Co-Immobilization of Laccase and Mediator into Fe-Doped ZIF-8 Significantly Enhances the Degradation of Organic Pollutants

Abstract

1. Introduction

2. Results and Discussion

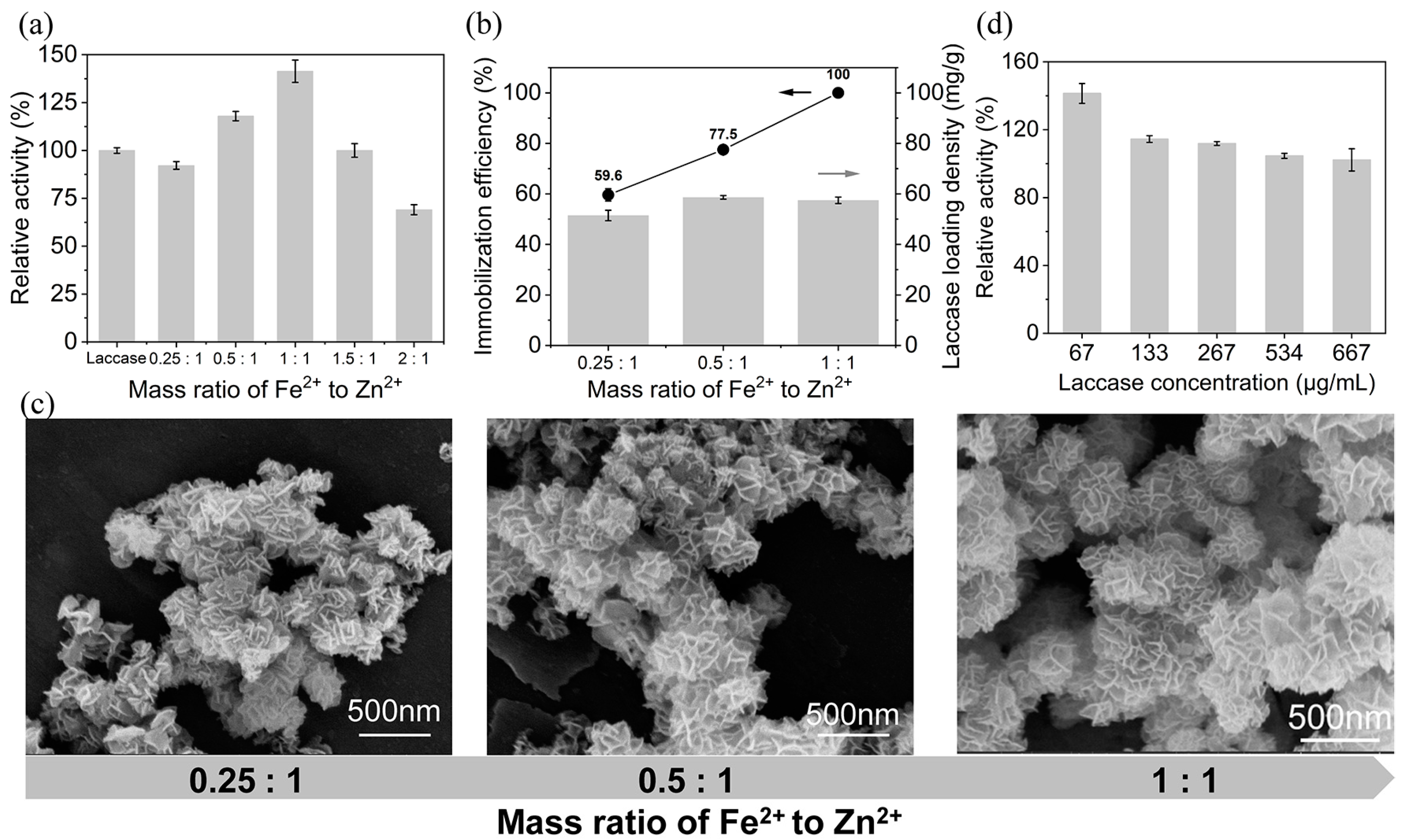

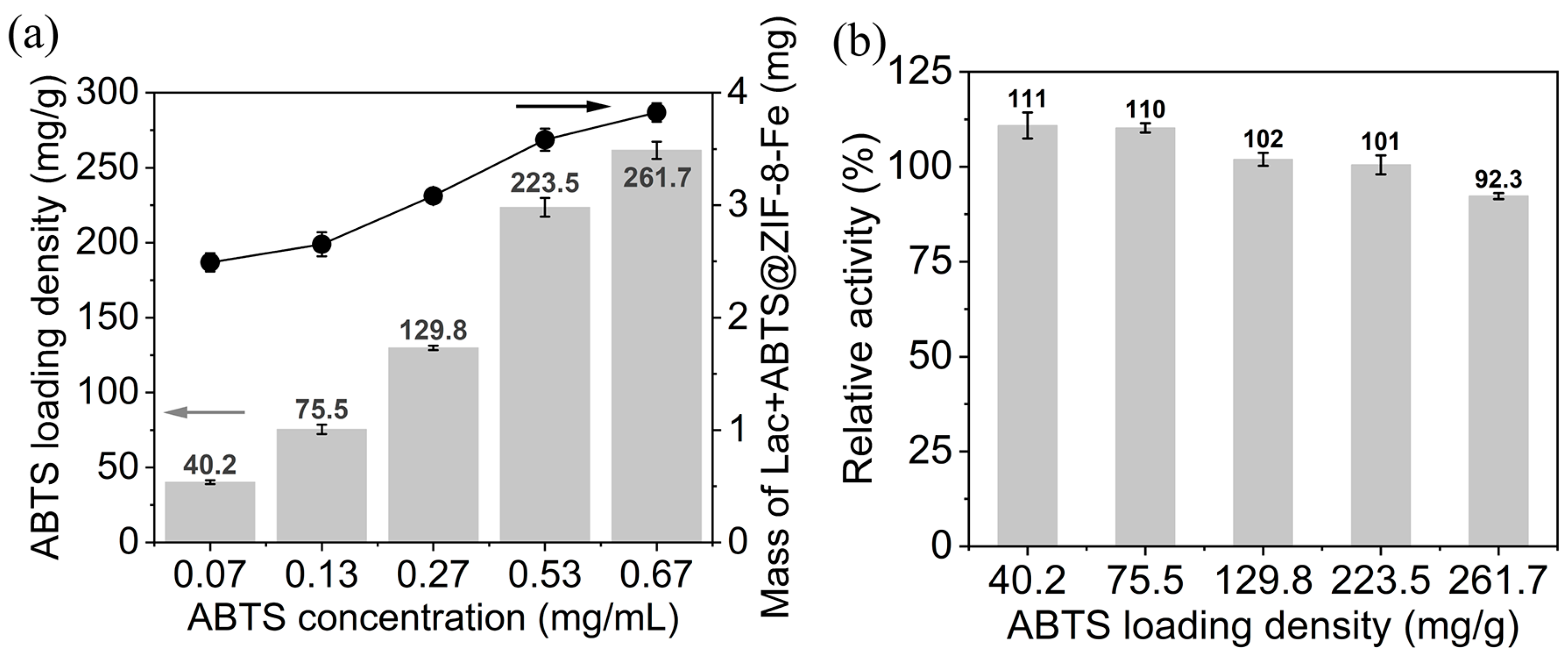

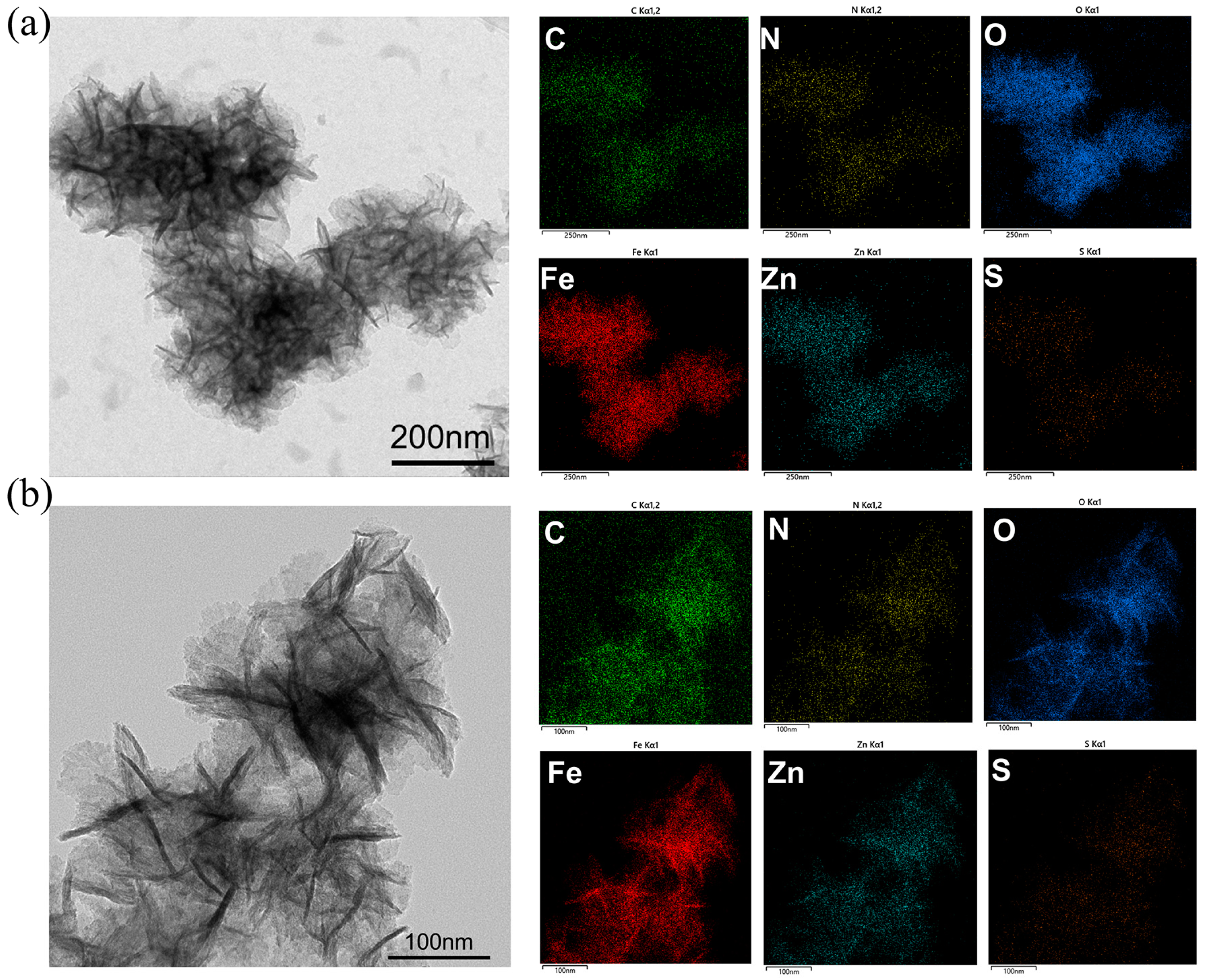

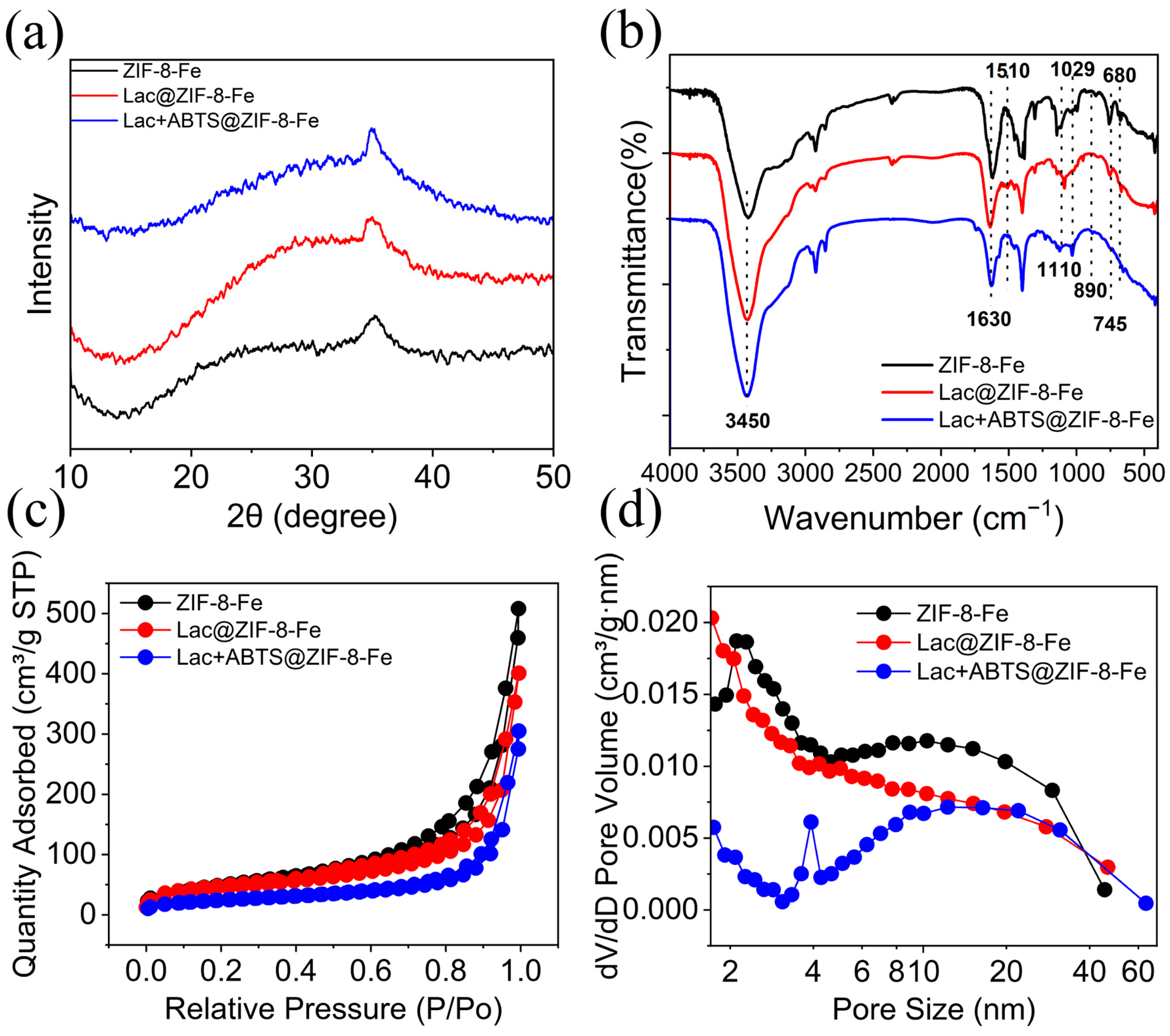

2.1. Characteristics of Lac@ZIF-8-Fe and Lac+ABTS@ZIF-8-Fe

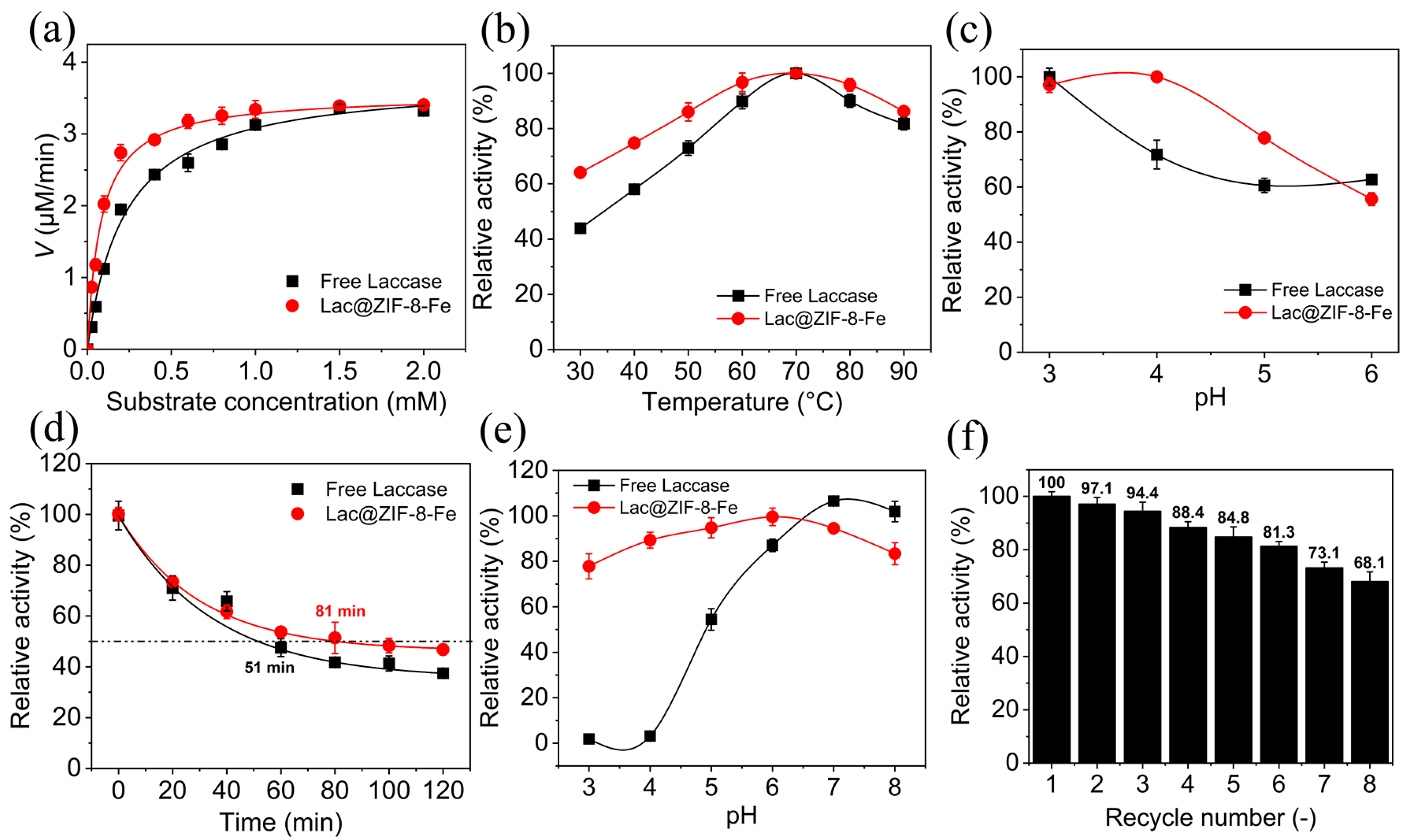

2.2. Enzymatic Properties of Free Laccase and Lac@ZIF-8-Fe

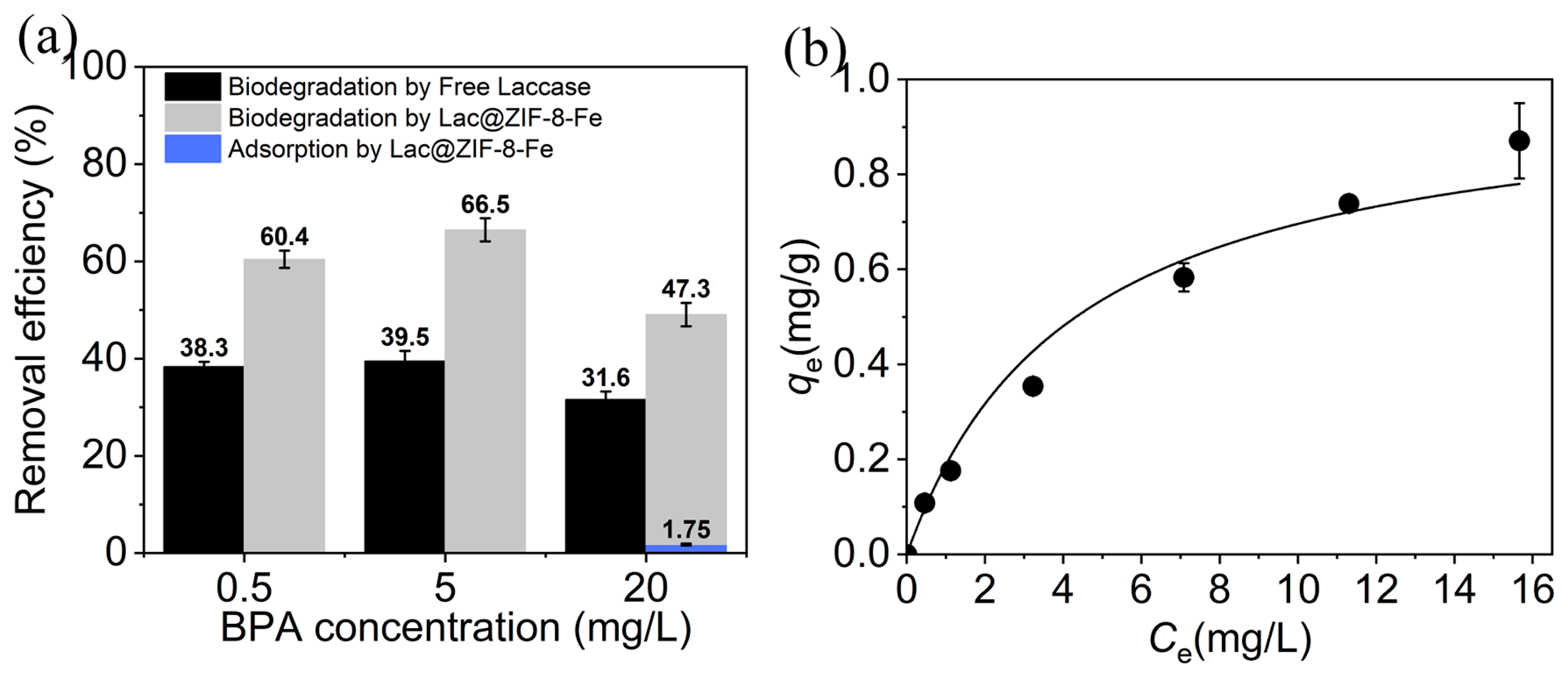

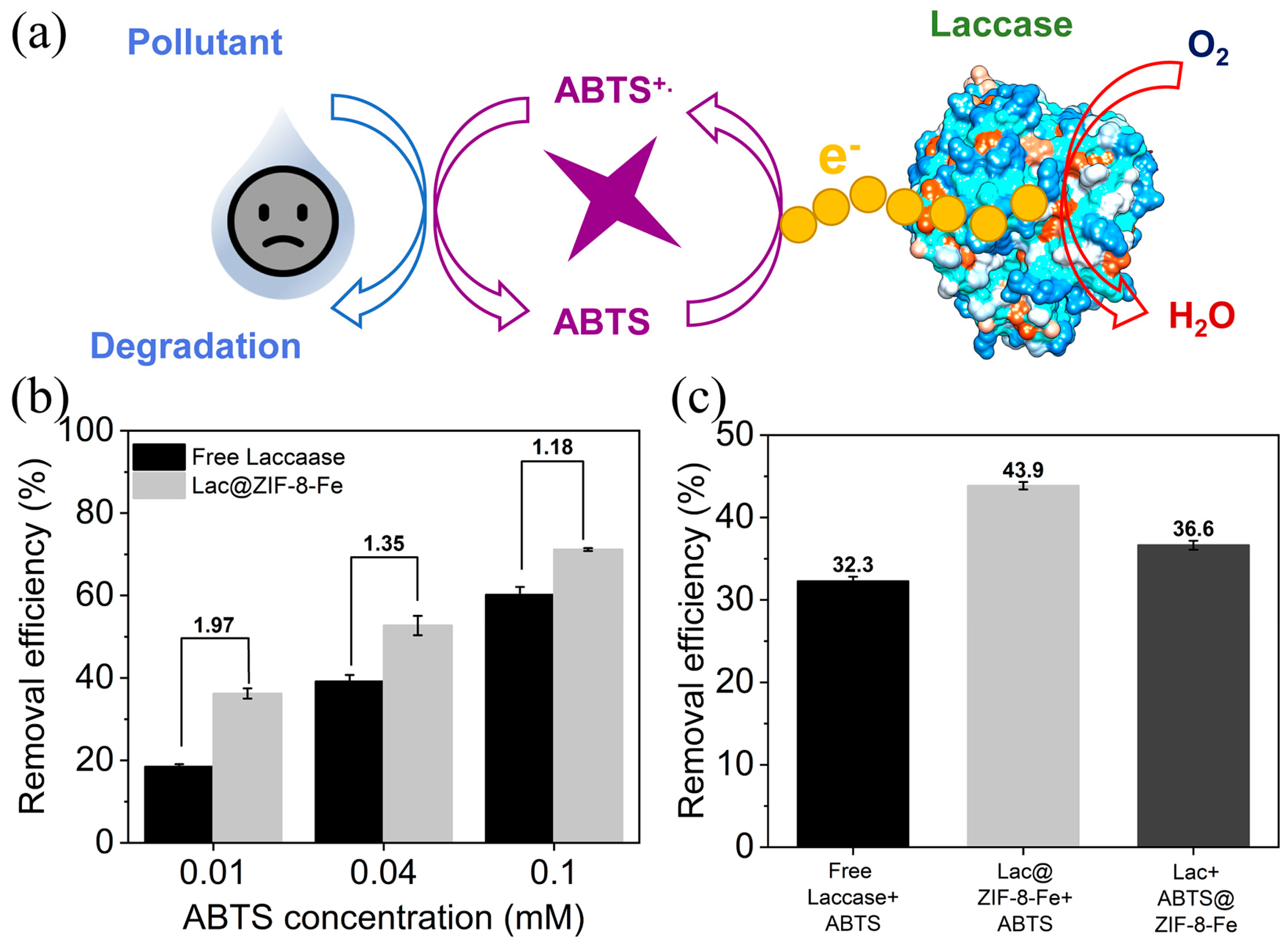

2.3. BPA Removal Experiments

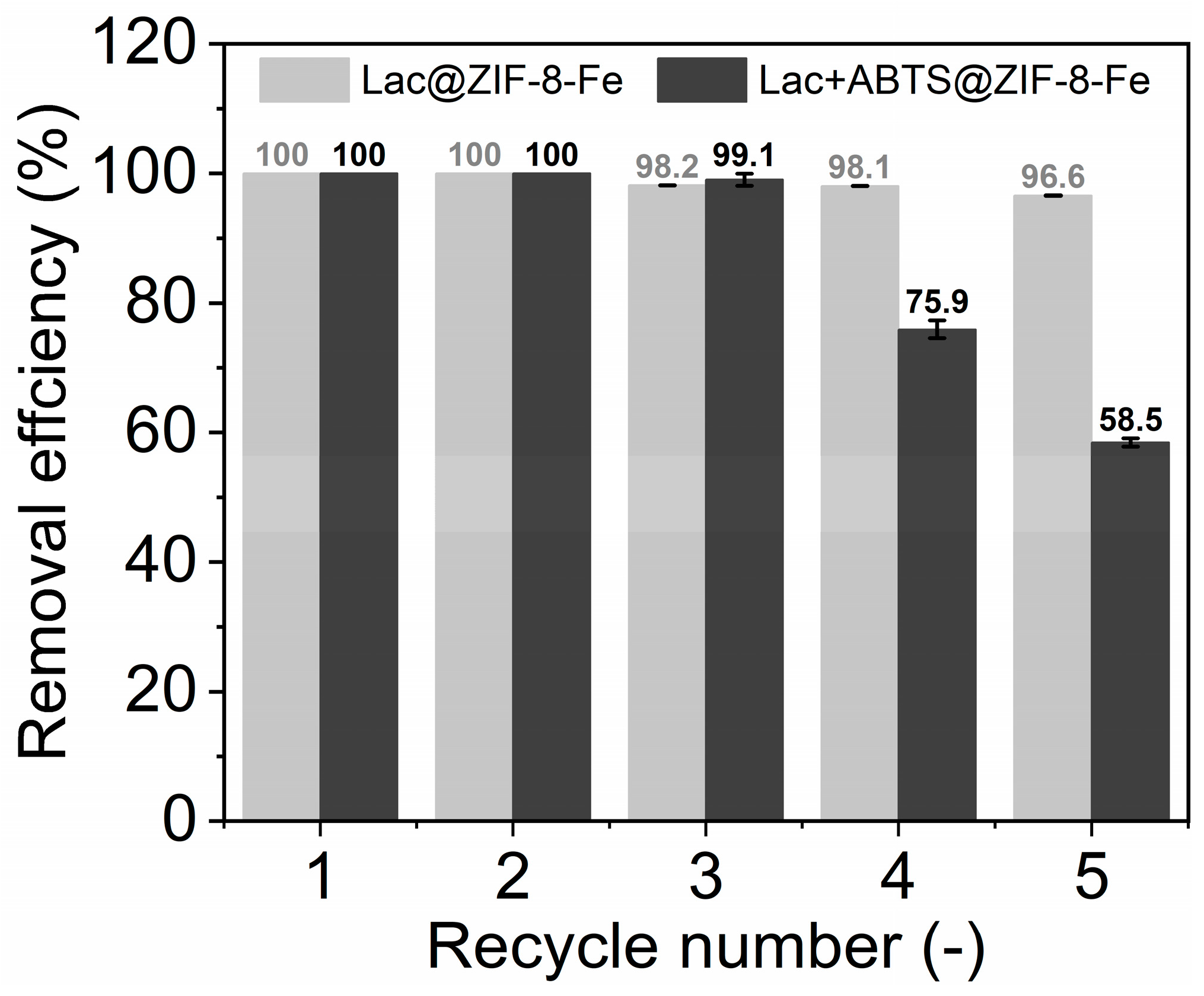

2.4. Reusability of Immobilized Laccase for MG Removal

3. Materials and Methods

3.1. Chemicals and Materials

3.2. Preparation of ZIF-8-Fe, Lac@ZIF-8-Fe, and Lac+ABTS@ZIF-8-Fe

3.3. Characterization of Materials

3.4. Characterization of Enzymatic Properties

3.5. Removal of BPA and MG

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, C.-C.; Li, J.-R.; Lv, X.-L.; Zhang, Y.-Q.; Guo, G. Photocatalytic organic pollutants degradation in metal–organic frameworks. Energy Environ. Sci. 2014, 7, 2831–2867. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Anastopoulos, I. Adsorptive removal of bisphenol A (BPA) from aqueous solution: A review. Chemosphere 2017, 168, 885–902. [Google Scholar] [CrossRef]

- Liu, R.; Zhang, W.; Wang, S.; Xu, H.; Hu, Y. Magnetic polyethyleneimine nanoparticles fabricated via ionic liquid as bridging agents for laccase immobilization and its application in phenolic pollutants removal. Molecules 2022, 27, 8522. [Google Scholar] [CrossRef]

- Liang, Y.; Chen, X.; Zeng, J.; Ye, J.; He, B.; Li, W.; Sun, J. Mesoporous polymeric ionic liquid via confined polymerization for laccase immobilization towards efficient degradation of phenolic pollutants. Molecules 2023, 28, 2569. [Google Scholar] [CrossRef]

- Lou, X.; Zhi, F.; Sun, X.; Wang, F.; Hou, X.; Lv, C.; Hu, Q. Construction of co-immobilized laccase and mediator based on MOFs membrane for enhancing organic pollutants removal. Chem. Eng. J. 2023, 451, 138080. [Google Scholar] [CrossRef]

- Zeng, S.; Qin, X.; Xia, L. Degradation of the herbicide isoproturon by laccase-mediator systems. Biochem. Eng. J. 2017, 119, 92–100. [Google Scholar] [CrossRef]

- Gu, Y.; Yuan, L.; Jia, L.; Xue, P.; Yao, H. Recent developments of a co-immobilized laccase-mediator system: A review. RSC Adv. 2021, 11, 29498–29506. [Google Scholar] [CrossRef]

- Song, Y.; Wang, Y.; Guo, Y.; Qiao, Y.; Ma, Q.; Ji, C.; Zhao, L. Degradation of zearalenone and aflatoxin B1 by Lac2 from Pleurotus pulmonarius in the presence of mediators. Toxicon 2021, 201, 1–8. [Google Scholar] [CrossRef]

- Gu, Y.; Xue, P.; Jia, F.; Shi, K. Co-immobilization of laccase and ABTS onto novel dual-functionalized cellulose beads for highly improved biodegradation of indole. J. Hazard. Mater. 2019, 365, 118–124. [Google Scholar] [CrossRef]

- Qiu, X.; Wang, S.; Miao, S.; Suo, H.; Xu, H.; Hu, Y. Co-immobilization of laccase and ABTS onto amino-functionalized ionic liquid-modified magnetic chitosan nanoparticles for pollutants removal. J. Hazard. Mater. 2021, 401, 123353. [Google Scholar] [CrossRef]

- Shan, H.; Wang, X.; Ge, Y.; Li, Z. Homologous amino acids promoted co-immobilization of laccase and mediator onto geopolymer microspheres for enhancing degradation of dyes in water. J. Hazard. Mater. 2022, 423 Pt A, 127107. [Google Scholar] [CrossRef]

- Cui, J.; Feng, Y.; Lin, T.; Tan, Z.; Zhong, C.; Jia, S. Mesoporous metal-organic framework with well-defined cruciate flower-like morphology for enzyme immobilization. ACS Appl. Mater. Interfaces 2017, 9, 10587–10594. [Google Scholar] [CrossRef]

- Akbari Beni, F.; Gholami, A.; Ayati, A.; Niknam Shahrak, M.; Sillanpää, M. UV-switchable phosphotungstic acid sandwiched between ZIF-8 and Au nanoparticles to improve simultaneous adsorption and UV light photocatalysis toward tetracycline degradation. Microporous Mesoporous Mater. 2020, 303, 110275. [Google Scholar] [CrossRef]

- Ranjbari, S.; Ayati, A.; Shahrak, M.N.; Tanhaei, B.; Tabrizi, S.H. Design of [BmIm]3PW12O40 ionic liquid encapsulated-ZIF-8 nanocomposite for cationic dye adsorptive removal: Modeling by response surface methodology. Ind. Eng. Chem. Res. 2023, 62, 4636–4645. [Google Scholar] [CrossRef]

- Liang, W.; Xu, H.; Carraro, F.; Maddigan, N.K.; Li, Q.; Bell, S.G.; Huang, D.M.; Tarzia, A.; Solomon, M.B.; Amenitsch, H.; et al. Enhanced activity of enzymes encapsulated in hydrophilic metal-organic frameworks. J. Am. Chem. Soc. 2019, 141, 2348–2355. [Google Scholar] [CrossRef]

- Huang, S.; Chen, G.; Ye, N.; Kou, X.; Zhang, R.; Shen, J.; Ouyang, G. Iron-mineralization-induced mesoporous metal-organic frameworks enable high-efficiency synergistic catalysis of natural/nanomimic enzymes. ACS Appl. Mater. Interfaces 2020, 12, 57343–57351. [Google Scholar] [CrossRef]

- Patra, S.; Sene, S.; Mousty, C.; Serre, C.; Chausse, A.; Legrand, L.; Steunou, N. Design of laccase-metal organic framework-based bioelectrodes for biocatalytic oxygen reduction reaction. ACS Appl. Mater. Interfaces 2016, 8, 20012–20022. [Google Scholar] [CrossRef]

- Chen, G.; Kou, X.; Huang, S.; Tong, L.; Shen, Y.; Zhu, W.; Zhu, F.; Ouyang, G. Modulating the biofunctionality of metal-organic-framework-encapsulated enzymes through controllable embedding patterns. Angew. Chem. Int. Ed. 2020, 59, 2867–2874. [Google Scholar] [CrossRef]

- Diamanti, E.; Santiago-Arcos, J.; Grajales-Hernandez, D.; Czarnievicz, N.; Comino, N.; Llarena, I.; Di Silvio, D.; Cortajarena, A.L.; Lopez-Gallego, F. Intraparticle kinetics unveil crowding and enzyme distribution effects on the performance of cofactor-dependent heterogeneous biocatalysts. ACS Catal. 2021, 11, 15051–15067. [Google Scholar] [CrossRef]

- Gan, X.; Tang, J.; Wang, X.; Gong, L.; Zhitomirsky, I.; Qie, L.; Shi, K. Aromatic additives with designed functions ameliorating chemo-mechanical reliability for zinc-ion batteries. Energy Storage Mater. 2023, 59, 102769. [Google Scholar] [CrossRef]

- Liang, K.; Ricco, R.; Doherty, C.M.; Styles, M.J.; Bell, S.; Kirby, N.; Mudie, S.; Haylock, D.; Hill, A.J.; Doonan, C.J.; et al. Biomimetic mineralization of metal-organic frameworks as protective coatings for biomacromolecules. Nat. Commun. 2015, 6, 7240. [Google Scholar] [CrossRef]

- Babaei, H.; Ghobadi Nejad, Z.; Yaghmaei, S.; Farhadi, F. Co-immobilization of multi-enzyme cascade system into the metal–organic frameworks for the removal of Bisphenol A. Chem. Eng. J. 2023, 461, 142050. [Google Scholar] [CrossRef]

- Patil, P.D.; Yadav, G.D. Rapid in situ encapsulation of laccase into metal-organic framework support (ZIF-8) under biocompatible conditions. ChemistrySelect 2018, 3, 4669–4675. [Google Scholar] [CrossRef]

- Tarasi, R.; Alipour, M.; Gorgannezhad, L.; Imanparast, S.; Yousefi-Ahmadipour, A.; Ramezani, A.; Ganjali, M.R.; Shafiee, A.; Faramarzi, M.A.; Khoobi, M. Laccase immobilization onto magnetic β-Cyclodextrin-modified chitosan: Improved enzyme stability and efficient performance for phenolic compounds elimination. Macromol. Res. 2018, 26, 755–762. [Google Scholar] [CrossRef]

- Li, Z.; Yang, Z.; Shi, Q.; Sun, Y. Removal of bisphenol A by integrated adsorption and biodegradation using immobilized laccase onto defective PCN-224. J. Environ. Chem. Eng. 2023, 11, 110166. [Google Scholar] [CrossRef]

- Cristóvão, R.O.; Tavares, A.P.M.; Brígida, A.I.; Loureiro, J.M.; Boaventura, R.A.R.; Macedo, E.A.; Coelho, M.A.Z. Immobilization of commercial laccase onto green coconut fiber by adsorption and its application for reactive textile dyes degradation. J. Mol. Catal. B Enzym. 2011, 72, 6–12. [Google Scholar] [CrossRef]

- Jafari-Nodoushan, H.; Fazeli, M.R.; Faramarzi, M.A.; Samadi, N. Hierarchically-structured laccase@Ni3(PO4)2 hybrid nanoflowers for antibiotic degradation: Application in real wastewater effluent and toxicity evaluation. Int. J. Biol. Macromol. 2023, 234, 123574. [Google Scholar] [CrossRef]

- Tarafdar, A.; Sirohi, R.; Balakumaran, P.A.; Reshmy, R.; Madhavan, A.; Sindhu, R.; Binod, P.; Kumar, Y.; Kumar, D.; Sim, S.J. The hazardous threat of Bisphenol A: Toxicity, detection and remediation. J. Hazard. Mater. 2022, 423 Pt A, 127097. [Google Scholar] [CrossRef]

- Fu, J.; Liu, M.; Liu, Y.; Woodbury, N.W.; Yan, H. Interenzyme substrate diffusion for an enzyme cascade organized on spatially addressable DNA nanostructures. J. Am. Chem. Soc. 2012, 134, 5516–5519. [Google Scholar] [CrossRef]

- Liu, Y.; Geng, Y.; Yan, M.; Huang, J. Stable ABTS immobilized in the MIL-100(Fe) metal-organic framework as an efficient mediator for laccase-catalyzed decolorization. Molecules 2017, 22, 920. [Google Scholar] [CrossRef]

- Xue, P.; Liu, X.; Gu, Y.; Zhang, W.; Ma, L.; Li, R. Laccase-mediator system assembling co-immobilized onto functionalized calcium alginate beads and its high-efficiency catalytic degradation for acridine. Colloids Surf. B 2020, 196, 111348. [Google Scholar] [CrossRef]

- Zhang, C.; You, S.; Liu, Y.; Wang, C.; Yan, Q.; Qi, W.; Su, R.; He, Z. Construction of luffa sponge-based magnetic carbon nanocarriers for laccase immobilization and its application in the removal of bisphenol A. Bioresour. Technol. 2020, 305, 123085. [Google Scholar] [CrossRef]

- Molina, M.A.; Díez-Jaén, J.; Sánchez-Sánchez, M.; Blanco, R.M. One-pot laccase@MOF biocatalysts efficiently remove bisphenol A from water. Catal. Today 2022, 390–391, 265–271. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, L.; Han, J.; Wu, J.; Li, C.; Ni, L.; Wang, Y. Improving laccase activity and stability by HKUST-1 with cofactor via one-pot encapsulation and its application for degradation of bisphenol A. J. Hazard. Mater. 2020, 383, 121130. [Google Scholar] [CrossRef]

- Yuan, Y.; Cai, W.; Xu, J.; Cheng, J.; Du, K.S. Recyclable laccase by coprecipitation with aciduric Cu-based MOFs for bisphenol A degradation in an aqueous environment. Colloids Surf. B 2021, 204, 111792. [Google Scholar] [CrossRef]

- Johannes, C.; Majcherczyk, A. Natural mediators in the oxidation of polycyclic aromatic hydrocarbons by laccase mediator systems. Appl. Environ. Microbiol. 2000, 66, 524–528. [Google Scholar] [CrossRef]

- Terzopoulou, A.; Hoop, M.; Chen, X.Z.; Hirt, A.M.; Charilaou, M.; Shen, Y.; Mushtaq, F.; Del Pino, A.P.; Logofatu, C.; Simonelli, L.; et al. Mineralization-inspired synthesis of magnetic zeolitic imidazole framework composites. Angew. Chem. Int. Ed. 2019, 58, 13550–13555. [Google Scholar] [CrossRef]

- Bradford, M.M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 1976, 72, 248–254. [Google Scholar] [CrossRef]

- Wang, K.; Li, C.; Liang, Y.; Han, T.; Huang, H.; Yang, Q.; Liu, D.; Zhong, C. Rational construction of defects in a metal–organic framework for highly efficient adsorption and separation of dyes. Chem. Eng. J. 2016, 289, 486–493. [Google Scholar] [CrossRef]

| Kinetic Parameters | Free Laccase | Lac@ZIF-8-Fe |

|---|---|---|

| Vmax (μM·min−1) | 3.78 | 3.55 |

| kcat (min−1) | 119.3 | 112.4 |

| Km (mM) | 0.22 | 0.08 |

| kcat/Km(min−1·mM−1) | 542.4 | 1404 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Shi, Q.; Dong, X.; Sun, Y. Co-Immobilization of Laccase and Mediator into Fe-Doped ZIF-8 Significantly Enhances the Degradation of Organic Pollutants. Molecules 2024, 29, 307. https://doi.org/10.3390/molecules29020307

Li Z, Shi Q, Dong X, Sun Y. Co-Immobilization of Laccase and Mediator into Fe-Doped ZIF-8 Significantly Enhances the Degradation of Organic Pollutants. Molecules. 2024; 29(2):307. https://doi.org/10.3390/molecules29020307

Chicago/Turabian StyleLi, Zixuan, Qinghong Shi, Xiaoyan Dong, and Yan Sun. 2024. "Co-Immobilization of Laccase and Mediator into Fe-Doped ZIF-8 Significantly Enhances the Degradation of Organic Pollutants" Molecules 29, no. 2: 307. https://doi.org/10.3390/molecules29020307

APA StyleLi, Z., Shi, Q., Dong, X., & Sun, Y. (2024). Co-Immobilization of Laccase and Mediator into Fe-Doped ZIF-8 Significantly Enhances the Degradation of Organic Pollutants. Molecules, 29(2), 307. https://doi.org/10.3390/molecules29020307