Wood-Based Micro-Biochars in a Cement Mixture

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Fabrication of μ-Biochar

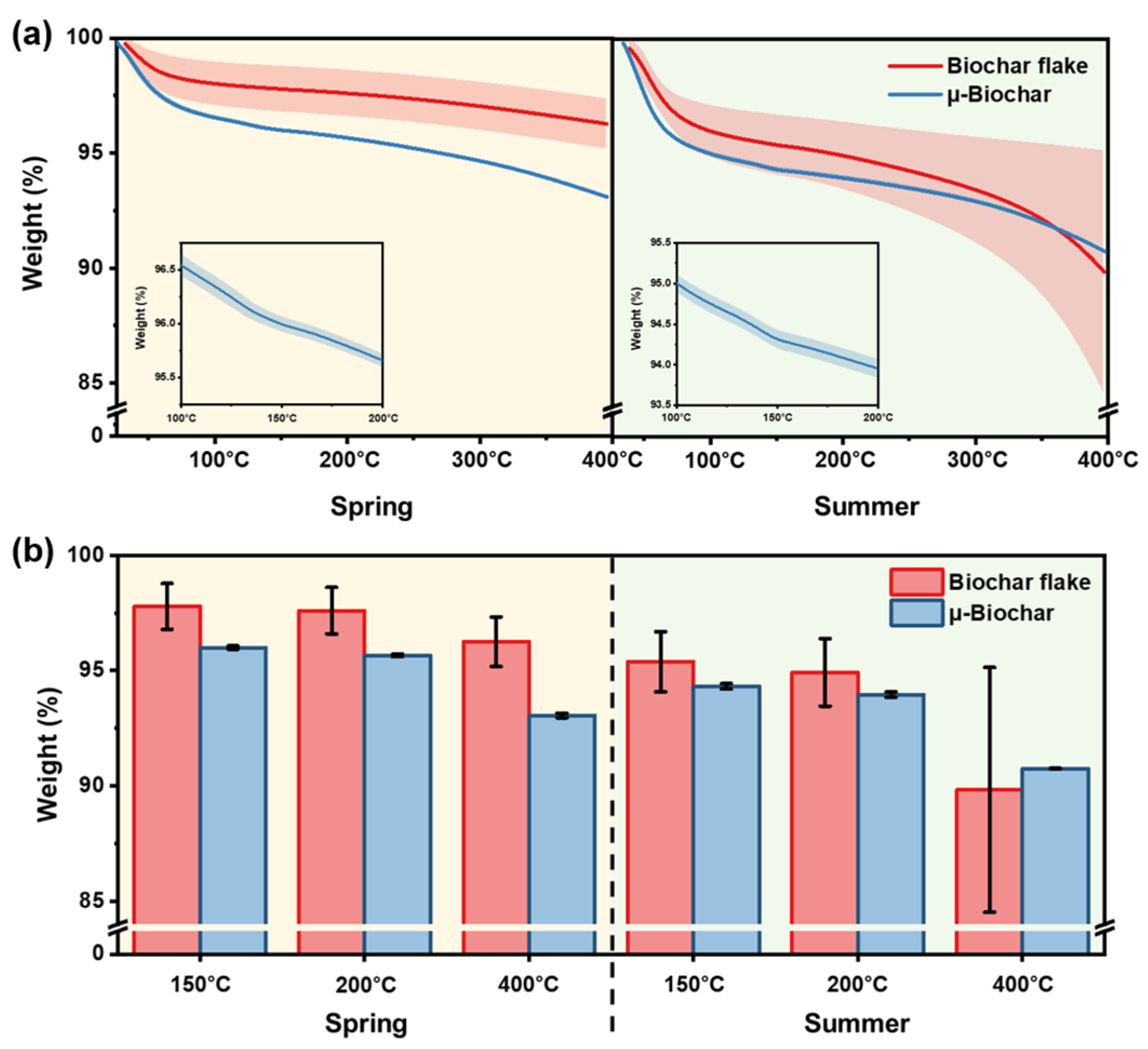

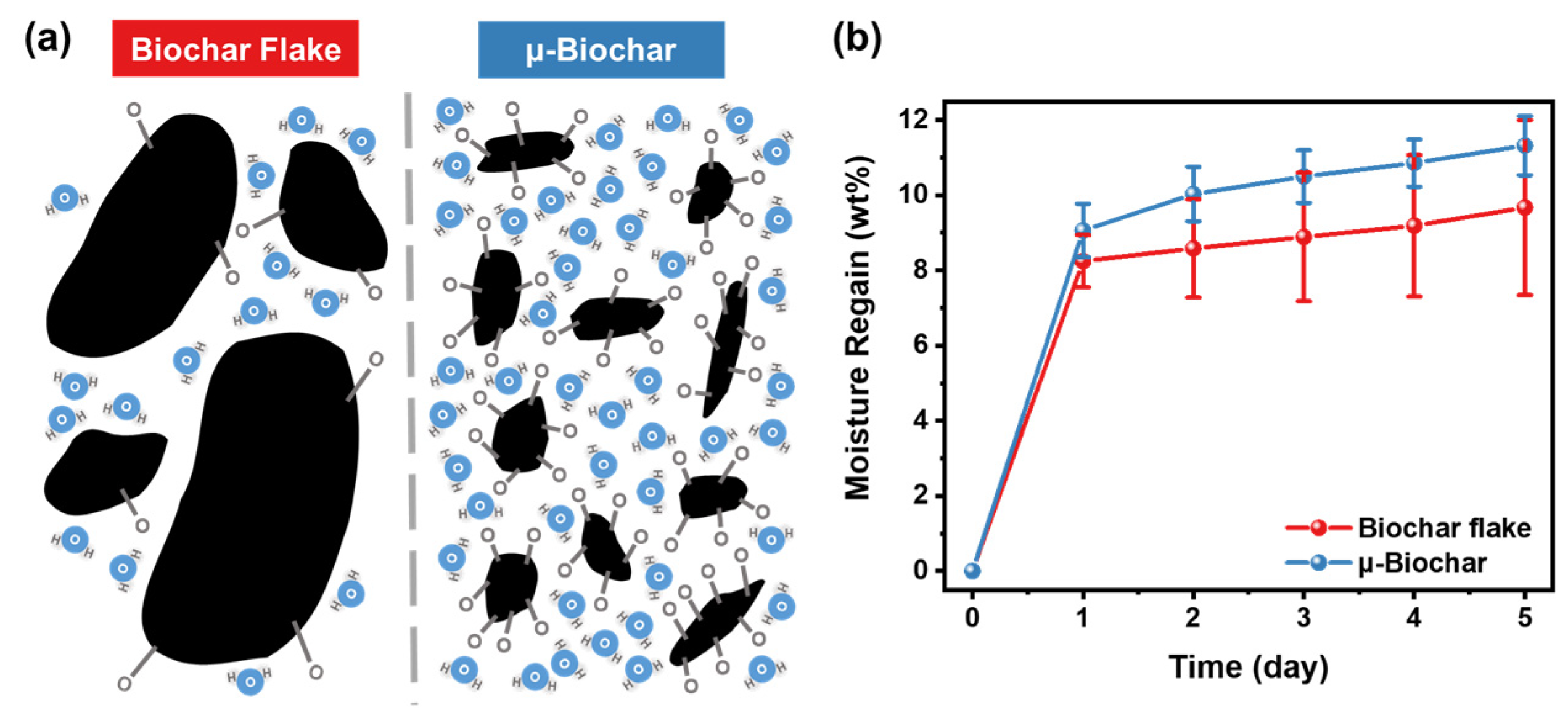

2.3. Moisture Absorption of Biochar

- A—mass of biochar in moisture-equilibrium at specified conditions;

- D—mass of dried biochar.

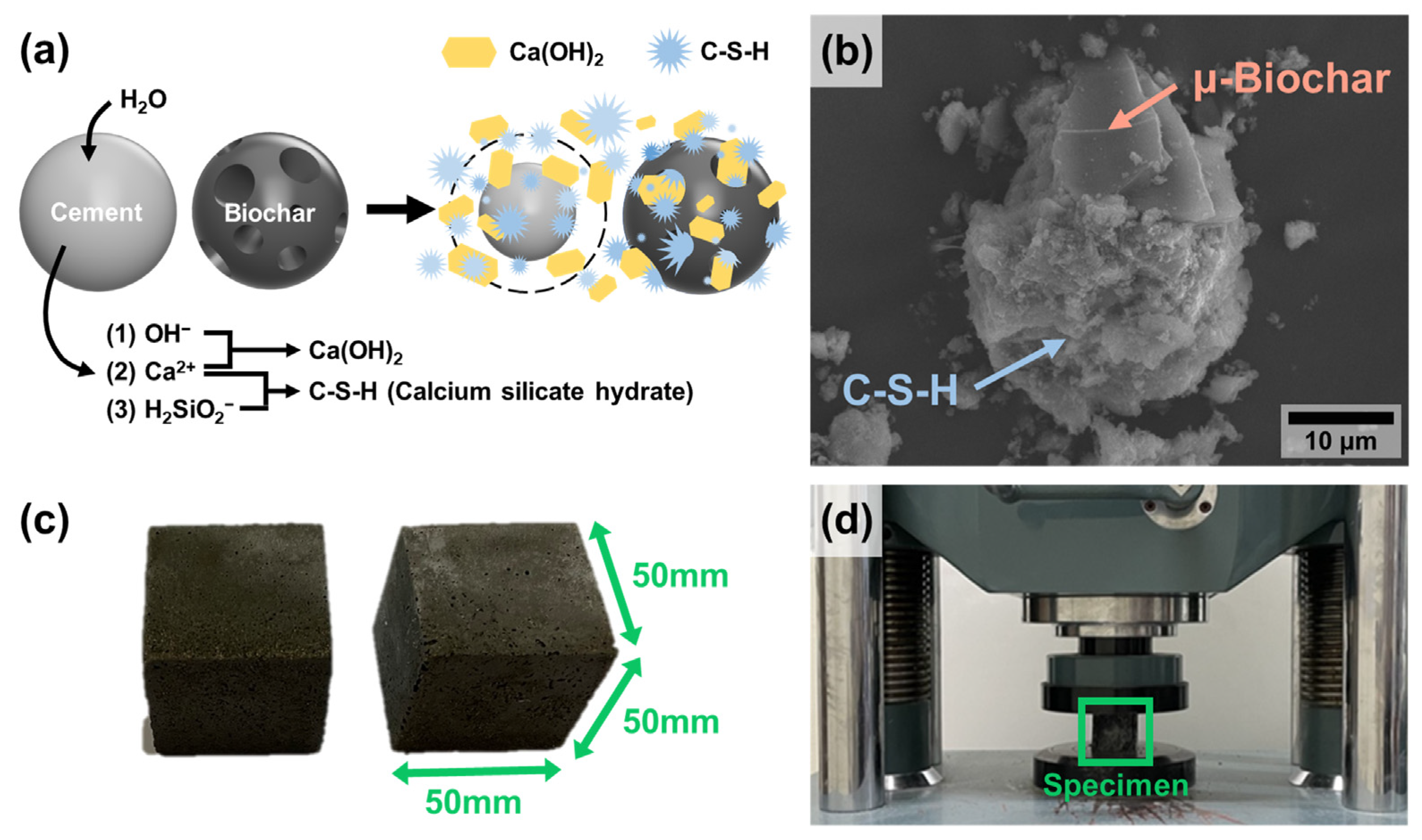

2.4. Compressive Strength Test of Biochar and Cement Mortar Mixture

2.5. Characterization

3. Properties of Wood-Based Biochar

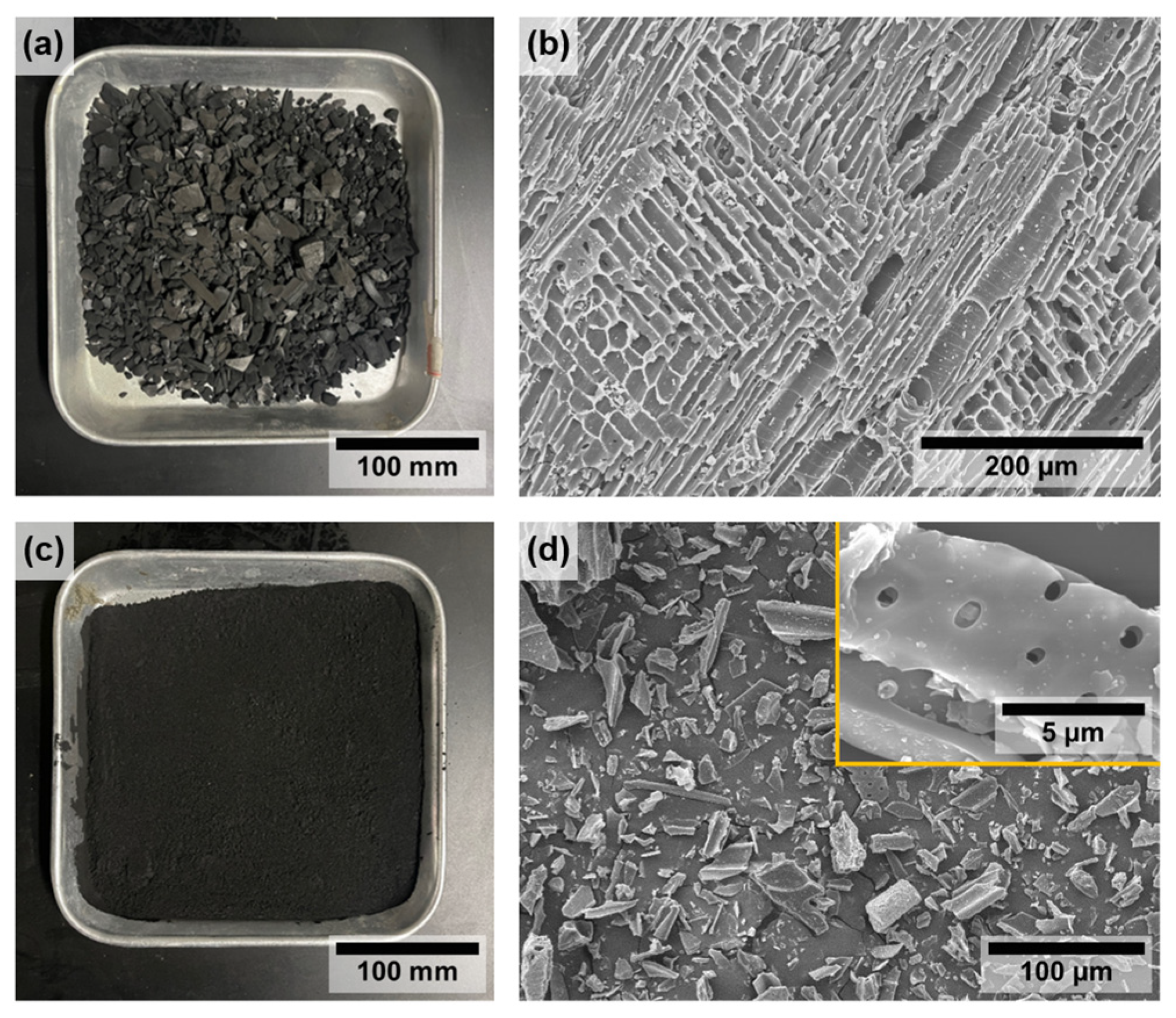

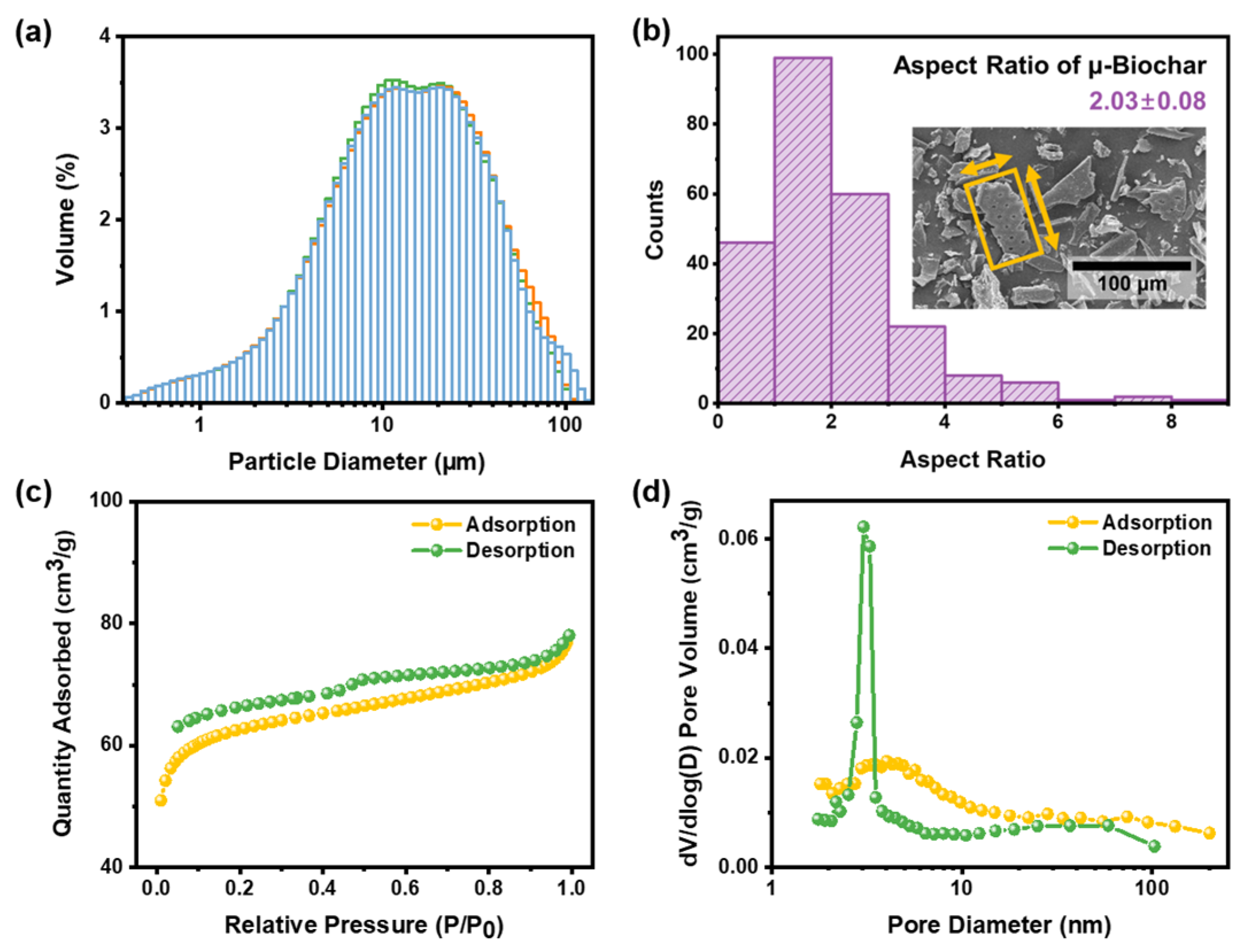

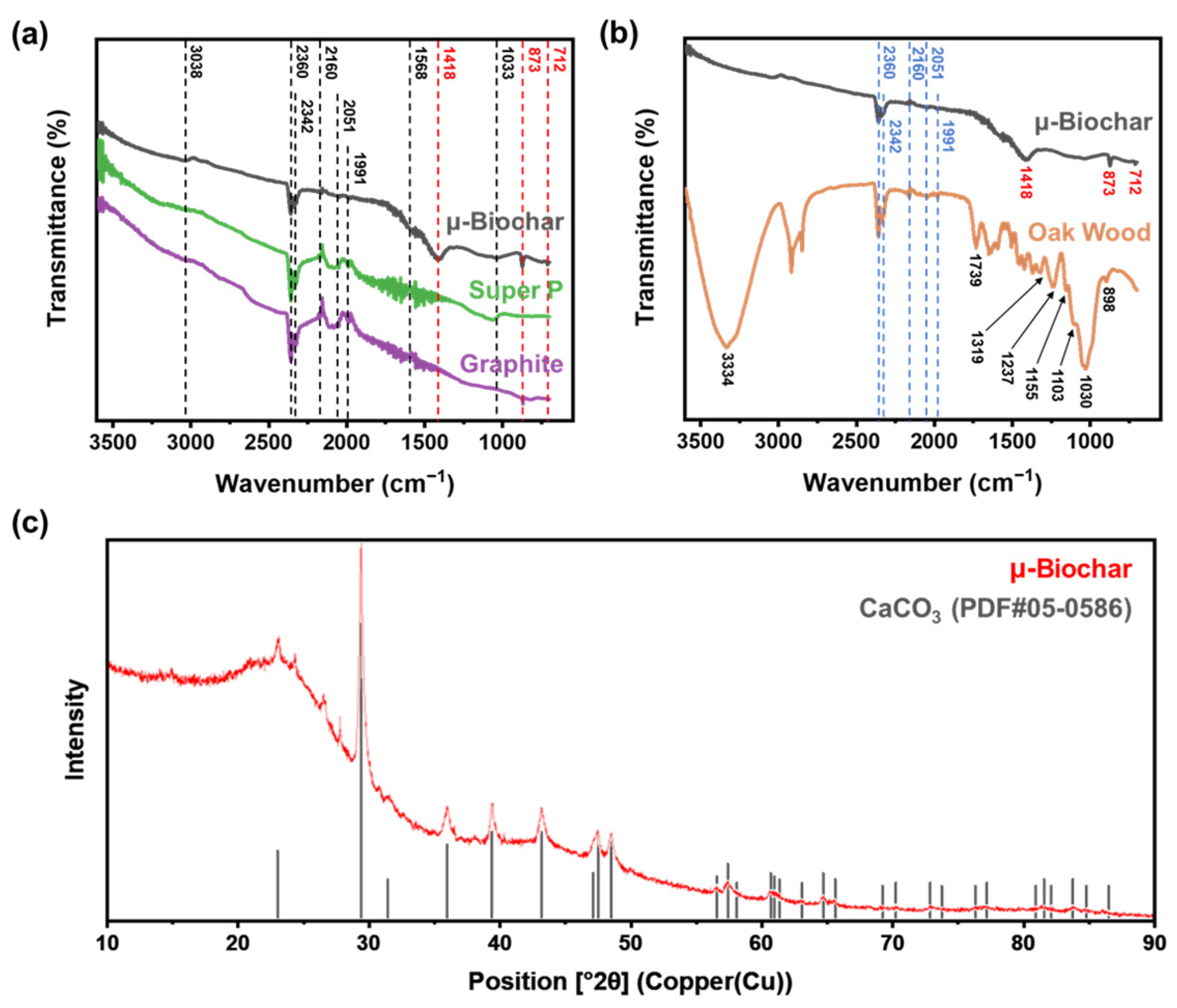

3.1. Structural Characterization of the μ-Biochar

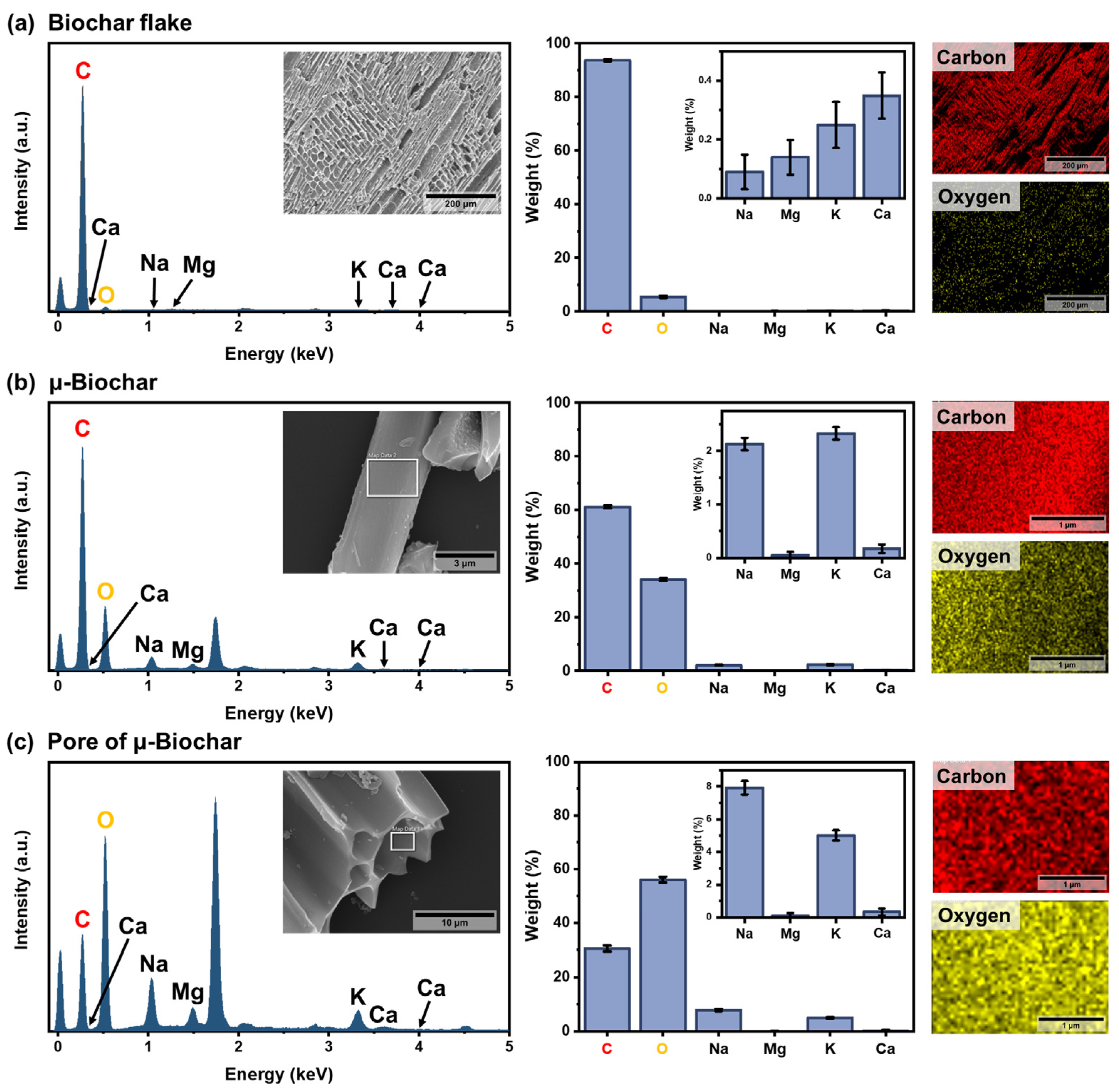

3.2. Elemental Analysis of the μ-Biochar

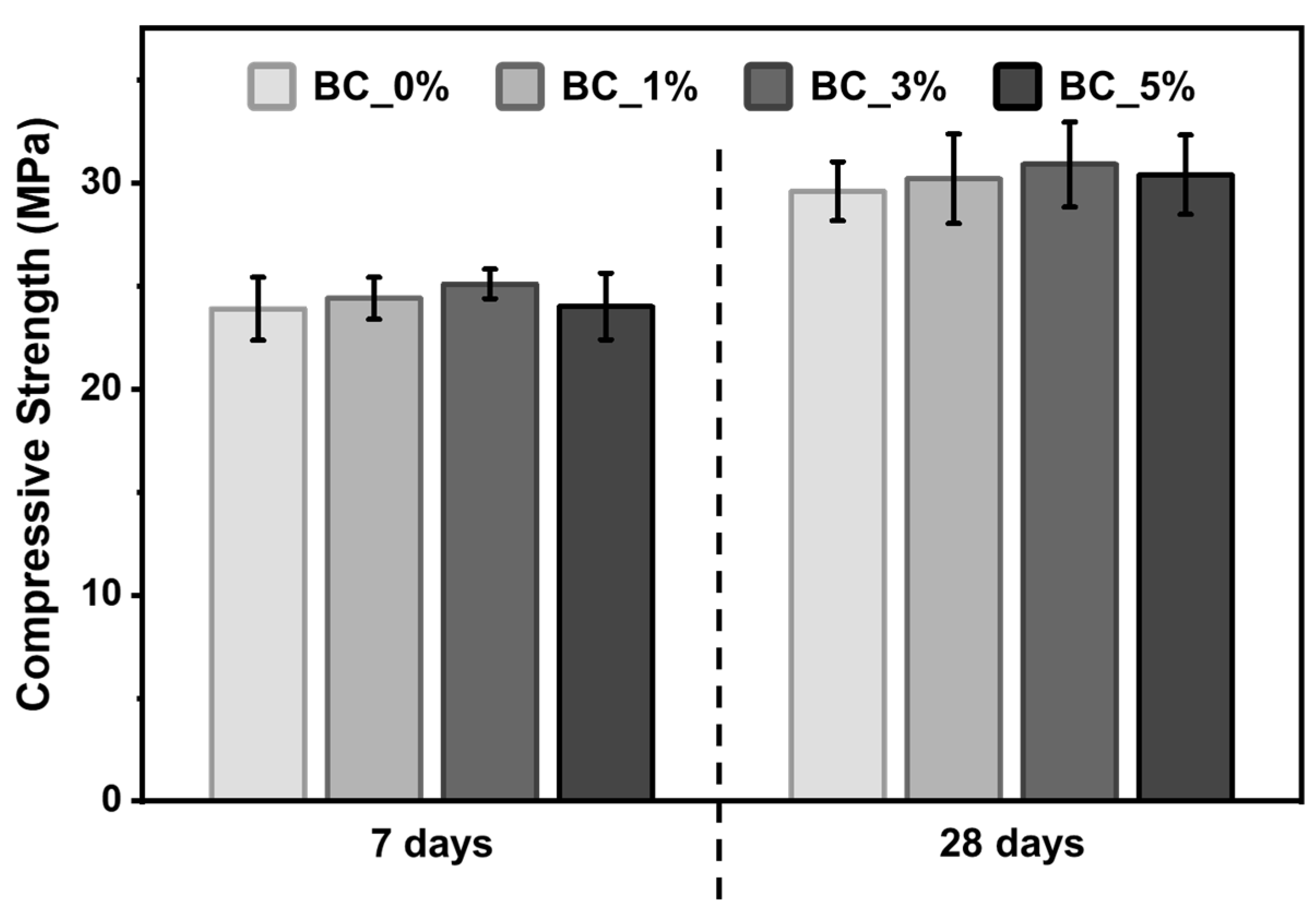

4. Properties of Cement Mortar Containing μ-Biochar

5. Conclusions

6. Future Outlook

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cement Carbon Dioxide Emissions Quietly Double in 20 Years. Available online: https://phys.org/news/2022-06-cement-carbon-dioxide-emissions-quietly.html (accessed on 16 September 2024).

- Maddalena, R.; Roberts, J.J.; Hamilton, A. Can Portland cement be replaced by low-carbon alternative materials? A study on the thermal properties and carbon emissions of innovative cements. J. Clean. Prod. 2018, 186, 933–942. [Google Scholar] [CrossRef]

- Shah, I.H.; Miller, S.A.; Jiang, D.; Myers, R.J. Cement substitution with secondary materials can reduce annual global CO2 emissions by up to 1.3 gigatons. Nat. Commun. 2022, 13, 5758. [Google Scholar] [CrossRef] [PubMed]

- KS L 5201; Portland Cement. KATS: Seoul, Republic of Korea, 2021.

- Seow, Y.X.; Tan, Y.H.; Mubarak, N.; Kansedo, J.; Khalid, M.; Ibrahim, M.L.; Ghasemi, M. A review on biochar production from different biomass wastes by recent carbonization technologies and its sustainable applications. J. Environ. Chem. Eng. 2022, 10, 107017. [Google Scholar] [CrossRef]

- Yaashikaa, P.; Kumar, P.S.; Varjani, S.; Saravanan, A. A critical review on the biochar production techniques, characterization, stability and applications for circular bioeconomy. Bioresour. Technol. Rep. 2020, 28, e00570. [Google Scholar] [CrossRef]

- Angın, D. Effect of pyrolysis temperature and heating rate on biochar obtained from pyrolysis of safflower seed press cake. Bioresour. Technol. 2013, 128, 593–597. [Google Scholar] [CrossRef]

- De Oliveira Paiva, I.; de Morais, E.G.; Jindo, K.; Silva, C.A. Biochar N Content, Pools and Aromaticity as Affected by Feedstock and Pyrolysis Temperature. Waste Biomass Valorization 2024, 15, 3599–3619. [Google Scholar] [CrossRef]

- Roshan, A.; Ghosh, D.; Maiti, S.K. How temperature affects biochar properties for application in coal mine spoils? A meta-analysis. Carbon Res. 2023, 2, 3. [Google Scholar] [CrossRef]

- Qambrani, N.A.; Rahman, M.M.; Won, S.; Shim, S.; Ra, C. Biochar properties and eco-friendly applications for climate change mitigation, waste management, and wastewater treatment: A review. Renew. Sustain. Energy Rev. 2017, 79, 255–273. [Google Scholar] [CrossRef]

- Choi, W.C.; Yun, H.D.; Lee, J.Y. Mechanical properties of mortar containing bio-char from pyrolysis. J. Korea Inst. Struct. Maint. Insp. 2012, 16, 67–74. [Google Scholar]

- Gupta, S.; Kua, H.W.; Low, C.Y. Use of biochar as carbon sequestering additive in cement mortar. Cem. Concr. Compos. 2018, 87, 110–129. [Google Scholar] [CrossRef]

- Han, S.; Choi, W. Evaluation of the mechanical properties of cement mortar containing wood-based bio-char. J. Korea Concr. Inst. 2023, 35, 285–292. [Google Scholar] [CrossRef]

- Javed, M.H.; Sikandar, M.A.; Ahmad, W.; Bashir, M.T.; Alrowais, R.; Wadud, M.B. Effect of various biochars on physical, mechanical, and microstructural characteristics of cement pastes and mortars. J. Build. Eng. 2022, 57, 104850. [Google Scholar] [CrossRef]

- Sirico, A.; Belletti, B.; Bernardi, P.; Malcevschi, A.; Pagliari, F.; Fornoni, P.; Moretti, E. Effects of biochar addition on long-term behavior of concrete. Theor. Appl. Fract. Mech. 2022, 122, 103626. [Google Scholar] [CrossRef]

- Suarez-Riera, D.; Restuccia, L.; Ferro, G. The use of Biochar to reduce the carbon footprint of cement-based materials. Procedia Struct. Integr. 2020, 26, 199–210. [Google Scholar] [CrossRef]

- Eom, H.S.; Jeon, B.J.; Shin, D. The Bending Strength Characteristics of Mortar Mixed with Biochar. J. Korea Soc. Waste Manag. 2022, 39, 521–531. [Google Scholar] [CrossRef]

- Ali, D.; Agarwal, R.; Hanifa, M.; Rawat, P.; Paswan, R.; Rai, D.; Tyagi, I.; Naik, B.S.; Pippal, A. Thermo-physical properties and microstructural behaviour of biochar-incorporated cementitious material. J. Build. Eng. 2023, 64, 105695. [Google Scholar] [CrossRef]

- Ling, Y.; Wu, X.; Tan, K.; Zou, Z. Effect of biochar dosage and fineness on the mechanical properties and durability of concrete. Materials 2023, 16, 2809. [Google Scholar] [CrossRef]

- Praneeth, S.; Saavedra, L.; Zeng, M.; Dubey, B.K.; Sarmah, A.K. Biochar admixtured lightweight, porous and tougher cement mortars: Mechanical, durability and micro computed tomography analysis. Sci. Total Environ. 2021, 750, 142327. [Google Scholar] [CrossRef]

- KS L ISO 679; Methods of Testing Cements-Determination of Strength. KATS: Seoul, Republic of Korea, 2006.

- ASTM D2654-22; Standard Test Methods for Moisture in Textiles. ASTM: West Conshohocken, PA, USA, 2023.

- KS L 5109; Testing method for mechanical mixing of hydraulic cement pastes and mortars of plastic consistency. KATS: Seoul, Republic of Korea, 2022.

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM: West Conshohocken, PA, USA, 2021.

- Gupta, S.; Kua, H.W. Effect of water entrainment by pre-soaked biochar particles on strength and permeability of cement mortar. Constr. Build. Mater. 2018, 159, 107–125. [Google Scholar] [CrossRef]

- Batista, E.; Shultz, J.; Matos, T.; Fornari, M.; Ferreira, T.; Szpoganicz, B.; De Freitas, R.; Mangrich, A. Effect of surface and porosity of biochar on water holding capacity aiming indirectly at preservation of the Amazon biome. Sci. Rep. 2018, 8, 10677. [Google Scholar] [CrossRef]

- Rasa, K.; Viherä-Aarnio, A.; Rytkönen, P.; Hyväluoma, J.; Kaseva, J.; Suhonen, H.; Jyske, T. Quantitative analysis of feedstock structural properties can help to produce willow biochar with homogenous pore system. Ind. Crops Prod. 2021, 166, 113475. [Google Scholar] [CrossRef]

- Rawal, A.; Joseph, S.D.; Hook, J.M.; Chia, C.H.; Munroe, P.R.; Donne, S.; Lin, Y.; Phelan, D.; Mitchell, D.R.; Pace, B. Mineral–biochar composites: Molecular structure and porosity. Environ. Sci. Technol. 2016, 50, 7706–7714. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Gao, B.; Fang, J.; Zhang, M.; Chen, H.; Zhou, Y.; Creamer, A.E.; Sun, Y.; Yang, L. Characterization and environmental applications of clay–biochar composites. Chem. Eng. J. 2014, 242, 136–143. [Google Scholar] [CrossRef]

- Zhang, M.; Gao, B.; Yao, Y.; Xue, Y.; Inyang, M. Synthesis, characterization, and environmental implications of graphene-coated biochar. Sci. Total Environ. 2012, 435, 567–572. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Koh, H.J. Application of biochar from food and wood waste as green admixture for cement mortar. Sci. Total Environ. 2018, 619-620, 419–435. [Google Scholar] [CrossRef]

- Tan, K.; Qin, Y.; Du, T.; Li, L.; Zhang, L.; Wang, J. Biochar from waste biomass as hygroscopic filler for pervious concrete to improve evaporative cooling performance. Constr. Build. Mater. 2021, 287, 123078. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Elnour, A.Y.; Alghyamah, A.A.; Shaikh, H.M.; Poulose, A.M.; Al-Zahrani, S.M.; Anis, A.; Al-Wabel, M.I. Effect of pyrolysis temperature on biochar microstructural evolution, physicochemical characteristics, and its influence on biochar/polypropylene composites. Appl. Sci. 2019, 9, 1149. [Google Scholar] [CrossRef]

- Lehmann, J. A handful of carbon. Nature 2007, 447, 143–144. [Google Scholar] [CrossRef]

- Shafie, S.T.; Salleh, M.; Hang, L.L.; Rahman, M.; Ghani, W. Effect of pyrolysis temperature on the biochar nutrient and water retention capacity. J. Purity Util. React. Environ. 2012, 1, 293–307. [Google Scholar]

- Gupta, S.; Kua, H.W. Carbonaceous micro-filler for cement: Effect of particle size and dosage of biochar on fresh and hardened properties of cement mortar. Sci. Total Environ. 2019, 662, 952–962. [Google Scholar] [CrossRef] [PubMed]

- Spokas, K.A. Review of the stability of biochar in soils: Predictability of O:C molar ratios. Carbon Manag. 2010, 1, 289–303. [Google Scholar] [CrossRef]

- Janu, R.; Mrlik, V.; Ribitsch, D.; Hofman, J.; Sedláček, P.; Bielská, L.; Soja, G. Biochar surface functional groups as affected by biomass feedstock, biochar composition and pyrolysis temperature. Carbon Resour. Convers. 2021, 4, 36–46. [Google Scholar] [CrossRef]

- Lee, Y.; Park, J.; Ryu, C.; Gang, K.S.; Yang, W.; Park, Y.-K.; Jung, J.; Hyun, S. Comparison of biochar properties from biomass residues produced by slow pyrolysis at 500 °C. Bioresour. Technol. 2013, 148, 196–201. [Google Scholar] [CrossRef]

- Bach, Q.-V.; Chen, W.-H.; Chu, Y.-S.; Skreiberg, Ø. Predictions of biochar yield and elemental composition during torrefaction of forest residues. Bioresour. Technol. 2016, 215, 239–246. [Google Scholar] [CrossRef]

- Wijitkosum, S.; Jiwnok, P. Elemental composition of biochar obtained from agricultural waste for soil amendment and carbon sequestration. Appl. Sci. 2019, 9, 3980. [Google Scholar] [CrossRef]

- Sun, X.; Shan, R.; Li, X.; Pan, J.; Liu, X.; Deng, R.; Song, J. Characterization of 60 types of Chinese biomass waste and resultant biochars in terms of their candidacy for soil application. GCB Bioenergy 2017, 9, 1423–1435. [Google Scholar] [CrossRef]

- Luo, L.; Xu, C.; Chen, Z.; Zhang, S. Properties of biomass-derived biochars: Combined effects of operating conditions and biomass types. Bioresour. Technol. 2015, 192, 83–89. [Google Scholar] [CrossRef]

- Oleszczuk, P.; Ćwikła-Bundyra, W.; Bogusz, A.; Skwarek, E.; Ok, Y.S. Characterization of nanoparticles of biochars from different biomass. J. Anal. Appl. Pyrolysis 2016, 121, 165–172. [Google Scholar] [CrossRef]

- Wu, H.; Che, X.; Ding, Z.; Hu, X.; Creamer, A.E.; Chen, H.; Gao, B. Release of soluble elements from biochars derived from various biomass feedstocks. Environ. Sci. Pollut. Res. 2016, 23, 1905–1915. [Google Scholar] [CrossRef]

- Kwapinski, W.; Byrne, C.M.; Kryachko, E.; Wolfram, P.; Adley, C.; Leahy, J.J.; Novotny, E.H.; Hayes, M.H. Biochar from biomass and waste. Waste Biomass Valorization 2010, 1, 177–189. [Google Scholar] [CrossRef]

- Oh, T.-K.; Choi, B.; Shinogi, Y.; Chikushi, J. Characterization of biochar derived from three types of biomass. J. Fac. Agric. 2012, 57, 61–66. [Google Scholar] [CrossRef]

- Dehkhoda, A.M.; Ellis, N.; Gyenge, E. Electrosorption on activated biochar: Effect of thermo-chemical activation treatment on the electric double layer capacitance. J. Appl. Electrochem. 2014, 44, 141–157. [Google Scholar] [CrossRef]

- Keiluweit, M.; Nico, P.S.; Johnson, M.G.; Kleber, M. Dynamic molecular structure of plant biomass-derived black carbon (biochar). Environ. Sci. Technol. 2010, 44, 1247–1253. [Google Scholar] [CrossRef] [PubMed]

- Jung, K.-W.; Hwang, M.-J.; Ahn, K.-H.; Ok, Y.-S. Kinetic study on phosphate removal from aqueous solution by biochar derived from peanut shell as renewable adsorptive media. Int. J. Environ. Sci. Technol. 2015, 12, 3363–3372. [Google Scholar] [CrossRef]

- ASTM C1437; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM: West Conshohocken, PA, USA, 2021.

- Maljaee, H.; Paiva, H.; Madadi, R.; Tarelho, L.A.; Morais, M.; Ferreira, V.M. Effect of cement partial substitution by waste-based biochar in mortars properties. Constr. Build. Mater. 2021, 301, 124074. [Google Scholar] [CrossRef]

| Raw Material of Biochar | Elemental Composition (wt%) | |||||

|---|---|---|---|---|---|---|

| Carbon | Oxygen | Sodium | Magnesium | Potassium | Calcium | |

| Wood-based biochar flake [This work] | 93.70 | 5.48 | 0.09 | 0.14 | 0.25 | 0.35 |

| Wood-based μ-biochar [This work] | 61.21 | 34.11 | 2.13 | 0.05 | 2.33 | 0.17 |

| Inner surface of wood-based μ-biochar pore [This work] | 30.57 | 56.08 | 7.93 | 0.08 | 5.01 | 0.32 |

| Wood [37] | 87.13 | 7.21 | - | 0.51 | 0.42 | 0.65 |

| Food waste [37] | 70.90 | 8.42 | 0.58 | 0.14 | 3.73 | 2.69 |

| Rice husk [37] | 66.22 | 13.63 | 1.98 | 3.40 | 2.69 | 0.11 |

| Forest residues [39] | 60 | 20 | 0.1 | 0.4 | 1.5 | 2 |

| Agricultural waste [40] | 67.5 | 25.3 | 0.2 | 0.7 | 2.1 | 2.5 |

| Chinese biomass waste [41] | 72.3 | 18.5 | 0.3 | - | 2.8 | 3.1 |

| Orange peel [42] | 65.1 | 21.7 | - | 0.3 | 1.9 | 1.7 |

| Wood [43] | 70 | 22 | 0.1 | 0.5 | 2 | 2.2 |

| Rice husk [44] | 55.6 | 34.1 | 0.3 | - | 3.4 | 1.8 |

| Corn stover [45] | 63.4 | 25.7 | 0.2 | 0.2 | 2.5 | 2.3 |

| Bamboo [46] | 75.3 | 18.9 | 0.4 | - | 2.3 | 3.4 |

| Sawdust [47] | 58.9 | 32.6 | 0.2 | 0.1 | 3.1 | 2 |

| Coconut shell [48] | 76.8 | 14.2 | 0.1 | 0.6 | 1.4 | 2.7 |

| Specimen | Cement (g) | μ-Biochar (g) | Sand (g) | Water (mL) |

|---|---|---|---|---|

| BC_0% | 1000 | - | 2750 | 485 |

| BC_1% | 990 | 10 | ||

| BC_3% | 970 | 30 | ||

| BC_5% | 950 | 50 |

| Specimen | Mortar Diameter | Difference |

|---|---|---|

| BC_0% | 124.3 mm | - |

| BC_1% | 119.7 mm | −3.7% |

| BC_3% | 116.3 mm | −6.4% |

| BC_5% | 112.0 mm | −9.9% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pyo, M.; Kim, J.; Seok, S.; Park, C.H.; Choi, W. Wood-Based Micro-Biochars in a Cement Mixture. Molecules 2025, 30, 1898. https://doi.org/10.3390/molecules30091898

Pyo M, Kim J, Seok S, Park CH, Choi W. Wood-Based Micro-Biochars in a Cement Mixture. Molecules. 2025; 30(9):1898. https://doi.org/10.3390/molecules30091898

Chicago/Turabian StylePyo, Minkyeong, Jongsun Kim, Seungwook Seok, Chan Ho Park, and Wonchang Choi. 2025. "Wood-Based Micro-Biochars in a Cement Mixture" Molecules 30, no. 9: 1898. https://doi.org/10.3390/molecules30091898

APA StylePyo, M., Kim, J., Seok, S., Park, C. H., & Choi, W. (2025). Wood-Based Micro-Biochars in a Cement Mixture. Molecules, 30(9), 1898. https://doi.org/10.3390/molecules30091898