A Review on Multifunctional Polymer–MXene Hybrid Materials for Electronic Applications

Abstract

1. Introduction

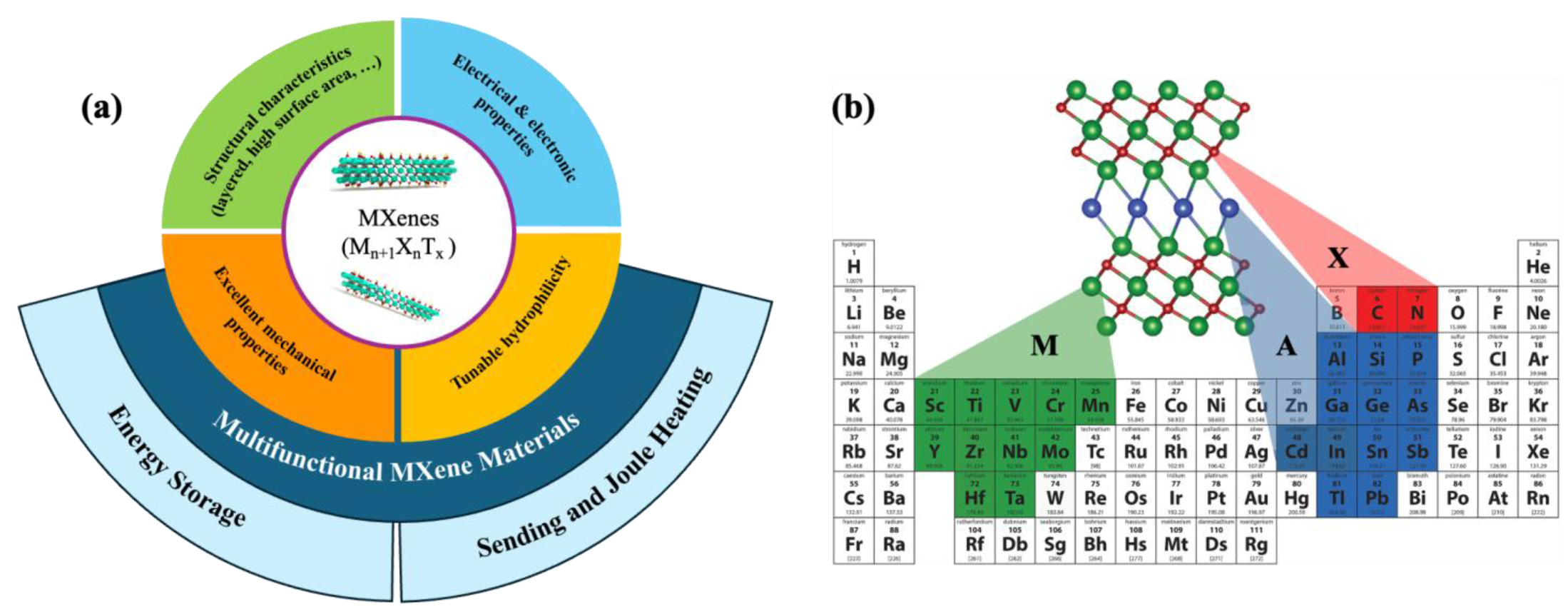

1.1. MXene Structure

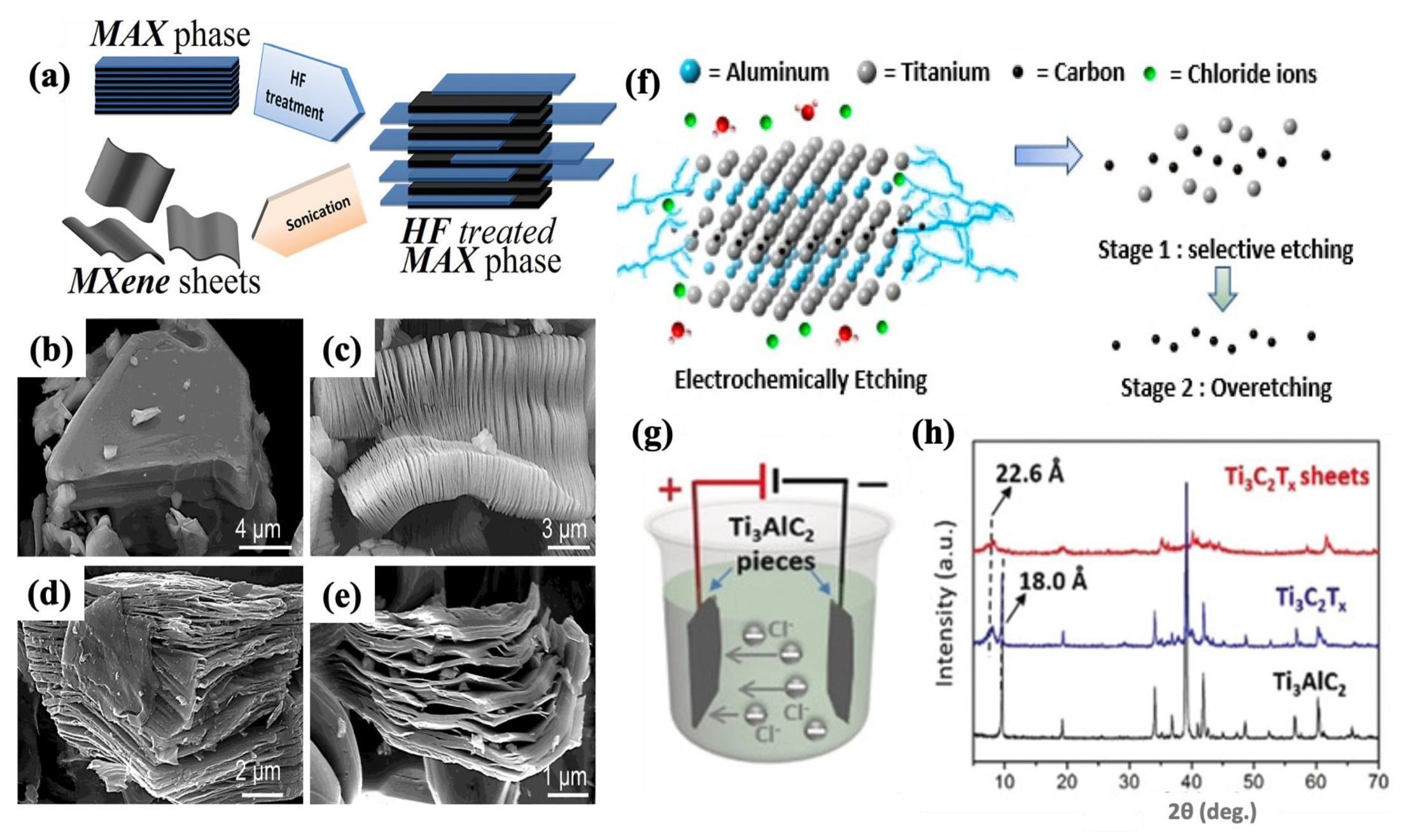

1.2. MXene Synthesis

1.2.1. Direct and Indirect (MILD) Synthesis Process

1.2.2. Electrochemical Etching

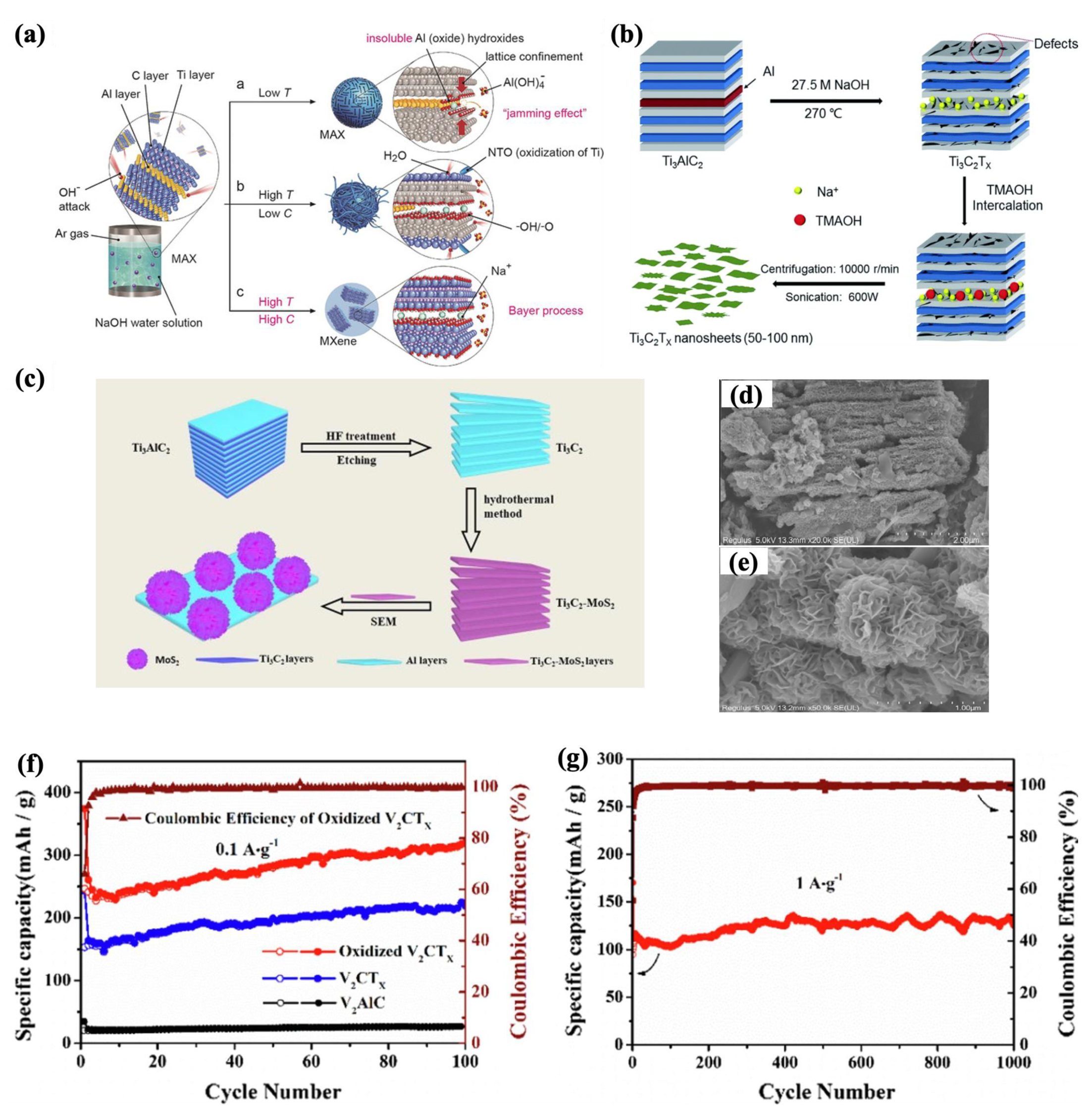

1.2.3. Hydrothermal Process

1.2.4. Quality, Stability, and Scalability of MXene Synthesis: Industrial Considerations

2. MXene Functionalities for Electronic Applications

2.1. Electrical Property

Theoretical Background and Manipulation of Electrical Conductivity in MXene–Polymer Nanocomposites

2.2. Dielectric Properties

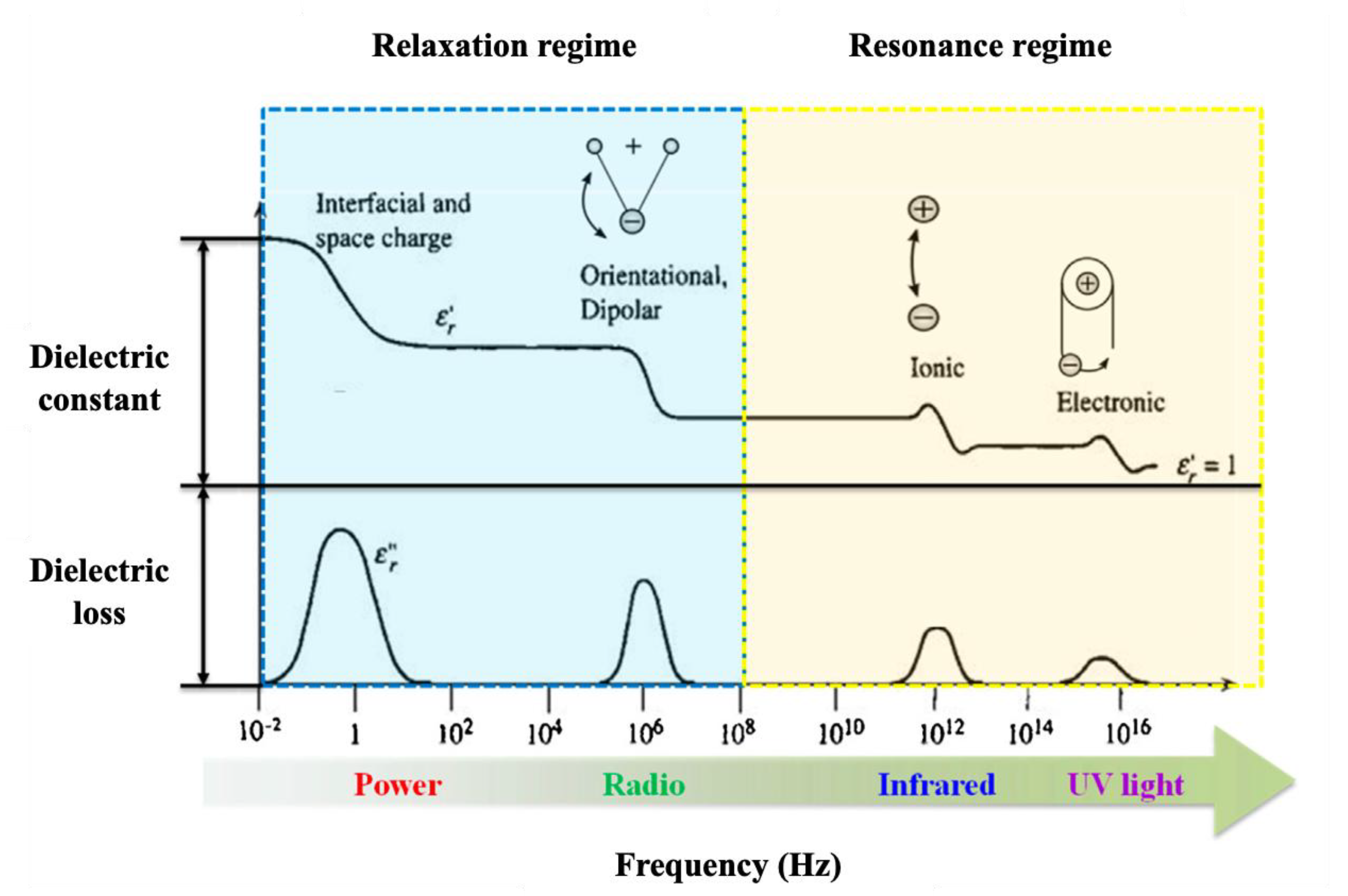

2.2.1. Theoretical Background

Dielectric Constant and Dielectric Loss

Polarization Mechanisms in Dielectric Materials

Importance of EMI-Shielding Properties

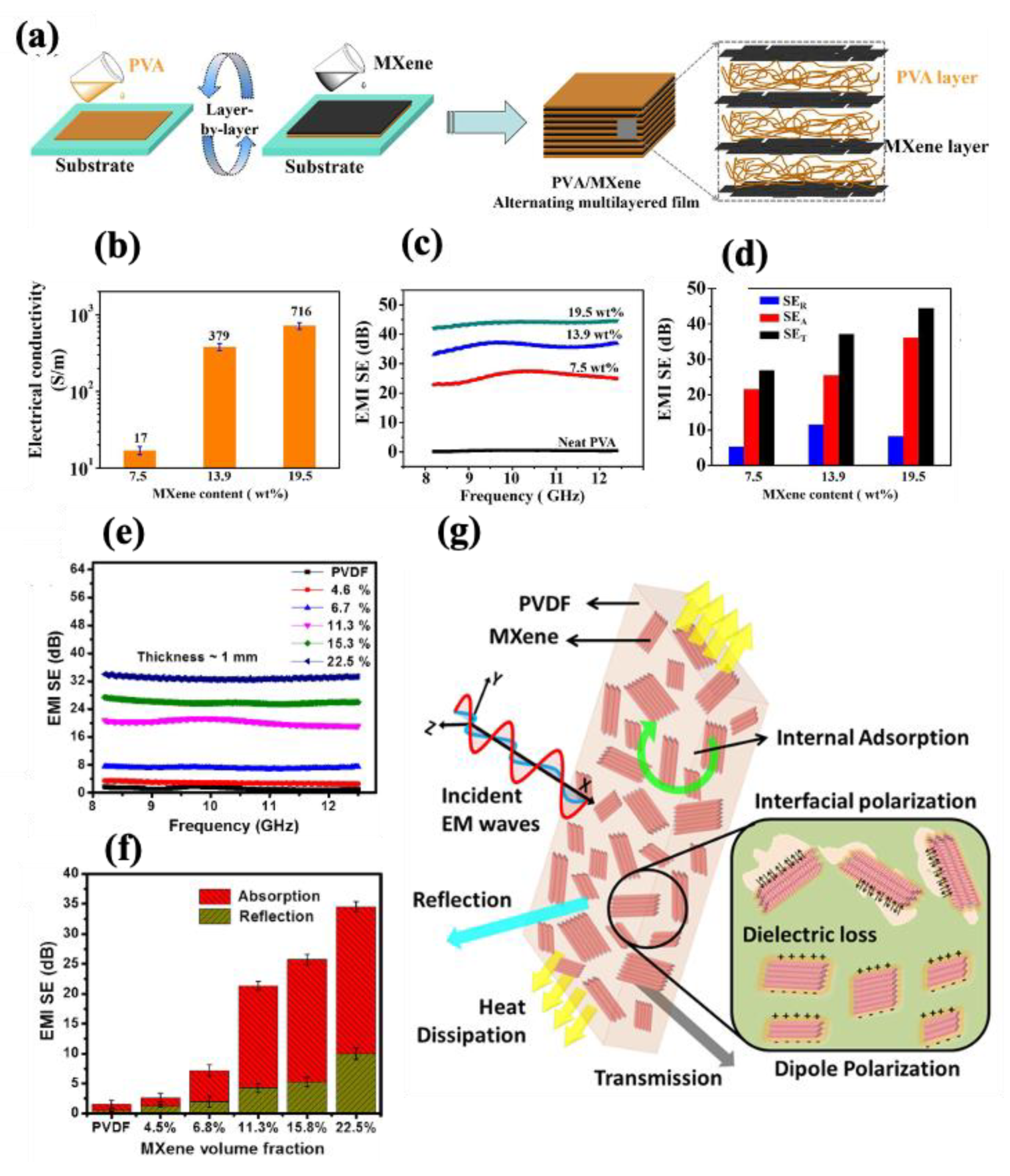

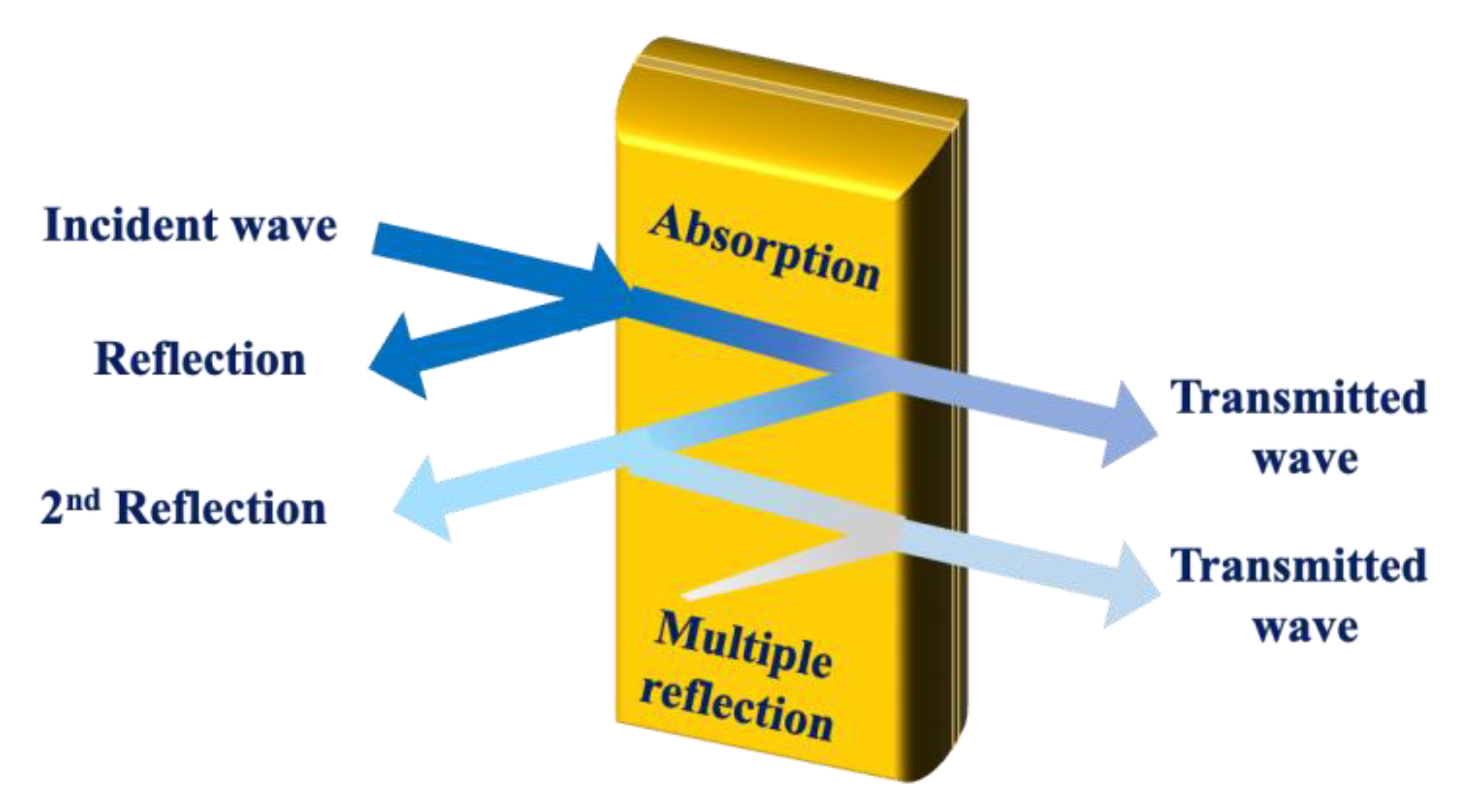

EMI-Shielding Mechanisms

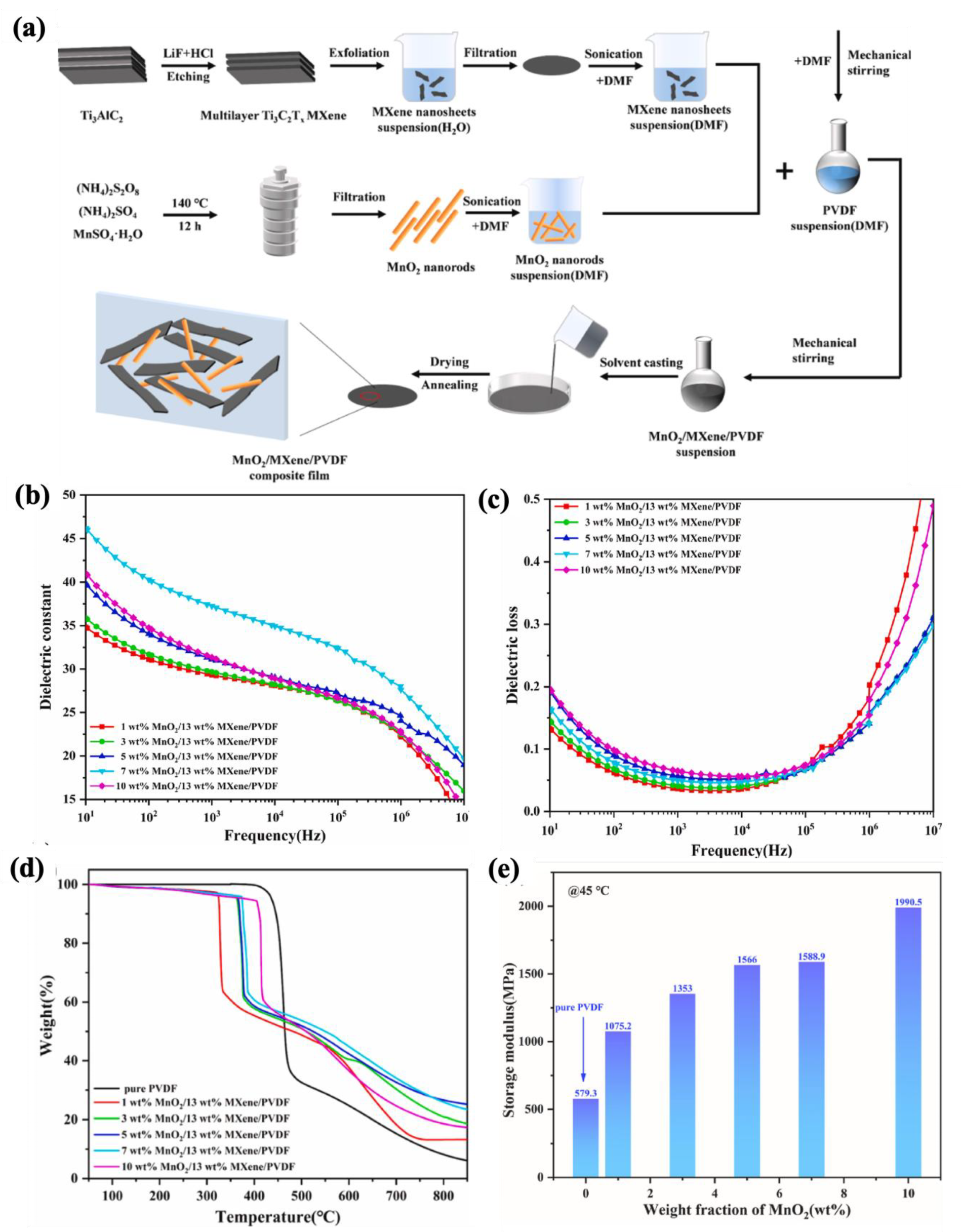

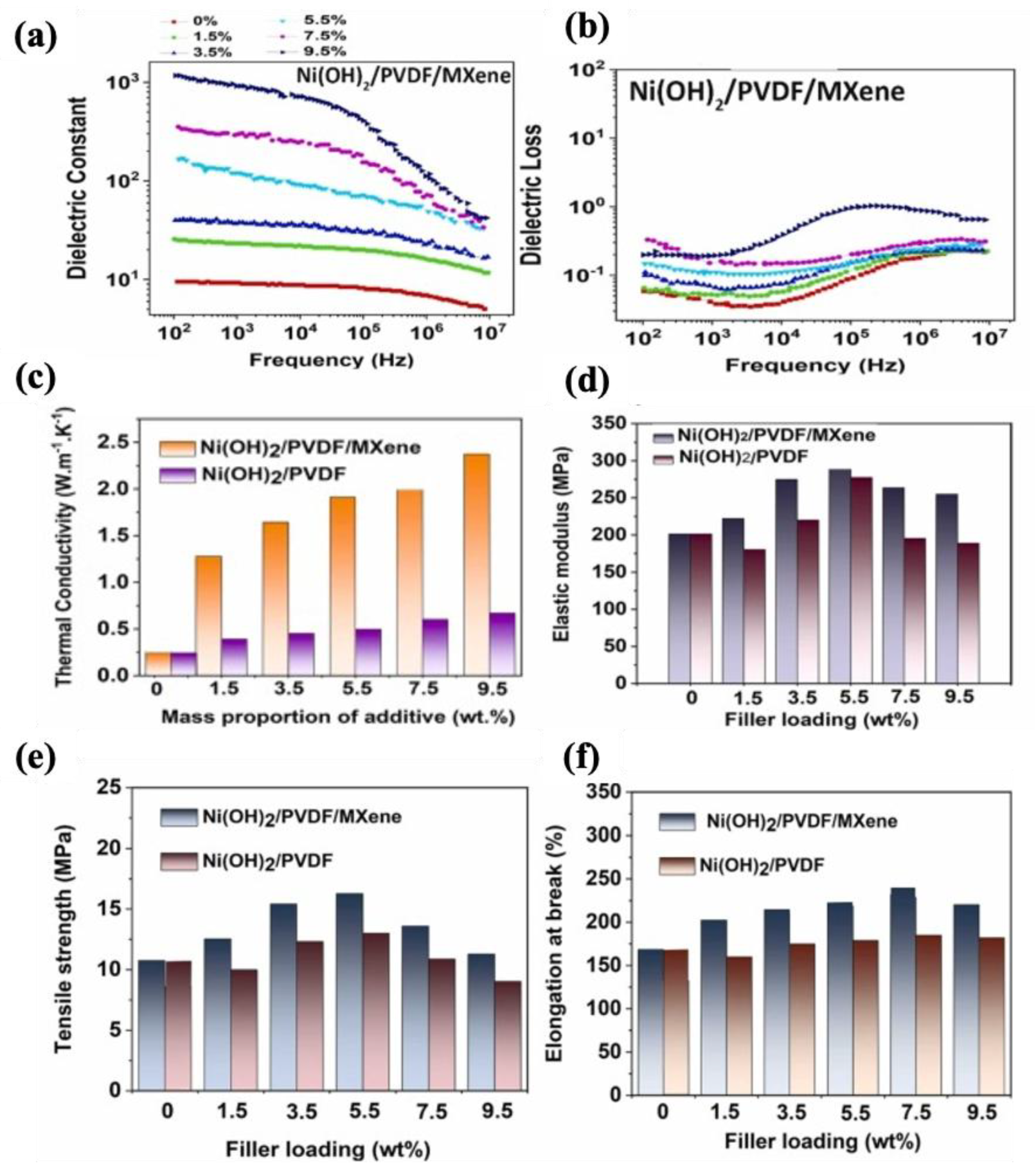

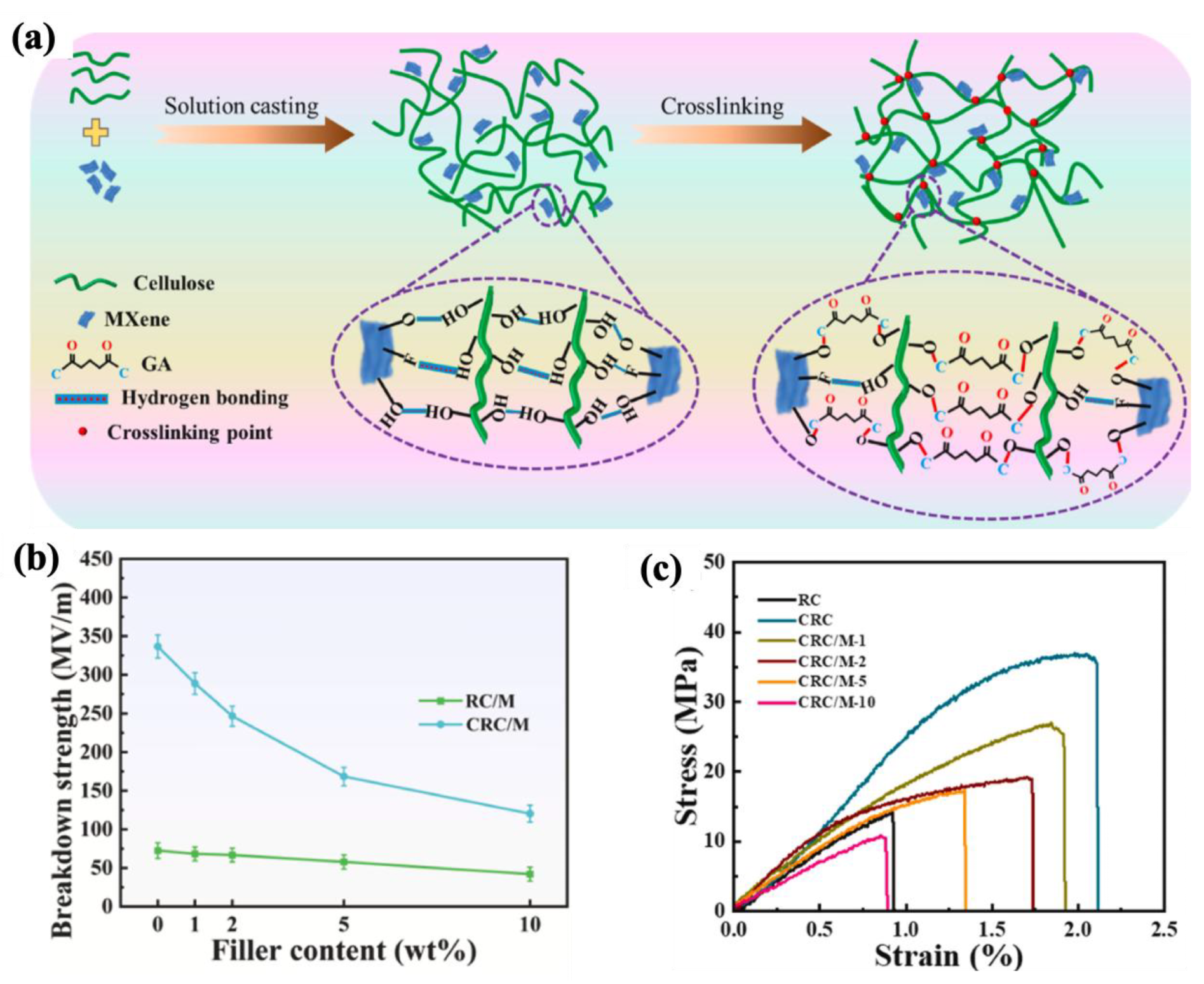

2.2.2. Advancements in Developing MXene Polymer Nanocomposites with High Dielectric Property

2.3. Mechanical Properties

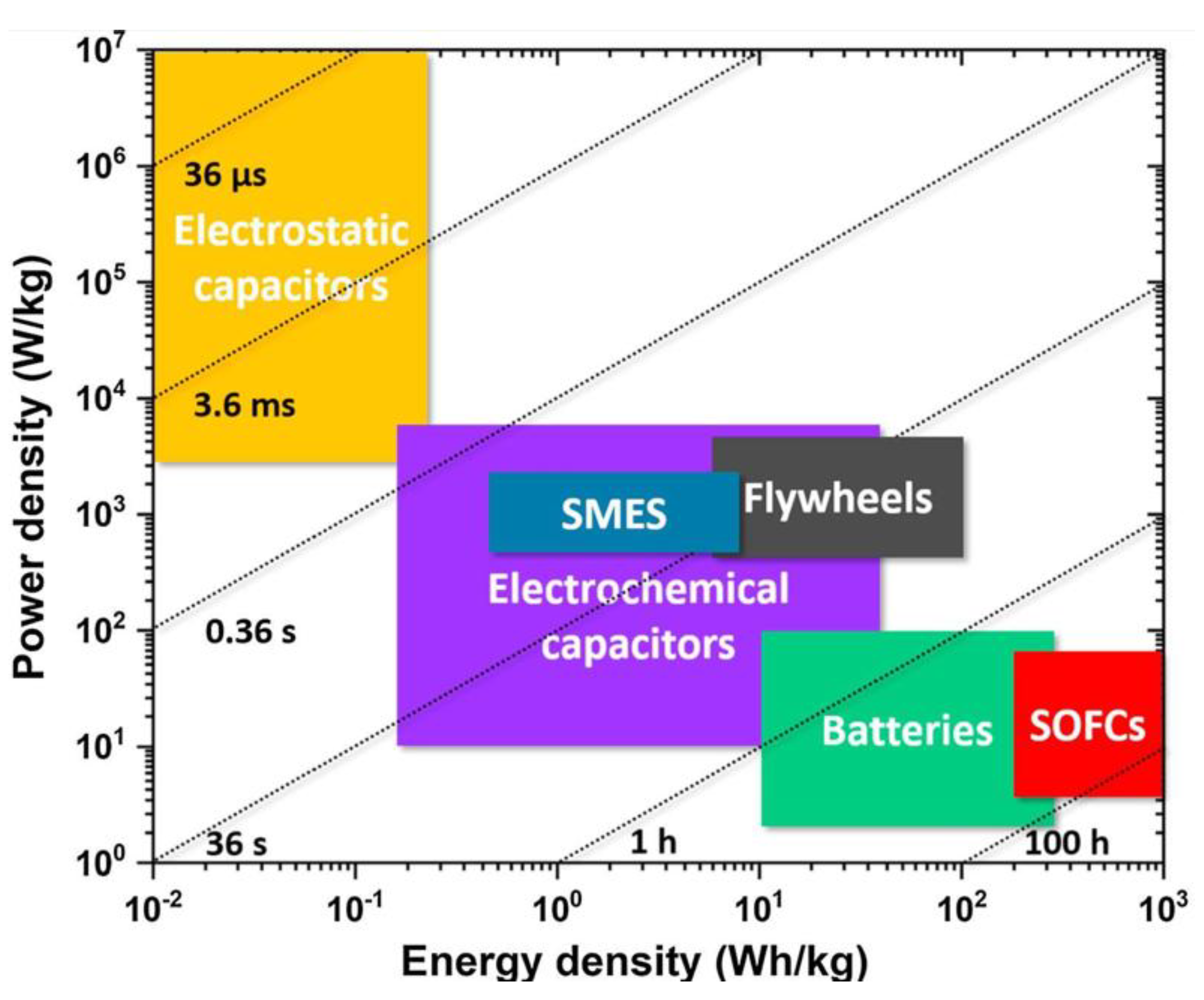

3. Multifunctional MXene Materials with the Primary Application of Energy Storage

3.1. Batteries

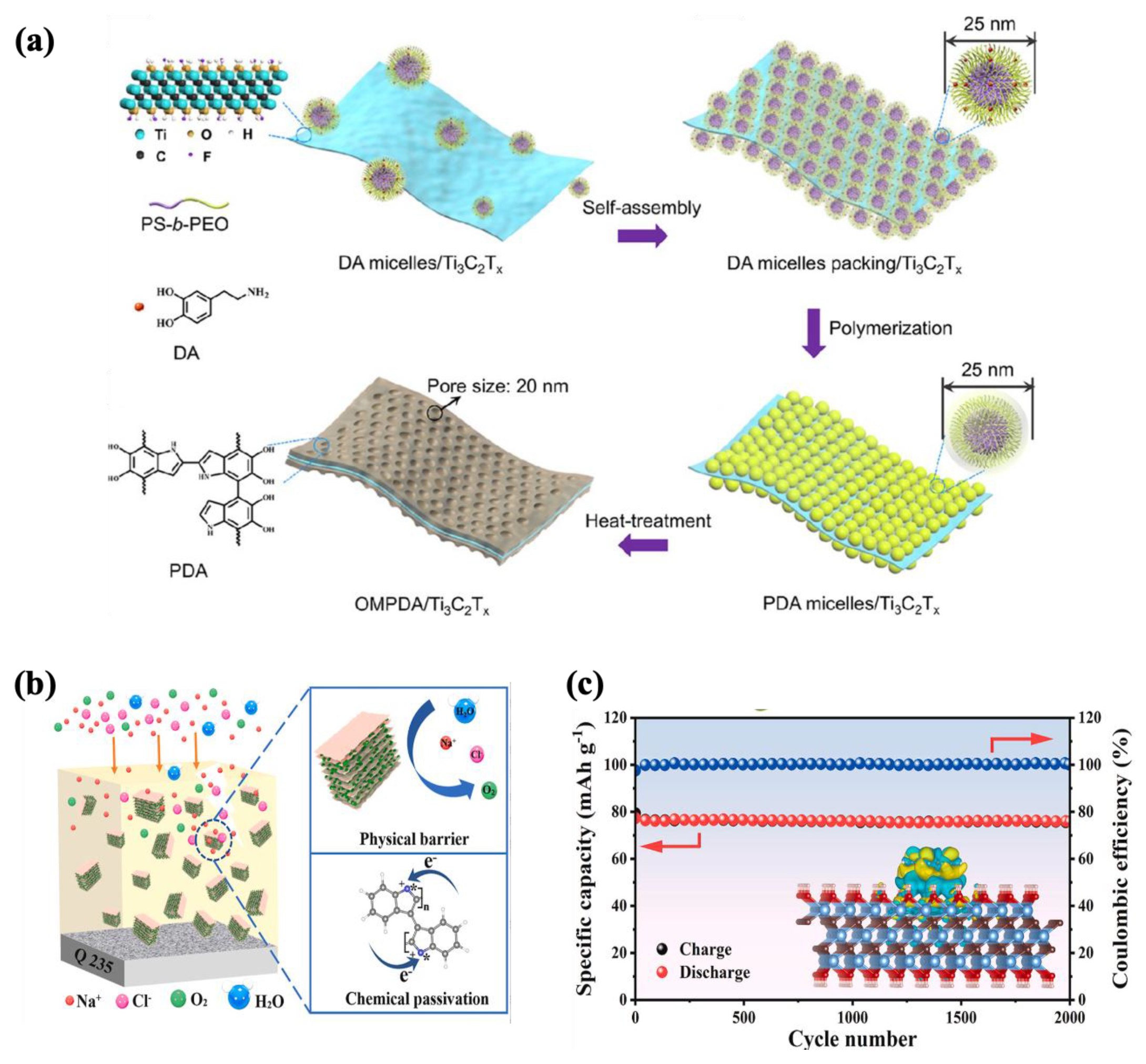

3.1.1. Electrodes

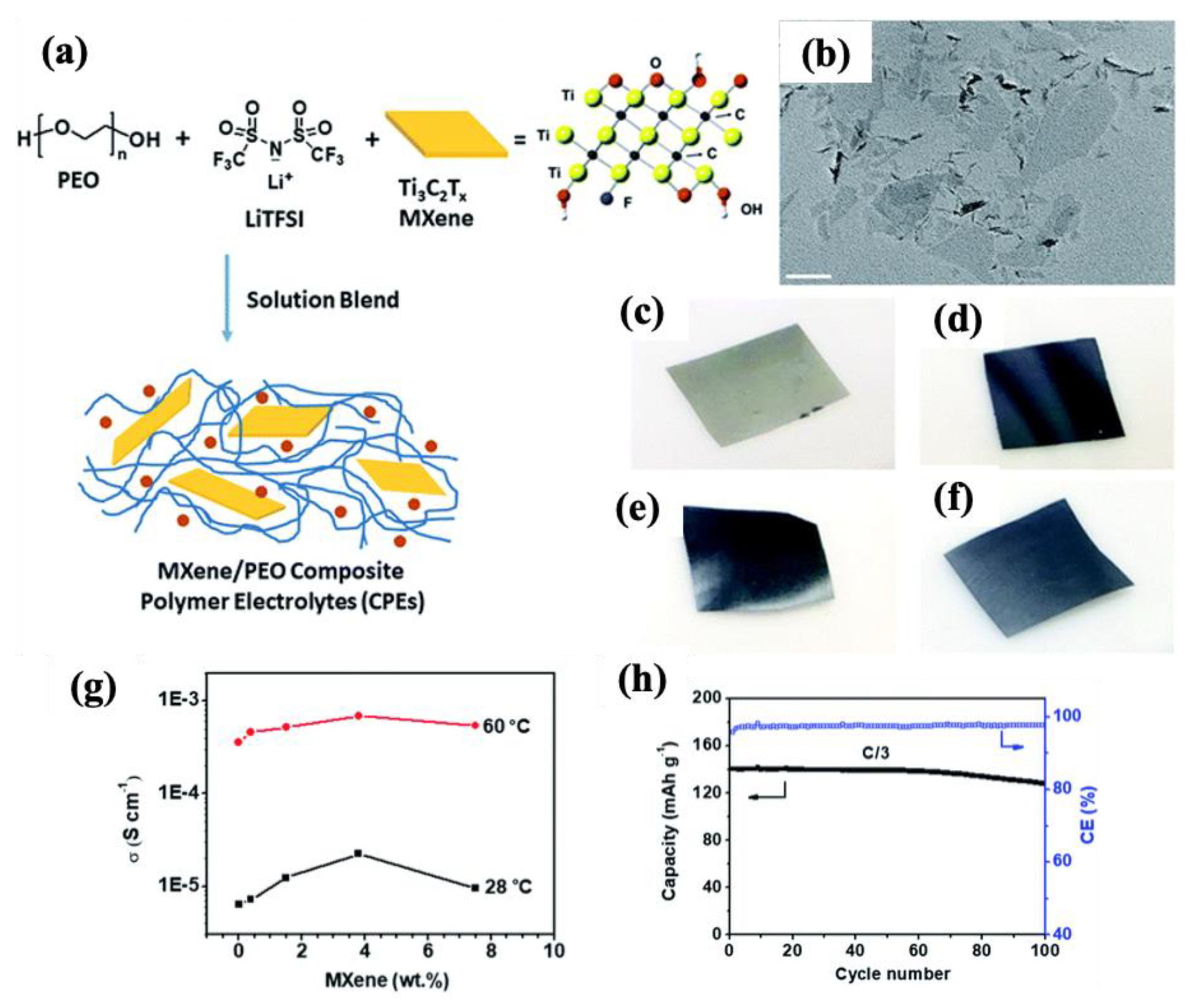

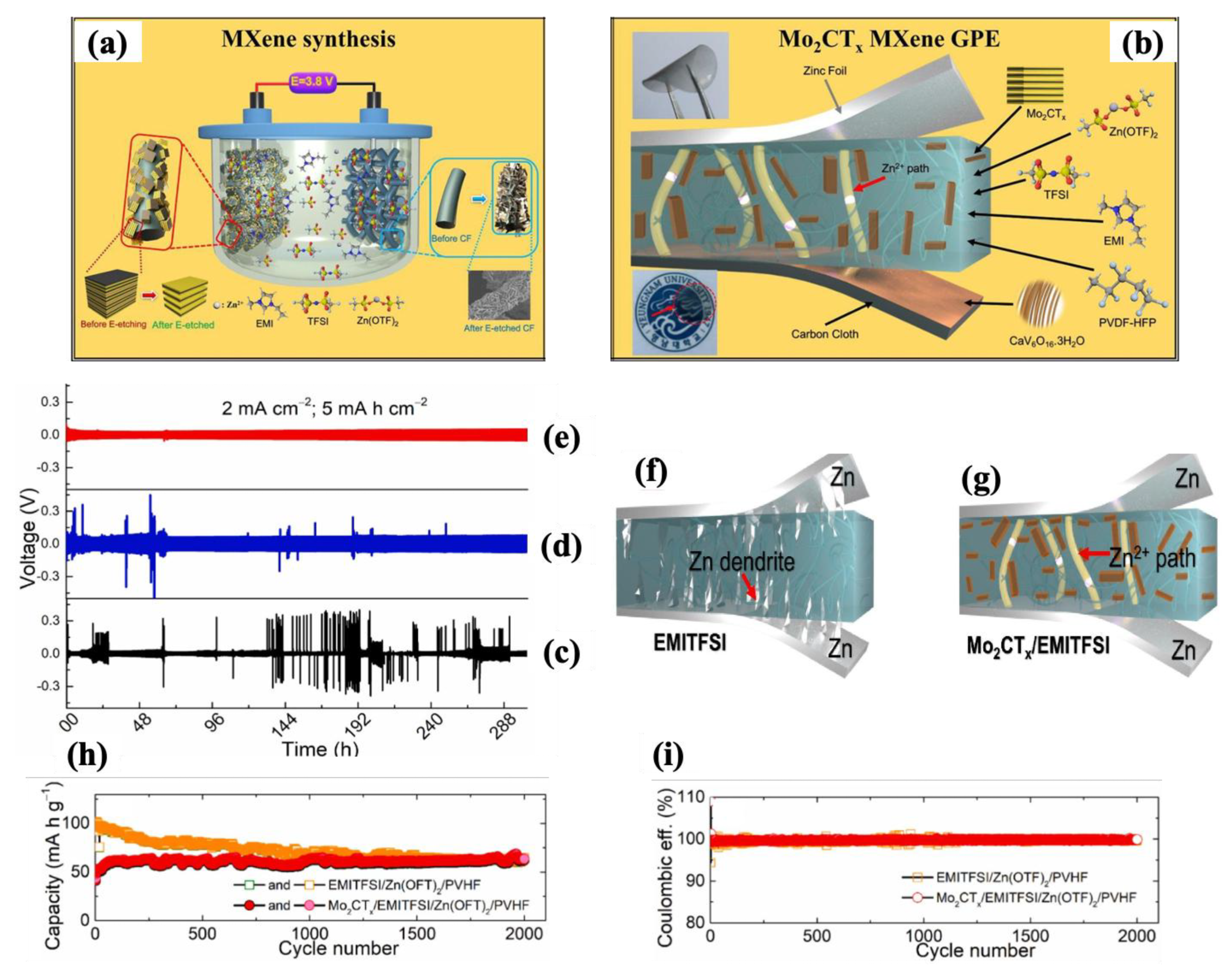

3.1.2. Electrolytes

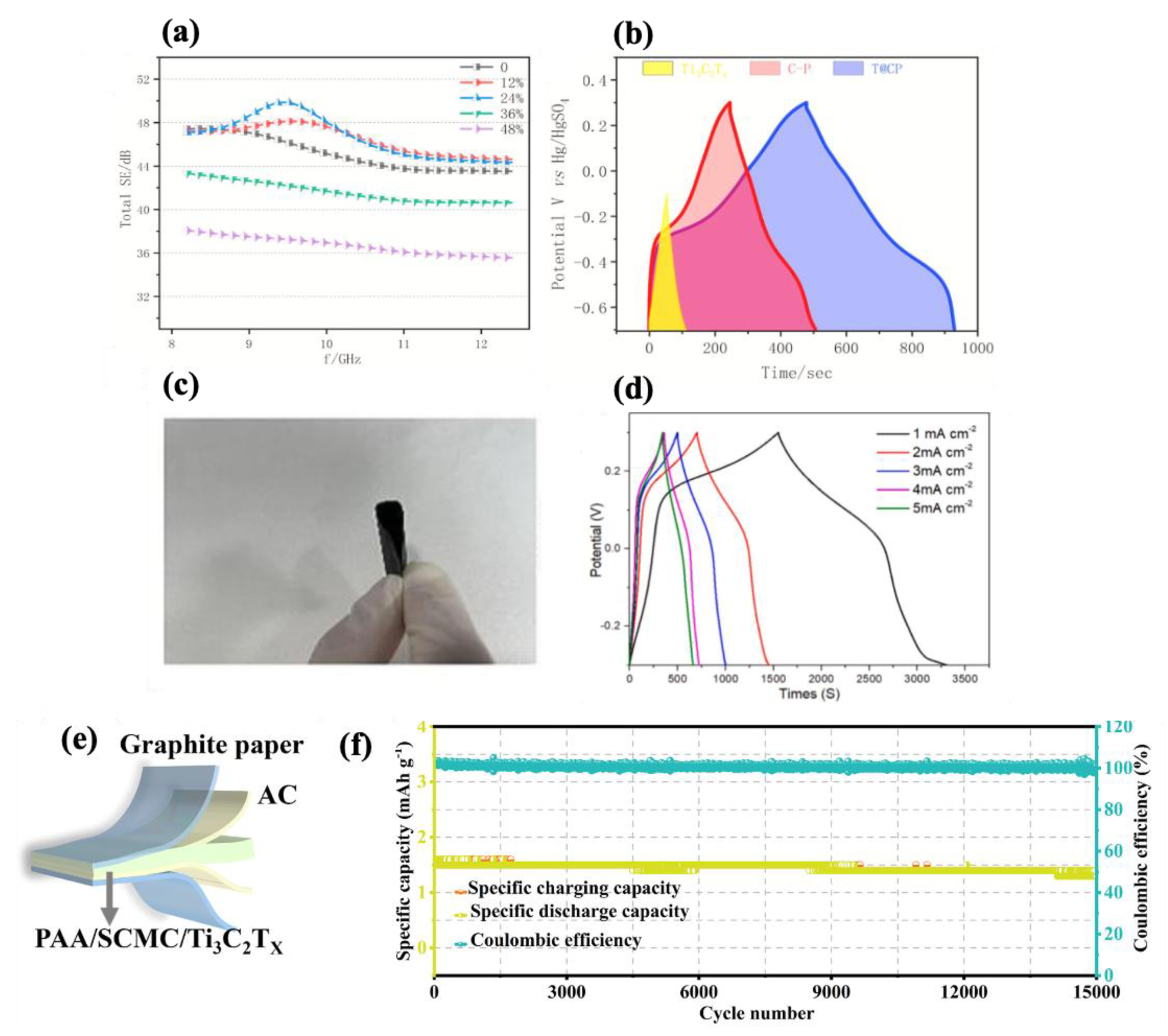

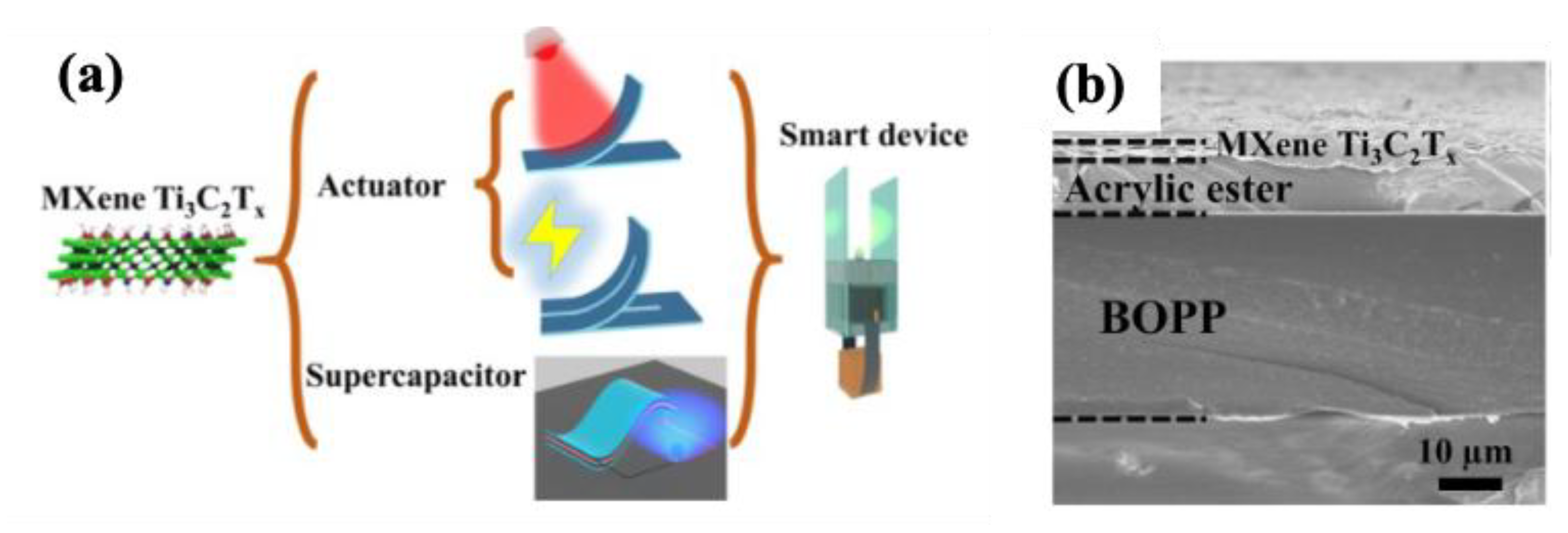

3.2. Supercapacitors

3.3. Electrostatic Capacitors

4. Multifunctional MXene Materials with the Primary Application of Sensing and Joule Heating

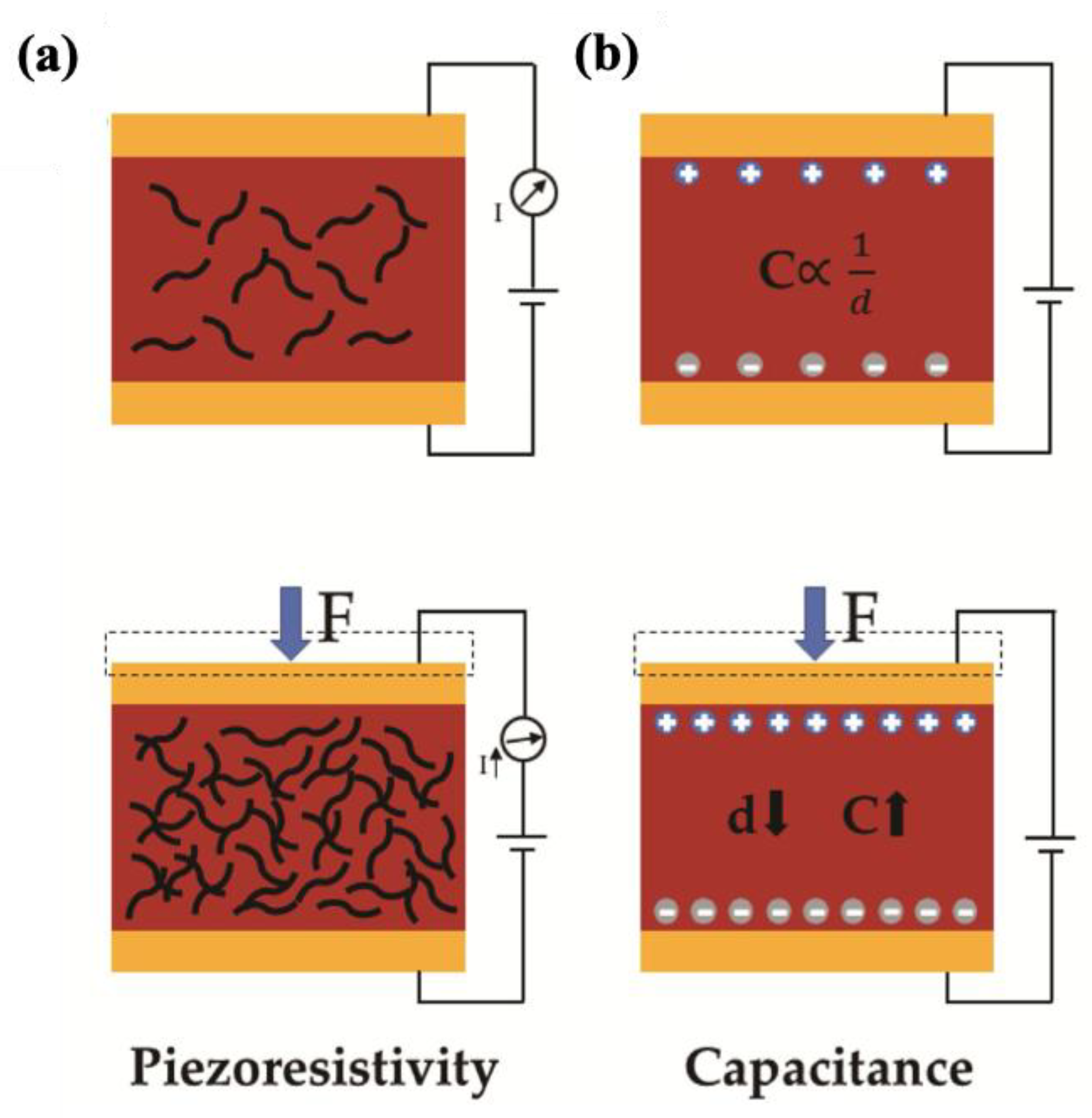

4.1. Theoretical Background on Sensing Mechanism

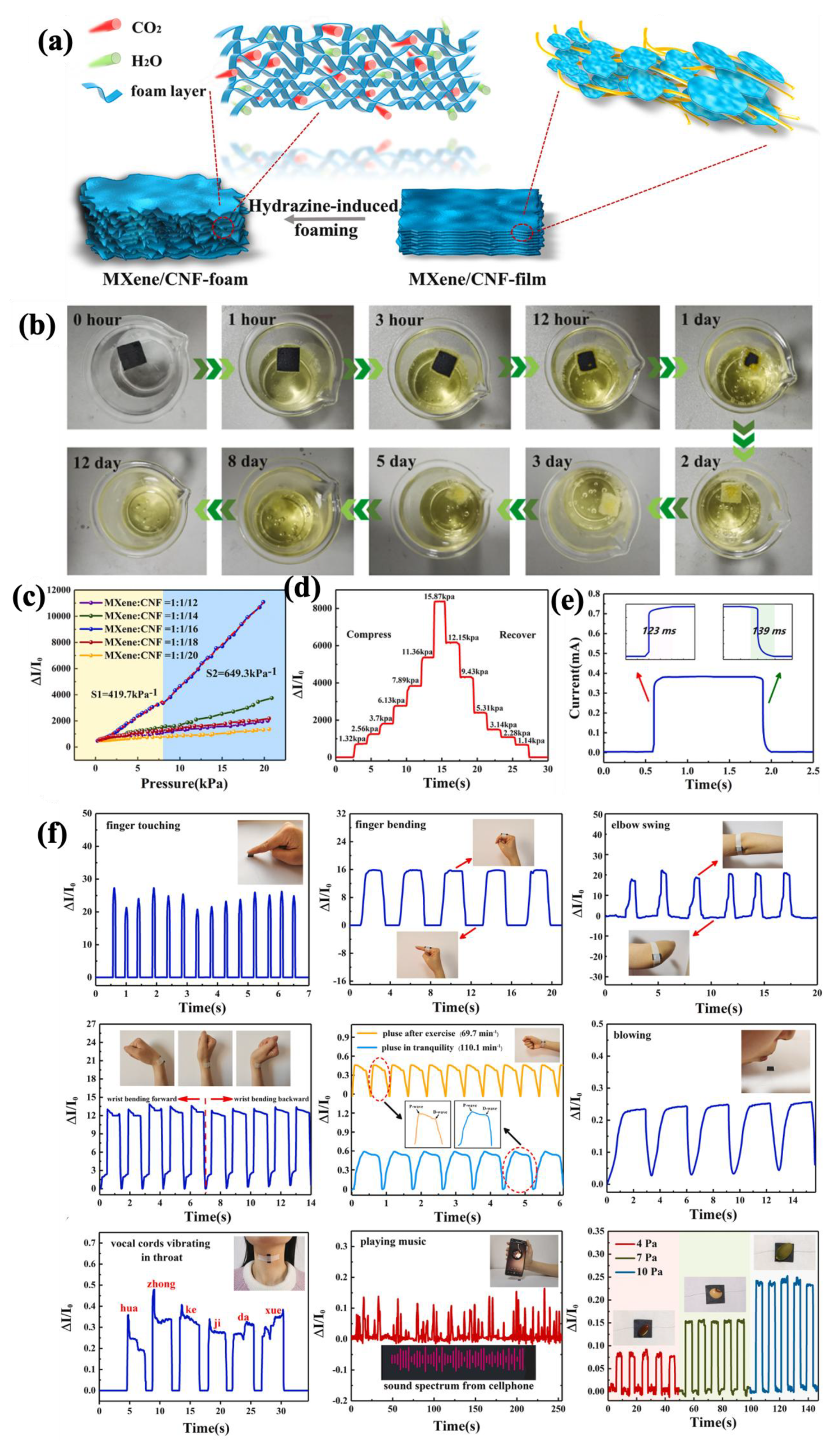

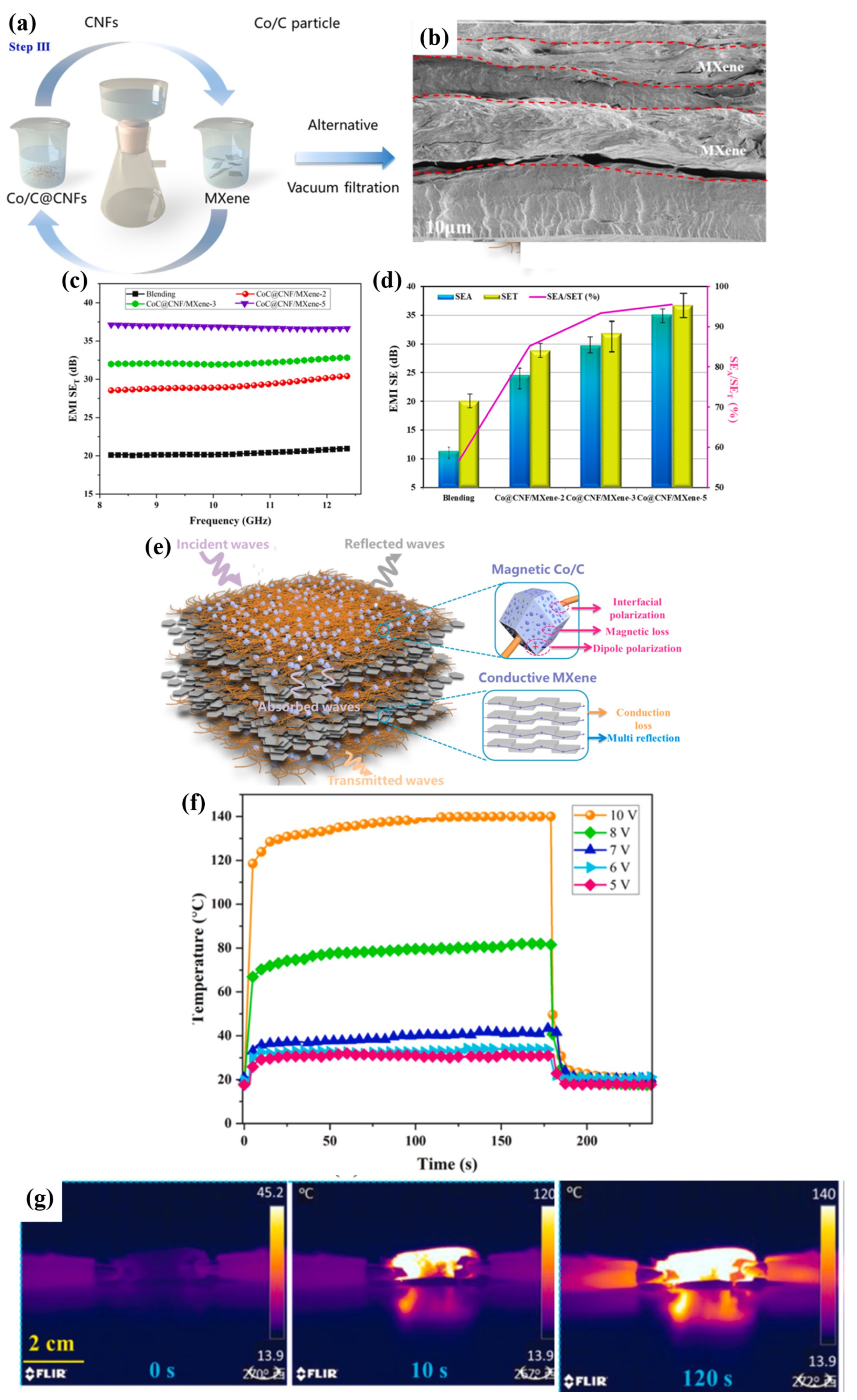

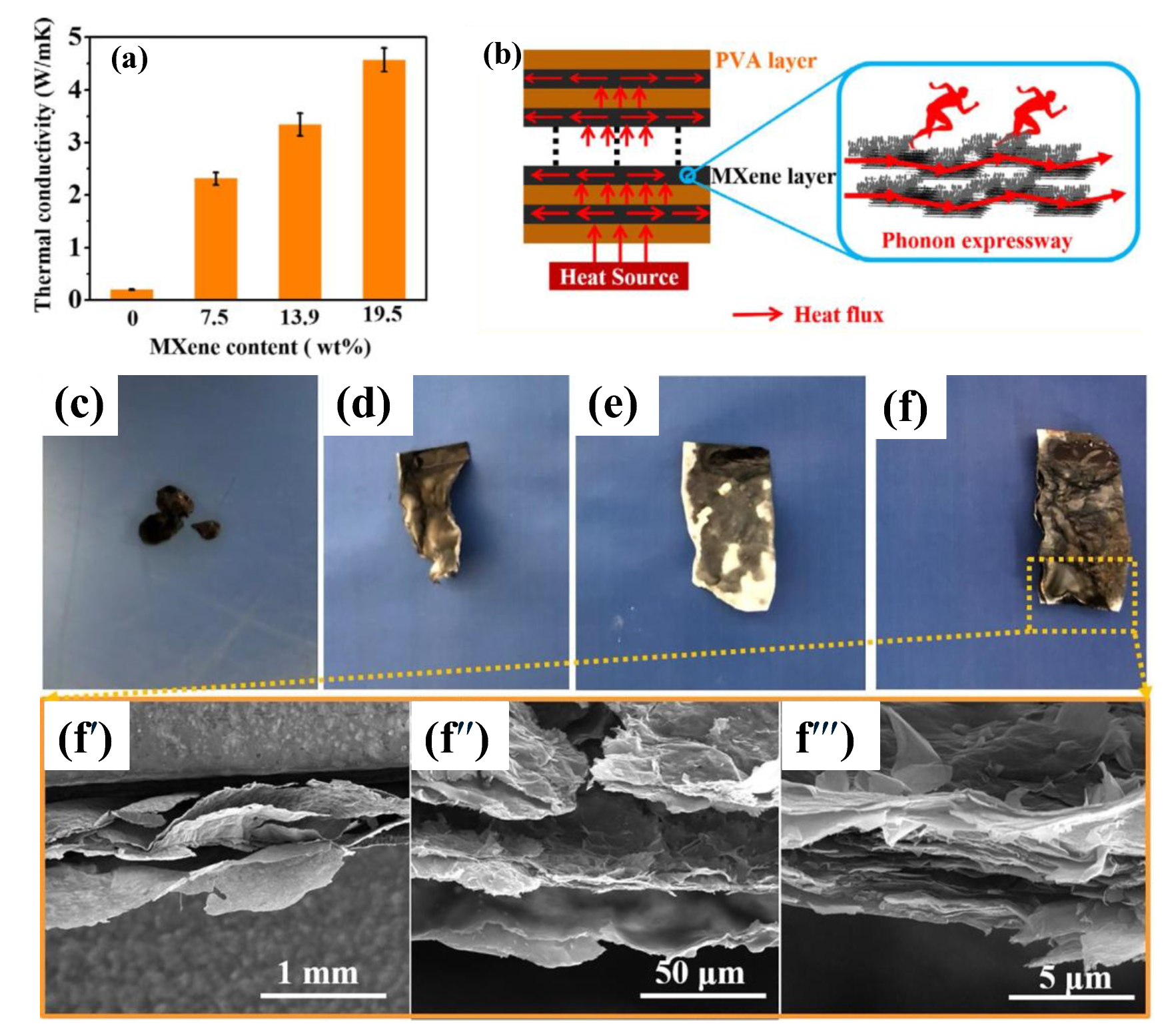

4.2. Different Sensors and Heaters Categories Based on Substrate’s Macrostructures

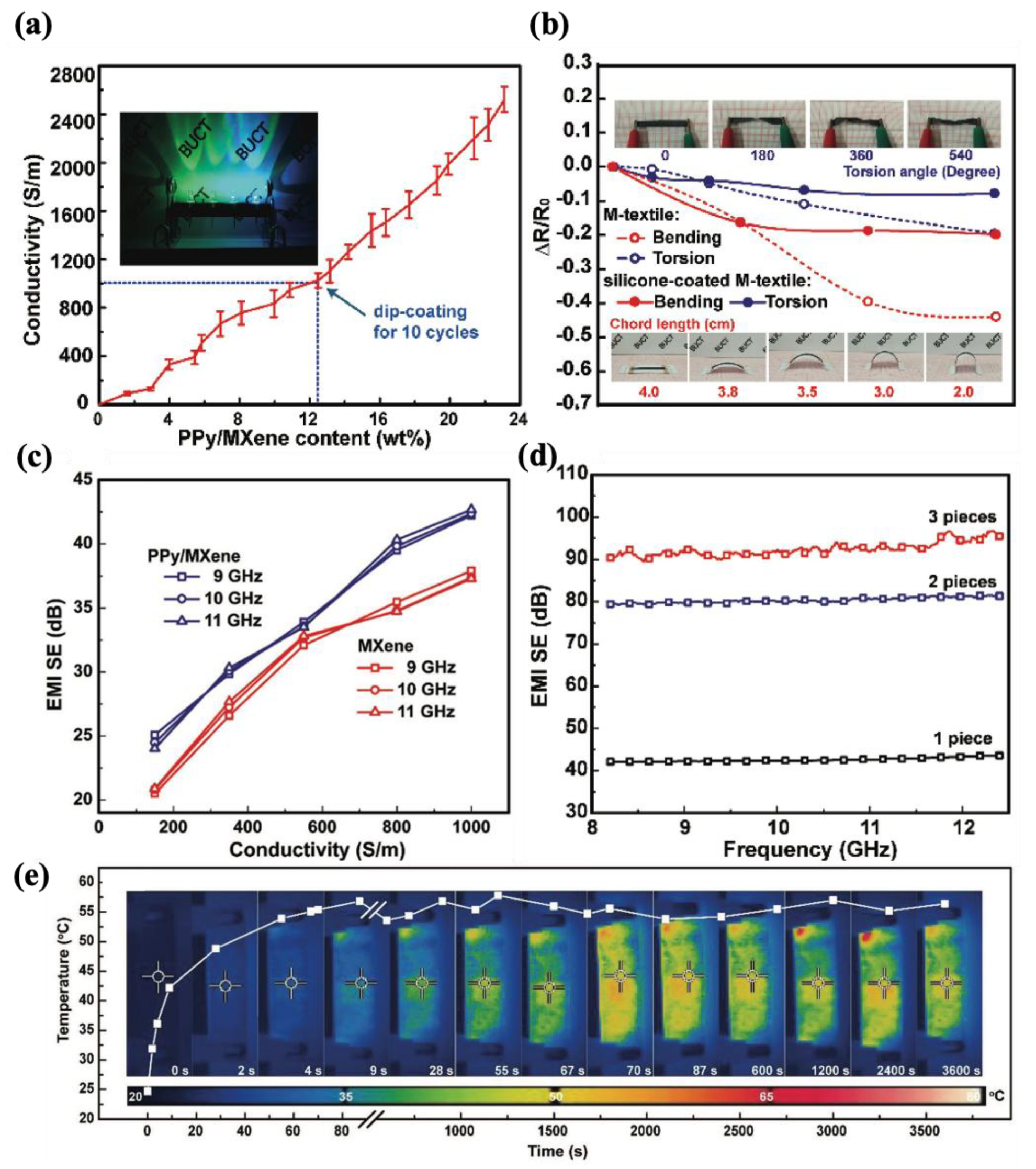

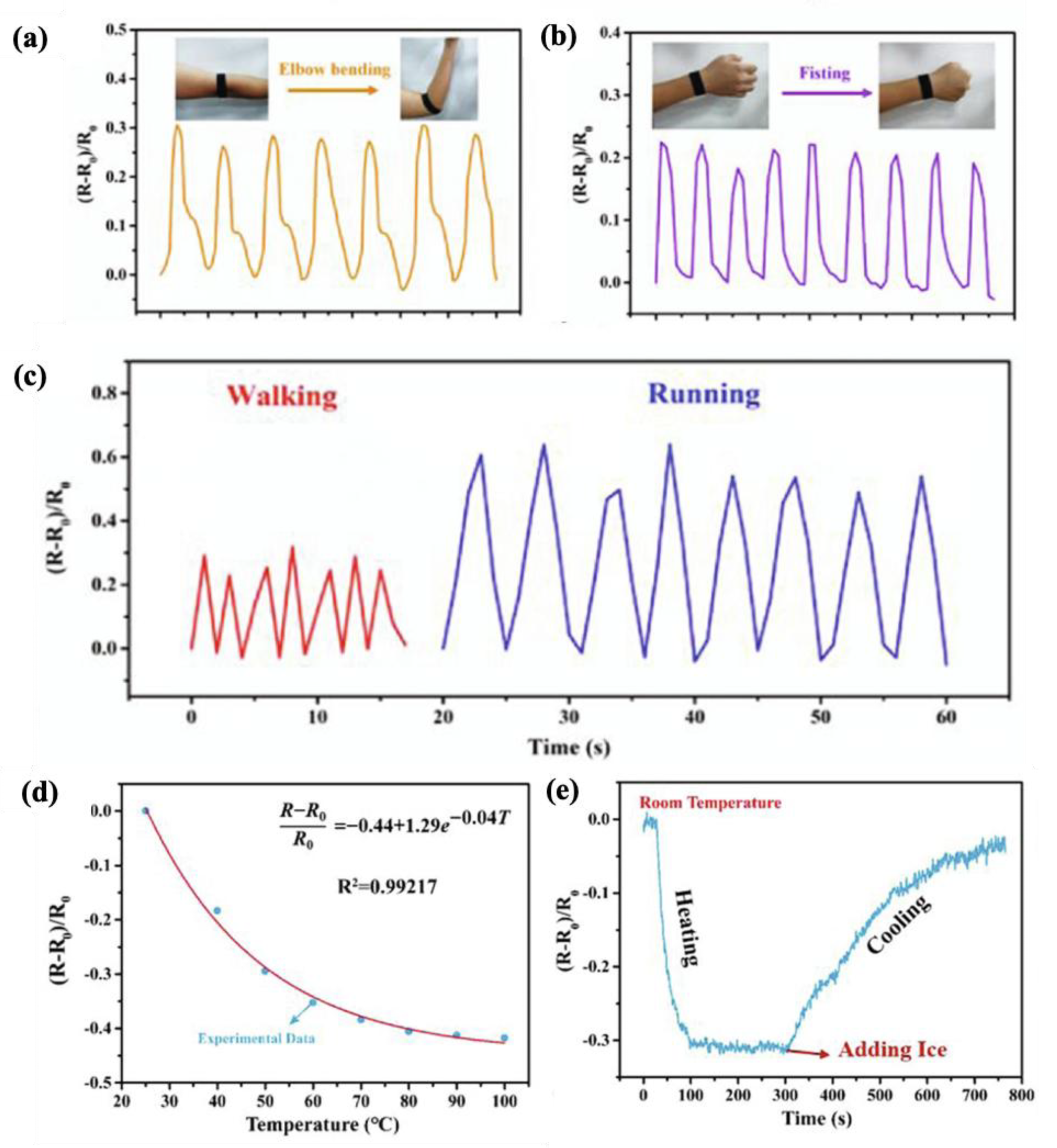

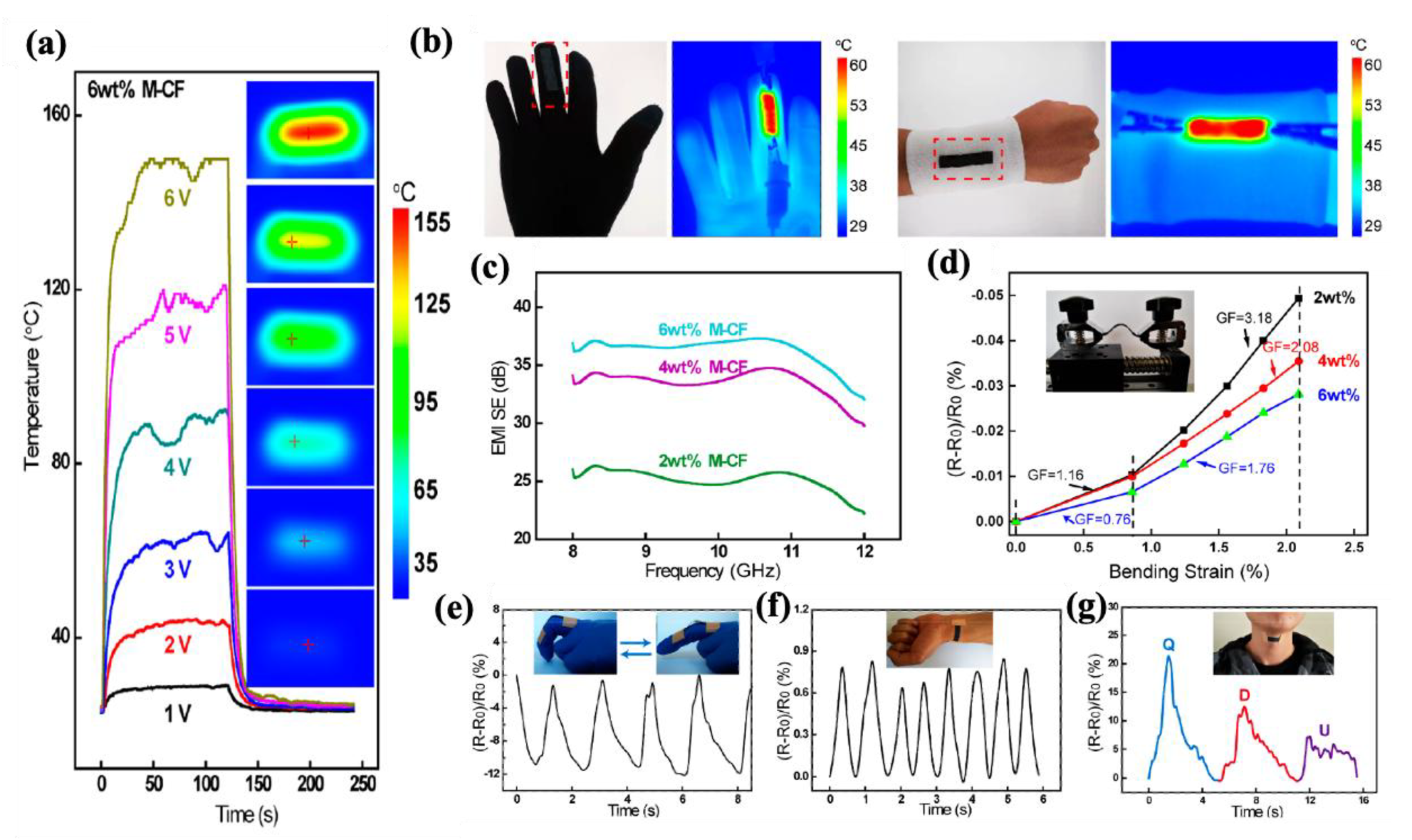

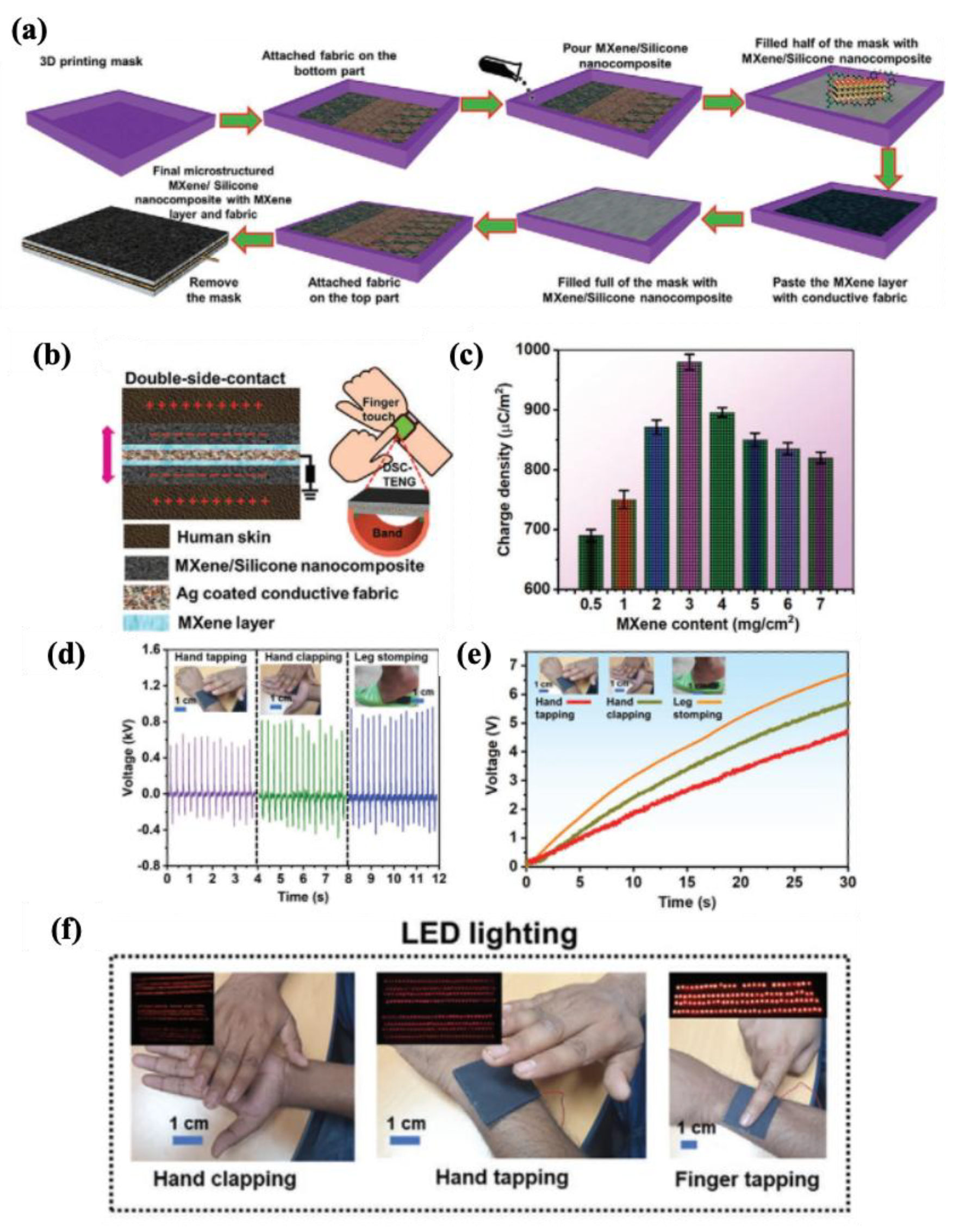

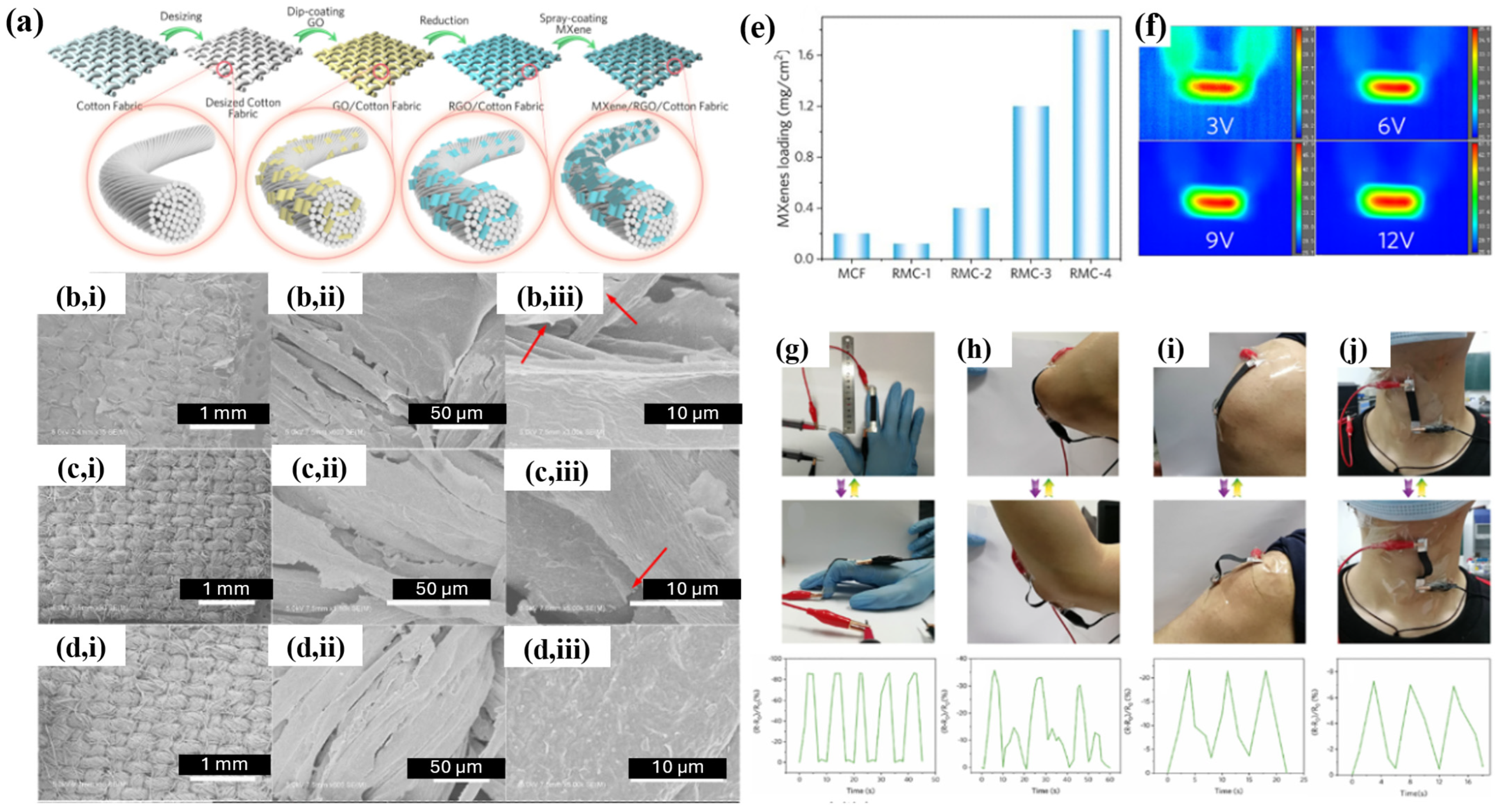

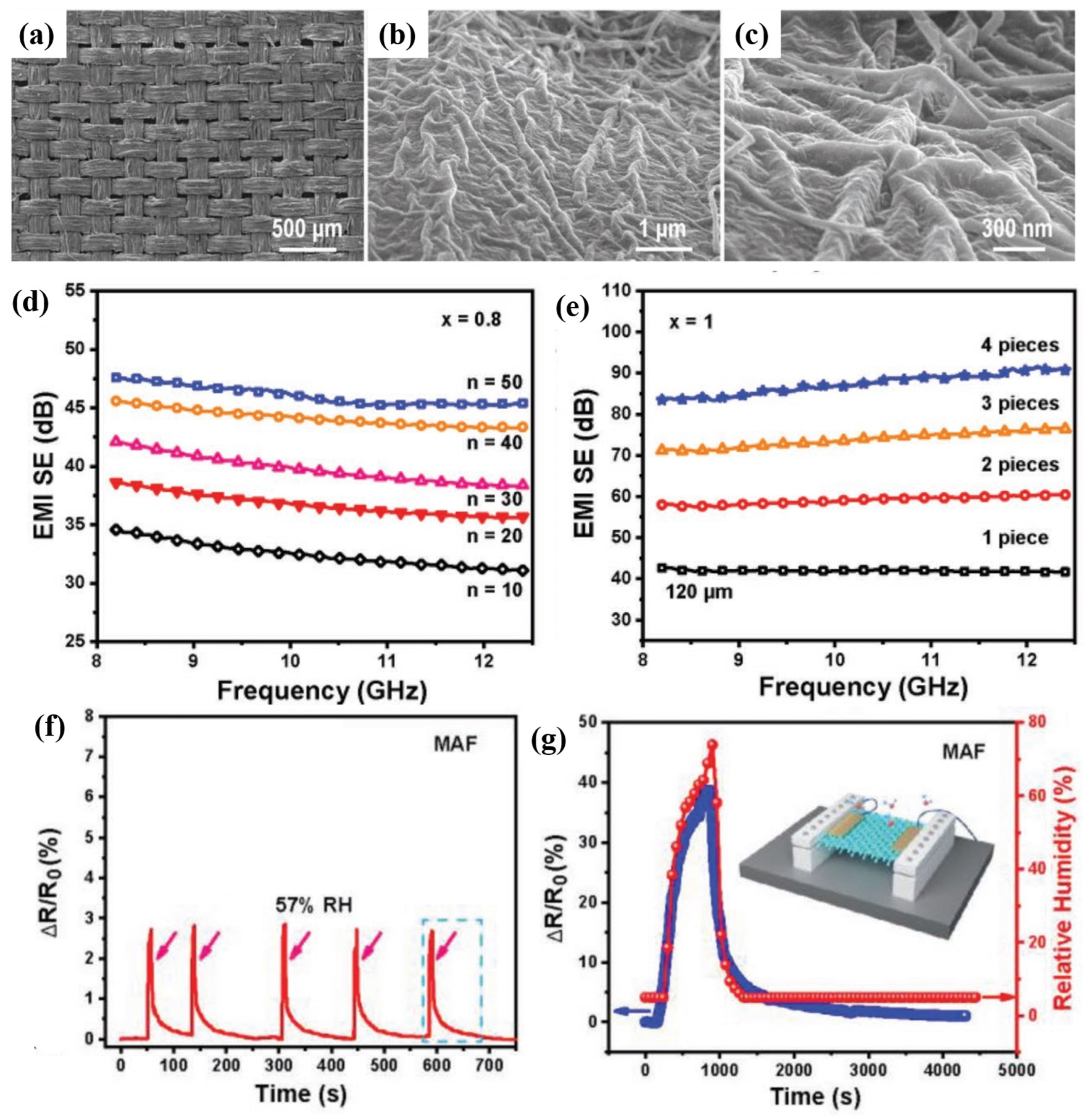

4.2.1. Fabric-Based Multifunctional Sensors and Heaters

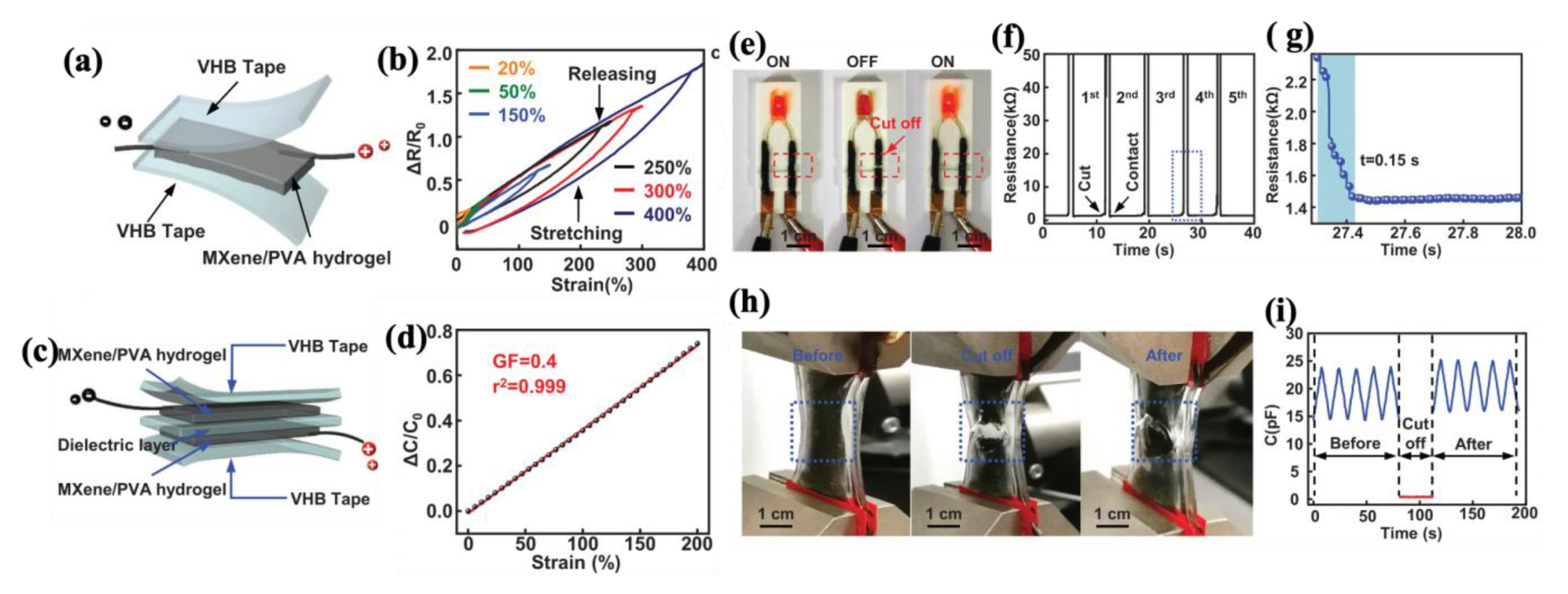

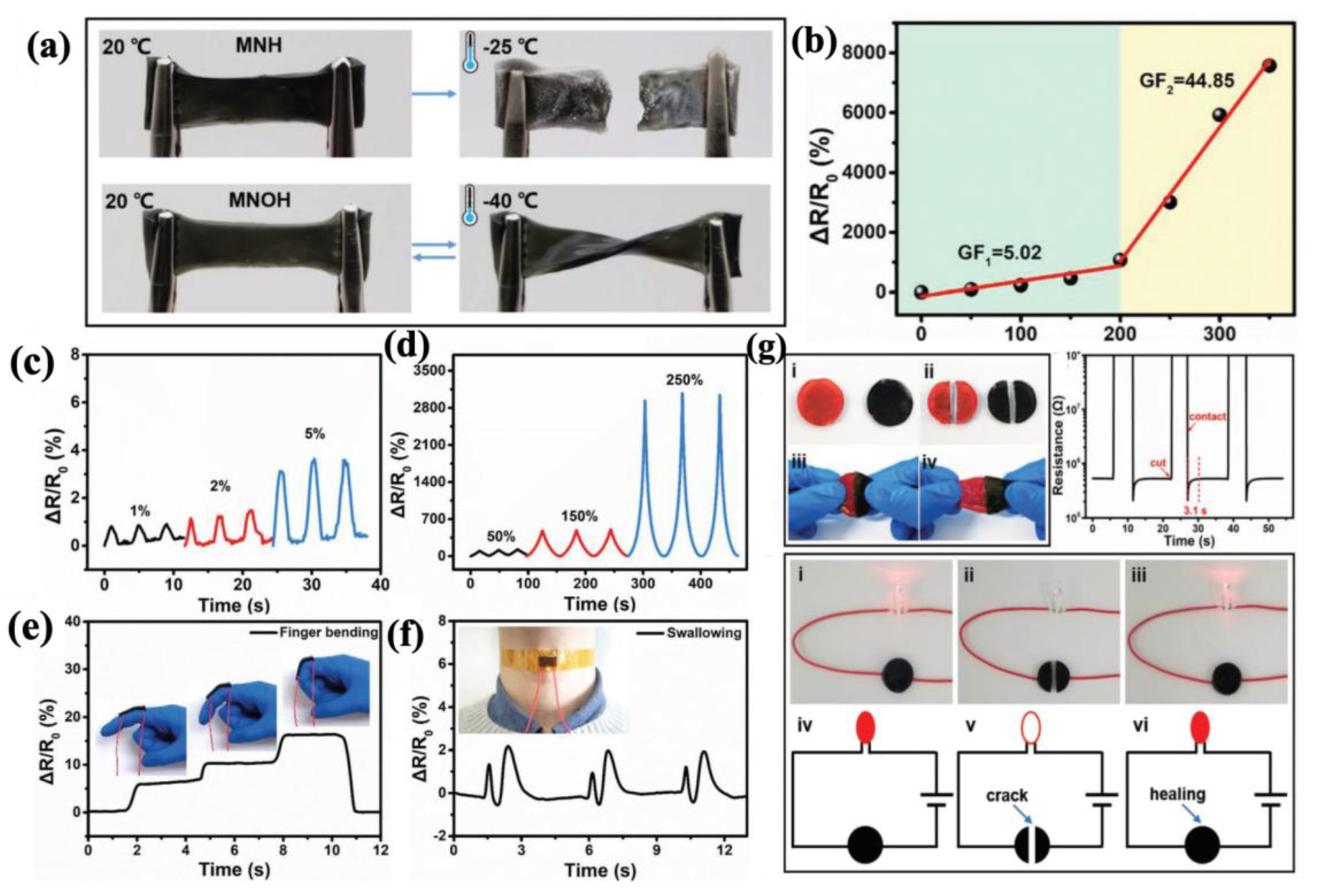

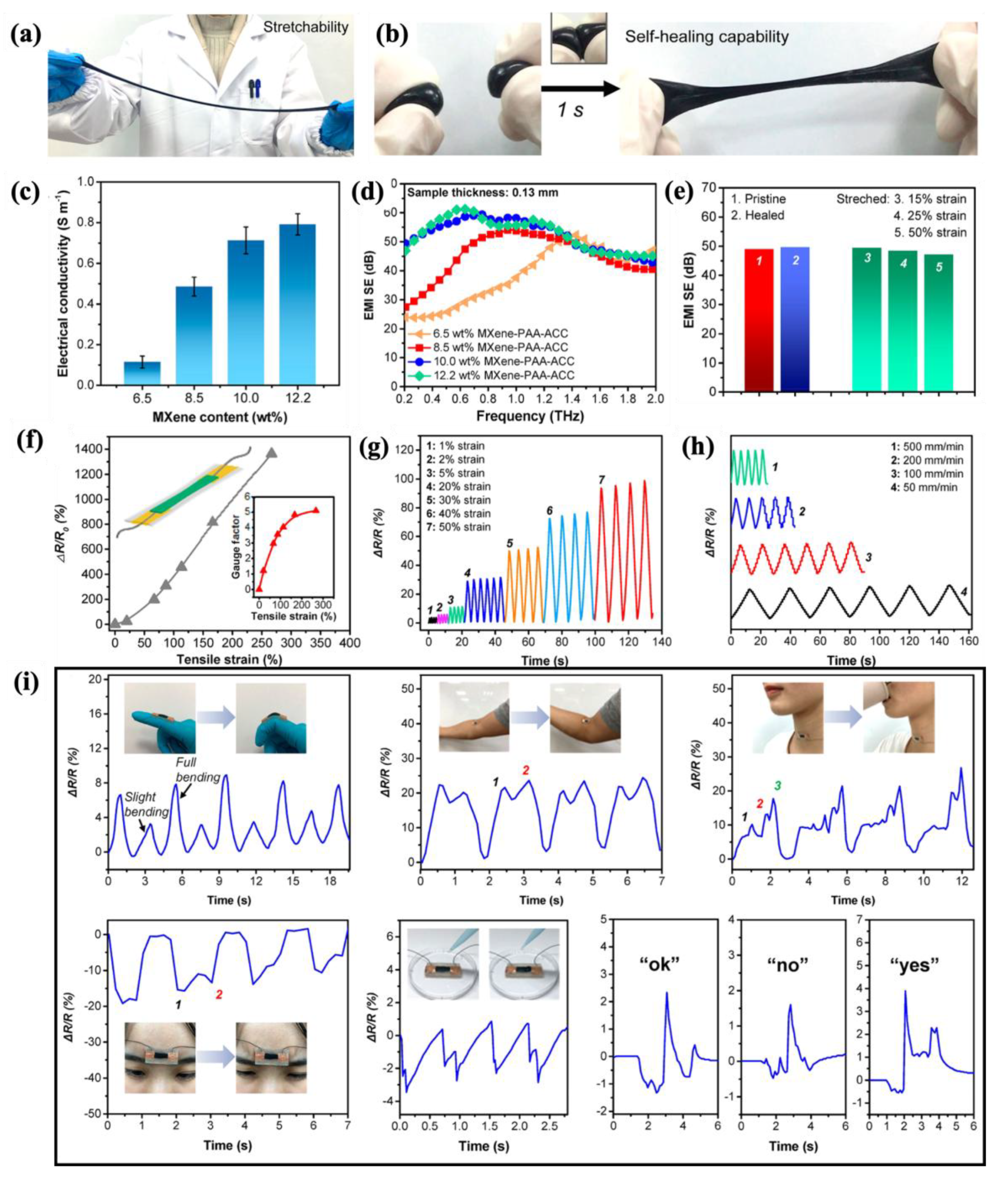

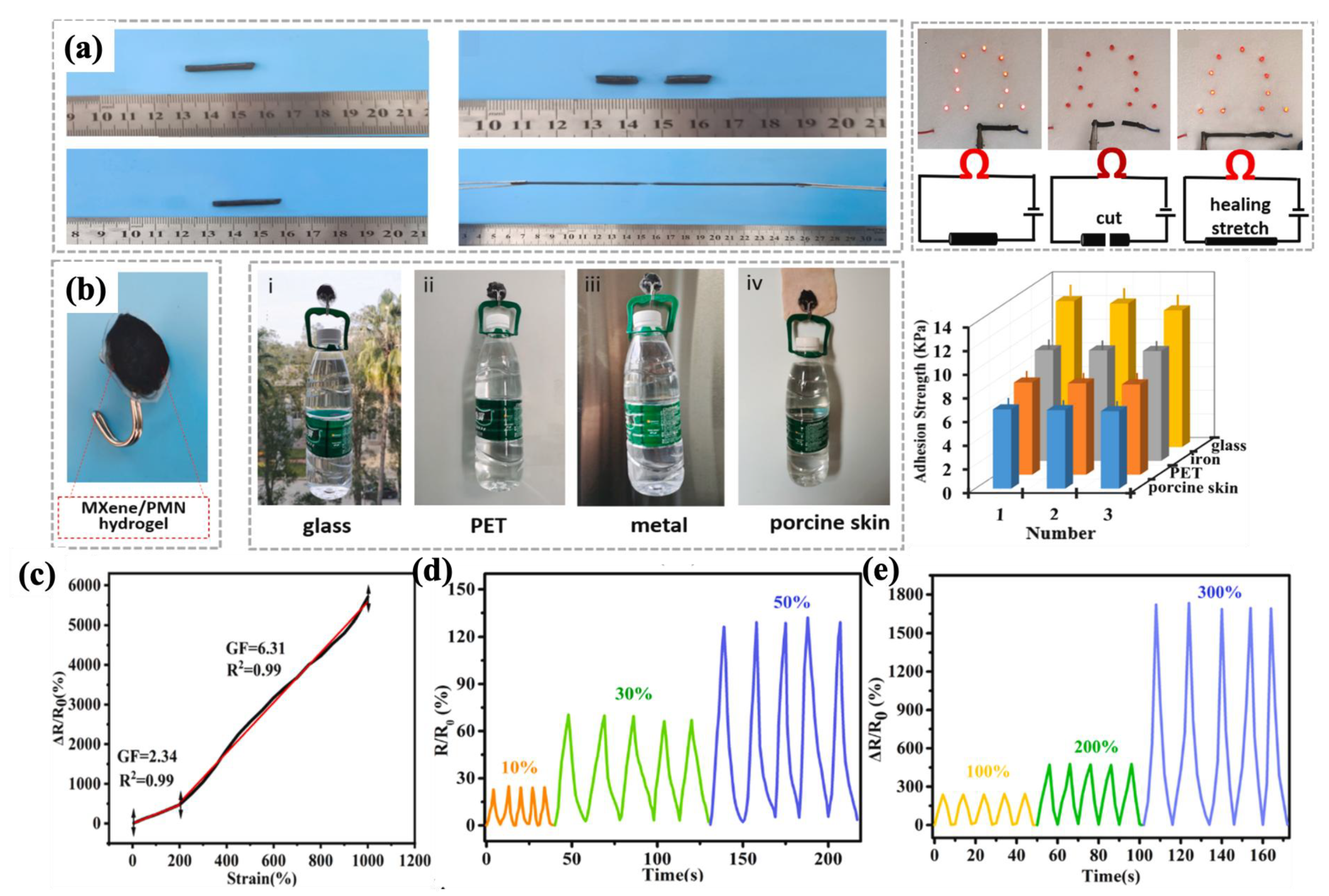

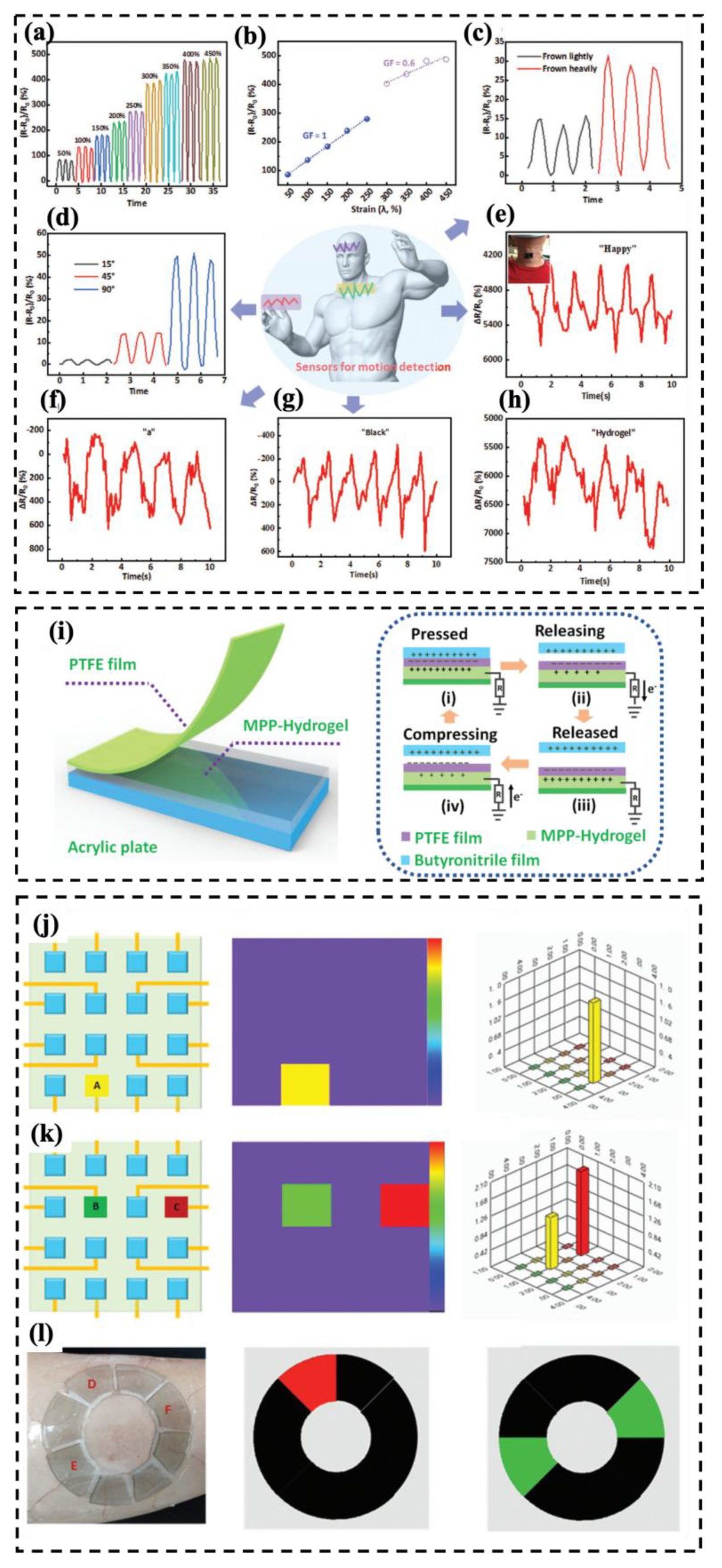

4.2.2. Hydrogel-Based Multifunctional Sensors and Heaters

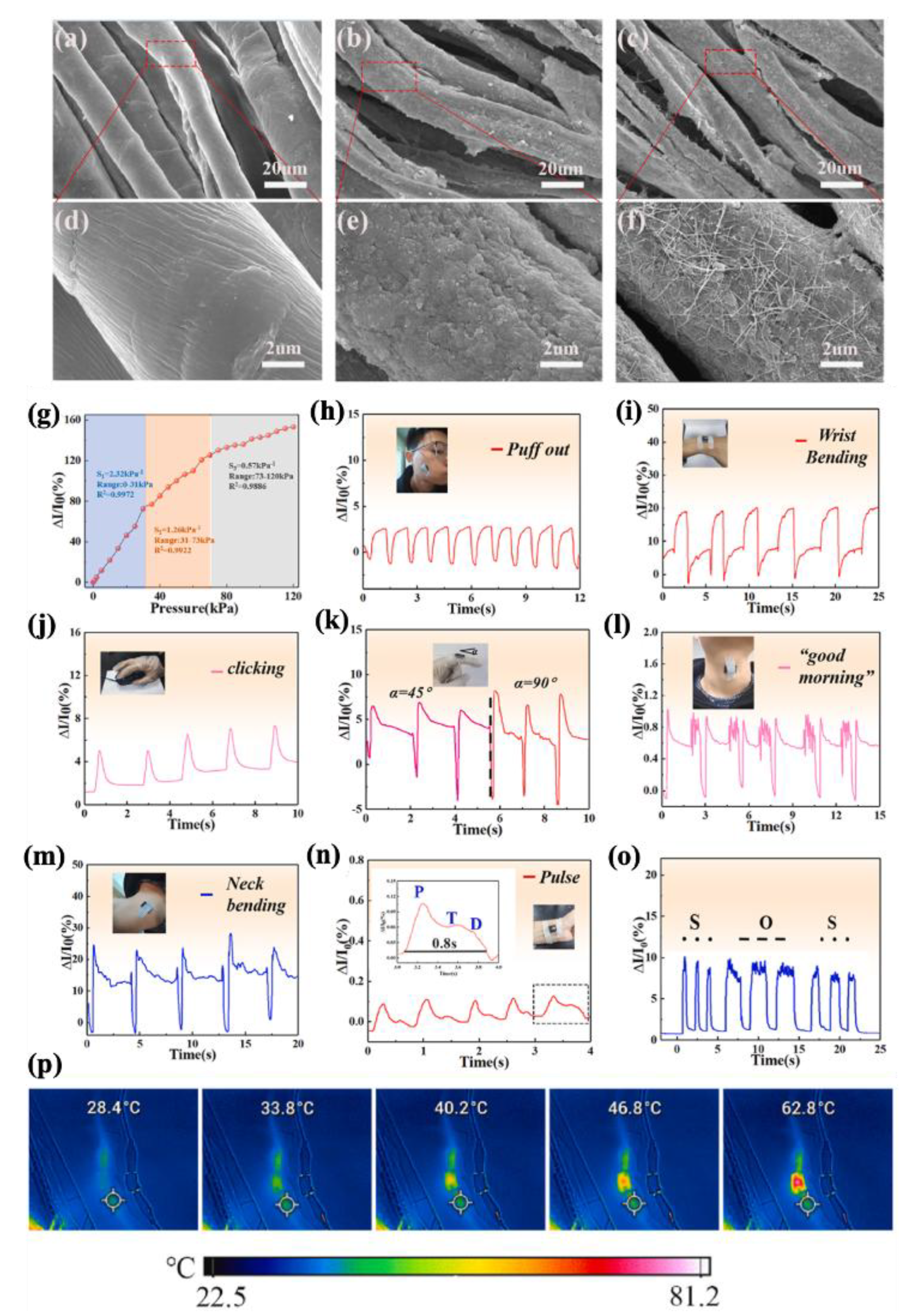

4.2.3. Other Types of Structures Multifunctional Sensors

5. Future Outlook

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wu, X.; Ma, P.; Sun, Y.; Du, F.; Song, D.; Xu, G. Application of MXene in Electrochemical Sensors: A Review. Electroanalysis 2021, 33, 1827–1851. [Google Scholar] [CrossRef]

- Song, P.; Liu, B.; Qiu, H.; Shi, X.; Cao, D.; Gu, J. MXenes for polymer matrix electromagnetic interference shielding composites: A review. Compos. Commun. 2021, 24, 100653. [Google Scholar] [CrossRef]

- Lang, L.; Zou, Y.; Wang, Y.; Men, J.; Cheng, J.; Yan, X.; Zhu, J.; Liu, Y.; Zhang, S.; Li, Z.; et al. A review of recent advances in MXenes/polymer-based electromagnetic interference shielding materials. Polym. Compos. 2024, 45, 11541–11559. [Google Scholar] [CrossRef]

- Zheng, M.; Liu, M.; Cheng, Y.; Chen, W.; Wang, L.; Qin, X. Stimuli-responsive fiber/fabric actuators for intelligent soft robots: From current progress to future opportunities. Nano Energy 2024, 129, 110050. [Google Scholar] [CrossRef]

- Bang, J.; Choi, S.H.; Pyun, K.R.; Jung, Y.; Hong, S.; Kim, D.; Lee, Y.; Won, D.; Jeong, S.; Shin, W.; et al. Bioinspired electronics for intelligent soft robots. Nat. Rev. Electr. Eng. 2024, 1, 597–613. [Google Scholar] [CrossRef]

- Xiong, J.; Chen, J.; Lee, P.S.; Xiong, J.; Chen, J.; Lee, S. Functional Fibers and Fabrics for Soft Robotics, Wearables, and Human–Robot Interface. Adv. Mater. 2021, 33, 2002640. [Google Scholar] [CrossRef] [PubMed]

- Gao, D.; Lv, J.; Lee, P.S. Natural Polymer in Soft Electronics: Opportunities, Challenges, and Future Prospects. Adv. Mater. 2022, 34, 2105020. [Google Scholar] [CrossRef]

- Zhu, M.; Biswas, S.; Dinulescu, S.I.; Kastor, N.; Hawkes, E.W.; Visell, Y. Soft, Wearable Robotics and Haptics: Technologies, Trends, and Emerging Applications. Proc. IEEE 2022, 110, 246–272. [Google Scholar] [CrossRef]

- Qu, J.; Cui, G.; Li, Z.; Fang, S.; Zhang, X.; Liu, A.; Han, M.; Liu, H.; Wang, X.; Wang, X. Advanced Flexible Sensing Technologies for Soft Robots. Adv. Funct. Mater. 2024, 34, 2401311. [Google Scholar] [CrossRef]

- Yin, S.; Yao, D.R.; Song, Y.; Heng, W.; Ma, X.; Han, H.; Gao, W. Wearable and Implantable Soft Robots. Chem. Rev. 2024, 124, 11585–11636. [Google Scholar] [CrossRef]

- Lee, J.H.; Cho, K.; Kim, J.K. Age of Flexible Electronics: Emerging Trends in Soft Multifunctional Sensors. Adv. Mater. 2024, 36, 2310505. [Google Scholar] [CrossRef]

- Yadlapalli, R.T.; Alla, R.K.R.; Kandipati, R.; Kotapati, A. Super capacitors for energy storage: Progress, applications and challenges. J. Energy Storage 2022, 49, 104194. [Google Scholar] [CrossRef]

- Kruželák, J.; Kvasničáková, A.; Hložeková, K.; Hudec, I. Progress in polymers and polymer composites used as efficient materials for EMI shielding. Nanoscale Adv. 2021, 3, 123–172. [Google Scholar] [CrossRef]

- Luan, H.; Zhang, D.; Xu, Z.; Zhao, W.; Yang, C.; Chen, X. MXene-based composite double-network multifunctional hydrogels as highly sensitive strain sensors. J. Mater. Chem. C Mater. 2022, 10, 7604–7613. [Google Scholar] [CrossRef]

- Li, L.; Liu, W.-D.; Liu, Q.; Chen, Z.-G.; Li, L.; Liu, Q.F.; Liu, W.-D.; Chen, Z.-G. Multifunctional Wearable Thermoelectrics for Personal Thermal Management. Adv. Funct. Mater. 2022, 32, 2200548. [Google Scholar] [CrossRef]

- Gupta, R.; Kumar, A.; Biswas, A.; Singh, R.; Gehlot, A.; Akram, S.V.; Verma, A.S. Advances in micro and nano-engineered materials for high-value capacitors for miniaturized electronics. J. Energy Storage 2022, 55, 105591. [Google Scholar] [CrossRef]

- Nan, J.; Guo, X.; Xiao, J.; Li, X.; Chen, W.; Wu, W.; Liu, H.; Wang, Y.; Wu, M.; Wang, G.; et al. Nanoengineering of 2D MXene-Based Materials for Energy Storage Applications. Small 2021, 17, 1902085. [Google Scholar] [CrossRef]

- Bai, Y.; Liu, C.; Shan, Y.; Chen, T.; Zhao, Y.; Yu, C.; Pang, H. Metal-Organic Frameworks Nanocomposites with Different Dimensionalities for Energy Conversion and Storage. Adv. Energy Mater. 2022, 12, 2100346. [Google Scholar] [CrossRef]

- Schneider, R.; Facure, M.H.M.; Chagas, P.A.M.; Andre, R.S.; Santos, D.M.D.; Correa, D.S. Tailoring the Surface Properties of Micro/Nanofibers Using 0D, 1D, 2D, and 3D Nanostructures: A Review on Post-Modification Methods. Adv. Mater. Interfaces 2021, 8, 2100430. [Google Scholar] [CrossRef]

- Cheong, J.Y.; Cho, S.H.; Lee, J.; Jung, J.W.; Kim, C.; Kim, I.D. Multifunctional 1D Nanostructures toward Future Batteries: A Comprehensive Review. Adv. Funct. Mater. 2022, 32, 2208374. [Google Scholar] [CrossRef]

- Lin, B.; Li, Z.T.; Yang, Y.; Li, Y.; Lin, J.C.; Zheng, X.M.; He, F.A.; Lam, K.H. Enhanced dielectric permittivity in surface-modified graphene/PVDF composites prepared by an electrospinning-hot pressing method. Compos. Sci. Technol. 2019, 172, 58–65. [Google Scholar] [CrossRef]

- Fu, J.; Yun, J.; Wu, S.; Li, L.; Yu, L.; Kim, K.H. Architecturally Robust Graphene-Encapsulated MXene Ti2CTx@Polyaniline Composite for High-Performance Pouch-Type Asymmetric Supercapacitor. ACS Appl. Mater. Interfaces 2018, 10, 34212–34221. [Google Scholar] [CrossRef]

- Sun, X.; Huang, C.; Wang, L.; Liang, L.; Cheng, Y.; Fei, W.; Li, Y. Recent Progress in Graphene/Polymer Nanocomposites. Adv. Mater. 2021, 33, 2001105. [Google Scholar] [CrossRef]

- Li, H.; Chen, Z.; Liu, L.; Chen, J.; Jiang, M.; Xiong, C. Poly(vinyl pyrrolidone)-coated graphene/poly(vinylidene fluoride) composite films with high dielectric permittivity and low loss. Compos. Sci. Technol. 2015, 121, 49–55. [Google Scholar] [CrossRef]

- Ponnamma, D.; Yin, Y.; Salim, N.; Parameswaranpillai, J.; Thomas, S.; Hameed, N. Recent progress and multifunctional applications of 3D printed graphene nanocomposites. Compos. B Eng. 2021, 204, 108493. [Google Scholar] [CrossRef]

- Sharma, S.; Sudhakara, P.; Omran, A.A.B.; Singh, J.; Ilyas, R.A. Recent Trends and Developments in Conducting Polymer Nanocomposites for Multifunctional Applications. Polymers 2021, 13, 2898. [Google Scholar] [CrossRef] [PubMed]

- Perera, A.A.P.R.; Madhushani, K.A.U.; Punchihewa, B.T.; Kumar, A.; Gupta, R.K. MXene-Based Nanomaterials for Multifunctional Applications. Materials 2023, 16, 1138. [Google Scholar] [CrossRef]

- Alhabeb, M.; Maleski, K.; Anasori, B.; Lelyukh, P.; Clark, L.; Sin, S.; Gogotsi, Y. Guidelines for Synthesis and Processing of Two-Dimensional Titanium Carbide (Ti3C2Tx MXene). Chem. Mater. 2017, 29, 7633–7644. [Google Scholar] [CrossRef]

- Zhang, Z.; Cai, Z.; Zhang, Y.; Peng, Y.; Wang, Z.; Xia, L.; Ma, S.; Yin, Z.; Wang, R.; Cao, Y.; et al. The recent progress of MXene-Based microwave absorption materials. Carbon 2021, 174, 484–499. [Google Scholar] [CrossRef]

- Kim, H.; Anasori, B.; Gogotsi, Y.; Alshareef, H.N. Thermoelectric Properties of Two-Dimensional Molybdenum-Based MXenes. Chem. Mater. 2017, 29, 6472–6479. [Google Scholar] [CrossRef]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-dimensional nanocrystals produced by exfoliation of Ti3ALC2; MXenes: From Discovery to Applications of Two-Dimensional Metal Carbides and Nitrides; Jenny Stanford Publishing: Singapore, 2023; pp. 15–29. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, H.; Han, Z.; Bo, Z.; Yan, J.; Cen, K.; Ostrikov, K.K. MXene-Based Electrodes for Supercapacitor Energy Storage. Energy Fuels 2022, 36, 2390–2406. [Google Scholar] [CrossRef]

- Li, R.; Zhang, L.; Shi, L.; Wang, P.; Ti, M.X.; Nano, A.C. MXene Ti3C2: An Effective 2D Light-to-Heat Conversion Material. ACS nano 2017, 11, 3752–3759. [Google Scholar] [CrossRef] [PubMed]

- Aslam, M.K.; AlGarni, T.S.; Javed, M.S.; Shah, S.S.A.; Hussain, S.; Xu, M. 2D MXene Materials for Sodium Ion Batteries: A review on Energy Storage. J Energy Storage 2021, 37, 102478. [Google Scholar] [CrossRef]

- Pan, Q.; Zheng, Y.; Kota, S.; Huang, W.; Wang, S.; Qi, H.; Kim, S.; Tu, Y.; Barsoum, M.W.; Li, C.Y. 2D MXene-containing polymer electrolytes for all-solid-state lithium metal batteries. Nanoscale Adv. 2019, 1, 395–402. [Google Scholar] [CrossRef]

- Prateek; Thakur, V.K.; Gupta, R.K. Recent Progress on Ferroelectric Polymer-Based Nanocomposites for High Energy Density Capacitors: Synthesis, Dielectric Properties, and Future Aspects. Chem. Rev. 2016, 116, 4260–4317. [Google Scholar] [CrossRef] [PubMed]

- Raza, W.; Ali, F.; Raza, N.; Luo, Y.; Kim, K.H.; Yang, J.; Kumar, S.; Mehmood, A.; Kwon, E.E. Recent advancements in supercapacitor technology. Nano Energy 2018, 52, 441–473. [Google Scholar] [CrossRef]

- Aravind, A.M.; Tomy, M.; Kuttapan, A.; Aippunny, A.M.K.; Suryabai, X.T. Progress of 2D MXene as an Electrode Architecture for Advanced Supercapacitors: A Comprehensive Review. ACS Omega 2023, 8, 44375–44394. [Google Scholar] [CrossRef]

- Khan, K.; Tareen, A.K.; Aslam, M.; Mahmood, A.; Khan, Q.; Zhang, Y.; Ouyang, Z.; Guo, Z.; Zhang, H. Going green with batteries and supercapacitor: Two dimensional materials and their nanocomposites based energy storage applications. Prog. Solid State Chem. 2020, 58, 100254. [Google Scholar] [CrossRef]

- Alam, S.; Khan, F.F.M.I.; Iqbal, M.Z.; Ahmad, Z.; Hegazy, H.H. Recent advancements in the performance of MXene and its various composites as an electrode material in asymmetric supercapacitors. J. Alloys. Compd. 2023, 961, 171007. [Google Scholar] [CrossRef]

- Tang, H.; Hu, Q.; Zheng, M.; Chi, Y.; Qin, X.; Pang, H.; Xu, Q. MXene–2D layered electrode materials for energy storage. Prog. Nat. Sci. Mater. Int. 2018, 28, 133–147. [Google Scholar] [CrossRef]

- Tang, M.; Sun, H.; Su, L.; Gao, Y.; Chen, F.; Wang, Z.; Wang, C. Organics-MXene Composites as Electrode Materials for Energy Storage. Batter. Supercaps 2023, 6, e202200402. [Google Scholar] [CrossRef]

- Ren, L.; Zhang, G.; Yan, Z.; Kang, L.; Xu, H.; Shi, F.; Lei, Z.; Liu, Z.H. Three-Dimensional Tubular MoS2/PANI Hybrid Electrode for High Rate Performance Supercapacitor. ACS Appl. Mater. Interfaces 2015, 7, 28294–28302. [Google Scholar] [CrossRef]

- Varghese, S.M.; Mohan, V.V.; Suresh, S.; Gowd, E.B.; Rakhi, R.B. Synergistically modified Ti3C2Tx MXene conducting polymer nanocomposites as efficient electrode materials for supercapacitors. J. Alloys. Compd. 2024, 973, 172923. [Google Scholar] [CrossRef]

- Xu, H.; Liu, S.; Li, Z.; Ding, F.; Wang, T.; Liu, T.; Wang, W.; Song, K.; Liu, J.; Hu, L. Ti3C2Tx MXene Enhanced PEO/SN-Based Solid Electrolyte for High-Performance Li Metal Battery. J. Mater. Sci. Technol. 2025, 219, 101–112. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, D.; Liang, Z. Two-dimensional MXenes for energy storage and conversion applications. Mater. Today Energy 2017, 5, 22–36. [Google Scholar] [CrossRef]

- Pomerantseva, E.; Resini, C.; Kovnir, K.; Kolen’ko, Y.V. Emerging nanostructured electrode materials for water electrolysis and rechargeable beyond Li-ion batteries. Adv. Phys. X 2017, 2, 211–253. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, S.; Tang, B. 2D filler-reinforced polymer nanocomposite dielectrics for high-k dielectric and energy storage applications. Energy Storage Mater. 2021, 34, 260–281. [Google Scholar] [CrossRef]

- Zeraati, A.S.; Mirkhani, S.A.; Sun, P.; Naguib, M.; Braun, P.V.; Sundararaj, U. Improved synthesis of Ti3C2Tx MXenes resulting in exceptional electrical conductivity, high synthesis yield, and enhanced capacitance. Nanoscale 2021, 13, 3572–3580. [Google Scholar] [CrossRef]

- Tu, S.; Qiu, L.; Liu, C.; Zeng, F.; Yuan, Y.Y.; Hedhili, M.N.; Musteata, V.; Ma, Y.; Liang, K.; Jiang, N.; et al. Suppressing Dielectric Loss in MXene/Polymer Nanocomposites through Interfacial Interactions. ACS Nano 2024, 18, 10196–10205. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, Y.; Sun, H.; Zhou, J.; Yang, F.; Li, H.; Chen, H.; Chen, Y.; Liu, Z.; Qiu, Z.; et al. Progress and Perspective: MXene and MXene-Based Nanomaterials for High-Performance Energy Storage Devices. Adv. Electron. Mater. 2021, 7, 2000967. [Google Scholar] [CrossRef]

- Pei, Y.; Zhang, X.; Hui, Z.; Zhou, J.; Huang, X.; Sun, G.; Huang, W. Ti3C2TxMXene for Sensing Applications: Recent Progress, Design Principles, and Future Perspectives. ACS Nano 2021, 15, 3996–4017. [Google Scholar] [CrossRef]

- Ye, C.; Zhao, L.; Yang, S.; Li, X. Recent Research on Preparation and Application of Smart Joule Heating Fabrics. Small 2024, 20, 2309027. [Google Scholar] [CrossRef]

- Jing, L.; Hsiao, L.Y.; Li, S.; Yang, H.; Ng, P.L.P.; Ding, M.; Van Truong, T.; Gao, S.P.; Li, K.; Guo, Y.X.; et al. 2D-Material-integrated hydrogels as multifunctional protective skins for soft robots. Mater. Horiz. 2021, 8, 2065–2078. [Google Scholar] [CrossRef]

- Li, L.; Ji, X.; Chen, K. Conductive, self-healing, and antibacterial Ag/MXene-PVA hydrogel as wearable skin-like sensors. J. Biomater. Appl. 2023, 37, 1169–1181. [Google Scholar] [CrossRef]

- Chen, K.; Hu, Y.; Wang, F.; Liu, M.; Liu, P.; Li, C.; Yu, Y.; Xiao, X.; Feng, Q. Ultra-stretchable; adhesive, and self-healing MXene/polyampholytes hydrogel as flexible and wearable epidermal sensors. Colloids. Surf. A Physicochem. Eng. Asp. 2022, 645, 128897. [Google Scholar] [CrossRef]

- Cai, Y.; Shen, J.; Yang, C.W.; Wan, Y.; Tang, H.L.; Aljarb, A.A.; Chen, C.; Fu, J.H.; Wei, X.; Huang, K.W.; et al. Mixed-dimensional MXene-hydrogel heterostructures for electronic skin sensors with ultrabroad working range. Sci. Adv. 2020, 6, 5367–5394. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, T.; Tian, Z.; Shi, L.; Barman, S.C.; Alshareef, H.N. MXenes for soft robotics. Matter 2023, 6, 2807–2833. [Google Scholar] [CrossRef]

- Iravani, S. Role of MXenes in advancing soft robotics. Soft Matter 2023, 19, 6196–6212. [Google Scholar] [CrossRef]

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2009, 39, 228–240. [Google Scholar] [CrossRef]

- Hajian, S.; Maddipatla, D.; Narakathu, B.B.; Atashbar, M.Z. MXene-based flexible sensors: A review. Front. Sens. 2022, 3, 1006749. [Google Scholar] [CrossRef]

- Kumar, P.; Hawari, H.F.; Gupta, M.; Leong, W.X.R.; Saheed, M.S.M.; Stojanović, G.M.; Izhar, L.I. Comparative investigation of surface-electrical properties of functionalized graphene and MXene thin films for CO2 gas sensing. J. Mater. Sci. 2024, 59, 22132–22148. [Google Scholar] [CrossRef]

- Ge, G.; Ke, N.; Ma, H.; Ding, J.; Zhang, W.; Fan, X. A fast response and highly sensitive flexible humidity sensor based on a nanocomposite film of MoS2 and graphene oxide. Nanoscale 2024, 16, 17804–17816. [Google Scholar] [CrossRef]

- Chen, J.; Qin, W.; Li, K.; Feng, L.; Chen, J.; Qiao, H.; Yang, M.; Tian, Z.; Li, X.; Gu, C.; et al. A high-sensitivity, fast-response and high-stability humidity sensor of curly flake Ti3C2Tx MXene prepared by electrolytic intercalation of NaOH solution. J. Mater. Chem. A Mater. 2022, 10, 22278–22288. [Google Scholar] [CrossRef]

- Yao, Y.; Jin, S.; Zou, H.; Li, L.; Ma, X.; Lv, G.; Gao, F.; Lv, X.; Shu, Q. Polymer-based lightweight materials for electromagnetic interference shielding: A review. J. Mater. Sci. 2021, 56, 6549–6580. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, Q.; Cui, J.; Zhao, S.; Zhang, G.; Gao, A.; Yan, Y. Structural design and preparation of Ti3C2Tx MXene/polymer composites for absorption-dominated electromagnetic interference shielding. Nanoscale Adv. 2023, 5, 3549–3574. [Google Scholar] [CrossRef]

- Wang, H.; Wu, Y.; Zhang, J.; Li, G.; Huang, H.; Zhang, X.; Jiang, Q. Enhancement of the electrical properties of MXene Ti3C2 nanosheets by post-treatments of alkalization and calcination. Mater. Lett. 2015, 160, 537–540. [Google Scholar] [CrossRef]

- Zeng, Z.H.; Wu, N.; Wei, J.J.; Yang, Y.F.; Wu, T.T.; Li, B.; Hauser, S.B.; Yang, W.D.; Liu, J.R.; Zhao, S.Y. Porous and Ultra-Flexible Crosslinked MXene/Polyimide Composites for Multifunctional Electromagnetic Interference Shielding. Nanomicro Lett. 2022, 14, 59. [Google Scholar] [CrossRef]

- Koo, C.M.; Shahzad, F.; Iqbal, A.; Kim, H. Electromagnetic Interference Shielding Using MXenes and Their Composites; 2D Metal Carbides and Nitrides (MXenes): Structure; Springer Nature Link: London, UK, 2019; pp. 399–416. [Google Scholar] [CrossRef]

- Iqbal, A.; Kwon, J.; Kim, M.K.; Koo, C.M. MXenes for electromagnetic interference shielding: Experimental and theoretical perspectives. Mater. Today Adv. 2021, 9, 100124. [Google Scholar] [CrossRef]

- Lovat, G. Equivalent circuit for electromagnetic interaction and transmission through graphene sheets. IEEE Trans. Electromagn. Compat. 2012, 54, 101–109. [Google Scholar] [CrossRef]

- Jovanović, S.; Huskić, M.; Kepić, D.; Yasir, M.; Haddadi, K. A review on graphene and graphene composites for application in electromagnetic shielding. Graphene 2d Mater. 2023, 8, 59–80. [Google Scholar] [CrossRef]

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Hong, S.M.; Koo, C.M.; Gogotsi, Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science (1979) 2016, 353, 1137–1140. [Google Scholar] [CrossRef]

- Amrillah, T.; Abdullah, C.A.C.; Hermawan, A.; Sari, F.N.I.; Alvani, V.N. Towards Greener and More Sustainable Synthesis of MXenes: A Review. Nanomaterials 2022, 12, 4280. [Google Scholar] [CrossRef]

- Amani, A.M.; Tayebi, L.; Vafa, E.; Abbasi, M.; Vaez, A.; Kamyab, H.; Chelliapan, S.; Azizli, M.J.; Bazargan-Lari, R. On the horizon of greener pathways to travel into a greener future portal: Green MXenes, environment-friendly synthesis, and their innovative applications. J. Clean Prod. 2024, 436, 140606. [Google Scholar] [CrossRef]

- Soomro, R.A.; Zhang, P.; Fan, B.; Wei, Y.; Xu, B. Progression in the Oxidation Stability of MXenes. Nanomicro Lett. 2023, 15, 108. [Google Scholar] [CrossRef]

- Kumar, S.; Kumari, N.; Singh, T.; Seo, Y. Shielding 2D MXenes against oxidative degradation: Recent advances, factors and preventive measures. J. Mater. Chem. C Mater. 2024, 12, 8243–8281. [Google Scholar] [CrossRef]

- Cao, F.; Zhang, Y.; Wang, H.; Khan, K.; Tareen, A.K.; Qian, W.; Zhang, H.; Ågren, H.; Cao, F.; Zhang, Y.; et al. Recent Advances in Oxidation Stable Chemistry of 2D MXenes. Adv. Mater. 2022, 34, 2107554. [Google Scholar] [CrossRef]

- Wu, X.; Wang, Z.; Yu, M.; Xiu, L.; Qiu, J.; Wu, X.H.; Wang, Z.Y.; Yu, M.Z.; Xiu, L.Y.; Qiu, J.S. Stabilizing the MXenes by Carbon Nanoplating for Developing Hierarchical Nanohybrids with Efficient Lithium Storage and Hydrogen Evolution Capability. Adv. Mater. 2017, 29, 1607017. [Google Scholar] [CrossRef]

- Pang, S.Y.; Wong, Y.T.; Yuan, S.; Liu, Y.; Tsang, M.K.; Yang, Z.; Huang, H.; Wong, W.T.; Hao, J. Universal Strategy for HF-Free Facile and Rapid Synthesis of Two-dimensional MXenes as Multifunctional Energy Materials. J. Am. Chem. Soc. 2019, 141, 9610–9616. [Google Scholar] [CrossRef]

- Naguib, M.; Mochalin, V.N.; Barsoum, M.W.; Gogotsi, Y. 25th Anniversary Article: MXenes: A New Family of Two-Dimensional Materials. Adv. Mater. 2014, 26, 992–1005. [Google Scholar] [CrossRef]

- Eklund, P.; Beckers, M.; Jansson, U.; Högberg, H.; Hultman, L. The Mn + 1AXn phases: Materials science and thin-film processing. Thin Solid Film. 2010, 518, 1851–1878. [Google Scholar] [CrossRef]

- Ronchi, R.M.; Arantes, J.T.; Santos, S.F. Synthesis, structure, properties and applications of MXenes: Current status and perspectives. Ceram. Int. 2019, 45, 18167–18188. [Google Scholar] [CrossRef]

- Pandey, M.; Deshmukh, K.; Raman, A.; Asok, A.; Appukuttan, S.; Suman, G.R. Prospects of MXene and graphene for energy storage and conversion. Renew. Sustain. Energy Rev. 2024, 189, 114030. [Google Scholar] [CrossRef]

- Gao, L.; Chen, H.; Kuklin, A.V.; Wageh, S.; Al-Ghamdi, A.A.; Ågren, H.; Zhang, H. Optical Properties of Few-Layer Ti3CN MXene: From Experimental Observations to Theoretical Calculations. ACS Nano 2022, 16, 3059–3069. [Google Scholar] [CrossRef] [PubMed]

- Downes, M.; Shuck, C.E.; McBride, B.; Busa, J.; Gogotsi, Y. Comprehensive Synthesis of Ti3C2Tx from MAX Phase to MXene. Nature Protocols 2024, 19, 1807–1834. [Google Scholar] [CrossRef] [PubMed]

- Naguib, M.; Mashtalir, O.; Carle, J.; Presser, V.; Lu, J.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-dimensional transition metal carbides. ACS Nano 2012, 6, 1322–1331. [Google Scholar] [CrossRef]

- Mashtalir, O.; Naguib, M.; Mochalin, V.N.; Dall’Agnese, Y.; Heon, M.; Barsoum, M.W.; Gogotsi, Y. Intercalation and delamination of layered carbides and carbonitrides, MXenes: From Discovery to Applications of Two-Dimensional Metal Carbides and Nitrides. Nat. Commun. 2013, 4, 1716. [Google Scholar] [CrossRef]

- Feng, A.; Yu, Y.; Wang, Y.; Jiang, F.; Yu, Y.; Mi, L.; Song, L. Two-dimensional MXene Ti3C2 produced by exfoliation of Ti3AlC2. Mater. Des. 2017, 114, 161–166. [Google Scholar] [CrossRef]

- Urbankowski, P.; Anasori, B.; Makaryan, T.; Er, D.; Kota, S.; Walsh, P.L.; Zhao, M.; Shenoy, V.B.; Barsoum, M.W.; Gogotsi, Y. Synthesis of two-dimensional titanium nitride Ti4N3 (MXene). Nanoscale 2016, 8, 11385–11391. [Google Scholar] [CrossRef]

- Melchior, S.A.; Raju, K.; Ike, I.S.; Erasmus, R.M.; Kabongo, G.; Sigalas, I.; Iyuke, S.E.; Ozoemena, K.I. High-Voltage Symmetric Supercapacitor Based on 2D Titanium Carbide (MXene, Ti2CTx)/Carbon Nanosphere Composites in a Neutral Aqueous Electrolyte. J. Electrochem. Soc. 2018, 165, A501–A511. [Google Scholar] [CrossRef]

- Lukatskaya, M.R.; Halim, J.; Dyatkin, B.; Naguib, M.; Buranova, Y.S.; Barsoum, M.W.; Gogotsi, Y. Room-Temperature Carbide-Derived Carbon Synthesis by Electrochemical Etching of MAX Phases. Angew. Chem. Int. Ed. 2014, 53, 4877–4880. [Google Scholar] [CrossRef]

- Sun, W.; Shah, S.A.; Chen, Y.; Tan, Z.; Gao, H.; Habib, T.; Radovic, M.; Green, M.J. Electrochemical etching of Ti2AlC to Ti2CTx (MXene) in low-concentration hydrochloric acid solution. J. Mater. Chem. A Mater. 2017, 5, 21663–21668. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, P.; Wang, F.; Ricciardulli, A.G.; Lohe, M.R.; Blom, P.W.M.; Feng, X. Fluoride-Free Synthesis of Two-Dimensional Titanium Carbide (MXene) Using A Binary Aqueous System. Angew. Chem. 2018, 130, 15717–15721. [Google Scholar] [CrossRef]

- Chen, J.; Chen, M.; Zhou, W.; Xu, X.; Liu, B.; Zhang, W.; Wong, C. Simplified Synthesis of Fluoride-Free Ti3C2Tx via Electrochemical Etching toward High-Performance Electrochemical Capacitors. ACS Nano 2022, 16, 2461–2470. [Google Scholar] [CrossRef] [PubMed]

- Pang, S.Y.; Io, W.F.; Wong, L.W.; Zhao, J.; Hao, J. Direct and in situ growth of 1T′ MoS2 and 1T MoSe2 on electrochemically synthesized MXene as an electrocatalyst for hydrogen generation. Nano Energy 2022, 103, 107835. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, M.; Wang, C.; Bi, M.; Xie, J.; Bai, W.; Zhang, Y.; Pan, S.; Liu, M.; Pan, X.; et al. N co-doped rGO/fluorine-free Ti3C2Tx aerogels for high performance all-solid-state supercapacitors. J. Energy Storage 2023, 71, 108140. [Google Scholar] [CrossRef]

- Unnikrishnan, B.; Wu, C.W.; Sangili, A.; Hsu, Y.J.; Tseng, Y.T.; Pandey, J.S.; Chang, H.T.; Huang, C.C. Synthesis and in situ sulfidation of molybdenum carbide MXene using fluorine-free etchant for electrocatalytic hydrogen evolution reactions. J. Colloid Interface Sci. 2022, 628, 849–857. [Google Scholar] [CrossRef] [PubMed]

- Saha, S.; Arole, K.; Radovic, M.; Lutkenhaus, J.L.; Green, M.J. One-step hydrothermal synthesis of porous Ti3C2Tz MXene/rGO gels for supercapacitor applications. Nanoscale 2021, 13, 16543–16553. [Google Scholar] [CrossRef]

- Thirumal, V.; Yuvakkumar, R.; Kumar, P.S.; Ravi, G.; Arun, A.; Guduru, R.K.; Velauthapillai, D. Heterostructured two dimensional materials of MXene and graphene by hydrothermal method for efficient hydrogen production and HER activities. Int. J. Hydrogen Energy 2023, 48, 6478–6487. [Google Scholar] [CrossRef]

- Ayub, A.; Kim, B.; Lim, Y.; Devarayapalli, K.C.; Kim, G.; Lee, D.S. Hydrothermal synthesis of cobalt ferrite-functionalized Ti3C2Tx MXene for the degradation of Congo red via peroxymonosulfate activation system. J. Alloys. Compd. 2023, 963, 171294. [Google Scholar] [CrossRef]

- Li, T.; Yao, L.; Liu, Q.; Gu, J.; Luo, R.; Li, J.; Yan, X.; Wang, W.; Liu, P.; Chen, B.; et al. Fluorine-Free Synthesis of High-Purity Ti3C2Tx (T=OH, O) via Alkali Treatment. Angew. Chem. Int. Ed. 2018, 57, 6115–6119. [Google Scholar] [CrossRef]

- Li, T.; Yan, X.; Huang, L.; Li, J.; Yao, L.; Zhu, Q.; Wang, W.; Abbas, W.; Naz, R.; Gu, J.; et al. Fluorine-free Ti3C2Tx (T = O, OH) nanosheets (~50–100 nm) for nitrogen fixation under ambient conditions. J. Mater. Chem. A Mater. 2019, 7, 14462–14465. [Google Scholar] [CrossRef]

- Liu, H.; Yang, C.; Jin, X.; Zhong, J.; Li, J. One-pot hydrothermal synthesis of MXene Ti3C2/TiO22/BiOCl ternary heterojunctions with improved separation of photoactivated carries and photocatalytic behavior toward elimination of contaminants. Colloids Surf. A Physicochem. Eng. Asp. 2020, 603, 125239. [Google Scholar] [CrossRef]

- Niu, R.; Han, R.; Huang, Y.; Dai, L.; Zhao, H.; Wang, Y.; Zhu, J.; Tang, S.; Sun, J. Hydrothermal ion exchange synthesis of CoM(M=Fe or Mn)/MXene 2D/2D hierarchal architectures for enhanced energy storage. J. Alloys. Compd. 2022, 894, 162385. [Google Scholar] [CrossRef]

- Alli, U.; McCarthy, K.; Baragau, I.A.; Power, N.P.; Morgan, D.J.; Dunn, S.; Killian, S.; Kennedy, T.; Kellici, S. In-situ continuous hydrothermal synthesis of TiO22 nanoparticles on conductive N-doped MXene nanosheets for binder-free Li-ion battery anodes. Chem. Eng. J. 2022, 430, 132976. [Google Scholar] [CrossRef]

- Qin, X.; Cao, R.; Gong, W.; Luo, L.; Shi, G.; Ji, L.; Zhu, A. Hydrothermal growth of ZnCdS/TiO22 nanoparticles on the surface of the Ti3C2 MXene sheet to enhance photocatalytic performance under visible light. J. Solid State Chem. 2022, 306, 122750. [Google Scholar] [CrossRef]

- Guo, T.; Lei, Y.; Hu, X.; Yang, G.; Liang, J.; Huang, Q.; Li, X.; Liu, M.; Zhang, X.; Wei, Y. Hydrothermal synthesis of MXene-MoS2 composites for highly efficient removal of pesticides. Appl. Surf. Sci. 2022, 588, 152597. [Google Scholar] [CrossRef]

- Luo, W.; Liu, Y.; Li, F.; Huo, J.; Zhao, D.; Zhu, J.; Guo, S. H2O2 assisted hydrothermal oxidation of partially etched vanadium carbides (MXene) and their electrochemical properties as anode for Li-ion batteries. Appl. Surf. Sci. 2020, 523, 146387. [Google Scholar] [CrossRef]

- Caffrey, N.M. Effect of mixed surface terminations on the structural and electrochemical properties of two-dimensional Ti3C2T2 and V2CT2 MXenes multilayers. Nanoscale 2018, 10, 13520–13530. [Google Scholar] [CrossRef]

- Yu, L.P.; Lu, L.; Zhou, X.H.; Xu, L.; Alhalili, Z.; Wang, F.J. Strategies for Fabricating High-Performance Electrochemical Energy-Storage Devices by MXenes. ChemElectroChem 2021, 8, 1948–1987. [Google Scholar] [CrossRef]

- Pant, B.; Park, M.; Kim, A.A. MXene-Embedded Electrospun Polymeric Nanofibers for Biomedical Applications: Recent Advances. Micromachines 2023, 14, 1477. [Google Scholar] [CrossRef]

- Chouhan, R.S.; Shah, M.; Prakashan, D.; Ramya, P.R.; Kolhe, P.; Gandhi, S. Emerging Trends and Recent Progress of MXene as a Promising 2D Material for Point of Care (POC) Diagnostics. Diagnostics 2023, 13, 697. [Google Scholar] [CrossRef] [PubMed]

- Murali, G.; Modigunta, J.K.R.; Park, Y.H.; Lee, J.H.; Rawal, J.; Lee, S.Y.; In, I.; Park, S.J. A Review on MXene Synthesis, Stability, and Photocatalytic Applications. ACS Nano 2022, 16, 13370–13429. [Google Scholar] [CrossRef]

- Zhang, C.J.; Anasori, B.; Seral-Ascaso, A.; Park, S.H.; McEvoy, N.; Shmeliov, A.; Duesberg, G.S.; Coleman, J.N.; Gogotsi, Y.; Nicolosi, V. Transparent, flexible, and Conductive 2D Titanium Carbide (MXene) Films with High Volumetric Capacitance. Adv. Mater. 2017, 29, 1702678. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, Y.; Zhuo, Z.; Neukirch, A.J.; Tretiak, S. Interlayer-Decoupled Sc-Based Mxene with High Carrier Mobility and Strong Light-Harvesting Ability. J. Phys. Chem. Lett. 2018, 9, 6915–6920. [Google Scholar] [CrossRef]

- Zaed, M.A.; Saidur, R.; Pandey, A.K.; Kadhom, M.; Tan, K.H.; Cherusseri, J.; Abdullah, N. Utilization of Recycled Materials for Low-Cost MXene Synthesis and Fabrication of Graphite/MXene Composite for Enhanced Water Desalination Performance. Sep Purif Technol 2025, 354, 129055. [Google Scholar] [CrossRef]

- Shuck, C.E.; Han, M.; Maleski, K.; Hantanasirisakul, K.; Kim, S.J.; Choi, J.; Reil, W.E.B.; Gogotsi, Y. Effect of Ti3AlC2 MAX Phase on Structure and Properties of Resultant Ti3C2Tx MXene. ACS Appl. Nano Mater. 2019, 2, 3368–3376. [Google Scholar] [CrossRef]

- Mathis, T.S.; Maleski, K.; Goad, A.; Sarycheva, A.; Anayee, M.; Foucher, A.C.; Hantanasirisakul, K.; Shuck, C.E.; Stach, E.A.; Gogotsi, Y. Modified MAX Phase Synthesis for Environmentally Stable and Highly Conductive Ti3C2MXene. ACS Nano 2021, 15, 6420–6429. [Google Scholar] [CrossRef] [PubMed]

- Sang, X.; Xie, Y.; Lin, M.W.; Alhabeb, M.; Van Aken, K.L.; Gogotsi, Y.; Kent, P.R.C.; Xiao, K.; Unocic, R.R. Atomic defects in monolayer titanium carbide (Ti3C2Tx) MXene. ACS Nano 2016, 10, 9193–9200. [Google Scholar] [CrossRef]

- Lipatov, A.; Alhabeb, M.; Lukatskaya, M.R.; Boson, A.; Gogotsi, Y.; Sinitskii, A. Effect of Synthesis on Quality, Electronic Properties and Environmental Stability of Individual Monolayer Ti3C2 MXene Flakes. Adv. Electron. Mater. 2016, 2, 1600255. [Google Scholar] [CrossRef]

- Mirkhani, S.A.; Zeraati, A.S.; Aliabadian, E.; Naguib, M.; Sundararaj, U. High Dielectric Constant and Low Dielectric Loss via Poly(vinyl alcohol)/Ti3C2Tx MXene Nanocomposites. ACS Appl. Mater. Interfaces 2019, 11, 18599–18608. [Google Scholar] [CrossRef]

- Zhao, M.Q.; Ren, C.E.; Ling, Z.; Lukatskaya, M.R.; Zhang, C.; Van Aken, K.L.; Barsoum, M.W.; Gogotsi, Y. Flexible MXene/Carbon Nanotube Composite Paper with High Volumetric Capacitance. Adv. Mater. 2015, 27, 339–345. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Wang, Z.; Dong, J.; Huang, T.; Zhang, Q.; Zhang, L. Annealing modification of MXene films with mechanically strong structures and high electrochemical performance for supercapacitor applications. J. Power Sources 2020, 470, 228356. [Google Scholar] [CrossRef]

- Maleski, K.; Ren, C.E.; Zhao, M.Q.; Anasori, B.; Gogotsi, Y. Size-Dependent Physical and Electrochemical Properties of Two-Dimensional MXene Flakes. ACS Appl. Mater. Interfaces 2018, 10, 24491–24498. [Google Scholar] [CrossRef]

- Ke, K.; Yue, L.; Shao, H.; Yang, M.B.; Yang, W.; Manas-Zloczower, I. Boosting electrical and piezoresistive properties of polymer nanocomposites via hybrid carbon fillers: A review. Carbon 2021, 173, 1020–1040. [Google Scholar] [CrossRef]

- Mayerberger, E.A.; Urbanek, O.; McDaniel, R.M.; Street, R.M.; Barsoum, M.W.; Schauer, C.L. Preparation and characterization of polymer-Ti3C2Tx (MXene) composite nanofibers produced via electrospinning. J. Appl. Polym. Sci. 2017, 134, 45295. [Google Scholar] [CrossRef]

- Sengupta, R.; Bhattacharya, M.; Bandyopadhyay, S.; Bhowmick, A.K. A review on the mechanical and electrical properties of graphite and modified graphite reinforced polymer composites. Prog. Polym. Sci. 2011, 36, 638–670. [Google Scholar] [CrossRef]

- Naguib, M.; Saito, T.; Lai, S.; Rager, M.S.; Aytug, T.; Paranthaman, M.P.; Zhao, M.Q.; Gogotsi, Y. Ti3C2Tx (MXene)–polyacrylamide nanocomposite films. RSC Adv. 2016, 6, 72069–72073. [Google Scholar] [CrossRef]

- Vieira, L.D.S.; Anjos, E.G.R.D.; Verginio, G.E.A.; Oyama, I.C.; Braga, N.F.; da Silva, T.F.; Montagna, L.S.; Passador, F.R. A review concerning the main factors that interfere in the electrical percolation threshold content of polymeric antistatic packaging with carbon fillers as antistatic agent. Nano Select 2022, 3, 248–260. [Google Scholar] [CrossRef]

- Khan, T.; Irfan, M.S.; Ali, M.; Dong, Y.; Ramakrishna, S.; Umer, R. Insights to low electrical percolation thresholds of carbon-based polypropylene nanocomposites. Carbon 2021, 176, 602–631. [Google Scholar] [CrossRef]

- Jin, X.; Wang, J.; Dai, L.; Liu, X.; Li, L.; Yang, Y.; Cao, Y.; Wang, W.; Wu, H.; Guo, S. Flame-retardant poly(vinyl alcohol)/MXene multilayered films with outstanding electromagnetic interference shielding and thermal conductive performances. Chem. Eng. J. 2020, 380, 122475. [Google Scholar] [CrossRef]

- Feng, A.; Hou, T.; Jia, Z.; Zhang, Y.; Zhang, F.; Wu, G. Preparation and Characterization of Epoxy Resin Filled with Ti3C2Tx MXene Nanosheets with Excellent Electric Conductivity. Nanomaterials 2020, 10, 162. [Google Scholar] [CrossRef] [PubMed]

- Rajavel, K.; Luo, S.; Wan, Y.; Yu, X.; Hu, Y.; Zhu, P.; Sun, R.; Wong, C. 2D Ti3C2Tx MXene/polyvinylidene fluoride (PVDF) nanocomposites for attenuation of electromagnetic radiation with excellent heat dissipation. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105693. [Google Scholar] [CrossRef]

- Sun, R.; Zhang, H.B.; Liu, J.; Xie, X.; Yang, R.; Li, Y.; Hong, S.; Yu, Z.Z. Highly Conductive Transition Metal Carbide/Carbonitride(MXene)@polystyrene Nanocomposites Fabricated by Electrostatic Assembly for Highly Efficient Electromagnetic Interference Shielding. Adv. Funct. Mater. 2017, 27, 1702807. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Song, P.; Liang, C.; Lu, Y.; Qiu, H.; Zhang, Y.; Kong, J.; Gu, J. Fabrication on the annealed Ti3C2Tx MXene/Epoxy nanocomposites for electromagnetic interference shielding application. Compos. B Eng. 2019, 171, 111–118. [Google Scholar] [CrossRef]

- Liu, R.; Miao, M.; Li, Y.; Zhang, J.; Cao, S.; Feng, X. Ultrathin Biomimetic Polymeric Ti3C2Tx MXene Composite Films for Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2018, 10, 44787–44795. [Google Scholar] [CrossRef]

- Tanvir, A.; Sobolčiak, P.; Popelka, A.; Mrlik, M.; Spitalsky, Z.; Micusik, M.; Prokes, J.; Krupa, I.; Conductive, E. Transparent Polymeric Nanocomposites Modified by 2D Ti3C2Tx (MXene). Polymers 2019, 11, 1272. [Google Scholar] [CrossRef]

- Nath, N.K.; Mohanta, R.R.; Parida, R.K.; Parida, B.N.; Nayak, N.C. Improving the energy storage efficiency and power density of polymer blend in combination with Ti3C2Tx for energy storage devices. Mater. Today Chem. 2024, 41, 102338. [Google Scholar] [CrossRef]

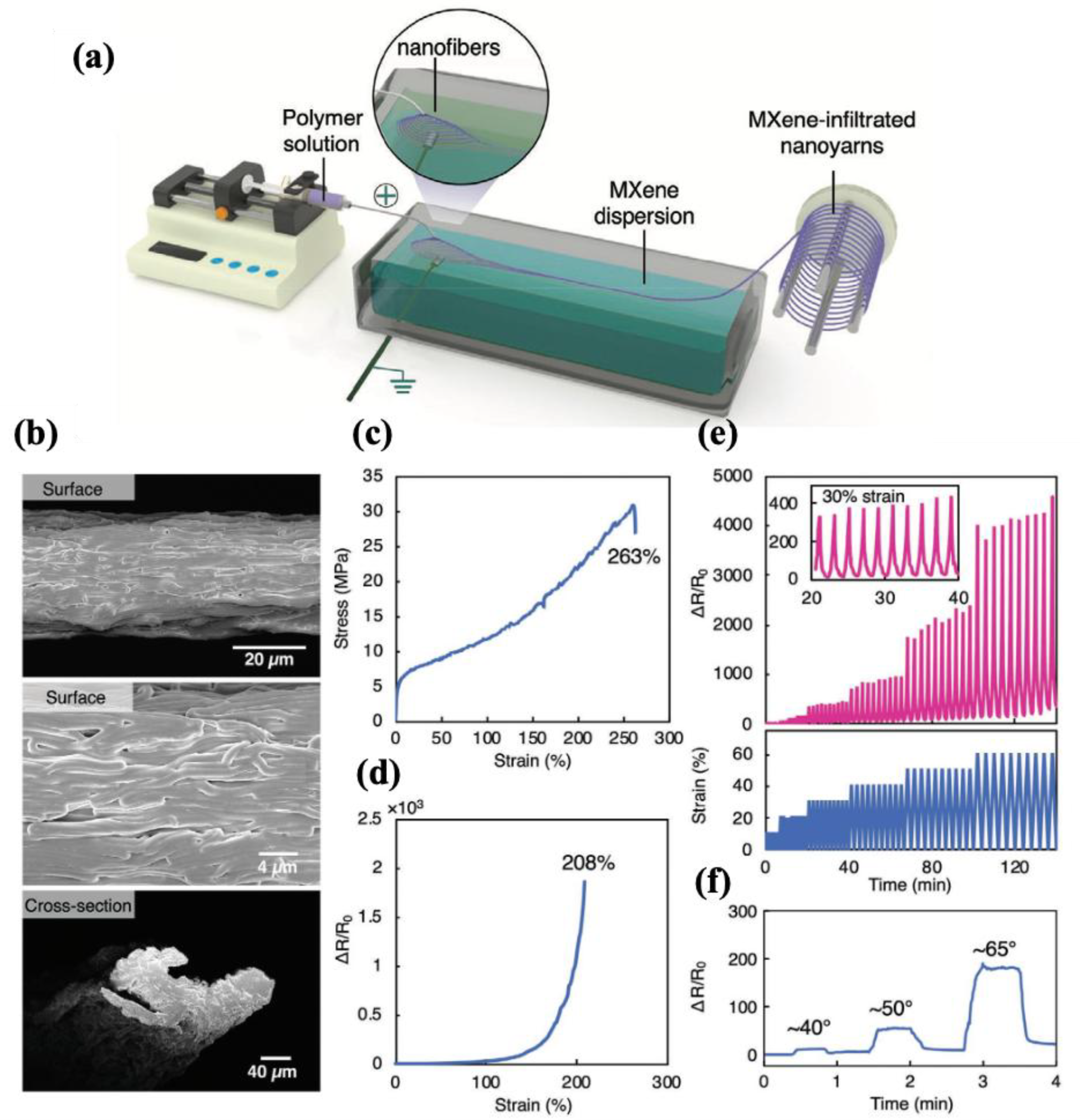

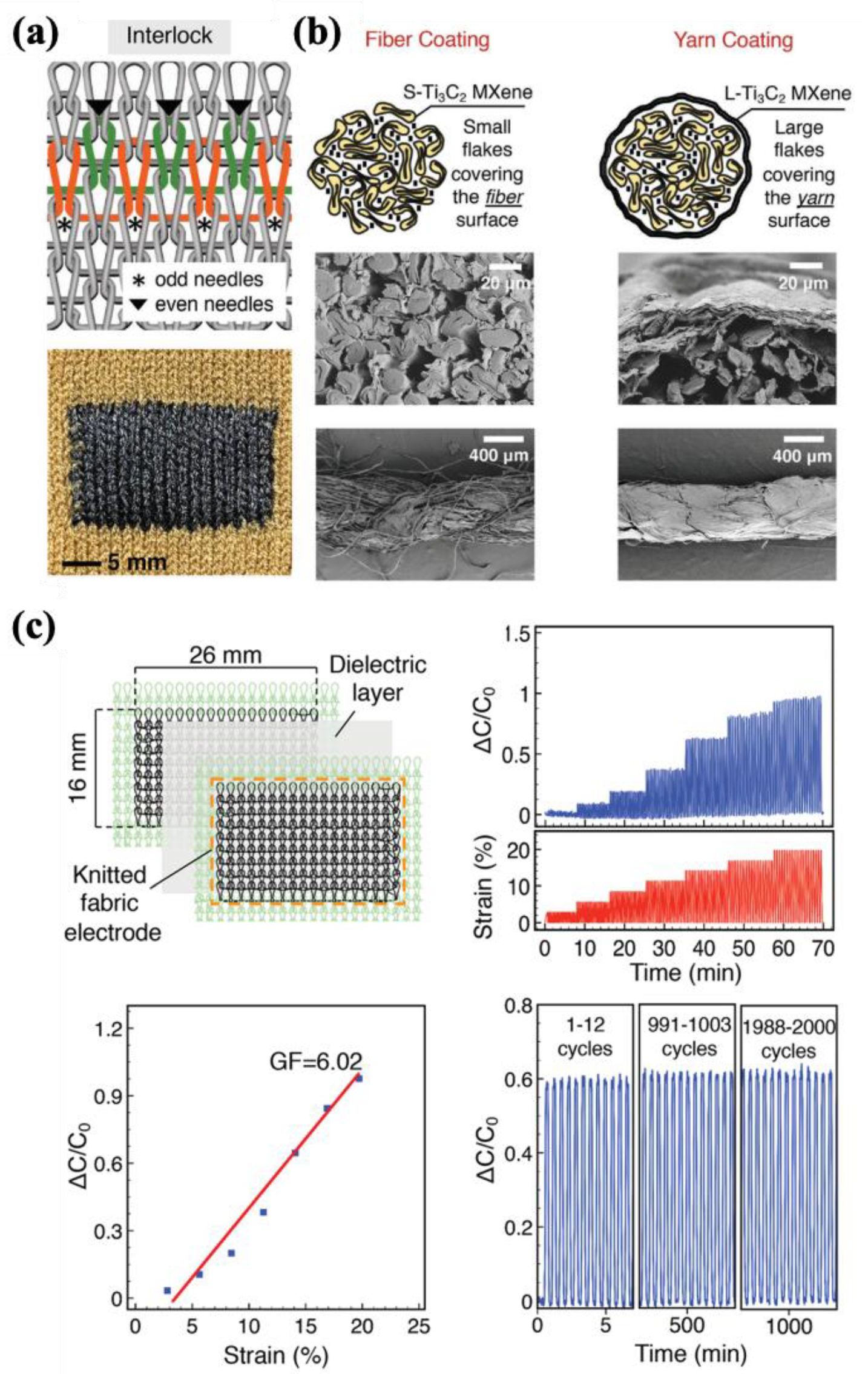

- Seyedin, S.; Uzun, S.; Levitt, A.; Anasori, B.; Dion, G.; Gogotsi, Y.; Razal, J.M. MXene Composite and Coaxial Fibers with High Stretchability and Conductivity for Wearable Strain Sensing Textiles. Adv. Funct. Mater. 2020, 30, 1910504. [Google Scholar] [CrossRef]

- Jiang, X.; Kuklin, A.V.; Baev, A.; Ge, Y.; Ågren, H.; Zhang, H.; Prasad, P.N. Two-dimensional MXenes: From morphological to optical, electric, and magnetic properties and applications. Phys. Rep. 2020, 848, 1–58. [Google Scholar] [CrossRef]

- Xu, G.; Wang, X.; Gong, S.; Wei, S.; Liu, J.; Xu, Y. Solvent-regulated preparation of well-intercalated Ti3C2Tx MXene nanosheets and application for highly effective electromagnetic wave absorption. Nanotechnology 2018, 29, 355201. [Google Scholar] [CrossRef]

- Cui, G.; Sun, X.; Zhang, G.; Zhang, Z.; Liu, H.; Gu, J.; Gu, G. Electromagnetic absorption performance of two-dimensional MXene Ti3C2Tx exfoliated by HCl + LiF etchant with diverse etching times. Mater. Lett. 2019, 252, 8–10. [Google Scholar] [CrossRef]

- Kumar, R.; Sahoo, S.; Joanni, E. Composites based on layered materials for absorption of microwaves and electromagnetic shielding. Carbon 2023, 211, 118072. [Google Scholar] [CrossRef]

- Shanmugasundram, H.P.P.V.; Jayamani, E.; Soon, K.H. A comprehensive review on dielectric composites: Classification of dielectric composites. Renew. Sustain. Energy Rev. 2022, 157, 112075. [Google Scholar] [CrossRef]

- Wang, S.; Yang, C.; Li, X.; Jia, H.; Liu, S.; Liu, X.; Minari, T.; Sun, Q. Polymer-based dielectrics with high permittivity and low dielectric loss for flexible electronics. J. Mater. Chem. C Mater. 2022, 10, 6196–6221. [Google Scholar] [CrossRef]

- Zha, J.W.; Zheng, M.S.; Fan, B.H.; Dang, Z.M. Polymer-based dielectrics with high permittivity for electric energy storage: A review. Nano Energy 2021, 89, 106438. [Google Scholar] [CrossRef]

- Fan, B.; Zhou, M.; Zhang, C.; He, D.; Bai, J. Polymer-based materials for achieving high energy density film capacitors. Prog. Polym. Sci. 2019, 97, 101143. [Google Scholar] [CrossRef]

- Verma, R.; Thakur, P.; Chauhan, A.; Jasrotia, R.; Thakur, A. A review on MXene and its’ composites for electromagnetic interference (EMI) shielding applications. Carbon 2023, 208, 170–190. [Google Scholar] [CrossRef]

- Idumah, C.I. Recent advancements in electromagnetic interference shielding of polymer and mxene nanocomposites. Polym-Plast. Technol. Mater. 2023, 62, 19–53. [Google Scholar] [CrossRef]

- Gao, Q.; Wang, X.; Schubert, D.W.; Liu, X. Review on polymer/MXene composites for electromagnetic interference shielding applications. Adv. Nanocompos. 2024, 1, 52–76. [Google Scholar] [CrossRef]

- Jia, X.; Shen, B.; Zhang, L.; Zheng, W. Construction of compressible Polymer/MXene composite foams for high-performance absorption-dominated electromagnetic shielding with ultra-low reflectivity. Carbon 2021, 173, 932–940. [Google Scholar] [CrossRef]

- Liu, J.; Mckeon, L.; Garcia, J.; Pinilla, S.; Barwich, S.; Möbius, M.; Stamenov, P.; Coleman, J.N.; Nicolosi, V. Additive Manufacturing of Ti3C2-MXene-Functionalized Conductive Polymer Hydrogels for Electromagnetic-Interference Shielding. Adv. Mater. 2022, 34, 2106253. [Google Scholar] [CrossRef] [PubMed]

- Wan, Y.J.; Li, X.M.; Zhu, P.L.; Sun, R.; Wong, C.P.; Liao, W.H. Lightweight, flexible MXene/polymer film with simultaneously excellent mechanical property and high-performance electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2020, 130, 105764. [Google Scholar] [CrossRef]

- Bora, P.J.; Anil, A.G.; Ramamurthy, P.C.; Tan, D.Q. MXene interlayered crosslinked conducting polymer film for highly specific absorption and electromagnetic interference shielding. Mater. Adv. 2020, 1, 177–183. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Chen, H.; Sun, H.; Xu, H.; Yang, D. Preparation and Studies of MXene@PDA/PVDF Composites with Improved Dielectric Properties. Polymer (Guildf) 2024, 307, 127239. [Google Scholar] [CrossRef]

- Tu, S.; Jiang, Q.; Zhang, X.; Alshareef, H.N. Large Dielectric Constant Enhancement in MXene Percolative Polymer Composites. ACS Nano 2018, 12, 3369–3377. [Google Scholar] [CrossRef] [PubMed]

- Nath, N.K.; Parida, R.; Parida, B.N.; Nayak, N.C. Synergistic Effects of MWCNT-MXene Nanohybrids on Dielectric and Ferroelectric Properties of PVDF/PMMA Blend Composites. ACS Appl Electron Mater 2025. [Google Scholar] [CrossRef]

- Wan, W.; Tao, M.; Cao, H.; Zhao, Y.; Luo, J.; Yang, J.; Qiu, T. Enhanced dielectric properties of homogeneous Ti3C2Tx MXene@SiO2/polyvinyl alcohol composite films. Ceram. Int. 2020, 46, 13862–13868. [Google Scholar] [CrossRef]

- Luo, H.; Feng, W.; Liao, C.; Deng, L.; Liu, S.; Zhang, H.; Xiao, P. Peaked dielectric responses in Ti3C2 MXene nanosheets enabled composites with efficient microwave absorption. J. Appl. Phys. 2018, 123, 104103. [Google Scholar] [CrossRef]

- Tu, S.; Jiang, Q.; Zhang, J.; He, X.; Hedhili, M.N.; Zhang, X.; Alshareef, H.N. Enhancement of Dielectric Permittivity of Ti3C2Tx MXene/Polymer Composites by Controlling Flake Size and Surface Termination. ACS Appl. Mater. Interfaces 2019, 11, 27358–27362. [Google Scholar] [CrossRef]

- Liu, T.; Liu, N.; An, Q.; Xiao, Z.; Zhai, S.; Li, Z. Designed construction of Ti3C2Tx@PPY composites with enhanced microwave absorption performance. J. Alloys. Compd. 2019, 802, 445–457. [Google Scholar] [CrossRef]

- Wang, L.; Li, X.; Qian, Y.; Li, W.; Xiong, T.; Tao, Y.; Li, Y.; Li, J.; Luo, Y.; Jiang, Q.; et al. MXene-Layered Double Hydroxide Reinforced Epoxy Nanocomposite with Enhanced Electromagnetic Wave Absorption, Thermal Conductivity, and Flame Retardancy in Electronic Packaging. Small 2024, 20, 2304311. [Google Scholar] [CrossRef] [PubMed]

- Naqvi, S.M.; Hassan, T.; Iqbal, A.; Zaman, S.; Cho, S.; Hussain, N.; Kong, X.; Khalid, Z.; Hao, Z.; Koo, C.M. Comparative Electromagnetic Shielding Performance of Ti3C2Tx-PVA Composites in Various Structural Forms: Compact Films, Hydrogels, and Aerogels. Nanoscale 2025, 17, 8563–8576. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.; Yang, K.; Wang, H.; Li, H. Poly(vinylidene fluoride- co-hexafluoropropylene)-MXene Nanosheet Composites for Microcapacitors. ACS Appl. Nano Mater. 2020, 3, 7992–8003. [Google Scholar] [CrossRef]

- Guo, J.; Wang, Y.; Wang, L.; Ding, B.; Wang, Y.; Sun, Y.; Dai, S.; Wang, D.; Bi, S. High Absorption of Electromagnetic Waves Based on 3D PMMA@Mxene@Co3O4 Composite Microsphere. Materials 2024, 17, 5427. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, Y.; Cai, X. Effects of ultralow concentration MXene (nano-Ti3C2Tx) on the electric and physical properties of ternary polyvinyl alcohol composites. Colloids. Surf. A Physicochem. Eng. Asp. 2021, 610, 125929. [Google Scholar] [CrossRef]

- Tian, S.; Zhou, K.; Huang, C.Q.; Qian, C.; Gao, Z.; Liu, Y. Investigation and understanding of the mechanical properties of MXene by high-throughput computations and interpretable machine learning. Extreme Mech. Lett. 2022, 57, 101921. [Google Scholar] [CrossRef]

- Rong, C.; Su, T.; Li, Z.; Chu, T.; Zhu, M.; Yan, Y.; Zhang, B.; Xuan, F.Z. Elastic properties and tensile strength of 2D Ti3C2Tx MXene monolayers. Nat. Commun. 2024, 15, 1566. [Google Scholar] [CrossRef]

- Borysiuk, V.N.; Mochalin, V.N.; Gogotsi, Y. Molecular dynamic study of the mechanical properties of two-dimensional titanium carbides Tin+1Cn (MXenes). Nanotechnology 2015, 26, 265705. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Chen, Q.; Li, P.; Zhou, A.; Cao, X.; Hu, Q. Preparation, mechanical and anti-friction performance of MXene/polymer composites. Mater. Des. 2016, 92, 682–689. [Google Scholar] [CrossRef]

- Cao, Y.; Deng, Q.; Liu, Z.; Shen, D.; Wang, T.; Huang, Q.; Du, S.; Jiang, N.; Lin, C.T.; Yu, J. Enhanced thermal properties of poly(vinylidene fluoride) composites with ultrathin nanosheets of MXene. RSC. Adv. 2017, 7, 20494–20501. [Google Scholar] [CrossRef]

- Sheng, X.; Zhao, Y.; Zhang, L.; Lu, X. Properties of two-dimensional Ti3C2 MXene/thermoplastic polyurethane nanocomposites with effective reinforcement via melt blending. Compos. Sci. Technol. 2019, 181, 107710. [Google Scholar] [CrossRef]

- Sobolčiak, P.; Ali, A.; Hassan, M.K.; Helal, M.I.; Tanvir, A.; Popelka, A.; Al-Maadeed, M.A.; Krupa, I.; Mahmoud, K.A. 2D Ti3C2Tx (MXene)-reinforced polyvinyl alcohol (PVA) nanofibers with enhanced mechanical and electrical properties. PLoS ONE 2017, 12, e0183705. [Google Scholar] [CrossRef] [PubMed]

- Zhi, W.; Xiang, S.; Bian, R.; Lin, R.; Wu, K.; Wang, T.; Cai, D. Study of MXene-filled polyurethane nanocomposites prepared via an emulsion method. Compos. Sci. Technol. 2018, 168, 404–411. [Google Scholar] [CrossRef]

- Vashishtha, P.; Abidi, I.H.; Giridhar, S.P.; Verma, A.K.; Prajapat, P.; Bhoriya, A.; Murdoch, B.J.; Tollerud, J.O.; Xu, C.; Davis, J.A.; et al. CVD-Grown Monolayer MoS2 and GaN Thin Film Heterostructure for a Self-Powered and Bidirectional Photodetector with an Extended Active Spectrum. ACS Appl. Mater. Interfaces 2024, 16, 31294–31303. [Google Scholar] [CrossRef]

- Qin, K.; Li, E.; Shen, Y.; Ma, D.; Yuan, P.; Wang, H.; Cui, Z. High-efficiency photocatalyst and high-response ultraviolet photodetector based on the Ga2SSe@GaN heterojunctions. Surf. Interfaces 2024, 52, 104996. [Google Scholar] [CrossRef]

- Prajapat, P.; Vashishtha, P.; Gupta, G. Gas-modulated optoelectronic properties of monolayer MoS2 for photodetection applications. APL Energy 2024, 2, 046103. [Google Scholar] [CrossRef]

- Verma, A.K.; Rahman, M.A.; Vashishtha, P.; Guo, X.; Sehrawat, M.; Mitra, R.; Giridhar, S.P.; Waqar, M.; Bhoriya, A.; Murdoch, B.J.; et al. Oxygen-Passivated Sulfur Vacancies in Monolayer MoS2 for Enhanced Piezoelectricity. ACS Nano 2025, 19, 3478–3489. [Google Scholar] [CrossRef]

- Huang, K.J.; Zhang, J.Z.; Liu, Y.J.; Wang, L.L. Novel electrochemical sensing platform based on molybdenum disulfide nanosheets-polyaniline composites and Au nanoparticles. Sens. Actuators B Chem. 2014, 194, 303–310. [Google Scholar] [CrossRef]

- Lee, D.W.; Lee, J.; Sohn, I.Y.; Kim, B.Y.; Son, Y.M.; Bark, H.; Jung, J.; Choi, M.; Kim, T.H.; Lee, C.; et al. Field-effect transistor with a chemically synthesized MoS2 sensing channel for label-free and highly sensitive electrical detection of DNA hybridization. Nano Res. 2015, 8, 2340–2350. [Google Scholar] [CrossRef]

- Lawal, A.T. Graphene-based nano composites and their applications. A review. Biosens. Bioelectron. 2019, 141, 111384. [Google Scholar] [CrossRef]

- Lin, H.; Wang, X.; Yu, L.; Chen, Y.; Shi, J. Two-Dimensional Ultrathin MXene Ceramic Nanosheets for Photothermal Conversion. Nano Lett. 2017, 17, 384–391. [Google Scholar] [CrossRef]

- Bertolazzi, S.; Brivio, J.; Kis, A. Stretching and breaking of ultrathin MoS 2. ACS Nano 2011, 5, 9703–9709. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Li, D.; Müller, M.B.; Gilje, S.; Kaner, R.B.; Wallace, G.G. Processable aqueous dispersions of graphene nanosheets. Nat. Nanotechnol. 2008, 3, 101–105. [Google Scholar] [CrossRef] [PubMed]

- Maleski, K.; Mochalin, V.N.; Gogotsi, Y. Dispersions of Two-Dimensional Titanium Carbide MXene in Organic Solvents. Chem. Mater. 2017, 29, 1632–1640. [Google Scholar] [CrossRef]

- Hu, H.; Zavabeti, A.; Quan, H.; Zhu, W.; Wei, H.; Chen, D.; Ou, J.Z. Recent advances in two-dimensional transition metal dichalcogenides for biological sensing. Biosens. Bioelectron. 2019, 142, 111573. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.; Zhang, F.; Luo, S.; Chang, W.; Yue, J.; Wang, C.H. Recent advances in rational design of polymer nanocomposite dielectrics for energy storage. Nano Energy 2020, 74, 104844. [Google Scholar] [CrossRef]

- Kshetri, T.; Tran, D.T.; Le, H.T.; Nguyen, D.C.; Van Hoa, H.; Kim, N.H.; Lee, J.H. Recent advances in MXene-based nanocomposites for electrochemical energy storage applications. Prog. Mater. Sci. 2021, 117, 100733. [Google Scholar] [CrossRef]

- Feng, Q.K.; Zhong, S.L.; Pei, J.Y.; Zhao, Y.; Zhang, D.L.; Liu, D.F.; Zhang, Y.X.; Dang, Z.M. Recent Progress and Future Prospects on All-Organic Polymer Dielectrics for Energy Storage Capacitors. Chem. Rev. 2022, 122, 3820–3878. [Google Scholar] [CrossRef]

- Yang, M.; Guo, M.; Xu, E.; Ren, W.; Wang, D.; Li, S.; Zhang, S.; Nan, C.W.; Shen, Y. Polymer nanocomposite dielectrics for capacitive energy storage. Nat. Nanotechnol. 2024, 19, 588–603. [Google Scholar] [CrossRef]

- Kumar, Y.A.; Raorane, C.J.; Hegazy, H.H.; Ramachandran, T.; Kim, S.C.; Moniruzzaman, M. 2D MXene-based supercapacitors: A promising path towards high-performance energy storage. J. Energy Storage 2023, 72, 108433. [Google Scholar] [CrossRef]

- Liu, H.J.; Dong, B. Recent advances and prospects of MXene-based materials for electrocatalysis and energy storage. Mater. Today Phys. 2021, 20, 100469. [Google Scholar] [CrossRef]

- Xiong, D.; Li, X.; Bai, Z.; Lu, S.; Xiong, D.; Li, X.; Bai, Z.; Lu, S. Recent Advances in Layered Ti3C2Tx MXene for Electrochemical Energy Storage. Small 2018, 14, 1703419. [Google Scholar] [CrossRef]

- Yadav, S.; Kurra, N. Diffusion kinetics of ionic charge carriers across Ti3C2Tx MXene-aqueous electrochemical interfaces. Energy Storage Mater. 2024, 65, 103094. [Google Scholar] [CrossRef]

- Abid, M.Z.; Rafiq, K.; Aslam, A.; Jin, R.; Hussain, E. Scope, Evaluation and Current Perspectives of MXene Synthesis Strategies for State of the Art Applications. J Mater Chem A Mater 2024, 12, 7351–7395. [Google Scholar] [CrossRef]

- FitzPatrick, J.; Bera, S.; Inman, A.; Cabrera, A.; Zhang, T.; Parker, T.; Mohammadlou, B.S.; Roslyk, I.; Ippolito, S.; Shevchuk, K.; et al. Record Efficiency of β-Phase PVDF-MXene Composites in Thin-Film Dielectric Capacitors. Advanced Materials 2025, 37, 2419088. [Google Scholar] [CrossRef]

- Yang, L.; Kong, X.; Li, F.; Hao, H.; Cheng, Z.; Liu, H.; Li, J.F.; Zhang, S. Perovskite lead-free dielectrics for energy storage applications. Prog. Mater. Sci. 2019, 102, 72–108. [Google Scholar] [CrossRef]

- Dong, Y.; Zheng, S.; Qin, J.; Zhao, X.; Shi, H.; Wang, X.; Chen, J.; Wu, Z.S. All-MXene-Based Integrated Electrode Constructed by Ti3C2 Nanoribbon Framework Host and Nanosheet Interlayer for High-Energy-Density Li-S Batteries. ACS Nano 2018, 12, 2381–2388. [Google Scholar] [CrossRef]

- Bashir, T.; Zhou, S.; Yang, S.; Ismail, S.A.; Ali, T.; Wang, H.; Zhao, J.; Gao, L. Progress in 3D-MXene Electrodes for Lithium/Sodium/Potassium/Magnesium/Zinc/Aluminum-Ion Batteries. Electrochem. Energy Rev. 2023, 6, 5. [Google Scholar] [CrossRef]

- Er, D.; Li, J.; Naguib, M.; Gogotsi, Y.; Shenoy, V.B. Ti3C2 MXene as a high capacity electrode material for metal (Li, Na, K, Ca) ion batteries. ACS Appl. Mater. Interfaces 2014, 6, 11173–11179. [Google Scholar] [CrossRef]

- Zhang, F.; Jia, Z.; Wang, C.; Feng, A.; Wang, K.; Hou, T.; Liu, J.; Zhang, Y.; Wu, G. Sandwich-like silicon/Ti3C2Tx MXene composite by electrostatic self-assembly for high performance lithium ion battery. Energy 2020, 195, 117047. [Google Scholar] [CrossRef]

- Shi, M.; Wang, R.; Li, L.; Chen, N.; Xiao, P.; Yan, C.; Yan, X.; Shi, M.; Wang, R.; Li, L.; et al. Redox-Active Polymer Integrated with MXene for Ultra-Stable and Fast Aqueous Proton Storage. Adv. Funct. Mater. 2023, 33, 2209777. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Z.; Hou, Z.; Mei, H.; Feng, Y.; Xu, B.; Sun, D. Self-assembly of MOF on MXene nanosheets and in-situ conversion into superior nickel phosphates/MXene battery-type electrode. Chem. Eng. J. 2021, 425, 130602. [Google Scholar] [CrossRef]

- Zhang, P.; Zhu, Q.; Guan, Z.; Zhao, Q.; Sun, N.; Xu, B. A Flexible Si@C Electrode with Excellent Stability Employing an MXene as a Multifunctional Binder for Lithium-Ion Batteries. ChemSusChem 2020, 13, 1621–1628. [Google Scholar] [CrossRef]

- Zhong, X.; Wang, D.; Sheng, J.; Han, Z.; Sun, C.; Tan, J.; Gao, R.; Lv, W.; Xu, X.; Wei, G.; et al. Freestanding and Sandwich MXene-Based Cathode with Suppressed Lithium Polysulfides Shuttle for Flexible Lithium-Sulfur Batteries. Nano Lett. 2022, 22, 1207–1216. [Google Scholar] [CrossRef]

- Li, T.; Ding, B.; Wang, J.; Qin, Z.; Fernando, J.F.S.; Bando, Y.; Nanjundan, A.K.; Kaneti, Y.V.; Golberg, D.; Yamauchi, Y. Sandwich-Structured Ordered Mesoporous Polydopamine/MXene Hybrids as High-Performance Anodes for Lithium-Ion Batteries. ACS Appl. Mater. Interfaces 2020, 12, 14993–15001. [Google Scholar] [CrossRef]

- Chen, N.; He, J.; Xuan, H.; Jin, J.; Yu, K.; Shi, M.; Yan, C. Dual-functional Polyindole/MXene composite for superior proton storage and corrosion protection. Compos. B Eng. 2024, 270, 111145. [Google Scholar] [CrossRef]

- Zhou, W.; Kuang, W.; Liang, X.; Zhou, W.; Guo, J.; Gan, L.; Huang, D. Exploration of MXene/polyaniline composites as promising anode materials for sodium ion batteries. J. Phys. D Appl. Phys. 2020, 54, 064001. [Google Scholar] [CrossRef]

- Mahajan, M.; Singla, G.; Ogale, S. Polypyrrole-Encapsulated Polyoxomolybdate Decorated MXene As a Functional 2D/3D Nanohybrid for a Robust and High Performance Li-Ion Battery. ACS Appl. Energy Mater. 2021, 4, 4541–4550. [Google Scholar] [CrossRef]

- Yan, J.; Ma, Y.; Zhang, C.; Li, X.; Liu, W.; Yao, X.; Yao, S.; Luo, S. Polypyrrole–MXene coated textile-based flexible energy storage device. RSC Adv. 2018, 8, 39742–39748. [Google Scholar] [CrossRef]

- Bai, W.; Yong, Z.; Wang, S.; Wang, X.; Li, C.; Pan, F.; Liang, D.; Cui, Y.; Wang, Z. Polyaniline-MXene composite electrode with excellent electrochemical properties for all-solid flexible supercapacitors. J. Energy Storage 2023, 71, 108053. [Google Scholar] [CrossRef]

- Chen, Z.; Li, X.; Wang, D.; Yang, Q.; Ma, L.; Huang, Z.; Liang, G.; Chen, A.; Guo, Y.; Dong, B.; et al. Grafted MXene/polymer electrolyte for high performance solid zinc batteries with enhanced shelf life at low/high temperatures. Energy Environ. Sci. 2021, 14, 3492–3501. [Google Scholar] [CrossRef]

- Liu, C.; Tian, Y.; An, Y.; Yang, Q.; Xiong, S.; Feng, J.; Qian, Y. Robust and flexible polymer/MXene-derived two dimensional TiO22 hybrid gel electrolyte for dendrite-free solid-state zinc-ion batteries. Chem. Eng. J. 2022, 430, 132748. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Chen, J.; Zhao, Y.; Mao, Z.; Wang, D. Durable sodium battery composed of conductive Ti3C2Tx MXene modified gel polymer electrolyte. Solid State Ion. 2021, 365, 115655. [Google Scholar] [CrossRef]

- Kumar, D.R.; Karthik, R.; Hasan, M.; Sayed, M.S.; Shim, J.J. Mo-MXene-filled gel polymer electrolyte for high-performance quasi-solid-state zinc metal batteries. Chem. Eng. J. 2023, 473, 145207. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, X.; Wang, Z.; Sun, F.; Dorrell, D.G. A review of supercapacitor modeling, estimation, and applications: A control/management perspective. Renew. Sustain. Energy Rev. 2018, 81, 1868–1878. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Narenthiran, B.; Sivanantham, A.; Bhatlu, L.D.; Maridurai, T. Supercapacitor: Evolution and review. Mater. Today Proc. 2021, 46, 3984–3988. [Google Scholar] [CrossRef]

- Zhan, C.; Naguib, M.; Lukatskaya, M.; Kent, P.R.C.; Gogotsi, Y.; Jiang, D.E. Understanding the MXene Pseudocapacitance. J. Phys. Chem. Lett. 2018, 9, 1223–1228. [Google Scholar] [CrossRef]

- Shimada, T.; Takenaka, N.; Ando, Y.; Otani, M.; Okubo, M.; Yamada, A. Relationship between Electric Double-Layer Structure of MXene Electrode and Its Surface Functional Groups. Chem. Mater. 2022, 34, 2069–2075. [Google Scholar] [CrossRef]

- Wang, X.; Kajiyama, S.; Iinuma, H.; Hosono, E.; Oro, S.; Moriguchi, I.; Okubo, M.; Yamada, A. Pseudocapacitance of MXene nanosheets for high-power sodium-ion hybrid capacitors. Nat. Commun. 2015, 6, 6544. [Google Scholar] [CrossRef]

- Li, L.; Zhang, D.; Deng, J.; Gou, Y.; Fang, J.; Cui, H.; Zhang, C.; Cao, M. Application of MXene-based materials in hybrid capacitors. Sustain. Energy Fuels 2021, 5, 3278–3291. [Google Scholar] [CrossRef]

- Wu, J. Understanding the Electric Double-Layer Structure, Capacitance, and Charging Dynamics. Chem. Rev. 2022, 122, 10821–10859. [Google Scholar] [CrossRef]

- Fleischmann, S.; Mitchell, J.B.; Wang, R.; Zhan, C.; Jiang, D.E.; Presser, V.; Augustyn, V. Pseudocapacitance: From Fundamental Understanding to High Power Energy Storage Materials. Chem. Rev. 2020, 120, 6738–6782. [Google Scholar] [CrossRef] [PubMed]

- Sohan, A.; Banoth, P.; Aleksandrova, M.; Grace, A.N.; Kollu, P. Review on MXene synthesis, properties, and recent research exploring electrode architecture for supercapacitor applications. Int J. Energy Res. 2021, 45, 19746–19771. [Google Scholar] [CrossRef]

- Panda, S.; Deshmukh, K.; Pasha, S.K.K.; Theerthagiri, J.; Manickam, S.; Choi, M.Y. MXene based emerging materials for supercapacitor applications: Recent advances, challenges, and future perspectives. Coord. Chem. Rev. 2022, 462, 214518. [Google Scholar] [CrossRef]

- Nasrin, K.; Sudharshan, V.; Subramani, K.; Sathish, M. Insights into 2D/2D MXene Heterostructures for Improved Synergy in Structure toward Next-Generation Supercapacitors: A Review. Adv. Funct. Mater. 2022, 32, 2110267. [Google Scholar] [CrossRef]

- Jiang, Q.; Lei, Y.; Liang, H.; Xi, K.; Xia, C.; Alshareef, H.N. Review of MXene electrochemical microsupercapacitors. Energy Storage Mater. 2020, 27, 78–95. [Google Scholar] [CrossRef]

- Luo, W.; Ma, Y.; Li, T.; Thabet, H.K.; Hou, C.; Ibrahim, M.M.; El-Bahy, S.M.; Xu, B.B.; Guo, Z. Overview of MXene/conducting polymer composites for supercapacitors. J. Energy Storage 2022, 52, 105008. [Google Scholar] [CrossRef]

- Jimmy, J.; Kandasubramanian, B. Mxene functionalized polymer composites: Synthesis and applications. Eur. Polym. J. 2020, 122, 109367. [Google Scholar] [CrossRef]

- Fang, Y.S.; He, P.; Cai, Y.Z.; Cao, W.Q.; Cao, M.S. Bifunctional Ti3C2Tx–CNT/PANI composite with excellent electromagnetic shielding and supercapacitive performance. Ceram. Int. 2021, 47, 25531–25540. [Google Scholar] [CrossRef]

- Yuan, T.; Zhang, Z.; Liu, Q.; Liu, X.T.; Miao, Y.N.; Yao, C.L. MXene (Ti3C2Tx)/cellulose nanofiber/polyaniline film as a highly conductive and flexible electrode material for supercapacitors. Carbohydr. Polym. 2023, 304, 120519. [Google Scholar] [CrossRef] [PubMed]

- Yin, H.; Liu, F.; Abdiryim, T.; Chen, J.; Liu, X. Sodium carboxymethyl cellulose and MXene reinforced multifunctional conductive hydrogels for multimodal sensors and flexible supercapacitors. Carbohydr. Polym. 2024, 327, 121677. [Google Scholar] [CrossRef]

- Han, L.; Li, Y.; Chen, C.; Liu, L.; Lu, Z. Multifunctional enhanced energy density of flexible wide-temperature supercapacitors based on MXene/PANI conductive hydrogel. Chem. Eng. J. 2024, 485, 149951. [Google Scholar] [CrossRef]

- Mahmud, S.T.; Hasan, M.M.; Bain, S.; Rahman, S.T.; Rhaman, M.; Hossain, M.M.; Ordu, M. Multilayer MXene Heterostructures and Nanohybrids for Multifunctional Applications: A Review. ACS Mater. Lett. 2022, 4, 1174–1206. [Google Scholar] [CrossRef]

- Wang, Y.; Luo, Z.; Qian, Y.; Zhang, W.; Chen, L. Monolithic MXene composites with multi-responsive actuating and energy-storage multi-functions. Chem. Eng. J. 2023, 454, 140513. [Google Scholar] [CrossRef]

- Boota, M.; Anasori, B.; Voigt, C.; Zhao, M.Q.; Barsoum, M.W.; Gogotsi, Y. Pseudocapacitive Electrodes Produced by Oxidant-Free Polymerization of Pyrrole between the Layers of 2D Titanium Carbide (MXene). Adv. Mater. 2016, 28, 1517–1522. [Google Scholar] [CrossRef]

- Qin, L.; Tao, Q.; El Ghazaly, A.; Fernandez-Rodriguez, J.; Persson, P.O.Å.; Rosen, J.; Zhang, F. High-Performance Ultrathin Flexible Solid-State Supercapacitors Based on Solution Processable Mo1.33C MXene and PEDOT:PSS. Adv Funct. Mater. 2018, 28, 1703808. [Google Scholar] [CrossRef]

- Zhou, Y.; Zou, Y.; Peng, Z.; Yu, C.; Zhong, W. Arbitrary deformable and high-strength electroactive polymer/MXene anti-exfoliative composite films assembled into high performance, flexible all-solid-state supercapacitors. Nanoscale 2020, 12, 20797–20810. [Google Scholar] [CrossRef]

- Li, K.; Wang, X.; Li, S.; Urbankowski, P.; Li, J.; Xu, Y.; Gogotsi, Y. An Ultrafast Conducting Polymer@MXene Positive Electrode with High Volumetric Capacitance for Advanced Asymmetric Supercapacitors. Small 2020, 16, 1906851. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Li, X.; Bai, Y.; Xiao, H.; Liu, Y.; Yuan, G. Scalable fabrication of polyaniline nanodots decorated MXene film electrodes enabled by viscous functional inks for high-energy-density asymmetric supercapacitors. Chem. Eng. J. 2021, 405, 126664. [Google Scholar] [CrossRef]

- Li, L.; Zhang, N.; Zhang, M.; Zhang, X.; Zhang, Z. Flexible Ti3C2Tx/PEDOT:PSS films with outstanding volumetric capacitance for asymmetric supercapacitors. Dalton Trans. 2019, 48, 1747–1756. [Google Scholar] [CrossRef]

- Luo, H.; Wang, F.; Guo, R.; Zhang, D.; He, G.; Chen, S.; Wang, Q. Progress on Polymer Dielectrics for Electrostatic Capacitors Application. Adv. Sci. 2022, 9, 2202438. [Google Scholar] [CrossRef] [PubMed]

- Behera, R.; Elanseralathan, K. A review on polyvinylidene fluoride polymer based nanocomposites for energy storage applications. J. Energy Storage 2022, 48, 103788. [Google Scholar] [CrossRef]

- Gebrekrstos, A.; Muzata, T.S.; Ray, S.S. Nanoparticle-Enhanced β-Phase Formation in Electroactive PVDF Composites: A Review of Systems for Applications in Energy Harvesting, EMI Shielding, and Membrane Technology. ACS Appl. Nano Mater. 2022, 5, 7632–7651. [Google Scholar] [CrossRef]

- Yang, M.; Ren, W.; Guo, M.; Shen, Y. High-Energy-Density and High Efficiency Polymer Dielectrics for High Temperature Electrostatic Energy Storage: A Review. Small 2022, 18, 2205247. [Google Scholar] [CrossRef] [PubMed]

- Chan, K.Y.; Jia, B.; Lin, H.; Hameed, N.; Lee, J.H.; Lau, K.T. A critical review on multifunctional composites as structural capacitors for energy storage. Compos. Struct. 2018, 188, 126–142. [Google Scholar] [CrossRef]

- Zhang, L.; Nie, L.; Zhang, S.; Dong, Z.; Zhou, Q.; Zhang, Z.; Pan, G.B. 2D conductive MOF modified MXene nanosheets for poly (vinylidene fluoride) nanocomposite with high permittivity. Mater. Lett. 2022, 314, 131820. [Google Scholar] [CrossRef]

- Li, J.; Claude, J.; Norena-Franco, L.E.; Seok, S.I.; Wang, Q. Electrical energy storage in ferroelectric polymer nanocomposites containing surface-functionalized BaTiO3 nanoparticles. Chem. Mater. 2008, 20, 6304–6306. [Google Scholar] [CrossRef]

- Cao, L.; Chen, Y.; Feng, S.; Su, Y. Reduced dielectric loss of MXene/PVDF composites with adding MnO2 nanorods. Ceram. Int. 2024, 50, 47655–47665. [Google Scholar] [CrossRef]

- Dizayee, W.; Hamarashid, M.M.; Zorah, M.; Mahmoud, H.A.M.A.; Al-Bahrani, M.; Taki, A.G.; Abdulkareem-Alsultan, G.; Nassar, M.F. Synergistic effect of Ni(OH)2 and MXene nanosheets in 3D framework on the improvement of dielectric, energy storage, mechanical and thermal characteristics of polyvinylidene fluoride(PVDF) polymeric composites. J. Alloys. Compd. 2024, 1004, 175825. [Google Scholar] [CrossRef]

- Zhang, F.; Gao, M.H.; Sun, D.X.; Zhang, N.; Yang, J.H.; Qi, X.D.; Wang, Y. Synchronously improved energy storage density and water resistance of cellulose/MXene composite film via glutaraldehyde-assisted crosslinking. Polymer 2024, 297, 126849. [Google Scholar] [CrossRef]

- Feng, Y.; Deng, Q.; Peng, C.; Wu, Q. High dielectric and breakdown properties achieved in ternary BaTiO3/MXene/PVDF nanocomposites with low-concentration fillers from enhanced interface polarization. Ceram. Int. 2019, 45, 7923–7930. [Google Scholar] [CrossRef]

- Mazhar, S.; Qarni, A.A.; Haq, Y.U.; Haq, Z.U.; Murtaza, I. Promising PVC/MXene based flexible thin film nanocomposites with excellent dielectric, thermal and mechanical properties. Ceram. Int. 2020, 46, 12593–12605. [Google Scholar] [CrossRef]

- Chen, L.; Cao, Y.; Guo, X.; Song, P.; Chen, K.; Li, D.; Lin, J. Simultaneously Improved Thermal and Dielectric Performance of Epoxy Composites Containing Ti3C2Tx Platelet Fillers. Polymers 2020, 12, 1608. [Google Scholar] [CrossRef]

- Deng, Q.; Zhou, F.; Qin, B.; Feng, Y.; Xu, Z. Eco-friendly poly(vinyl alcohol)/delaminated V2C MXene high-k nanocomposites with low dielectric loss enabled by moderate polarization and charge density at the interface. Ceram. Int. 2020, 46, 27326–27335. [Google Scholar] [CrossRef]

- Marhoon, I.I.; Atiyah, I.A.; Rasheed, A.K. 3D g-C3N4 porous nanoribbons pillared-MXene/ PVA nanocomposite: An architecture with high dielectric, breakdown strength, thermal conductivity, and mechanical strength characteristics. J. Alloys. Compd. 2023, 969, 172229. [Google Scholar] [CrossRef]

- Li, W.; Song, Z.; Zhong, J.; Qian, J.; Tan, Z.; Wu, X.; Chu, H.; Nie, W.; Ran, X. Multilayer-structured transparent MXene/PVDF film with excellent dielectric and energy storage performance. J. Mater. Chem. C Mater. 2019, 7, 10371–10378. [Google Scholar] [CrossRef]

- Haq, Y.U.; Murtaza, I.; Mazhar, S.; Ahmad, N.; Qarni, A.A.; Haq, Z.U.; Khan, S.A.; Iqbal, M. Investigation of improved dielectric and thermal properties of ternary nanocomposite PMMA/MXene/ZnO fabricated by in-situ bulk polymerization. J. Appl. Polym. Sci. 2020, 137, 49197. [Google Scholar] [CrossRef]

- Wang, H.Q.; Wang, J.W.; Wang, X.Z.; Gao, X.H.; Zhuang, G.C.; Yang, J.B.; Ren, H. Dielectric properties and energy storage performance of PVDF-based composites with MoS2@MXene nanofiller. Chem. Eng. J. 2022, 437, 135431. [Google Scholar] [CrossRef]

- Ma, W.; Yang, K.; Zhou, C.; Li, H. Enhanced dielectric constant and suppressed electrical conductivity in polymer nanocomposite films via loading MXene/TiO22/MoS2 nanosheets. Ceram. Int. 2022, 48, 10447–10457. [Google Scholar] [CrossRef]

- Feng, Y.; Qiu, H.; Mao, B.; Bo, M.; Deng, Q. Preparation of hybrid ceramic/PVC composites showing both high dielectric constant and breakdown strength ascribed to interfacial effect between V2C MXene and Cu2O. Colloids Surf. A Physicochem. Eng. Asp. 2021, 630, 127650. [Google Scholar] [CrossRef]

- Yu, S.; Ding, C.; Liu, Y.; Liu, Y.; Zhang, Y.; Luo, H.; Zhang, D.; Chen, S. Enhanced breakdown strength and energy density over a broad temperature range in polyimide dielectrics using oxidized MXenes filler. J. Power Sources 2022, 535, 231415. [Google Scholar] [CrossRef]

- Cao, X.; Lu, C.; Zhao, W.; Tong, Y.; He, G.; Zou, X.; Feng, Y.; Yang, Z. Cetyltrimethylammonium bromide decorated MXene/polyimide nanocomposites with enhanced dielectric properties, thermostability, and moisture resistance. J. Appl. Polym. Sci. 2022, 139, e53142. [Google Scholar] [CrossRef]

- Geng, Z.; Liu, H.; Xiong, W. PVC/Ti2C MXene/Diamond-Blend Films with High Dielectric Constants and Breakdown Strength Due to Electrical Synergy Between the Filler Materials. J. Electron. Mater. 2022, 51, 6964–6974. [Google Scholar] [CrossRef]

- Yang, J.B.; Wang, J.W.; Zhuang, G.C.; Wang, X.Z.; Wang, H.Q.; Ma, Y.J.; Zhang, Y. High dielectric constant acrylic resin based percolative composite with acidified carbon nanotubes intercalation of MXene. Eur. Polym. J. 2023, 190, 112006. [Google Scholar] [CrossRef]

- Zeng, Y.; Tang, L.; Xin, Z.; Guo, F.; Li, G.; Chen, N.; Du, G. Ti3C2Tx MXene-Ag/silicone rubber composites with enhanced dielectric properties and improved mechanical properties. J. Alloys. Compd. 2023, 930, 167419. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Choi, S.; Lee, H.; Ghaffari, R.; Hyeon, T.; Kim, D.H. Recent Advances in Flexible and Stretchable Bio-Electronic Devices Integrated with Nanomaterials. Adv. Mater. 2016, 28, 4203–4218. [Google Scholar] [CrossRef]

- Rim, Y.S.; Bae, S.H.; Chen, H.; De Marco, N.; Yang, Y. Recent Progress in Materials and Devices toward Printable and Flexible Sensors. Adv. Mater. 2016, 28, 4415–4440. [Google Scholar] [CrossRef]

- Zang, Y.; Zhang, F.; Di, C.A.; Zhu, D. Advances of flexible pressure sensors toward artificial intelligence and health care applications. Mater. Horiz. 2015, 2, 140–156. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, M.; Yang, B.; Tan, J.; Ding, X.; Li, W. Recent Advances in Multidimensional (1D, 2D, and 3D) Composite Sensors Derived from MXene: Synthesis, Structure, Application, and Perspective. Small Methods 2021, 5, 2100409. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.; Wang, J.; Kang, W.; Cui, M.; Wang, X.; Foo, C.Y.; Chee, K.J.; Lee, P.S. Highly stretchable piezoresistive graphene-nanocellulose nanopaper for strain sensors. Adv. Mater. 2014, 26, 2022–2027. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Wang, G.; Yang, R.; Lu, X.; Cheng, M.; He, C.; Xie, G.; Meng, J.; Shi, D.; Zhang, G. Tunable piezoresistivity of nanographene films for strain sensing. ACS Nano 2015, 9, 1622–1629. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Yan, X. Progress in achieving high-performance piezoresistive and capacitive flexible pressure sensors: A review. J. Mater. Sci. Technol. 2020, 43, 175–188. [Google Scholar] [CrossRef]

- De Marcellis, A.; Ferri, G. Analog Circuits and Systems for Voltage-Mode and Current-Mode Sensor Interfacing Applications; Springer: Dordrecht, The Netherlands, 2011. [Google Scholar] [CrossRef]

- Levitt, A.; Seyedin, S.; Zhang, J.; Wang, X.; Razal, J.M.; Dion, G.; Gogotsi, Y. Bath Electrospinning of Continuous and Scalable Multifunctional MXene-Infiltrated Nanoyarns. Small 2020, 16, 2002158. [Google Scholar] [CrossRef]

- Uzun, S.; Seyedin, S.; Stoltzfus, A.L.; Levitt, A.S.; Alhabeb, M.; Anayee, M.; Strobel, C.J.; Razal, J.M.; Dion, G.; Gogotsi, Y. Knittable and Washable Multifunctional MXene-Coated Cellulose Yarns. Adv. Funct. Mater. 2019, 29, 1905015. [Google Scholar] [CrossRef]

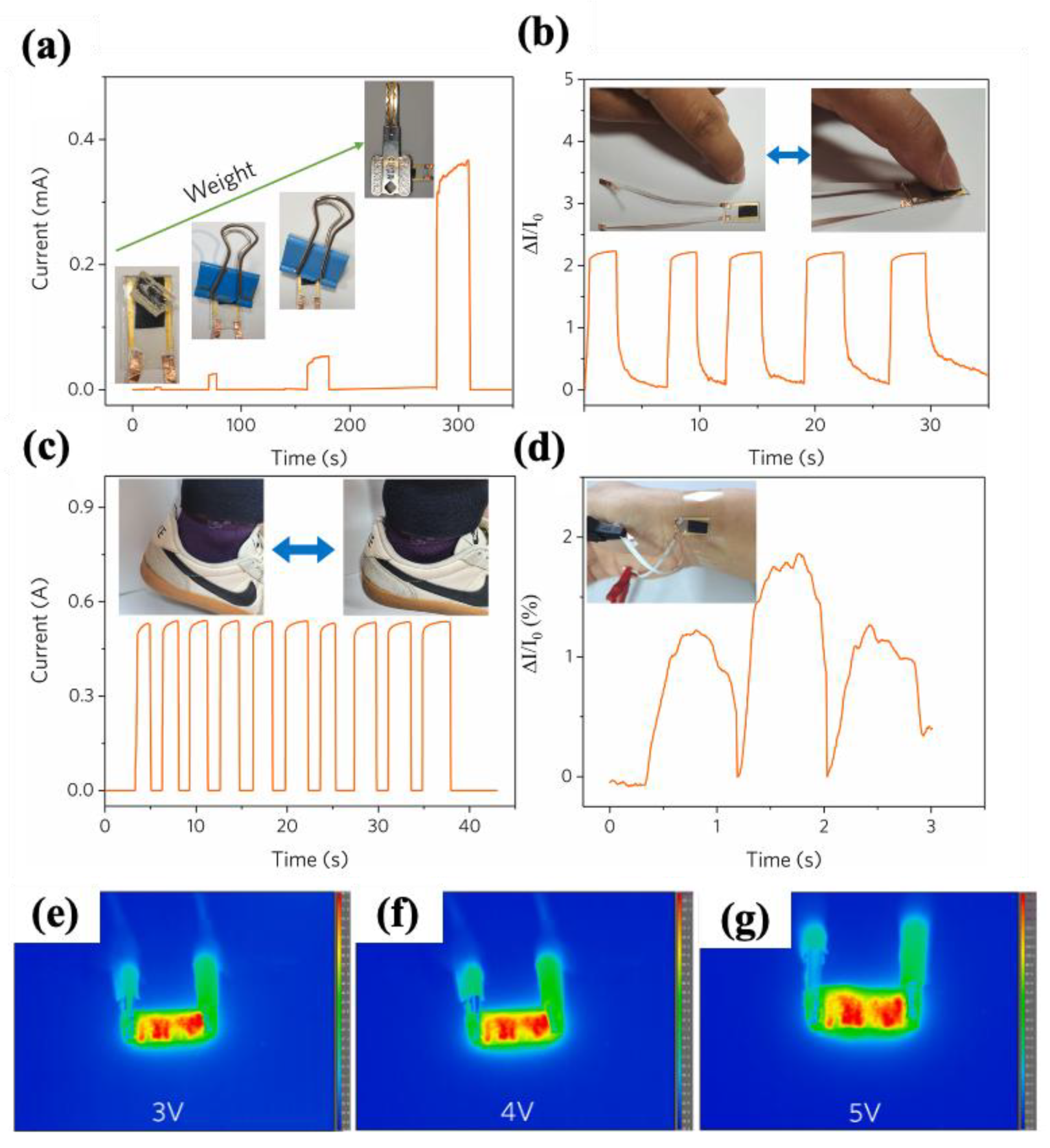

- Zheng, X.; Wang, P.; Zhang, X.; Hu, Q.; Wang, Z.; Nie, W.; Zou, L.; Li, C.; Han, X. Breathable, durable and bark-shaped MXene/textiles for high-performance wearable pressure sensors, EMI shielding and heat physiotherapy. Compos. Part A Appl. Sci. Manuf. 2022, 152, 106700. [Google Scholar] [CrossRef]

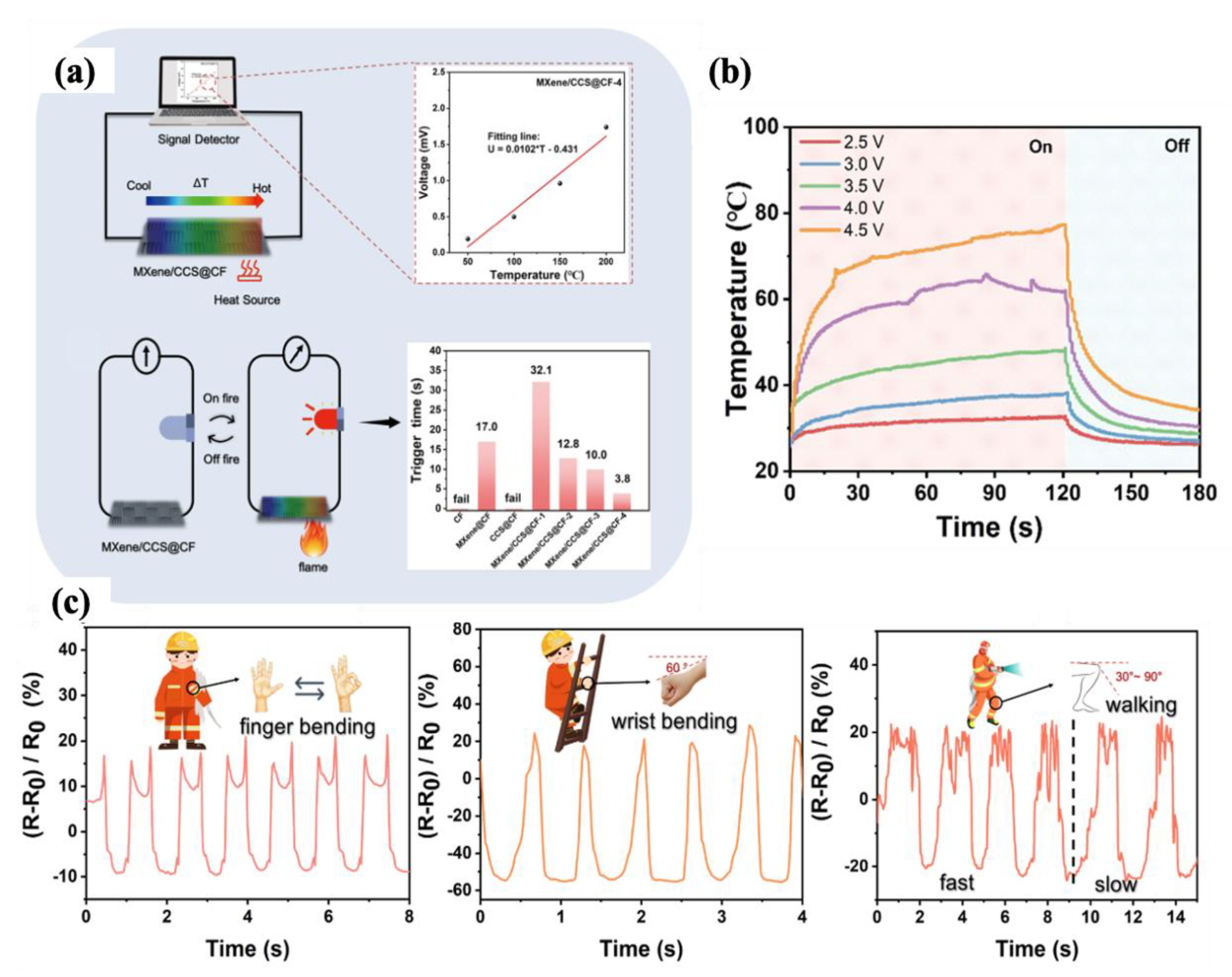

- Wang, B.; Lai, X.; Li, H.; Jiang, C.; Gao, J.; Zeng, X. Multifunctional MXene/Chitosan-Coated Cotton Fabric for Intelligent Fire Protection. ACS Appl. Mater. Interfaces 2021, 13, 23020–23029. [Google Scholar] [CrossRef]

- Wang, Q.W.; Zhang, H.B.; Liu, J.; Zhao, S.; Xie, X.; Liu, L.; Yang, R.; Koratkar, N.; Yu, Z.Z. Multifunctional and Water-Resistant MXene-Decorated Polyester Textiles with Outstanding Electromagnetic Interference Shielding and Joule Heating Performances. Adv. Funct. Mater. 2019, 29, 1806819. [Google Scholar] [CrossRef]

- Luo, J.; Gao, S.; Luo, H.; Wang, L.; Huang, X.; Guo, Z.; Lai, X.; Lin, L.; Li, R.K.Y.; Gao, J. Superhydrophobic and breathable smart MXene-based textile for multifunctional wearable sensing electronics. Chem. Eng. J. 2021, 406, 1806819. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, S.; Du, Z.; Yang, L.; Cheng, X.; Wang, H. Multifunctional wearable electronic textile based on fabric modified by MXene/Ag NWs for pressure sensing, EMI and personal thermal management. Compos. B Eng. 2023, 266, 110999. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, X.; Lei, Z.; Wang, L.; Tian, M.; Zhu, S.; Xiao, H.; Tang, X.; Qu, L. Flexible MXene-Decorated Fabric with Interwoven Conductive Networks for Integrated Joule Heating, Electromagnetic Interference Shielding, and Strain Sensing Performances. ACS Appl. Mater. Interfaces 2020, 12, 14459–14467. [Google Scholar] [CrossRef]

- Salauddin, M.; Rana, S.M.S.; Rahman, M.T.; Sharifuzzaman, M.; Maharjan, P.; Bhatta, T.; Cho, H.; Lee, S.H.; Park, C.; Shrestha, K.; et al. Fabric-Assisted MXene/Silicone Nanocomposite-Based Triboelectric Nanogenerators for Self-Powered Sensors and Wearable Electronics. Adv. Funct. Mater. 2022, 32, 2107143. [Google Scholar] [CrossRef]

- Zheng, X.; Hu, Q.; Wang, Z.; Nie, W.; Wang, P.; Li, C. Roll-to-roll layer-by-layer assembly bark-shaped carbon nanotube/Ti3C2Tx MXene textiles for wearable electronics. J. Colloid Interface Sci. 2021, 602, 680–688. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Chen, L.; Yang, X.; Chen, X.; Zhang, Z.; Zhao, T.; Li, X.; Zhang, J. A flexible pressure sensor based on an MXene-textile network structure. J Mater. Chem. C Mater. 2019, 7, 1022–1027. [Google Scholar] [CrossRef]

- Zheng, X.; Nie, W.; Hu, Q.; Wang, X.; Wang, Z.; Zou, L.; Hong, X.; Yang, H.; Shen, J.; Li, C. Multifunctional RGO/Ti3C2Tx MXene fabrics for electrochemical energy storage, electromagnetic interference shielding, electrothermal and human motion detection. Mater. Des. 2021, 200, 109442. [Google Scholar] [CrossRef]

- Liu, L.X.; Chen, W.; Zhang, H.B.; Wang, Q.W.; Guan, F.; Yu, Z.Z. Flexible and Multifunctional Silk Textiles with Biomimetic Leaf-Like MXene/Silver Nanowire Nanostructures for Electromagnetic Interference Shielding, Humidity Monitoring, and Self-Derived Hydrophobicity. Adv. Funct. Mater. 2019, 29, 1905197. [Google Scholar] [CrossRef]

- Zhang, J.; Wan, L.; Gao, Y.; Fang, X.; Lu, T.; Pan, L.; Xuan, F. Highly Stretchable and Self-Healable MXene/Polyvinyl Alcohol Hydrogel Electrode for Wearable Capacitive Electronic Skin. Adv. Electron. Mater. 2019, 5, 1900285. [Google Scholar] [CrossRef]

- Liao, H.; Guo, X.; Wan, P.; Yu, G. Conductive MXene Nanocomposite Organohydrogel for Flexible, Healable, Low-Temperature Tolerant Strain Sensors. Adv. Funct. Mater. 2019, 29, 1904507. [Google Scholar] [CrossRef]

- Zhu, Y.; Liu, J.; Guo, T.; Wang, J.J.; Tang, X.; Nicolosi, V. Multifunctional Ti3C2TxMXene Composite Hydrogels with Strain Sensitivity toward Absorption-Dominated Electromagnetic-Interference Shielding. ACS Nano 2021, 15, 1465–1474. [Google Scholar] [CrossRef]

- Liu, S.; Tian, X.; Zhang, X.; Xu, C.; Wang, L.; Xia, Y. A green MXene-based organohydrogel with tunable mechanics and freezing tolerance for wearable strain sensors. Chin. Chem. Lett. 2022, 33, 2205–2211. [Google Scholar] [CrossRef]

- Long, Y.; Wang, Z.; Xu, F.; Jiang, B.; Xiao, J.; Yang, J.; Wang, Z.L.; Hu, W. Mechanically Ultra-Robust, elastic, conductive, and Multifunctional hybrid Hydrogel for a triboelectric nanogenerator and flexible/wearable sensor. Small 2022, 18, 2203956. [Google Scholar] [CrossRef] [PubMed]

- Su, T.; Liu, N.; Gao, Y.; Lei, D.; Wang, L.; Ren, Z.; Zhang, Q.; Su, J.; Zhang, Z. MXene/cellulose nanofiber-foam based high performance degradable piezoresistive sensor with greatly expanded interlayer distances. Nano Energy 2021, 87, 106151. [Google Scholar] [CrossRef]

- Ran, L.; Qiu, L.; Sun, F.; Chen, Z.; Zhao, L.; Yi, L.; Ji, X. Multilayer assembly of strong and tough MXene/cellulose films for excellent electromagnetic shielding. J. Alloys. Compd. 2023, 961, 171020. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Min, B.K.; Yi, Y.; Kim, S.J.; Choi, C.G. MXene(Ti3C2Tx)/graphene/PDMS composites for multifunctional broadband electromagnetic interference shielding skins. Chem. Eng. J. 2020, 393, 124608. [Google Scholar] [CrossRef]

| Synthesis Method | Large-Scale Production | |

|---|---|---|

| Application-Based Properties | Scalability | |

| HF direct etching |

|

|

| Indirect (MILD) etching |

|

|

| Electrochemical etching |

|

|

| Hydrothermal |

|

|

| MXene Type | Synthesis | Delamination | Details/Effective Parameters | Conductivity (S.cm−1) | Refs. |

|---|---|---|---|---|---|

| Mo2CTx | HF (50%) | TBAOH | Type of MXene | 1300 | [30] |

| Ti3C2Tx | MILD | Li+ | MAX phase: graphite as carbon source | 4400 | [118] |

| Ti3C2Tx | MILD | Li+ | MAX phase: TiC as carbon source | 3480 | [118] |

| Ti3C2Tx | MILD | Li+ | MAX phase: lampblack as carbon source | 1020 | [118] |

| Ti3C2Tx | HF (50%) | Li+ | Excess aluminum in MAX phase | 20,000 | [119] |

| Ti3C2Tx | MILD | Li+ | Number of layers: Monolayer | 6760 | [120] |

| Ti3C2Tx | MILD | Li+ | Synthesis method: ratio of LiF/HCl | 4600 | [121] |

| Ti3C2Tx | MILD | Li+ | Synthesis method: N2 atmosphere | 14,000 | [122] |

| Ti3C2Tx | HF (50%) | DMSO | Delamination treatment | 123 | [123] |

| Ti3C2Tx | MILD | Li+ | Removing fluorine-containing surface terminations by annealing treatment | 3697 | [124] |

| Ti3C2Tx | MILD | Li+ | Flake size: large size | 5000 | [125] |

| Ti3C2Tx | MILD | Li+ | Flake size: small size | 1000 | [125] |

| Polymer Matrix | MXene/ Loading | Processing Method | Conductivity (S/cm) | Other Functionalities/ Applications | Ref. |

|---|---|---|---|---|---|

| Polystyrene (PS) | Ti3C2Tx/1.9 vol% | Solution and vacuum filtration | 10.81 | High EMI SE and mechanical properties/EMI shielding | [135] |

| Epoxy | Ti3C2Tx/15 wt% | Solution casting | 1.05 | High EMI SE and mechanical properties/EMI shielding | [136] |

| PEDOT:PSS | Ti3C2Tx/87.5 wt% | Solution and vacuum filtration | 340.5 | High EMI SE and mechanical properties/EMI shielding | [137] |

| Poly(ethylene oxide) (PEO)/ Succinonitrile (SN) | Ti3C2Tx/0.8 wt% | Solution casting | 2.17 × 10−3 | Electrochemical performance, high mechanical properties, and capacity retention/electrolyte | [45] |

| Copolyimide | Ti3C2Tx/5.0 wt% | Solution casting | 1.4 × 10−2 | High electrical, mechanical, and transparency/flexible electronics | [138] |

| Poly(ethylene oxide) (PEO) | Ti3C2Tx/3.6 wt% | Solution blending | 2.2 × 10−7 | High ionic conductivity, rate capability, and stability/electrolyte in batteries | [35] |

| Polyaniline | Ti3C2Tx | In situ polymerization | 88.4 | High specific capacitance and capacitance retention/ electrode in supercapacitors | [44] |

| PVDF/ PMMA | Ti3C2Tx/15.0 wt% | Solution blending | 10−3 @ 1 MHz frequency | High energy and power density/dielectric materials in capacitors | [139] |

| Polyurethane (PU) | Ti3C2Tx/23.1 wt% | Wet spinning | 22.6 | High gauge factor, large sensing strain/strain sensors in health and sports | [140] |

| Polymer Matrix | Filler(s)/ Loading | Processing Method | Applications | Refs. | |

|---|---|---|---|---|---|

| PVDF/PMMA | MWCNT a/Ti3C2Tx 15 wt% | Solution casting | 246/(~0.2) @ 100 Hz | Capacitors | [158] |

| PVA | Ti3C2Tx @SiO2 2.5/5 wt% | Solution coating | 27.2/(0.057) @ 100 Hz | Electronics | [159] |

| paraffin | Ti3C2Tx 6.67 vol% | Melt mixing | ~37.5/~52 @ 2 GHz | Microwave absorption | [160] |

| P[VDF-TrFE-CFE] | L-Ti3C2Tx 15.3 wt% | Solution casting | 139,830/4.1 @ 1 kHz | Electronics, capacitors, and triboelectric generators | [161] |

| PPy | Ti3C2Tx 0.8 g | In situ polymerization | 11.61/6.47 @ 2 GHz | Microwave absorption | [162] |