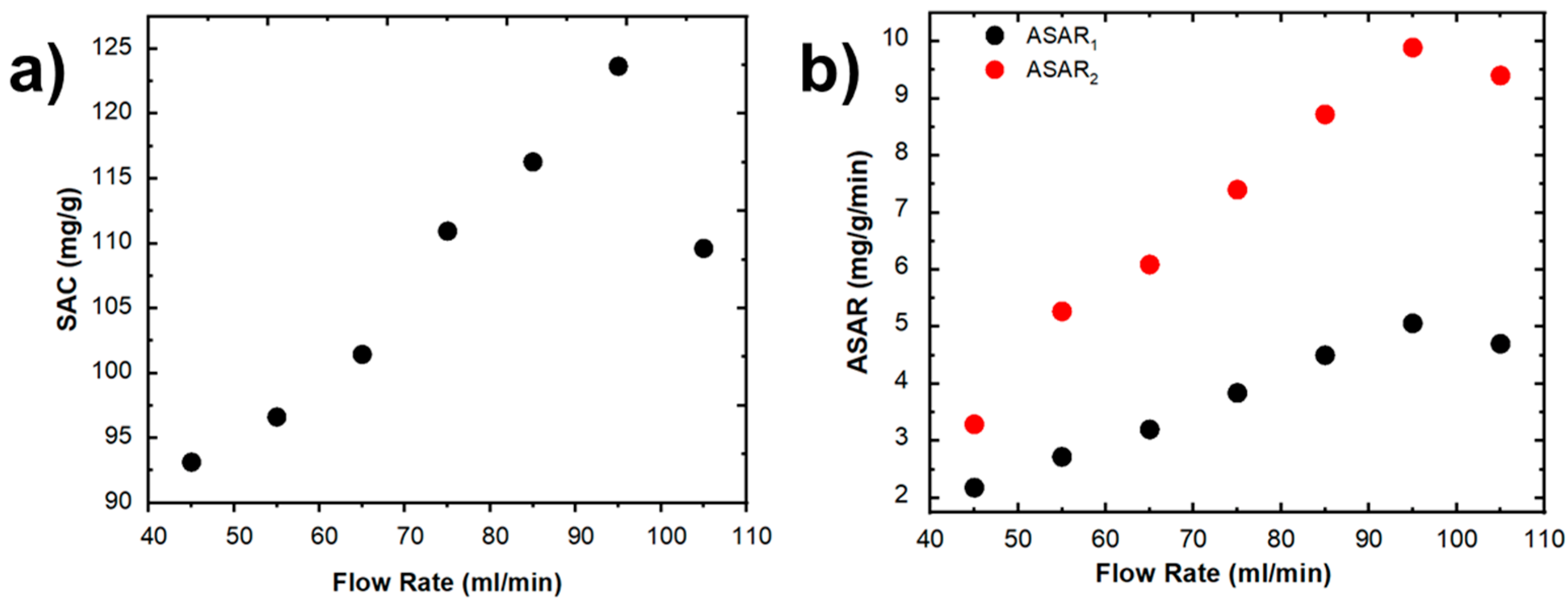

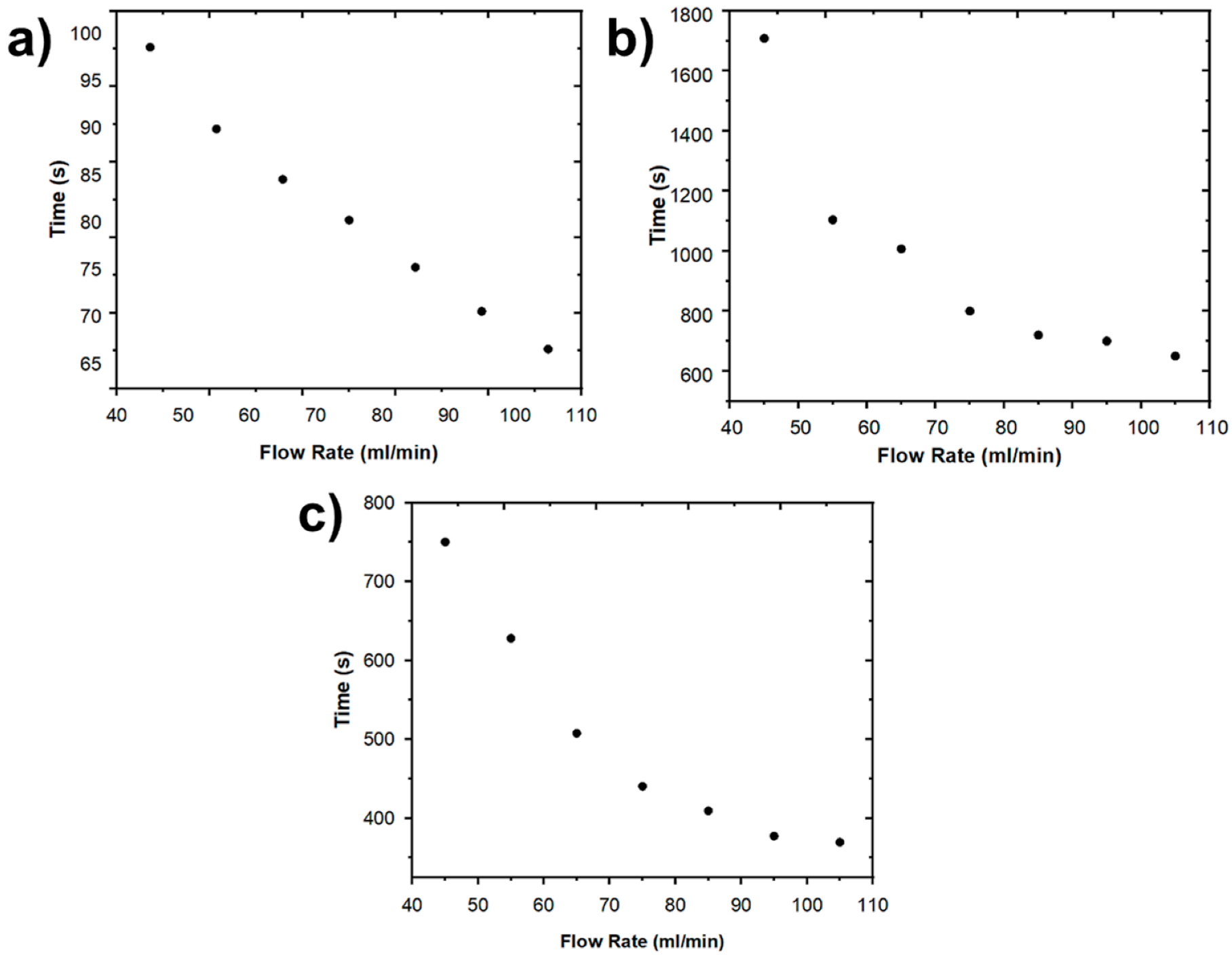

2.2. Cell Performance

2.3. Specific Energy Consumption

2.4. Gibbs Free Energy of Separation

3. Materials and Methods

3.1. Materials

3.2. Synthesis of ZnO Nanostructures

3.3. Fabrication of the Electrode

3.4. Fabrication of CDI Cell

3.5. Electrochemical Setup

3.6. Characterization Techniques

3.7. CDI Measurements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xing, W.; Liang, J.; Tang, W.; He, D.; Yan, M.; Wang, X.; Luo, Y.; Tang, N.; Huang, M. Versatile applications of capacitive deionization (CDI)-based technologies. Desalination 2020, 482, 114390. [Google Scholar] [CrossRef]

- Elsaid, K.; Kamil, M.; Sayed, E.T.; Abdelkareem, M.A.; Wilberforce, T.; Olabi, A. Environmental impact of desalination technologies: A review. Sci. Total Environ. 2020, 748, 141528. [Google Scholar] [CrossRef]

- Gamaethiralalage, J.G.; Singh, K.; Sahin, S.; Yoon, J.; Elimelech, M.; Suss, M.E.; Liang, P.; Biesheuvel, P.M.; Zornitta, R.L.; De Smet, L.C.P.M. Recent advances in ion selectivity with capacitive deionization. Energy Environ. Sci. 2021, 14, 1095–1120. [Google Scholar] [CrossRef]

- Zhang, X.; Zuo, K.; Zhang, X.; Zhang, C.; Liang, P. Selective ion separation by capacitive deionization (CDI) based technologies: A state-of-the-art review. Environ. Sci. Water Res. Technol. 2020, 6, 243–257. [Google Scholar] [CrossRef]

- Suss, M.E.; Porada, S.; Sun, X.; Biesheuvel, P.M.; Yoon, J.; Presser, V. Water desalination via capacitive deionization: What is it and what can we expect from it? Energy Environ. Sci. 2015, 8, 2296–2319. [Google Scholar] [CrossRef]

- Smith, K.C.; Dmello, R. Na-Ion Desalination (NID) Enabled by Na-Blocking Membranes and Symmetric Na-Intercalation: Porous-Electrode Modeling. J. Electrochem. Soc. 2016, 163, A530. [Google Scholar] [CrossRef]

- Yasin, A.S.; Mohamed, H.O.; Mohamed, I.M.A.; Mousa, H.M.; Barakat, N.A.M. Enhanced desalination performance of capacitive deionization using zirconium oxide nanoparticles-doped graphene oxide as a novel and effective electrode. Sep. Purif. Technol. 2016, 171, 34–43. [Google Scholar] [CrossRef]

- Singh, K.; Porada, S.; De Gier, H.D.; Biesheuvel, P.M.; De Smet, L.C.M.P. Timeline on the application of intercalation materials in Capacitive Deionization. Desalination 2019, 455, 115–134. [Google Scholar] [CrossRef]

- Liu, Y.; Nie, C.; Liu, X.; Xu, X.; Sun, Z.; Pan, L. Review on carbon-based composite materials for capacitive deionization. RSC Adv. 2015, 5, 15205–15225. [Google Scholar] [CrossRef]

- Oladunni, J.; Zain, J.H.; Hai, A.; Banat, F.; Bharath, G.; Alhseinat, E. A comprehensive review on recently developed carbon based nanocomposites for capacitive deionization: From theory to practice. Sep. Purif. Technol. 2018, 207, 291–320. [Google Scholar] [CrossRef]

- Thamilselvan, A.; Nesaraj, A.S.; Noel, M. Review on carbon-based electrode materials for application in capacitive deionization process. Int. J. Environ. Sci. Technol. 2016, 13, 2961–2976. [Google Scholar] [CrossRef]

- Folaranmi, G.; Bechelany, M.; Sistat, P.; Cretin, M.; Zaviska, F. Comparative Investigation of Activated Carbon Electrode and a Novel Activated Carbon/Graphene Oxide Composite Electrode for an Enhanced Capacitive Deionization. Materials 2020, 13, 5185. [Google Scholar] [CrossRef] [PubMed]

- Xie, J.; Ma, J.; Wu, L.; Xu, M.; Ni, W.; Yan, Y.M. Carbon nanotubes in-situ cross-linking the activated carbon electrode for high-performance capacitive deionization. Sep. Purif. Technol. 2020, 239, 116593. [Google Scholar] [CrossRef]

- Kyaw, H.H.; Al-Mashaikhi, S.M.; Myint, M.T.Z.; Al-Harthi, S.; El-Shafey, E.S.I.; Al-Abri, M. Activated carbon derived from the date palm leaflets as multifunctional electrodes in capacitive deionization system. Chem. Eng. Process 2021, 161, 108311. [Google Scholar] [CrossRef]

- Yeh, C.L.; Hsi, H.C.; Li, K.C.; Hou, C.H. Improved performance in capacitive deionization of activated carbon electrodes with a tunable mesopore and micropore ratio. Desalination 2015, 367, 60–68. [Google Scholar] [CrossRef]

- Ahmed, M.A.; Tewari, S. Capacitive deionization: Processes, materials and state of the technology. J. Electroanal. Chem. 2018, 813, 178–192. [Google Scholar] [CrossRef]

- Yasin, A.S.; Mohamed, A.Y.; Mohamed, I.M.A.; Cho, D.Y.; Park, C.H.; Kim, C.S. Theoretical insight into the structure-property relationship of mixed transition metal oxides nanofibers doped in activated carbon and 3D graphene for capacitive deionization. Chem. Eng. J. 2019, 371, 166–181. [Google Scholar] [CrossRef]

- Yasin, A.S.; Kim, D.; Lee, K. One-pot synthesis of activated carbon decorated with ZnO nanoparticles for capacitive deionization application. J. Alloys Compd. 2021, 870, 159422. [Google Scholar] [CrossRef]

- Feng, J.; Xiong, S.; Wang, Y. Atomic layer deposition of TiO2 on carbon-nanotube membranes for enhanced capacitive deionization. Sep. Purif. Technol. 2019, 213, 70–77. [Google Scholar] [CrossRef]

- Yasin, A.S.; Mohamed, A.Y.; Kim, D.; Yoon, S.; Ra, H.; Lee, K. Efficiency Enhancement of Electro-Adsorption Desalination Using Iron Oxide Nanoparticle-Incorporated Activated Carbon Nanocomposite. Micromachines 2021, 12, 1148. [Google Scholar] [CrossRef]

- Jaoude, M.A.; Alhseinat, E.; Polychronopoulou, K.; Bharath, G.; Farouq, I.; Darawsheh, F.; Anwer, S.; Baker, M.A.; Hinder, S.J.; Banat, F. Morphology-dependent electrochemical performance of MnO2 nanostructures on graphene towards efficient capacitive deionization. Electrochim. Acta 2020, 330, 135202. [Google Scholar] [CrossRef]

- Myint, M.T.Z.; Al-Harthi, S.H.; Dutta, J. Brackish water desalination by capacitive deionization using zinc oxide micro/nanostructures grafted on activated carbon cloth electrodes. Desalination 2014, 344, 236–242. [Google Scholar] [CrossRef]

- Ramos, P.G.; Sánchez, L.A.; Rodriguez, J.M. A review on improving the efficiency of photocatalytic water decontamination using ZnO nanorods. J. Sol-Gel Sci. Technol. 2022, 102, 105–124. [Google Scholar] [CrossRef]

- Vasei, H.V.; Masoudpanah, S.M.; Habibollahzadeh, M. Different morphologies of ZnO via solution combustion synthesis: The role of fuel. Mater. Res. Bull. 2020, 125, 110784. [Google Scholar] [CrossRef]

- Peter, I.J.; Praveen, E.; Vignesh, G.; Nithiananthi, P. ZnO nanostructures with different morphology for enhanced photocatalytic activity. Mater. Res. Express 2017, 4, 124003. [Google Scholar] [CrossRef]

- Liu, J.; Lu, M.; Yang, J.; Cheng, J.; Cai, W. Capacitive desalination of ZnO/activated carbon asymmetric capacitor and mechanism analysis. Electrochim. Acta 2015, 151, 312–318. [Google Scholar] [CrossRef]

- Younes, H.; Zou, L. Asymmetric configuration of pseudocapacitive composite electrodes for enhanced capacitive deionization. Environ. Sci. Water Res. Technol. 2020, 6, 392–403. [Google Scholar] [CrossRef]

- Al Suwaidi, F.; Younes, H.; Sreepal, V.; Nair, R.R.; Aubry, C.; Zou, L. Strategies for tuning hierarchical porosity of 3D rGO to optimize ion electrosorption. 2D Mater. 2019, 6, 04506. [Google Scholar] [CrossRef]

- Ferrone, E.; Araneo, R.; Notargiacomo, A.; Pea, M.; Rinaldi, A. ZnO Nanostructures and Electrospun ZnO–Polymeric Hybrid Nanomaterials in Biomedical, Health, and Sustainability Applications. Nanomaterials 2019, 9, 1449. [Google Scholar] [CrossRef]

- Ramos, P.G.; Luyo, C.; Sánchez, L.A.; Gomez, E.D.; Rodriguez, J.M. The Spinning Voltage Influence on the Growth of ZnO-rGO Nanorods for Photocatalytic Degradation of Methyl Orange Dye. Catalysts 2020, 10, 660. [Google Scholar] [CrossRef]

- Martinez, J.; Colán, M.; Catillón, R.; Huamán, J.; Paria, R.; Sánchez, L.; Rodríguez, J.M. Desalination Using the Capacitive Deionization Technology with Graphite/AC Electrodes: Effect of the Flow Rate and Electrode Thickness. Membranes 2022, 12, 717. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.; Dykstra, J.E.; Porada, S.; Van der Wal, A.; Yoon, J.; Biesheuvel, P.M. Enhanced charge efficiency and reduced energy use in capacitive deionization by increasing the discharge voltage. J. Colloid Interface Sci. 2015, 446, 317–326. [Google Scholar] [CrossRef] [PubMed]

- Singh, K.; Zhang, L.; Zuilhof, H.; De Smet, L.C.P.M. Water desalination with nickel hexacyanoferrate electrodes in capacitive deionization: Experiment, model and comparison with carbon. Desalination 2020, 496, 114647. [Google Scholar] [CrossRef]

- Hawks, S.A.; Knipe, J.M.; Campbell, P.G.; Loeb, C.K.; Hubert, M.A.; Santiago, J.G.; Stadermann, M. Quantifying the flow efficiency in constant-current capacitive deionization. Water Res. 2018, 129, 327–336. [Google Scholar] [CrossRef]

- Wang, L.; Dykstra, J.E.; Lin, S. Energy Efficiency of Capacitive Deionization. Environ. Sci. Technol. 2019, 53, 3366–3378. [Google Scholar] [CrossRef]

- Wang, L.; Biesheuvel, P.M.; Lin, S. Reversible thermodynamic cycle analysis for capacitive deionization with modified Donnan model. J. Colloid Interface Sci. 2018, 512, 522–528. [Google Scholar] [CrossRef]

- Hemmatifar, A.; Ramachandran, A.; Liu, K.; Oyarzun, D.I.; Bazant, M.Z.; Santiago, J.G. Thermodynamics of Ion Separation by Electrosorption. Environ. Sci. Technol. 2018, 52, 10196–10204. [Google Scholar] [CrossRef]

- Wirunmongkol, T.; O-Charoen, N.; Pavasupree, S. Simple Hydrothermal Preparation of Zinc Oxide Powders Using Thai Autoclave Unit. Energy Procedia 2013, 34, 801–807. [Google Scholar] [CrossRef]

- Maddah, H.A.; Shihon, M.A. Activated Carbon Cloth for Desalination of Brackish Water Using Capacitive Deionization. In Desalination and Water Treatment; IntechOpen: London, UK, 2018; Volume 10. [Google Scholar]

| ZnO Mass (g) | Measured Thickness (μm) | Specific Capacitance (F/g) |

|---|---|---|

| 3 | 104 | 67.6 |

| 5 | 102 | 109.4 |

| 7 | 101 | 124.7 |

| 9 | 99 | 135.7 |

| Flow Rate | SAC | ASAR1 | ASAR2 |

|---|---|---|---|

| (mL/min) | (mg/g) | mg/g/min | mg/g/min |

| 45 | 93.14 | 2.18 | 3.29 |

| 55 | 96.63 | 2.72 | 5.27 |

| 65 | 101.45 | 3.20 | 6.09 |

| 75 | 110.95 | 3.84 | 7.40 |

| 85 | 116.29 | 4.50 | 8.72 |

| 95 | 123.66 | 5.06 | 9.89 |

| 105 | 109.62 | 4.70 | 9.40 |

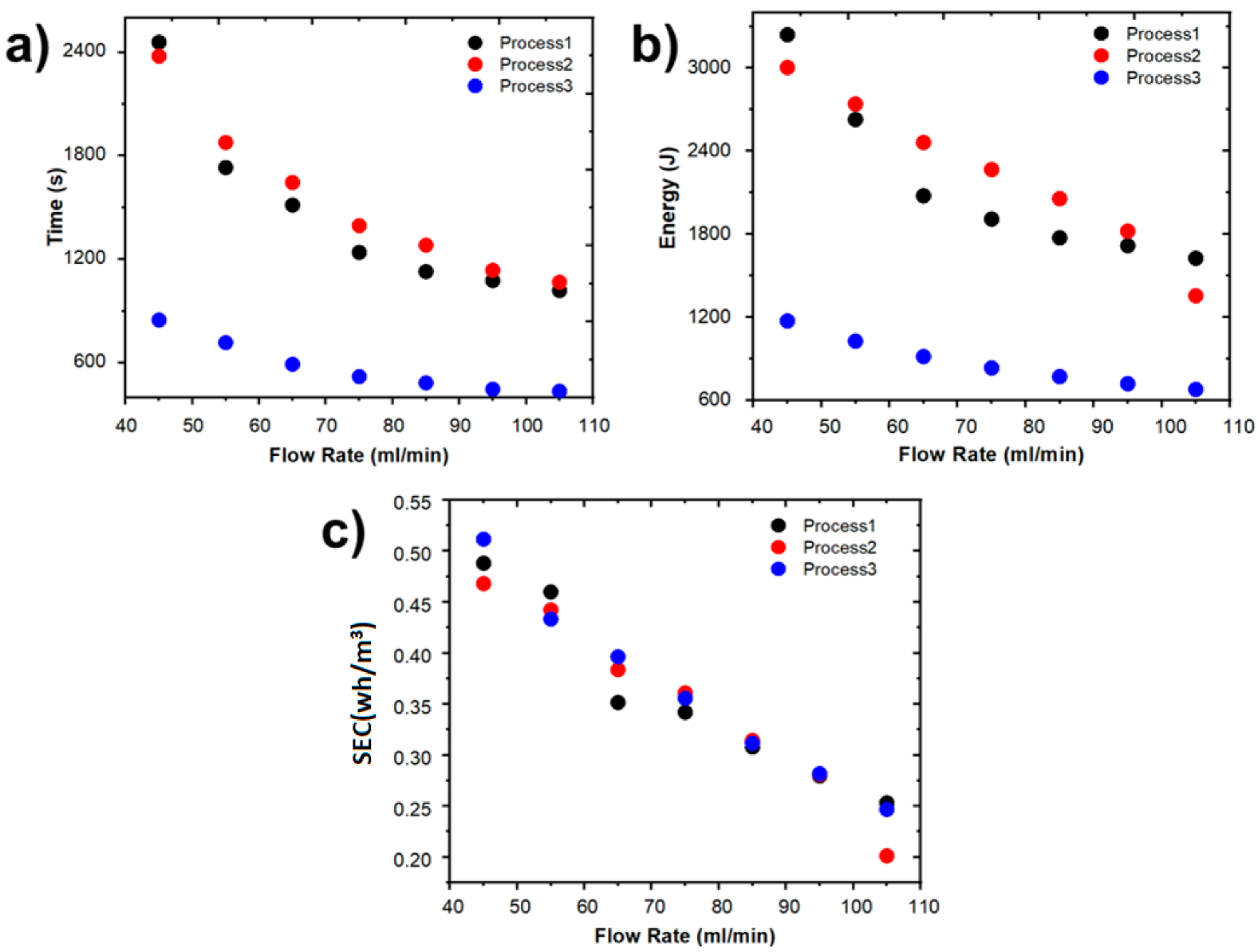

| Flow Rate | Process 1 | Process 2 | Process 3 | |||

|---|---|---|---|---|---|---|

| Time | Energy Consumed | Time | Energy Consumed | Time | Energy Consumed | |

| (mL/min) | (s) | (J) | (s) | (J) | (s) | (J) |

| 45 | 2458 | 3239.1 | 2377 | 3003.4 | 849 | 1172.6 |

| 55 | 1732 | 2628.0 | 1877 | 2739.2 | 718 | 1026.6 |

| 65 | 1515 | 2076.2 | 1645 | 2461.2 | 592 | 915.5 |

| 75 | 1240 | 1908.2 | 1396 | 2266.1 | 521 | 833.0 |

| 85 | 1129 | 1772.7 | 1283 | 2056.1 | 485 | 770.2 |

| 95 | 1077 | 1716.3 | 1137 | 1820.9 | 448 | 719.4 |

| 105 | 1020 | 1625.5 | 1068 | 1354.3 | 436 | 677.8 |

| Flow Rate (mL/min) | Process 1 | Process 2 | Process 3 |

|---|---|---|---|

| SEC | |||

| (Wh/m3) | (Wh/m3) | (Wh/m3) | |

| 45 | 0.49 | 0.47 | 0.51 |

| 55 | 0.46 | 0.44 | 0.43 |

| 65 | 0.35 | 0.38 | 0.40 |

| 75 | 0.34 | 0.36 | 0.36 |

| 85 | 0.31 | 0.31 | 0.31 |

| 95 | 0.28 | 0.28 | 0.28 |

| 105 | 0.25 | 0.20 | 0.25 |

| Flow Rate (mL/min) | Process 1 | Process 2 | Process 3 | |||

|---|---|---|---|---|---|---|

| ΔG (×10−6 KWh) | TEE (×10−2) | ΔG (×10−6 KWh) | TEE (×10−2) | ΔG (×10−6 KWh) | TEE (×10−2) | |

| 45 | 3.36 | 6.85 | 4.17 | 8.87 | 3.48 | 6.82 |

| 55 | 2.87 | 6.23 | 3.37 | 7.66 | 3.10 | 7.21 |

| 65 | 2.62 | 7.48 | 2.87 | 7.55 | 3.03 | 7.57 |

| 75 | 2.15 | 6.32 | 1.79 | 4.96 | 2.37 | 6.58 |

| 85 | 1.86 | 6.00 | 1.59 | 5.14 | 2.21 | 7.13 |

| 95 | 2.58 | 9.21 | 2.30 | 8.21 | 2.75 | 9.82 |

| 105 | 2.95 | 11.79 | 2.80 | 13.98 | 2.43 | 9.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martinez, J.; Colán, M.; Castillón, R.; Ramos, P.G.; Paria, R.; Sánchez, L.; Rodríguez, J.M. Fabrication of Activated Carbon Decorated with ZnO Nanorod-Based Electrodes for Desalination of Brackish Water Using Capacitive Deionization Technology. Int. J. Mol. Sci. 2023, 24, 1409. https://doi.org/10.3390/ijms24021409

Martinez J, Colán M, Castillón R, Ramos PG, Paria R, Sánchez L, Rodríguez JM. Fabrication of Activated Carbon Decorated with ZnO Nanorod-Based Electrodes for Desalination of Brackish Water Using Capacitive Deionization Technology. International Journal of Molecular Sciences. 2023; 24(2):1409. https://doi.org/10.3390/ijms24021409

Chicago/Turabian StyleMartinez, Jhonatan, Martín Colán, Ronald Castillón, Pierre G. Ramos, Robert Paria, Luis Sánchez, and Juan M. Rodríguez. 2023. "Fabrication of Activated Carbon Decorated with ZnO Nanorod-Based Electrodes for Desalination of Brackish Water Using Capacitive Deionization Technology" International Journal of Molecular Sciences 24, no. 2: 1409. https://doi.org/10.3390/ijms24021409

APA StyleMartinez, J., Colán, M., Castillón, R., Ramos, P. G., Paria, R., Sánchez, L., & Rodríguez, J. M. (2023). Fabrication of Activated Carbon Decorated with ZnO Nanorod-Based Electrodes for Desalination of Brackish Water Using Capacitive Deionization Technology. International Journal of Molecular Sciences, 24(2), 1409. https://doi.org/10.3390/ijms24021409