Metabolic Engineering and Synthetic Biology Approaches for the Heterologous Production of Aromatic Polyketides

Abstract

1. Introduction

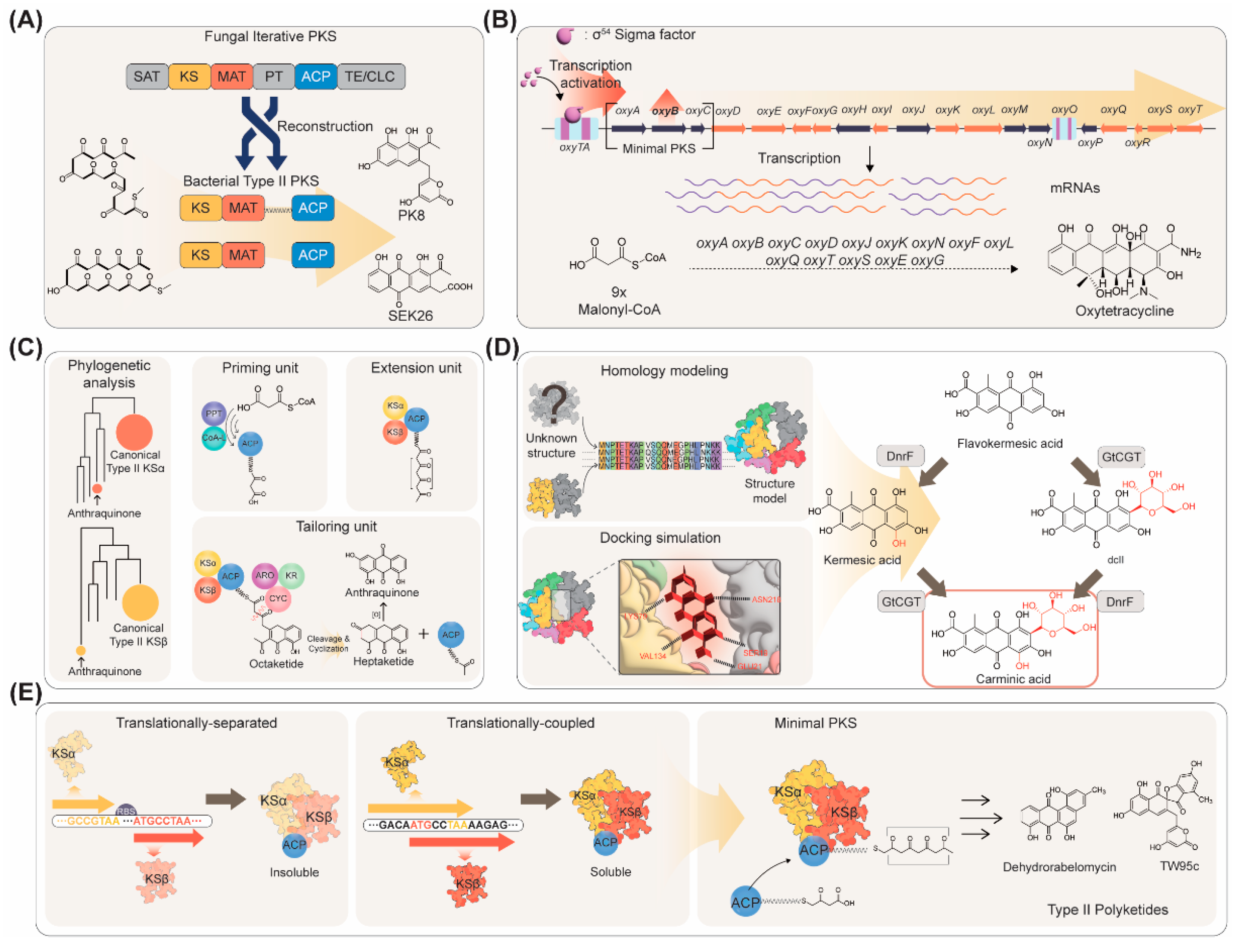

2. Strategies for the Heterologous Production of Type II Aromatic Polyketides

3. Strategies for the Heterologous Production of Type III Aromatic Polyketides

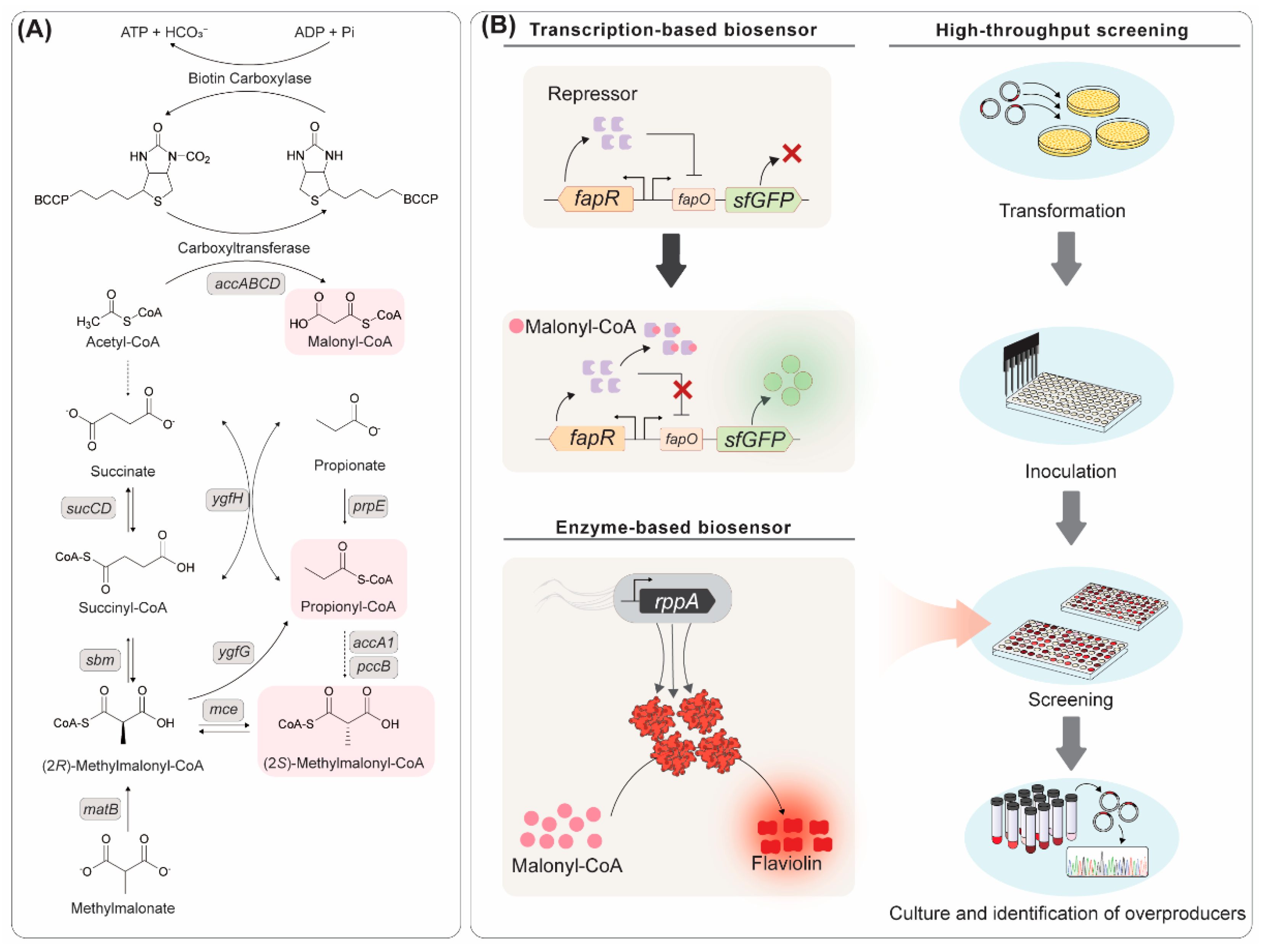

4. Metabolic Engineering and Synthetic Biology Strategies for Enhancing the Production of Aromatic Polyketides

5. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Staunton, J.; Weissman, K.J. Polyketide biosynthesis: A millennium review. Nat. Prod. Rep. 2001, 18, 380–416. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Wang, Y.; Wu, J.; Skalina, K.; Pfeifer, B.A. Complete biosynthesis of erythromycin A and designed analogs using E. coli as a heterologous host. Chem. Biol. 2010, 17, 1232–1240. [Google Scholar] [CrossRef] [PubMed]

- Mutka, S.C.; Carney, J.R.; Liu, Y.Q.; Kennedy, J. Heterologous production of epothilone C and D in Escherichia coli. Biochemistry 2006, 45, 1321–1330. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, K.; Rude, M.A.; Walsh, C.T.; Khosla, C. Engineered biosynthesis of an ansamycin polyketide precursor in Escherichia coli. Proc. Natl. Acad. Sci. USA 2003, 100, 9774–9778. [Google Scholar] [CrossRef] [PubMed]

- Yuzawa, S.; Kim, W.; Katz, L.; Keasling, J.D. Heterologous production of polyketides by modular type I polyketide synthases in Escherichia coli. Curr. Opin. Biotechnol. 2012, 23, 727–735. [Google Scholar] [CrossRef]

- Liu, Y.; Tu, X.; Xu, Q.; Bai, C.; Kong, C.; Liu, Q.; Yu, J.; Peng, Q.; Zhou, X.; Zhang, Y.; et al. Engineered monoculture and co-culture of methylotrophic yeast for de novo production of monacolin J and lovastatin from methanol. Metab. Eng. 2018, 45, 189–199. [Google Scholar] [CrossRef]

- Bond, C.M.; Tang, Y. Engineering Saccharomyces cerevisiae for production of simvastatin. Metab. Eng. 2019, 51, 1–8. [Google Scholar] [CrossRef]

- Hertweck, C.; Luzhetskyy, A.; Rebets, Y.; Bechthold, A. Type II polyketide synthases: Gaining a deeper insight into enzymatic teamwork. Nat. Prod. Rep. 2007, 24, 162–190. [Google Scholar] [CrossRef]

- Hulst, M.B.; Grocholski, T.; Neefjes, J.J.C.; van Wezel, G.P.; Metsa-Ketela, M. Anthracyclines: Biosynthesis, engineering and clinical applications. Nat. Prod. Rep. 2022, 39, 814–841. [Google Scholar] [CrossRef]

- Jeong, Y.; Kim, J.N.; Kim, M.W.; Bucca, G.; Cho, S.; Yoon, Y.J.; Kim, B.G.; Roe, J.H.; Kim, S.C.; Smith, C.P.; et al. The dynamic transcriptional and translational landscape of the model antibiotic producer Streptomyces coelicolor A3(2). Nat. Commun. 2016, 7, 11605. [Google Scholar] [CrossRef]

- Pham, D.N.; Kim, C.J. A Novel Two-stage pH Control Strategy for the Production of 5-Aminolevulinic Acid Using Recombinant Streptomyces coelicolor. Biotechnol. Bioprocess Eng. 2021, 26, 669–676. [Google Scholar] [CrossRef]

- Sohn, Y.J.; Jo, S.Y.; Song, H.M.; Baritugo, K.-A.; Pyo, J.; Choi, J.-I.; Joo, J.C.; Park, S.J. Recent Advances in Systems Metabolic Engineering Strategies for the Production of Biopolymers. Biotechnol. Bioprocess Eng. 2020, 25, 848–861. [Google Scholar] [CrossRef]

- Pfeifer, B.A.; Admiraal, S.J.; Gramajo, H.; Cane, D.E.; Khosla, C. Biosynthesis of complex polyketides in a metabolically engineered strain of E. coli. Science 2001, 291, 1790–1792. [Google Scholar] [CrossRef]

- Lee, S.Y.; Kim, H.U.; Chae, T.U.; Cho, J.S.; Kim, J.W.; Shin, J.H.; Kim, D.I.; Ko, Y.S.; Jang, W.D.; Jang, Y.S. A comprehensive metabolic map for production of bio-based chemicals. Nat. Catal. 2019, 2, 18–33. [Google Scholar] [CrossRef]

- Yang, D.; Park, S.Y.; Park, Y.S.; Eun, H.; Lee, S.Y. Metabolic engineering of Escherichia coli for natural product biosynthesis. Trends Biotechnol. 2020, 38, 745–765. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, R.; Chen, X.; Sun, X.; Yan, Y.; Shen, X.; Yuan, Q. Biosynthesis of aromatic polyketides in microorganisms using type II polyketide synthases. Microb. Cell Fact. 2020, 19, 110. [Google Scholar] [CrossRef]

- Gao, X.; Wang, P.; Tang, Y. Engineered polyketide biosynthesis and biocatalysis in Escherichia coli. Appl. Microbiol. Biotechnol. 2010, 88, 1233–1242. [Google Scholar] [CrossRef]

- Yang, D.; Kim, W.J.; Yoo, S.M.; Choi, J.H.; Ha, S.H.; Lee, M.H.; Lee, S.Y. Repurposing type III polyketide synthase as a malonyl-CoA biosensor for metabolic engineering in bacteria. Proc. Natl. Acad. Sci. USA 2018, 115, 9835–9844. [Google Scholar] [CrossRef]

- Cummings, M.; Peters, A.D.; Whitehead, G.F.S.; Menon, B.R.K.; Micklefield, J.; Webb, S.J.; Takano, E. Assembling a plug-and-play production line for combinatorial biosynthesis of aromatic polyketides in Escherichia coli. PLoS Biol. 2019, 17, e3000347. [Google Scholar] [CrossRef]

- Qian Zhang, X.W.; Zeng, W.; Xu, S.; Li, D.; Yu, S.; Zhou, J. De novo biosynthesis of carminic acid in Saccharomyces cerevisiae. Metab. Eng. 2023; in press. [Google Scholar]

- Liu, X.; Hua, K.; Liu, D.; Wu, Z.L.; Wang, Y.; Zhang, H.; Deng, Z.; Pfeifer, B.A.; Jiang, M. Heterologous biosynthesis of type II polyketide products using E. coli. ACS Chem. Biol. 2020, 15, 1177–1183. [Google Scholar] [CrossRef] [PubMed]

- Hua, K.; Liu, X.; Zhao, Y.; Gao, Y.; Pan, L.; Zhang, H.; Deng, Z.; Jiang, M. Offloading role of a discrete thioesterase in type II polyketide biosynthesis. mBio 2020, 11, e01334-20. [Google Scholar] [CrossRef] [PubMed]

- Jakociunas, T.; Klitgaard, A.K.; Kontou, E.E.; Nielsen, J.B.; Thomsen, E.; Romero-Suarez, D.; Blin, K.; Petzold, C.J.; Gin, J.W.; Tong, Y.J.; et al. Programmable polyketide biosynthesis platform for production of aromatic compounds in yeast. Synth. Syst. Biotechnol. 2020, 5, 11–18. [Google Scholar] [CrossRef]

- Yang, D.; Jang, W.D.; Lee, S.Y. Production of carminic acid by metabolically engineered Escherichia coli. J. Am. Chem. Soc. 2021, 143, 5364–5377. [Google Scholar] [CrossRef] [PubMed]

- Tan, Z.; Clomburg, J.M.; Gonzalez, R. Synthetic pathway for the production of olivetolic acid in Escherichia coli. ACS Synth. Biol. 2018, 7, 1886–1896. [Google Scholar] [CrossRef]

- Stevens, D.C.; Conway, K.R.; Pearce, N.; Villegas-Penaranda, L.R.; Garza, A.G.; Boddy, C.N. Alternative sigma factor over-expression enables heterologous expression of a type II polyketide biosynthetic pathway in Escherichia coli. PLoS ONE 2013, 8, e64858. [Google Scholar] [CrossRef]

- Zha, W.J.; Rubin-Pitel, S.B.; Shao, Z.Y.; Zhao, H.M. Improving cellular malonyl-CoA level in Escherichia coli via metabolic engineering. Metab. Eng. 2009, 11, 192–198. [Google Scholar] [CrossRef]

- Zhang, W.J.; Li, Y.R.; Tang, Y. Engineered biosynthesis of bacterial aromatic polyketides in Escherichia coli. Proc. Natl. Acad. Sci. USA 2008, 105, 20683–20688. [Google Scholar] [CrossRef]

- Markham, K.A.; Palmer, C.M.; Chwatko, M.; Wagner, J.M.; Murray, C.; Vazquez, S.; Swaminathan, A.; Chakravarty, I.; Lynd, N.A.; Alper, H.S. Rewiring Yarrowia lipolytica toward triacetic acid lactone for materials generation. Proc. Natl. Acad. Sci. USA 2018, 115, 2096–2101. [Google Scholar] [CrossRef]

- Choi, K.R.; Shin, J.H.; Cho, J.S.; Yang, D.; Lee, S.Y. Systems Metabolic Engineering of Escherichia coli. EcoSal Plus 2016, 7. [Google Scholar] [CrossRef]

- Medema, M.H.; Kottmann, R.; Yilmaz, P.; Cummings, M.; Biggins, J.B.; Blin, K.; de Bruijn, I.; Chooi, Y.H.; Claesen, J.; Coates, R.C.; et al. Minimum Information about a Biosynthetic Gene cluster. Nat. Chem. Biol. 2015, 11, 625–631. [Google Scholar] [CrossRef]

- Bräuer, A.; Zhou, Q.; Grammbitter, G.L.C.; Schmalhofer, M.; Rühl, M.; Kaila, V.R.I.; Bode, H.B.; Groll, M. Structural snapshots of the minimal PKS system responsible for octaketide biosynthesis. Nat. Chem. 2020, 12, 755–763. [Google Scholar] [CrossRef]

- Kim, J.; Yi, G.S. PKMiner: A database for exploring type II polyketide synthases. BMC Microbiol. 2012, 12, 169. [Google Scholar] [CrossRef]

- Blin, K.; Shaw, S.; Kloosterman, A.M.; Charlop-Powers, Z.; van Wezel, G.P.; Medema, M.H.; Weber, T. antiSMASH 6.0: Improving cluster detection and comparison capabilities. Nucleic Acids Res. 2021, 49, W29–W35. [Google Scholar] [CrossRef]

- Shi, S.P.; Wanibuchi, K.; Morita, H.; Endo, K.; Noguchi, H.; Abe, I. Enzymatic formation of unnatural novel chalcone, stilbene, and benzophenone scaffolds by plant type III polyketide synthase. Org. Lett. 2009, 11, 551–554. [Google Scholar] [CrossRef]

- Abe, I.; Utsumi, Y.; Oguro, S.; Morita, H.; Sano, Y.; Noguchi, H. A plant type III polyketide synthase that produces pentaketide chromone. J. Am. Chem. Soc. 2005, 127, 1362–1363. [Google Scholar] [CrossRef]

- Abe, I.; Morita, H.; Oguro, S.; Noma, H.; Wanibuchi, K.; Kawahara, N.; Goda, Y.; Noguchi, H.; Kohno, T. Structure-based engineering of a plant type III polyketide synthase: Formation of an unnatural nonaketide naphthopyrone. J. Am. Chem. Soc. 2007, 129, 5976–5980. [Google Scholar] [CrossRef]

- Abe, I.; Oguro, S.; Utsumi, Y.; Sano, Y.; Noguchi, H. Engineered biosynthesis of plant polyketides: Chain length control in an octaketide-producing plant type III polyketide synthase. J. Am. Chem. Soc. 2005, 127, 12709–12716. [Google Scholar] [CrossRef]

- Wanibuchi, K.; Morita, H.; Noguchi, H.; Abe, I. Enzymatic formation of an aromatic dodecaketide by engineered plant polyketide synthase. Bioorg. Med. Chem. Lett. 2011, 21, 2083–2086. [Google Scholar] [CrossRef]

- Frandsen, R.J.N.; Khorsand-Jamal, P.; Kongstad, K.T.; Nafisi, M.; Kannangara, R.M.; Staerk, D.; Okkels, F.T.; Binderup, K.; Madsen, B.; Møller, B.L.; et al. Heterologous production of the widely used natural food colorant carminic acid in Aspergillus nidulans. Sci. Rep. 2018, 8, 12853. [Google Scholar] [CrossRef]

- Austin, M.B.; Noel, A.J.P. The chalcone synthase superfamily of type III polyketide synthases. Nat. Prod. Rep. 2003, 20, 79–110. [Google Scholar] [CrossRef] [PubMed]

- Abe, I.; Morita, H. Structure and function of the chalcone synthase superfamily of plant type III polyketide synthases. Nat. Prod. Rep. 2010, 27, 809–838. [Google Scholar] [CrossRef] [PubMed]

- Park, S.Y.; Yang, D.; Ha, S.H.; Lee, S.Y. Production of phenylpropanoids and flavonolignans from glycerol by metabolically engineered Escherichia coli. Biotechnol. Bioeng. 2022, 119, 946–962. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.Z.; Reiter, M.A.; d’Espaux, L.; Wong, J.; Denby, C.M.; Lechner, A.; Zhang, Y.F.; Grzybowski, A.T.; Harth, S.; Lin, W.Y.; et al. Complete biosynthesis of cannabinoids and their unnatural analogues in yeast. Nature 2019, 567, 123–126. [Google Scholar] [CrossRef]

- Okorafor, I.C.; Chen, M.; Tang, Y. High-titer production of olivetolic acid and analogs in engineered fungal host using a nonplant biosynthetic pathway. ACS Synth. Biol. 2021, 10, 2159–2166. [Google Scholar] [CrossRef]

- Choi, G.S.; Choo, H.J.; Kim, B.G.; Ahn, J.H. Synthesis of acridone derivatives via heterologous expression of a plant type III polyketide synthase in Escherichia coli. Microb Cell Fact 2020, 19, 73. [Google Scholar] [CrossRef]

- Huang, J.P.; Fang, C.; Ma, X.; Wang, L.; Yang, J.; Luo, J.; Yan, Y.; Zhang, Y.; Huang, S.X. Tropane alkaloids biosynthesis involves an unusual type III polyketide synthase and non-enzymatic condensation. Nat. Commun. 2019, 10, 4036. [Google Scholar] [CrossRef]

- Bedewitz, M.A.; Jones, A.D.; D’Auria, J.C.; Barry, C.S. Tropinone synthesis via an atypical polyketide synthase and P450-mediated cyclization. Nat. Commun. 2018, 9, 5281. [Google Scholar] [CrossRef]

- Srinivasan, P.; Smolke, C.D. Biosynthesis of medicinal tropane alkaloids in yeast. Nature 2020, 585, 614–619. [Google Scholar] [CrossRef]

- Wei, J.; Tong, L. Crystal structure of the 500-kDa yeast acetyl-CoA carboxylase holoenzyme dimer. Nature 2015, 526, 723–727. [Google Scholar] [CrossRef]

- Wu, J.; Zhou, L.; Duan, X.; Peng, H.; Liu, S.; Zhuang, Q.; Pablo, C.M.; Fan, X.; Ding, S.; Dong, M.; et al. Applied evolution: Dual dynamic regulations-based approaches in engineering intracellular malonyl-CoA availability. Metab. Eng. 2021, 67, 403–416. [Google Scholar] [CrossRef]

- Johnson, A.O.; Gonzalez-Villanueva, M.; Wong, L.; Steinbuchel, A.; Tee, K.L.; Xu, P.; Wong, T.S. Design and application of genetically-encoded malonyl-CoA biosensors for metabolic engineering of microbial cell factories. Metab. Eng. 2017, 44, 253–264. [Google Scholar] [CrossRef]

- Yuzawa, S.; Chiba, N.; Katz, L.; Keasling, J.D. Construction of a part of a 3-hydroxypropionate cycle for heterologous polyketide biosynthesis in Escherichia coli. Biochemistry 2012, 51, 9779–9781. [Google Scholar] [CrossRef]

- Herbst, E.; Lee, A.; Tang, Y.; Snyder, S.A.; Cornish, V.W. Heterologous Catalysis of the Final Steps of Tetracycline Biosynthesis by Saccharomyces cerevisiae. ACS Chem. Biol. 2021, 16, 1425–1434. [Google Scholar] [CrossRef]

- Zhao, S.; Jones, J.A.; Lachance, D.M.; Bhan, N.; Khalidi, O.; Venkataraman, S.; Wang, Z.; Koffas, M.A. Improvement of catechin production in Escherichia coli through combinatorial metabolic engineering. Metab. Eng. 2015, 28, 43–53. [Google Scholar] [CrossRef]

- Nielsen, J.; Fussenegger, M.; Keasling, J.; Lee, S.Y.; Liao, J.C.; Prather, K.; Palsson, B. Engineering synergy in biotechnology. Nat. Chem. Biol. 2014, 10, 319–322. [Google Scholar] [CrossRef]

- Keatinge-Clay, A.T.; Maltby, D.A.; Medzihradszky, K.F.; Khosla, C.; Stroud, R.M. An antibiotic factory caught in action. Nat. Struct. Mol. Biol. 2004, 11, 888–893. [Google Scholar] [CrossRef]

- Du, D.; Katsuyama, Y.; Horiuchi, M.; Fushinobu, S.; Chen, A.; Davis, T.D.; Burkart, M.D.; Ohnishi, Y. Structural basis for selectivity in a highly reducing type II polyketide synthase. Nat. Chem. Biol. 2020, 16, 776–782. [Google Scholar] [CrossRef]

- Grammbitter, G.L.C.; Schmalhofer, M.; Karimi, K.; Shi, Y.M.; Schoner, T.A.; Tobias, N.J.; Morgner, N.; Groll, M.; Bode, H.B. An Uncommon Type II PKS Catalyzes Biosynthesis of Aryl Polyene Pigments. J. Am. Chem. Soc. 2019, 141, 16615–16623. [Google Scholar] [CrossRef]

- Jumper, J.; Evans, R.; Pritzel, A.; Green, T.; Figurnov, M.; Ronneberger, O.; Tunyasuvunakool, K.; Bates, R.; Zidek, A.; Potapenko, A.; et al. Highly accurate protein structure prediction with AlphaFold. Nature 2021, 596, 583–589. [Google Scholar] [CrossRef]

- Baek, M.; DiMaio, F.; Anishchenko, I.; Dauparas, J.; Ovchinnikov, S.; Lee, G.R.; Wang, J.; Cong, Q.; Kinch, L.N.; Schaeffer, R.D.; et al. Accurate prediction of protein structures and interactions using a three-track neural network. Science 2021, 373, 871–876. [Google Scholar] [CrossRef] [PubMed]

- Tong, Y.; Charusanti, P.; Zhang, L.; Weber, T.; Lee, S.Y. CRISPR-Cas9 based engineering of actinomycetal genomes. ACS Synth. Biol. 2015, 4, 1020–1029. [Google Scholar] [CrossRef] [PubMed]

- Tong, Y.; Whitford, C.M.; Robertsen, H.L.; Blin, K.; Jorgensen, T.S.; Klitgaard, A.K.; Gren, T.; Jiang, X.; Weber, T.; Lee, S.Y. Highly efficient DSB-free base editing for streptomycetes with CRISPR-BEST. Proc. Natl. Acad. Sci. USA 2019, 116, 20366–20375. [Google Scholar] [CrossRef]

- Wang, W.; Li, S.; Li, Z.; Zhang, J.; Fan, K.; Tan, G.; Ai, G.; Lam, S.M.; Shui, G.; Yang, Z.; et al. Harnessing the intracellular triacylglycerols for titer improvement of polyketides in Streptomyces. Nat. Biotechnol. 2020, 38, 76–83. [Google Scholar] [CrossRef] [PubMed]

- Chan, D.I.; Vogel, H.J. Current understanding of fatty acid biosynthesis and the acyl carrier protein. Biochem. J. 2010, 430, 1–19. [Google Scholar] [CrossRef]

- Gajewski, J.; Buelens, F.; Serdjukow, S.; Janssen, M.; Cortina, N.; Grubmuller, H.; Grininger, M. Engineering fatty acid synthases for directed polyketide production. Nat. Chem. Biol. 2017, 13, 363–365. [Google Scholar] [CrossRef]

- Yuzawa, S.; Mirsiaghi, M.; Jocic, R.; Fujii, T.; Masson, F.; Benites, V.T.; Baidoo, E.E.K.; Sundstrom, E.; Tanjore, D.; Pray, T.R.; et al. Short-chain ketone production by engineered polyketide synthases in Streptomyces albus. Nat. Commun. 2018, 9, 4569. [Google Scholar] [CrossRef]

- Hadadi, N.; Hafner, J.; Shajkofci, A.; Zisaki, A.; Hatzimanikatis, V. ATLAS of biochemistry: A repository of all possible biochemical reactions for synthetic biology and metabolic engineering studies. ACS Synth. Biol. 2016, 5, 1155–1166. [Google Scholar] [CrossRef]

| Product | Substrate | Concentration (mg/L) | Scale 2 | Refs. |

|---|---|---|---|---|

| 6-Methylsalicylic acid | Glycerol | 440.3 | 2 L Fed-batch | [18] |

| Aloesone | Glucose | 30.9 | 50 mL flask | [18] |

| AQ256 | LB | 2.5 | 6 L | [19] |

| Carminic acid | Glucose | 7.58 | 2.5 L fed-batch | [20] |

| Dehydrorabelomycin | Tryptone, yeast extract, glycerol | 500 | 250 mL flask | [21,22] |

| Dihydrokalafungin | Glucose | N/A | N/A | [23] |

| Flaviolin | Glucose | 26 | 50 mL flask | [18] |

| Flavokermesic acid | Glucose | 3660 | 2 L fed-batch | [24] |

| Neochaetomycin | Glucose | 0.73 | 150 mL | [19] |

| Neomedicamycin | LB | 1.04 | 4.8 L | [19] |

| Olivetolic acid | Glycerol | 80 | 400 mL batch | [25] |

| Oxytetracycline | LB | 2 | 25 mL flask | [26] |

| Phloroglucinol | LB | 1280 | 2 mL batch | [27] |

| SEK26 | Glucose | 3 | 1 L Fed-batch | [28] |

| Triacetic acid lactone | Glucose | 3590 | 3 L Batch | [29] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.; Eun, H.; Prabowo, C.P.S. Metabolic Engineering and Synthetic Biology Approaches for the Heterologous Production of Aromatic Polyketides. Int. J. Mol. Sci. 2023, 24, 8923. https://doi.org/10.3390/ijms24108923

Yang D, Eun H, Prabowo CPS. Metabolic Engineering and Synthetic Biology Approaches for the Heterologous Production of Aromatic Polyketides. International Journal of Molecular Sciences. 2023; 24(10):8923. https://doi.org/10.3390/ijms24108923

Chicago/Turabian StyleYang, Dongsoo, Hyunmin Eun, and Cindy Pricilia Surya Prabowo. 2023. "Metabolic Engineering and Synthetic Biology Approaches for the Heterologous Production of Aromatic Polyketides" International Journal of Molecular Sciences 24, no. 10: 8923. https://doi.org/10.3390/ijms24108923

APA StyleYang, D., Eun, H., & Prabowo, C. P. S. (2023). Metabolic Engineering and Synthetic Biology Approaches for the Heterologous Production of Aromatic Polyketides. International Journal of Molecular Sciences, 24(10), 8923. https://doi.org/10.3390/ijms24108923