Point Defect Detection and Classification in MoS2 Scanning Tunneling Microscopy Images: A Deep Learning Approach

Abstract

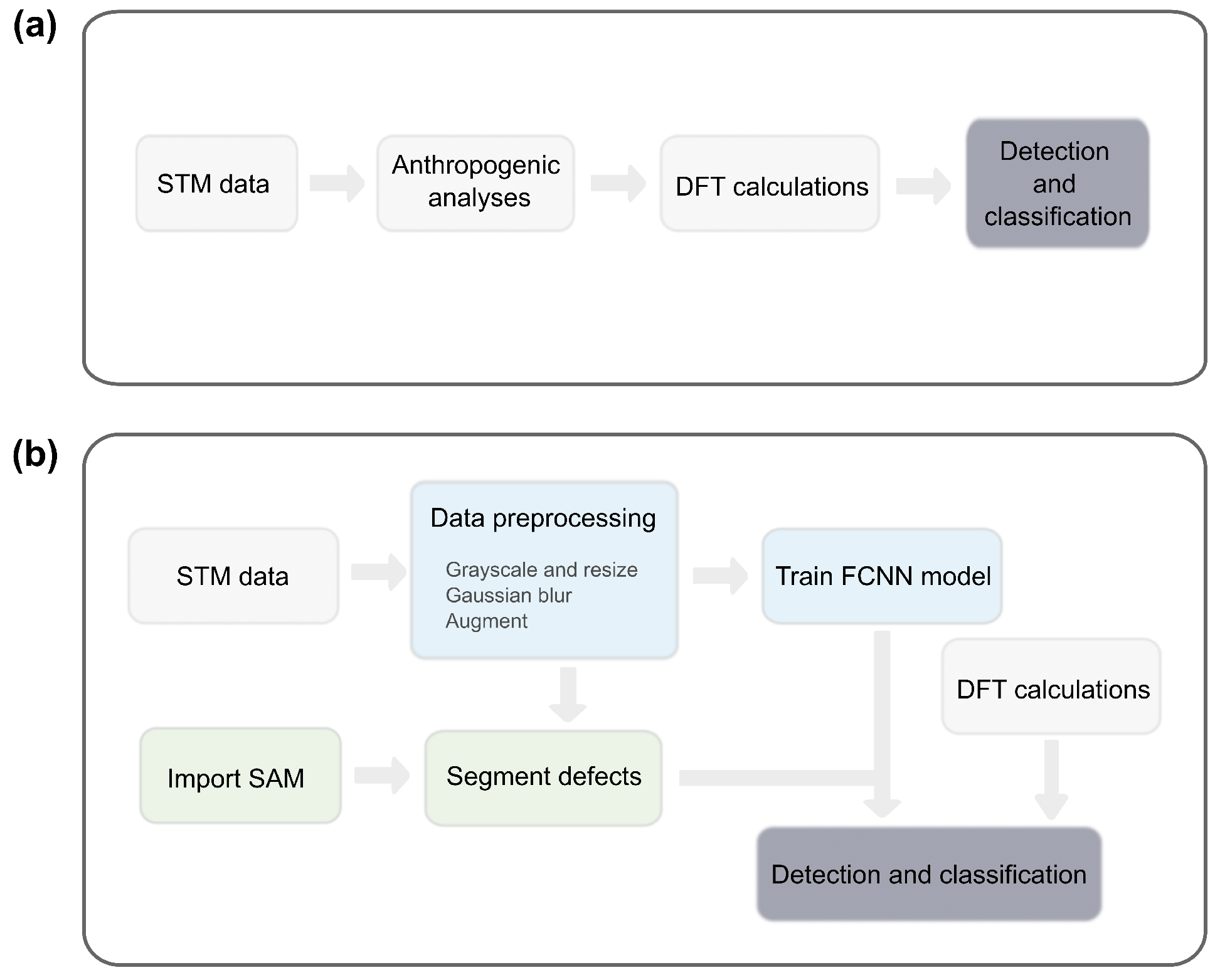

1. Introduction

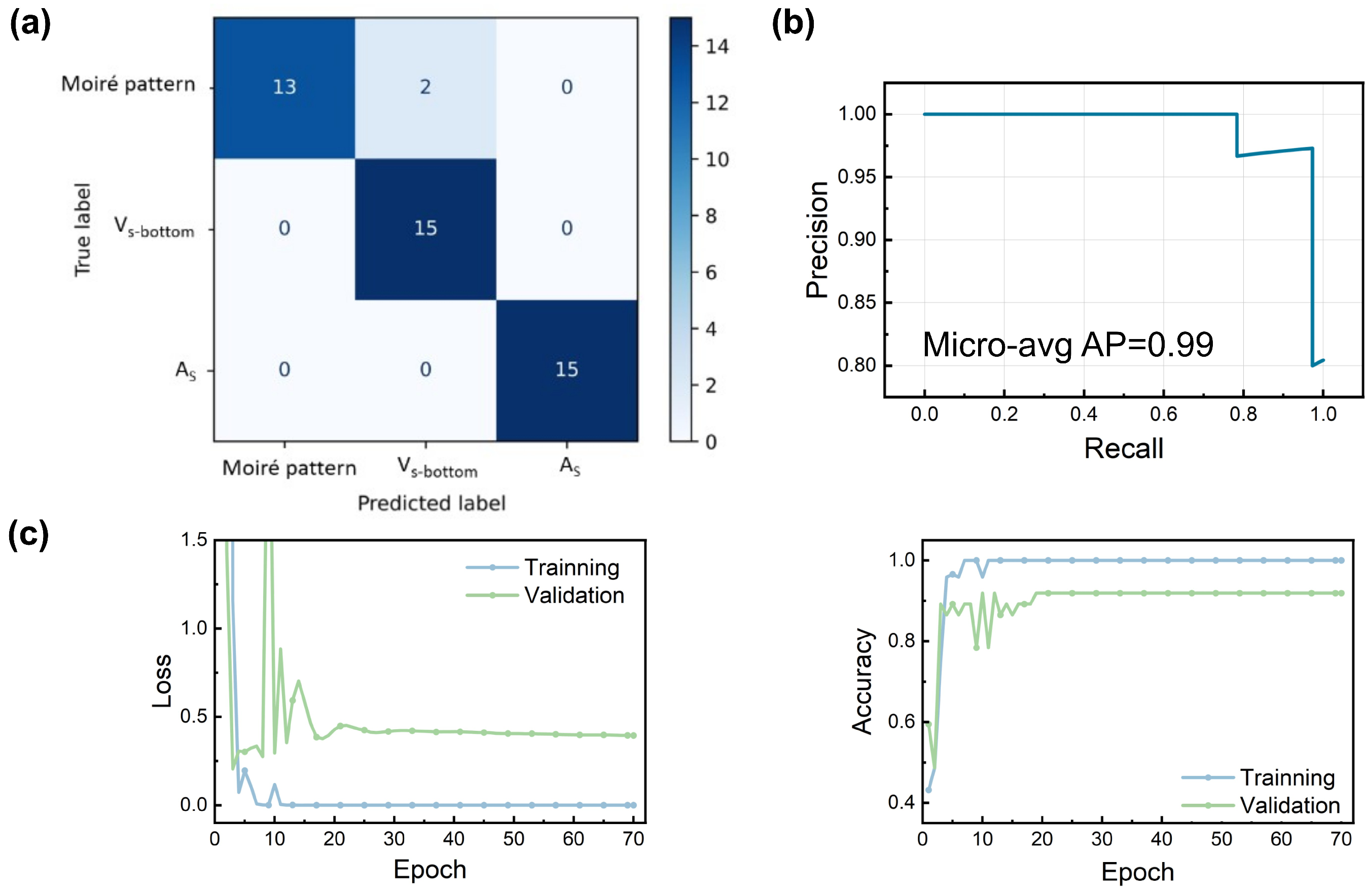

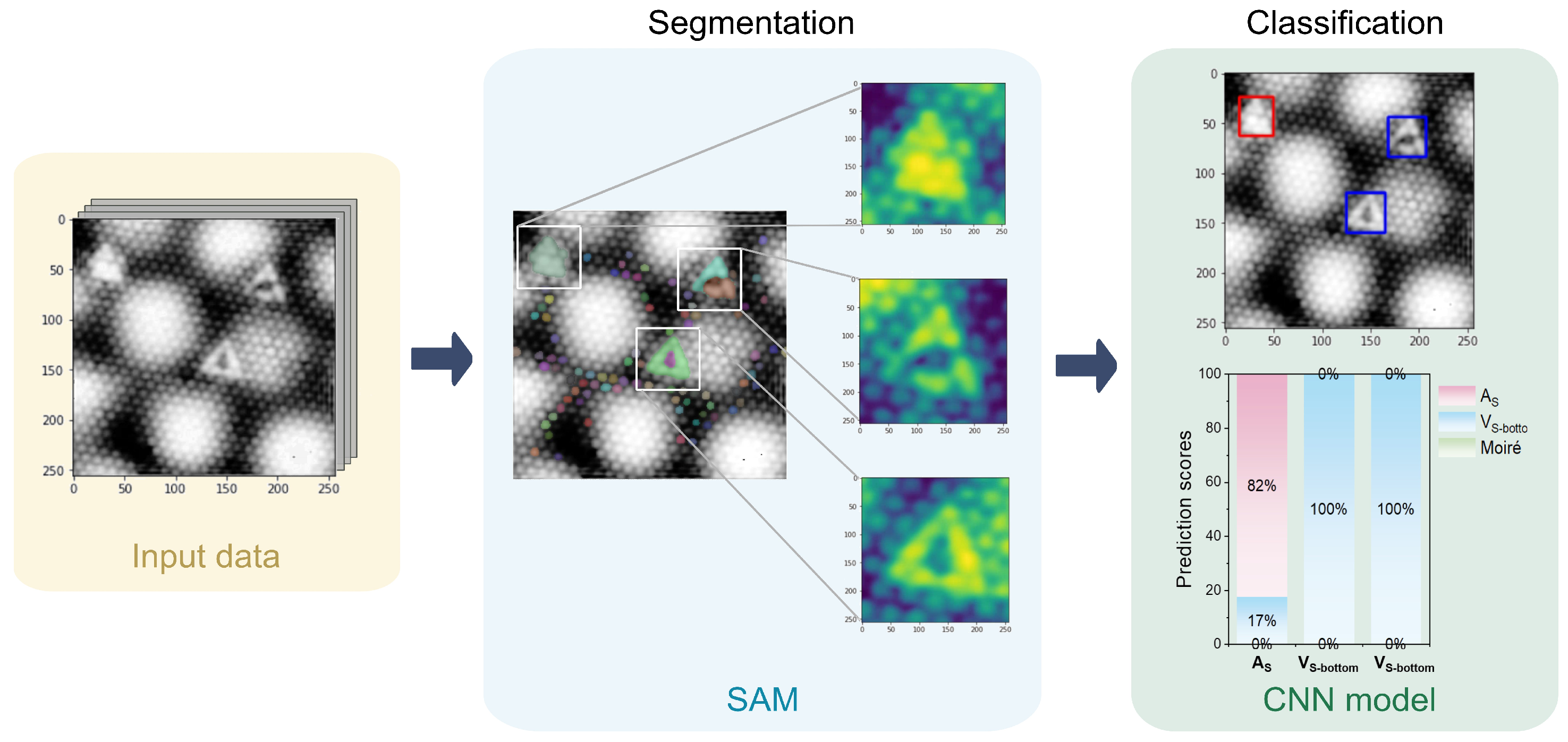

2. Results and Discussion

3. Materials and Methods

3.1. Sample Preparation and STM Measurements

3.2. Data Preprocessing and Augmentation

3.3. SAM Segmentation of Defects

3.4. Convolutional Neural Network Architecture

3.5. Training and Evaluation Metrics

3.6. DFT Modeling of Defects

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Manzeli, S.; Ovchinnikov, D.; Pasquier, D.; Yazyev, O.V.; Kis, A. 2D transition metal dichalcogenides. Nat. Rev. Mater. 2017, 2, 17033. [Google Scholar] [CrossRef]

- Liu, Y.; Duan, X.; Shin, H.J.; Park, S.; Huang, Y.; Duan, X. Promises and prospects of two-dimensional transistors. Nature 2021, 591, 43–53. [Google Scholar] [CrossRef] [PubMed]

- Radisavljevic, B.; Radenovic, A.; Brivio, J.; Giacometti, V.; Kis, A. Single-layer MoS2 transistors. Nat. Nanotechnol. 2011, 6, 147–150. [Google Scholar] [CrossRef]

- Mak, K.F.; Lee, C.; Hone, J.; Shan, J.; Heinz, T.F. Atomically Thin MoS2: A New Direct-Gap Semiconductor. Phys. Rev. Lett. 2010, 105, 136805. [Google Scholar] [CrossRef] [PubMed]

- Mak, K.F.; He, K.; Shan, J.; Heinz, T.F. Control of valley polarization in monolayer MoS2 by optical helicity. Nat. Nanotechnol. 2012, 7, 494–498. [Google Scholar] [CrossRef]

- Wu, W.; Wang, L.; Li, Y.; Zhang, F.; Lin, L.; Niu, S.; Chenet, D.; Zhang, X.; Hao, Y.; Heinz, T.F.; et al. Piezoelectricity of single-atomic-layer MoS2 for energy conversion and piezotronics. Nature 2014, 514, 470–474. [Google Scholar] [CrossRef]

- Yu, Z.; Ong, Z.Y.; Li, S.; Xu, J.B.; Zhang, G.; Zhang, Y.W.; Shi, Y.; Wang, X. Analyzing the Carrier Mobility in Transition-Metal Dichalcogenide MoS2 Field-Effect Transistors. Adv. Funct. Mater. 2017, 27, 1604093. [Google Scholar] [CrossRef]

- Song, S.H.; Joo, M.-K.; Neumann, M.; Kim, H.; Lee, Y.H. Probing defect dynamics in monolayer MoS2 via noise nanospectroscopy. Nat. Commun. 2017, 8, 2121. [Google Scholar] [CrossRef]

- Mak, K.F.; He, K.; Lee, C.; Lee, G.H.; Hone, J.; Heinz, T.F.; Shan, J. Tightly bound trions in monolayer MoS2. Nat. Mater. 2013, 12, 207–211. [Google Scholar] [CrossRef]

- Schuler, B.; Qiu, D.Y.; Refaely-Abramson, S.; Kastl, C.; Chen, C.T.; Barja, S.; Koch, R.J.; Ogletree, D.F.; Aloni, S.; Schwartzberg, A.M.; et al. Large Spin-Orbit Splitting of Deep In-Gap Defect States of Engineered Sulfur Vacancies in Monolayer WS2. Phys. Rev. Lett. 2019, 123, 076801. [Google Scholar] [CrossRef]

- Refaely-Abramson, S.; Qiu, D.Y.; Louie, S.G.; Neaton, J.B. Defect-Induced Modification of Low-Lying Excitons and Valley Selectivity in Monolayer Transition Metal Dichalcogenides. Phys. Rev. Lett. 2018, 121, 167402. [Google Scholar] [CrossRef]

- Wu, J.; Liu, Y.; Liu, Y.; Cai, Y.; Zhao, Y.; Ng, H.K.; Watanabe, K.; Taniguchi, T.; Zhang, G.; Qiu, C.W.; et al. Large enhancement of thermoelectric performance in MoS2/h-BN heterostructure due to vacancy-induced band hybridization. Proc. Natl. Acad. Sci. USA 2020, 117, 13929. [Google Scholar] [CrossRef] [PubMed]

- Széchenyi, G.; Chirolli, L.; Pályi, A. Impurity-assisted electric control of spin-valley qubits in monolayer MoS2. 2D Mater. 2018, 5, 035004. [Google Scholar] [CrossRef]

- Klein, J.; Lorke, M.; Florian, M.; Sigger, F.; Sigl, L.; Rey, S.; Wierzbowski, J.; Cerne, J.; Müller, K.; Mitterreiter, E.; et al. Site-selectively generated photon emitters in monolayer MoS2 via local helium ion irradiation. Nat. Commun. 2019, 10, 2755. [Google Scholar] [CrossRef]

- Barthelmi, K.; Klein, J.; Hötger, A.; Sigl, L.; Sigger, F.; Mitterreiter, E.; Rey, S.; Gyger, S.; Lorke, M.; Florian, M.; et al. Atomistic defects as single-photon emitters in atomically thin MoS2. Appl. Phys. Lett. 2020, 117, 070501. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, C.G.; Li, M.Y.; Huang, D.; Li, L.J.; Ji, W.; Wu, S. Defect structure of localized excitons in a WSe2 monolayer. Phys. Rev. Lett. 2017, 119, 046101. [Google Scholar] [CrossRef] [PubMed]

- Hong, J.; Hu, Z.; Probert, M.; Li, K.; Lv, D.; Yang, X.; Gu, L.; Mao, N.; Feng, Q.; Xie, L.; et al. Exploring atomic defects in molybdenum disulphide monolayers. Nat. Commun. 2015, 6, 6293. [Google Scholar] [CrossRef]

- Komsa, H.P.; Kotakoski, J.; Kurasch, S.; Lehtinen, O.; Kaiser, U.; Krasheninnikov, A.V. Two-dimensional transition metal dichalcogenides under electron irradiation: Defect production and doping. Phys. Rev. Lett. 2012, 109, 035503. [Google Scholar] [CrossRef]

- Barja, S.; Refaely-Abramson, S.; Schuler, B.; Qiu, D.Y.; Pulkin, A.; Wickenburg, S.; Ryu, H.; Ugeda, M.M.; Kastl, C.; Chen, C.; et al. Identifying substitutional oxygen as a prolific point defect in monolayer transition metal dichalcogenides. Nat. Commun. 2019, 10, 3382. [Google Scholar] [CrossRef]

- Tumino, F.; Casari, C.S.; Bassi, A.L.; Tosoni, S. Nature of Point Defects in Single-Layer MoS2 Supported on Au(111). J. Phys. Chem. C 2020, 124, 12424–12431. [Google Scholar] [CrossRef]

- Ziatdinov, M.; Dyck, O.; Maksov, A.; Li, X.; Sang, X.; Xiao, K.; Unocic, R.R.; Vasudevan, R.; Jesse, S.; Kalinin, S.V. Deep learning of atomically resolved scanning transmission electron microscopy images: Chemical identification and tracking local transformations. ACS Nano 2017, 11, 12742–12752. [Google Scholar] [CrossRef]

- Vancsó, P.; Magda, G.Z.; Pető, J.; Noh, J.Y.; Kim, Y.S.; Hwang, C.; Biró, L.P.; Tapasztó, L. The intrinsic defect structure of exfoliated MoS2 single layers revealed by Scanning Tunneling Microscopy. Sci. Rep. 2016, 6, 29726. [Google Scholar] [CrossRef] [PubMed]

- Smalley, D.; Lough, S.D.; Holtzman, L.; Xu, K.; Holbrook, M.; Rosenberger, M.R.; Hone, J.C.; Barmak, K.; Ishigami, M. Detecting Atomic Scale Surface Defects in STM of TMDs with Ensemble Deep Learning. arXiv 2023, arXiv:2312.05160. [Google Scholar] [CrossRef]

- Chen, F.-X.R.; Lin, C.-Y.; Siao, H.-Y.; Jian, C.-Y.; Yang, Y.-C.; Lin, C.-L. Deep learning based atomic defect detection framework for two-dimensional materials. Sci. Data 2023, 10, 91. [Google Scholar] [CrossRef] [PubMed]

- Archit, A.; Freckmann, L.; Nair, S.; Khalid, N.; Hilt, P.; Rajashekar, V.; Freitag, M.; Teuber, C.; Spitzner, M.; Contreras, C.T.; et al. Segment Anything for Microscopy. Nat. Methods 2025, 22, 579–591. [Google Scholar] [CrossRef] [PubMed]

- Barja, S.; Wickenburg, S.; Liu, Z.-F.; Zhang, Y.; Ryu, H.; Ugeda, M.M.; Hussain, Z.; Shen, Z.-X.; Mo, S.-K.; Wong, E.; et al. Charge density wave order in 1D mirror twin boundaries of single layer MoSe2. Nat. Phys. 2016, 12, 751–756. [Google Scholar] [CrossRef]

- Zhong, X.; Gallagher, B.; Liu, S.; Kailkhura, B.; Hiszpanski, A.; Han, T.Y.-J. Explainable machine learning in materials science. npj Comput. Mater. 2022, 8, 204. [Google Scholar] [CrossRef]

- Zhang, L.; Shao, S. Image-based machine learning for materials science. J. Appl. Phys. 2022, 132, 10. [Google Scholar] [CrossRef]

- Wani, J.A.; Sharma, S.; Muzamil, M.; Ahmed, S.; Sharma, S.; Singh, S. Machine Learning and Deep Learning Based Computational Techniques in Automatic Agricultural Diseases Detection: Methodologies, Applications, and Challenges. Arch. Comput. Method. Eng. 2022, 29, 641–677. [Google Scholar] [CrossRef]

- Pratap, A.; Sardana, N. Machine learning-based image processing in materials science and engineering: A review. Mater. Today Proc. 2022, 62, 7341–7347. [Google Scholar] [CrossRef]

- Yang, S.-H.; Choi, W.; Cho, B.W.; Agyapong Fordjour, F.O.-T.; Park, S.; Yun, S.J.; Kim, H.-J.; Han, Y.-K.; Lee, Y.-H.; Kim, K.K.; et al. Deep Learning-Assisted Quantification of Atomic Dopants and Defects in 2D Materials. Adv. Sci. 2021, 8, e2101099. [Google Scholar] [CrossRef] [PubMed]

- Maksov, A.; Dyck, O.; Wang, K.; Xiao, K.; Geohegan, D.B.; Sumpter, B.G.; Vasudevan, R.K.; Jesse, S.; Kalinin, S.V.; Ziatdinov, M. Deep learning analysis of defect and phase evolution during electron beam induced transformations in WS2. npj Comput. Mater. 2019, 5, 12. [Google Scholar] [CrossRef]

- Kirillov, A.; Mintun, E.; Ravi, N.; Mao, H.; Rolland, C.; Gustafson, L.; Xiao, T.; Whitehead, S.; Berg, A.C.; Lo, W.-Y. Segment anything. In Proceedings of the IEEE/CVF International Conference on Computer Vision, Paris, France, 2–3 October 2023; pp. 4015–4026. [Google Scholar]

- Bradski, G. The OpenCV Library. Dr. Dobb’s J. Softw. Tools 2000, 25, 120–123. [Google Scholar]

- Krane, N.; Lotze, C.; Franke, K.J. Moiré structure of MoS2 on Au(111): Local structural and electronic properties. Surf. Sci. 2018, 678, 136–142. [Google Scholar] [CrossRef]

- Grønborg, S.S.; Ulstrup, S.; Bianchi, M.; Dendzik, M.; Sanders, C.E.; Lauritsen, J.V.; Hofmann, P.; Miwa, J.A. Synthesis of Epitaxial Single-Layer MoS2 on Au(111). Langmuir 2015, 31, 9700–9706. [Google Scholar] [CrossRef]

- Xing, F.; Xie, Y.; Su, H.; Liu, F.; Yang, L. Deep Learning in Microscopy Image Analysis: A Survey. IEEE Trans. Neural Netw. Learn. Syst. 2018, 29, 4550–4568. [Google Scholar] [CrossRef]

- Abadi, M.; Agarwal, A.; Barham, P.; Brevdo, E.; Chen, Z.; Citro, C.; Corrado, G.S.; Davis, A.; Dean, J.; Devin, M.; et al. TensorFlow: Large-Scale Machine Learning on Heterogeneous Distributed Systems. arXiv 2016, arXiv:1603.04467. [Google Scholar]

- Kresse, G.; Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 1996, 54, 11169–11186. [Google Scholar] [CrossRef]

- Klimeš, J.; Bowler, D.R.; Michaelides, A. Van der Waals density functionals applied to solids. Phys. Rev. B 2011, 83, 195131. [Google Scholar] [CrossRef]

- Tersoff, J.; Hamann, D.R. Theory of the scanning tunneling microscope. Phys. Rev. B 1985, 31, 805–813. [Google Scholar] [CrossRef]

- Minato, T.; Sainoo, Y.; Kim, Y.; Kato, H.S.; Aika, K.; Kawai, M.; Zhao, J.; Petek, H.; Huang, T.; He, W.; et al. The electronic structure of oxygen atom vacancy and hydroxyl impurity defects on titanium dioxide (110) surface. J. Chem. Phys. 2009, 130, 124502. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Luo, J.; Huang, W.; Ling, Y.; Zhu, J.; Li, W.-X.; Yang, F.; Bao, X. Probing surface defects of ZnO using formaldehyde. J. Chem. Phys. 2020, 152, 074714. [Google Scholar] [CrossRef] [PubMed]

- Shao, W.; Zhang, Y.; Zhou, Z.; Li, N.; Jiao, F.; Ling, Y.; Li, Y.; Zhou, Z.; Cao, Y.; Liu, Z.; et al. Dynamic control and quantification of active sites on ceria for CO activation and hydrogenation. Nat. Commun. 2024, 15, 9620. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Chen, G.; Shen, S.; Yan, J. Point Defect Detection and Classification in MoS2 Scanning Tunneling Microscopy Images: A Deep Learning Approach. Molecules 2025, 30, 2644. https://doi.org/10.3390/molecules30122644

Wu S, Chen G, Shen S, Yan J. Point Defect Detection and Classification in MoS2 Scanning Tunneling Microscopy Images: A Deep Learning Approach. Molecules. 2025; 30(12):2644. https://doi.org/10.3390/molecules30122644

Chicago/Turabian StyleWu, Shiru, Guoyang Chen, Si Shen, and Jiaxu Yan. 2025. "Point Defect Detection and Classification in MoS2 Scanning Tunneling Microscopy Images: A Deep Learning Approach" Molecules 30, no. 12: 2644. https://doi.org/10.3390/molecules30122644

APA StyleWu, S., Chen, G., Shen, S., & Yan, J. (2025). Point Defect Detection and Classification in MoS2 Scanning Tunneling Microscopy Images: A Deep Learning Approach. Molecules, 30(12), 2644. https://doi.org/10.3390/molecules30122644