Abstract

Single-ring aromatic compounds including BTX (benzene, toluene, xylene) serve as essential building blocks for high-performance fuels and specialty chemicals, with extensive applications spanning polymer synthesis, pharmaceutical manufacturing, and aviation fuel formulation. Current industrial production predominantly relies on non-renewable petrochemical feedstocks, posing the dual challenges of resource depletion and environmental sustainability. The catalytic hydrodeoxygenation (HDO) of lignin-derived phenolic substrates emerges as a technologically viable pathway for sustainable aromatic hydrocarbon synthesis, offering critical opportunities for lignin valorization and biorefinery advancement. This article reviews the relevant research on the conversion of lignin-derived phenolic compounds’ HDO to benzene and aromatic hydrocarbons, systematically categorizing and summarizing the different types of catalysts and their reaction mechanisms. Furthermore, we propose a strategic framework addressing current technical bottlenecks, highlighting the necessity for the synergistic development of robust heterogeneous catalysts with tailored active sites and energy-efficient process engineering to achieve scalable biomass conversion systems.

1. Introduction

The progressive depletion of conventional hydrocarbon reserves coupled with escalating ecological degradation necessitates paradigm-shifting innovations in sustainable energy systems. Within this context, lignocellulosic biomass has emerged as a strategic carbon-neutral feedstock, with its cascade conversion technologies attracting concerted research efforts across global scientific and industrial communities. Particularly, the inherent aromaticity of lignin derivatives positions them as biogenic precursors for synthetic aromatics’ production—a critical pathway for circular carbon economy implementation [1,2,3,4].

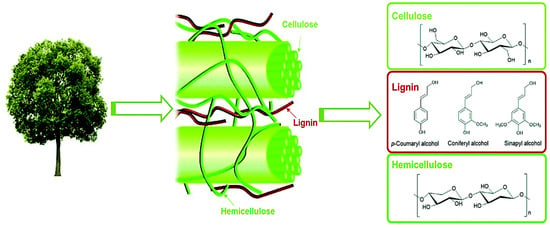

As the predominant biomass reservoir on Earth, lignocellulosic materials yield an annual global output exceeding 170 billion metric tons [5,6,7,8]. Structurally characterized by a heterogeneous macromolecular matrix, these materials are constituted by three interwoven biopolymers: (1) cellulose (30–50%), a crystalline glucose polymer; (2) hemicellulose (20–30%), an amorphous heteropolysaccharide; and (3) lignin (15–30%), a methoxylated phenylpropanoid network (Figure 1) [9,10,11]. The structurally well-defined carbohydrate polymers (cellulose/hemicellulose) have been extensively valorized through established biorefinery protocols, serving as feedstocks for second-generation bioethanol and platform chemicals [12,13,14,15,16]. Conversely, lignin’s highly branched polyphenolic architecture—featuring C-C/C-O-C interunit linkages—creates a persistent technological bottleneck for selective depolymerization [1,4,17]. This structural recalcitrance confines over 98% of industrial lignin to low-value thermal applications [18,19,20], where its combustion not only exhibits suboptimal energy efficiency (~50% lower calorific value than coal) but also exacerbates carbon sequestration deficits through non-circular CO2 emissions [21,22]. Such systemic underutilization underscores the imperative for advanced catalytic strategies to unlock lignin’s latent potential as a renewable aromatic reservoir.

Figure 1.

The schematic diagram of the composition of lignocellulosic biomass [23]. Copyright 2016 Royal Society of Chemistry.

Contemporary lignin valorization strategies predominantly employ a two-stage cascade biorefinery paradigm: initial depolymerization of the macromolecular matrix into phenolic monomers, followed by precision HDO catalysis to yield premium aromatic hydrocarbons [24,25]. Mechanistic studies reveal two competing reaction coordinates in phenolic HDO processes: (i) a C-O bond scission with aromatic ring preservation via selective hydrogenolysis and (ii) ring hydrogenation concurrent with oxygen removal. The former pathway proves particularly advantageous for synthesizing drop-in fuel components, given aromatic hydrocarbons’ superior octane ratings (e.g., toluene: ~120 RON) and direct compatibility with existing fuel infrastructure [26]. Notably, the aromatic-selective routes demonstrate enhanced process economics, with hydrogen consumption metrics reduced by 30–50% compared to saturation pathways—a critical efficiency parameter for industrial scalability.

The technological impasse resides in achieving kinetically favored C-O cleavage over thermodynamically preferential C-C bond rupture. This selectivity conundrum necessitates atomic-level catalyst engineering to manipulate adsorption configurations and transition-state energetics. Recent breakthroughs in adsorption configuration engineering (e.g., tilted vs. flat phenol adsorption modes) and electronic perturbation strategies (metal–support charge-transfer effects) have opened new frontiers in aromatic yield optimization [27,28].

Improving the selectivity and yield of phenol HDO for the preparation of BTX (benzene, toluene, xylene) faces multiple challenges, with the core issue being how to precisely regulate the dynamic competition between catalyst active sites and reaction pathways [29,30,31,32]. Firstly, catalyst designs need to balance the dual-functional requirements of deoxygenation and aromatic ring stabilization: metal sites need to provide moderate hydrogenation capacity to avoid oversaturation of aromatic rings, while acidic supports need to promote deoxygenation but avoid strong acid-induced side reactions. Secondly, selective control of the reaction pathway is particularly crucial. Phenol HDO may be carried out through direct deoxygenation or hydrogenation dehydration pathways. The former directly generates aromatic hydrocarbons but requires inhibition of the deep hydrogenation of intermediates such as cyclohexanone, while the latter can easily lead to aromatic ring saturation and reduce BTX yield. In addition, the complexity of lignin-derived phenolic substrates, such as substituent positions and methoxy steric hindrance, can significantly interfere with deoxygenation efficiency.

Accordingly, a great deal of exceedingly excellent articles and reviews concerning the HDO of lignin-derived phenolic compounds have been published due to the importance of the HDO reaction in biomass conversion and upgradation. Seminal reviews by Zhong et al. established the methodological compendium for phenolic HDO across heterogeneous, homogeneous, and enzymatic systems [33]. Subsequent analyses by Wang’s team systematically deconstructed the multifunctional synergy in metal–acid bifunctional catalysts [34], while Sreedhar’s work mapped the reaction landscape for cycloalkane intermediates’ production [35]. Collectively, these intellectual foundations provide the crucial guides required for next-generation catalyst architectures [2,33,34,35].

At present, a large number of excellent articles have been published on the conversion of phenolic compounds’ HDO into aromatic hydrocarbons, among which benzene, toluene, and xylene (BTX) are three typical aromatic compounds [36]. In the current research field, there are few systematic reviews on the development of catalysts for the selective HDO of phenols to prepare aromatic hydrocarbons. In view of this, we did not focus on precious metal/non-precious metal catalysts or general lignin conversion pathways as in previous reviews but comprehensively reviewed the latest research results on the catalytic system and related strategies of lignin-derived phenolic compounds for the sustainable production of aromatic hydrocarbons through HDO catalysis. At the same time, a summary and explanation of the reaction pathways and mechanisms involved were provided to help deepen the understanding of the basic characteristics of catalysts. Finally, we put forward some preliminary suggestions for future research, hoping to promote the industrialization process of synthesizing high-value-added aromatic hydrocarbons and other chemicals from renewable lignin resources.

2. Catalytic Conversion of Phenolics into Aromatics

Benzene–toluene–xylene (BTX) constitutes the principal aromatic triad in petrochemical manufacturing, commanding an annual global output exceeding 10,000 tons through conventional naphtha reforming and steam-cracking processes [37]. They are currently used in a wide range of applications. In addition to being used as fuel additives and solvents, they can also be considered as the starting materials for the manufacture of various chemicals and polymers [25,26,37,38,39,40,41]. With escalating decarbonization mandates, biogenic BTX production via lignin-derived phenolic HDO has emerged as a carbon-negative alternative to fossil-derived routes—demonstrating lower lifecycle greenhouse gas emissions [42]. The evolving frontier in catalyst engineering has witnessed remarkable progress in designing heterogeneous catalytic systems for aromatic compound production. Advanced material platforms spanning loaded metal to transition metal compounds (sulfides, carbides, nitrides, phosphides) now demonstrate tailored efficacy in transforming lignocellulosic phenolic derivatives into benzene–toluene–xylene (BTX). This diversification in catalytic design strategies enables precise control over deoxygenation pathways and aromatic stabilization mechanisms.

2.1. Noble Metal Catalysts

Noble metals dominate phenolic HDO research due to their unparalleled hydrogen dissociation efficiency and oxygen-removal capabilities. Currently, three major noble metals, including palladium, platinum, and ruthenium, were studied extensively and considered as the most suitable metal catalysts in the BTX production from lignin-derived phenolic compounds.

2.1.1. Palladium (Pd)-Based Catalysts

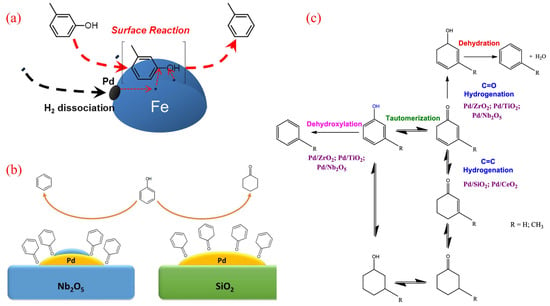

Palladium (Pd), a precious and costly metal, plays a significant role in the hydrodeoxygenation (HDO) of phenolics. Hong et al. explored the synergistic catalytic effects of Pd and Fe in the HDO of m-cresol using Pd/Fe2O3 catalysts [43]. Their study revealed that the addition of Pd enhances the reduction of Fe under an H2 atmosphere, and the reduced catalyst demonstrates resistance to the Fe surface oxidation caused by reactants and water during the HDO process. Through characterization and kinetic studies, the synergistic effect between Pd and Fe was identified, being attributed to three key factors: the promotion of H2 activation by Pd, the stabilization of metallic Fe, and the enhancement of product desorption by Pd. The mechanism of Pd-Fe synergy is illustrated in Figure 2a. It involves H2 preferentially adsorbing and dissociating on Pd entities attached to the Fe surface, followed by spillover to metallic Fe sites where m-cresol adsorbs and activates [34]. The unique adsorption pattern of m-cresol on the Fe surface contributes to the high selectivity of BTX as direct HDO products. Additionally, Pd serves as the active site for H2 activation, maintaining high hydrogen coverage on the metallic Fe surface. These findings suggest that the proposed synergistic catalysis could be extended to other noble metal-promoted Fe catalysts, offering a promising strategy for designing highly active HDO catalysts in the future.

The choice of load material significantly influences both the activity and product distribution in HDO reactions. Barrios and colleagues investigated the performance of Pd loaded on SiO2 and Nb2O5 [44,45]. Their results showed that the reaction rate for phenol HDO over Pd/Nb2O5 was 90 times higher than that of the SiO2-loaded catalyst. Furthermore, the main product varied depending on the support: cyclohexanone was predominantly formed over Pd/SiO2, while benzene was the primary product over Pd/Nb2O (Figure 2b). The high activity and selectivity toward benzene for Pd/Nb2O were likely due to the strong interaction between the oxygenophilic Nb5+/Nb4+ cations and the oxygen in the phenol molecule [44]. Similarly, De Souza and colleagues compared the catalytic performance of Pd supported on various carriers, including SiO2, Al2O3, TiO2, ZrO2, CeO2, and CeZrO2, for phenol HDO [46]. For instance, benzene was the main product for Pd/TiO2 and Pd/ZrO2, whereas cyclohexanone predominated for Pd/SiO2, Pd/Al2O3, Pd/CeO2, and Pd/CeZrO2. The high selectivity toward benzene for the Pd/TiO2 and Pd/ZrO2 catalysts may be attributed to the oxophilic sites represented by the incompletely coordinated Ti4+ and Zr4+ cations near the metal particle periphery. In contrast, the weaker interaction between the metal cations of other supports and oxygen favored the hydrogenation of phenol to cyclohexanone.

Recent studies further explored the reaction pathways for the HDO of phenolics using Pd supported on different carriers in a fixed-bed reactor at 573 K [47]. The results demonstrated that the support type significantly influences the product distribution. For example, Pd supported on SiO2 and CeO2 favored ring hydrogenation, leading to oxidation products such as cyclohexanone. In contrast, the use of ZrO2, TiO2, and Nb2O5 as supports promoted the formation of benzene and toluene through either the carbonyl hydrogenation or direct deoxygenation of reciprocal isomeric intermediates (Figure 2c). Additionally, the reaction pathway for the removal of the methoxy group in the HDO of anisole was found to depend on the support. For all catalysts except Pd/Nb2O5, the preferred pathway involved demethylation to produce phenol, followed by further deoxygenation to benzene. However, the superior oxygenophilicity of Nb cations in Pd/Nb2O5 favored direct deoxygenation, resulting in the formation of benzene and methanol.

Figure 2.

(a) Mechanism of Pd-Fe synergy in HDO of m-cresol [43]. Copyright 2014 American Chemical Society. (b) The HDO reaction of phenol over Pd/SiO2 and Pd/Nb2O5 [44]. Copyright 2017 Elsevier. (c) Reaction scheme for the HDO of phenolics over Pd supported on various oxides [47]. Copyright 2021 American Chemical Society.

2.1.2. Ruthenium (Ru)-Based Catalysts

Ruthenium-based catalysts have demonstrated exceptional performance in the hydrodeoxygenation (HDO) of lignin-derived phenolics, particularly in enhancing BTX (benzene, toluene, xylene) formation. A breakthrough study by Wang et al. revealed that Ru/Nb2O5 systems achieved 64% BTX selectivity with a 35.5% yield during 20 h organosolv lignin conversion, substantially outperforming Ru catalysts supported on ZrO2, Al2O3, and TiO2 [48]. Notably, this configuration exhibited 80% toluene selectivity in p-cresol conversion through optimized C-O bond scission. Mechanistic investigations combining spectroscopic characterization and density functional theory (DFT) analyses elucidated Nb2O5’s dual functionality: a strong phenol adsorption capacity and remarkable reduction in the activation energy for aromatic C-O cleavage. The catalytic synergy arises from Ru’s hydrogenolytic activity, where surface-adsorbed H* species facilitate aryl-O bond dissociation. Crucially, the weak π-complex interaction between the generated aromatics and Nb2O5 surface enables rapid product desorption, effectively suppressing overhydrogenation side reactions. This mechanistic framework aligns with recent advancements in Au-Nb2O5 nanocomposites, which demonstrated analogous C-O bond activation efficiency during lignin hydrogenolysis [30].

Solvent engineering significantly regulates the efficiency and product distribution of hydrogenolysis deoxygenation (HDO) reactions through key parameters such as solubility, polarity, and hydrogen supply capacity. Currently, biomass-catalyzed HDO mainly uses water, alcohols, and their composite solvent systems [49,50]. Based on this, the research team developed the Ru/Nb2O5-MC catalyst through an initial wet impregnation method and systematically investigated its solvent effect in phenolic compound HDO [51]. Under optimized conditions of 250 °C and 2-bar H2, the biphasic catalytic system achieved the complete conversion of phenol and obtained 80% benzene selectivity. Compared to a single decahydronaphthalene or aqueous system, the decahydronaphthalene/water biphasic system increases benzene selectivity by 15–20%. Its advantage lies in the metal–acid dual-functional synergistic mechanism: Ru nanoparticles activate hydrogen molecules through dissociation adsorption, while the acidic sites of the Nb2O5-MC carrier can specifically adsorb oxygen-containing intermediates, promoting deoxygenation pathways through polarized Caryl-OH bonds and stable dehydration transition states. The water phase at the biphasic interface effectively suppresses the benzene ring hydrogenation side reaction through thermodynamic regulation, resulting in a 30–40% increase in selectivity. The kinetic isotope effect experiment confirms that this process mainly follows the direct deoxygenation mechanism. This solvent-mediated catalytic strategy achieved the efficient synthesis of benzene with low hydrogen consumption under mild conditions, providing a new engineering solution for the conversion of lignin-derived phenolic compounds into high-value chemicals.

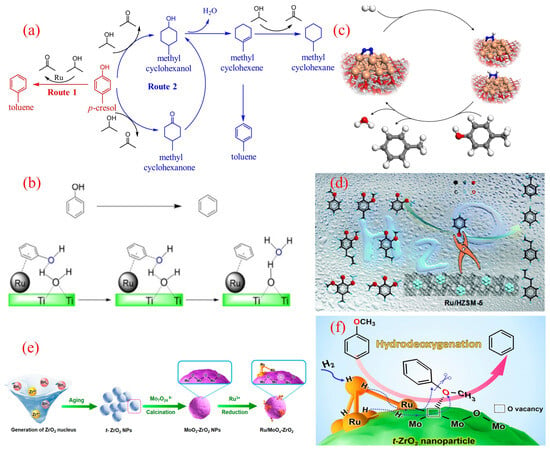

The innovative application of hydrogen donor reagents provides an effective strategy for the directed conversion of phenolic compounds into BTX, replacing traditional hydrogen gas. Guo’s research team recently developed the Ru/Nb2O5-SiO2 catalytic system, which achieved the efficient conversion of p-cresol to toluene in a 2-propanol hydrogen-transfer medium [52]. The system achieved a toluene yield of 84.0% under reaction conditions at 230 °C, and its superiority lies in the significant reduction in the C-O bond dissociation energy by the NbOx species and the synergistic effect of the moderate hydrogen-transfer activity of Ru nanoparticles. The analysis of reaction pathways (Figure 3a) shows that in the presence of 2-propanol, the system mainly follows the direct deoxygenation pathway (DDO, route 1), generating only trace amounts of methylcyclohexanone/alcohol intermediates (route 2, total selectivity of 5.2%), which can be further converted to toluene through subsequent dehydrogenation reactions. It is worth noting that compared to the molecular hydrogen system, the hydrogen-transfer strategy increases the selectivity of aromatic hydrocarbons, which is attributed to the steric hindrance effect of the donor alcohol effectively suppressing excessive hydrogenation of aromatic rings. This breakthrough work establishes a new paradigm for the preparation of BTX from lignin-derived phenols through a nonhydrogen atmosphere catalytic conversion, providing important theoretical support for the optimization of the hydrogen economy in biomass-refining processes.

The study of ruthenium-based catalytic systems has been further expanded to titanium dioxide supports, and the mechanism of Ru/TiO2 in the direct hydrogenation deoxygenation (HDO) of phenol has revealed a unique catalytic pathway mediated by water [53]. The initial benzene selectivity of the system was only 38% at 573 K and 3.79 MPa, while the introduction of 10 wt% water significantly increased the selectivity to 95%, attributed to the dynamic proton network formed by water molecules on the TiO2 surface. As shown in Figure 3b, the water molecules adsorbed on the surface of hydroxylated TiO2 achieve bidirectional proton transfer through the Ru/TiO2 interface. During the extraction of phenolic hydroxyl groups, the C-O bond dissociation energy is reduced through a proton synergistic transfer mechanism. The synchronous hydrogen overflow effect induces the generation of oxygen vacancies in TiO2, and its amphiphilic properties promote the cleavage of H2 to generate active hydrogen species, forming a continuous deoxygenation–dehydrogenation cycle. The latest research progress indicates that reactive atmosphere engineering can further optimize the performance of the system. The Duan team achieved the efficient conversion of cresol to toluene by introducing 6-bar N2 at 160 °C and 1-bar H2 (Figure 3c) [54]. Nitrogen forms hydrogenated nitrogen species on the Ru metal surface through chemical adsorption, and the activation energy of the Caryl-O bond is reduced through a proton-relay mechanism. At the same time, the nitrogen coating dynamically regulates the distribution of active sites, increasing the adsorption rate of cresol and reducing the apparent activation energy of the reaction. This gas–solid interface regulation strategy provides a new process enhancement approach for lignin catalytic conversion.

Figure 3.

(a) Reaction pathway of p-cresol HDO over the Ru/Nb2O5-SiO2 catalyst [52]. Copyright 2017 Elsevier. (b) Water-assisted HDO of phenol over the Ru/TiO2 catalyst [53]. Copyright 2015 American Chemical Society. (c) The combination of N2 activation and an HDO reaction over the Ru/TiO2 catalyst [54]. Copyright 2019 Springer Nature. (d) The selective HDO of phenolics to BTX over Ru/HZSM-5 in water [55]. Copyright 2016 Royal Society of Chemistry. (e) Schematic synthetic process for MoOx-decorated ZrO2-supported Ru nanocluster catalysts; (f) The selective HDO of anisole to benzene over the Ru/MoOx-ZrO2 catalyst [56]. Copyright 2021 American Chemical Society.

The research on ruthenium-based catalyst systems has further extended to the field of molecular sieve supports, and Ru/HZSM-5 has demonstrated excellent performance in the directional conversion of phenolic monomers (phenol, anisole, guaiacol, and eugenol) to benzene derivatives (BTX) [55]. In an aqueous reaction system composed of 240 °C, 2-bar H2, and 6-bar N2, the catalyst achieved 100% BTX selectivity for the conversion of guaiacol. In-depth research has shown that the topology of HZSM-5 has a decisive impact on catalytic performance: the cross-shaped HZSM-5-supported ruthenium catalyst (Ru/c-HZSM-5) achieved a 97% benzene yield under the same conditions. X-ray photoelectron spectroscopy (XPS) and infrared spectroscopy (IR) analysis revealed that the special pore structure of the cross-shaped molecular sieve induces the generation of electron-deficient ruthenium species, whose strong electronegativity significantly enhances the adsorption capacity of reactants. Additionally, the adsorption of guaiacol and hydrogen on cross-shaped Ru/HZSM-5 was more significant than other catalysts, which may be due to the abundant Lewis acid sites on cross-shaped Ru/HZSM-5, thus promoting the adsorption of oxygen atoms inside guaiacol (Figure 3d). The synergistic effect of electronic structure adsorption performance reduces the C-O bond dissociation energy, ultimately achieving the high-fidelity deoxygenation of aromatic ring structures [55].

The latest research breakthrough has achieved a performance leap of ruthenium-based catalysts in the aqueous hydrogenation deoxygenation (HDO) of benzyl ether through an interface engineering strategy [56]. The research team innovatively constructed a MoO3 modification layer on the surface of tetragonal zirconia (t-ZrO2) and formed a Ruδ+-Ov-Mo5+ ternary active interface by precisely loading Ru nanoclusters (Figure 3e). Under mild reaction conditions, the benzene selectivity of the catalyst reached 84.7%. Its performance leap is attributed to a unique electronic synergistic effect: MoOx defect clusters induce Ru nanoclusters to exhibit partial oxidation states through charge transfer, significantly enhancing the chemical adsorption energy of methoxy groups (Figure 3f). Advanced microscopic and spectroscopic analyses revealed a precisely engineered architecture where atomic-scale Ru clusters coexist with defective MoOx moieties on tetragonal zirconia (t-ZrO2) substrates. This unique configuration induces charge redistribution at metal–oxide interfaces, generating the electron-deficient Ruδ+ sites and coordinatively unsaturated oxygen vacancies. The established SMS creates robust electronic coupling between metallic Ru and MoOx species. Such synergistic interactions not only optimize active-site configuration but also endow the hybrid system with exceptional thermal stability during prolonged catalytic operation [56].

2.1.3. Platinum (Pt)-Based Catalysts

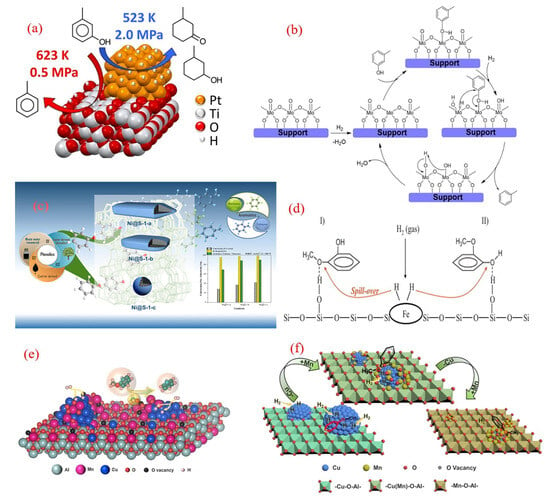

The platinum-based catalytic system exhibits unique advantages in the field of directed deoxygenation of phenolic compounds through precise interface regulation. The Pt/HBeta bifunctional catalyst developed by the Resasco team achieved the efficient conversion of meta cresol and benzyl ether under low-pressure conditions at 673 K [57,58]. The catalytic conversion frequency of this system was three times higher than that of a pure HBeta molecular sieve, and the BTX selectivity exceeded 90%. Mechanistic studies have shown that Pt nanoparticles and Brønsted acid sites form a dual-functional synergistic mechanism: the metal site selectively activates the adjacent aromatic ring of Caryl-OH to generate a hexadienol intermediate, and the adjacent acid site immediately triggers a dehydration reaction to complete the deoxygenation cycle (Figure 4a) [59]. Zhu’s research group further expanded the application of this system in the conversion of guaiacol and found that Pt/HBeta was regulated by a unique adsorption configuration—the aromatic ring plane adsorbed on the Pt crystal surface and the oxygen atom anchored acid site—resulting in a direct deoxygenation pathway contribution rate of over 85%, successfully inhibiting competitive reactions such as demethylation and decarbonylation [60].

Figure 4.

(a) The HDO reaction of m-cresol over the Pt/TiO2 catalyst [61]. Copyright 2016 American Chemical Society. (b) Mechanism of the direct deoxygenation route of m-cresol on a schematic molybdenum oxide-site species [62]. Copyright 2017 Elsevier. (c) The upgrading of phenolics to BTX over the different Ni@silicalite-1 catalysts [63]. Copyright 2021 American Chemical Society. (d) Possible reaction mechanism of the HDO conversion of guaiacol over the Fe/SiO2 catalyst [39]. Copyright 2012 Elsevier. (e) The HDO of anisole to benzene over the Mn-doped Cu/Al2O3 catalysts; (f) the mechanism for the anisole HDO on Cu/MnAlOx with the Mn/Cu molar ratio increasing [64]. Copyright 2021 Elsevier.

A significant breakthrough has been made in the study of the structure–activity relationship between the carrier effect and reaction pathway of platinum-based catalysts. Griffin’s team systematically analyzed the performance differences between Pt/C and Pt/TiO2 in the hydrogenation deoxygenation (HDO) of meta cresol using an experimental computational strategy [61]. This study used a gas-phase flow reactor to simulate two process conditions, catalytic rapid pyrolysis (CFP: 623 K, 0.5 MPa) and hydroprocessing (HT: 523 K, 2.0 MPa), and conducted comparative analysis under a unified control of a 35% conversion rate. The experimental data show that under CFP conditions, the toluene carbon selectivity of Pt/TiO2 reaches 78%, which is significantly higher than that of Pt/C at 46%. Under HT conditions, both types of catalysts mainly generate 3-methylcyclohexanone/alcohol (selectivity >95%), which is highly consistent with Ruddy’s thermodynamic regulation law [65]: aromatic ring hydrogenation tends to be in the low-temperature region, while direct deoxygenation and acid-catalyzed reactions dominate the high-temperature region (>623 K). Mechanistic studies have shown (Figure 4a) that the Pt metal phase dominates the hydrogenation pathway at 523 K, while the oxygen vacancy effect of TiO2 support is significantly enhanced at 623 K, resulting in a decrease in deoxidation activation energy through metal–carrier electronic interaction. This temperature-dependent synergistic mechanism is reflected in the participation of TiO2 surface hydroxyl groups in proton-transfer networks at high temperatures, optimizing the Caryl-O bond dissociation pathway and increasing toluene selectivity.

Noble metal catalysts (e.g., Pd, Pt, Ru) exhibit unparalleled efficiency in phenolic HDO, primarily due to their exceptional hydrogen dissociation capabilities and tailored interactions with oxygen-containing functional groups. Despite their superior performance, noble metals face critical limitations, including high cost, susceptibility to coking during prolonged operation, and limited availability, which restrict their large-scale industrial adoption.

2.2. Non-Noble Metal Catalysts

Due to the high cost of noble metal-based catalysts, which makes them less viable for large-scale industrial applications, researchers have been developing cost-effective, non-precious metal-loaded catalysts as alternative systems for the conversion of phenolic compounds to benzene, toluene, and xylene (BTX). These systems have shown great promise in hydrodeoxygenation (HDO) processes.

The group of Prasomsri explored the use of a homogeneous MoO3 catalyst, under reaction conditions of 593 K, 3 h, and 0.1 MPa H2, and they achieved 94% overall conversion with high yields of benzene and toluene [66]. The success of the MoO3 catalyst was primarily attributed to its ability to selectively cleave the phenolic Ph-OMe bond over the weaker aliphatic Ph-O-Me bond. Advancing this research direction, Zhang’s team conducted a systematic evaluation of defect-engineered MoO3 catalysts for aromatic production under lower H2 environments [62]. Their work demonstrated effective phenol-to-benzene transformation (98.1% conversion, 99.5% selectivity) under mild hydrotreatment conditions (340 °C, H2/N2 = 1:6 v/v at 3.5 MPa total pressure). Mechanistic studies revealed that coordinatively unsaturated sites generated by surface oxygen vacancies served as active centers, facilitating selective C-O bond scission while inhibiting aromatic ring hydrogenation. Specifically, the oxygen vacancies (Mo5+ sites) acted as the active centers for phenol HDO, facilitating the adsorption of lone-pair electrons from phenol and enabling the hydrolysis of carbonyl intermediates to form benzene. Additionally, the introduction of N2 into the reactor prevented the over-reduction of MoO3, maintaining a high-oxygen-vacancy content on the catalyst surface and enhancing the HDO conversion of phenol to benzene.

The hydrodeoxygenation (HDO) of m-cresol to toluene was investigated using MoO3-based catalysts supported on various materials, including SiO2, Al2O3, TiO2, ZrO2, and CeO2 [67]. The catalytic systems selectively exhibited C-O bond scission capabilities while preserving aromatic unsaturation, enabling the effective transformation of m-cresol into toluene with notable conversion efficiency and exceptional selectivity. Supporting materials play a crucial role in molybdenum-based catalysts, especially in stabilizing specific low-oxidation-state molybdenum ions and affecting their reduction performance, with TiO2 and ZrO2 identified as the most effective supports for enhancing activity and stability. The reaction mechanism remained inconclusive, but the rate of reaction appeared to be influenced by ligand-unsaturated Mo sites, which are essential for the oxygen-vacancy-driven mechanism. Further studies by Vinicius et al. explored the impact of different supports on MoOx-based catalysts for m-cresol HDO at 340 °C and a total pressure of 4 MPa (Figure 4b) [68]. Regardless of the catalyst used, the selectivity for m-cresol to toluene consistently exceeded 80%, with the catalytic activity influenced by the nature of the support, following the order as follows: MoOx/Al2O3 > MoOx/SBA-15 > MoOx/SiO2. This variation was attributed to differences in the reducibility of Mo species, which could be enhanced by using acidic carriers like Al2O3 or mesoporous materials like SBA-15 compared to commercial SiO2. The proposed reaction mechanism involves the adsorption of oxygen from the reactant onto oxygen vacancies, followed by the heterolytic dissociation of H2 into proton and hydride species. The hydride adds to a carbon atom bearing an OH group, leading to the cleavage of the C-O bond and the formation of toluene. Oxygen vacancies are restored by releasing water during the process [67,69]. Mo species are present as polymolybdate phases, including Mo6+, which reacts with H2 to form MoOx species (Mo IV) and release water, facilitating the breaking of C-O bonds [70]. This study highlights the importance of support materials in optimizing MoO3 catalysts for HDO processes, offering insights into the development of cost-effective and efficient catalytic systems for industrial applications [68].

However, despite these advantages, MoO3-based catalysts face challenges such as deactivation due to coke deposition and over-reduction, which can lead to the formation of inactive Mo species [62,68]. These limitations have prompted researchers to explore alternative non-precious metal catalysts for HDO processes.

Nickel-based catalysts have emerged as a promising alternative for the HDO of phenolics to BTX [71,72,73]. Researchers have investigated a wide range of Ni-containing catalysts supported on diverse carriers [74]. The comparative evaluation of nickel-based catalytic systems revealed significant carrier-dependent performance in aromatic production. When supported on microporous carbon matrices, Ni nanoparticles achieved an 80% benzene yield under optimized conditions (310 °C, 3-bar H2). The superior performance of the Ni/C catalyst was attributed to its strong acidic sites and excellent metal dispersion, which favored the selective cleavage of the C-O bond. Similarly, the Ni/TiO2 catalyst demonstrated high selectivity for benzene, albeit with limited anisole conversion, due to strong metal–support interactions [75]. These findings suggest that the catalytic activity and selectivity of Ni-based catalysts are significantly influenced by the nature of the support material.

The catalytic mechanism of Ni-based catalysts involves the adsorption of reactants onto ligand-unsaturated Ni sites, which promote the activation of hydrogen and stabilize transition states, leading to the cleavage of the C-O bond. The size of the Ni particles also plays a crucial role in determining reaction pathways and product selectivity [76]. Smaller Ni particles tend to enhance the conversion rate by providing more active sites, while larger particles may influence the selectivity toward specific products. This highlights the importance of optimizing the Ni particle size and support properties to achieve desired catalytic outcomes.

This study further explores the optimization of Ni-based catalysts for the hydrodeoxygenation (HDO) of phenolics to BTX. Notably, Ni/Ce1−xNbxO2 catalysts were developed, demonstrating exceptional performance in the HDO of phenol. At 300 °C, the Ni/CeO2 catalyst achieved a remarkable 92% yield of benzene [77]. The reaction mechanism involves phenol tautomerization followed by hydrogenation to cyclohexanone and hydrolysis to methane [74]. The addition of Nb significantly alters the product distribution, with the increased Nb content enhancing benzene selectivity while reducing the formation of hydrogenation and hydrolysis products. This improvement is attributed to the niobium-rich surface and the strong interaction between phenol’s oxygen and the oxygenophilic Nb5+ sites, which promotes carbonyl hydrogenation.

In another approach, Ni@S-1 catalysts with varying crystal sizes were synthesized using an in situ encapsulation method and applied to m-cresol conversion (Figure 4c) [63]. These catalysts exhibited outstanding stability over 300 h, achieving 78.4% phenol conversion and a 73.1% BTX yield. The encapsulation of Ni nanoparticles within the zeolite matrix modulates reactant adsorption patterns and leverages the shape-selective properties of silicalite-1, enhancing aromatic selectivity and catalyst stability. The reduction in the Ni@silicalite-1 crystal size is further improved by selectively eliminating the hydroxyl groups that hindered the further hydrogenation of aromatics [63]. This design also prevents the migration and aggregation of Ni nanoparticles, maintaining catalyst performance even during long-term runs and avoiding undesired benzene ring reactions.

The exploration of cost-effective and environmentally friendly catalysts for the hydrodeoxygenation (HDO) of phenolics to BTX has recently expanded to include iron (Fe)- and manganese–copper (Mn-Cu)-based systems. In a notable study, Fe/SiO2 catalysts were investigated for the gas-phase HDO of guaiacol, achieving 74% conversion and a 38% BTX yield at 400 °C and 10 bar [39]. These Fe-based catalysts demonstrated advantages such as minimal aromatic ring hydrogenation and low-coking tendencies. The mechanism involves the adsorption of guaiacol’s oxygen atoms at weak acidic OH sites on the silica surface, favoring C-O bond cleavage over C-C bond breakage [64]. Active hydrogen species, derived from H2 dissociation on Fe particles, play a critical role in facilitating the reaction (Figure 4d). This work highlights Fe as a promising, sustainable catalyst for lignin-to-BTX production via rapid pyrolysis and the subsequent HDO of lignin vapors.

In another development, Mn-doped Cu/Al2O3 catalysts, synthesized from layered double hydroxides, were tested for the liquid-phase HDO of anisole (Figure 4e) [78]. The addition of Mn significantly enhanced benzene selectivity, reaching ~65% for the 4Cu/8Mn4AlOx catalyst—six times higher than that of undoped Cu/Al2O3. Structural studies revealed that MnOx doping optimized the surface structure of Cu particles and generated a high density of oxygen vacancies (OVs). These OV sites, along with metallic Cu, synergistically activated the C-O bond in anisole, improving HDO activity. However, excessive Mn/Cu ratios led to MnOx encapsulating Cu particles, reducing the active sites for H2 activation and suppressing catalytic performance. This study demonstrates the potential of Mn-Cu/Al2O3 catalysts for selective and efficient HDO processes.

Non-noble metal catalysts (e.g., Mo, Ni, Fe, Mn-Cu) offer cost-effective alternatives for HDO, leveraging earth-abundant elements to achieve selective deoxygenation. However, these catalysts often suffer from lower intrinsic activity compared to noble metals, as well as challenges like metal leaching (Ni) and redox instability (Mo), requiring further advancements in stability and regeneration protocols.

2.3. Bimetallic Catalysts

The addition of a second metal can modify the electronic or structural properties of the primary-metal-loaded catalyst compared to its monometallic counterpart, potentially enhancing catalytic activity, selectivity, and durability. This modification can occur through changes in the d-band electron density of the primary metal or by altering its surface configuration [34,79,80,81,82]. Additionally, the two metals may fulfill distinct roles during the reaction process [83].

2.3.1. Fe-Containing Bimetallic Catalysts

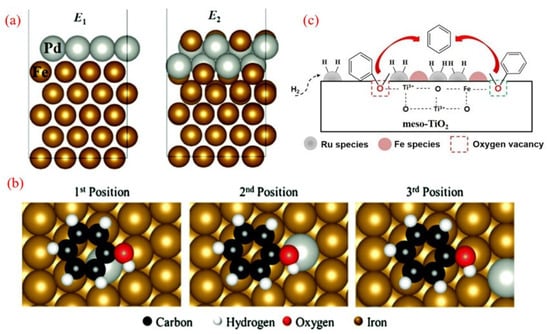

The oxophilic nature of iron (Fe) makes it highly effective for deoxygenation processes, particularly due to its strong affinity for oxygen-containing groups in phenolic compounds. However, Fe has a limitation: its poor ability to dissociate H2 [34]. To overcome this, researchers developed a carbon-supported PdFe bimetallic catalyst, which enhances the overall hydrodeoxygenation (HDO) rate while maintaining efficient oxygen removal during the HDO of guaiacol [84]. This PdFe/C catalyst demonstrated superior performance, achieving an 83.2% benzene yield at 450 °C, significantly outperforming the monometallic Fe/C catalyst, which yielded only 43.3%. The possible structures of the bimetallic catalyst, as shown in Figure 5a, include a monolayer of Pd on the Fe (110) surface or a mixed surface of Pd and Fe atoms. Characterization and density functional theory (DFT) studies reveal that the Pd-Fe alloy surface is enriched with Pd nanodots, while Fe particles dominate the subsurface, indicating that Fe serves as the primary active site for the reaction. Meanwhile, Pd modifies the electronic structure, enhancing catalytic activity. Figure 5b revealed three distinct adsorption configurations on the catalyst surface. Adsorption energetics analysis demonstrated a positive correlation between the binding strength and proximity to Pd active centers, with the third adsorption position exhibiting the most thermodynamically favorable adsorption energy, conclusively establishing preferential phenol adsorption at the Fe surface sites. As phenol interacts strongly with the Fe surface, the C-O bond weakens, making the HDO of phenol more susceptible.

The addition of a second metal can create additional active sites, often acidic in nature, which can significantly enhance deoxygenation [34,85]. Phan et al. demonstrated that incorporating Fe into a Ru/meso-TiO2 catalyst drastically alters its surface properties and catalytic performance, achieving over 80% benzene selectivity in the HDO of anisole at 250 °C and 1 MPa of H2 [86]. In this system, Ru particles efficiently dissociate H2, while the oxygenophilic Fe sites strengthen interactions between the oxygen-containing functional groups and the carrier surface. The synergistic interaction between Ru and Fe enhances C-O bond cleavage without ring hydrogenation, thereby minimizing H2 consumption (Figure 5c). Additionally, the bimetallic catalyst’s improved activity is linked to an increase in oxygen vacancies on the carrier surface. Similarly, a bimetallic FeReOx/ZrO2 catalyst was investigated for the mild HDO of various phenolic compounds [26]. Notably, at 250 °C, it delivered a BTX yield of 50.5% in the HDO of m-cresol, along with high stability, retaining 93.7% activity after 160 consecutive reactions. The catalyst’s mesoporous structure, oxygenophilic nature, and balanced acidity—induced by rhenium oxide and zirconium oxide carriers—contribute to its high dehydration efficiency. This system offers a cost-effective, sustainable route for BTX production under atmospheric pressure at 350 °C, bringing functional chemicals from lignin biorefining closer to commercialization.

Figure 5.

(a) The structure of the Pd layer in the matrix on the Fe (110) surface. (b) Adsorption conformation of phenol on the Fe (110) surface Pd atom. The distance from the adsorbate to the palladium atom increases from position 1 to position 3 [84]. Copyright 2013 Elsevier. (c) The possible mechanism of the anisole HDO over the RuFe/meso-TiO2 catalyst [86]. Copyright 2018 Elsevier.

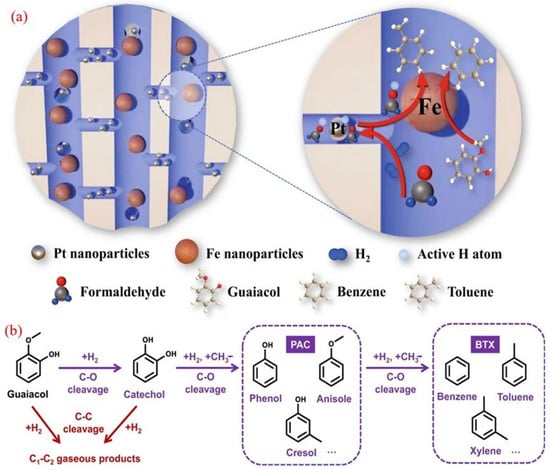

The key role of the hydrogen overflow effect in the heterogeneous catalytic hydrogenation deoxygenation (HDO) process has been experimentally verified [87]. Taking the bimetallic Pt@Fe@SiO2 system as an example [88], the catalyst accurately constructs a hierarchical pore structure through a dual-mode plate method: Pt nanoparticles are located in SiO2 micropores, and Fe nanoparticles are distributed in macropores. In the HDO reaction of guaiacol, although it is difficult to achieve surface hydrogen migration with SiO2 as a non-reducible carrier, the introduction of C1 to C3 carbonyl compounds or ester oxygen-containing additives allows the active hydrogen atoms generated at Pt sites to migrate across scales to Fe active sites, improving the migration efficiency (Figure 6a). This molecular-mediated hydrogen-transfer mechanism significantly enhances the deoxygenation activity of bimetallic systems compared to single-metal Pt/Fe catalysts.

Figure 6.

(a) Hydrogen spillover enhanced by oxygenate additives during catalysis; (b) the suggested HDO route of guaiacol to produce BTX [88]. Copyright 2022 Springer Nature.

Dynamics analysis shows that oxygen-containing additives reduce the activation energy of the key hydrogenation steps on the Fe surface by stabilizing transition-state hydrogen species. It is worth noting that such hydrogen carriers can be generated through the in situ dehydrogenation or steam reforming of alcohol precursors, simultaneously providing H2 sources for BTX synthesis. This study has pioneered a new strategy of “molecular assisted hydrogen overflow”, providing a universal solution for the synergistic catalysis of spatially isolated active sites on inert carriers.

2.3.2. Ni-Containing Bimetallic Catalysts

Ni-based catalysts possess superior hydrogenation abilities for biomass upgrading. However, their limited propensity for oxygen removal restricts their application in HDO reactions [89,90]. As a result, numerous bimetallic Ni catalysts have been developed to enhance their deoxygenation efficiency. Tao and colleagues developed highly reactive NiMo bimetallic catalysts [91]. Interestingly, the synthesized Ni-Mo/SiO2 catalyst demonstrated remarkable selectivity (>96%) for BTX and achieved a 99% conversion rate under low-H2 partial-pressure conditions. Additionally, the catalyst’s plentiful acid sites significantly promoted the methyl-transfer reaction, leading to reduced carbon losses. Similarly, Yang et al. reported that the bimetallic Ni-Mo/SiO2 catalyst exhibited high activity and selectivity (>80%) for the HDO of m-cresol to toluene across a broad temperature range (250–350 °C) under atmospheric hydrogen pressure. Further confirmation revealed that the interaction between the Ni core surface and the optimal MoOx species enhancing the Ni surface is crucial for attaining high activity and selectivity [92]. This study offers novel insights into cost-effective HDO processes for products derived from lignin thermal degradation.

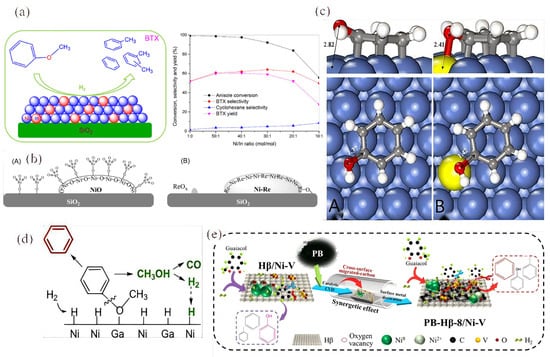

Wang’s group studied the influence of indium on the catalytic performance of Ni/SiO2 in the hydrodeoxygenation (HDO) [93]. Under conditions of 300 °C, 0.1 MPa, and a H2/anisole ratio of 25, the Ni40In/SiO2 catalyst with 40% Ni content achieved a higher BTX yield of 60.4%, compared to that of 51.6% from the Ni/SiO2 catalyst (Figure 7a). They found that the size of the Ni-In bimetallic microcrystals was similar to that of monometallic Ni with the same Ni content. However, the bimetallic Ni-In catalyst absorbed significantly less H2 because the In atoms diluted the Ni atoms.

Charge transfer from In to Ni was observed in the bimetallic Ni-In catalysts, indicating a close interaction between the Ni and In atoms, along with geometrical and electronic modifications of Ni by In. In anisole HDO, the Ni-In bimetallic catalysts showed lower activity than monometallic Ni but exhibited higher selectivity for BTX. Furthermore, the bimetallic catalysts demonstrated reduced methanation activity, leading to higher carbon yields and decreased hydrogen consumption [94]. Additionally, a lower Ni/In ratio resulted in a greater impact of In on catalytic performance, with BTX selectivity primarily determined by the Ni/In ratio and nearly independent of the Ni content [93].

Furthermore, the geometric and electronic effects of bimetallic Ni-Re catalysts for the selective HDO of m-cresol to toluene were further investigated [95]. The incorporation of Re into the Ni/SiO2 catalyst stabilizes highly dispersed NiO through robust Ni-O-Re interactions. As anticipated, the bimetallic catalysts exhibit both geometric and electronic effects: (1) Re disperses the Ni surface into smaller aggregates and creates Ni-Re adjacent sites, and (2) the proximity between Ni and Re reduces the occupancy of the Ni d-band. Unlike the adsorption of phenol on the bare Ni (111) surface via the benzene ring (with O pointing away from the surface), the adsorption of phenol on the (Re)Ni (111) surface occurs via the benzene ring on Ni and the O atom on Re at Ni-Re adjacent sites, which facilitates C-O bond cleavage (Figure 7c). The incorporation of Re in the surface alloy modifies the Ni surface by breaking it into smaller, discrete regions (geometric effect) and reduces the d-band electron density of Ni (electronic effect) [95]. DFT calculations indicate that the Ni-Re neighboring site facilitates the cleavage of the C-O bond by adsorbing the O atom on Re and the benzene ring on the adjacent Ni atom, thus enhancing deoxygenation and promoting toluene production. At the same time, the reduced electron density in the Ni d-band weakens the adsorption of benzene rings on the surface, preventing the C-C hydrogenolysis of aromatic products.

Figure 7.

(a) The performance of the In on Ni/SiO2 catalyst in the HDO of anisole with different products [93]. Copyright 2017 Elsevier. (b) Schematic representation of the structure of the bimetallic Ni-Re catalyst before (left) and after (right) reduction at 450 °C [95]. Copyright 2017 Elsevier. (c) Phenol adsorption onto the Ni (A) surface and (B) phenol adsorption onto the (Re)Ni (111) surface [95]. Copyright 2017 Elsevier. (d) The plausible reaction mechanism in the HDO of anisole on NixGa/SiO2 [96]. Copyright 2017 Elsevier. (e) The proposed mechanism of modification between aromatic selectivity, oxygen vacancies, and H2 absorption [97]. Copyright 2021 American Chemical Society.

The bimetallic NixGa/SiO2 catalysts were synthesized using the impregnation method followed by reduction at 550 °C and were evaluated for the vapor hydrodeoxygenation (HDO) of anisole at 0.1 MPa and 300 °C [96]. The results demonstrated that NixGa/SiO2 exhibited higher anisole conversion and benzene selectivity compared to the monometallic Ni/SiO2, while also showing lower selectivity for phenol. Specifically, at the same anisole conversion rate of 31%, the selectivities for benzene were 75.2%, 83.0%, and 92.6% for Ni/SiO2, Ni6Ga/SiO2, and Ni3Ga/SiO2, respectively.

The preferential cleavage of the CAr-O bond on the Ni-Ga alloy and the Ni3Ga intermetallic compound (IMC) results from the synergistic effects between adjacent Ni and Ga sites, as illustrated in Figure 7d. In the case of the Ni-Ga alloy and Ni3Ga IMC, the oxygen in anisole is more likely to be adsorbed at Ga sites, where Ga shows a stronger affinity for O compared to Ni, as inferred from H2 studies. This sequence of interactions ultimately leads to the cleavage of the CAr-O bond, allowing for the formation of benzene. In summary, the NixGa/SiO2 bimetallic catalyst achieved a higher benzene yield while significantly lowering hydrogen consumption, marking a crucial advancement for the rational design of future catalysts in biomass upgrading applications.

In an innovative approach, biochar-modified Hβ/Ni-V catalysts were developed and tested for the atmospheric hydrodeoxygenation (HDO) of guaiacol to produce benzene, toluene, and xylene (BTX) [97]. Among these, the catalyst modified with pine nut shell biochar (PB), specifically PB-Hβ-8/Ni-V, achieved the highest selectivity for benzene and toluene at 69.17%. This enhancement in selectivity was attributed to the synergistic effects between the biochar and the Hβ/Ni-V catalyst. The mechanism behind this improvement involves the formation of a stable carbon layer on the Hβ/Ni-V catalyst, created through a metal-catalyzed chemical vapor deposition process utilizing volatiles from pyrolyzed PB (as illustrated in Figure 7e). In addition to forming this carbon layer, the thermal reduction of the carbon effectively decorated the surface metal, increasing the availability of active sites, particularly Ni0 and V3+. This increase in Ni0 sites enhances the catalyst’s ability to adsorb and dissociate hydrogen, thereby boosting its hydrogenation activity.

Moreover, the presence of biochar enhances the affinity of the catalyst surface for reactants, along with creating more oxygen vacancies [98]. This combination contributes to the improved selective adsorption of oxygen-containing groups and facilitates the breaking of CAr-OH bonds, leading to enhanced deoxygenation activity [97]. Overall, the incorporation of biochar modifications significantly improved the HDO activity of the catalysts, resulting in a greater yield of BTX. The use of pyrolytic biochar also presents a promising and cost-effective alternative to traditional zeolite–metal catalysts, making it a viable option for sustainable biomass conversion strategies.

2.3.3. Re- and W-Based Bimetallic Catalysts

In addition to Ni- and Fe-based bimetallic catalysts, a variety of other bimetallic combinations, including Pd-Re, Re-Mo, Re-V, Ru-W, and Pt-Wu, have been developed and utilized for converting various phenolic compounds into benzene, toluene, and xylene (BTX) [99,100,101,102,103,104]. For instance, research conducted by Pouya et al. found that ZrO2 showed better catalytic performance compared to cerium dioxide, attributed to its higher acid density, which enhances catalytic activity. All the hydrogenated metals were effective in promoting the hydrogenation of carbonyl groups, leading to selective BTX production. Among the developed catalysts, PdReOx/ZrO2 exhibited the highest BTX yield of 77.2%. This high activity is partially due to the weak acid strength contributed by the zirconium oxide carrier and rhenium oxide, which prevents phenolic adsorption and trapping at lower temperatures [99].

In another study focusing on anisole HDO, bimetallic Re-MoOx/TiO2 and Re-VOx/TiO2 catalysts were evaluated under conditions of 300 °C and 3 MPa of H2 [101]. Re-based catalysts exhibited a unique ability to favor the production of aromatic compounds due to their oxygenophilic properties. When combined with Mo and V cations in lower oxidation states, the selectivity for desired aromatic products like benzene and toluene was significantly improved. This enhanced selectivity can be attributed to the stronger adsorption of anisole on the surface oxygen vacancy sites of MoOx or VOx. However, the extent of this improvement depended on the specific combination of Re with Mo or V, highlighting the synergistic interactions present between the Re and MoOx species in particular. The catalytic activity, measured in terms of the intrinsic reaction rate, was determined by the nature of the specific surface species present. For instance, in the Re-MoOx/TiO2 catalyst, the activity was primarily linked to the exposed Mo5+ sites, while in the Re-VOx/TiO2 catalyst, the activity was mainly influenced by the Re4+ sites [101]. This research underscores the critical importance of designing catalysts with specific active sites tailored for the formation of targeted products, facilitating more efficient pathways for the transformation of lignin-derived phenolic compounds into valuable aromatic products like BTX.

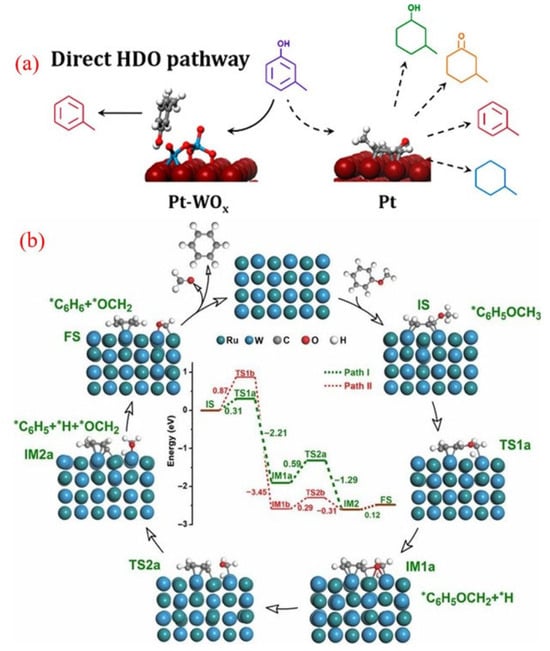

Bimetallic tungsten (W)-based catalysts have shown remarkable catalytic performance for hydrodeoxygenation (HDO). Notably, the Pt-WOx/C catalyst exhibited exceptional activity and selectivity for the HDO of m-cresol (Figure 8a) [103]. Under various reaction conditions, this catalyst achieved over 94% selectivity for the desired products and demonstrated high stability, showing resistance to deactivation from coking. In contrast, the Pt/C catalyst showed lower selectivity for toluene production during the HDO process of m-cresol.

Figure 8.

(a) The direct HDO of m-cresol over WOx-decorated Pt/C catalysts [103]. Copyright 2018 American Chemical Society. (b) The tentative reaction mechanism for the SSH reaction of anisole on a RuW/SiO2 catalyst [104]. Copyright 2019 Springer science.

Reactivity studies, along with density functional theory (DFT) calculations, revealed that the HDO reaction on the Pt-WOx/C catalyst occurs via the direct hydrogenolysis of the C-O bond in m-cresol, which is adsorbed onto the oxygen vacancy sites present on the WOx species. The interaction between Pt and the WOx complexes not only stabilizes the oxide but also reduces the energy barrier for the formation of oxygen vacancies. These vacancies are crucial for creating redox sites on WOx that actively participate in the direct C-O bond hydrogenolysis of adsorbed phenolics [103]. Moreover, the selective adsorption at these sites reduces the interaction of the aromatic ring with the Pt surface, thus minimizing the occurrence of side reactions.

Additionally, pioneering work by Meng and colleagues recently introduced a novel self-supported hydrogenolysis (SSH) process for converting aromatic ethers to BTX, utilizing hydrogen generated from the reactants themselves [104]. The RuW alloy nanoparticles served as efficient catalysts for these reactions. Notably, this method is unique because it eliminates the need for external hydrogen or other reducing agents and avoids the hydrogenation of the aromatic ring.

Mechanistic studies suggest that the adjacent Ru and W species in the RuW alloy nanoparticles work synergistically to enhance the SSH reaction. DFT studies (Figure 8b) identified two primary reaction pathways for the SSH of anisole with benzene: In path I, the aliphatic C-H (CAl-H) bond is first activated to produce a *C6H5OCH2 + *H intermediate (IM1a), followed by the hydrogenolysis of the CAr-O bond in *C6H5OCH2 to generate benzene and formaldehyde (path I, green dashed lines). Path II involves initial cleavage of the CAr-O bond to a *C6H5 + *OCH3 intermediate (IM1b), followed by the activation and dissociation of the CAl-H bond in *OCH3 to formaldehyde and benzene (Path II, red dashed line). This innovative, hydrogen-free, and efficient approach presents significant potential for producing functional chemicals from renewable biomass resources. The discovery of this method has opened avenues for exploring numerous other reactions and optimizing biomass conversion technologies.

Bimetallic catalysts enhance HDO performance through synergistic interactions between two metals, optimizing active-site configuration and reaction pathways. These systems balance activity, selectivity, and stability while reducing noble metal loading, but their complex synthesis and thermal management requirements pose challenges for industrial scaling.

2.4. Transition Metal-Based Catalysts

2.4.1. Metal Sulfide Catalysts

Transition metal sulfides represent classic catalysts widely researched for hydrogenation reactions, demonstrating superior activity compared to transition metal oxides. They are extensively utilized in the hydrogenation of petroleum and coal-based liquid fuels, offering seamless compatibility with large-scale industrial hydrogenation units and catalyst production facilities [2,105,106,107].

The cobalt molybdenum sulfur (CoMoS) catalyst system has made significant progress in expanding its application from traditional petroleum refining and hydrogenation desulfurization (HDS) to biomass catalytic deoxygenation [108,109]. The Bui team conducted the first systematic study on the carrier effect of a CoMoS catalyst in the guaiacol HDO reaction [110] and found that compared with the commonly used Al2O3 carrier in industry, the CoMoS system loaded with ZrO2 increased the benzene selectivity to 42%. Its superiority lies in the strong electronic interaction between the CoMoS active phase and the carrier. However, the CoMoS catalyst obtained by traditional preparation methods has bottleneck problems such as high-temperature sulfur loss and rapid deactivation [111].

In response to the above challenges, the Liu team innovatively developed a novel catalyst that anchors isolated Co atoms with single-layer MoS2 [111]. By using H2 high-temperature treatment to construct sulfur vacancy defects on the MoS2 substrate, Co atoms are covalently bonded with vacancies to form Co-S-Mo active sites, exhibiting excellent activity, selectivity, and stability without sulfur loss in the 4-methylphenol conversion reaction. This breakthrough provides a new paradigm for the design of highly stable sulfide catalysts for biomass HDO processes.

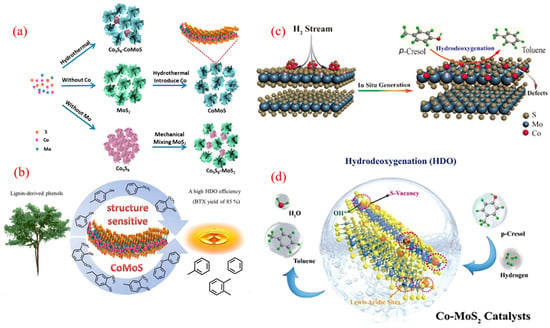

Song et al. demonstrated a surface atom engineering strategy that significantly enhanced the catalytic activity and selectivity of sulfide catalysts by achieving well-dispersed Co-doped MoS2 nanomaterials, maximizing the Co-Mo-S phase for efficient phenolic conversion to BTX (Figure 9a) [112]. Their self-induced method optimally modulates Co-substituted S sites, allowing Co atoms to bond well to the upper surface of the MoS2 nanosheets while preserving their structure. The characterization results showed a high density of Co-Mo-S phases on the catalyst’s surface, contributing to accelerated HDO reactions. As a result, using the engineered CoMoS catalyst led to the effective conversion of mixed phenols to BTX, achieving high yields exceeding 85% (Figure 9b). These findings may inspire further surface engineering of transition metal-doped catalytic nanomaterials.

Liu’s group utilized zeolitic imidazolate framework-67 as a cobalt precursor and template, employing a simple hydrothermal method to create CoMoS catalysts by depositing MoS2 ultrathin sheets inside the framework [113]. The optimized CoMoS-0.18 catalyst achieved a 92.4% conversion of cresol and a 95.5% selectivity for toluene at 250 °C. This high performance was linked to the development of accessible surface CoMoS phases. Additionally, H2 preactivation facilitated the creation of sulfur vacancies in MoS2, enhancing CoMoS interfaces through surface recombination. As illustrated in Figure 9c, the in situ generation of the CoMoS phase highlights the importance of H2 preactivation in boosting HDO activity. Both showed improved p-cresol conversion and toluene selectivity after H2 pre-reduction, suggesting a significant enhancement of the HDO pathway’s activity.

In another approach, Zhang and colleagues introduced a straightforward H2O2 etching method to modify the concentration of acidic sites on the CoMoS catalyst surface (Figure 9d) [114]. By adjusting the stoichiometric ratio of H2O2 to MoS2, the researchers optimized sulfur defects on the MoS2 surface, thereby stabilizing cobalt species. This process culminated in the formation of active CoMoS catalytic sites. The optimized Co-MoS2-2 catalyst exhibited the highest density of acidic sites, which translated into a 3.4-fold enhancement in catalytic activity for the hydrodeoxygenation (HDO) of toluene derived from p-cresol, compared to the baseline Co-MoS2 sample. Furthermore, a direct correlation was observed between the HDO activity and the surface acid content (encompassing both Lewis and Brønsted acidity) within the Co-MoS2 catalysts. This relationship is crucial for effectively cleaving C-O bonds, highlighting the importance of surface acidity in determining catalytic performance. Overall, enhancing surface acidic sites represents a promising strategy for designing more efficient catalytic systems.

Figure 9.

(a) Surface engineering of the CoMoS catalyst for the conversion of the phenolic HDO to the product BTX; (b) synthesis diagram of cobalt-doped MoS2 nanohybrids [112]. Copyright 2019 American Chemical Society. (c) Illustration of the hydrogen-flow-induced in situ formation of active CoMoS sites for the selective HDO of p-cresol to toluene [104]. Copyright 2020 American Chemical Society. (d) Tailoring of surface acidic sites in Co-MoS2 catalysts for the HDO of p-cresol to toluene [114]. Copyright 2021 American Chemical Society.

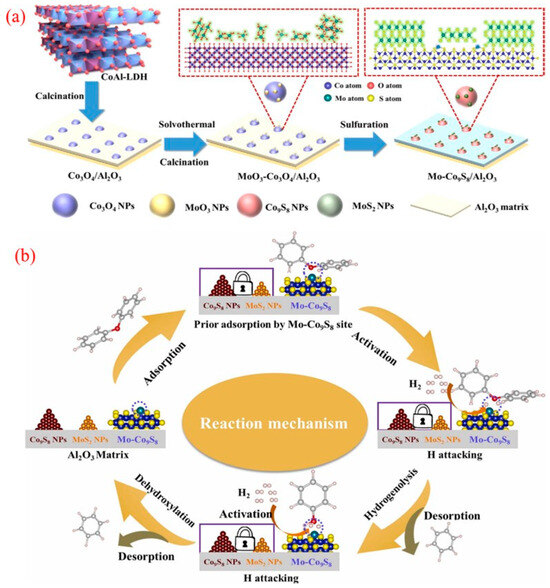

A robust catalyst composed of Mo-doped Co9S8 nanoparticles supported on an Al2O3 matrix was successfully developed through a simple method using CoAl-hydrotalcite as a precursor. This multifunctional Mo-Co9S8/Al2O3 catalyst demonstrates exceptional hydrodeoxygenation (HDO) activity and selectivity in converting lignin to benzene, as illustrated in Figure 10a [115]. The catalyst facilitates the electron transfer from the Co to Mo sites within the Mo-Co9S8 structure, enabling the effective adsorption of oxidized compounds and contributing to its outstanding HDO performance. Notably, during the HDO of diphenyl ethers (DPEs), the catalyst achieved an impressive 99.8% conversion and a 91% yield of benzene, maintaining stability over at least 10 reaction cycles at 265 °C. The Mo-Co9S8 structure forms the covalent Mo-S-Co bonds on the Co9S8 surface, enhancing its ability to adsorb and activate oxygen-containing substrates. This feature promotes the efficient cleavage of C-O bonds while minimizing the unwanted hydrogenation of benzene rings, further highlighting its catalytic efficiency and selectivity.

Figure 10.

(a) Schematic illustration of the preparation of the Mo-Co9S8/Al2O3 catalyst; (b) illustration on the catalytic mechanism of the DPE HDO reaction over the eMo-Co9S8 site [115]. Copyright 2022 Elsevier.

The proposed catalytic mechanism for HDO over Mo-Co9S8/Al2O3, as depicted in Figure 10b, involves several critical steps. Initially, the negatively charged carbonyl oxygen in DPEs is adsorbed by the unsaturated Mo sites on the catalyst surface, which weakens the C-O bond. The electron transfer from Co to Mo enhances hydrogen dissociation activity, enabling dissociated hydrogen species at the Mo-Co9S8 site to attack the C-O group. This results in the effective cleavage of the 4-O-5 bond, ultimately producing phenol and benzene [116]. Subsequently, phenol undergoes a similar adsorption and activation process to convert into benzene through deoxygenation. This strategy highlights an innovative approach for rationally designing efficient and stable sulfide catalysts suitable for high-temperature reactions.

In addition to cobalt, nickel (Ni) serves as another promoter in sulfide catalysts primarily to enhance activity, although it often negatively affects aromatic selectivity [117,118]. Wang and colleagues explored the effectiveness of NiMoS2 catalysts in the hydrodeoxygenation (HDO) of cresol and found that adding Ni increases the catalyst’s activity [106]. However, they observed a decline in the selectivity for toluene as the Ni content increased. To further investigate, the authors synthesized NiSx using a microwave-assisted hydrothermal method, which was then mixed with MoS2 to promote cresol HDO at 300 °C and 40 bar [119]. The results indicated that the combination of NiSx with MoS2 improved conversion rates but did not alter product distribution. Comparisons between Ni-Mo-S, NiSx/MoS2, and physically mixed NiSx + MoS2 suggested that synergies between NiSx and MoS2—beyond merely forming a Ni-Mo-S phase—were key to enhancing activity [106].

The researchers proposed a remote-control model to explain their findings: cresols predominantly adsorb on MoS2 sites and are subsequently transferred to MoS2, where they react with hydrogen atoms that are dissociated on NiSx sites. This interaction highlights the importance of using NiSx in conjunction with MoS2 to optimize performance in cresol HDO reactions, balancing high activity with product selectivity [107,109,120].

2.4.2. Transition Metal Phosphides

Transition metal phosphides, such as molybdenum phosphide (MoP), have emerged as highly effective catalysts for the hydrodeoxygenation (HDO) of phenolic compounds. MoP has demonstrated superior performance compared to its sulfide and oxide counterparts, exhibiting higher catalytic activity, lower activation energy, and greater selectivity towards aromatic compounds in the HDO conversion of p-cresols [121]. The enhanced catalytic performance of MoP is primarily attributed to the increased electron density of molybdenum in its phosphide form. This higher electron density around the molybdenum center likely enhances its nucleophilic properties, which can improve the catalyst’s ability to bind reactants and facilitate bond cleavage. Consequently, this leads to faster reaction kinetics and a lower activation energy, making the catalytic process more efficient.

According to molecular orbital theory, the lowest unoccupied molecular orbital (LUMO) of the C-O bond is antibonding, meaning that electrons donated from the catalyst to this orbital can facilitate C-O bond dissociation. Consequently, MoP, possessing the highest electron density among the catalysts studied, shows the strongest activity [122]. In experiments, MoP achieved a toluene selectivity of 60% and a conversion of 58% at 623 K and 4.4 MPa. To improve the selectivity for benzene in BTX production, Rensel and colleagues incorporated oxophilic iron (Fe) into the MoP catalyst, resulting in the bimetallic FeMoP catalyst. This bimetallic formulation produced benzene with up to 90% selectivity during the conversion of phenol at 673 K and 2.1 MPa of hydrogen [123]. Similarly, the conversion of anisole using the FeMoP catalyst also reached 90% selectivity for benzene. Further investigations of the FeMoP catalysts revealed the presence of two distinct metal sites: the metal site itself and a coordination unsaturation site (CUS) [124]. The CUS site likely arises from Moδ+ species on the catalyst surface and is proposed to act as the active site for binding the hydroxyl group in phenol, destabilizing the Caryl-O bond. This bond is subsequently cleaved by hydrogen dissociated from the metal site, enhancing the overall HDO activity and selectivity of the catalyst [125].

A series of phosphide catalysts, including MoP, Fe2P, Co2P, WP, and Ni2P, have been utilized for the hydrodeoxygenation (HDO) of phenolics into BTX [126,127,128]. Among these, Ni2P-based catalysts demonstrated superior conversion of phenolics and higher selectivity for BTX, attributed to their desirable stability and deoxygenation capabilities [34]. The Ni2P/SiO2 catalyst achieved the highest turnover frequency and a benzene selectivity of 60%. Kinetic studies revealed an apparent activation energy of 40 kJ/mol for Ni2P/SiO2, lower than the activation energy for direct C-O bond cleavage. This suggests that increased benzene production is primarily due to the hydrogenation of the C=C double bond in the aromatic ring, followed by dehydration.

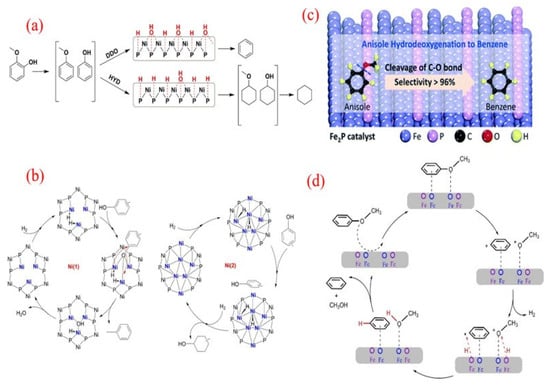

Further investigation into the HDO properties of Ni2P/SiO2 with guaiacol under varying reaction conditions showed that the reaction pressure significantly influenced the reaction pathways and product distribution [129]. At 1 bar and 300 °C, the direct deoxygenation (DDO) pathway to benzene was favored, achieving 62% selectivity. Conversely, at 8 bar, the prehydrogenation (HYD) pathway led to cyclohexane as the major product, resulting in only 8% benzene selectivity (Figure 11a). This finding aligns with previous studies where cyclohexane was the primary O-free product in the HDO of anisole, emphasizing that low temperatures and higher pressures favor ring saturation [130]. X-ray Absorption Fine Structure (XAFS) measurements and density functional theory (DFT) calculations indicated that both the atomic hydrogen (H) and hydroxyl (OH) groups could adsorb on the unsaturated triple hollow (TFH) Ni sites. These results suggest that the DDO pathway is facilitated by surface OH groups, whereas the HYD pathway is promoted by more reduced surfaces. Consequently, the selectivity for BTX products can be modulated by adjusting the balance of H and OH groups on the catalyst surface.

Additionally, variations in product distribution may also result from different active sites on the Ni2P phases and their adsorption behaviors [131,132]. Ni2P crystals, characterized by a rhombohedral structure, comprise two types of nickel sites: Ni(1) and Ni(2) [133]. The Ni(1) site, with a sub-tetrahedral structure terminated by Ni3P2, serves as an active site for H2 dissociation and can adsorb phenolic molecules through the oxygen atom of the C-OH bond [132]. After a nucleophilic attack by hydride species, the adsorbed C-OH bonds are cleaved, forming aromatic products (Figure 11b). In contrast, the Ni(2) site may facilitate the flat adsorption of phenolic substrates, promoting hydrogenation of the aromatic rings.

In recent years, Lan and colleagues have further studied the performance of the Ni2P/SiO2 catalyst in HDO reaction, specifically investigating the removal of cinnamic acid and cresol by the catalyst under 300 °C and 1-bar conditions [134]. The results are encouraging, as it was found that the selectivity of cinnamic acid and cresol for the oxidation of benzene reached 86% and 81%, respectively. However, as the reaction time prolongs, the selectivity of benzene gradually decreases, while the selectivity of phenol significantly increases. This change is closely related to the changes in the surface properties of the catalyst. Specifically, the content of Niδ+ and Ni0 on the catalyst surface increases, while the P/Ni ratio decreases. Research suggests that Niδ+, as a Lewis acid site, tends to catalyze demethylation reactions rather than demethoxylation reactions, while Ni0 only exhibits low levels of dehydroxylation activity. In addition, the decrease in the P/Ni ratio reduces the number of Brønsted acid sites, thereby inhibiting the dehydroxylation reaction. These changes resulted in a transition from a phosphorus-rich environment on the catalyst surface to a nickel-rich environment, causing the HDO product of cinnamic acid to change from benzene to phenol.

Figure 11.

(a) The proposed reaction routes of the HDO of guaiacol over the Ni2P catalyst [129]. Copyright 2014 Elsevier. (b) Different Ni sites on Ni2P for the deoxygenation of cresol [132]. Copyright 2017 Elsevier. (c) The HDO of anisole to benzene over the Fe2P catalyst; (d) the possible reaction route of anisole HDO over Fe2P [135]. Copyright 2020 Royal Society of Chemistry.

In addition to the Ni2P catalyst, the Fe2P single-metal catalyst also exhibits high selectivity for cresol in HDO reactions [135]. At 200 °C and atmospheric hydrogen conditions, Fe2P can convert cresol to benzene, ultimately achieving a benzene yield of 96% (Figure 11c). It is worth noting that even when the conversion rate is increased to 97.3%, the high selectivity of benzene remains unchanged, indicating that Fe2P has unique advantages in Caryl-O bond cleavage. In-depth DFT calculations support this observation, indicating that the oxygen atoms in cresol form a stable conformation with the Fe atoms on the Fe2P surface, making the breaking of Caryl-OCH3 bonds thermodynamically more favorable (Figure 11d). The calculation results show that compared with other possible cleavage pathways, the adsorption energy for Caryl-OCH3 bond cleavage is higher, at −2.9 eV. This further confirms the superiority of Fe2P in promoting specific bond cleavage.

The specific mechanism of the reaction can be summarized as follows: the phenol molecule first adsorbs on the Fe2P surface, and the benzene ring and oxygen atoms form coordinated bonds with the Fe sites on the surface. Subsequently, the Caryl-O bond is broken, resulting in the formation of C6H5* and CH3O* intermediates. These intermediates further bind with hydrogen atoms dissociated from adjacent Fe sites, ultimately forming benzene. This study not only deepens the understanding of iron-based phosphide catalysts but also broadens the application scope of transition metal phosphides in HDO reactions, providing new ideas for future catalyst designs.

Transition metal phosphide catalysts, such as nickel phosphide (Ni2P) and molybdenum phosphide (MoP), have shown remarkable potential in the hydrodeoxygenation (HDO) of phenolic compounds [59,136]. Their superior catalytic activity and selectivity compared to traditional catalysts can be attributed to their unique electronic properties. Moreover, these phosphide catalysts demonstrate higher selectivity towards aromatic compounds, likely due to their ability to stabilize specific intermediates and provide active sites that favor aromatic product formation [137]. However, their poor stability and tendency to deactivate in aqueous environments pose significant challenges for industrial applications.

2.4.3. Transition Metal Carbides, Nitrides

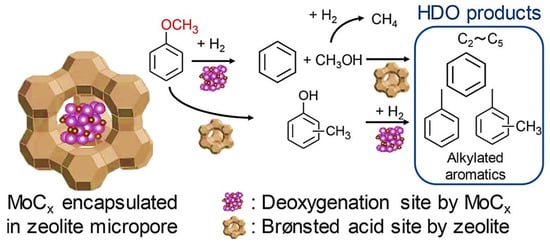

Transition metal carbonitrides exhibit noble metal-like catalytic behavior in the field of directed deoxygenation of phenolic compounds due to their unique electronic structural properties [138,139]. In this type of material, the insertion of carbon/nitrogen atoms into the metal lattice triggers a d-band contraction effect, resulting in an increase in the metal bond length and an increase in the surface electron density, thereby optimizing the C-O bond activation ability [140]. Although the selective regulation law of BTX in this system has not been fully elucidated, the groundbreaking work of Lee’s team has confirmed that the Mo2C catalyst can achieve the efficient conversion of benzyl ether under normal temperature and pressure conditions, with BTX selectivity exceeding 90% [141]. Its superiority lies in the selective passivation of hydrogenation sites by oxygen-containing intermediates generated in situ, which has been further validated in the guaiacol conversion system (benzene selectivity >90%) [142].

Reaction pathway analysis reveals that the lower dissociation energy of the Caryl-OCH3 bond compared to Caryl-OH promotes the preferential removal of methoxy groups [142]. Synchronous characterization confirmed that phenolic compounds form strong electronic coupling with the Mo2C surface through Caryl-O bonds, and this specific adsorption configuration promotes weaker CarylO-CH3 bonds to preferentially break over C-OH bonds. In addition, methanol/water titration experiments showed that the dynamic modification of surface-oxygen-containing species can inhibit aromatic ring hydrogenation activity, increasing aromatic selectivity [122].

In recent years, in-depth research has been conducted on the surface chemical properties of Mo2C catalysts in HDO reactions, especially when using the operating state NAP-XPS technology [143]. It was found that the Mo3+ phase on the surface of Mo2C is dominant, and there is also a small amount of high-valence molybdenum ions (Mo5+ and Mo6+) on the surface. It is worth noting that even in the presence of oxygenated compound feeds, the oxidation state and oxygen coverage of molybdenum remain constant throughout the entire reaction process. Meanwhile, the dominant position of Mo2+ and the slight changes in its high-valence-state molybdenum ions (Mo5+/Mo6+) indicate that the carbonyl phase is the main active site of Mo2C in the HDO reaction.

In this regard, Wang et al. further investigated the performance of a Mo2C-MoCxOy composite catalyst on activated carbon for the HDO reaction of meta-methylphenol [144]. At a 623 K and 4.3 MPa H2 pressure, the catalyst can selectively generate toluene with 75% selectivity. Through detailed study of kinetics, it was found that catalysts with different Mo2C-MoCxOy ratios exhibit consistent apparent activation energies on the direct oxidation and hydrogenation reaction pathways. This indicates that the active sites of the catalyst are determined by their own state and may be related to the adsorption or exchange of oxygen on the catalyst surface. From this, it can be inferred that both the Mo2C and MoCxOy phases may promote the oxidation reaction.