A Review of Current Trends on Polyvinyl Alcohol (PVA)-Based Solid Polymer Electrolytes

Abstract

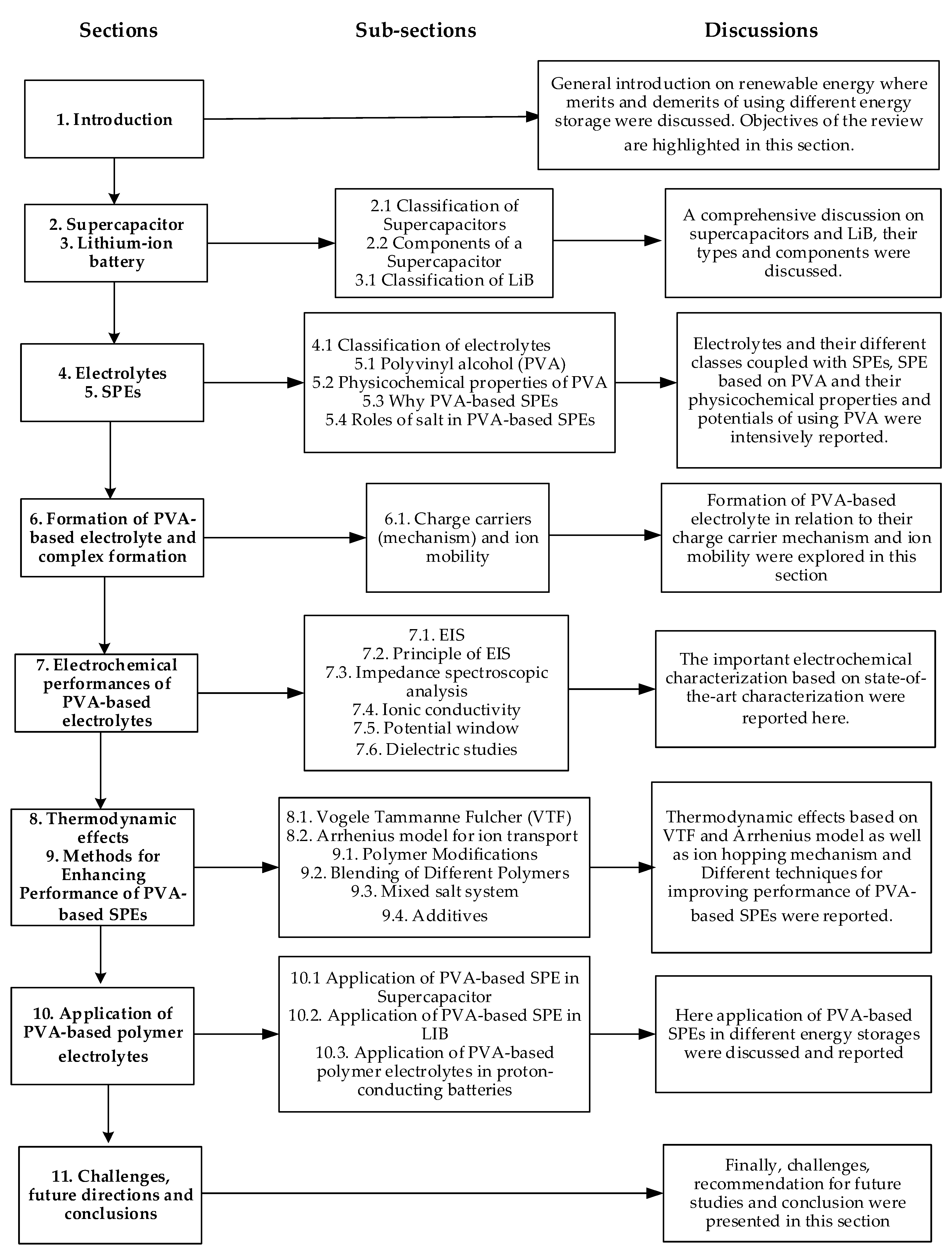

:1. Introduction

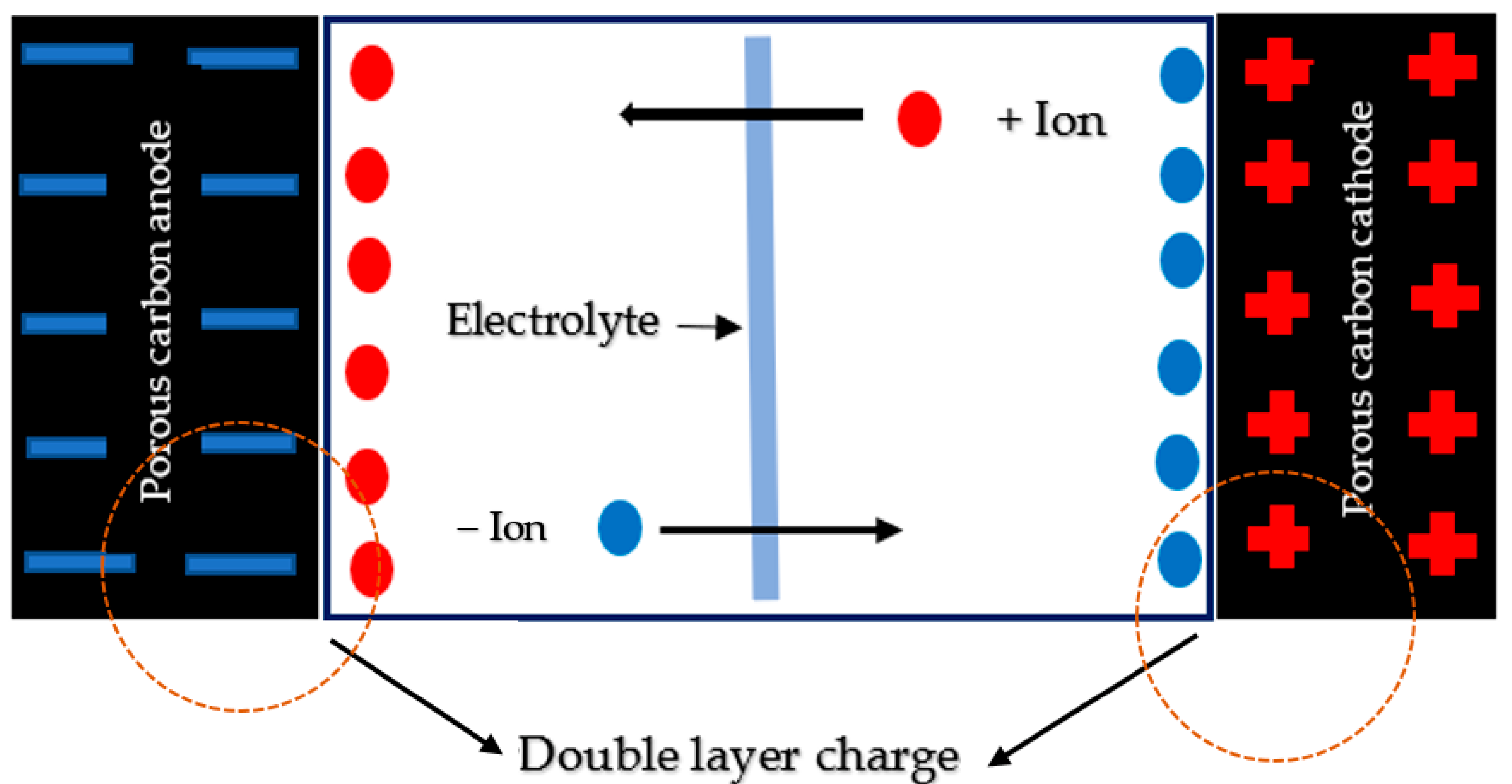

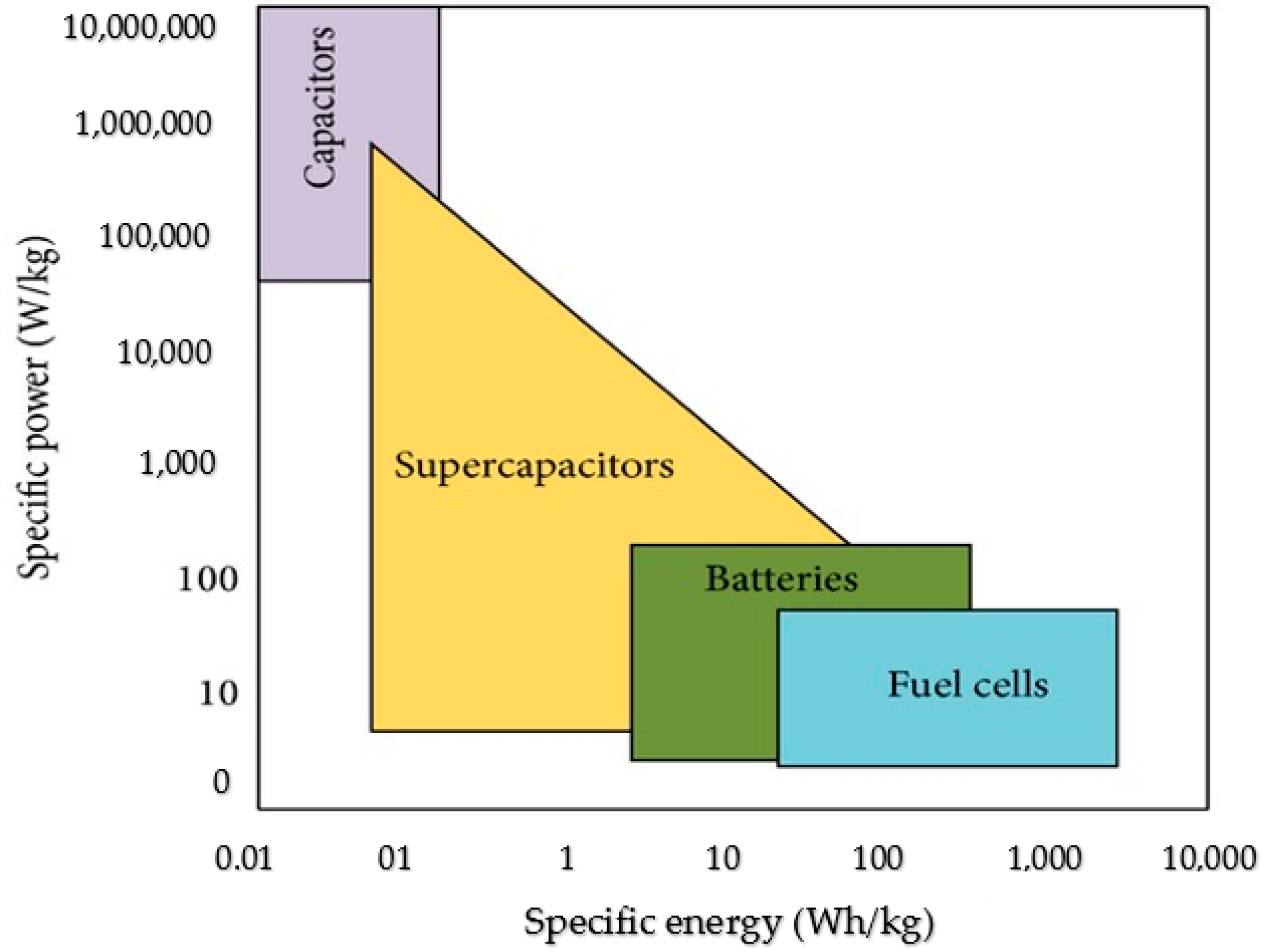

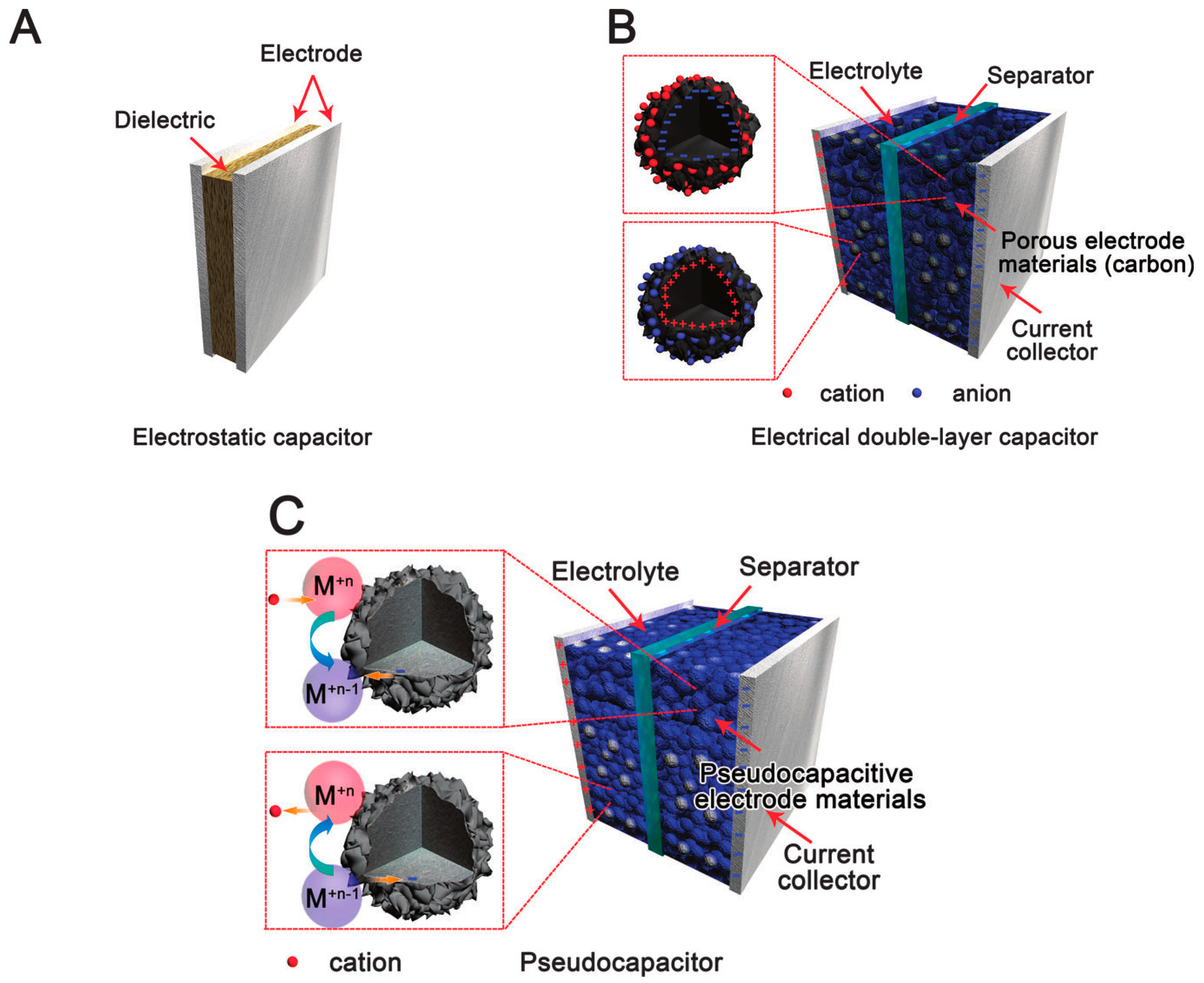

2. Supercapacitor

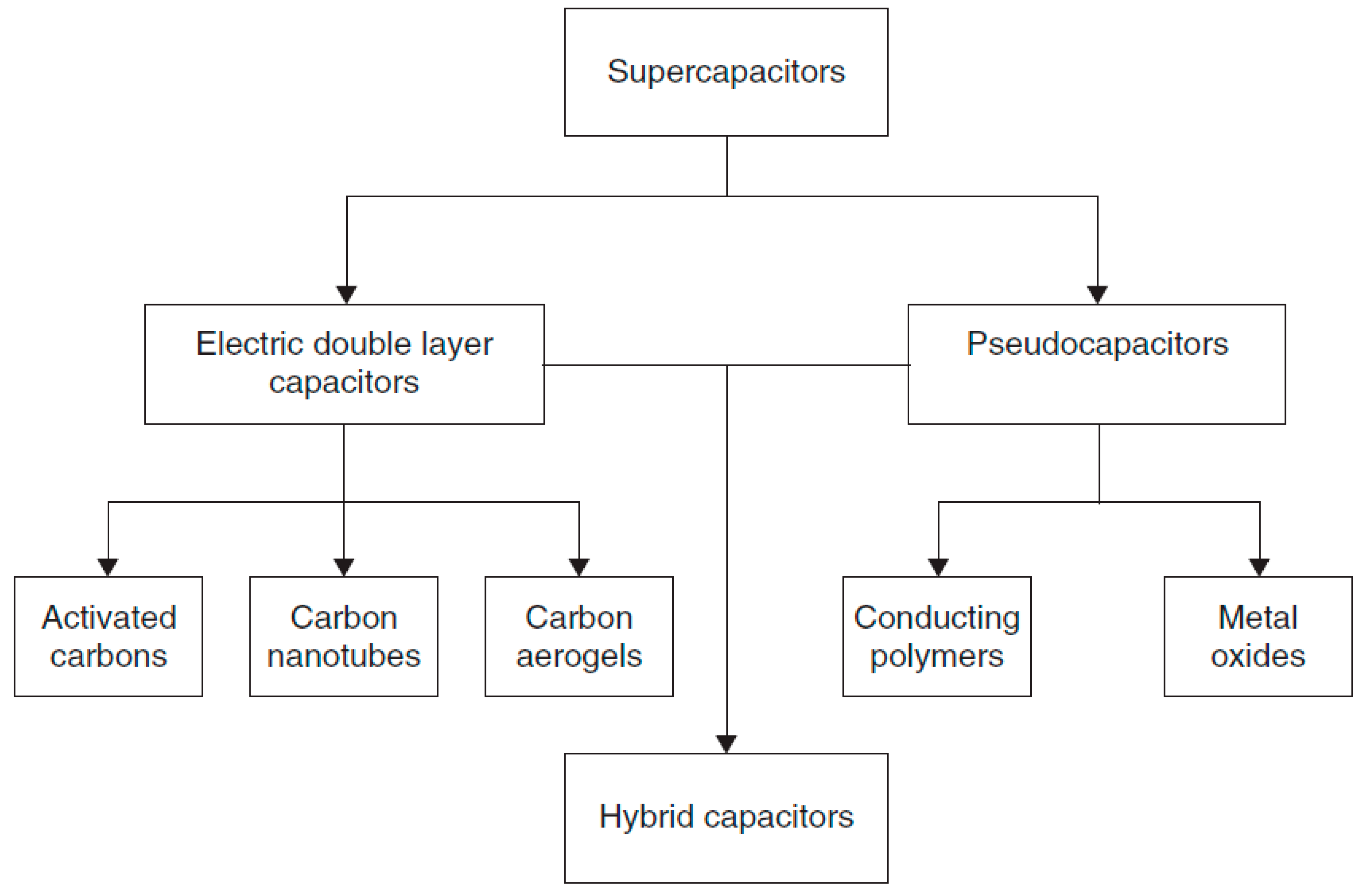

2.1. Classification of Supercapacitors

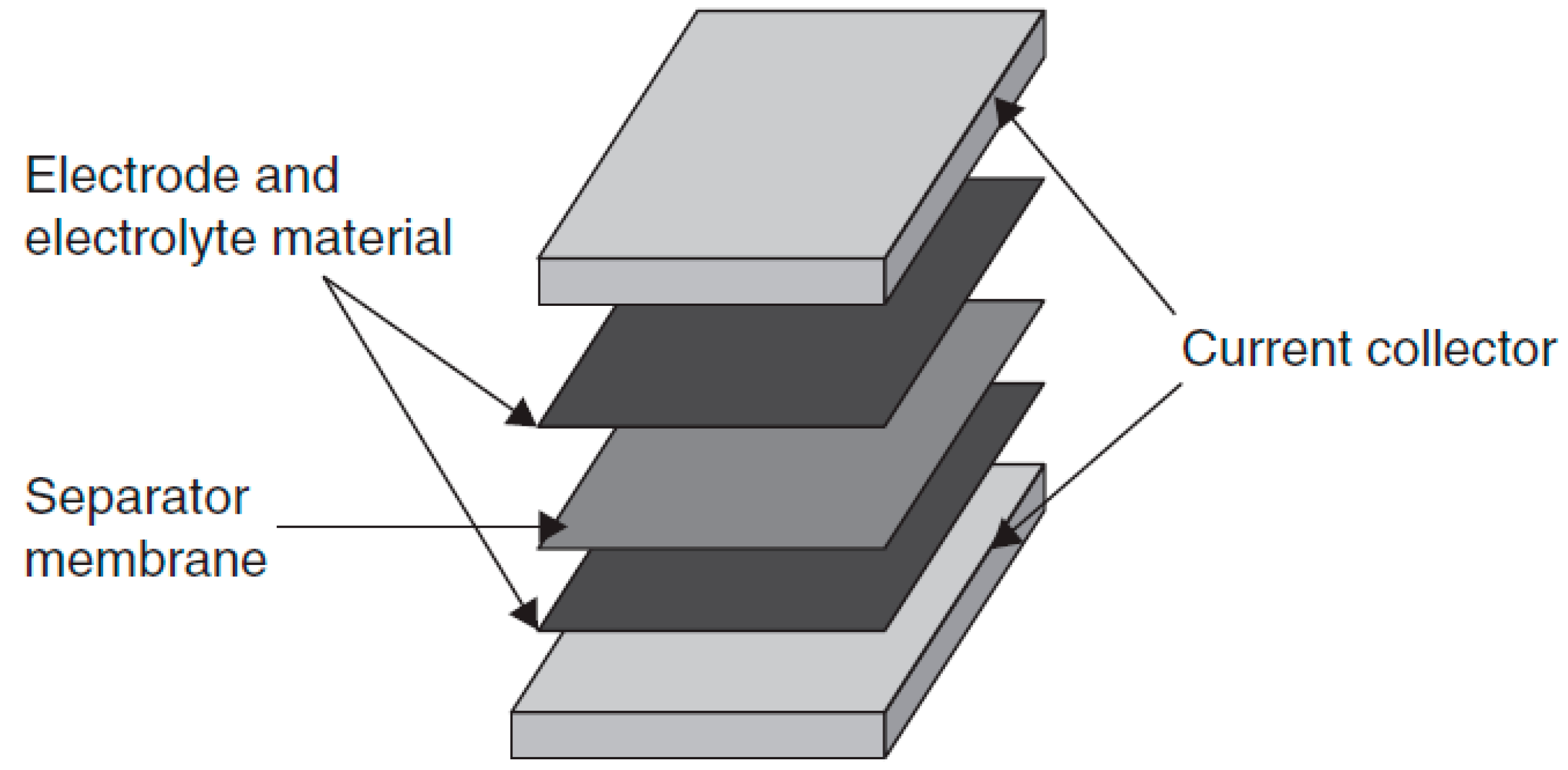

2.2. Components of a Supercapacitor

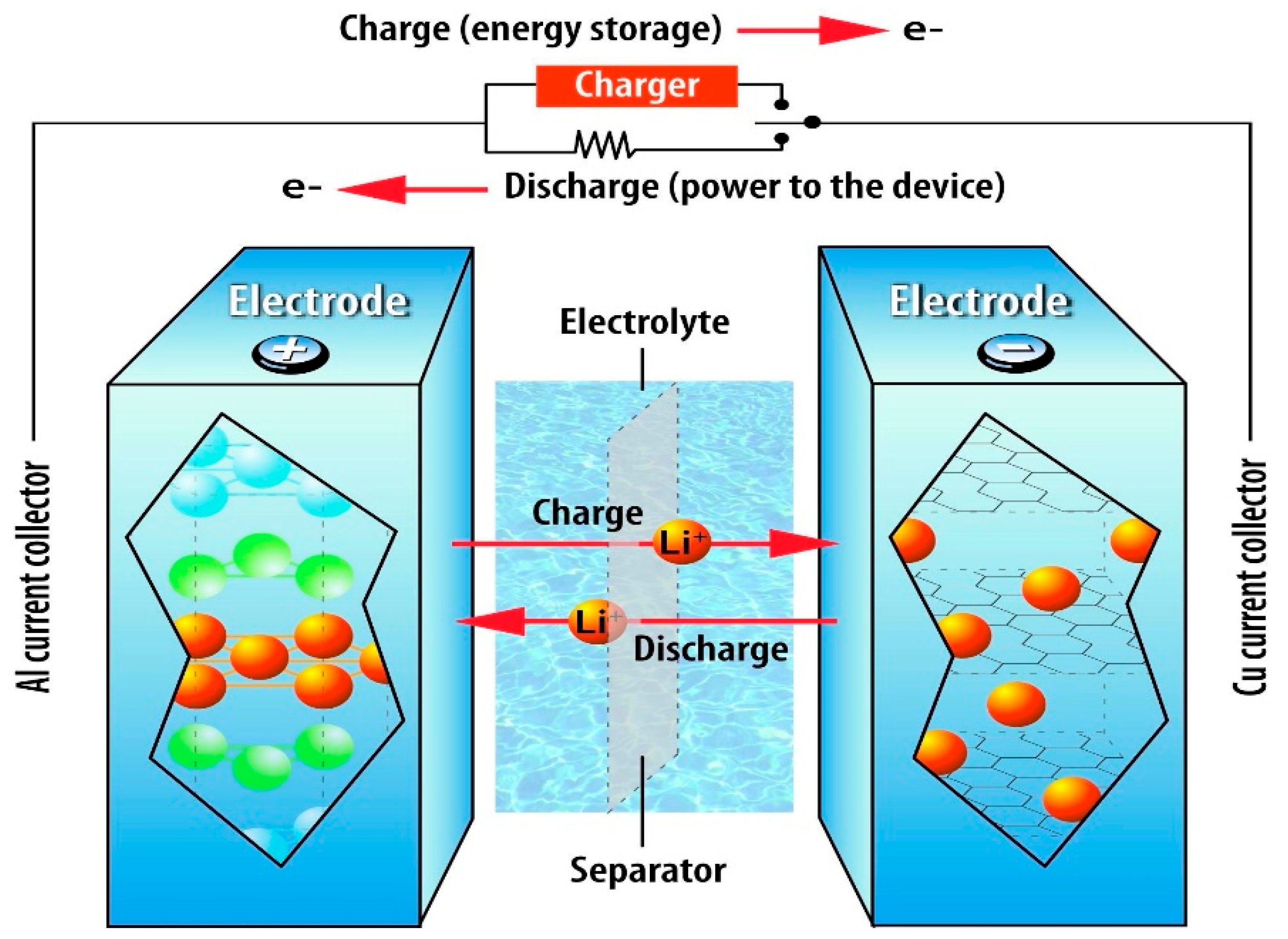

3. Lithium-Ion Battery (LiB)

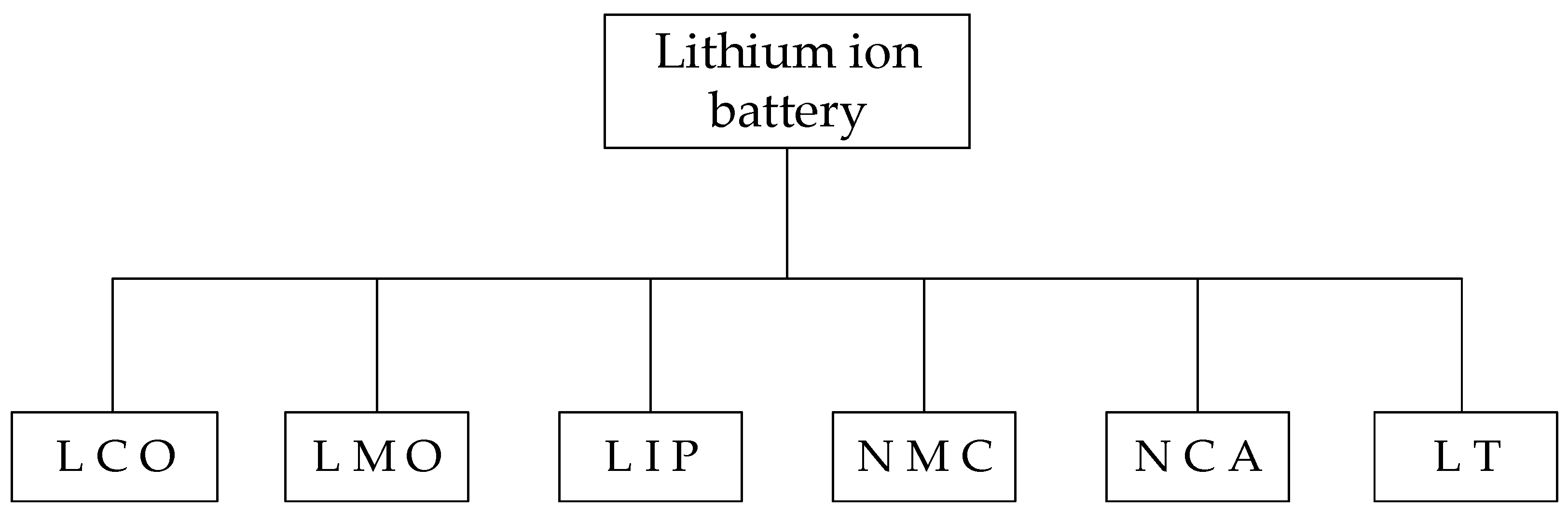

Classifications of Lithium-Ion Batteries

4. Electrolytes

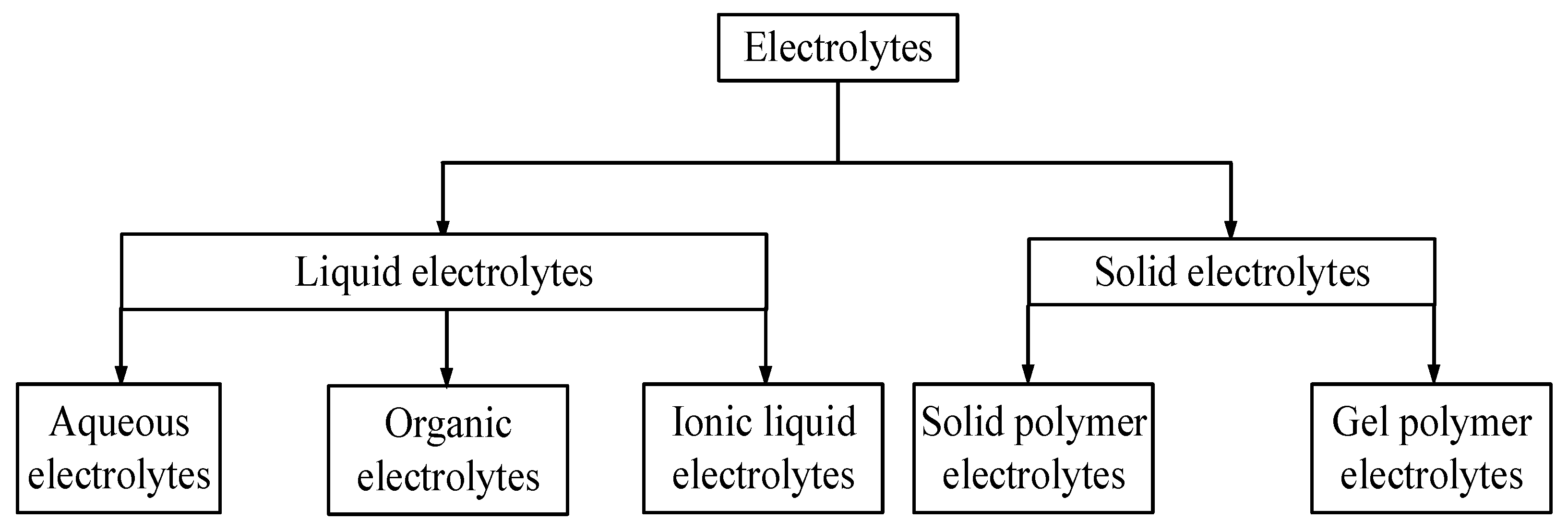

Classification of Electrolytes

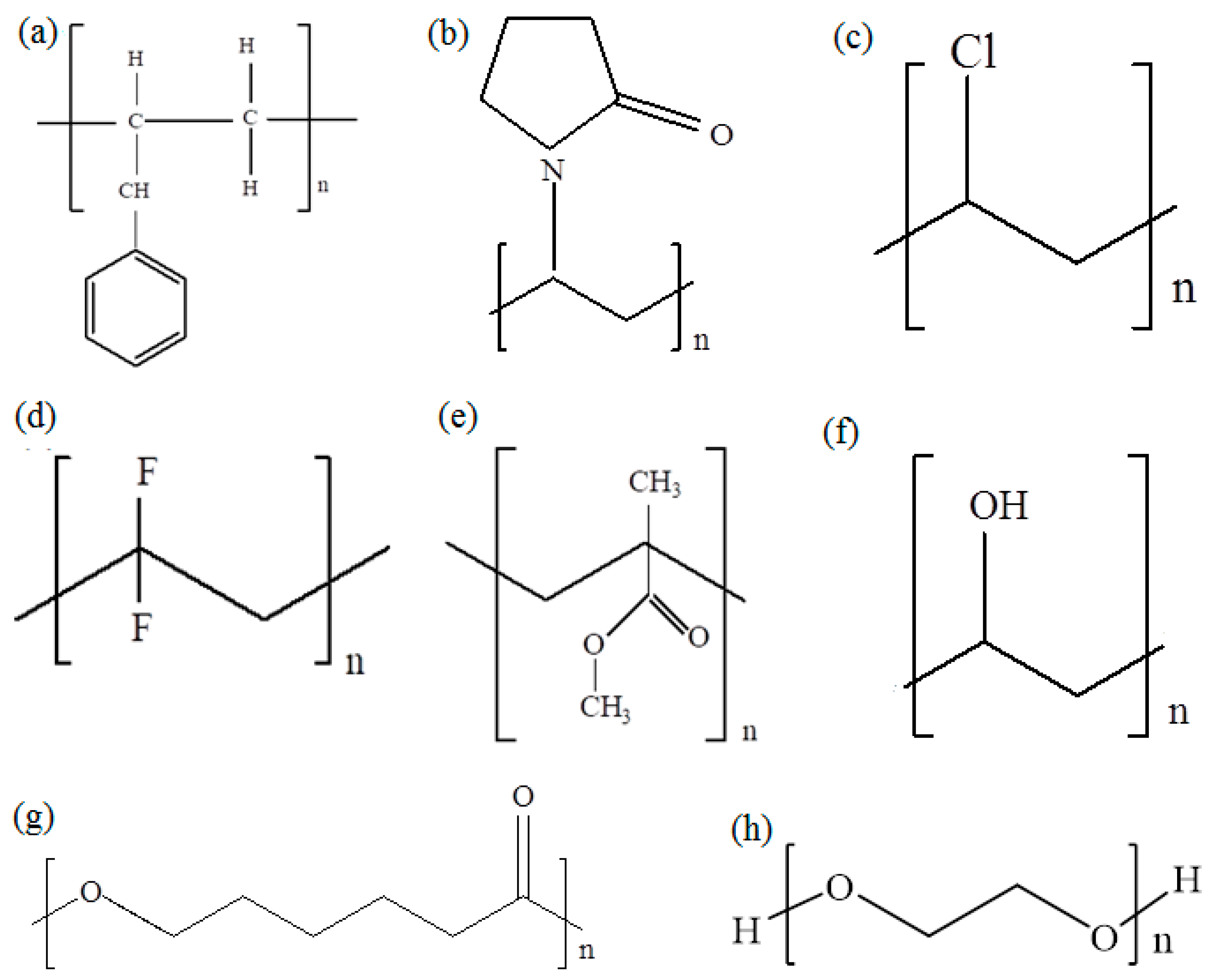

5. Solid Polymer Electrolytes (SPEs)

5.1. Polyvinyl Alcohol (PVA)

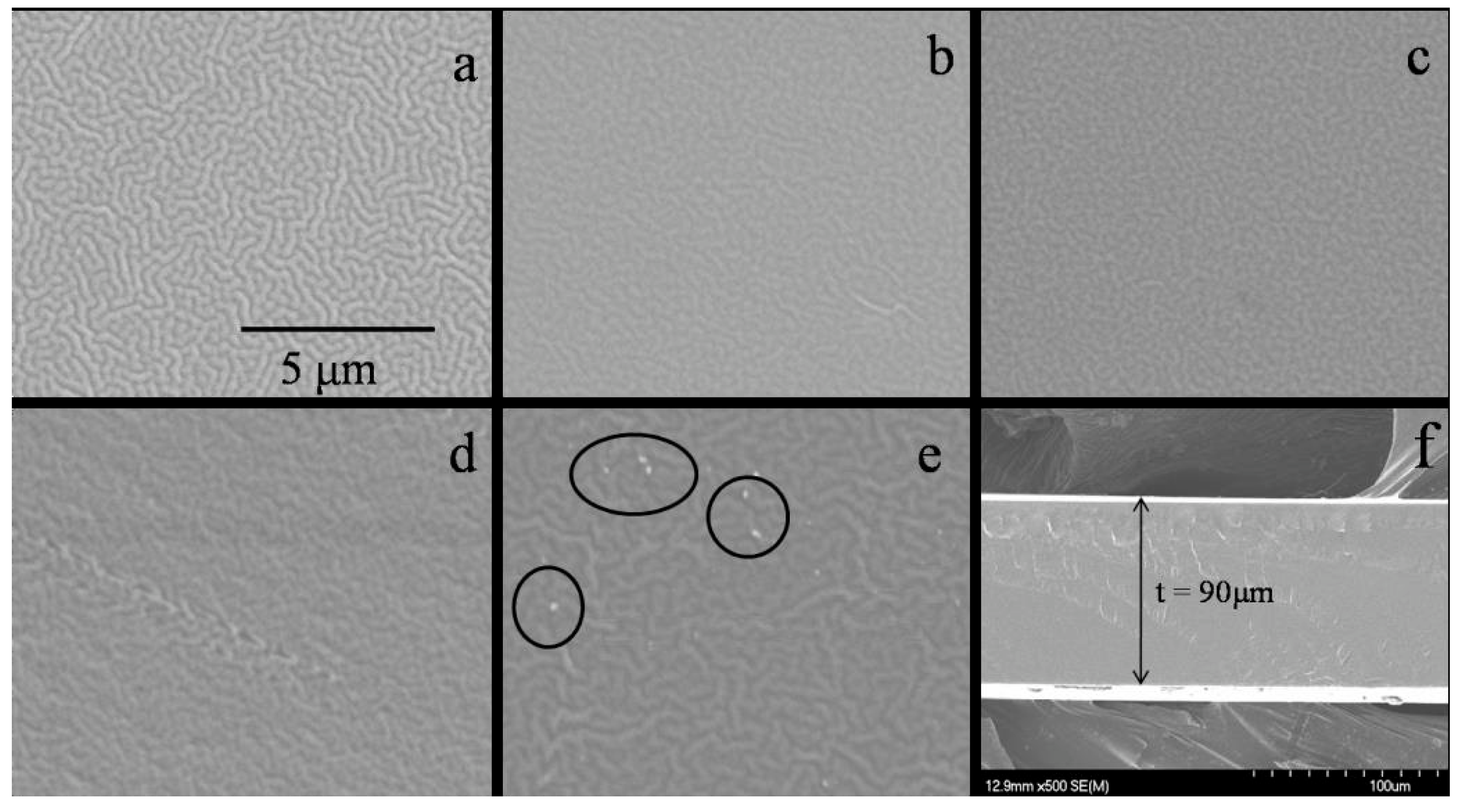

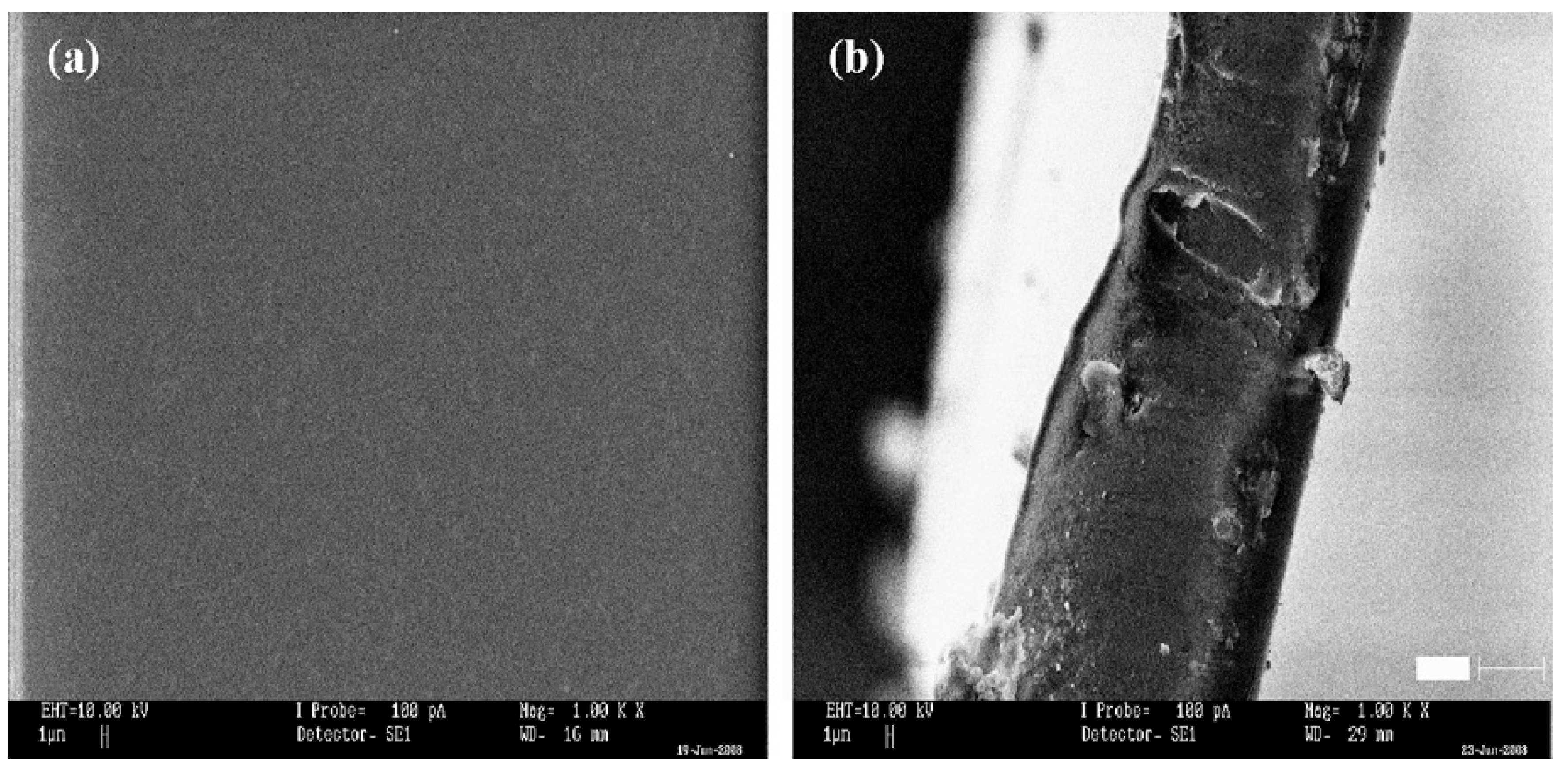

5.2. Physicochemical Properties of PVA

5.3. Why PVA-Based SPEs

5.4. Roles of Salt in PVA-Based SPEs

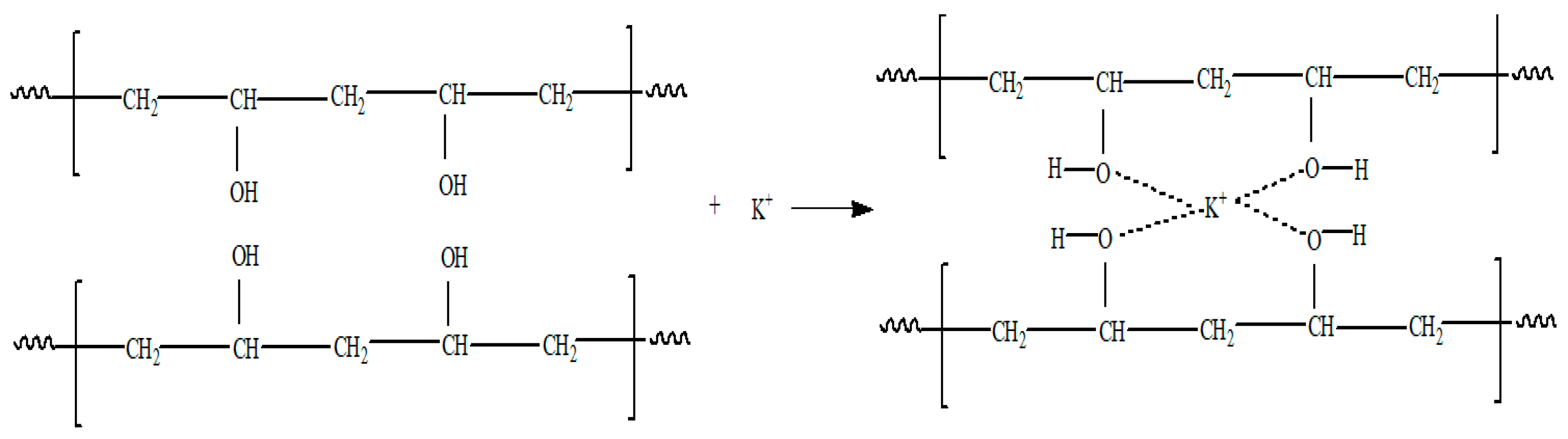

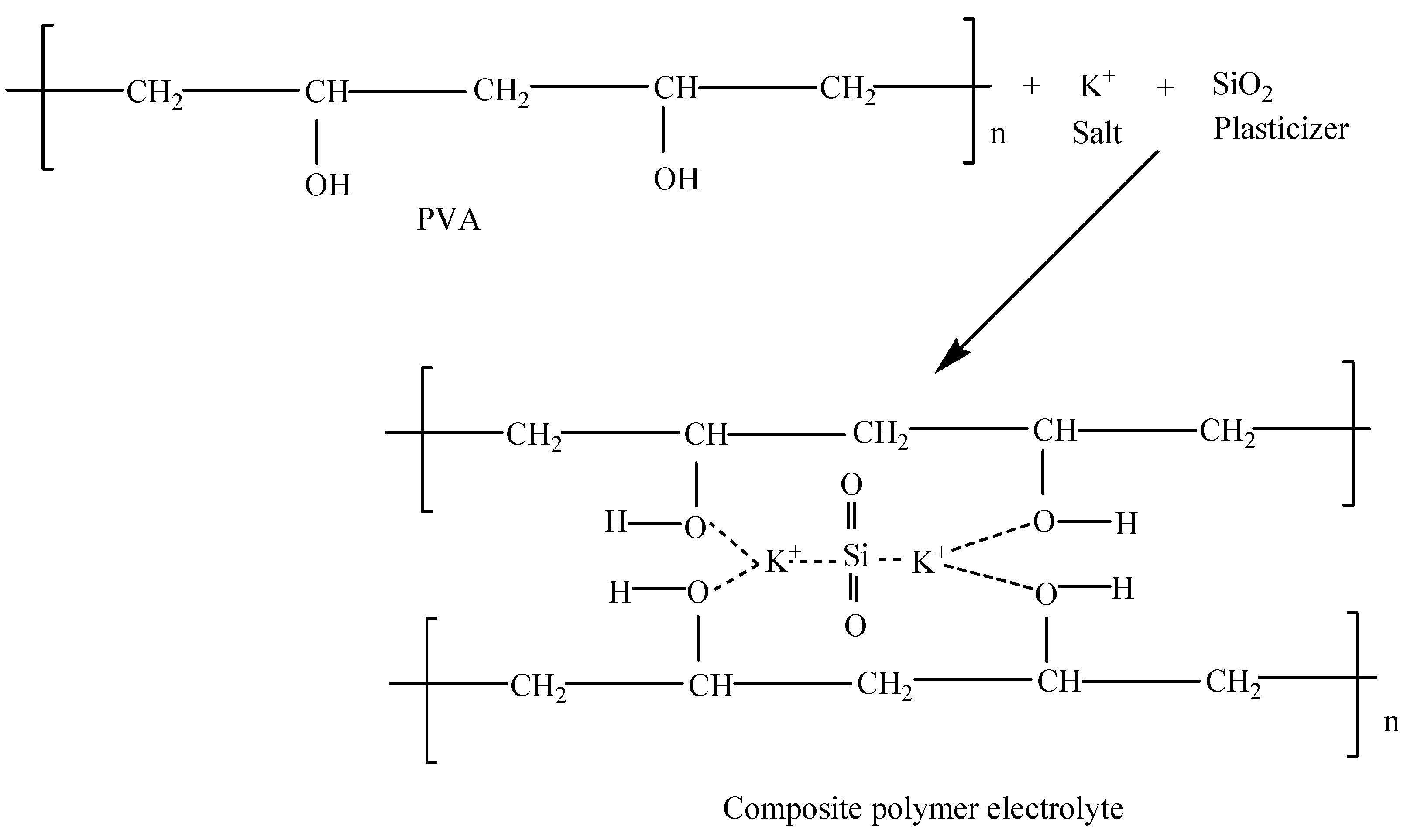

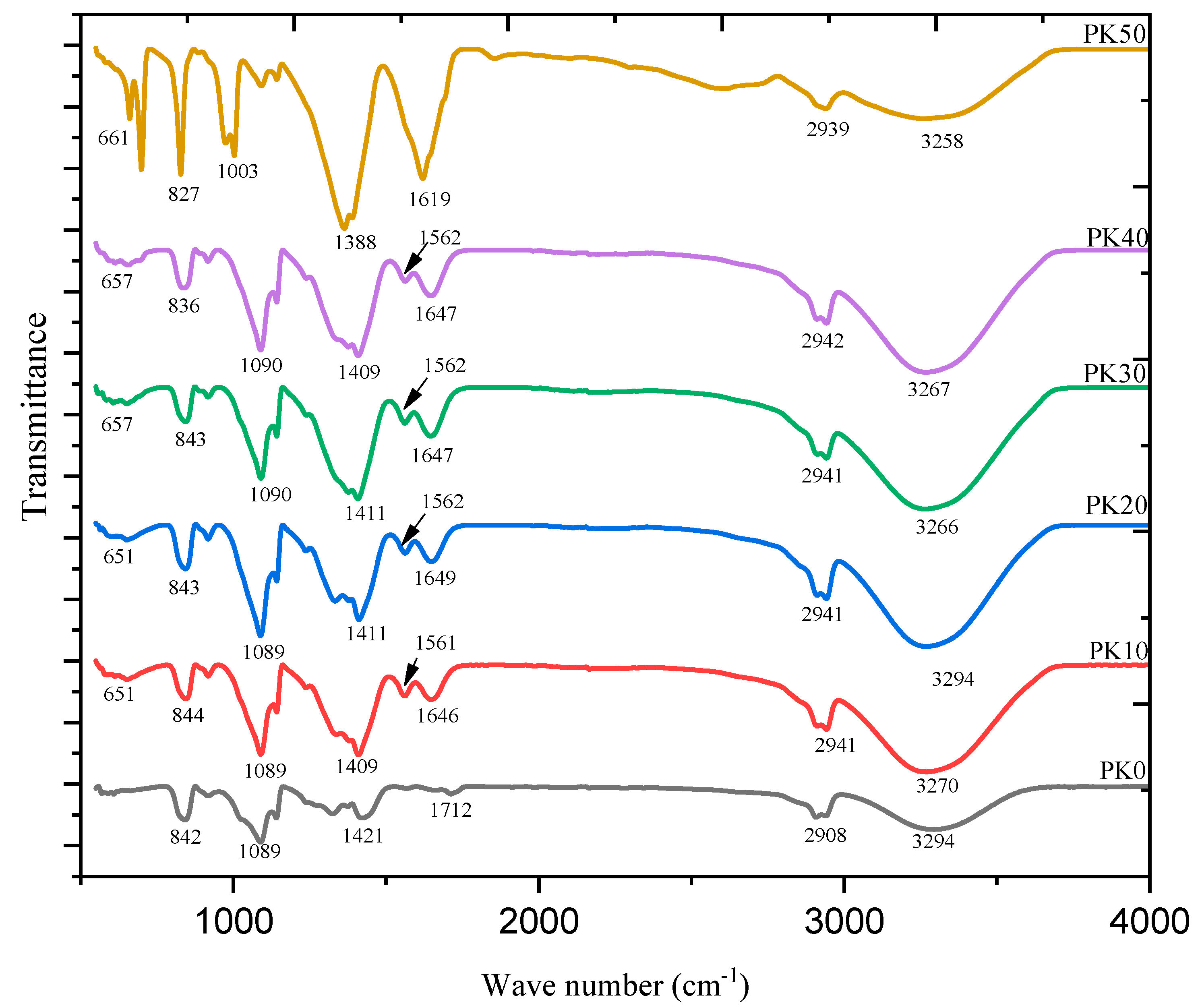

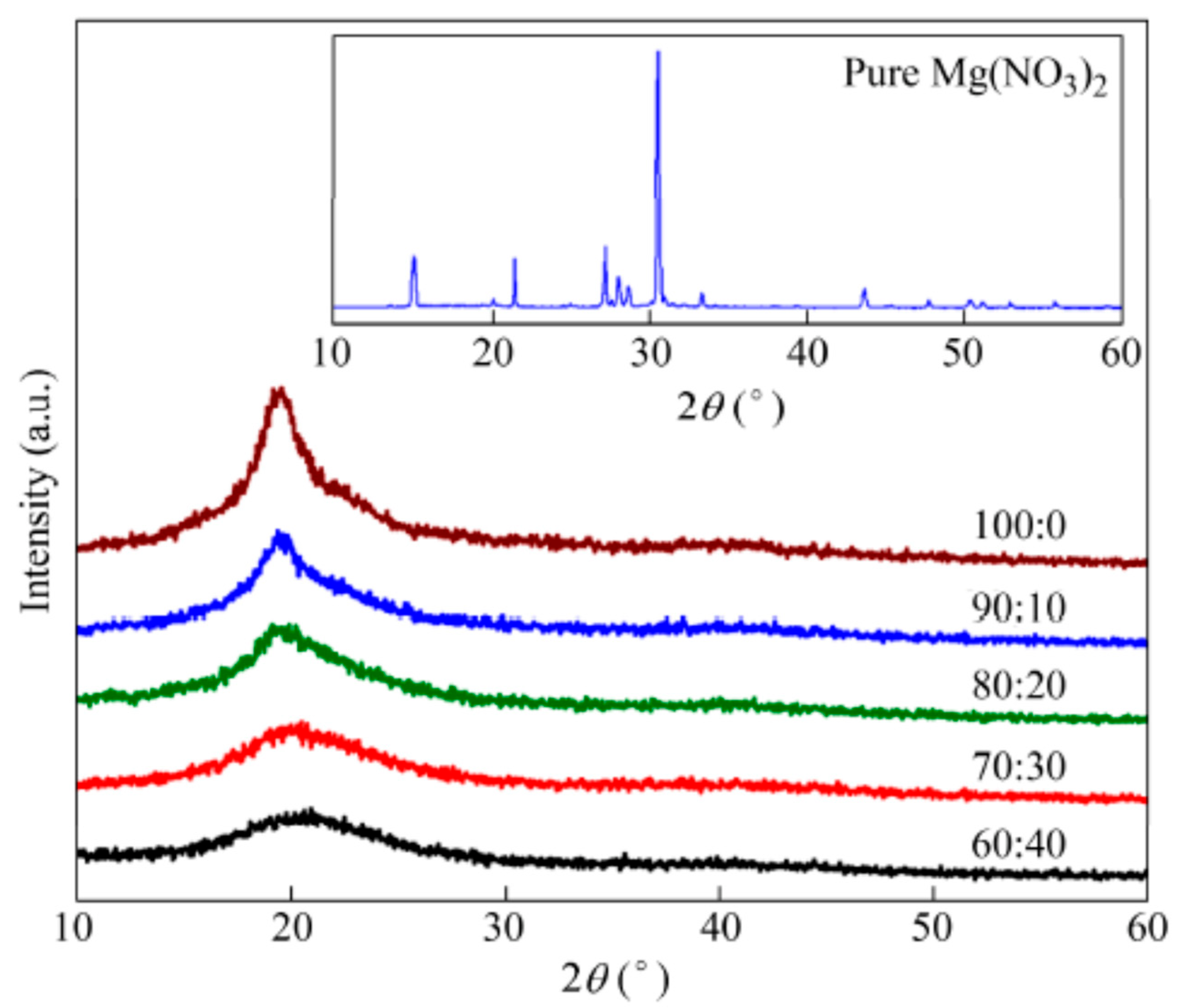

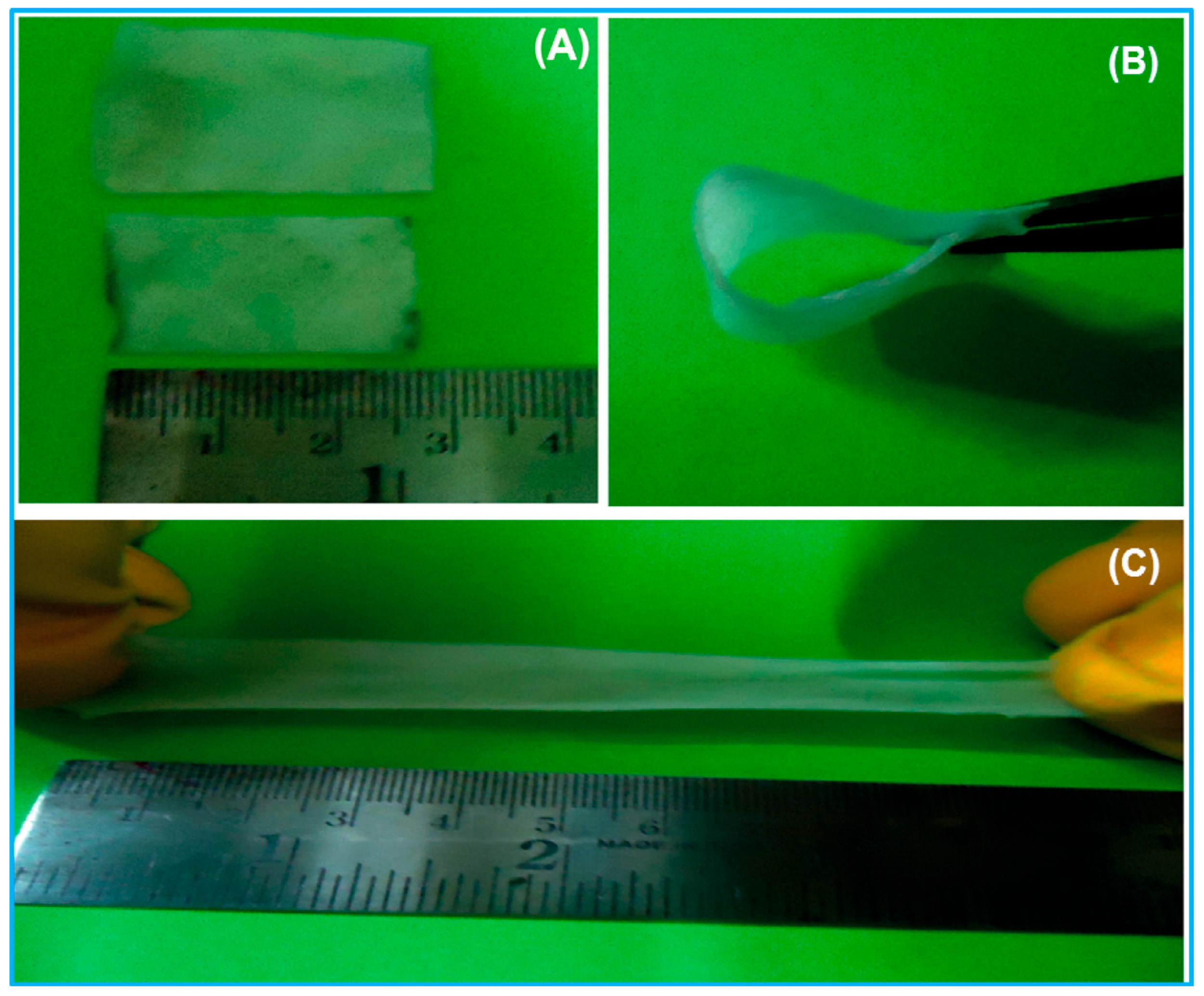

6. Formation of PVA-Based Polymer Electrolyte and Complex Formation

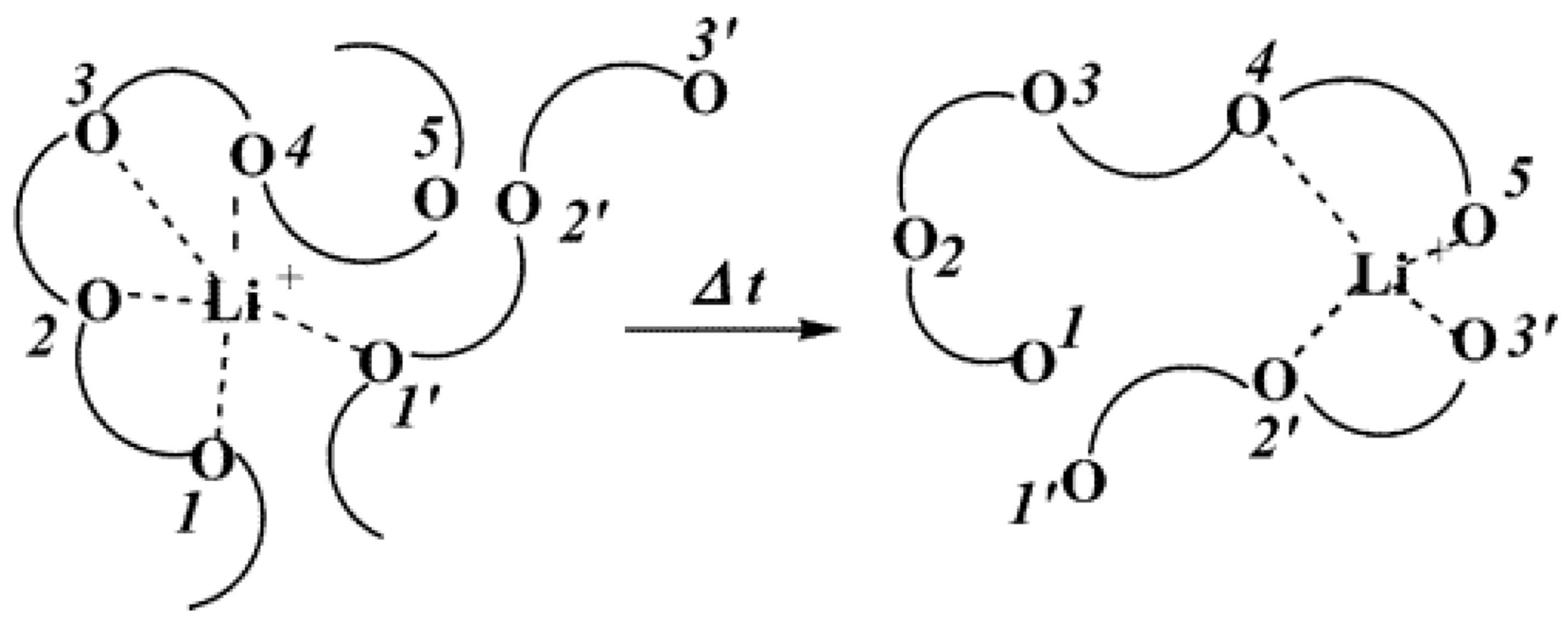

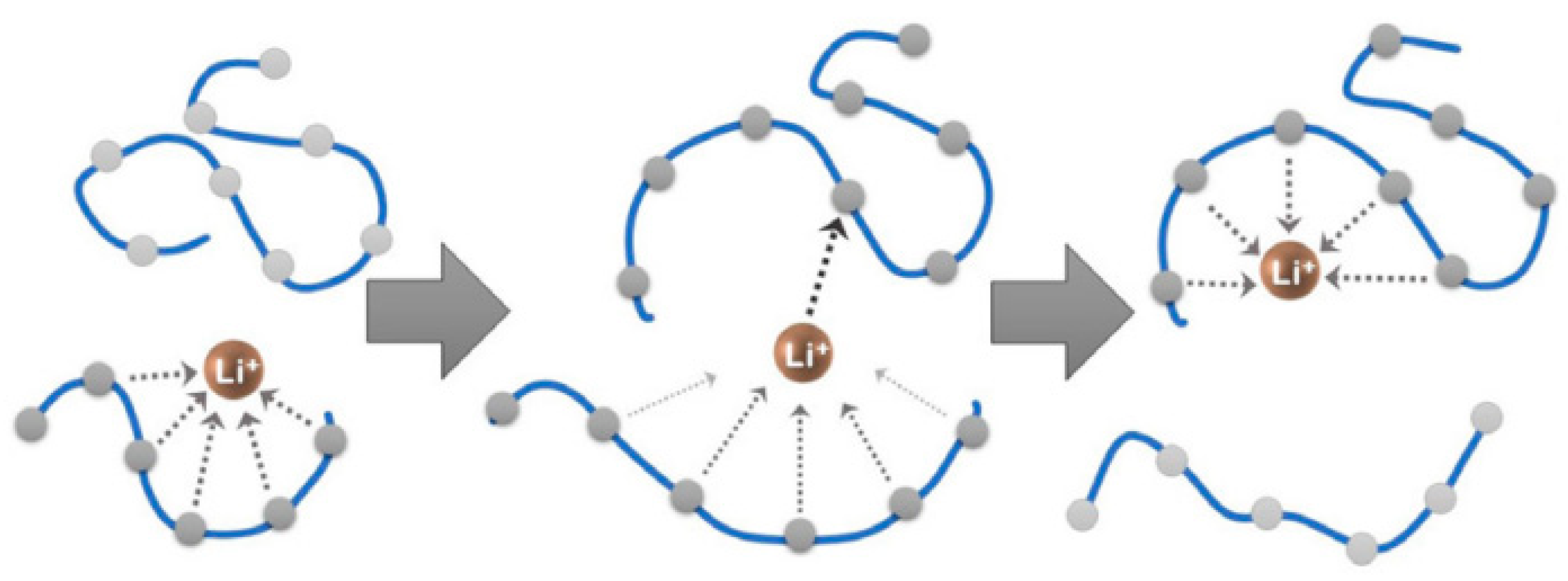

Charge Carriers (Mechanism) and Ion Mobility

7. Electrochemical Performances of PVA-Based Polymer Electrolytes

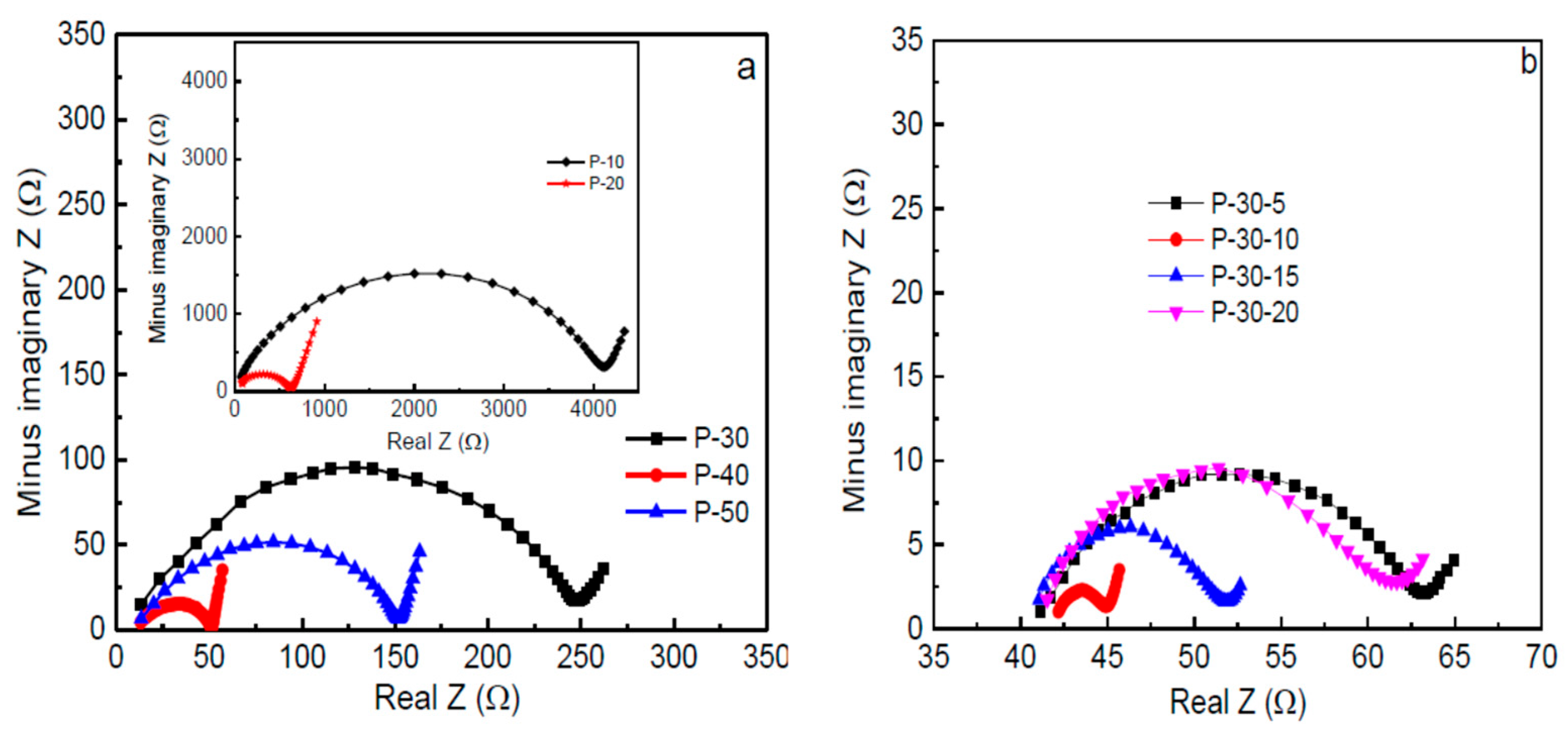

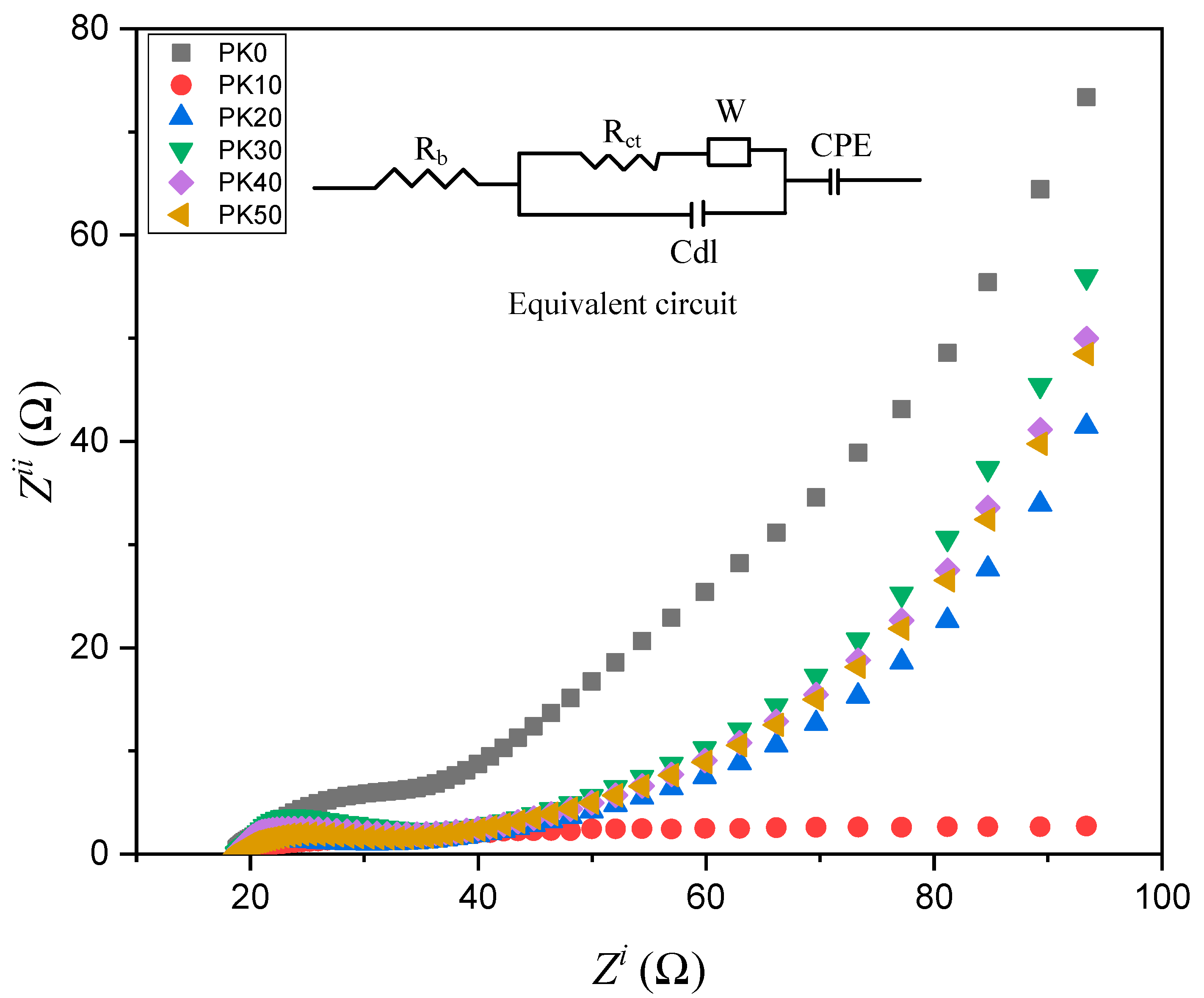

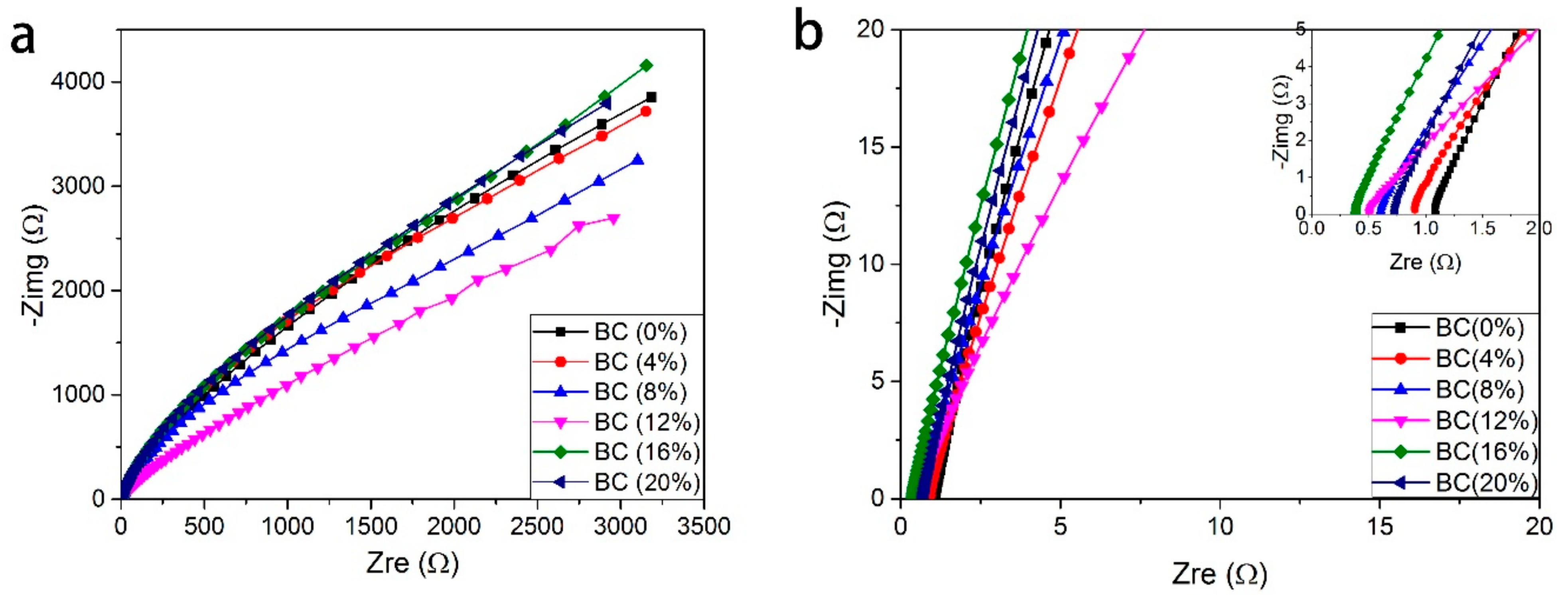

7.1. Electrochemical Impedance Spectroscopy (EIS)

7.2. Principle of Electrochemical Impedance Spectroscopy

7.3. Impedance Spectroscopic Analysis

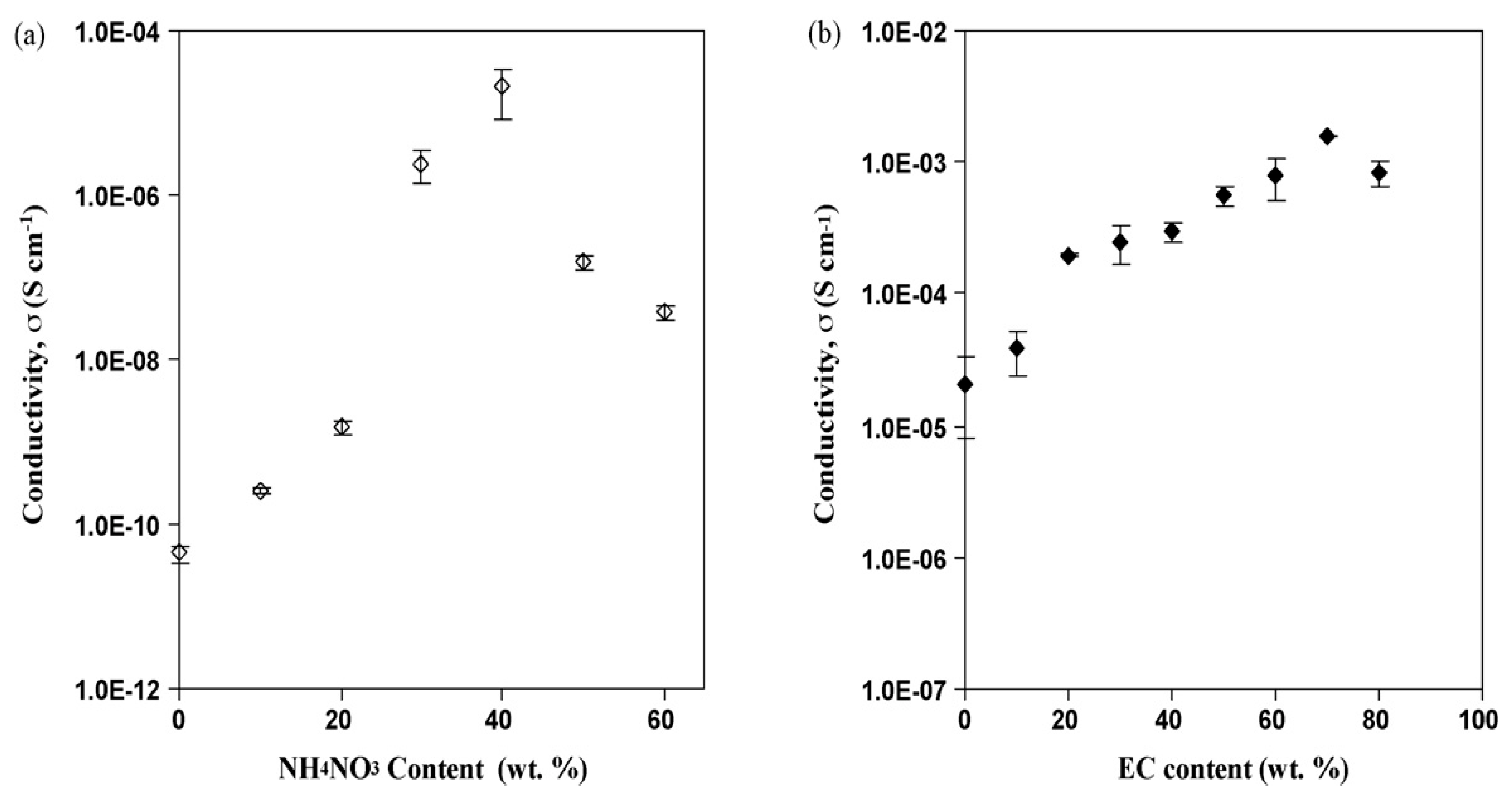

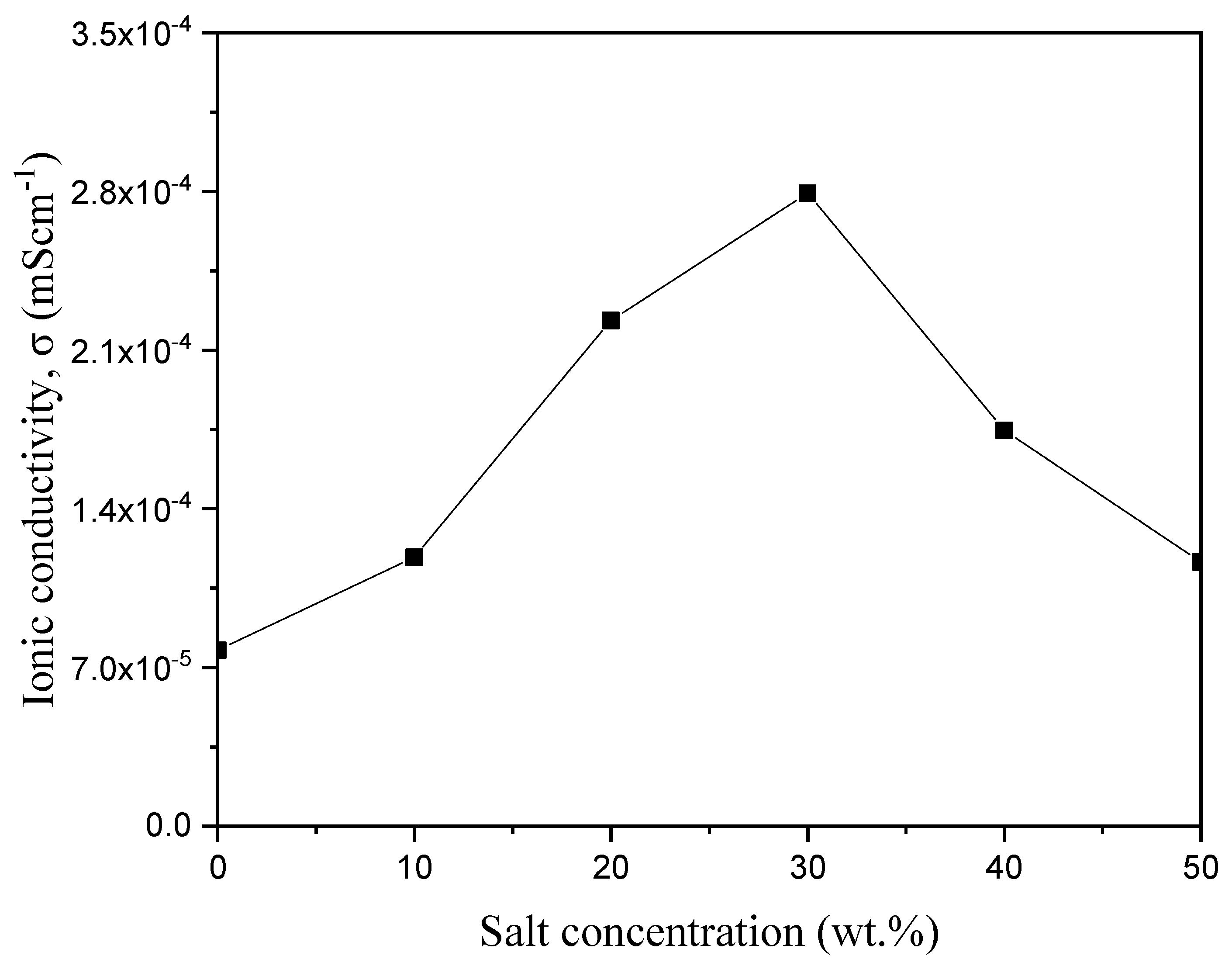

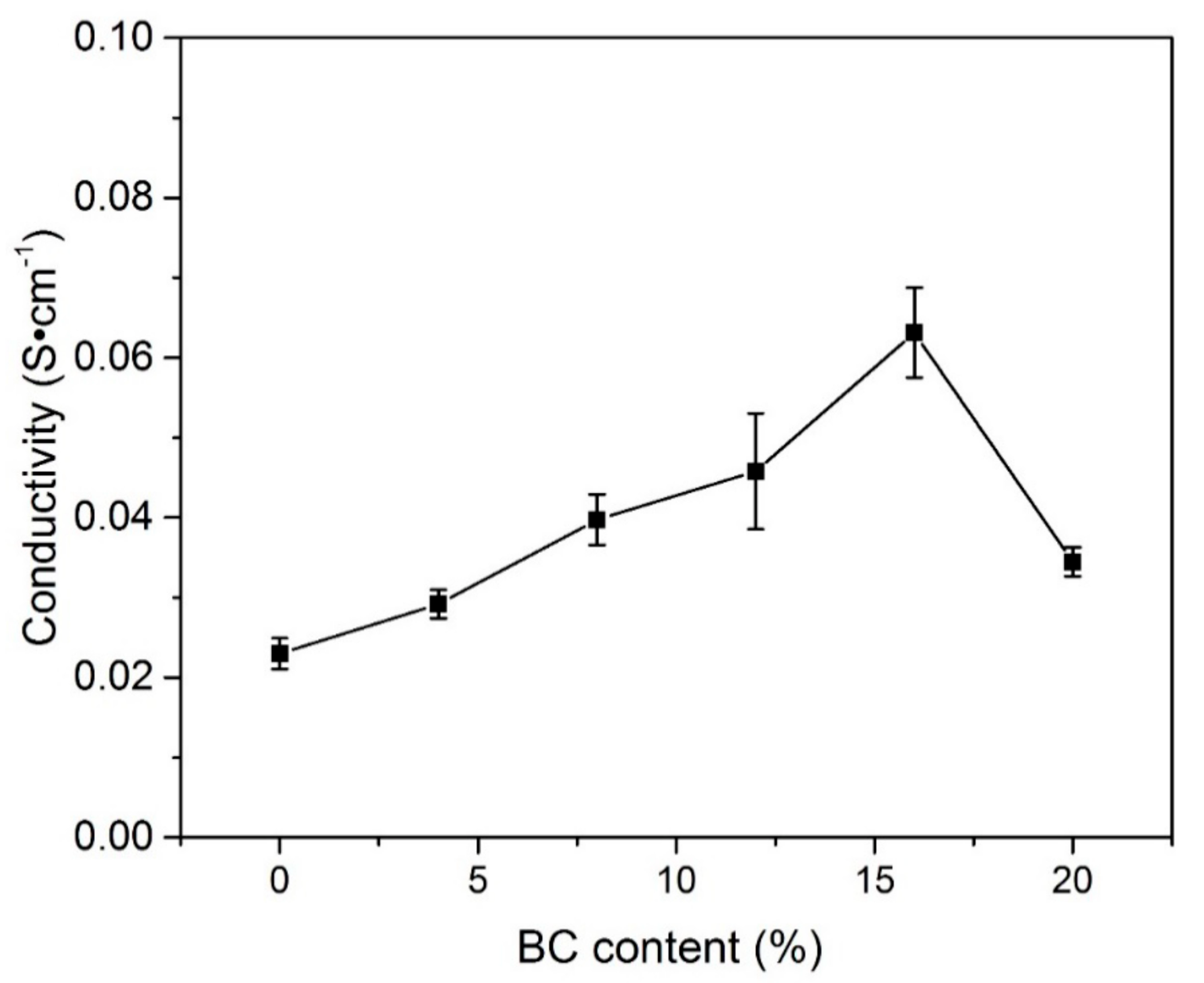

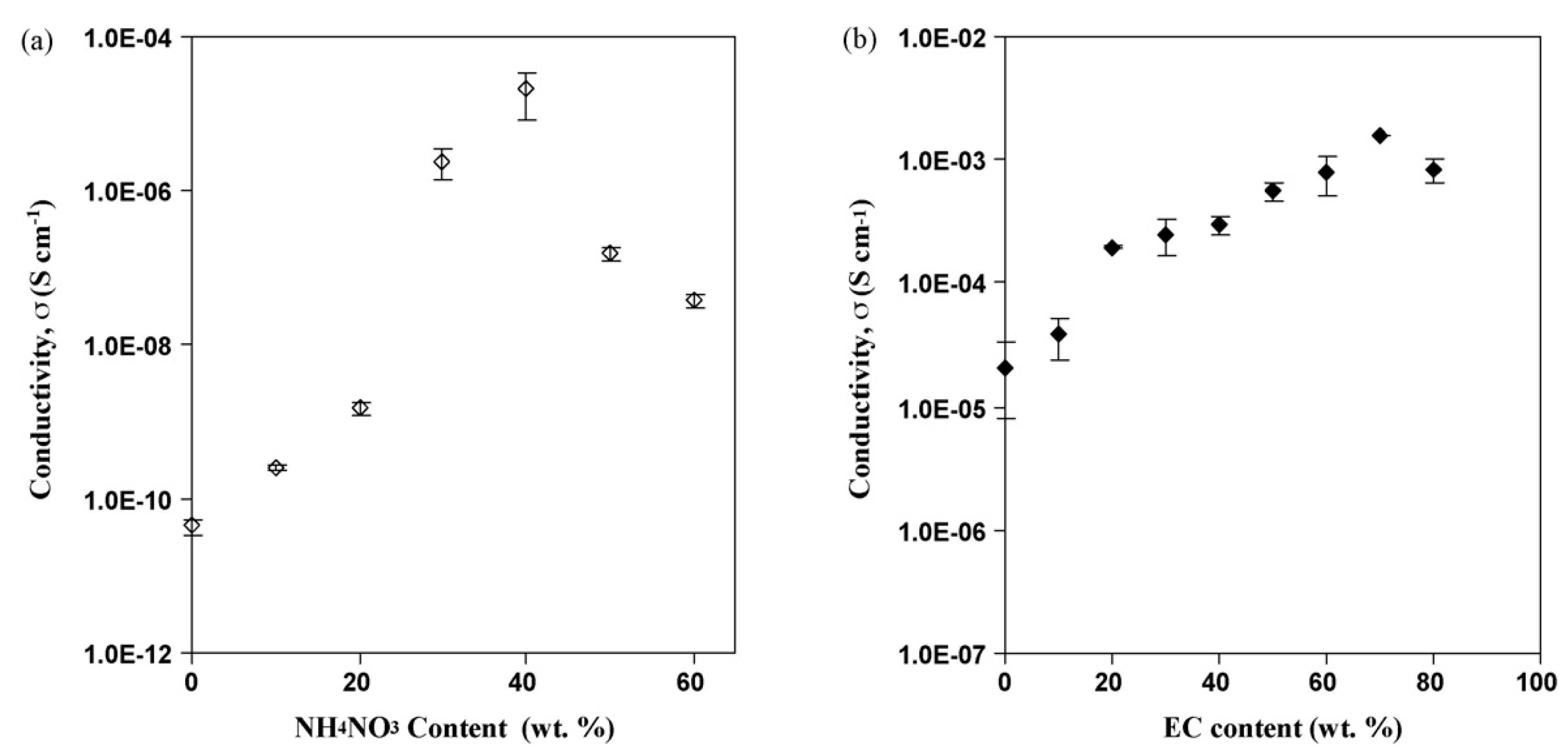

7.4. Ionic Conductivity

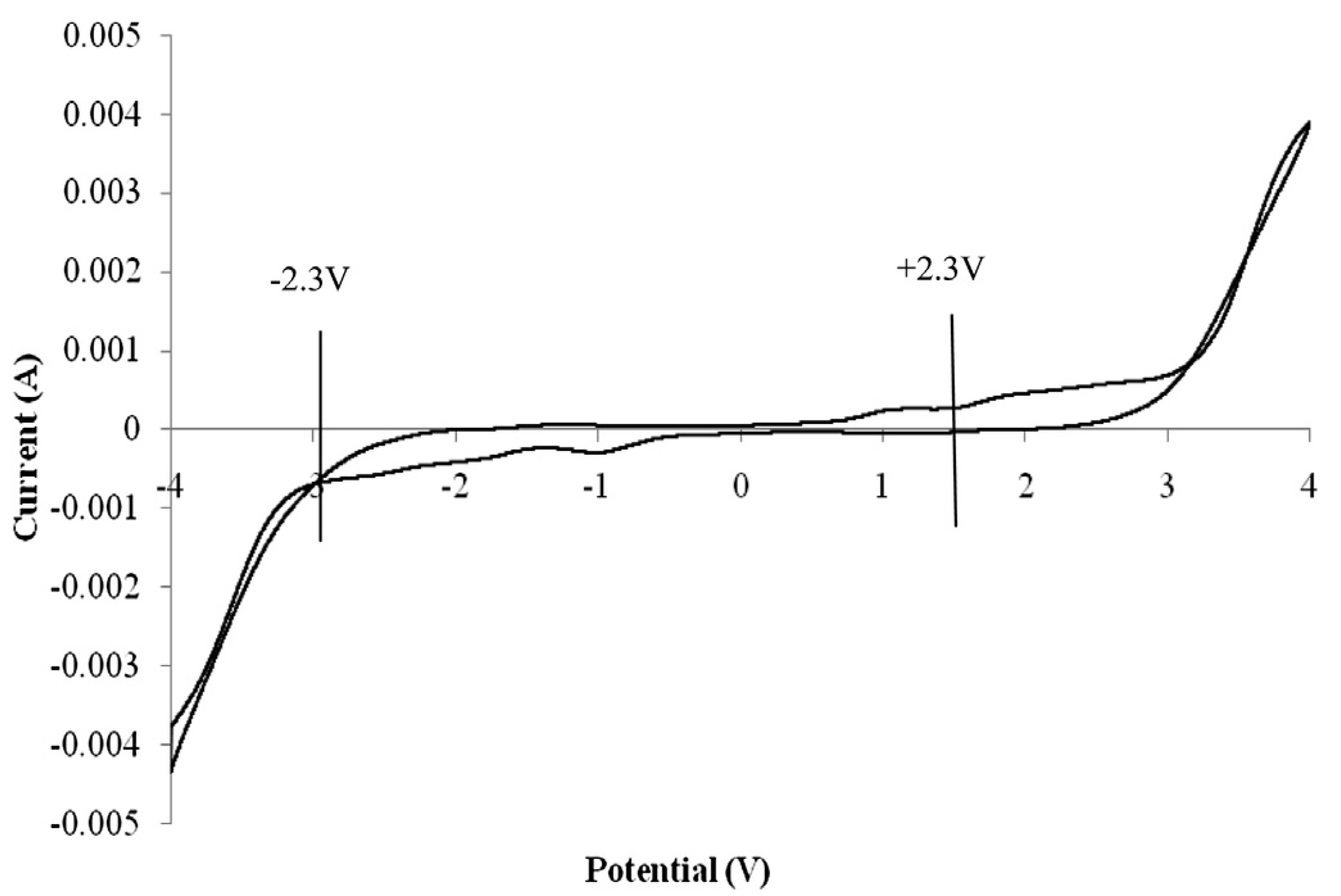

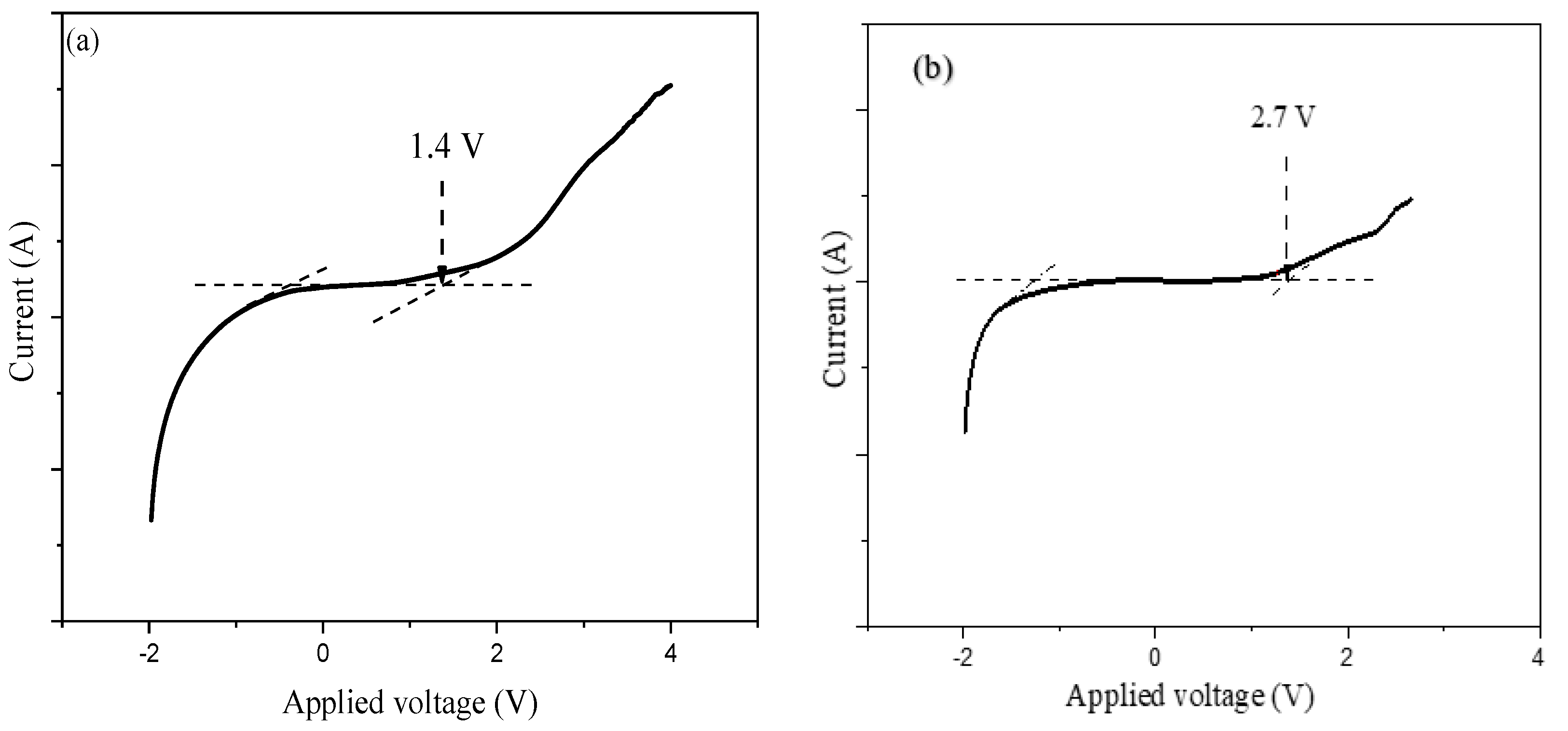

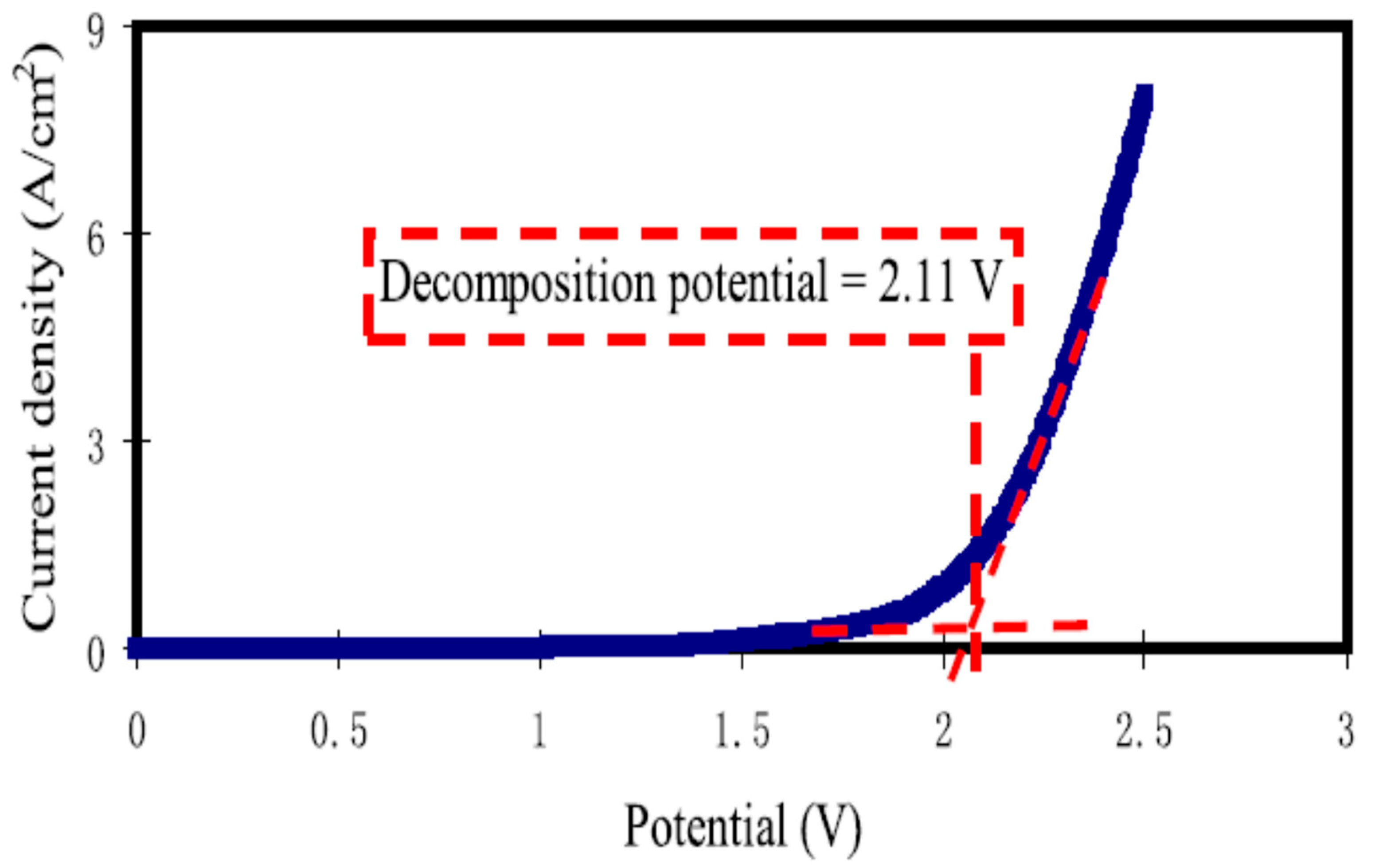

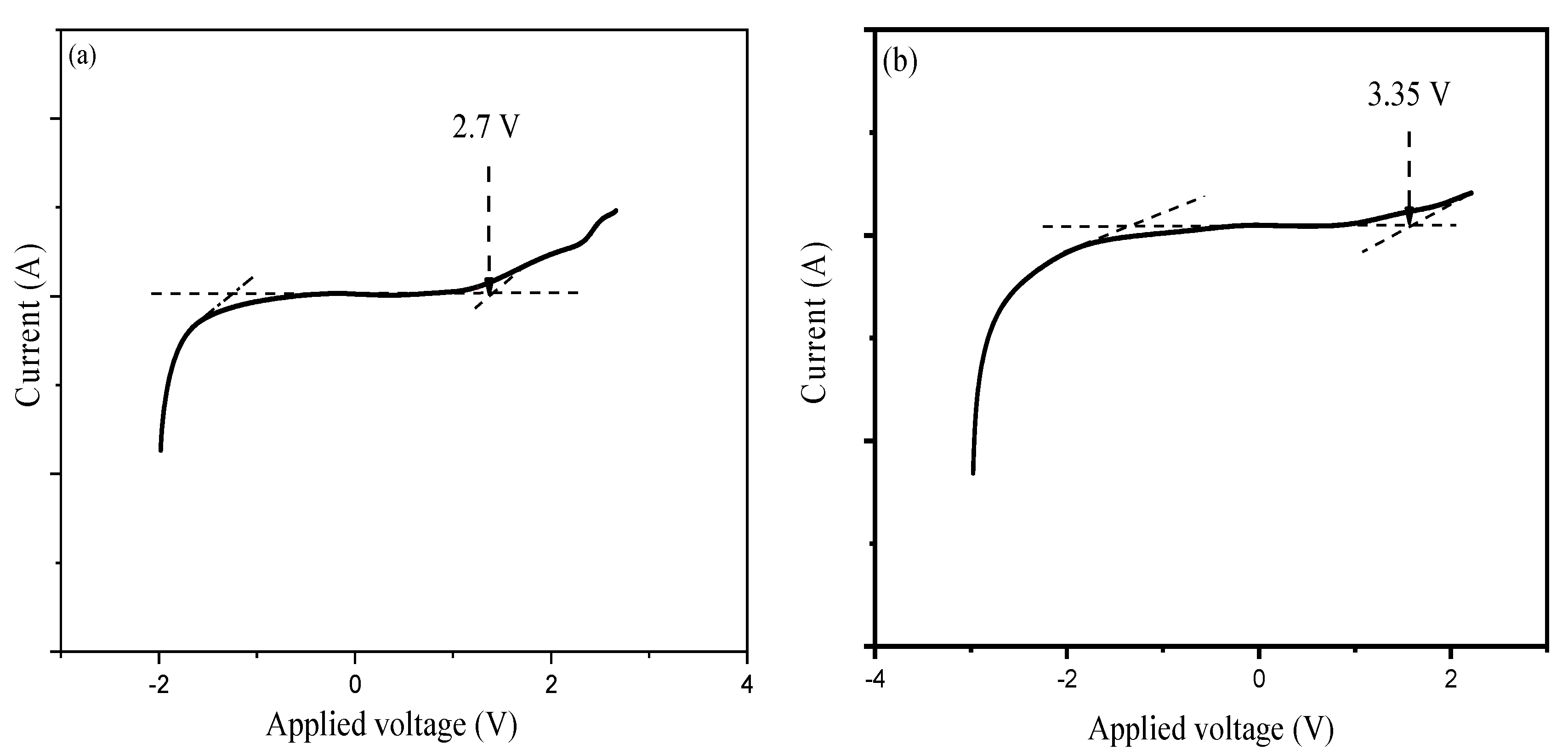

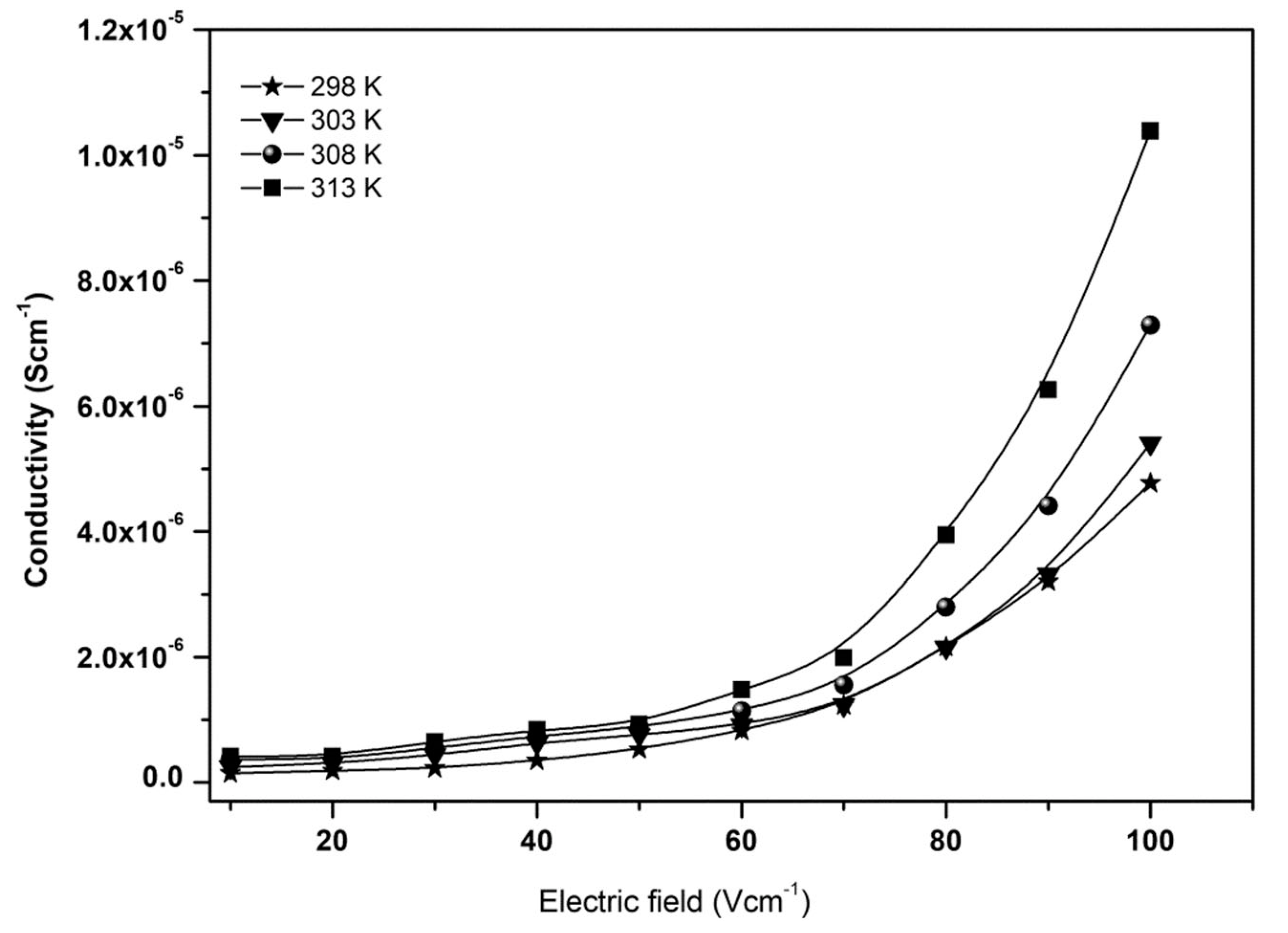

7.5. Potential Window

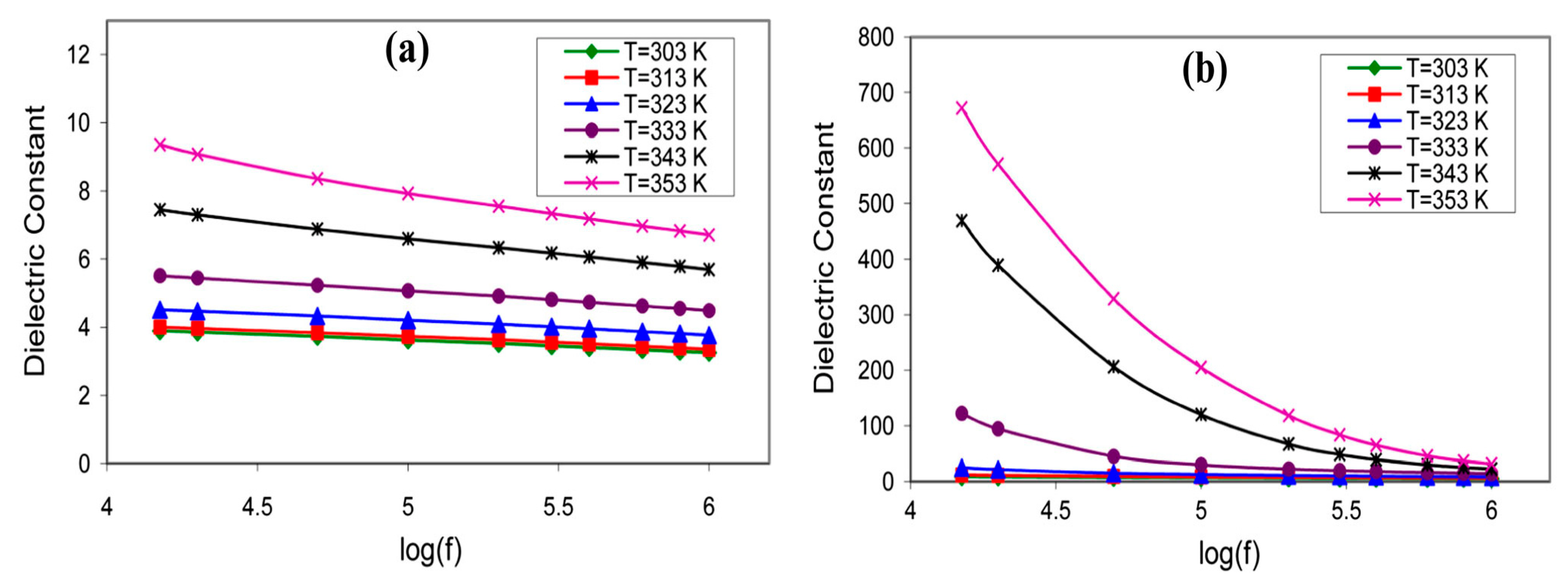

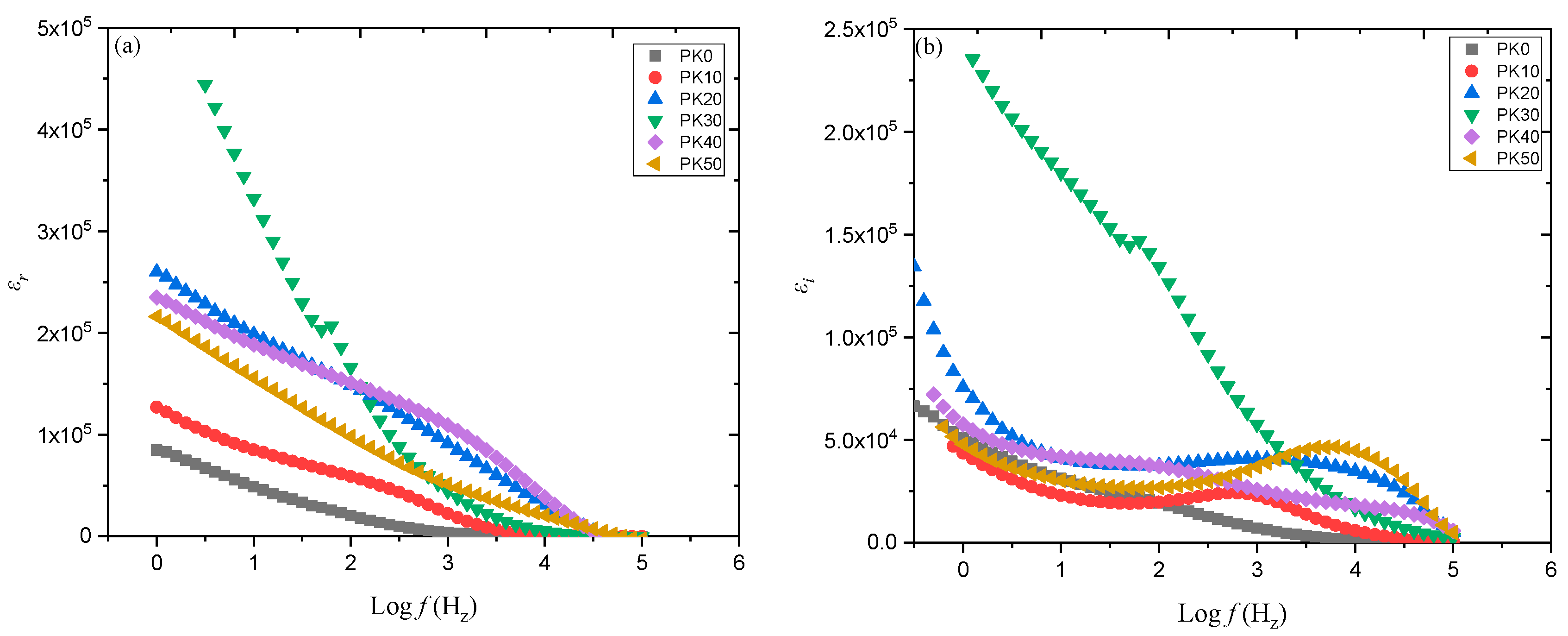

7.6. Dielectric Studies

8. Thermodynamic Effects and Ion Transport Models for Polymer Electrolytes

8.1. Vogel–Tammann–Fulcher (VTF) Model for Ion Transport

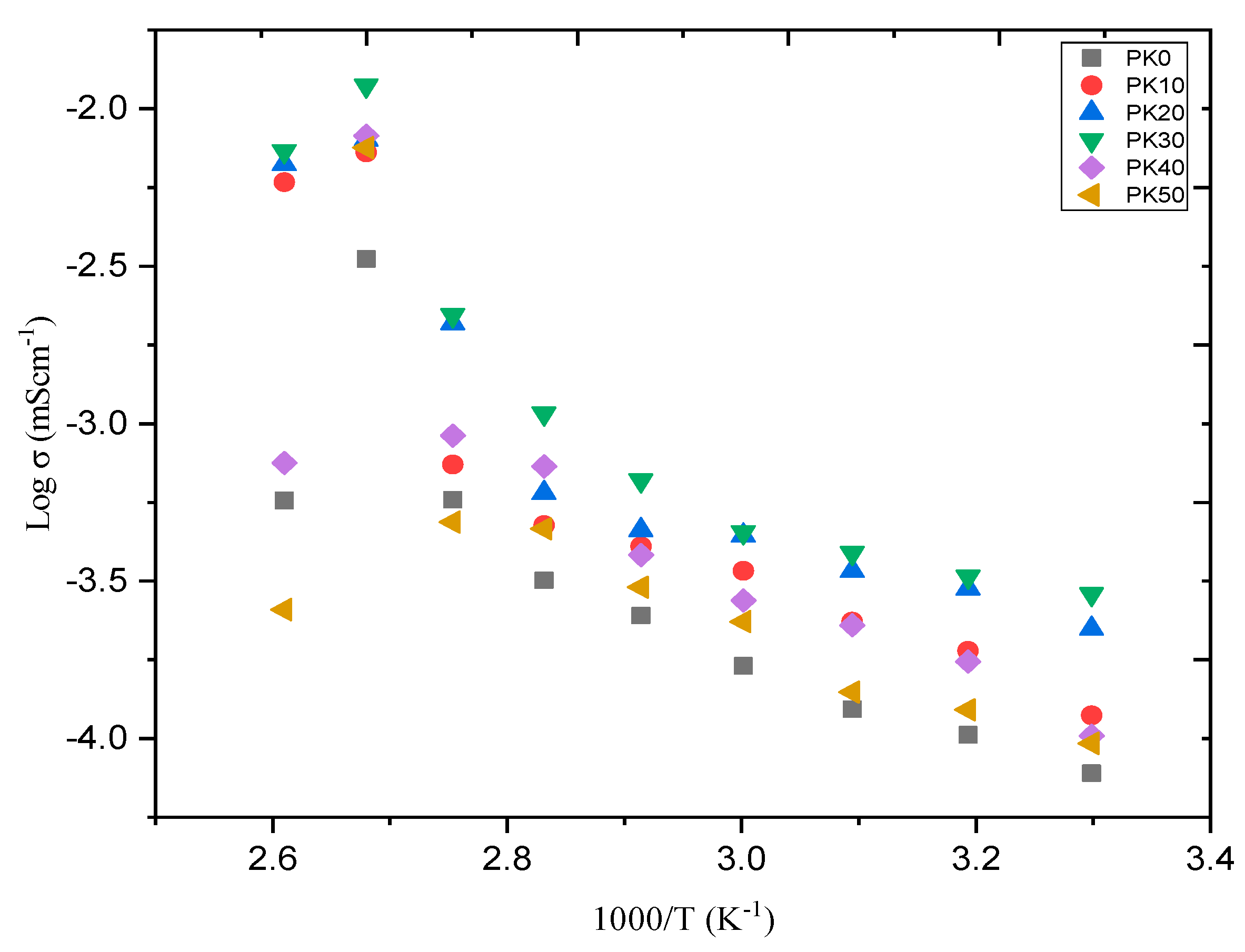

8.2. Arrhenius Model for Ion Transport

9. Methods for Enhancing Performance of PVA-Based SPEs

9.1. Polymer Modifications

9.2. Blending of Different Polymers

9.3. Mixed Salt System

9.4. Additives

9.4.1. Plasticizer

9.4.2. Filler

- (a)

- Increase physical properties of polymer matrix;

- (b)

- Reduce the crystallinity and increase the amorphous degree of the PEs;

- (c)

- Decrease glass transition temperature (Tg) of polymer membrane;

- (d)

- Increase the long-term electrochemical stability and electrochemical devices;

- (e)

- Increase the morphological properties of PEs;

- (f)

- Improve the thermal stability of polymer matrix etc. [140].

10. Application of PVA-Based Polymer Electrolytes

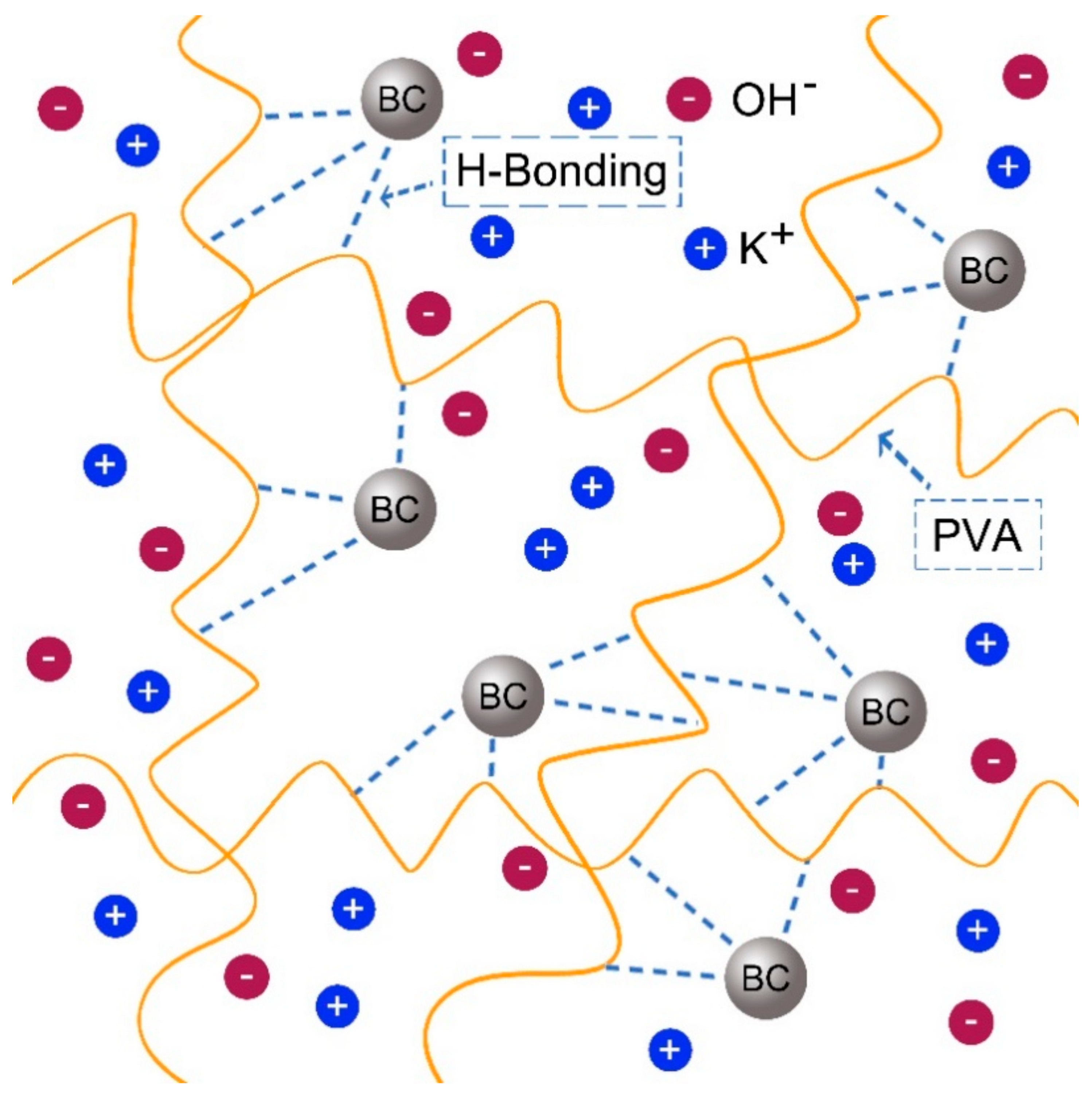

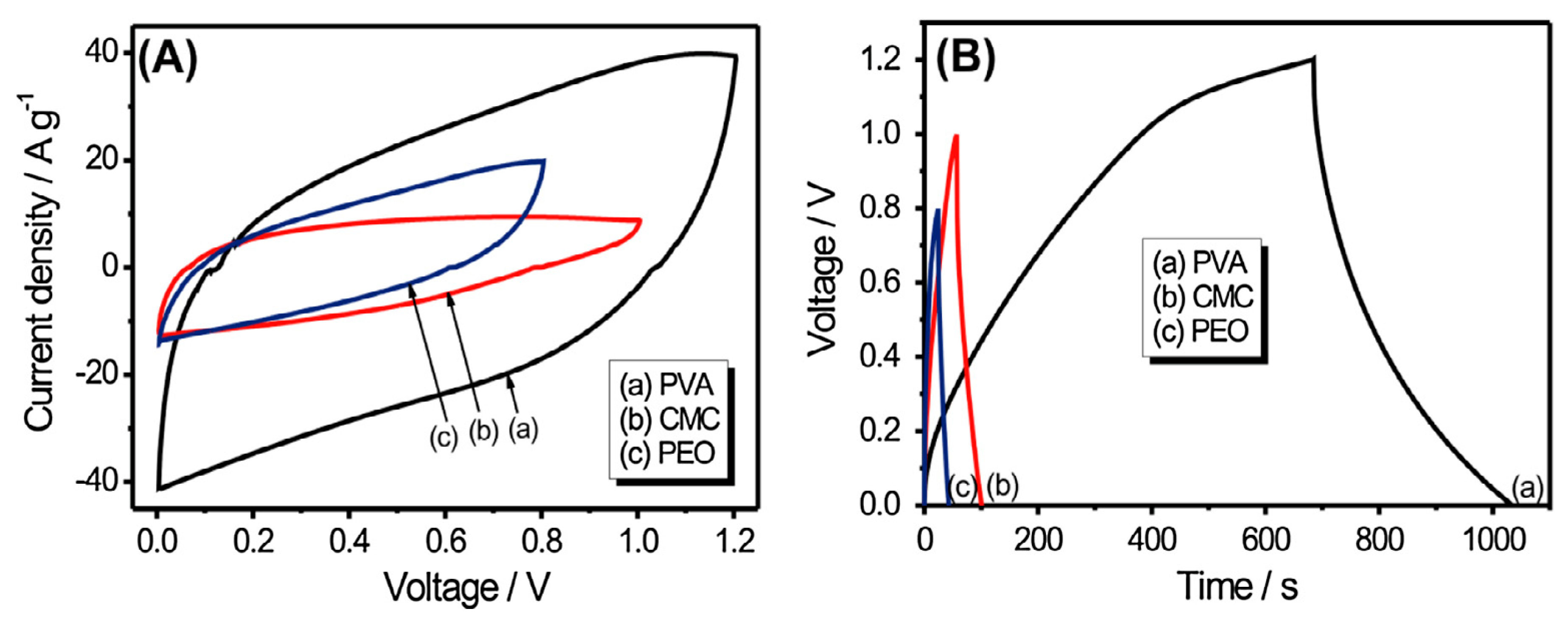

10.1. Application of PVA-Based Polymer Electrolytes in Supercapacitor

10.2. Application of PVA-Based Polymer Electrolytes in LIB

10.3. Application of PVA-Based Polymer Electrolytes in Proton-Conducting Batteries

11. Challenges and Future Directions

12. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Burke, A.; Miller, M. The power capability of ultracapacitors and lithium batteries for electric and hybrid vehicle applications. J. Power Sources 2011, 196, 514–522. [Google Scholar] [CrossRef]

- Chmiola, J.; Yushin, G.; Gogotsi, Y.; Portet, P.; Simon, P.; Taberna, P.L. Anomalous Increase in Carbon Capacitance at Pore Sizes Less Than 1 Nanometer. Science 2006, 313, 1760–1763. [Google Scholar] [CrossRef] [PubMed]

- Mun, Y.; Jo, C.; Hyeon, T.; Lee, J.; Ha, K.S.; Jun, K.W.; Lee, S.H.; Hong, S.W.; Lee, H.I.; Yoon, S.; et al. Simple synthesis of hierarchically structured partially graphitized carbon by emulsion/blockcopolymer co-template method for high power supercapacitors. Carbon 2013, 64, 391–402. [Google Scholar] [CrossRef]

- Naoi, K.; Ishimoto, S.; Miyamoto, J.I.; Naoi, W. Second generation ‘nanohybrid supercapacitor’: Evolution of capacitive energy storage devices. Energy Environ. Sci. 2012, 11, 9363–9373. [Google Scholar] [CrossRef]

- Zhang, L.L.; Zhao, X.S. Carbon-based materials as supercapacitor electrodes. Chem. Soc. Rev. 2009, 38, 2520–2531. [Google Scholar] [CrossRef]

- Chen, Q.; Hu, Y.; Hu, C.; Cheng, H.; Zhang, Z.; Shao, H.; Qu, L. Graphene quantum dots–three-dimensional graphene composites for high-performance supercapacitors. Phys. Chem. Chem. Phys. 2014, 16, 19307–19313. [Google Scholar] [CrossRef]

- Jana, M.; Khanra, P.; Murmu, N.C.; Samanta, P.; Lee, J.H.; Kuila, T. Covalent surface modification of chemically derived graphene and its application as supercapacitor electrode material. Phys. Chem. Chem. Phys. 2014, 16, 7618–7626. [Google Scholar] [CrossRef]

- Deng, L.; Wang, J.; Zhu, G.; Kang, L.; Hao, Z.; Lei, Z.; Yang, Z.; Liu, Z.H. RuO2/graphene hybrid material for high performance electrochemical capacitor. J. Power Sources 2014, 248, 407–415. [Google Scholar] [CrossRef]

- Schneuwly, A.; Gallay, R. Properties and applications of supercapacitors from the state-of-the-art to future trends. In Proceedings of the PCIM 2000, Nürnberg, Germany, 6–8 June 2000; pp. 1–10. [Google Scholar]

- Yu, H.; Tang, Q.; Wu, J.; Lin, Y.; Fan, L.; Huang, M.; Lin, L.; Li, Y.; Yu, F. Using eggshell membrane as a separator in supercapacitor. J. Power Sources 2012, 206, 463–468. [Google Scholar] [CrossRef]

- Sharma, P.; Bhatti, T.S. A review on electrochemical double-layer capacitors. Energy Convers. Manag. 2010, 51, 2901–2912. [Google Scholar] [CrossRef]

- Han, X.; Xiao, G.; Wang, Y.; Chen, X.; Duan, G.; Wu, Y.; Gong, X.; Wang, H. Design and fabrication of conductive polymer hydrogels and their applications in flexible supercapacitors. J. Mater. Chem. A 2020, 8, 23059–23095. [Google Scholar] [CrossRef]

- Lou, J.; Liu, T. Electrochemical valorization of lignin: Status, challenges, and prospects. J. Bioresour. Bioprod. 2023, 8, 1–14. [Google Scholar]

- Zheng, S.; Zhang, J.; Deng, H.; Du, Y.; Shi, X. Chitin derived nitrogen-doped porous carbons with ultrahigh specific surface area and tailored hierarchical porosity for high performance supercapacitors. J. Bioresour. Bioprod. 2021, 6, 142–151. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Hou, H.; Xu, W.; Duan, G.; He, S.; Liu, K.; Jiang, S. Recent progress in carbon-based materials for supercapacitor electrodes: A review. J. Mater. Sci. 2020, 56, 173–200. [Google Scholar] [CrossRef]

- Xiao, J.; Li, H.; Zhang, H.; He, S.; Zhang, Q.; Liu, K.; Jiang, S.; Duan, G.; Zhang, K. Nanocellulose and its derived composite electrodes toward supercapacitors: Fabrication, properties, and challenges. J. Bioresour. Bioprod. 2022, 7, 245–269. [Google Scholar] [CrossRef]

- Zhong, C.; Deng, Y.; Hu, W.; Qiao, J.; Zhang, L.; Zhang, J. A review of electrolyte materials and compositions for electrochemical supercapacitors. Chem. Soc. Rev. 2015, 44, 21. [Google Scholar] [CrossRef]

- Jiří, L.; Josef, M.; Jiří, V.; Ondřej, Č.; Marie, S. Supercapacitors: Properties and applications. J. Energy Storage 2018, 17, 224–227. [Google Scholar]

- Faisal, M.; Hannan, M.A.; Member, S.; Blaabjerg, F. Review of Energy Storage System Technologies in Microgrid Applications: Issues and Challenges. IEEE Access 2018, 6, 35143–35164. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, G.; Zhou, T.; Sun, S. Recent Developments of Planar Micro-Supercapacitors: Fabrication, Properties, and Applications. Adv. Funct. Mater. 2020, 30, 191000. [Google Scholar] [CrossRef]

- Molina, M.G. Distributed Energy Storage Systems for Applications in Future Smart Grids. In Proceedings of the 2012 6th IEEE/PES Transmission and Distribution: Latin America Conference and Exposition (T&D-LA), Montevideo, Uruguay, 3–5 September 2012; pp. 1–7. [Google Scholar]

- Brandt, A.; Pohlmann, S.; Varzi, A.; Balducci, A.; Passerini, S. Ionic liquids in supercapacitors. MRS Bull. 2013, 38, 554–559. [Google Scholar] [CrossRef]

- Yang, H.; Liu, Y.; Kong, L.; Kang, L.; Ran, F. Biopolymer-based carboxylated chitosan hydrogel fi lm crosslinked by HCl as gel polymer electrolyte for all-solid-sate supercapacitors. J. Power Sources 2019, 426, 47–54. [Google Scholar] [CrossRef]

- Li, Y.; Wong, K.W.; Ng, K.M. Ionic liquid decorated mesoporous silica nanoparticles: A new high-performance hybrid electrolyte for lithium batteries. Chem. Comm. 2013, 10, 4369–4372. [Google Scholar] [CrossRef]

- Zheng, C.; Gao, J.; Yoshio, M.; Qi, L.; Wang, H. Non-porous activated mesophase carbon microbeads as a negative electrode material for asymmetric electrochemical capacitors. J. Power Sources 2013, 231, 29–33. [Google Scholar] [CrossRef]

- Fic, K.; Lota, G.; Meller, M.; Frackowiak, E. Novel insight into neutral medium as electrolyte for high-voltage supercapacitors. Energy Environ. Sci. 2012, 5, 5842–5850. [Google Scholar] [CrossRef]

- Gao, Y. Graphene and Polymer Composites for Supercapacitor Applications: A Review. Nanoscale Res. Lett. 2017, 387, 387. [Google Scholar] [CrossRef]

- Arof, A.K.; Kufian, M.Z.; Syukur, M.F.; Aziz, M.F.; Abdelrahman, A.E.; Majid, S.R. Electrical double layer capacitor using poly (methyl methacrylate)–C4BO8 Li gel polymer electrolyte and carbonaceous material from shells of mata kucing (Dimocarpus longan) fruit. Electrochim. Acta 2012, 74, 39–45. [Google Scholar] [CrossRef]

- Na, R.; Lu, N.; Zhang, S.; Huo, G.; Yang, Y.; Zhang, C.; Mu, Y.; Luo, Y.; Wang, G. Facile synthesis of a high-performance, fire-retardant organic gel polymer electrolyte for flexible solid-state supercapacitors. Electrochim. Acta 2018, 290, 262–272. [Google Scholar] [CrossRef]

- Qingsong, Z.; Jianghao, N.; Ziheng, Z.; Qiong, W. Research on the effect of thermal runaway gas components and explosion limits of lithium-ion batteries under different charge states. J. Energy Storage 2022, 45, 103659. [Google Scholar]

- Yang, W.; Zhou, F.; Chen, X.; Li, K.; Shen, J. Thermal performance of honeycomb-type cylindrical lithium-ion battery pack with air distribution plate and bionic heat sinks. Appl. Therm. Eng. 2023, 218, 119299. [Google Scholar] [CrossRef]

- Ham, S.H.; Jang, D.S.; Lee, M.; Jang, Y.; Kim, Y. Effective thermal management of pouch-type lithium-ion batteries using tab-cooling method involving highly conductive ceramics. Appl. Therm. Eng. 2023, 220, 119790. [Google Scholar] [CrossRef]

- Lyu, P.; Liu, X.; Liu, C.; Rao, Z. Experimental and modeling investigation on thermal risk evaluation of tabs for pouch-type lithium-ion battery and the relevant heat rejection strategies. Int. J. Heat Mass Transf. 2023, 202, 123770. [Google Scholar] [CrossRef]

- Mao, N.; Zhang, T.; Wang, Z.; Gadkari, S.; Wang, J.; He, T.; Gao, T.; Cai, Q. Revealing the thermal stability and component heat contribution ratio of overcharged lithium-ion batteries during thermal runaway. Energy 2023, 262, 125786. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Li, X.; Zhao, J.; Liu, G.; Yu, W.; Dong, X.; Wang, J. Review on composite solid electrolytes for solid-state lithium-ion batteries. Mater. Today Sustain. 2023, 5, 100316. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Z.; Guo, P.; Chen, S.; Bian, H.; Tong, X.; Ni, L. Carbon oxides emissions from lithium-ion batteries under thermal runaway from measurements and predictive model. J. Energy Storage 2021, 33, 101863. [Google Scholar] [CrossRef]

- Gogotsi, Y.; Simon, P. True performance metrics in electrochemical energy storage. Science 2011, 334, 917–918. [Google Scholar] [CrossRef]

- Han, G.; Lian, K. Proton-Conducting Polymer Electrolytes and Their Applications in Solid Supercapacitors: A Review. RSC Adv. 2010, 4, 33091–33113. [Google Scholar]

- Polu, A.R.; Kumar, R. Preparation and characterization of PVA-based solid polymer electrolytes for electrochemical cell applications. Chin. J. Polym. Sci. 2013, 4, 641–648. [Google Scholar] [CrossRef]

- Chen, D.; Lou, Z.; Jiang, K.; Shen, G. Device Configurations and Future Prospects of Flexible/Stretchable Lithium-Ion Batteries. Adv. Funct. Mater. 2018, 28, 1805596. [Google Scholar] [CrossRef]

- Wu, W.; Wang, S.; Wu, W.; Chen, K.; Hong, S.; Lai, Y. A critical review of battery thermal performance and liquid-based battery thermal management. Energy Convers. Manag. 2019, 182, 262–281. [Google Scholar] [CrossRef]

- Xu, K. Electrolytes and Interphases in Li-Ion Batteries and Beyond. Chem. Rev. 2014, 114, 11503–11618. [Google Scholar] [CrossRef]

- Grégory, G.; Sylvie, G.; Gebrekidan, G.E.; Mathiron, D.; Ribière, P.; Armand, M.; Stephane, L. Thermal behaviour of the lithiated-graphite/electrolyte interface through GC/MS analysis. Electrochim. Acta 2012, 83, 402–409. [Google Scholar]

- Hossein, M.; Guoping, D.; Inna, K.; Anaba, A.; Jason, N.H. Thermal Stability Studies of Binder Materials in Anodes for Lithium-Ion Batteries. J. Electrochem. Soc. 2000, 147, 4470–4475. [Google Scholar]

- Liu, K.; Liu, Y.; Lin, D.; Pei, A.; Cui, Y. Materials for lithium-ion battery safety. Sci. Adv. 2018, 4, 9820. [Google Scholar] [CrossRef]

- Lee, S. A shape-deformable and thermally stable solidstate electrolyte based on a plastic crystal composite polymer electrolyte for flexible/safer lithium-ion batteries. J. Mater. Chem. A 2014, 2, 1112–1121. [Google Scholar]

- Liu, W.; Song, M.; Kong, B.; Cui, Y. Flexible and Stretchable Energy Storage: Recent Advances and Future Perspectives. Adv. Mater 2016, 4, 1603436. [Google Scholar] [CrossRef]

- Zhou, G.; Li, F.; Cheng, H.M. Progress in flexible lithium batteries and future prospects. Energy Environ. Sci. 2014, 7, 1307. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, X.; Li, C.; Sun, X.; Meng, Q.; Ma, Y. Chemically Crosslinked Hydrogel Film Leads to Integrated Flexible Supercapacitors with Superior Performance. Adv. Mater. 2015, 3, 7451–7457. [Google Scholar] [CrossRef]

- Tayser, S.G.; Abu Bakar, S.; Majid, N.A.; Abdul Amir, H.K.; Abu Bakar, M.; Ahmed, A.A. Properties and Applications of Polyvinyl Alcohol, Halloysite Nanotubes and Their Nanocomposites. Molecules 2015, 20, 22833–22847. [Google Scholar]

- Bashir, A.A.; John, O.D.; Abbas, A.A.; Yerima, M.H.; Nurrul, A.S.; Shukur, M.F. Preparation and characterization of solid biopolymer electrolytes based on polyvinyl alcohol/cellulose acetate blend doped with potassium carbonate (K2CO3) salt. J. Electroanal. Chem. 2022, 919, 116539. [Google Scholar]

- Henry, C.O.; Chinomso, M.E.; Iheoma, C.N.; Chizoba, M.O.; Joseph, T.N. Packaging and degradability properties of polyvinyl alcohol/gelatin nanocomposite films filled water hyacinth cellulose nanocrystals. J. Bioresour. Bioprod. 2021, 6, 168–185. [Google Scholar]

- John, O.D.; Mohammed, K.M.; Khalid, H.I.; Aldaghri, O.; Naglaa, F.M.A.A.; Abdullahi, A.A.; Fahad, U.; Yarima, M.H.; Bashir, A.A. Effect of ZnO Nanofiller on Structural and Electrochemical Performance Improvement of Solid Polymer Electrolytes Based on Polyvinyl Alcohol–Cellulose Acetate–Potassium Carbonate Composites. Molecules 2022, 27, 5528. [Google Scholar]

- Fan, L.; Wang, M.; Zhang, Z.; Qin, G.; Hu, X.; Chen, Q. Preparation and Characterization of PVA Alkaline Solid Polymer Electrolyte with Addition of Bamboo Charcoal. Materials 2018, 11, 679. [Google Scholar] [CrossRef] [PubMed]

- Aziz, S.B.; Abdullah, O.G. Effect of PVA Blending on Structural and Ion Transport Properties of CS:AgNt-Based Polymer. Polymers 2017, 9, 622. [Google Scholar] [CrossRef] [PubMed]

- Chmelar, J.; Dodda, J.M.; Be, P.; Toma, M.; Kullova, L.; Kadlec, J. Comparative study of PVA/SiO2 and PVA/SiO2/glutaraldehyde (GA) nanocomposite membranes prepared by single-step solution casting method. J. Mater. Sci. 2015, 10, 6477–6490. [Google Scholar]

- Jung, H.; Ju, D.; Lee, W.; Zhang, X.; Kotek, R. Electrospun hydrophilic fumed silica/polyacrylonitrile nanofiber-based composite electrolyte membranes. Electrochim. Acta 2009, 54, 3630–3637. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, A.; Cui, Z.; Zhu, B.; Han, G.; Xu, Y. Preparation and properties of gel membrane containing porous PVDF-HFP matrix and cross-linked PEG for lithium ion conduction. J. Funct. Mater. 2008, 2, 89–94. [Google Scholar] [CrossRef]

- Yu, H.; Wu, J.; Fan, L.; Lin, Y.; Xu, K.; Tang, Z.; Cheng, C.; Tang, S.; Lin, J.; Huang, M.; et al. A novel redox-mediated gel polymer electrolyte for high-performance supercapacitor. J. Power Sources 2012, 198, 402–407. [Google Scholar] [CrossRef]

- Miao, Y.; Yan, J.; Huang, Y.; Fan, W.; Liu, T. Electrospun polymer nanofiber membrane electrodes and an electrolyte for highly flexible and foldable all-solid-state supercapacitors. RSC Adv. 2015, 5, 26189–26196. [Google Scholar] [CrossRef]

- He, T.; Jia, R.; Lang, X.; Wu, X.; Wang, Y. Preparation and Electrochemical Performance of PVdF Ultrafine Porous Fiber Separator-Cum-Electrolyte for Supercapacitor. J. Electrochem. Soc. 2017, 164, 379–384. [Google Scholar] [CrossRef]

- Kim, J.I.; Chung, K.Y.; Park, J.H. Design of a porous gel polymer electrolyte for sodium ion batteries. J. Membr. Sci. 2018, 566, 122–128. [Google Scholar] [CrossRef]

- Zhu, Y.; Yang, Y.; Fu, L.; Wu, Y. A porous gel-type composite membrane reinforced by nonwoven: Promising polymer electrolyte with high performance for sodium ion batteries. Electrochim. Acta 2017, 224, 405–411. [Google Scholar] [CrossRef]

- Reddy, M.J.; Kumar, J.S.; Rao, U.V.S.; Chu, P.P. Structural and ionic conductivity of PEO blend PEG solid polymer electrolyte. Solid State Ion. 2006, 177, 253–256. [Google Scholar] [CrossRef]

- Aziz, S.B.; Woo, T.J.; Kadir, M.F.Z.; Ahmed, H.M. A conceptual review on polymer electrolytes and ion transport models. J. Sci. Adv. Mater. Devices 2018, 3, 1–17. [Google Scholar] [CrossRef]

- Abdulkadir, B.A.; Dennis, J.O.; Shukur, M.F.B.A.; Nasef, M.M.E.; Usman, F. Preparation and characterization of gel polymer electrolyte based on PVA-K2CO3. Polym. Technol. Mater. 2020, 59, 1679–1697. [Google Scholar] [CrossRef]

- Çavuş, S.; Durgun, E. Poly (vinyl alcohol) Based Polymer Gel Electrolytes: Investigation on Their Conductivity and Characterization. Acta Phys. Pol. A 2016, 129, 621–624. [Google Scholar] [CrossRef]

- Hema, M.; Selvasekarapandian, S.; Arunkumar, D.; Sakunthala, A.; Nithya, H. FTIR, XRD and ac impedance spectroscopic study on PVA based polymer electrolyte doped with NH4X (X = Cl, Br, I). J. Non. Cryst. Solids 2009, 355, 84–90. [Google Scholar] [CrossRef]

- Kadir, M.F.Z.; Majid, S.R.; Arof, A.K. Plasticized chitosan—PVA blend polymer electrolyte-based proton battery. Electrochim. Acta 2010, 55, 1475–1482. [Google Scholar] [CrossRef]

- Chodankar, N.R.; Dubal, D.P.; Lokhande, A.C.; Lokhande, C.D. Ionically conducting PVA–LiClO4 gel electrolyte for high performance flexible solid-state supercapacitors. J. Colloid Interface Sci. 2015, 460, 370–376. [Google Scholar] [CrossRef]

- Patachia, S.; Rinja, M.; Isac, L. Some methods for doping poly(vinyl alcohol) hydrogels [pva-hg]. Phys. Chem. 2006, 51, 253–262. [Google Scholar]

- Gouda, M.H.; Gouveia, W.; Afonso, M.L.; Šljukić, B.; El Essawy, N.A.; Nassr, A.A.; Santos, D.M.F. Poly (vinyl alcohol)-based crosslinked ternary polymer blend doped with sulfonated graphene oxide as a sustainable composite membrane for direct borohydride fuel cells. J. Power Sources 2019, 432, 92–101. [Google Scholar] [CrossRef]

- Long, L.; Wang, S.; Xiao, M.; Meng, Y. Polymer electrolytes for lithium polymer batteries. J. Mater. Chem. A Mater. Energy Sustain. 2016, 4, 10038–10069. [Google Scholar] [CrossRef]

- An, Q.; Li, F.; Ji, Y.; Chen, H. Influence of polyvinyl alcohol on the surface morphology, separation and anti-fouling performance of the composite polyamide nanofiltration membranes. J. Membr. Sci. 2011, 367, 158–165. [Google Scholar] [CrossRef]

- Bashir, A.-A.; John, O.-D.; Al-Hadeethi, Y.; Shukur, M.F.; Mkawi, E.M.; Nuha, A.; Ibnaouf, K.H.; Aldaghri, O.; Fahad, U.; Abdullahi, A.A. Optimization of the Electrochemical Performance of a Composite Polymer Electrolyte Based on PVA-K2CO3-SiO2 Composite. Polymers 2021, 13, 92. [Google Scholar]

- Garaga, M.N.; Aguilera, L.; Yaghini, N. Achieving enhanced ionic mobility in nanoporous silica by controlled surface interactions. Phys. Chem. Phys. 2016, 19, 5727–5736. [Google Scholar] [CrossRef] [PubMed]

- Sharma, J.P.; Sekhon, S.S. Effect of plasticizer and fumed silica on ionic conductivity behaviour of proton conducting polymer electrolytes containing HPF6. Bull. Mater. Sci. 2013, 36, 629–634. [Google Scholar] [CrossRef]

- Hu, J.; Wang, W.; Yu, R.; Guo, M.; He, C.; Xie, X.; Peng, H.; Xue, Z. Solid polymer electrolyte based on ionic bond or covalent bond functionalized silica nanoparticles. RSC Adv. 2017, 7, 54986–54994. [Google Scholar] [CrossRef]

- Yao, P.; Yu, H.; Ding, Z.; Liu, Y.; Lu, J.; Lavorgna, M.; Wu, J.; Liu, X. Review on Polymer-Based Composite Electrolytes for Lithium Batteries. Front. Chem. 2019, 7, 522. [Google Scholar] [CrossRef]

- Xu, K. Nonaqueous Liquid Electrolytes for Lithium-Based Rechargeable Batteries. Chem. Rev. 2004, 104, 4303–4417. [Google Scholar] [CrossRef]

- Young, W.; Kuan, W.; Epps, T.H. Block Copolymer Electrolytes for Rechargeable Lithium Batteries. J. Polym. Sci. Part B Polym. Phys. 2014, 52, 1–16. [Google Scholar] [CrossRef]

- Samui, A.B.; Sivaraman, P. Solid polymer electrolytes for supercapacitors. Polym. Electrolytes 2010, 11, 431–470. [Google Scholar]

- Aziz, S.B.; Abidin, Z.H.Z. Ion-transport study in nanocomposite solid polymer electrolytes based on chitosan: Electrical and dielectric analysis. J. Appl. Polym. Sci. 2015, 132, 41774. [Google Scholar] [CrossRef]

- Liew, C.; Ramesh, S.; Arof, A.K. Characterization of ionic liquid added poly (vinyl alcohol)-based proton conducting polymer electrolytes and electrochemical studies on the supercapacitors. Int. J. Hydrogen Energy 2014, 40, 852–862. [Google Scholar] [CrossRef]

- Nair, J.R.; Imholt, L.; Brunklaus, G.; Winter, M. Lithium Metal Polymer Electrolyte Batteries: Opportunities and Challenges. Electrochem. Soc. Interface 2019, 28, 25. [Google Scholar] [CrossRef]

- Aziz, A.B. Occurrence of electrical percolation threshold and observation of phase transition in chitosan(1−x):AgIx (0.05 ≤ x ≤ 0.2)-based ion-conducting solid polymer composites. Appl. Phys. A 2016, 126, 706. [Google Scholar] [CrossRef]

- Huang, Q.; Luo, Q.; Chen, Z.; Yao, L.; Fua, P.; Lin, Z. The Effect of Electrolyte Concentration on Electrochemical Impedance for Evaluating Polysulfone Membranes. Environ. Sci. Water Res. Technol. 2018, 4, 1145–1151. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, Z.; Song, S.; Ma, Q.; Liu, R. High Performance Poly (vinyl alcohol)-Based Li-Ion Conducting Gel Polymer Electrolyte Films for Electric Double-Layer Capacitors. Polymers 2018, 10, 1179. [Google Scholar] [CrossRef]

- Kang, D.; Kim, J. Characterization of fibrous gel polymer electrolyte for lithium polymer batteries with enhanced electrochemical propertie. J. Electroanal. Chem. 2016, 775, 37–42. [Google Scholar] [CrossRef]

- Lim, C.; Teoh, K.H.; Liew, C.; Ramesh, S. Capacitive behavior studies on electrical double layer capacitor using poly (vinyl alcohol)-lithium perchlorate-based polymer electrolyte incorporated with TiO2. Mater. Chem. Phys. 2014, 143, 661–667. [Google Scholar] [CrossRef]

- Majid, S.R.; Arof, A.K. FTIR Studies of Chitosan-Orthophosphoric Acid-Ammonium Nitrate-Aluminosilicate Polymer Electrolyte. Mol. Cryst. Liq. Cryst. 2014, 484, 117–126. [Google Scholar] [CrossRef]

- Chagnes, A.; Allouchi, H.; Carre, B.; Odou, G.; Willmann, P.; Lemordant, D. c-Butyrolactone-ethylene carbonate-based electrolytes for lithium-ion batteries. J. Appl. Electrochem. 2003, 33, 589–595. [Google Scholar] [CrossRef]

- Wang, C.; Wu, D.; Wang, H.; Gao, Z.; Xu, F.; Jiang, K. Biomass derived nitrogen-doped hierarchical porous carbon sheets for supercapacitors with high performance. J. Colloid Interface Sci. 2018, 523, 133–143. [Google Scholar] [CrossRef] [PubMed]

- Hirankumar, G.; Selvasekarapandian, S.; Kuwata, N.; Kawamura, S.; Hattori, T. Thermal, electrical and optical studies on the poly (vinyl alcohol) based polymer electrolytes. J. Power Sources 2005, 144, 262–267. [Google Scholar] [CrossRef]

- Ramya, C.S.; Savitha, T.; Selvasekarapandian, S.; Hirankumar, G. Transport Mechanism of Cu-ion Conducting PVA Based Solid-Polymer Electrolyte. Ionics 2005, 11, 436–441. [Google Scholar] [CrossRef]

- Hirankumar, G.; Selvasekarapandian, S.; Bhuvaneswari, M.S.; Baskaran, R.; Vijayakumar, M. Ag+ ion transport studies in a polyvinyl alcohol-based polymer electrolyte system. J. Solid State Electrochem. 2006, 10, 193–197. [Google Scholar] [CrossRef]

- Sa’adu, L.; Hashim, M.A.; Baharuddin, M. Conductivity Studies and Characterizations of PVA-Orthophosphoric Electrolytes. J. Mater. Sci. Res. 2014, 3, 48–58. [Google Scholar] [CrossRef]

- Varishetty, M.M.; Qiu, W.; Gao, Y.; Chen, W. Structure, Electrical and Optical Properties of (PVA/LiAsF6) Polymer Composite Electrolyte Films. Polym. Eng. Sci. 2010, 50, 878–884. [Google Scholar] [CrossRef]

- Sunitha, V.R.; Suraj, K.M.K.; Pavan, G.S.; Sandesh, N.; Suhas, M.R.; Lalithnarayan, C.; Laxman, N.; Radhakrishnan, S. Lithium-ion conduction in PVA-based polymer electrolyte system modified with combination of nanofillers. Ionics 2020, 26, 823–829. [Google Scholar] [CrossRef]

- Mohammed, B.A.; Muaffaq, M.N.; Shujahadeen, B.A.; Sameerah, I.A.; Mohamad, A.B.; Elham, M.A.D.; Ary, R.M. The study of ion transport parameters associated with dissociated cation using EIS model in solid polymer electrolytes (SPEs) based on PVA host polymer: XRD, FTIR, and dielectric properties. Arab. J. Chem. 2022, 15, 104196. [Google Scholar]

- Srivastava, S.; Varshney, P.K. Conductivity and structural studies of PVA based mixed-ion composite polymer electrolytes. Int. J. Eng. Technol. 2018, 7, 887–890. [Google Scholar] [CrossRef]

- Prajapati, G.K.; Roshan, R.; Gupta, P.N. Effect of plasticizer on ionic transport and dielectric properties of PVA–H3PO4 proton conducting polymeric electrolytes. J. Phys. Chem. Solids 2010, 71, 1717–1723. [Google Scholar] [CrossRef]

- Brza, M.A.; Aziz, S.B.; Anuar, H.; Ali, F. Structural, ion transport parameter and electrochemical properties of plasticized polymer composite electrolyte based on PVA: A novel approach to fabricate high performance EDLC devices. Polym. Test. 2020, 91, 106813. [Google Scholar] [CrossRef]

- Sik, D.; Bum, H.; Won, J.; Lee, Y.M. Preparation and characterization of crosslinked PVA/SiO2 hybrid membranes containing sulfonic acid groups for direct methanol fuel cell applications. J. Membr. Sci. 2004, 240, 37–48. [Google Scholar]

- Liang, S.; Yan, W.; Wu, X.; Zhang, Y.; Zhu, Y.; Wang, H. Gel polymer electrolytes for lithium-ion batteries: Fabrication, characterization and performance. Solid State Ion. 2018, 318, 2–18. [Google Scholar] [CrossRef]

- Yan, D.; Bazant, M.Z.; Biesheuvel, P.M.; Pugh, M.C.; Dawson, F.P. Theory of linear sweep voltammetry with diffuse charge: Unsupported electrolytes, thin films, and leaky membranes. Phys. Rev. E95 2017, 95, 033303. [Google Scholar] [CrossRef]

- Shang, D.; Fu, J.; Lu, Q.; Chen, L.; Yin, J.; Dong, X.; Xu, Y.; Jia, R.; Yuan, S.; Chen, Y.; et al. A novel polyhedral oligomeric silsesquioxane based ionic liquids (POSS-ILs) polymer electrolytes for lithium-ion batteries. Solid State Ion. 2018, 319, 247–255. [Google Scholar] [CrossRef]

- Chen, L.; Fu, J.; Lu, Q.; Shi, L.; Li, M.; Dong, L.; Xu, Y.; Jia, R. Cross-linked polymeric ionic liquids ion gel electrolytes by in situ radical polymerization. Chem. Eng. J. 2019, 378, 122245. [Google Scholar] [CrossRef]

- Philipsen, H.; Monnens, W. Immersion and electrochemical deposition of Ru on Si. Electrochim. Acta 2018, 274, 306–315. [Google Scholar] [CrossRef]

- Shukur, M.F.; Kadir, M.F.Z. Hydrogen ion conducting starch-chitosan blend-based electrolyte for application in electrochemical devices. Electrochim. Acta 2015, 158, 152–165. [Google Scholar] [CrossRef]

- Tran, H.K.; Wu, Y.S.; Chien, W.C.; Wu, S.H.; Jose, R.; Lue, S.J.; Yang, C.C. Composite Polymer Electrolytes Based on PVA/PAN for All-Solid-State Lithium Metal Batteries Operated at Room Temperature. ACS Appl. Energy Mater. 2020, 3, 11024–11035. [Google Scholar] [CrossRef]

- Kadir, M.F.Z.; Arof, A.K. Application of PVA—Chitosan blend polymer electrolyte membrane in electrical double layer capacitor. Mater. Res. Innov. 2016, 8917, 217–220. [Google Scholar] [CrossRef]

- Bashir, A.A.; John, O.D.; Shukur, M.F.; Mohamed, M.E.N.; Fahad, U. Study on Dielectric Properties of Gel Polymer Electrolyte Based on PVA-K2CO3 Composites. Int. J. Electrochem. Sci. 2021, 16, 150296. [Google Scholar]

- Abdullah, O.G.; Aziz, S.B.; Rasheed, M.A. Incorporation of NH4NO3 into MC-PVA blend-based polymer to prepare proton-conducting polymer electrolyte films. Ionics 2017, 24, 777–785. [Google Scholar] [CrossRef]

- Yusof, Y.M.; Shukur, M.F.; Illias, H.A.; Kadir, M.F.Z. Conductivity and electrical properties of corn starch-chitosan blend biopolymer electrolyte incorporated with ammonium iodide. Phys. Scr. 2014, 89, 035701. [Google Scholar] [CrossRef]

- Jawad, M.K.; Al-sammarraie, A.M.A. Investigate the Conductivity and Dielectric Properties of Polymer Electrolytes Address for Correspondence. Indian J. Nat. Sci. 2018, 9, 14891–14899. [Google Scholar]

- Chang, J.; Lai, H.; Samarahan, K. Polyvinyl alcohol/silica/clay composites: Effect of clay on surface morphology and thermo-mechanical. Silica Clay Dispersed Polym. Nanocompos. 2016, 1, 45–53. [Google Scholar] [CrossRef]

- Aziz, S.B. Li+ ion conduction mechanism in poly (e-caprolactone)-based polymer electrolyte. Iran. Polym. J. 2013, 22, 877–883. [Google Scholar] [CrossRef]

- Xiong, G.; Meng, C.; Reifenberger, R.G.; Irazoqui, P.P.; Fisher, T.S. A review of graphene-based electrochemical microsupercapacitors. Electroanalysis 2014, 26, 30–51. [Google Scholar] [CrossRef]

- Rajendran, S.; Sivakumar, M.; Subadevi, R.; Nirmala, M. Characterization of PVA—PVdF based solid polymer blend electrolytes. Phys. B. 2004, 348, 73–78. [Google Scholar] [CrossRef]

- Aziz, S.B.; Abdullah, O.G.; Rasheed, M.A.; Ahmed, H.M. Effect of High Salt Concentration (HSC) on Structural, Morphological, and Electrical Characteristics of Chitosan Based Solid Polymer Electrolytes. Polymers 2017, 9, 187. [Google Scholar] [CrossRef]

- Sudha, L.K.; Roy, S.; Rao, U. Evaluation of Activation Energy (Ea) Profiles of Nanostructured Alumina Polycarbonate Composite Insulation Materials. Int. J. Mater. Mech. Manuf. 2014, 2, 96–100. [Google Scholar]

- Shukur, M.F.; Kadir, M.F.Z.; Ahmad, Z.; Ithnin, R. Transport Properties of Chitosan/PEO Blend Based Proton Conducting Polymer Electrolyte. Adv. Mater. Res. 2012, 488, 114–117. [Google Scholar] [CrossRef]

- Yup, J.; Kang, D.A.; Un, N.; Min, J.; Hak, J. Bicontinuously crosslinked polymer electrolyte membranes with high ion conductivity and mechanical strength. J. Memb. Sci. 2019, 589, 117250. [Google Scholar]

- Ping, J.; Pan, Y.; Pan, H.; Wu, B.; Zhou, H.; Shen, Z.; Fan, X.H. Microphase Separation and High Ionic Conductivity at High Temperatures of Lithium Salt-Doped Amphiphilic Alternating Copolymer Brush with Rigid Side Chains. Macromolecules 2015, 23, 8557–8564. [Google Scholar] [CrossRef]

- Hu, X.; Chen, Y.; Hu, Z.; Li, Y.; Ling, Z. All-Solid-State Supercapacitors Based on a Carbon-Filled Porous/Dense/Porous Layered Ceramic Electrolyte. J. Electrochem. Soc. 2018, 165, 1269–1274. [Google Scholar] [CrossRef]

- Muthiah, M.; Chellasamy, G.; Natarajan, R.; Subramanian, S.; Chinnappa, S. Proton conducting polymer electrolytes based on PVdF-PVA with NH4NO3. Polym. Eng. 2013, 33, 315–322. [Google Scholar] [CrossRef]

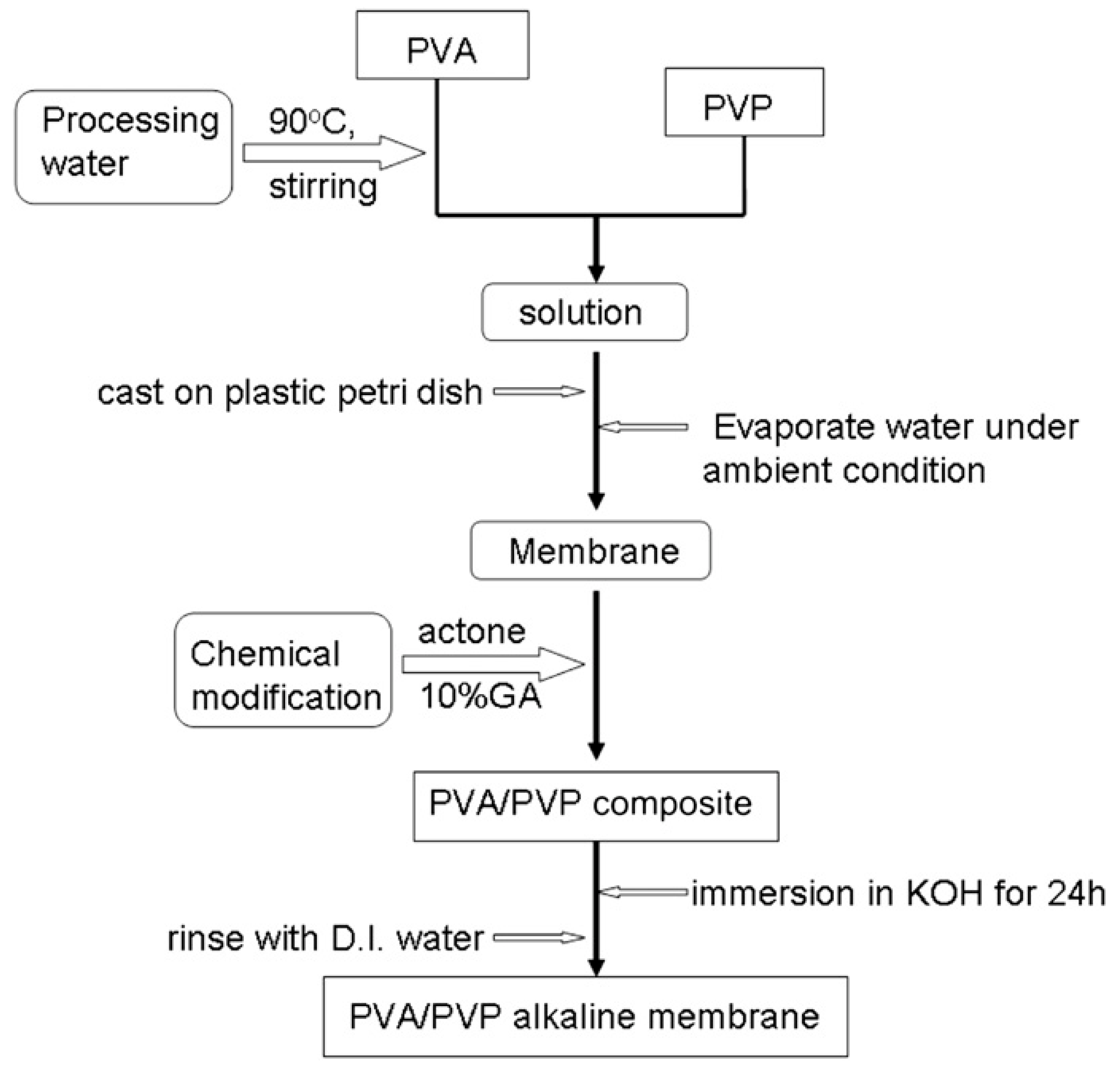

- Qiao, J.; Fu, J.; Lin, J.; Ma, R.; Liu, J. Alkaline solid polymer electrolyte membranes based on structurally modified PVA/PVP with improved alkali stability. Polymer 2010, 51, 4850–4859. [Google Scholar] [CrossRef]

- Shamsuri, N.A.; Zaine, S.N.A.; Yusof, Y.M.; Yahya, W.Z.N.; Shukur, M.F. Effect of ammonium thiocyanate on ionic conductivity and thermal properties of polyvinyl alcohol-methylcellulose—Based polymer electrolytes. Ionics 2020, 26, 6083–6093. [Google Scholar] [CrossRef]

- Muthuvinayagam, M.; Gopinathan, C. Characterization of proton conducting polymer blend electrolytes based on PVdF-PVA. Polymer 2015, 68, 122–130. [Google Scholar] [CrossRef]

- Rajendran, S.; Sivakumar, M.; Subadevi, R. Investigations on the effect of various plasticizers in PVA–PMMA solid polymer blend electrolytes. Mater. Lett. 2004, 58, 641–649. [Google Scholar] [CrossRef]

- Morsi, M.A.; Oraby, A.H.; Elshahawy, A.G.; El-hady, R.M.A. Preparation, structural analysis, morphological investigation and electrical properties of gold nanoparticles filled polyvinyl alcohol/carboxymethyl cellulose blend. JMR&T 2019, 8, 5996–6010. [Google Scholar]

- Liew, C.; Ramesh, S.; Arof, A.K. A novel approach on ionic liquid-based poly (vinyl alcohol) proton conductive polymer electrolytes for fuel cell applications. Int. J. Hydrogen Energy 2013, 39, 2917–2928. [Google Scholar] [CrossRef]

- Zhao, B.; Lu, X.; Wang, Q.; Yang, J.; Zhao, J.; Zhou, H. Enhancing the ionic conductivity in a composite polymer electrolyte with ceramic nanoparticles anchored to charged polymer brushes. Chin. Chem. Lett. 2019, 31, 831–835. [Google Scholar] [CrossRef]

- Shekibi, Y.; Pringle, J.M.; Sun, J.; Pas, S.J.; Rocher, N.M.; Clare, B.R.; Hill, A.J.; MacFarlane, D.R.; Forsyth, M. Lithium-functionalised silica nanoparticles for enhanced ionic conductivity in an organic ionic plastic crystal. J. Mater. Chem. 2010, 20, 338–344. [Google Scholar] [CrossRef]

- Pandey, K.; Asthana, N.; Dwivedi, M.M.; Chaturvedi, S.K. Effect of Plasticizers on Structural and Dielectric Behavior of [PEO + (NH4)2C4H8(COO)2] Polymer Electrolyte. J. Polym. 2013, 2013, 752596. [Google Scholar]

- Dhatarwal, P.; Sengwa, R.J. Dielectric relaxation, Li-ion transport, electrochemical, and structural behaviour of PEO/PVDF/LiClO4/TiO2/PC-based plasticized nanocomposite solid polymer electrolyte films. Compos. Commun. 2020, 17, 182–191. [Google Scholar] [CrossRef]

- Liu, Y.; Lee, J.Y.; Hong, L. In situ preparation of poly (ethylene oxide)–SiO2 composite polymer electrolytes. J. Power Sources 2004, 129, 303–331. [Google Scholar] [CrossRef]

- Lee, K.H.; Lee, Y.G.; Park, J.K.; Seung, D.Y. Effect of silica on the electrochemical characteristics of the plasticized polymer electrolytes based on the P(AN-co-MMA) copolymer. Solid State Ion. 2000, 133, 257–263. [Google Scholar] [CrossRef]

- Abdulwahid, R.T.; Woo, H.J. Increase of metallic silver nanoparticles in Chitosan: AgNt based polymer electrolytes incorporated with alumina filler. Results Phys. 2019, 13, 102326. [Google Scholar]

- Potphode, D.; Sayed, M.S.; Tamang, T.L.; Shim, J. High-performance binder-free flower-like (Ni 0.66 Co 0.3 Mn 0.04)2(OH)2 (CO3) array synthesized using ascorbic acid for supercapacitor applications. Chem. Eng. J. 2019, 378, 122129. [Google Scholar] [CrossRef]

- Andrew, B.; Hengbing, Z. Applications of Supercapacitors in Electric and Hybrid Vehicles. In Proceedings of the 5th European Symposium on Supercapacitor and Hybrid Solutions (ESSCAP), Brasov, Romania, 23–25 April 2015; Volume 15, pp. 23–25. [Google Scholar]

- Ko, R.; Carlen, M. Principles and applications of electrochemical capacitors. Electrochim. Acta 2000, 45, 2483–2498. [Google Scholar]

- Yusof, Y.M.; Majid, N.A.; Kasmani, R.M.; Illias, H.A.; Kadir, M.F.Z. The Effect of Plasticization on Conductivity and Other Properties of Starch/Chitosan Blend Biopolymer Electrolyte Incorporated with Ammonium Iodide. Mol. Cryst. Liq. Cryst. 2014, 603, 73–88. [Google Scholar] [CrossRef]

- Takaki, K.; Minoru, I.; Takakazu, Y. New solid-state electric double-layer capacitor using poly(vinyl alcohol)-based polymer solid electrolyte. J. Power Sources 1991, 36, 87–93. [Google Scholar]

- Nishihara, M.; Terayama, Y.; Haji, T.; Lyth, S.M.; Satokawa, S.; Matsumoto, H. Proton-conductive nano zeolite-PVA composite film as a new water-absorbing electrolyte for water electrolysis. Express Polym. Lett. 2018, 12, 256–264. [Google Scholar] [CrossRef]

- Sun, C.; Liu, J.; Gong, Y.; Wilkinson, D.P.; Zhang, J. Recent advances in all-solid-state rechargeable lithium batteries. Nano Energy 2017, 33, 363–386. [Google Scholar] [CrossRef]

- Chen, L.; Li, W.; Fan, L.; Nan, C.; Zhang, Q. Intercalated Electrolyte with High Transference Number for Dendrite-Free Solid-State Lithium Batteries. Adv. Funct. Mater 2019, 29, 1901047. [Google Scholar] [CrossRef]

- Fan, L.; Wei, S.; Li, S.; Li, Q.; Lu, Y. Recent Progress of the Solid-State Electrolytes for High-Energy Metal-Based Batteries. Adv. Energy Mater. 2018, 8, 1702657. [Google Scholar] [CrossRef]

- Wang, Y.; Yuan, A.; Wang, X. Pseudocapacitive behaviors of nanostructured manganese dioxide. J. Solid State Electrochem. 2016, 12, 1101–1107. [Google Scholar] [CrossRef]

| S/N | Polymer | Salts | Ionic Conductivity (σ) | References |

|---|---|---|---|---|

| 1 | PVA | NH4I | 2.50 × 10−3 Scm−1 | [68] |

| 2 | PVA | NH4Br | 5.70 ×10−4 S cm−1 | [68] |

| 3 | PVA | NH4Cl | 1.00 × 10−5 S cm−1 | [68] |

| 4 | PVA | Mg(NO3)2 | 7.36 × 10−7 S/cm | [39] |

| 5 | PVA | NH4NO3 | 2.07 × 10−5 Scm−1 | [69] |

| 6 | PVA | CH3COONH4 | 5.62 × 10−6 Scm−1 | [94] |

| 7 | PVA | Cu(NO3)2 | 1.60 × 10−5 Scm−1 | [95] |

| 8 | PVA | AgNO3 | 7.56 × 10−7 Scm−1 | [96] |

| 9 | PVA | K2CO3 | 4.53 × 10−3 Scm−1 | [66] |

| 10 | PVA | H3PO4 | 2.50 × 10−3 Scm−1 | [97] |

| 11 | PVA | LiAsF-TiO2 | 5.10 × 10−4 Scm−1 | [98] |

| 12 | PVA | KI-I2 | 8.41 × 10−3 Scm−1 | [51] |

| 13 | PVA | NH4NO3 | 1.60 × 10−3 Scm−1 | [67] |

| 14 | PVA | TiO3-SrTiO3-Al2O | 5.20 × 10−5 Scm−1 | [99] |

| 15 | PVA | NaI | 2.41 × 10−4 Scm−1 | [100] |

| 16 | PVA | LiClO4 | 4.80 × 10−3 Scm−1 | [70] |

| 17 | PVA | LiTFSI-EMITFSI | 5.30 × 10−7 Scm−1 | [88] |

| 18 | PVA | LiClO4-TiO2 | 1.30 × 10−4 Scm−1 | [90] |

| 19 | PVA | BC | 6.63 × 10−2 Scm−1 | [54] |

| 20 | PVA | NaClO4-LiClO4 | 1.57 × 10−3 Scm−1 | [101] |

| 20 | PVA | H3PO4 | 8.06 × 10−5 Scm−1 | [102] |

| 22 | PVA | K2CO3-SiO2 | 7.86 × 10−3 Scm−1 | [75] |

| 23 | PVA | Ce(III)-NH4SCN | 2.07 × 10−3 Scm−1 | [103] |

| 24 | PVA | SiO2 | 2.0 × 10−2 Scm−1 | [104] |

| Polymers | Salts | Potential Window (V) | References |

|---|---|---|---|

| PVA | LiCLO4-TiO2 | 4.60 | [90] |

| PVA | K2CO3 | 2.70 | [66] |

| PVA | NH4NO3 | 3.30 | [69] |

| PVA/PAN | LATP | 5.10 | [111] |

| PVA | LiTFSI-EMITFSI | 5.00 | [88] |

| PVA | Ce(III)-NH4SCN | 2.11 | [103] |

| PVA | K2CO3-SiO2 | 3.35 | [75] |

| PVA–chitosan | NH4NO3 | 1.70 | [112] |

| Polymers | Salt | Solvents | Conductivity (S/cm) | References |

|---|---|---|---|---|

| PVdF-PVA | NH4NO3 | DMF | 2.91 × 10−4 | [127] |

| PVA/PVP | KOH | Distilled water | 0.53 | [128] |

| CS/PVA | NH4NO3 | Acetic acid | 1.60 × 10−3 | [69] |

| PVA-MC | NH4SCN | Distilled water | 1.45 × 10−4 | [129] |

| PVdF-PVA | NH4SCN | DMF | 1.09 × 10−3 | [130] |

| PVA–PMMA | LiBF4 | DMF | 1.28 × 10−3 | [131] |

| PVA-PEO-PVdF | NaOH | H2SO4 | 0.18 × 10−5 | [72] |

| PVA-MC | NH4NO3 | Distilled water | 7.39 × 10−8 | [114] |

| PVA-MC | AuNPs | Distilled water | 3.08 × 10−8 | [132] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dennis, J.O.; Shukur, M.F.; Aldaghri, O.A.; Ibnaouf, K.H.; Adam, A.A.; Usman, F.; Hassan, Y.M.; Alsadig, A.; Danbature, W.L.; Abdulkadir, B.A. A Review of Current Trends on Polyvinyl Alcohol (PVA)-Based Solid Polymer Electrolytes. Molecules 2023, 28, 1781. https://doi.org/10.3390/molecules28041781

Dennis JO, Shukur MF, Aldaghri OA, Ibnaouf KH, Adam AA, Usman F, Hassan YM, Alsadig A, Danbature WL, Abdulkadir BA. A Review of Current Trends on Polyvinyl Alcohol (PVA)-Based Solid Polymer Electrolytes. Molecules. 2023; 28(4):1781. https://doi.org/10.3390/molecules28041781

Chicago/Turabian StyleDennis, John Ojur, M. F. Shukur, Osamah A. Aldaghri, Khalid Hassan Ibnaouf, Abdullahi Abbas Adam, Fahad Usman, Yarima Mudassir Hassan, A. Alsadig, Wilson L. Danbature, and Bashir Abubakar Abdulkadir. 2023. "A Review of Current Trends on Polyvinyl Alcohol (PVA)-Based Solid Polymer Electrolytes" Molecules 28, no. 4: 1781. https://doi.org/10.3390/molecules28041781

APA StyleDennis, J. O., Shukur, M. F., Aldaghri, O. A., Ibnaouf, K. H., Adam, A. A., Usman, F., Hassan, Y. M., Alsadig, A., Danbature, W. L., & Abdulkadir, B. A. (2023). A Review of Current Trends on Polyvinyl Alcohol (PVA)-Based Solid Polymer Electrolytes. Molecules, 28(4), 1781. https://doi.org/10.3390/molecules28041781