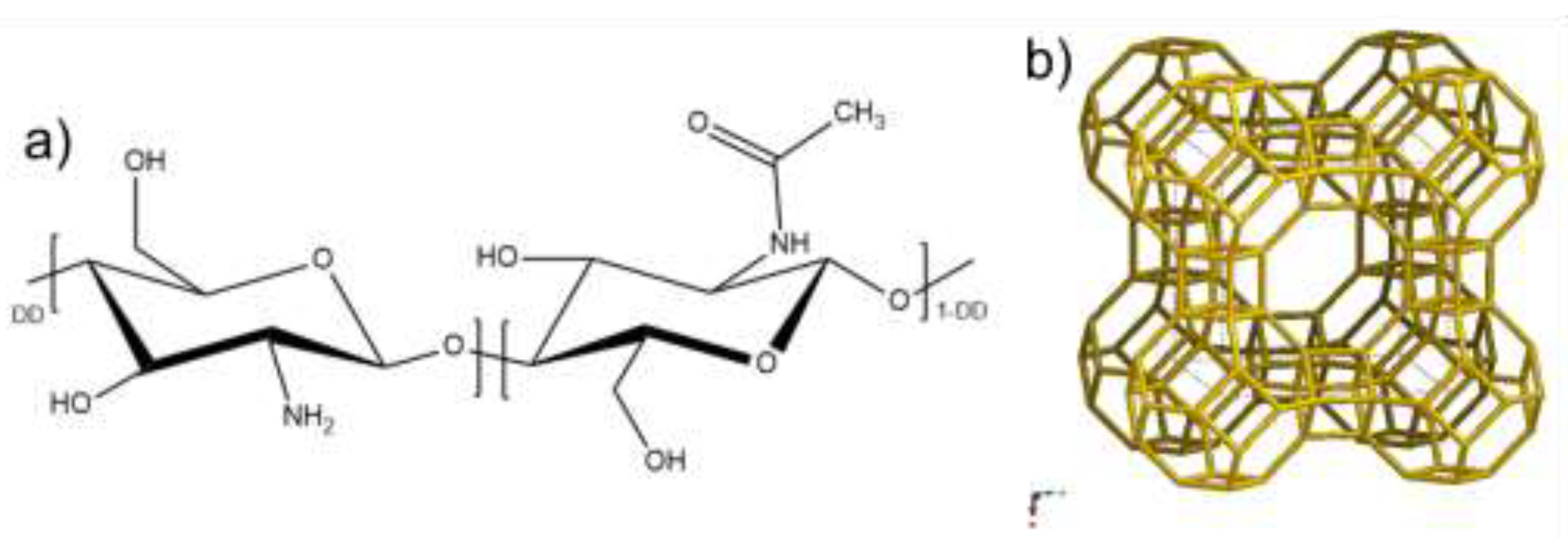

Tailoring Chitosan/LTA Zeolite Hybrid Aerogels for Anionic and Cationic Dye Adsorption

Abstract

1. Introduction

2. Materials and Methods

2.1. Aereogel Preparation

2.2. Aereogel Characterization

3. Results and Discussion

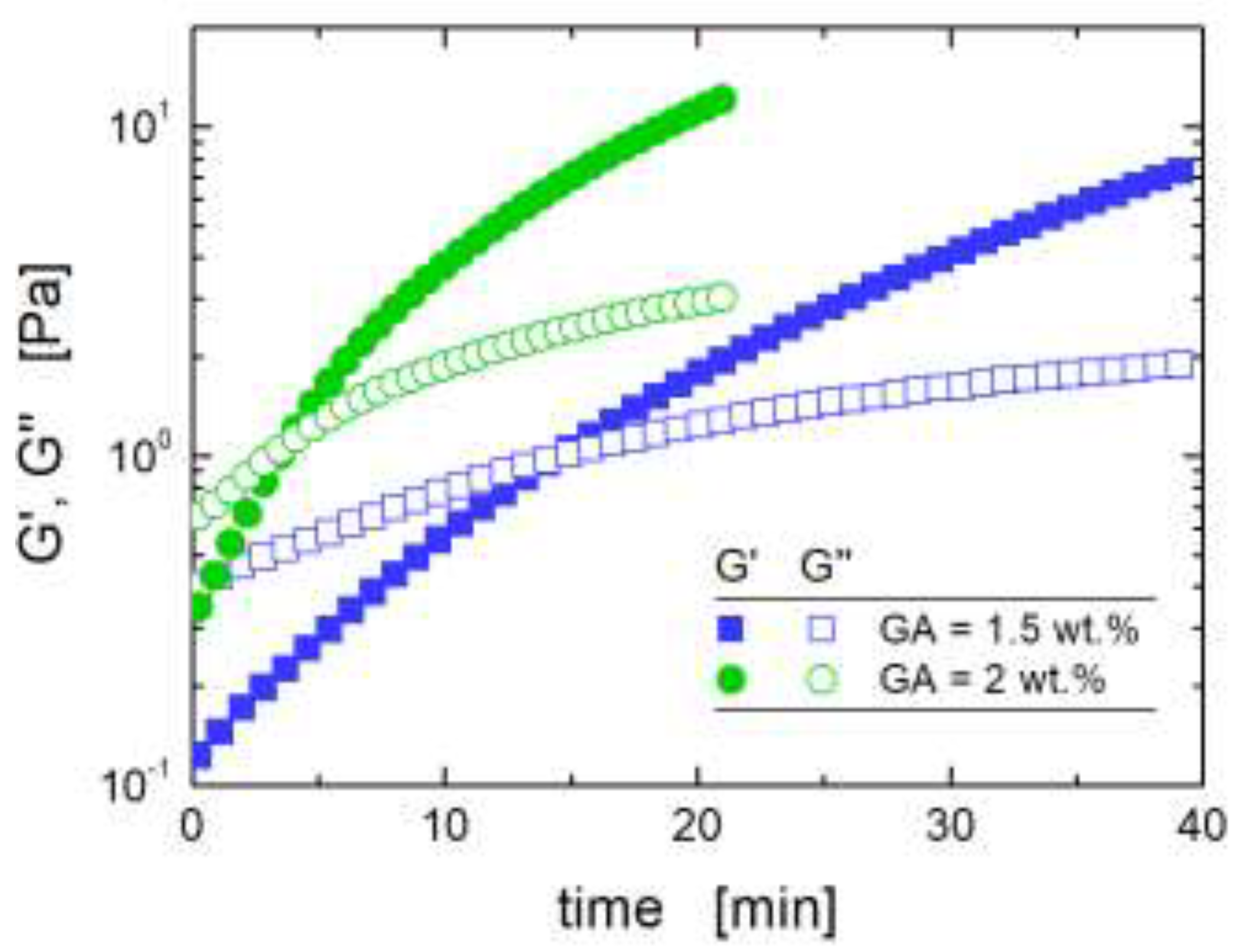

3.1. Optimization of the Preparation Process

- (i)

- it has to be present at a low enough concentration so as to avoid the gelation of the dispersion before it is completely frozen in the refrigerator;

- (ii)

- it has to be present at a high enough concentration so as to allow the crosslinking reactions to occur in freeze-dried samples subjected to a thermal treatment (see Section 3.1 for details on the aerogel preparation protocol).

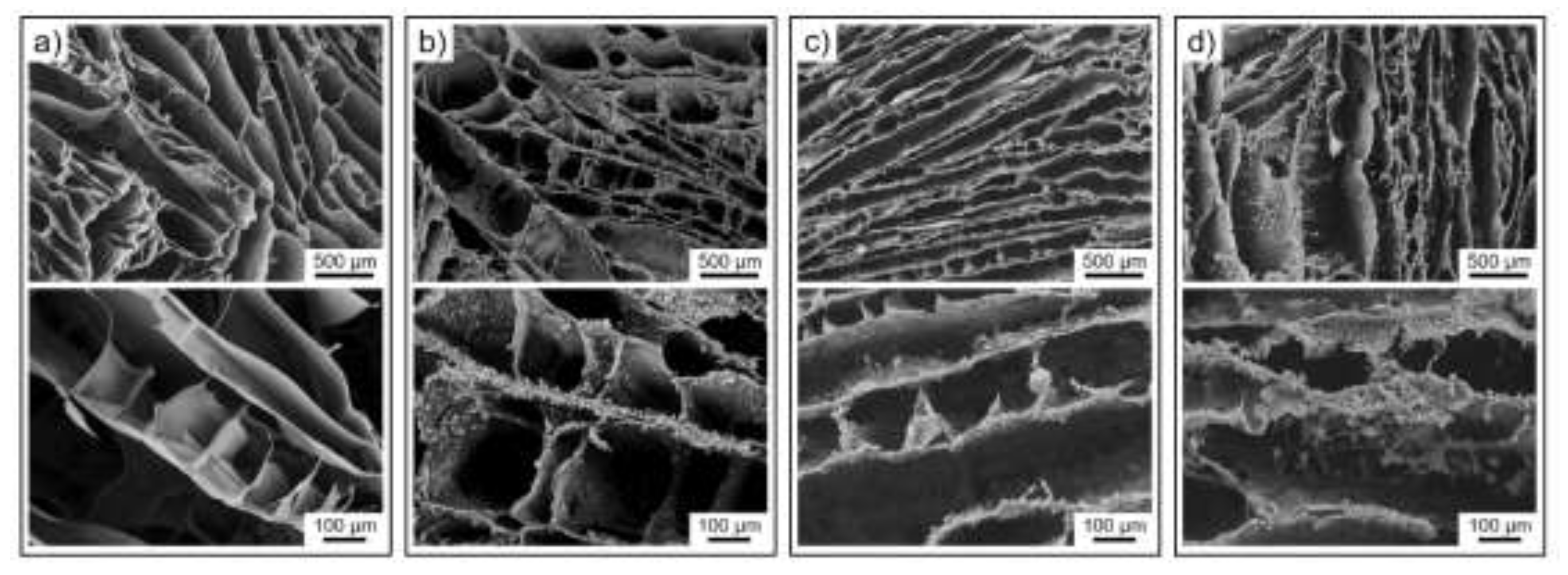

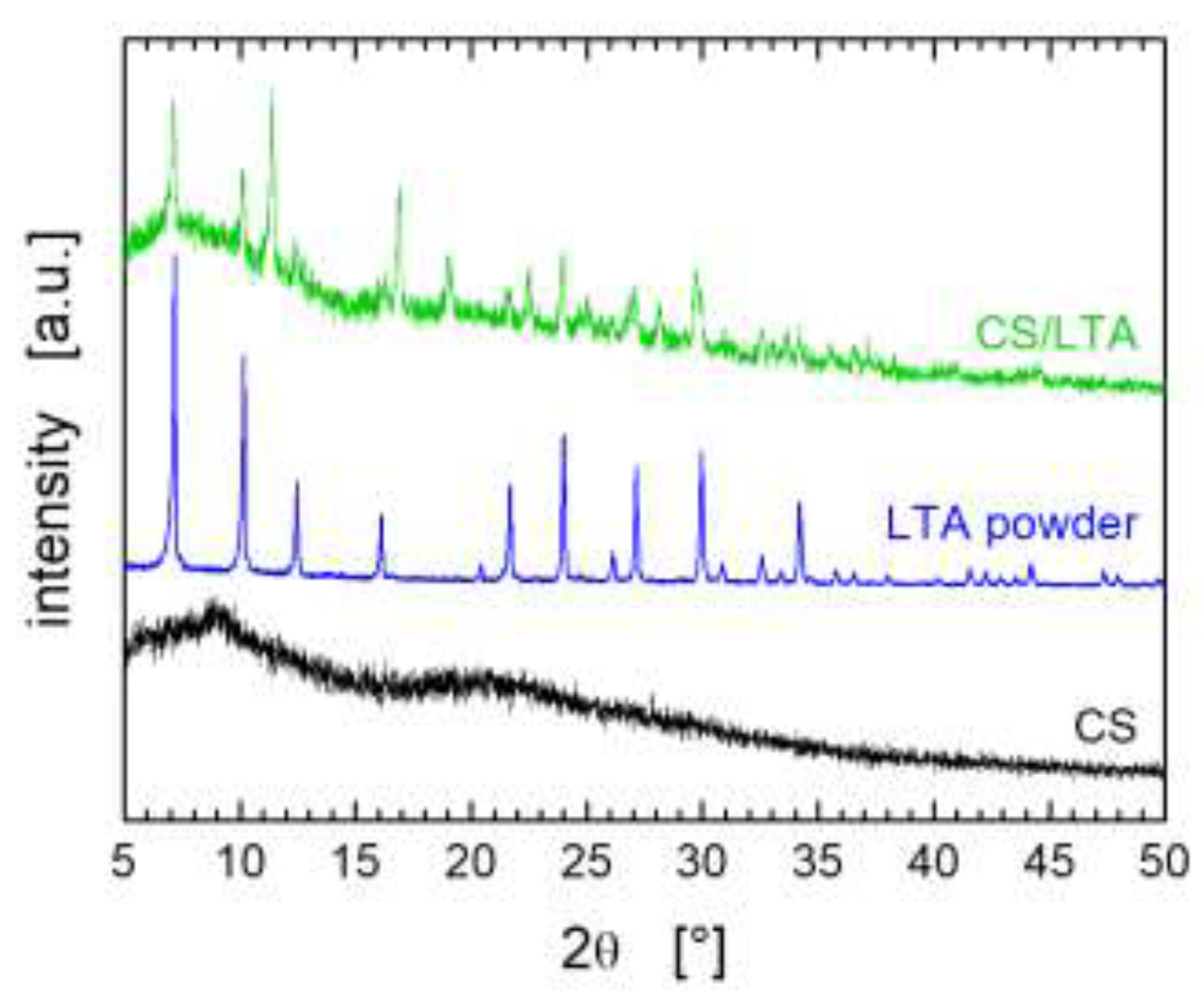

3.2. Structure of the Aerogels

3.3. Adsorption Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nešić, A.R.; Veličković, S.J.; Antonović, D.G. Modification of chitosan by zeolite A and adsorption of Bezactive Orange 16 from aqueous solution. Compos. Part B Eng. 2013, 53, 145–151. [Google Scholar] [CrossRef]

- Aysan, H.; Edebali, S.; Ozdemir, C.; Karakaya, M.C.; Karakaya, N. Use of chabazite, a naturally abundant zeolite, for the investigation of the adsorption kinetics and mechanism of methylene blue dye. Microporous Mesoporous Mater. 2016, 235, 78–86. [Google Scholar] [CrossRef]

- Khanday, W.A.; Asif, M.; Hameed, B.H. Cross-linked beads of activated oil palm ash zeolite/chitosan composite as a bio-adsorbent for the removal of methylene blue and acid blue 29 dyes. Int. J. Biol. Macromol. 2017, 95, 895–902. [Google Scholar] [CrossRef] [PubMed]

- Ussia, M.; Bruno, E.; Spina, E.; Vitalini, D.; Pellegrino, G.; Ruffino, F.; Privitera, V.; Carroccio, S.C. Freestanding photocatalytic materials based on 3D graphene and polyporphyrins. Sci. Rep. 2018, 8, 1–12. [Google Scholar] [CrossRef]

- Ussia, M.; Ruffino, F.; Bruno, E.; Spina, E.; Conticello, I.; Privitera, V.; Carroccio, S.C. The role of solvent on the formulation of graphene/polyporphyrin hybrid material versus photocatalytic activity. Polym. Bull. 2020, 77, 2073–2087. [Google Scholar] [CrossRef]

- Yaseen, D.A.; Scholz, M. Textile dye wastewater characteristics and constituents of synthetic effluents: A critical review; Springer: Berlin/Heidelberg, Germany, 2019; Volume 16, ISBN 0123456789. [Google Scholar]

- Bolisetty, S.; Peydayesh, M.; Mezzenga, R. Sustainable technologies for water purification from heavy metals: Review and analysis. Chem. Soc. Rev. 2019, 48, 463–487. [Google Scholar] [CrossRef]

- Dabrowski, A. Adsorption—From theory to practice. Adv. Colloid Interface Sci. 2001, 93, 135–224. [Google Scholar] [CrossRef]

- Singh, N.B.; Nagpal, G.; Agrawal, S. Rachna Water purification by using Adsorbents: A Review. Environ. Technol. Innov. 2018, 11, 187–240. [Google Scholar] [CrossRef]

- Gusain, R.; Kumar, N.; Ray, S.S. Recent advances in carbon nanomaterial-based adsorbents for water purification. Coord. Chem. Rev. 2020, 405, 213111. [Google Scholar] [CrossRef]

- Zhou, Y.; Lu, J.; Zhou, Y.; Liu, Y. Recent advances for dyes removal using novel adsorbents: A review. Environ. Pollut. 2019, 252, 352–365. [Google Scholar] [CrossRef]

- Crini, G.; Badot, P.M. Application of chitosan, a natural aminopolysaccharide, for dye removal from aqueous solutions by adsorption processes using batch studies: A review of recent literature. Prog. Polym. Sci. 2008, 33, 399–447. [Google Scholar] [CrossRef]

- Mokhtar, A.; Abdelkrim, S.; Djelad, A.; Sardi, A.; Boukoussa, B.; Sassi, M.; Bengueddach, A. Adsorption behavior of cationic and anionic dyes on magadiite-chitosan composite beads. Carbohydr. Polym. 2020, 229, 115399. [Google Scholar] [CrossRef]

- Le, T.T.N.; Le, V.T.; Dao, M.U.; Nguyen, Q.V.; Vu, T.T.; Nguyen, M.H.; Tran, D.L.; Le, H.S. Preparation of magnetic graphene oxide/chitosan composite beads for effective removal of heavy metals and dyes from aqueous solutions. Chem. Eng. Commun. 2019, 206, 1337–1352. [Google Scholar] [CrossRef]

- Dotto, G.L.; Moura, J.M.; Cadaval, T.R.S.; Pinto, L.A.A. Application of chitosan films for the removal of food dyes from aqueous solutions by adsorption. Chem. Eng. J. 2013, 214, 8–16. [Google Scholar] [CrossRef]

- Salzano de Luna, M.; Castaldo, R.; Altobelli, R.; Gioiella, L.; Filippone, G.; Gentile, G.; Ambrogi, V. Chitosan hydrogels embedding hyper-crosslinked polymer particles as reusable broad-spectrum adsorbents for dye removal. Carbohydr. Polym. 2017, 177, 347–354. [Google Scholar] [CrossRef] [PubMed]

- Salzano de Luna, M.; Altobelli, R.; Gioiella, L.; Castaldo, R.; Scherillo, G.; Filippone, G. Role of polymer network and gelation kinetics on the mechanical properties and adsorption capacity of chitosan hydrogels for dye removal. J. Polym. Sci. Part B Polym. Phys. 2017, 55, 1843–1849. [Google Scholar] [CrossRef]

- Lai, K.C.; Hiew, B.Y.Z.; Lee, L.Y.; Gan, S.; Thangalazhy-Gopakumar, S.; Chiu, W.S.; Khiew, P.S. Ice-templated graphene oxide/chitosan aerogel as an effective adsorbent for sequestration of metanil yellow dye. Bioresour. Technol. 2019, 274, 134–144. [Google Scholar] [CrossRef] [PubMed]

- Yu, R.; Shi, Y.; Yang, D.; Liu, Y.; Qu, J.; Yu, Z.Z. Graphene Oxide/Chitosan Aerogel Microspheres with Honeycomb-Cobweb and Radially Oriented Microchannel Structures for Broad-Spectrum and Rapid Adsorption of Water Contaminants. ACS Appl. Mater. Interfaces 2017, 9, 21809–21819. [Google Scholar] [CrossRef]

- Salzano de Luna, M.; Sirignano, M. Upcycling soot particles into chitosan-based aerogels for water purification from organic pollutants. J. Hazard. Mater. Lett. 2021, 2, 100019. [Google Scholar] [CrossRef]

- Maleki, H. Recent advances in aerogels for environmental remediation applications: A review. Chem. Eng. J. 2016, 300, 98–118. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, L.; Bai, H.; Li, L. Graphene oxide-chitosan composite hydrogels as broad-spectrum adsorbents for water purification. J. Mater. Chem. A 2013, 1, 1992–2001. [Google Scholar] [CrossRef]

- Xiao, J.; Lv, W.; Xie, Z.; Song, Y.; Zheng, Q. L-Cysteine-Reduced Graphene Oxide/Poly(Vinyl Alcohol) Ultralight Aerogel As a Broad-Spectrum Adsorbent for Anionic and Cationic Dyes. J. Mater. Sci. 2017, 52, 5807–5821. [Google Scholar] [CrossRef]

- Panic, V.V.; Velickovic, S.J. Removal of model cationic dye by adsorption onto poly(methacrylic acid)/zeolite hydrogel composites: Kinetics, equilibrium study and image analysis. Sep. Purif. Technol. 2014, 122, 384–394. [Google Scholar] [CrossRef]

- Salzano de Luna, M.; Ascione, C.; Santillo, C.; Verdolotti, L.; Lavorgna, M.; Buonocore, G.G.; Castaldo, R.; Filippone, G.; Xia, H.; Ambrosio, L. Optimization of dye adsorption capacity and mechanical strength of chitosan aerogels through crosslinking strategy and graphene oxide addition. Carbohydr. Polym. 2019, 211, 195–203. [Google Scholar] [CrossRef] [PubMed]

- Normand, V.; Muller, S.; Ravey, J.C.; Parker, A. Gelation kinetics of gelatin: A master curve and network modeling. Macromolecules 2000, 33, 1063–1071. [Google Scholar] [CrossRef]

- Shao, G.; Hanaor, D.A.H.H.; Shen, X.; Gurlo, A. Freeze Casting: From Low-Dimensional Building Blocks to Aligned Porous Structures—A Review of Novel Materials, Methods, and Applications. Adv. Mater. 2020, 32, 1907176. [Google Scholar] [CrossRef]

- Yang, J.; Yang, W.; Chen, W.; Tao, X. An elegant coupling: Freeze-casting and versatile polymer composites. Prog. Polym. Sci. 2020, 109. [Google Scholar] [CrossRef]

- Dos Anjos, F.S.C.; Vieira, E.F.S.; Cestari, A.R. Interaction of indigo carmine dye with chitosan evaluated by adsorption and thermochemical data. J. Colloid Interface Sci. 2002, 253, 243–246. [Google Scholar] [CrossRef]

- Cestari, A.R.; Vieira, E.F.S.; Tavares, A.M.G.; Bruns, R.E. The removal of the indigo carmine dye from aqueous solutions using cross-linked chitosan-Evaluation of adsorption thermodynamics using a full factorial design. J. Hazard. Mater. 2008, 153, 566–574. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Zhong, H.; Wang, S.; Xue, J.; Zhang, Z. Removal of basic dye (methylene blue) from aqueous solution using zeolite synthesized from electrolytic manganese residue. J. Ind. Eng. Chem. 2015, 23, 344–352. [Google Scholar] [CrossRef]

- Wang, S.; Li, H.; Xu, L. Application of zeolite MCM-22 for basic dye removal from wastewater. J. Colloid Interface Sci. 2006, 295, 71–78. [Google Scholar] [CrossRef] [PubMed]

- Pereira, P.M.; Ferreira, B.F.; Oliveira, N.P.; Nassar, E.J.; Ciuffi, K.J.; Vicente, M.A.; Trujillano, R.; Rives, V.; Gil, A.; Korili, S.; et al. Synthesis of zeolite A from metakaolin and its application in the adsorption of cationic dyes. Appl. Sci. 2018, 8, 608. [Google Scholar] [CrossRef]

- Hernández-Montoya, V.; Pérez-Cruz, M.A.; Mendoza-Castillo, D.I.; Moreno-Virgen, M.R.; Bonilla-Petriciolet, A. Competitive adsorption of dyes and heavy metals on zeolitic structures. J. Environ. Manage. 2013, 116, 213–221. [Google Scholar] [CrossRef] [PubMed]

- Jin, X.; Jiang, M.Q.; Shan, X.Q.; Pei, Z.G.; Chen, Z. Adsorption of methylene blue and orange II onto unmodified and surfactant-modified zeolite. J. Colloid Interface Sci. 2008, 328, 243–247. [Google Scholar] [CrossRef]

- Bain, A.J.; Chandna, P.; Butcher, G.; Bryant, J. Picosecond polarized fluorescence studies of anisotropic fluid media. II. Experimental studies of molecular order and motion in jet aligned rhodamine 6G and resorufin solutions. J. Chem. Phys. 2000, 112, 10435–10449. [Google Scholar] [CrossRef]

- Shirazian, S.; Ashrafizadeh, S.N. LTA and ion-exchanged LTA zeolite membranes for dehydration of natural gas. J. Ind. Eng. Chem. 2015, 22, 132–137. [Google Scholar] [CrossRef]

- Sivalingam, S.; Sen, S. Swift sono-hydrothermal synthesis of pure NaX nanocrystals with improved sorption capacity from industrial resources. Appl. Surf. Sci. 2019, 463, 190–196. [Google Scholar] [CrossRef]

- Al-Ghouti, M.A.; Da’ana, D.A. Guidelines for the use and interpretation of adsorption isotherm models: A review. J. Hazard. Mater. 2020, 393, 122383. [Google Scholar] [CrossRef]

- Cook, W.G.; Ross, R.A. Heterogeneous Interactions of Methylamines on Porous Adsorbents. Part III. The Adsorption Characteristics of Methylamines on γ-alumina and Types “3A” and “13X” “Molecular Sieves.” Can. J. Chem. 1973, 51, 533–537. [Google Scholar] [CrossRef]

- Mahmodi, G.; Zarrintaj, P.; Taghizadeh, A.; Taghizadeh, M.; Manouchehri, S.; Dangwal, S.; Ronte, A.; Ganjali, M.R.; Ramsey, J.D.; Kim, S.J.; et al. From microporous to mesoporous mineral frameworks: An alliance between zeolite and chitosan. Carbohydr. Res. 2020, 489, 107930. [Google Scholar] [CrossRef]

- Yassue-Cordeiro, P.H.; Zandonai, C.H.; Genesi, B.P.; Lopes, P.S.; Sanchez-Lopez, E.; Garcia, M.L.; Fernandes-Machado, N.R.C.; Severino, P.; Souto, E.B.; da Silva, C.F. Development of chitosan/silver sulfadiazine/zeolite composite films for wound dressing. Pharmaceutics 2019, 11, 523. [Google Scholar] [CrossRef]

- Pastore, R.; Raos, G. Glassy dynamics of a polymer monolayer on a heterogeneous disordered substrate. Soft Matter 2015, 11, 8083–8091. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Z.; Li, F.; Liu, J.; Pastore, R.; Raos, G.; Wu, Y.; Zhang, L. Effects of chemically heterogeneous nanoparticles on polymer dynamics: Insights from molecular dynamics simulations. Soft Matter 2018, 14, 1219–1226. [Google Scholar] [CrossRef] [PubMed]

- Pastore, R.; David, A.; Casalegno, M.; Greco, F.; Raos, G. Influence of wall heterogeneity on nanoscopically confined polymers. Phys. Chem. Chem. Phys. 2019, 21, 772–779. [Google Scholar] [CrossRef] [PubMed]

- Klebes, J.; Finnigan, S.; Bray, D.J.; Anderson, R.L.; Swope, W.C.; Johnston, M.A.; Conchuir, B.O. The Role of Chemical Heterogeneity in Surfactant Adsorption at Solid-Liquid Interfaces. J. Chem. Theory Comput. 2020, 16, 7135–7147. [Google Scholar] [CrossRef]

- Jawad, A.H.; Abdulhameed, A.S.; Reghioua, A.; Yaseen, Z.M. Zwitterion composite chitosan-epichlorohydrin/zeolite for adsorption of methylene blue and reactive red 120 dyes. Int. J. Biol. Macromol. 2020, 163, 756–765. [Google Scholar] [CrossRef]

- Kazemi, J.; Javanbakht, V. Alginate beads impregnated with magnetic Chitosan@Zeolite nanocomposite for cationic methylene blue dye removal from aqueous solution. Int. J. Biol. Macromol. 2020, 154, 1426–1437. [Google Scholar] [CrossRef] [PubMed]

- Habiba, U.; Siddique, T.A.; Joo, T.C.; Salleh, A.; Ang, B.C.; Afifi, A.M. Synthesis of chitosan/polyvinyl alcohol/zeolite composite for removal of methyl orange, Congo red and chromium(VI) by flocculation/adsorption. Carbohydr. Polym. 2017, 157, 1568–1576. [Google Scholar] [CrossRef]

- Dehghani, M.H.; Dehghan, A.; Najafpoor, A. Removing Reactive Red 120 and 196 using chitosan/zeolite composite from aqueous solutions: Kinetics, isotherms, and process optimization. J. Ind. Eng. Chem. 2017, 51, 185–195. [Google Scholar] [CrossRef]

| Adsorbate | Adsorbent | qemax [mg g−1] | b [L mg−1] | R2 |

|---|---|---|---|---|

| IC | CS aerogel | 212.8 ± 3.4 | 0.4239 ± 0.0398 | 0.986 |

| IC | LTA powder | 124.5 ± 15.1 | 0.0010 ± 0.0001 | 0.992 |

| RH | LTA powder | 101.1 ± 1.5 | 0.0141 ± 0.0008 | 0.994 |

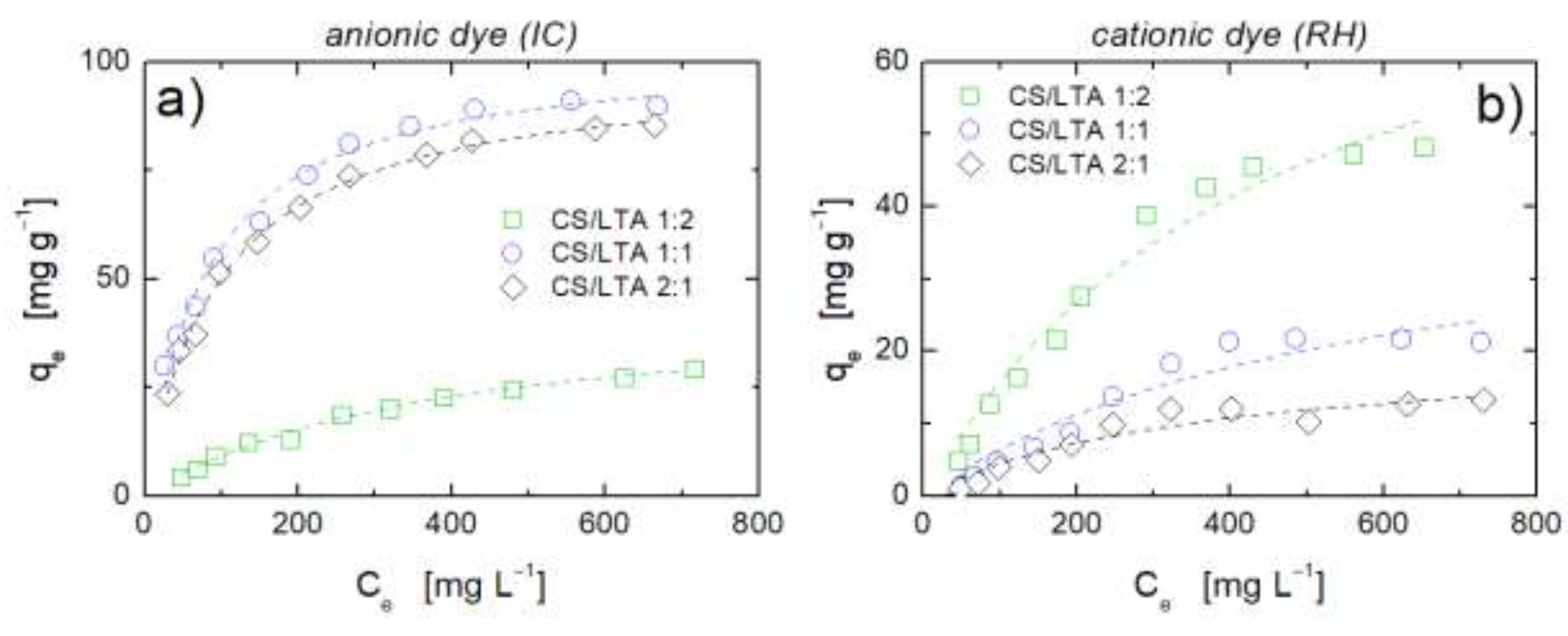

| Adsorbate | Adsorbent | qecalc [mg g−1] | qemax [mg g−1] | b [L mg−1] | R2 |

|---|---|---|---|---|---|

| Anionic dye (IC) | CS/LTA 1:2 | 152.4 | 44.7 ± 2.0 | 0.0026 ± 0.0002 | 0.992 |

| CS/LTA 1:1 | 168.7 | 103.1 ± 2.3 | 0.0125 ± 0. 0010 | 0.985 | |

| CS/LTA 2:1 | 181.5 | 98.9 ± 1.4 | 0.0103 ± 0.0005 | 0.995 | |

| Cationic dye (RH) | CS/LTA 1:2 | 67.4 | 89.3 ± 11.8 | 0.0021 ± 0.0005 | 0.966 |

| CS/LTA 1:1 | 51.6 | 43.4 ± 10.3 | 0.0017 ± 0.0005 | 0.917 | |

| CS/LTA 2:1 | 34.7 | 20.6 ± 3.6 | 0.0027 ± 0.0010 | 0.899 |

| Adsorbent | Anionic Dye(s) | qemax [mg g−1] | Cationic Dye(s) | qemax [mg g−1] | Ref. |

|---|---|---|---|---|---|

| Alginate beads with magnetic Chitosan-Zeolite | - | - | Methylene blue | 6 | [48] |

| Chitosan/zeolite A film | B. Orange 16 | 305 | - | - | [1] |

| Chitosan/polyvinyl alcohol/zeolite membrane | Methyl orange | 153 | - | - | [49] |

| Chitosan/zeolite composite | Reactive Red 120 and 196 | 19.1, 35.6 | - | - | [50] |

| Activated oil palm ash zeolite/chitosan beads | Acid blue 29 | 213 | Methylene blue | 152 | [3] |

| CS/LTA 1:1 aerogel | Indigo carmine | 103 | Rhodamine 6G | 43.4 | This study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salzano de Luna, M.; Greco, F.; Pastore, R.; Mensitieri, G.; Filippone, G.; Aprea, P.; Mallamace, D.; Mallamace, F.; Chen, S.-H. Tailoring Chitosan/LTA Zeolite Hybrid Aerogels for Anionic and Cationic Dye Adsorption. Int. J. Mol. Sci. 2021, 22, 5535. https://doi.org/10.3390/ijms22115535

Salzano de Luna M, Greco F, Pastore R, Mensitieri G, Filippone G, Aprea P, Mallamace D, Mallamace F, Chen S-H. Tailoring Chitosan/LTA Zeolite Hybrid Aerogels for Anionic and Cationic Dye Adsorption. International Journal of Molecular Sciences. 2021; 22(11):5535. https://doi.org/10.3390/ijms22115535

Chicago/Turabian StyleSalzano de Luna, Martina, Francesco Greco, Raffaele Pastore, Giuseppe Mensitieri, Giovanni Filippone, Paolo Aprea, Domenico Mallamace, Francesco Mallamace, and Sow-Hsin Chen. 2021. "Tailoring Chitosan/LTA Zeolite Hybrid Aerogels for Anionic and Cationic Dye Adsorption" International Journal of Molecular Sciences 22, no. 11: 5535. https://doi.org/10.3390/ijms22115535

APA StyleSalzano de Luna, M., Greco, F., Pastore, R., Mensitieri, G., Filippone, G., Aprea, P., Mallamace, D., Mallamace, F., & Chen, S.-H. (2021). Tailoring Chitosan/LTA Zeolite Hybrid Aerogels for Anionic and Cationic Dye Adsorption. International Journal of Molecular Sciences, 22(11), 5535. https://doi.org/10.3390/ijms22115535