A Brief Review of Recent Theoretical Advances in Fe-Based Catalysts for CO2 Hydrogenation

Abstract

1. Introduction

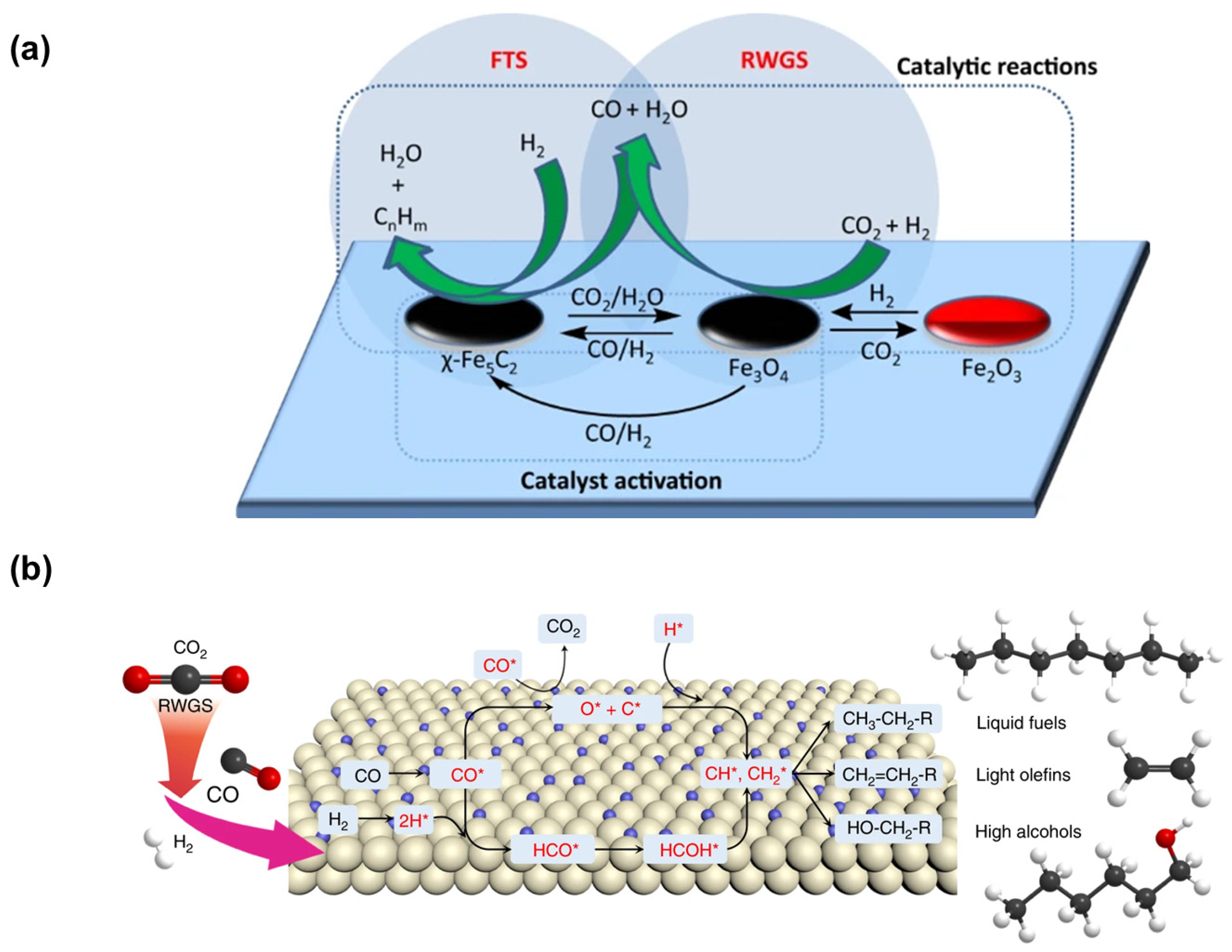

2. Related Reactions and Computational Methods

3. Modelling Fe-Based Catalyst Surfaces

3.1. Iron-Based Catalysts

3.1.1. Metallic Irons

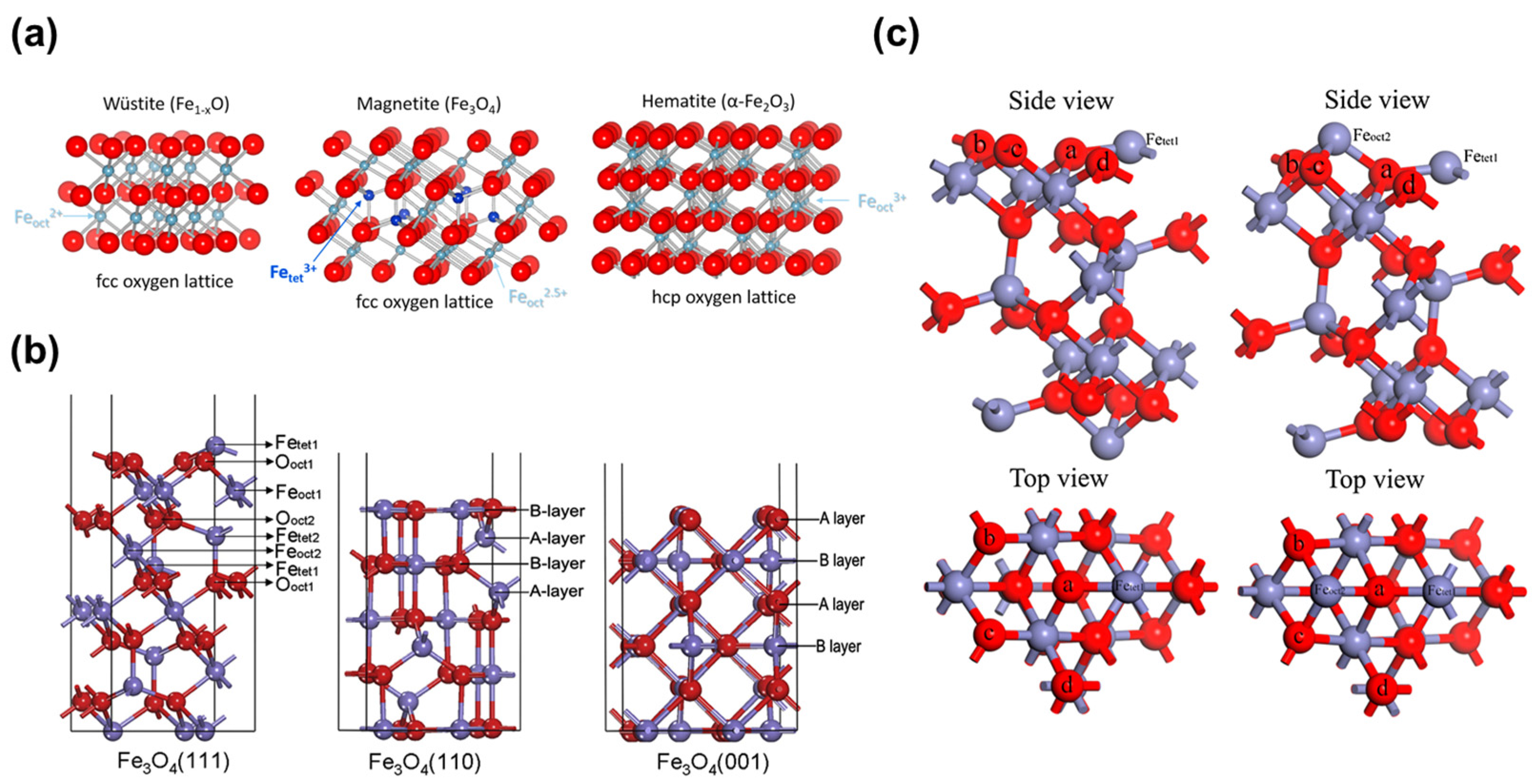

3.1.2. Iron Oxides

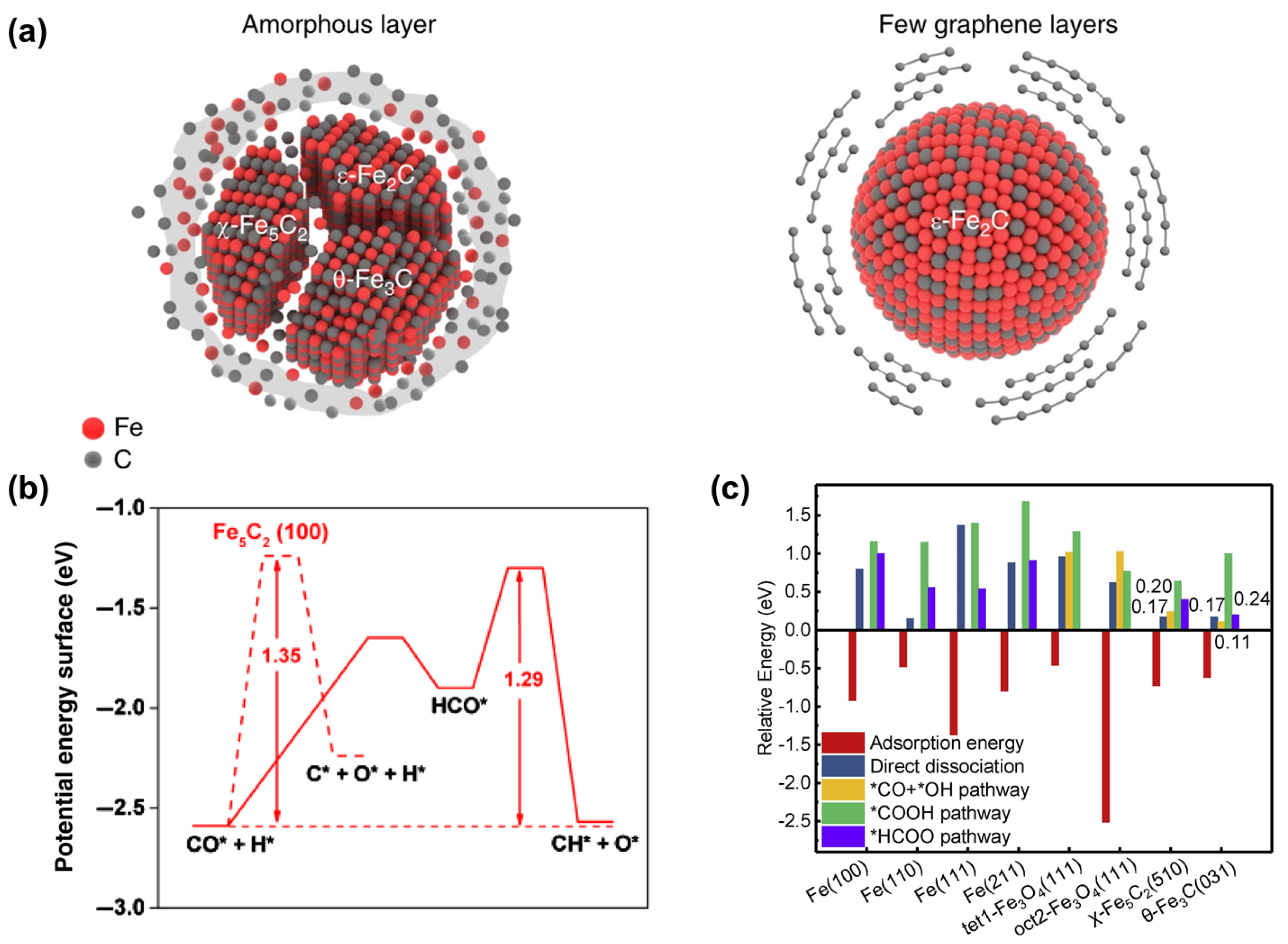

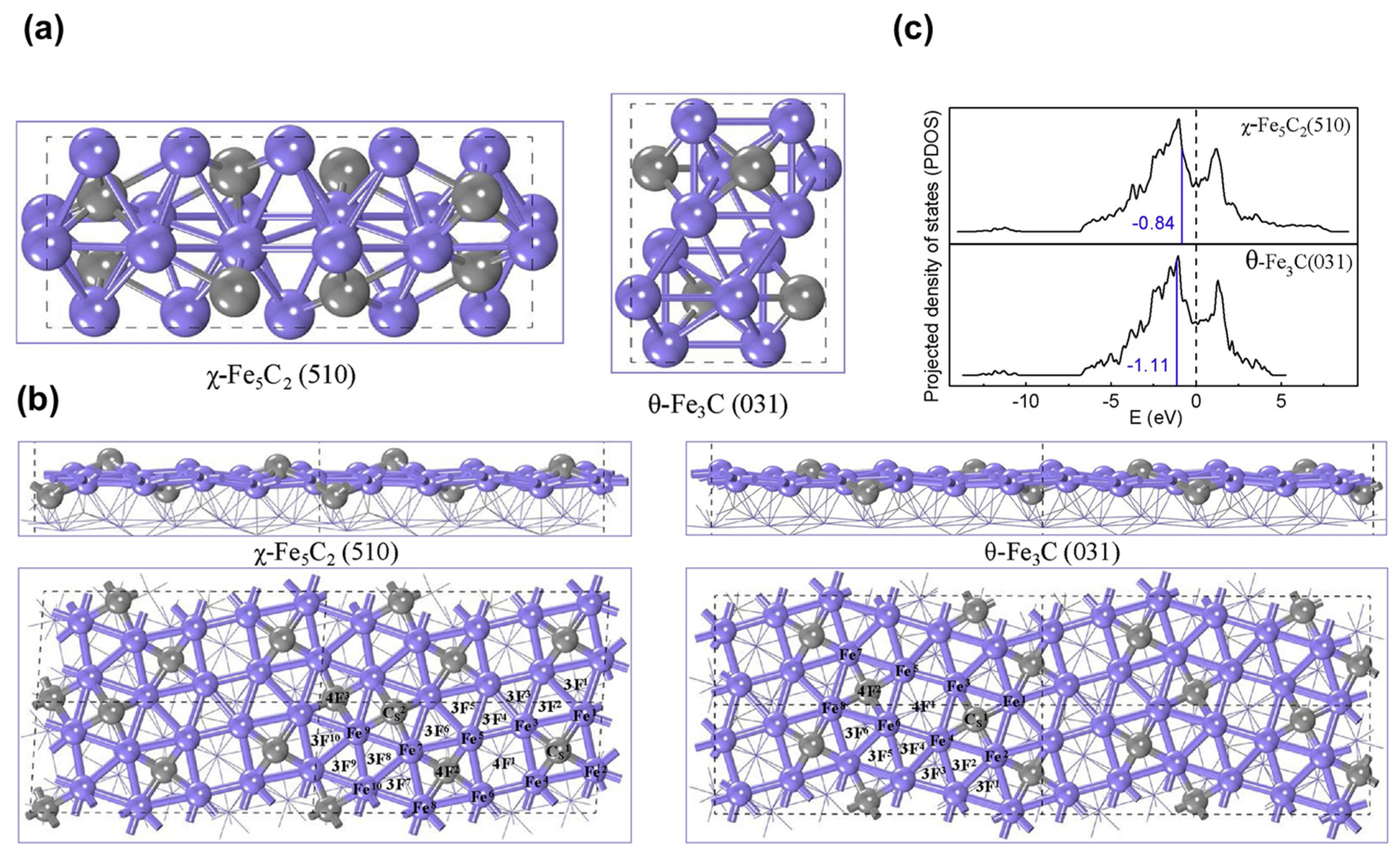

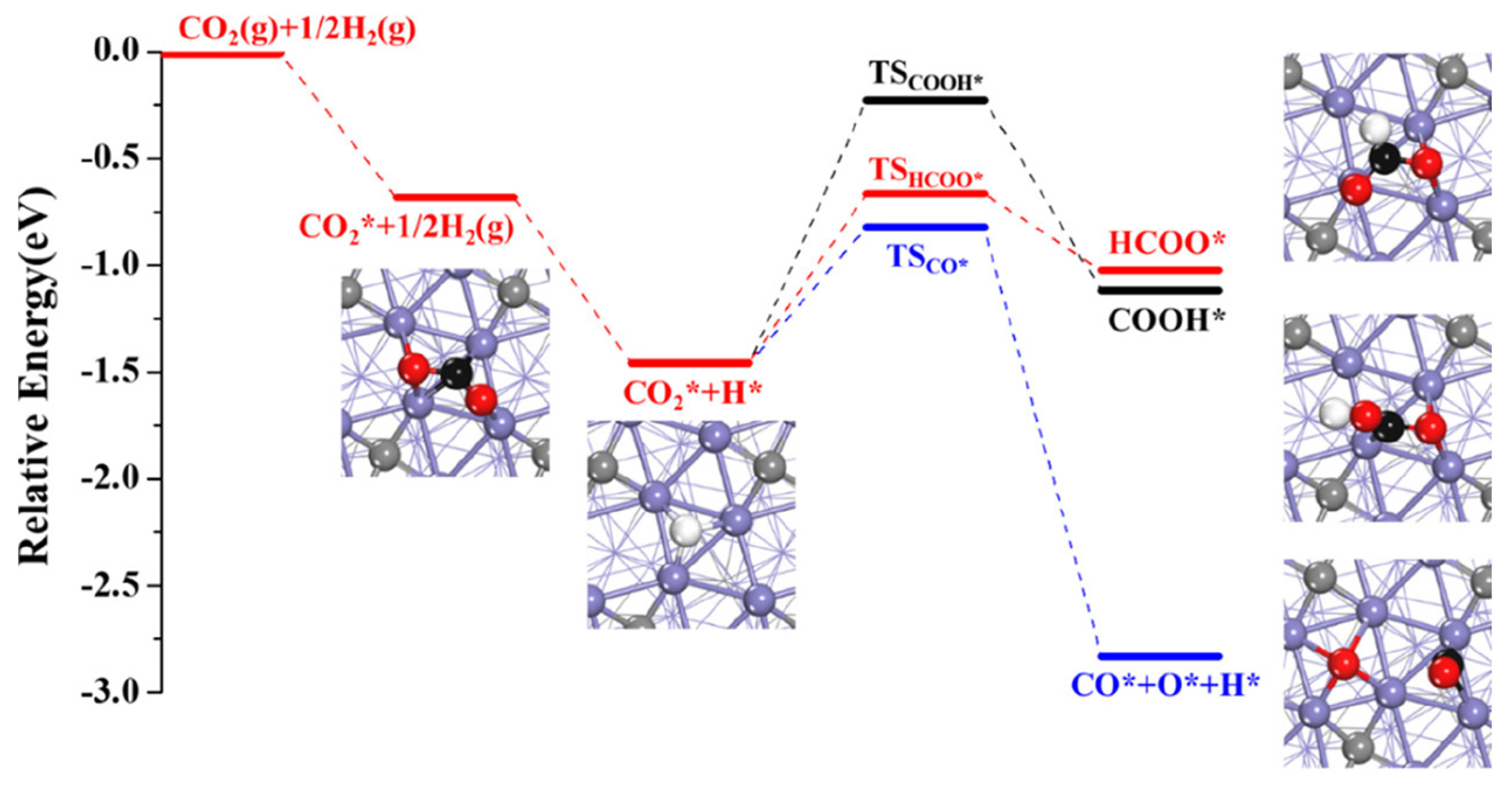

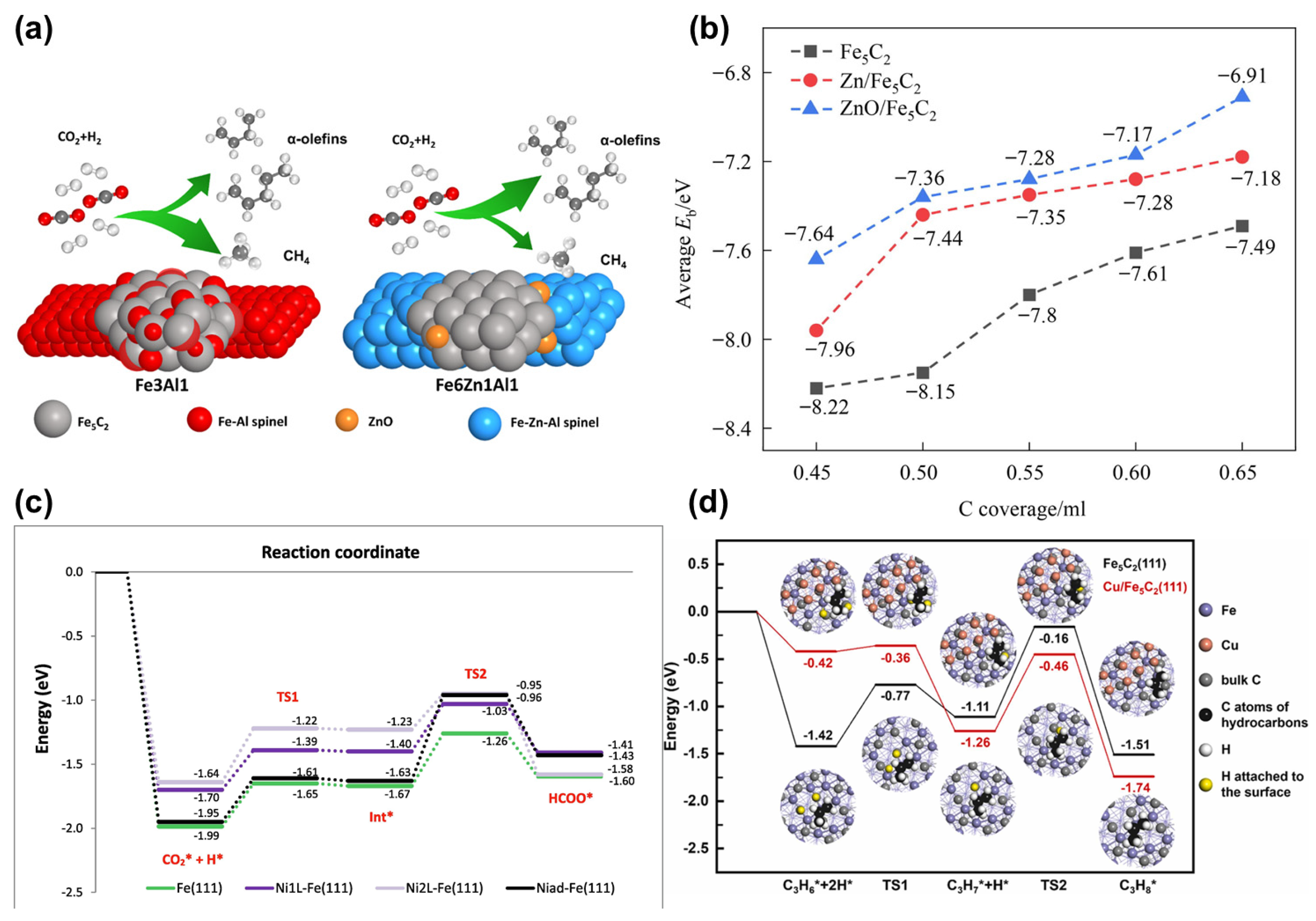

3.1.3. Iron Carbides

3.2. Promoters

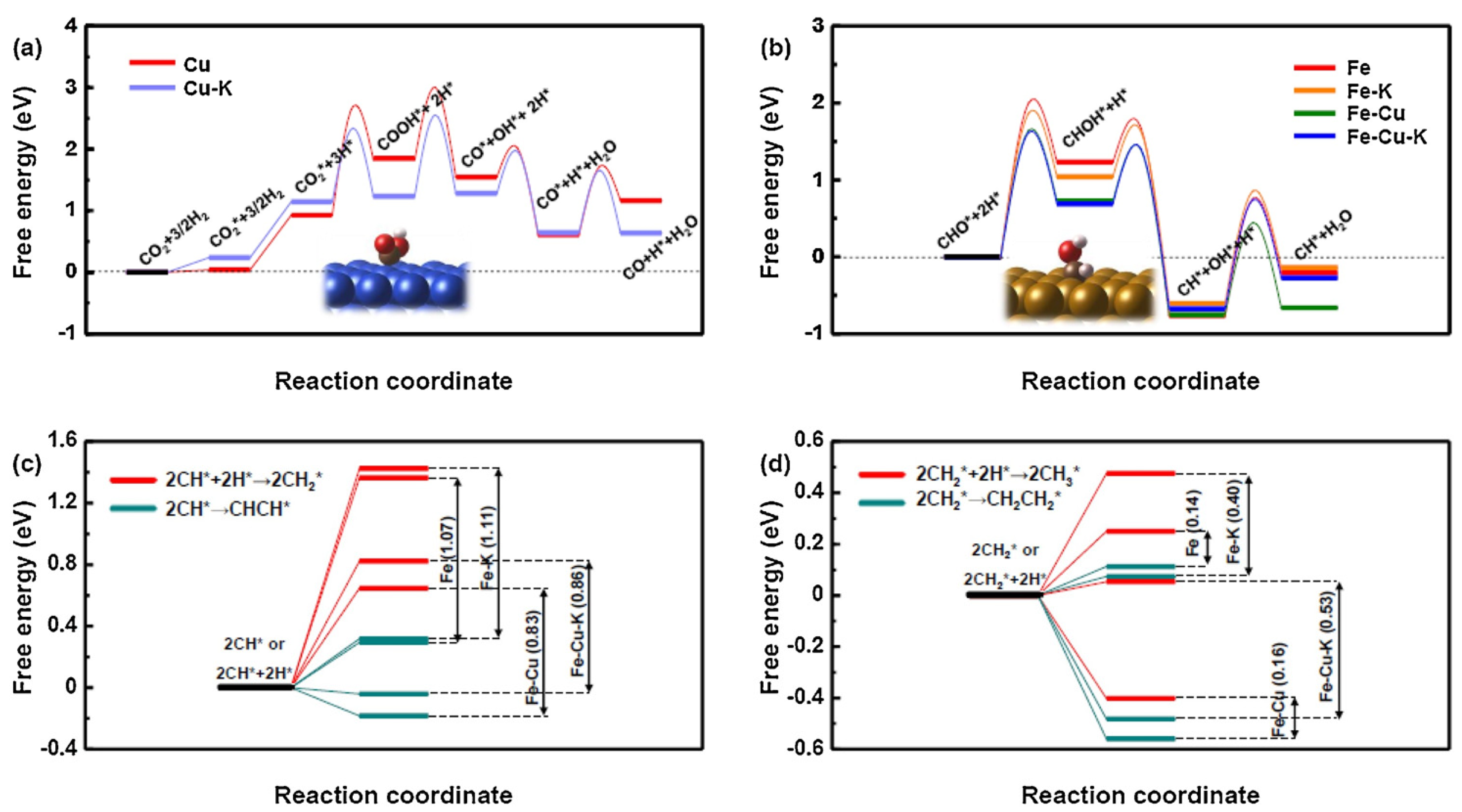

3.2.1. Alkali Metals

3.2.2. Transition Metals

3.2.3. Synergistic Effect

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Goeppert, A.; Czaun, M.; Jones, J.-P.; Surya Prakash, G.K.; Olah, G.A. Recycling of carbon dioxide to methanol and derived products–closing the loop. Chem. Soc. Rev. 2014, 43, 7995–8048. [Google Scholar] [CrossRef]

- Snoeckx, R.; Bogaerts, A. Plasma technology—A novel solution for CO2 conversion? Chem. Soc. Rev. 2017, 46, 5805–5863. [Google Scholar] [CrossRef]

- Nazir, G.; Rehman, A.; Hussain, S.; Mahmood, Q.; Fteiti, M.; Heo, K.; Ikram, M.; Aizaz Ud Din, M. Towards a sustainable conversion of biomass/biowaste to porous carbons for CO2 adsorption: Recent advances, current challenges, and future directions. Green Chem. 2023, 25, 4941–4980. [Google Scholar] [CrossRef]

- Kätelhön, A.; Meys, R.; Deutz, S.; Suh, S.; Bardow, A. Climate change mitigation potential of carbon capture and utilization in the chemical industry. Proc. Natl. Acad. Sci. USA 2019, 116, 11187–11194. [Google Scholar] [CrossRef]

- de Kleijne, K.; Hanssen, S.V.; van Dinteren, L.; Huijbregts, M.A.J.; van Zelm, R.; de Coninck, H. Limits to Paris compatibility of CO2 capture and utilization. One Earth 2022, 5, 168–185. [Google Scholar] [CrossRef]

- Choi, Y.H.; Jang, Y.J.; Park, H.; Kim, W.Y.; Lee, Y.H.; Choi, S.H.; Lee, J.S. Carbon dioxide Fischer-Tropsch synthesis: A new path to carbon-neutral fuels. Appl. Catal. B 2017, 202, 605–610. [Google Scholar] [CrossRef]

- Ra, E.C.; Kim, K.Y.; Kim, E.H.; Lee, H.; An, K.; Lee, J.S. Recycling Carbon Dioxide through Catalytic Hydrogenation: Recent Key Developments and Perspectives. ACS Catal. 2020, 10, 11318–11345. [Google Scholar] [CrossRef]

- Atsbha, T.A.; Yoon, T.; Seongho, P.; Lee, C.-J. A review on the catalytic conversion of CO2 using H2 for synthesis of CO, methanol, and hydrocarbons. J. CO2 Util. 2021, 44, 101413. [Google Scholar] [CrossRef]

- Hepburn, C.; Adlen, E.; Beddington, J.; Carter, E.A.; Fuss, S.; Mac Dowell, N.; Minx, J.C.; Smith, P.; Williams, C.K. The technological and economic prospects for CO2 utilization and removal. Nature 2019, 575, 87–97. [Google Scholar] [CrossRef] [PubMed]

- Krevor, S.; de Coninck, H.; Gasda, S.E.; Ghaleigh, N.S.; de Gooyert, V.; Hajibeygi, H.; Juanes, R.; Neufeld, J.; Roberts, J.J.; Swennenhuis, F. Subsurface carbon dioxide and hydrogen storage for a sustainable energy future. Nat. Rev. Earth Environ. 2023, 4, 102–118. [Google Scholar] [CrossRef]

- Kamkeng, A.D.N.; Wang, M.; Hu, J.; Du, W.; Qian, F. Transformation technologies for CO2 utilisation: Current status, challenges and future prospects. Chem. Eng. J. 2021, 409, 128138. [Google Scholar] [CrossRef]

- Pahija, E.; Panaritis, C.; Gusarov, S.; Shadbahr, J.; Bensebaa, F.; Patience, G.; Boffito, D.C. Experimental and Computational Synergistic Design of Cu and Fe Catalysts for the Reverse Water–Gas Shift: A Review. ACS Catal. 2022, 12, 6887–6905. [Google Scholar] [CrossRef]

- Amoyal, M.; Vidruk-Nehemya, R.; Landau, M.V.; Herskowitz, M. Effect of potassium on the active phases of Fe catalysts for carbon dioxide conversion to liquid fuels through hydrogenation. J. Catal. 2017, 348, 29–39. [Google Scholar] [CrossRef]

- Wang, X.; Yang, G.; Zhang, J.; Chen, S.; Wu, Y.; Zhang, Q.; Wang, J.; Han, Y.; Tan, Y. Synthesis of isoalkanes over a core (Fe–Zn–Zr)–shell (zeolite) catalyst by CO2 hydrogenation. Chem. Comm. 2016, 52, 7352–7355. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Seo, J.-C.; Chun, H.-J.; Yang, S.; Sim, E.-h.; Lee, J.; Kim, Y.T. Selective olefin production on silica based iron catalysts in Fischer–Tropsch synthesis. Catal. Sci. Technol. 2022, 12, 5814–5828. [Google Scholar] [CrossRef]

- Samanta, A.; Landau, M.V.; Vidruk-Nehemya, R.; Herskowitz, M. CO2 hydrogenation to higher hydrocarbons on K/Fe–Al–O spinel catalysts promoted with Si, Ti, Zr, Hf, Mn and Ce. Catal. Sci. Technol. 2017, 7, 4048–4063. [Google Scholar] [CrossRef]

- Zhu, M.; Wachs, I.E. Iron-Based Catalysts for the High-Temperature Water–Gas Shift (HT-WGS) Reaction: A Review. ACS Catal. 2016, 6, 722–732. [Google Scholar] [CrossRef]

- Theofanidis, S.A.; Kasun Kalhara Gunasooriya, G.T.; Itskou, I.; Tasioula, M.; Lemonidou, A.A. On-purpose Ethylene Production via CO2-assisted Ethane Oxidative Dehydrogenation: Selectivity Control of Iron Oxide Catalysts. ChemCatChem 2022, 14, e202200032. [Google Scholar] [CrossRef]

- Nie, X.; Meng, L.; Wang, H.; Chen, Y.; Guo, X.; Song, C. DFT insight into the effect of potassium on the adsorption, activation and dissociation of CO2 over Fe-based catalysts. Phys. Chem. Chem. Phys. 2018, 20, 14694–14707. [Google Scholar] [CrossRef]

- Claeys, M.; van Steen, E.; Botha, T.; Crous, R.; Ferreira, A.; Harilal, A.; Moodley, D.J.; Moodley, P.; du Plessis, E.; Visagie, J.L. Oxidation of Hägg Carbide during High-Temperature Fischer–Tropsch Synthesis: Size-Dependent Thermodynamics and In Situ Observations. ACS Catal. 2021, 11, 13866–13879. [Google Scholar] [CrossRef]

- Liu, X.; Xu, M.; Cao, C.; Yang, Z.; Xu, J. Effects of zinc on χ-Fe5C2 for carbon dioxide hydrogenation to olefins: Insights from experimental and density function theory calculations. Chin. J. Chem. Eng. 2023, 54, 206–214. [Google Scholar] [CrossRef]

- Saeidi, S.; Najari, S.; Hessel, V.; Wilson, K.; Keil, F.J.; Concepción, P.; Suib, S.L.; Rodrigues, A.E. Recent advances in CO2 hydrogenation to value-added products—Current challenges and future directions. Prog. Energy Combust. Sci. 2021, 85, 100905. [Google Scholar] [CrossRef]

- Liu, W.; Cheng, S.; Malhi, H.S.; Gao, X.; Zhang, Z.; Tu, W. Hydrogenation of CO2 to Olefins over Iron-Based Catalysts: A Review. Catalysts 2022, 12, 1432. [Google Scholar] [CrossRef]

- Xu, Y.; Zhai, P.; Deng, Y.; Xie, J.; Liu, X.; Wang, S.; Ma, D. Highly Selective Olefin Production from CO2 Hydrogenation on Iron Catalysts: A Subtle Synergy between Manganese and Sodium Additives. Angew. Chem. Int. Ed. 2020, 59, 21736–21744. [Google Scholar] [CrossRef]

- Han, Y.; Fang, C.; Ji, X.; Wei, J.; Ge, Q.; Sun, J. Interfacing with Carbonaceous Potassium Promoters Boosts Catalytic CO2 Hydrogenation of Iron. ACS Catal. 2020, 10, 12098–12108. [Google Scholar] [CrossRef]

- Gnanamani, M.K.; Hamdeh, H.H.; Shafer, W.D.; Hopps, S.D.; Davis, B.H. Hydrogenation of carbon dioxide over iron carbide prepared from alkali metal promoted iron oxalate. Appl. Catal. A 2018, 564, 243–249. [Google Scholar] [CrossRef]

- Chaipraditgul, N.; Numpilai, T.; Kui Cheng, C.; Siri-Nguan, N.; Sornchamni, T.; Wattanakit, C.; Limtrakul, J.; Witoon, T. Tuning interaction of surface-adsorbed species over Fe/K-Al2O3 modified with transition metals (Cu, Mn, V, Zn or Co) on light olefins production from CO2 hydrogenation. Fuel 2021, 283, 119248. [Google Scholar] [CrossRef]

- Kim, K.Y.; Lee, H.; Noh, W.Y.; Shin, J.; Han, S.J.; Kim, S.K.; An, K.; Lee, J.S. Cobalt Ferrite Nanoparticles to Form a Catalytic Co–Fe Alloy Carbide Phase for Selective CO2 Hydrogenation to Light Olefins. ACS Catal. 2020, 10, 8660–8671. [Google Scholar] [CrossRef]

- Barrios, A.J.; Peron, D.V.; Chakkingal, A.; Dugulan, A.I.; Moldovan, S.; Nakouri, K.; Thuriot-Roukos, J.; Wojcieszak, R.; Thybaut, J.W.; Virginie, M.; et al. Efficient Promoters and Reaction Paths in the CO2 Hydrogenation to Light Olefins over Zirconia-Supported Iron Catalysts. ACS Catal. 2022, 12, 3211–3225. [Google Scholar] [CrossRef]

- Karre, A.V.; Dadyburjor, D.B. Review of iron-based catalysts with and without zeolite supports used in fischer-tropsch processes. Chem. Eng. Commun. 2022, 209, 967–987. [Google Scholar] [CrossRef]

- Yan, P.; Peng, H.; Vogrin, J.; Rabiee, H.; Zhu, Z. Selective CO2 hydrogenation over zeolite-based catalysts for targeted high-value products. J. Mater. Chem. A 2023, 11, 17938–17960. [Google Scholar] [CrossRef]

- Han, X.; Xia, H.; Tu, W.; Wei, Y.; Xue, D.; Li, M.; Yan, W.; Zhang, J.-N.; Han, Y.-F. Zeolite-confined Fe-site Catalysts for the Hydrogenation of CO2 to Produce High-value Chemicals. Chem. Res. Chin. Univ. 2024, 40, 78–95. [Google Scholar] [CrossRef]

- Hoffmann, R. Small but strong lessons from chemistry for nanoscience. Angew. Chem. Int. Ed. 2013, 52, 93–103. [Google Scholar] [CrossRef] [PubMed]

- Horton, M.K.; Montoya, J.H.; Liu, M.; Persson, K.A. High-throughput prediction of the ground-state collinear magnetic order of inorganic materials using Density Functional Theory. npj Comput. Mater. 2019, 5, 64. [Google Scholar] [CrossRef]

- Xu, L.; Papanikolaou, K.G.; Lechner, B.A.J.; Je, L.; Somorjai, G.A.; Salmeron, M.; Mavrikakis, M. Formation of active sites on transition metals through reaction-driven migration of surface atoms. Science 2023, 380, 70–76. [Google Scholar] [CrossRef]

- Cheng, D.; Negreiros, F.R.; Aprà, E.; Fortunelli, A. Computational Approaches to the Chemical Conversion of Carbon Dioxide. ChemSusChem 2013, 6, 944–965. [Google Scholar] [CrossRef]

- Nezam, I.; Zhou, W.; Gusmão, G.S.; Realff, M.J.; Wang, Y.; Medford, A.J.; Jones, C.W. Direct aromatization of CO2 via combined CO2 hydrogenation and zeolite-based acid catalysis. J. CO2 Util. 2021, 45, 101405. [Google Scholar] [CrossRef]

- Choi, S.; Sang, B.-I.; Hong, J.; Yoon, K.J.; Son, J.-W.; Lee, J.-H.; Kim, B.-K.; Kim, H. Catalytic behavior of metal catalysts in high-temperature RWGS reaction: In-situ FT-IR experiments and first-principles calculations. Sci. Rep. 2017, 7, 41207. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, C.; Gao, P.; Wang, H.; Li, X.; Zhong, L.; Wei, W.; Sun, Y. A review of the catalytic hydrogenation of carbon dioxide into value-added hydrocarbons. Catal. Sci. Technol. 2017, 7, 4580–4598. [Google Scholar] [CrossRef]

- Weijing, D.; Weihong, Z.; Xiaodong, Z.; Baofeng, Z.; Lei, C.; Laizhi, S.; Shuangxia, Y.; Haibin, G.; Guanyi, C.; Liang, Z.; et al. The application of DFT in catalysis and adsorption reaction system. Energy Procedia 2018, 152, 997–1002. [Google Scholar] [CrossRef]

- Cui, W.-G.; Zhang, G.-Y.; Hu, T.-L.; Bu, X.-H. Metal-organic framework-based heterogeneous catalysts for the conversion of C1 chemistry: CO, CO2 and CH4. Coord. Chem. Rev. 2019, 387, 79–120. [Google Scholar] [CrossRef]

- Podrojková, N.; Sans, V.; Oriňak, A.; Oriňaková, R. Recent Developments in the Modelling of Heterogeneous Catalysts for CO2 Conversion to Chemicals. ChemCatChem 2020, 12, 1802–1825. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhang, O.; Borgs, C.; Chayes, J.T.; Yaghi, O.M. ChatGPT Chemistry Assistant for Text Mining and the Prediction of MOF Synthesis. J. Am. Chem. Soc. 2023, 145, 18048–18062. [Google Scholar] [CrossRef]

- Rommens, K.T.; Saeys, M. Molecular Views on Fischer–Tropsch Synthesis. Chem. Rev. 2023, 123, 5798–5858. [Google Scholar] [CrossRef]

- González-Castaño, M.; Dorneanu, B.; Arellano-García, H. The reverse water gas shift reaction: A process systems engineering perspective. React. Chem. Eng. 2021, 6, 954–976. [Google Scholar] [CrossRef]

- Wei, J.; Yao, R.; Han, Y.; Ge, Q.; Sun, J. Towards the development of the emerging process of CO2 heterogenous hydrogenation into high-value unsaturated heavy hydrocarbons. Chem. Soc. Rev. 2021, 50, 10764–10805. [Google Scholar] [CrossRef] [PubMed]

- Centi, G.; Quadrelli, E.A.; Perathoner, S. Catalysis for CO2 conversion: A key technology for rapid introduction of renewable energy in the value chain of chemical industries. Energy Environ. Sci. 2013, 6, 1711–1731. [Google Scholar] [CrossRef]

- Yao, B.; Xiao, T.; Makgae, O.A.; Jie, X.; Gonzalez-Cortes, S.; Guan, S.; Kirkland, A.I.; Dilworth, J.R.; Al-Megren, H.A.; Alshihri, S.M.; et al. Transforming carbon dioxide into jet fuel using an organic combustion-synthesized Fe-Mn-K catalyst. Nat. Commun. 2020, 11, 6395. [Google Scholar] [CrossRef]

- Riedel, T.; Claeys, M.; Schulz, H.; Schaub, G.; Nam, S.-S.; Jun, K.-W.; Choi, M.-J.; Kishan, G.; Lee, K.-W. Comparative study of Fischer–Tropsch synthesis with H2/CO and H2/CO2 syngas using Fe- and Co-based catalysts. Appl. Catal. A 1999, 186, 201–213. [Google Scholar] [CrossRef]

- He, Z.; Cui, M.; Qian, Q.; Zhang, J.; Liu, H.; Han, B. Synthesis of liquid fuel via direct hydrogenation of CO2. Proc. Natl. Acad. Sci. USA 2019, 116, 12654–12659. [Google Scholar] [CrossRef]

- Ye, R.-P.; Ding, J.; Gong, W.; Argyle, M.D.; Zhong, Q.; Wang, Y.; Russell, C.K.; Xu, Z.; Russell, A.G.; Li, Q.; et al. CO2 hydrogenation to high-value products via heterogeneous catalysis. Nat. Commun. 2019, 10, 5698. [Google Scholar] [CrossRef]

- Han, S.J.; Hwang, S.-M.; Park, H.-G.; Zhang, C.; Jun, K.-W.; Kim, S.K. Identification of active sites for CO2 hydrogenation in Fe catalysts by first-principles microkinetic modelling. J. Mater. Chem. A 2020, 8, 13014–13023. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, B.; Jia, L.; Liu, W.; Gao, X.; Gao, J.; Meng, B.; Tan, Y.; He, Y.; Tu, W.; et al. Unraveling the role of Fe5C2 in CH4 formation during CO2 hydrogenation over hydrophobic iron catalysts. Appl. Catal. B 2023, 327, 122449. [Google Scholar] [CrossRef]

- Huš, M.; Grilc, M.; Pavlišič, A.; Likozar, B.; Hellman, A. Multiscale modelling from quantum level to reactor scale: An example of ethylene epoxidation on silver catalysts. Catal. Today 2019, 338, 128–140. [Google Scholar] [CrossRef]

- Li, B.; Shao, Z.-G.; Feng, Y.-T. First-principles investigation of CO and CO2 adsorption on pristine and Fe-doped planar carbon allotrope net-Y. Phys. Chem. Chem. Phys. 2021, 23, 12771–12779. [Google Scholar] [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef] [PubMed]

- Dudarev, S.L.; Botton, G.A.; Savrasov, S.Y.; Humphreys, C.J.; Sutton, A.P. Electron-energy-loss spectra and the structural stability of nickel oxide: An LSDA+U study. Phys. Rev. B 1998, 57, 1505–1509. [Google Scholar] [CrossRef]

- Liu, W.; Carrasco, J.; Santra, B.; Michaelides, A.; Scheffler, M.; Tkatchenko, A. Benzene adsorbed on metals: Concerted effect of covalency and van der Waals bonding. Phys. Rev. B 2012, 86, 245405. [Google Scholar] [CrossRef]

- Grimme, S. Semiempirical GGA-type density functional constructed with a long-range dispersion correction. J. Comput. Chem. 2006, 27, 1787–1799. [Google Scholar] [CrossRef]

- Suvarna, M.; Araújo, T.P.; Pérez-Ramírez, J. A generalized machine learning framework to predict the space-time yield of methanol from thermocatalytic CO2 hydrogenation. Appl. Catal. B 2022, 315, 121530. [Google Scholar] [CrossRef]

- Al-Mahayni, H.; Wang, X.; Harvey, J.-P.; Patience, G.S.; Seifitokaldani, A. Experimental methods in chemical engineering: Density functional theory. Can. J. Chem. Eng. 2021, 99, 1885–1911. [Google Scholar] [CrossRef]

- Naimatullah; Li, D.; Gahungu, G.; Li, W.; Zhang, J. First-principles calculations on CO2 hydrogenation to formic acid over a metal-doped boron phosphide. Mol. Catal. 2022, 527, 112412. [Google Scholar] [CrossRef]

- Bhandari, S.; Rangarajan, S.; Mavrikakis, M. Combining Computational Modeling with Reaction Kinetics Experiments for Elucidating the In Situ Nature of the Active Site in Catalysis. Acc. Chem. Res. 2020, 53, 1893–1904. [Google Scholar] [CrossRef]

- Chen, B.W.J.; Xu, L.; Mavrikakis, M. Computational Methods in Heterogeneous Catalysis. Chem. Rev. 2021, 121, 1007–1048. [Google Scholar] [CrossRef]

- Wang, Y.; Su, Y.-Q.; Hensen, E.J.M.; Vlachos, D.G. Insights into Supported Subnanometer Catalysts Exposed to CO via Machine-Learning-Enabled Multiscale Modeling. Chem. Mater. 2022, 34, 1611–1619. [Google Scholar] [CrossRef]

- Clay, J.P.; Greeley, J.P.; Ribeiro, F.H.; Nicholas Delgass, W.; Schneider, W.F. DFT comparison of intrinsic WGS kinetics over Pd and Pt. J. Catal. 2014, 320, 106–117. [Google Scholar] [CrossRef]

- Dietz, L.; Piccinin, S.; Maestri, M. Mechanistic Insights into CO2 Activation via Reverse Water–Gas Shift on Metal Surfaces. J. Phys. Chem. C 2015, 119, 4959–4966. [Google Scholar] [CrossRef]

- Huynh, H.L.; Zhu, J.; Zhang, G.; Shen, Y.; Tucho, W.M.; Ding, Y.; Yu, Z. Promoting effect of Fe on supported Ni catalysts in CO2 methanation by in situ DRIFTS and DFT study. J. Catal. 2020, 392, 266–277. [Google Scholar] [CrossRef]

- Serrer, M.-A.; Gaur, A.; Jelic, J.; Weber, S.; Fritsch, C.; Clark, A.H.; Saraçi, E.; Studt, F.; Grunwaldt, J.-D. Structural dynamics in Ni–Fe catalysts during CO2 methanation—Role of iron oxide clusters. Catal. Sci. Technol. 2020, 10, 7542–7554. [Google Scholar] [CrossRef]

- Krishnan, R.; Yang, K.; Hashem, K.; Jiang, J. Metallated porphyrinic metal–organic frameworks for CO2 conversion to HCOOH: A computational screening and mechanistic study. Mol. Catal. 2022, 527, 112407. [Google Scholar] [CrossRef]

- Khodakov, A.Y.; Chu, W.; Fongarland, P. Advances in the Development of Novel Cobalt Fischer–Tropsch Catalysts for Synthesis of Long-Chain Hydrocarbons and Clean Fuels. Chem. Rev. 2007, 107, 1692–1744. [Google Scholar] [CrossRef]

- de Smit, E.; Weckhuysen, B.M. The renaissance of iron-based Fischer–Tropsch synthesis: On the multifaceted catalyst deactivation behaviour. Chem. Soc. Rev. 2008, 37, 2758–2781. [Google Scholar] [CrossRef]

- Li, X.; Yang, Z.; Zhang, L.; He, Z.; Fang, R.; Wang, Z.; Yan, Y.; Ran, J. Effect of Pd doping in (Fe/Ni)/CeO2 catalyst for the reaction path in CO2 oxidative ethane dehydrogenation/reforming. Energy 2021, 234, 121261. [Google Scholar] [CrossRef]

- Liu, C.; Cundari, T.R.; Wilson, A.K. CO2 Reduction on Transition Metal (Fe, Co, Ni, and Cu) Surfaces: In Comparison with Homogeneous Catalysis. J. Phys. Chem. C 2012, 116, 5681–5688. [Google Scholar] [CrossRef]

- Liu, S.; Li, Y.-W.; Wang, J.; Jiao, H. Reactions of CO, H2O, CO2, and H2 on the Clean and Precovered Fe(110) Surfaces—A DFT Investigation. J. Phys. Chem. C 2015, 119, 28377–28388. [Google Scholar] [CrossRef]

- Liu, X.; Sun, L.; Deng, W.-Q. Theoretical Investigation of CO2 Adsorption and Dissociation on Low Index Surfaces of Transition Metals. J. Phys. Chem. C 2018, 122, 8306–8314. [Google Scholar] [CrossRef]

- Wang, H.; Nie, X.; Chen, Y.; Guo, X.; Song, C. Facet effect on CO2 adsorption, dissociation and hydrogenation over Fe catalysts: Insight from DFT. J. CO2 Util. 2018, 26, 160–170. [Google Scholar] [CrossRef]

- Chen, H.; Yang, M.; Liu, J.; Lu, G.; Feng, X. Insight into the effects of electronegativity on the H2 catalytic activation for CO2 hydrogenation: Four transition metal cases from a DFT study. Catal. Sci. Technol. 2020, 10, 5641–5647. [Google Scholar] [CrossRef]

- Wang, H.; Nie, X.; Guo, X.; Song, C. A computational study of adsorption and activation of CO2 and H2 over Fe(100) surface. J. CO2 Util. 2016, 15, 107–114. [Google Scholar] [CrossRef]

- Yang, L.; Pastor-Pérez, L.; Villora-Pico, J.J.; Gu, S.; Sepúlveda-Escribano, A.; Reina, T.R. CO2 valorisation via reverse water-gas shift reaction using promoted Fe/CeO2-Al2O3 catalysts: Showcasing the potential of advanced catalysts to explore new processes design. Appl. Catal. A 2020, 593, 117442. [Google Scholar] [CrossRef]

- Kim, D.H.; Han, S.W.; Yoon, H.S.; Kim, Y.D. Reverse water gas shift reaction catalyzed by Fe nanoparticles with high catalytic activity and stability. J. Ind. Eng. Chem. 2015, 23, 67–71. [Google Scholar] [CrossRef]

- Mirabella, F.; Zaki, E.; Ivars-Barcelo, F.; Schauermann, S.; Shaikhutdinov, S.; Freund, H.J. CO2 Adsorption on Magnetite Fe3O4(111). J. Phys. Chem. C 2018, 122, 27433–27441. [Google Scholar] [CrossRef]

- Parkinson, G.S. Iron oxide surfaces. Surf. Sci. Rep. 2016, 71, 272–365. [Google Scholar] [CrossRef]

- Chou, C.-Y.; Loiland, J.A.; Lobo, R.F. Reverse Water-Gas Shift Iron Catalyst Derived from Magnetite. Catalysts 2019, 9, 773. [Google Scholar] [CrossRef]

- Fishman, Z.S.; He, Y.; Yang, K.R.; Lounsbury, A.W.; Zhu, J.; Tran, T.M.; Zimmerman, J.B.; Batista, V.S.; Pfefferle, L.D. Hard templating ultrathin polycrystalline hematite nanosheets: Effect of nano-dimension on CO2 to CO conversion via the reverse water-gas shift reaction. Nanoscale 2017, 9, 12984–12995. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Paier, J. Vibrational properties of CO2 adsorbed on the Fe3O4 (111) surface: Insights gained from DFT. J. Chem. Phys. 2020, 152, 104702. [Google Scholar] [CrossRef]

- Yang, T.; Wen, X.-D.; Huo, C.-F.; Li, Y.-W.; Wang, J.; Jiao, H. Structure and energetics of hydrogen adsorption on Fe3O4(111). J. Mol. Catal. A Chem. 2009, 302, 129–136. [Google Scholar] [CrossRef]

- Yu, X.; Huo, C.-F.; Li, Y.-W.; Wang, J.; Jiao, H. Fe3O4 surface electronic structures and stability from GGA+U. Surf. Sci. 2012, 606, 872–879. [Google Scholar] [CrossRef]

- Santos-Carballal, D.; Roldan, A.; Grau-Crespo, R.; de Leeuw, N.H. A DFT study of the structures, stabilities and redox behaviour of the major surfaces of magnetite Fe3O4. Phys. Chem. Chem. Phys. 2014, 16, 21082–21097. [Google Scholar] [CrossRef]

- Su, T.; Qin, Z.; Huang, G.; Ji, H.; Jiang, Y.; Chen, J. Density functional theory study on the interaction of CO2 with Fe3O4(111) surface. Appl. Surf. Sci. 2016, 378, 270–276. [Google Scholar] [CrossRef]

- Stegelmann, C.; Andreasen, A.; Campbell, C.T. Degree of Rate Control: How Much the Energies of Intermediates and Transition States Control Rates. J. Am. Chem. Soc. 2009, 131, 8077–8082. [Google Scholar] [CrossRef]

- Campbell, C.T. The Degree of Rate Control: A Powerful Tool for Catalysis Research. ACS Catal. 2017, 7, 2770–2779. [Google Scholar] [CrossRef]

- Campbell, C.T.; Mao, Z. Analysis and prediction of reaction kinetics using the degree of rate control. J. Catal. 2021, 404, 647–660. [Google Scholar] [CrossRef]

- de Smit, E.; Cinquini, F.; Beale, A.M.; Safonova, O.V.; van Beek, W.; Sautet, P.; Weckhuysen, B.M. Stability and Reactivity of ϵ–χ–θ Iron Carbide Catalyst Phases in Fischer–Tropsch Synthesis: Controlling μC. J. Am. Chem. Soc. 2010, 132, 14928–14941. [Google Scholar] [CrossRef]

- Lyu, S.; Wang, L.; Li, Z.; Yin, S.; Chen, J.; Zhang, Y.; Li, J.; Wang, Y. Stabilization of ε-iron carbide as high-temperature catalyst under realistic Fischer–Tropsch synthesis conditions. Nat. Commun. 2020, 11, 6219. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, J.-X.; Yang, C.; Yao, S.; Su, H.-Y.; Gao, Z.; Dong, M.; Wang, J.; Rykov Alexandre, I.; Wang, J.; et al. Synthesis of Iron-Carbide Nanoparticles: Identification of the Active Phase and Mechanism of Fe-Based Fischer–Tropsch Synthesis. CCS Chem. 2020, 3, 2712–2724. [Google Scholar] [CrossRef]

- Liu, X.; Cao, C.; Tian, P.; Zhu, M.; Zhang, Y.; Xu, J.; Tian, Y.; Han, Y.-F. Resolving CO2 activation and hydrogenation pathways over iron carbides from DFT investigation. J. CO2 Util. 2020, 38, 10–15. [Google Scholar] [CrossRef]

- Huang, L.; Han, B.; Zhang, Q.; Fan, M.; Cheng, H. Mechanistic Study on Water Gas Shift Reaction on the Fe3O4 (111) Reconstructed Surface. J. Phys. Chem. C 2015, 119, 28934–28945. [Google Scholar] [CrossRef]

- Zhang, M.; Ren, J.; Yu, Y. Insights into the Hydrogen Coverage Effect and the Mechanism of Fischer–Tropsch to Olefins Process on Fe5C2 (510). ACS Catal. 2020, 10, 689–701. [Google Scholar] [CrossRef]

- Wang, H.; Nie, X.; Liu, Y.; Janik, M.J.; Han, X.; Deng, Y.; Hu, W.; Song, C.; Guo, X. Mechanistic Insight into Hydrocarbon Synthesis via CO2 Hydrogenation on χ-Fe5C2 Catalysts. ACS Appl. Mater. Interfaces 2022, 14, 37637–37651. [Google Scholar] [CrossRef] [PubMed]

- Gao, R.; Cao, D.-B.; Liu, S.; Yang, Y.; Li, Y.-W.; Wang, J.; Jiao, H. Density functional theory study into H2O dissociative adsorption on the Fe5C2(010) surface. Appl. Catal. A 2013, 468, 370–383. [Google Scholar] [CrossRef]

- Raje, A.P.; O’Brien, R.J.; Davis, B.H. Effect of Potassium Promotion on Iron-Based Catalysts for Fischer–Tropsch Synthesis. J. Catal. 1998, 180, 36–43. [Google Scholar] [CrossRef]

- Ma, Y.-P.; Wang, G.-C. Comparative theoretical study of CO2 activation on clean and potassium-preadsorbed low index surfaces of transition metals. J. Mol. Model. 2023, 29, 375. [Google Scholar] [CrossRef] [PubMed]

- Huo, C.-F.; Wu, B.-S.; Gao, P.; Yang, Y.; Li, Y.-W.; Jiao, H. The Mechanism of Potassium Promoter: Enhancing the Stability of Active Surfaces. Angew. Chem. Int. Ed. 2011, 50, 7403–7406. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Ma, N.; Wang, C.; Liu, C.; Shen, J.; Wang, Y.; Xu, G.; Yang, Q.; Feng, X. Insight into the activation of CO2 and H2 on K2O-adsorbed Fe5C2(110) for olefins production: A density functional theory study. Mol. Catal. 2022, 524, 112323. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, C.; Tian, P.; Xu, M.; Cao, C.; Yang, Z.; Zhu, M.; Xu, J. Revealing the Effect of Sodium on Iron-Based Catalysts for CO2 Hydrogenation: Insights from Calculation and Experiment. J. Phys. Chem. C 2021, 125, 7637–7646. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, K.; Zhang, B.; Peng, X.; Gao, X.; Yang, G.; Hu, H.; Wu, M.; Tsubaki, N. Direct Conversion of CO2 to Ethanol Boosted by Intimacy-Sensitive Multifunctional Catalysts. ACS Catal. 2021, 11, 11742–11753. [Google Scholar] [CrossRef]

- Mahyuddin, M.H.; Belosludov, R.V.; Khazaei, M.; Mizuseki, H.; Kawazoe, Y. Effects of Alkali Adatoms on CO and H2S Adsorptions on the Fe(100) Surface: A Density Functional Theory Study. J. Phys. Chem. C 2011, 115, 23893–23901. [Google Scholar] [CrossRef]

- Ahmed, S.; Irshad, M.; Yoon, W.; Karanwal, N.; Sugiarto, J.R.; Khan, M.K.; Kim, S.K.; Kim, J. Evaluation of MgO as a promoter for the hydrogenation of CO2 to long-chain hydrocarbons over Fe-based catalysts. Appl. Catal. B 2023, 338, 123052. [Google Scholar] [CrossRef]

- Xu, M.; Liu, X.; Cao, C.; Sun, Y.; Zhang, C.; Yang, Z.; Zhu, M.; Ding, X.; Liu, Y.; Tong, Z.; et al. Ternary Fe–Zn–Al Spinel Catalyst for CO2 Hydrogenation to Linear α-Olefins: Synergy Effects between Al and Zn. ACS Sustain. Chem. Eng. 2021, 9, 13818–13830. [Google Scholar] [CrossRef]

- Xu, M.; Liu, X.; Song, G.; Cai, Y.; Shi, B.; Liu, Y.; Ding, X.; Yang, Z.; Tian, P.; Cao, C.; et al. Regulating iron species compositions by Fe-Al interaction in CO2 hydrogenation. J. Catal. 2022, 413, 331–341. [Google Scholar] [CrossRef]

- Belelli, P.G.; Rossi-Fernández, A.C.; Ferullo, R.M. CO2 dissociation and hydrogenation on pure and Ni-doped Fe(111). A DFT theoretical approach. Appl. Surf. Sci. 2023, 617, 156569. [Google Scholar] [CrossRef]

- Yang, H.; Dang, Y.; Cui, X.; Bu, X.; Li, J.; Li, S.; Sun, Y.; Gao, P. Selective synthesis of olefins via CO2 hydrogenation over transition-metal-doped iron-based catalysts. Appl. Catal. B 2023, 321, 122050. [Google Scholar] [CrossRef]

- Hwang, S.-M.; Han, S.J.; Min, J.E.; Park, H.-G.; Jun, K.-W.; Kim, S.K. Mechanistic insights into Cu and K promoted Fe-catalyzed production of liquid hydrocarbons via CO2 hydrogenation. J. CO2 Util. 2019, 34, 522–532. [Google Scholar] [CrossRef]

- Hwang, S.-M.; Han, S.J.; Park, H.-G.; Lee, H.; An, K.; Jun, K.-W.; Kim, S.K. Atomically Alloyed Fe–Co Catalyst Derived from a N-Coordinated Co Single-Atom Structure for CO2 Hydrogenation. ACS Catal. 2021, 11, 2267–2278. [Google Scholar] [CrossRef]

- Schlexer Lamoureux, P.; Winther, K.T.; Garrido Torres, J.A.; Streibel, V.; Zhao, M.; Bajdich, M.; Abild-Pedersen, F.; Bligaard, T. Machine Learning for Computational Heterogeneous Catalysis. ChemCatChem 2019, 11, 3581–3601. [Google Scholar] [CrossRef]

- Yang, W.; Fidelis, T.T.; Sun, W.-H. Machine Learning in Catalysis, From Proposal to Practicing. ACS Omega 2020, 5, 83–88. [Google Scholar] [CrossRef] [PubMed]

- Guan, Y.; Chaffart, D.; Liu, G.; Tan, Z.; Zhang, D.; Wang, Y.; Li, J.; Ricardez-Sandoval, L. Machine learning in solid heterogeneous catalysis: Recent developments, challenges and perspectives. Chem. Eng. Sci. 2022, 248, 117224. [Google Scholar] [CrossRef]

| Reaction Steps | Redox Pathway | COOH Pathway | HCOO Pathway |

|---|---|---|---|

| CO + * ⇆ CO* | CO2 + H2 | CO2 + H2 | CO2 + H2 |

| H2 + 2* ⇆ 2H* | CO2* + 2H* | COOHtrans* + H* | HCOO* + H* |

| H2O + * ⇆ H2O* | CO* + O* + 2H* | COOHcis* + H* | HCO* + O* + H* |

| H2O + * ⇆ H* + OH* | CO* + OH* + H* | CO* + OH* + H* | CO* + O* + 2H* |

| CO2* ⇆ CO2 + * | CO* + H2O* | CO* + H2O* | CO* + OH* + H* |

| OH + * ⇆ O* + H* | CO* + H2O | CO* + H2O | CO* + H2O* |

| OH* + OH* ⇆ H2O* + O* | CO + H2O | CO + H2O | CO* + H2O |

| CO* + O* ⇆ CO2* + * | CO + H2O | ||

| CO* + OH* ⇆ COOHcis* + * | |||

| COOHtrans* + * ⇆ CO2* + H* | |||

| COOHtrans* + OH* ⇆ CO2* + H2O | |||

| CO* + OH* ⇆ HCOO* + * | |||

| CO2* + H2O* ⇆ HCOO* + OH* | |||

| OH* + OH* ⇆ H2O* + O* | |||

| COOH* + * ⇆ HCOOH** | |||

| COOHcis* ⇆ COOHtrans* |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, H.; Qiu, T.; Wang, X.; Zhang, C.; Zhang, Z. A Brief Review of Recent Theoretical Advances in Fe-Based Catalysts for CO2 Hydrogenation. Molecules 2024, 29, 1194. https://doi.org/10.3390/molecules29061194

Tang H, Qiu T, Wang X, Zhang C, Zhang Z. A Brief Review of Recent Theoretical Advances in Fe-Based Catalysts for CO2 Hydrogenation. Molecules. 2024; 29(6):1194. https://doi.org/10.3390/molecules29061194

Chicago/Turabian StyleTang, Haoxiang, Tongyue Qiu, Xuerui Wang, Chundong Zhang, and Zunmin Zhang. 2024. "A Brief Review of Recent Theoretical Advances in Fe-Based Catalysts for CO2 Hydrogenation" Molecules 29, no. 6: 1194. https://doi.org/10.3390/molecules29061194

APA StyleTang, H., Qiu, T., Wang, X., Zhang, C., & Zhang, Z. (2024). A Brief Review of Recent Theoretical Advances in Fe-Based Catalysts for CO2 Hydrogenation. Molecules, 29(6), 1194. https://doi.org/10.3390/molecules29061194